Page 1

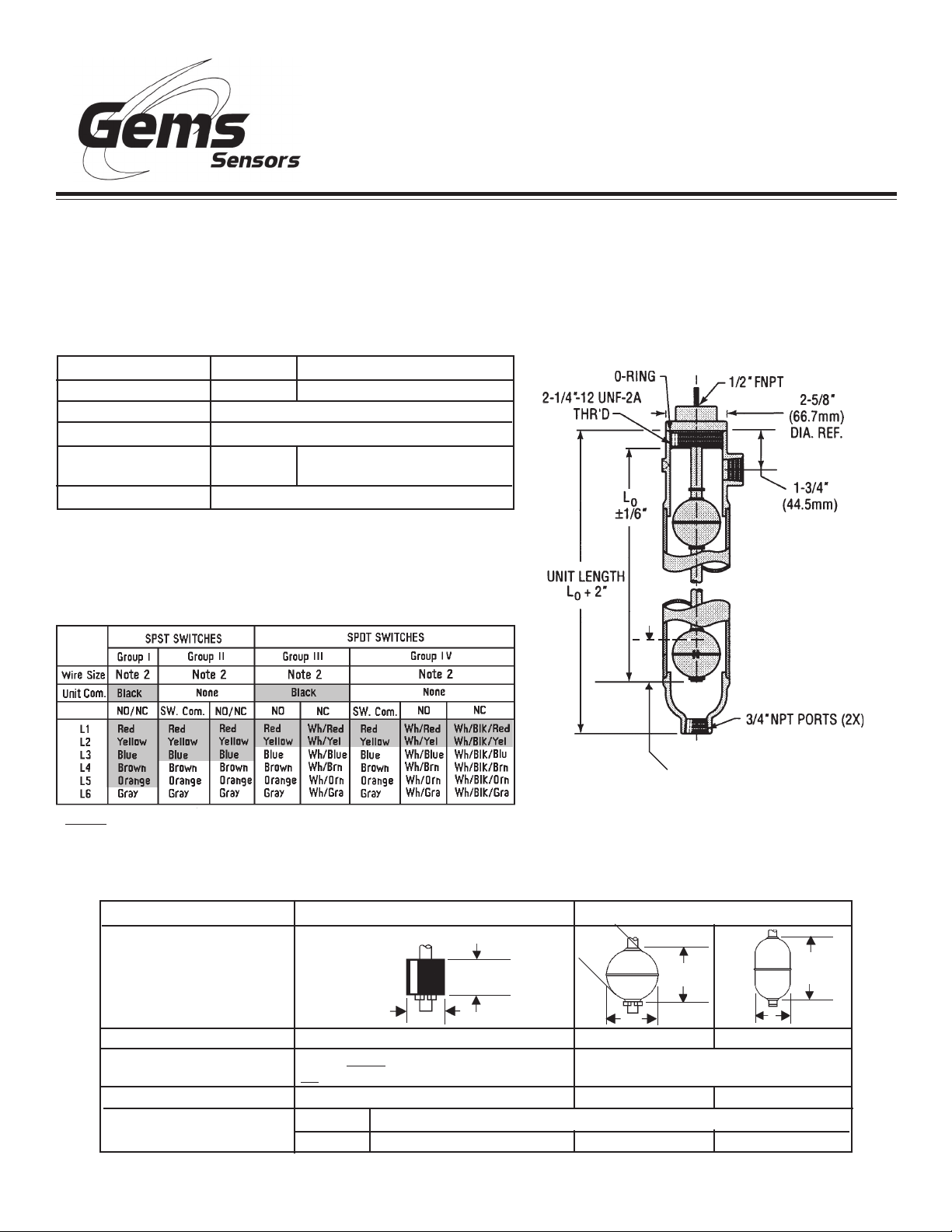

Externally-Mounted Bottle-Style Level Switches

LS-800 Type 5

Instruction Bulletin No. 78799

To Install . . .

Locate and prepare entrances in tank side so that level switch unit will be in vertical position with wire leads up when

installed on outside of tank. Connect NPT inlet and outlet ports of unit to tank entrances. 1/2" NPT in top of unit

provides for electrical connection. (See wiring information below and on back of sheet.) Use 1/4"-20 threaded

mounting holes or optional mounting bracket (Kit P/N 167809) to attach unit on any suitable vertical surface.

- Multi-Level Units -

Specifications

Housing Material

Stem and Mounting

Port Sizes

Max. Length (LO)

Float Stops**

Switch

Units greater than 72" overall length are supplied with collars with

**

setscrews (made of same material as stem and mounting) in place of

float-stop rings. Collars are optional on units less than 72" overall

length. Units requiring 316 SS float stops must be special ordered with

316 SS collars instead of grip rings.

Brass

Brass

Beryllium

Copper

20 VA (Pilot Duty)

316 Stainless Steel

316 Stainless Steel

3/4" NPT

140" (355.6 cm)

S.S. ARMCO

PH-15-7 MO

Standard Wiring Groups - Color Code

Notes:

1. Shaded area designates UL-recognized wiring configurations.

2. Non-UL-recognized units (unshaded areas) use #22 AWG, 24" L.,

Teflon lead wires.

3. Units with 100 VA switches are not UL-recognized or CSA-listed.

LS-800 (Type 5) - Float Types

Float Material Buna N

Float Dimensions

1-7/8" DIA.

(47.6 mm)

Part Number

Operating Temperature

Min. Media Specific Gravity

Pressure Rating (PSI, Max.)

A single float type is selected for use at all actuation points.

Water: to 180°F (82.2°C)

Oil: -40°F to +230°F (-40°C to +110°C)

Brass

316 S.S.

10558

.55

1-13/16"

(46.0 mm)

150

(50.8 mm)

316 Stainless Steel

2"

(50.8 mm)

(53.3 mm)

2-1/16"

(52.4 mm)

14569 15666

-40°F to +300°F (-40°C to +148.9°C)

.80

100 @ +70°F (21.1°C)

750 300

2" MIN

2-3/32"

.75

2-11/16"

(68.3 mm)

2-1/16"

(52.4 mm)

Page 2

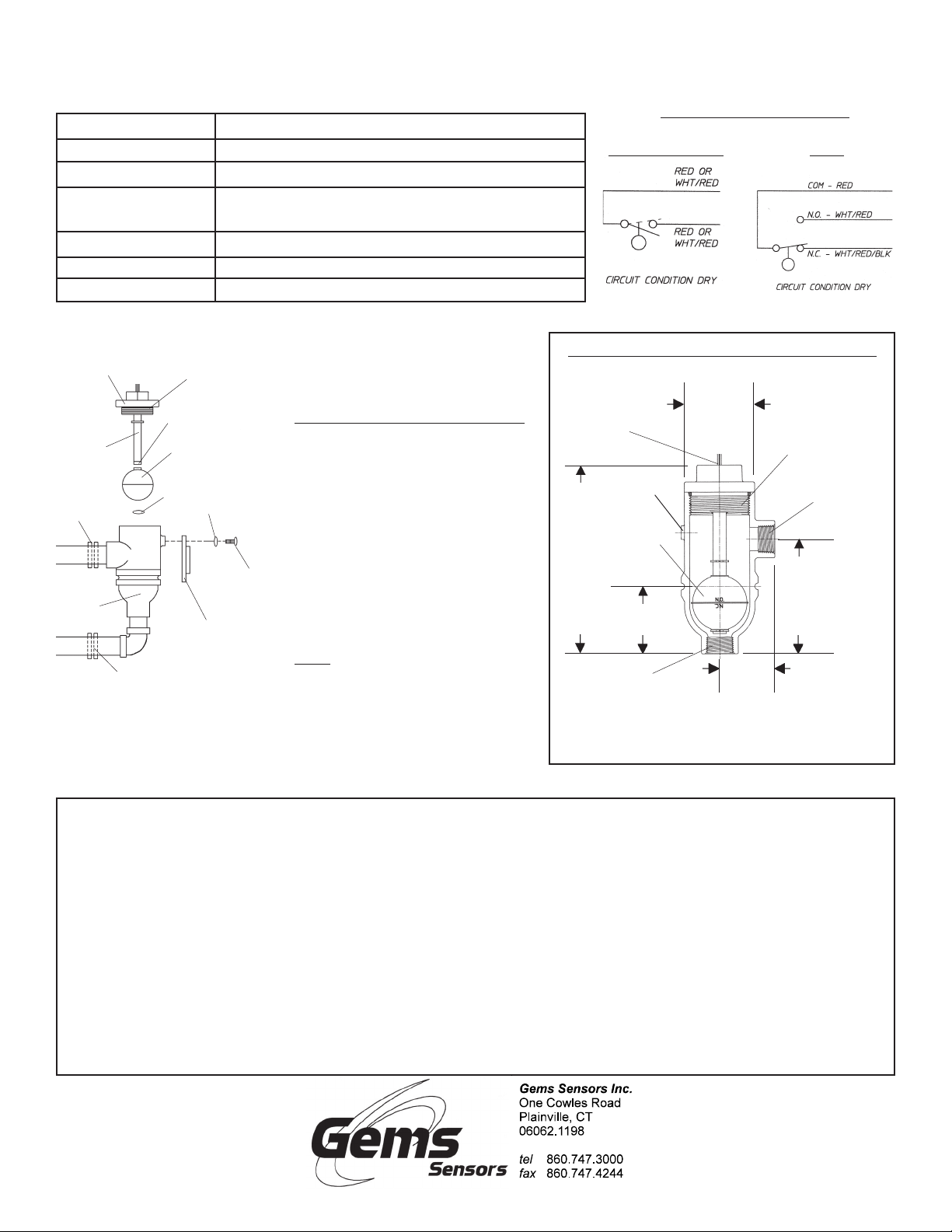

- Standard Single Level Units -

Operating Temperature

Pressure Rating

Electrical Termination

- Specifications -

-40°F to 300°F (-40°C to 148.9°C)

P/N 167810: (500 psig Max) P/N 167811: (750 psig Max)

No. 18 AWG, 24" L, Polymeric Lead Wires

SPST, N.O. or N.C.

Typical Wiring Diagrams

SPDT

U.L. Recognized File No. E45168

Approvals

Switch Operation

Mounting Attitude

Switch

Mounting

Plug

Stem

Union

Housing

Union

or

Pipe Fitting

Groove

Float

Grip

Ring

CSA Report LR 30200

Selectable, N.O. or N.C. by Inverting Float On Stem

Vertical with Lead Wires Up

20 VA (Pilot Duty)

Standard single level units are

O-Ring

supplied with SPST switch operation, N.O. (Dry).

To convert operation to N.C. (Dry):

Remove level switch unit from

housing, remove lower grip ring

and invert float on unit stem.

Reinstall lower grip ring into

Lockwasher

groove and reinstall level switch

unit** in housing.

**Clean or replace O-ring on

1/4-20

Screw

mounting plug (if required) before

reinstalling float/stem assembly

in housing. Mounting plug must

Mtg.

Bracket

be installed flush with housing.

Note

Switch operation can be selected

without disturbing installation of

unit on tank.

P/N 172625 (Brass) and P/N 172635 (SS)

2-5/8"

1/2" NPT

(Female)

Approx.

7"

1/4-20 Thd.

2" Dia.

Float

2-1/2" *

3/4" NPT

Inlet

Dia. Ref.

2 1/4 - 12 Thd.

W/ O-ring

3/4" NPT

Outlet

4-1/4"

Ref.

2-1/8"

Dia.

*Switch actuation level nominal

(Based on a liquid specific gravity of 1.0)

Maintenance (All Units) . . . An occasional "wipe-down" cleaning is the only maintenance normally required.

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and GEMS technical brochure and

instruction bulletin. Failure to observe this warning could result in

serious injuries or damages.

An appropriate explosion-proof enclosure or intrinsically safe interface device must be used for hazardous area applications involving such things as (but not limited to) ignitable mixtures, combustible

dust and flammable materials.

*** Warning: To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing.

Pressure and temperature limitations shown on individual catalog

pages and drawings for the specified level switches must not be exceeded. These pressures and temperatures take into consideration

possible system surge pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical to

P/N 78799

Rev. J

the life and operation of GEMS level switches. Take care in the

proper selection of materials of construction; particularly wetted

materials.

Life expectancy of switch contacts varies with applications. Contact GEMS if life cycle testing is required.

Ambient temperature changes do affect switch set points, since

the specific gravity of a liquid can vary with temperature.

Level switches have been designed to resist shock and vibration;

however, shock and vibration should be minimized.

Liquid media containing particulate and/or debris should be filtered

to ensure proper operation of GEMS products.

Electrical entries and mounting points may require liquid/vapor

sealing if located in an enclosed tank.

Level switches must not be field repaired.

Physical damage sustained by the product may render it unserviceable.

Loading...

Loading...