Page 1

Model LS-750

Steel Tank Sensor

Instruction Bulletin No. 157728

Environmental Products

These Sensors may not be compatible with indicating

and alarm equipment supplied by other manufacturers

Note: LS-750 sensors are non-voltage producing devices and do not contain energy storing

components. However, since primary use is in hazardous locations, an appropriate intrinsically safe interface device is required.

With its compact size, the Gems LS-750 single float, liquid level sensor is ideally suited for use in steel doublewall tanks. It requires no calibration, and is easy to install and maintain. When positioned vertically at the bottom

of a steel tank’s stand pipe, it reliably senses the presence of a liquid. It detects hydrocarbons and water as low

as 3/4" from the bottom of a tank or sump. The LS-750 sensor features an epoxy-encapsulated design providing

an environmental seal, that makes it a fine choice for harsh environments. An integral slosh shield guards the

float from debris; thereby assuring dependable service.

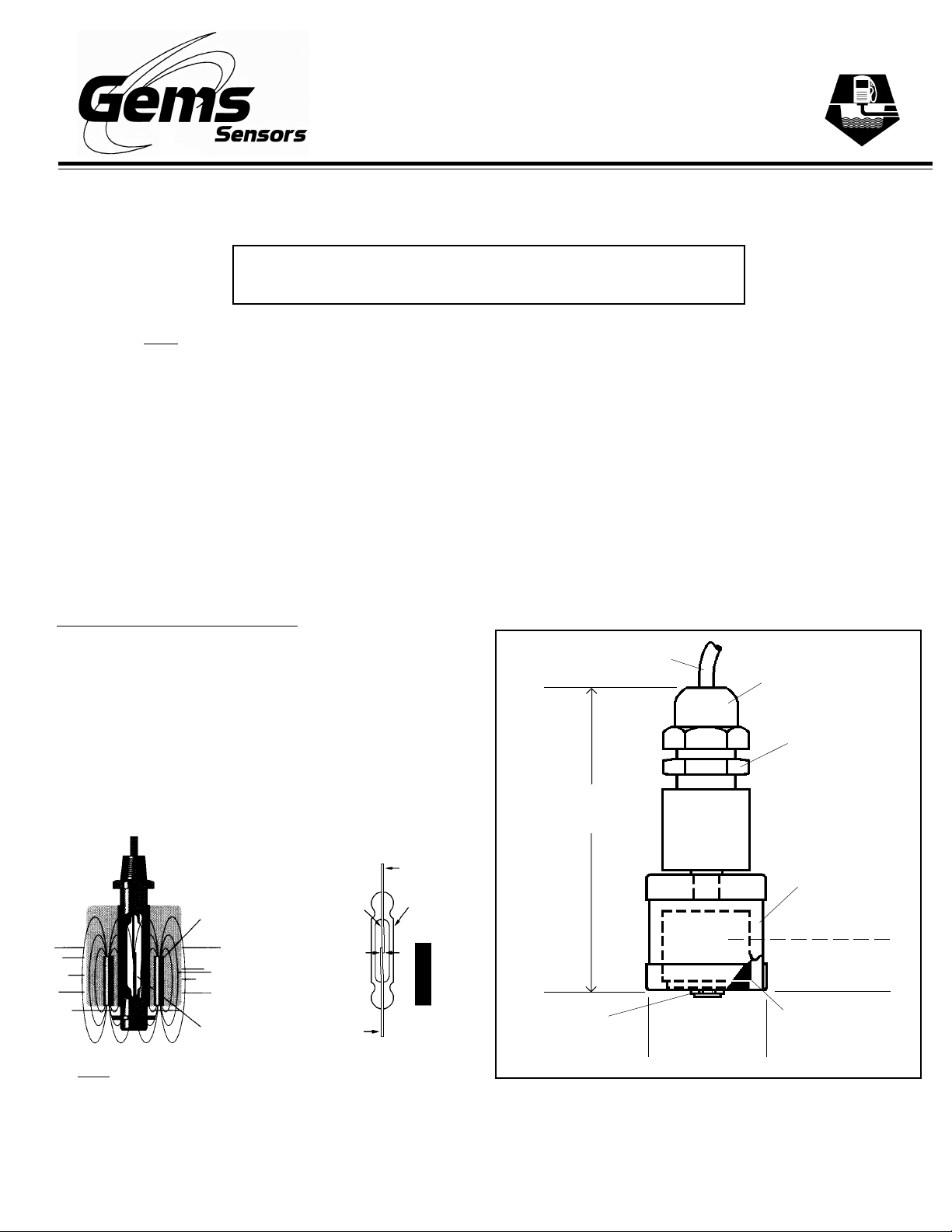

Sensor Operating Principle

Gems LS-750 liquid level sensor operates on a direct, simple

principle. A float is equipped with powerful, permanent magnets. As the float rises or lowers with liquid level, it actuates a

magnetic reed switch mounted within the stem. This condition either opens or closes the electrical circuit to operate an

external alarm or control circuit. When mounted vertically,

this basic design provides a consistent accuracy

of ±1/8th inch.

N

Permanent

Magnet

Float

Hermetically

Sealed Magnetic

Reed Switch

Reed

Switch

N

Envelope

S

S

Glass

S

MAGNET

N

Dimensions

3-1/2" Ref.

(88.9 mm)

Retaining Ring

Cable

!

1-7/16" Ref.

(36.5 mm)

Sealing

Nut

Liquid-Tight

Fitting

Slosh

Shield

3/4" Actuation

(19.0 mm)

Float

!

!

!

Note: Please refer to specific Gems outline drawings for

operational specifications.

Page 2

Read all instructions before beginning - Follow all safety precautions

Barricade the area

Do not allow vehicles

or unauthorized people

in the work area

Do not smoke or allow

open flames in the

work area

WARNINGS

Read the instructions and warnings carefully before installing the sensor. This unit must be installed in accordance with National Electrical Code ANSI/NPFA-70, 1990; as well as Federal, State and local codes and any

other applicable safety codes.

1. To avoid electrical shock, which could kill you, be sure AC power to monitor is off during installation.

2. The nature of the sensor is that it is a non-voltage producing device, containing limited energy-storing

components. However, since its primary use is in a hazardous location, an appropriate intrinsically safe

interface device must be used.

Dangerous environment.

Failure to install this equipment in

accordance with NFPA 30A and

NFPA 70 could result in severe

injury or death.

Read, understand and follow

NFPA 30A and NFPA 70.

Note: Failure to observe these warnings could result in serious injury and

death, as well as undetected potential environmental and health hazards.

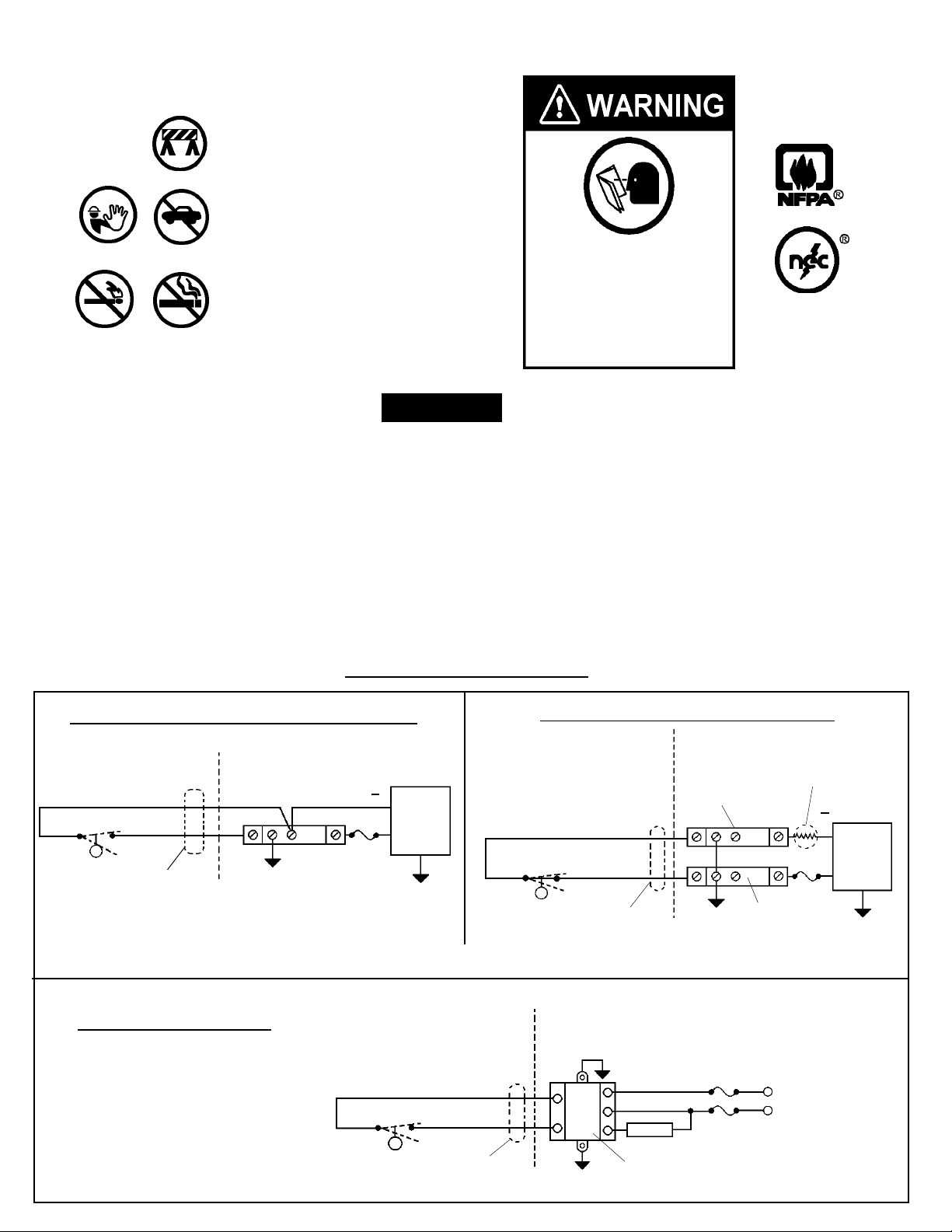

Typical Wiring Diagrams

Non-Isolated System – Single Zener Barrier

Hazardous

Area

Black

Red

N.O. Dry

or

N.C. Dry

2-Conductor

Cable

If two signal lines must be maintained at above ground potential, an individual zener barrier is required per single line.

Single Safe-Pak® Relay

Non-Hazard-

ous Area

3

21

Fuse

( )

(+)

DC

Power

Supply

Annunc.

N.O. Dry

N.C. Dry

Hazardous

Area

Safe-Pak® is an intrinsically

safe, solid-state relay.

N.O. Dry

or

N.C. Dry

Black

Red

2-Conductor

Cable

Isolated System – Dual Zener Barrier

Hazardous

Area

Black

Red

or

2-Conductor

Cable

Non-Hazard-

ous Area

Load

SAFE-PAK

Non-Hazard-

ous Area

Supply Barrier

3

2

3

2

Fuse

Fuse

1

1

Fuse

Signal

Return

Barrier

Hot VAC

Neutral VAC

Sense

Resistor

( )

Power

Supply

Annunc.

(+)

DC

Page 3

- IMPORTANT -

This manual assumes all preliminary site preparation is completed and that

field wiring from the monitor to the sensor junction box is in place.

Installation Instructions

A. Pre-installation Sensor Testing

1. Temporarily connect the two-wire sensor cable to the field wires in the sensor junction box. Turn Power on.

3. Turn the LS-750 upside down. Audible and visual indicators should alarm.

4. To remove alarm condition, turn the sensor right side up.

5. Secure the riser cap to the riser pipe.

6. Feed the sensor cable through the cord grip on the junction box.

7. Tighten the cable bushing nuts on the riser cap and junction box to ensure a watertight seal at the cable entry.

8. Using wire nuts, connect the two-wire sensor cable to the field wires in the sensor junction box.

B. Sensor Installation Instructions

1. Turn off power to the control. Note: Do not install the sensor if any liquid is present in the annular space.

Failure to comply will lead to an alarm.

2. Make sure no liquid is present in the annular space.

3. To be sure the sensor will reach the bottom of the annular space, first measure the sensor riser pipe from the

bottom of the pipe to the top. Then measure the same distance up the leader cable from its connection to the

sensing element and mark the leader cable.

4. Lower the float switch assembly into the

riser pipe until the float switch touches the

bottom of the tank.

5. Keeping the cable taut, secure the

sensor assembly in place by attaching the

grip cord.

Note: The float switch assembly should

not hang by the cable, but should rest

lightly on the bottom of the tank

supported by the cable.

Typical Installation

Weatherproof

Junction Box

Epoxy Seal

Per NFPA Spec.

To Probe

Junction Box

1/2" - 2" Dia.

Reducer

This product is suitable for Class I and Class

II applications only, per the requirements of

standard EN60730 and any additional specific

requirements for a particular application or

medium being sensed. Class I compliance of

metal bodied units requires a ground connection between the metal body and the earthing

system of the installation. Class I compliance of plastic bodied units in contact with a

conductive medium requires that the medium be effectively earthed so as to provide

an earthed

barrier between the unit and accessible areas. For Class III compliance, a supply at

safety extra-low voltage (SELV) must be provided. Please consult the Factory for compliance

information on specific part numbers.

Cable

2" Dia. Riser

STEEL

T ANK

See inset

Note: The float switch assembly should not hang by the cable, but should

rest lightly on the bottom of the tank supported by the cable.

LS-750 Sensor

must reach

bottom of tank

View of sensor

at bottom of tank

Page 4

Maintenance

Note: Please consult your state E.P.A. office or appropriate regulatory

agency regarding periodic inspection of the sensor. There are no user

serviceable parts.

WARNING

Product must be maintained and installed in strict accordance with the

National Electrical Code and the applicable GEMS technical bulletin and

instruction bulletin. Failure to observe this warning could result in serious

injuries or damages.

Warranty

Gems’ standard warranty applies

P/N 157728

Rev. B

Loading...

Loading...