Page 1

RFS-2500 Series

RotorFlow® Sensors

(For Additional Information, See Gems' "Level, Flow and Pressure Catalog)

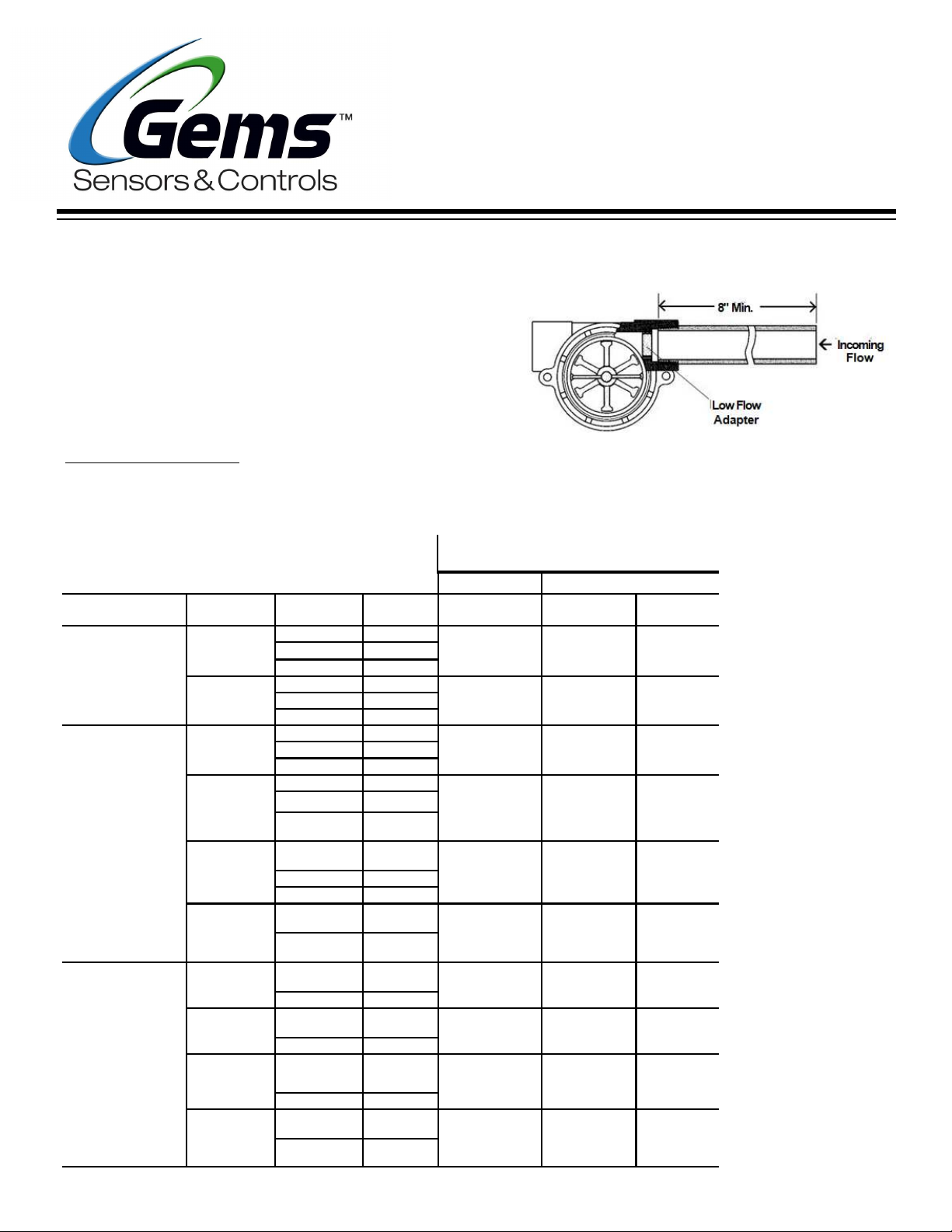

RotorFlow units monitor dynamic fluid flow. The rotor reacts to

turbulence, pulsation, entrained air, and other flow anomalies induced in

the flow stream by other process hardware. For optimum performance,

install RotorFlow units where nominal flow conditions exist, with ports

located at the top. Incoming flow may be placed to either port. A

minimum of 8" of straight pipe on the inlet side is recommended.

Low Flow Applications

Instruction Bulletin No.

157261

Rev. G

A low flow adapter is supplied with all RotorFlow units. It is used to produce accurate response at low flow rates. Press fit the

adapter as shown above, in the port selected for incoming flow.

Body

Material

Polypropylene

Brass

Port Size

NPT

.25"

.50"

.25"

.50"

.75"

1.0"

Input

Power

12 VDC 155424

24 VDC 155425

110 VAC 155876

12 VDC 155484

110 VAC 155886

12 VDC 156264

110 VAC 156266

12 VDC 156267

24 VDC 156268

110 VAC 156269

12 VDC 180394

24 VDC 180395

110 VAC 180396

24 VDC 181688

115 VAC 181689

Part

Number

See Flow Range Chart below.

Flow Range-GPM

Standard

Range

0.5 - 5.0 0.1 - 1.0 152147

4.0 - 20.0 1.5 - 12.0 151832 24 VDC 155485

0.5 - 5.0 0.1 - 1.0 152147 24 VDC 156265

4.0 - 20.0 1.5 - 12.0 151832

5.0 - 30.0 N/A N/A

8.0 - 60.0 N/A N/A

Range

Low Flow*

Adapter

Part Number

*

With use of low flow

adapter supplied

316 Stainless

Steel

9/16”-18**

.50”

.75”

1.0”

24 VDC 165073

110 VAC 165074

24 VDC 165077

110 VAC 165078

24 VDC

115 VAC 181692

24 VDC 181693

115 VAC 181694

181691

0.5 - 5.0 0.1 to 1.0 152147

4.0 to 20.0 1.5 to 12.0 151832

5.0 - 30.0 N/A N/A

8.0 - 60.0 N/A N/A

**

Straight thread with O-

ring seal

Page 2

Installation:

provided to assist with installation for a leak-free seal, without damage to the unit: 1) Apply pipe thread sealant to male

pipe threads. 2) Thread RotorFlow unit onto male pipe thread until hang-tight . 3) Tighten pipe 1 to 1/2 additional turns.

4) If improper seal results, continue turning pipe into unit in 1/4 turn increments.

Recommended pipe Sealants:

(a) Permatex

Filtration and Cleaning:

RotorFlow sensor, accumulation is easily cleared by removing the lens from the body. The lens is removed by turning

its center rib 45°C counter-clockwise and then pulling it out. To reinstall the lens, simply reverse the process.

Pressure must be relieved

RotorFlow sensors connect to piping via NPT mating threads forms. The following guidelines are

Do not exceed one additional turn.

® “

No More Leaks” (b) Teflon® Thread Tape.

150 micron filtration is recommended.

from the system prior to sensor clean-out.

However, should foreign particles enter the

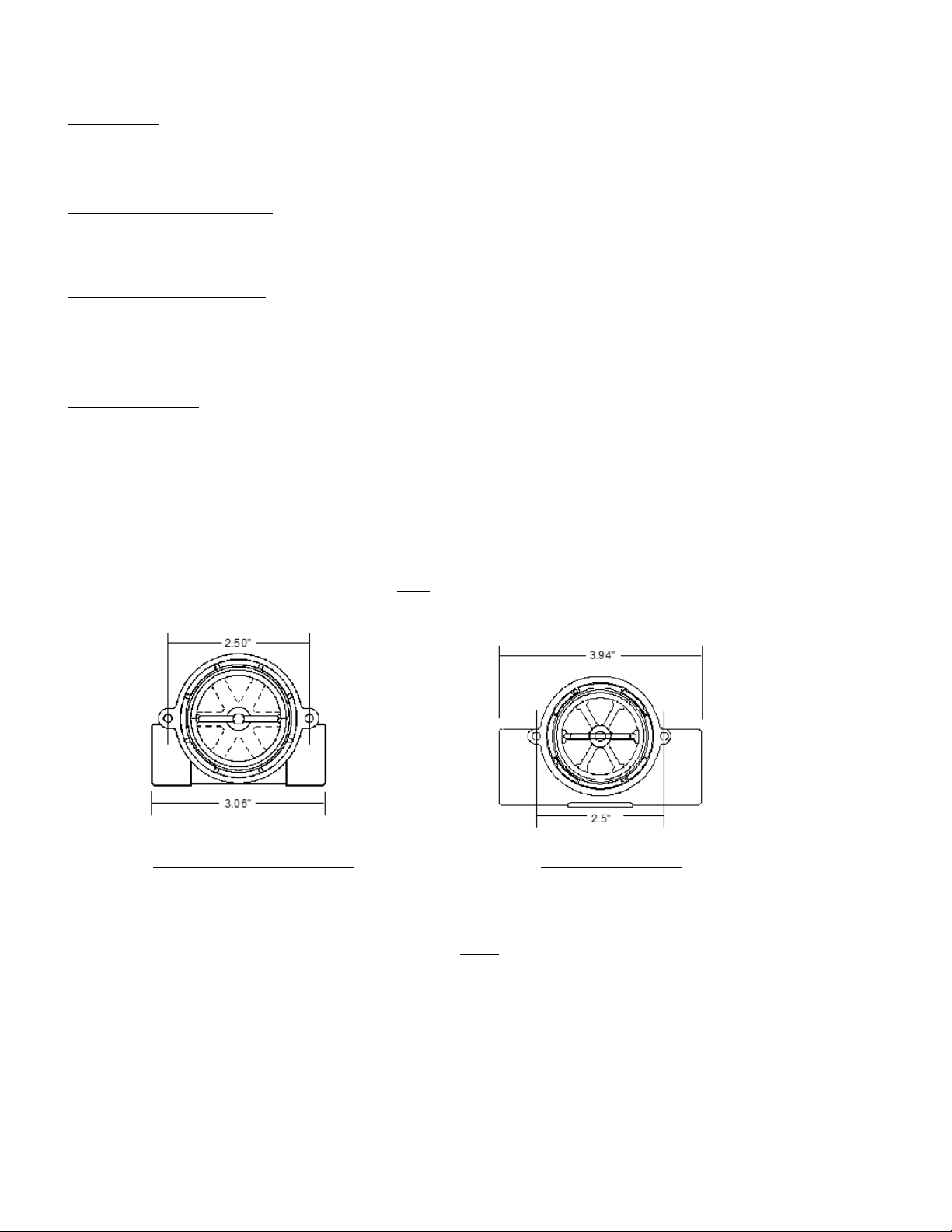

Panel Mounting

Any RotorFlow sensor may be panel mounted using holes integrated into the bodies.

Plastic Bodies

Two (2) mounting ears are provided at the body centerline to receive #8 Self- tapping screws.

ies use 8-32 UNC2B screws.).

(

Brass and stainless steel bod-

See recommended panel preparation diagram.

They may be replaced with standard machine screws if reinstallation should be required.

: ANSI T Type 23 self-tapping screws are recommended for plastic.

Note

Plastic, Brass , Stainless Steel Brass/Stainless Steel

1/4”, 1/2”, 9/16”-18 3/4” & 1”

Note

A RotorFlow Repair Kit is available, including the following replacement

parts: lens, O-ring, shaft, and rotor. Consult Factory to order.

Page 3

Switch Set Point Calibration with LED Signal

With the unit installed in the line and power supplied, complete the following steps to calibrate switch actuation point with

proper flow rate. A small flat-blade screwdriver is all that is required.

1. Adjust liquid flow in the line to the

rate at which actuation is desired.

2. Insert screwdriver into opening on

backside of housing and fit blade into

the potentiometer adjustment screw

inside.

3. If LED is not illuminated, slowly turn

screwdriver counter-clockwise and

stop as soon as LED illuminates.

4. If LED is illuminated, turn screwdriver

clockwise until LED light goes out.

Then, slowly turn screwdriver

counter-clockwise and stop as soon

as LED illuminates.

Specifications

Wetted Materials

Body

Rotor Pin

Rotor

Lens

O-Ring

Operating Pressure, Max. Brass

Body & 316 SS Body

Polypropylene Body

Operating Temperature, Max.

Brass Body

Polypropylene Body

316 SS Body

Electronics (All Bodies)

Viscosity, Max.

Input Power

Relay Contact Ratings (SPDT)

Repeatability

Set Point Accuracy (Factory Set)

Set Point Differential

Electrical Termination

Brass, 316 SS or Polypropylene, Hydrolytically Stable, Glass-Reinforced

Ceramic

PPS Composite/Teflon/PPS Composite

Polysulfone

Buna N/Viton

200 PSIG @ 70°F 80 PSIG @ 212°F

100 PSIG @ 70°F 40 PSIG @ 212°F

212°F (100°C)

180°F (82.2°C)

212°F (100°C)

150°F (65.5°C)

200 SSU

12 VDC, 24 VDC or 110 VAC

1 Amp, 24 VDC Resistive 0.3 Amp, 110 VAC

2% Maximum Deviation

±5%

15% Maximum

22 AWG PVC-Jacketed, 24" Cable. Color codes: Red = +VAC/VDC;

†

Black = Ground; White = N.O. Contact; Brown = N.C. Contact; Green = Common.

†

Hydrolytically stable, glass-reinforced, Polypropylene is UL-recognized to UL746B at a

relative temperature index of 65°C

Page 4

Electrical Data

Input power and output are connected via a

Multi-conductor, PVC-jacketed 24” cable.

Color codes are as shown below:

+VAC/VDC Red

-Power Black

N.O. Contact White

N.C. Contact Brown

Common Green

This product is suitable for Class I and Class II applications only, per the requirements of standard EN60730 and any additional specific

requirements for a particular application or medium being sensed. Class I compliance of metal bodied units requires a ground

connection between the metal body and the earthing system of the installation. Class I compliance of plastic bodied units in contact

with a conductive medium requires that the medium be effectively earthed so as to provide an earthed barrier between the unit and

accessible areas. For Class III compliance, a supply at safety extra-low voltage (SELV) must be provided. Please consult the Factory

for compliance information on specific part numbers.

WARNING

When determining chemical compatibility of

materials of construction, the flow media and

application-associated environmental conditions

should be carefully considered.

Important Points!

Product must be maintained and installed in strict

accordance with the National Electrical Code and GEMS

product catalog and instruction bulletin. Failure to observe

this warning could result in serious injuries or damages.

Pressure and temperature limitations shown on individual

catalog pages and drawings for the specified flow

switches must not be exceeded. These pressures and

temperatures take into consideration possible system

surge pressures/temperatures and their frequencies

Selection of materials for compatibility with the media is

critical to the life and operation of GEMS flow switches.

Take care in the proper selection of materials of

construction; particularly wetted materials.

Life expectancy of switch contacts varies with

applications. Contact GEMS if life cycle testing is

required.

.

Ambient temperature changes do affect switch set

points, since the specific gravity of a liquid can vary

with temperature.

Flow switches have been designed to resist shock and

vibration; however, shock and vibration should be

minimized.

Liquid media containing particulate and/or debris

should be filtered to ensure proper operation of

GEMS products.

Electrical entries and mounting points may require

liquid/vapor sealing if located in an enclosed tank.

Flow switches must not be field repaired.

Physical damaged sustained by the product may

render it unserviceable.

Gems Sensors & Controls

Telephone: 1-800-378-1600 | Email: info@gemssensors.com | www.GemsSensors.com

| One Cowles Road | Plainville, CT 06062-1198

Loading...

Loading...