Page 1

Turbine Low Flow Rate Sensor

FT-210 Series - TurboFlow

®

Instruction Bulletin No. 217952

Operating and Installation Instructions

Prior to installation, confirm system versus sensor specifications and media compatibility of sensor. The

system needs to be filtered to 50 microns prior to the sensor, and pulses/water hammer effects should be

minimized to prevent unit damage. Observe arrow on bottom of unit for correct inlet and outlet port. Sensor

can be mounted in any horizontal, vertical, or skewed orientation. Correctly installed, the sensor works

maintenance-free.

Installation

1/4" NPT Units:

Apply a sparse amount of thread sealant (Permatex "No More Leaks" ®) or Teflon® tape to male threads.

Insure that sealant does not enter into the turbine and bearing internal area. Hand-tighten unit in place.

Turn an additional 1/4 turn to provide seal. If seal leaks, turn an additional 1/4 turn until leak stops.

Do not exceed one additional turn total.

G 1/4 Units:

G 1/4 units mate with a flat face seal washer (70 shore, 7 mm ID, 13 mm OD, 2, 0 mm thick)

similar to a garden hose arrangement. This arrangement requires no sealants; hand-tightening should be

sufficient for sealing.

Specifications

Wetted Parts

Operating Pressure

Burst Pressure

Operating Temperature

Viscosity

Filter

Input Power

Output

Accuracy

Repeatability

Electrical Connection

Spade Terminal Connection

(2.8 mm)

Body: Nylon 12/Turbine: Nylon 12 Composite/Bearings: PTFE/ 15% Graphite

350 psi (24 Bar)

1400 psi (100 Bar)

-4° to 212°F (-20° to 100°C)

32 to 80 SSU (1-15 Centistokes)

< 50 Microns

5-24 VDC @ 8 mA

NPN Sinking Open Collector @ 20 mA, Max.

± 3% of Rdg. Normal Range

0.5% FS Normal Range

Spade Terminals .110/.275 X .020" (2.8/7 X .5 mm) or Din Connector (2 Poles + Ground)

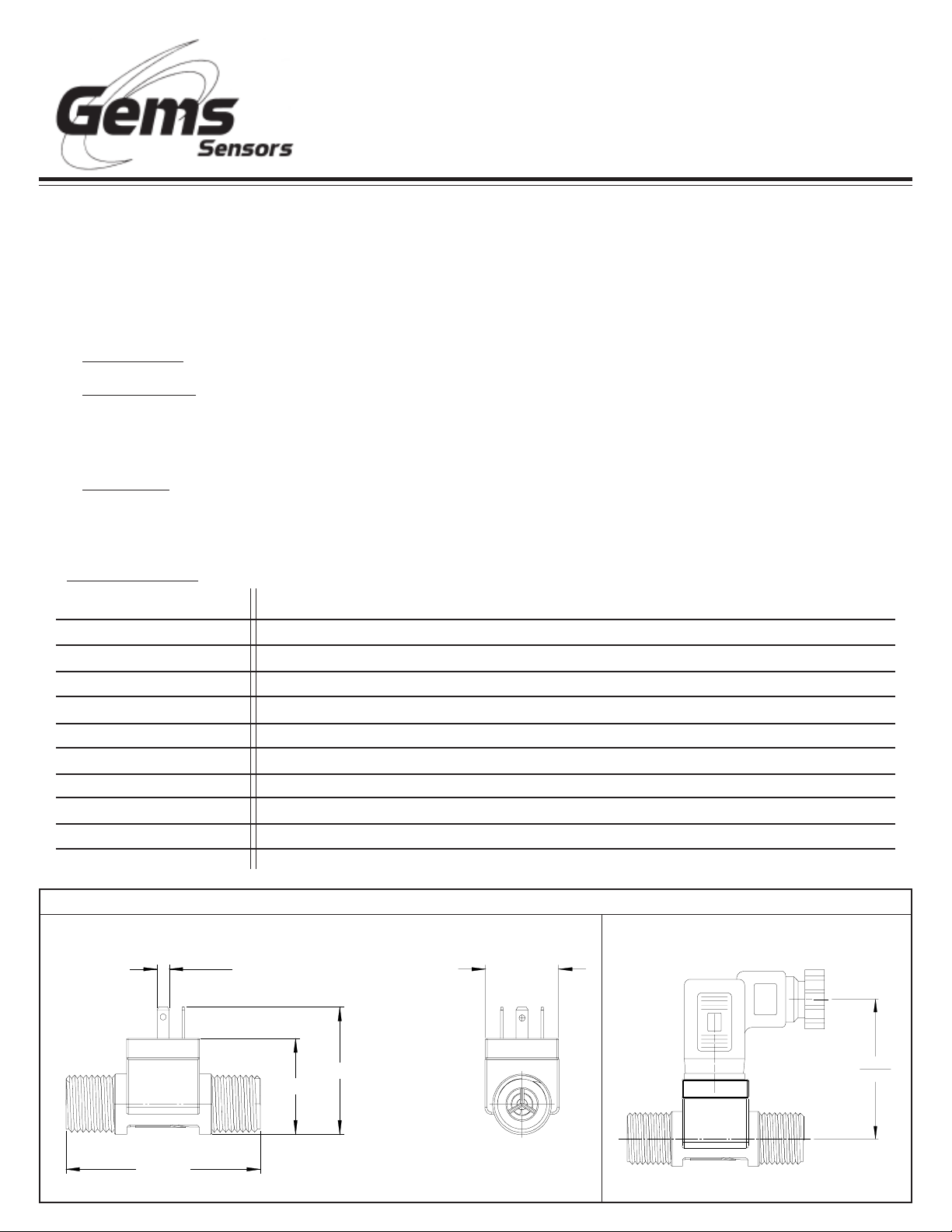

Dimensions

With optional Din Connector

.11"

3 PLCS

.67"

(17 mm)

1.78"

(45 mm)

1.14"(29 mm)

.86"(22 mm)

1.37"

(35mm)

Page 2

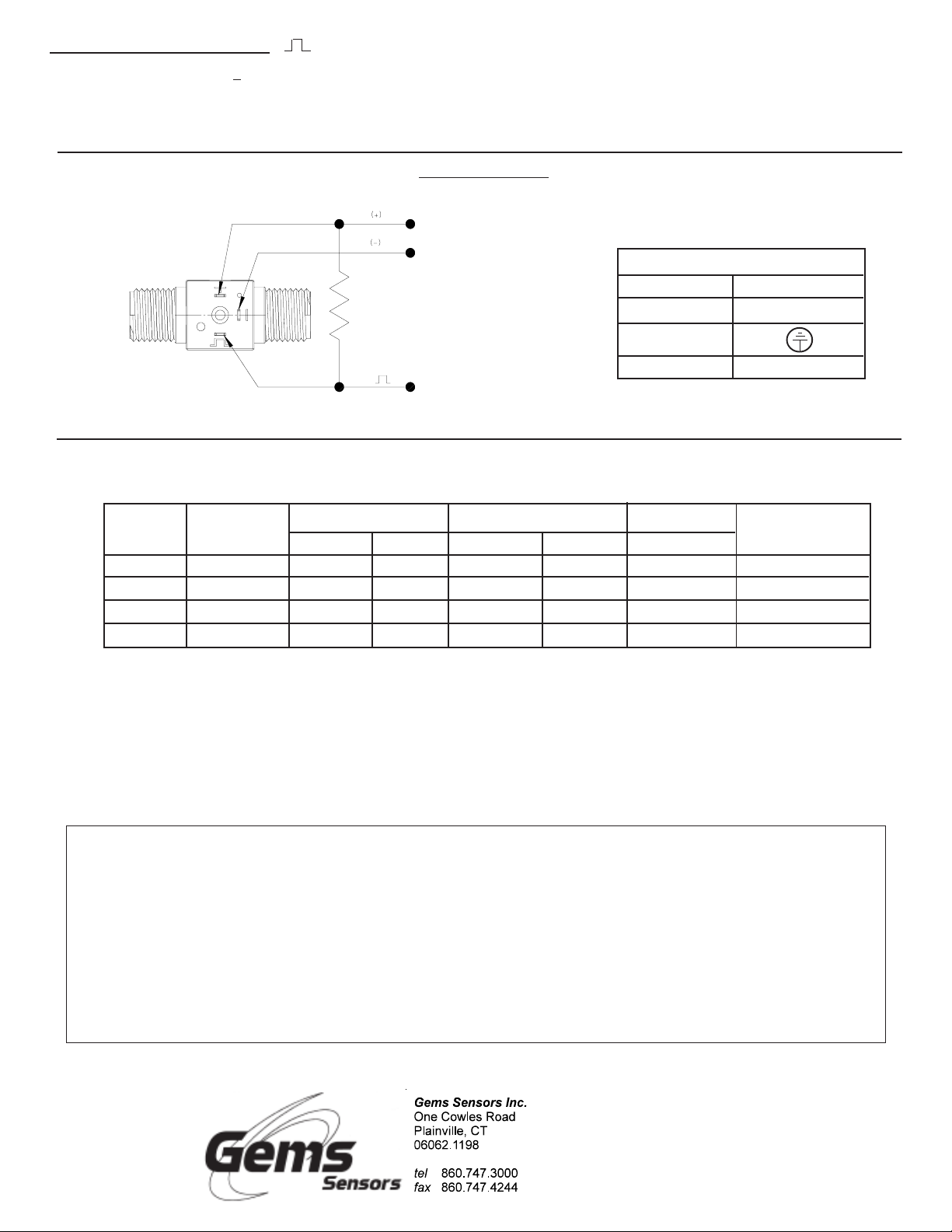

Electrical/Output Signal ( )

The output signal is a square wave signal, whose frequency varies linearly with flow rate. An external pull-up resistor

(user-supplied) is required to insure that the open collector will sink less than 20 mA.

Wiring Diagram

5-24 VDC

Part

Number

212460

212465

212460E

212465E

Port

G 1/4

1/4" NPT

G 1/4

1/4" NPT

2K-10K Ohms

Customer Supplied

Flow Ranges

GPM

0.03-.66

0.03-.66

0.03-.66

0.03-.66

0.1-2.5

0.1-2.5

0.1-2.5

0.1-2.5

LPM

0 VDC

OUTPUT

Per Gallons

83200

83200

83200

83200

Pulses

Per Liters

22000

22000

22000

22000

W/ Optional Din Connector

Function

V+

Din Termination

1

-

Output

Frequency

Output

37 - 917 Hz

37 - 917 Hz

37 - 917 Hz

37 - 917 Hz

Spade Terminals

Spade Terminals

2

Electrical

Termination

Din Connector

Din Connector

The product is designed and manufactured in accordance with Sound Engineering Practice as defined by the Pressure Equipment

Directive 97/23/EC. This product must not be used as a “safety accessory” as defined by the Pressure Equipment Directive,

Article 1, Paragraph 2.1.3. The presence of a CE Mark on the unit does not relate to the Pressure Equipment Directive.

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and GEMS technical brochure

and instruction bulletin. Failure to observe this warning could

result in serious injuries or damages.

Pressure and temperature limitations shown on individual

catalog pages and drawings for the specified flow sensors must

not be exceeded.

Selection of materials for compatibility with the media is

critical to the life and operation of GEMS flow sensors. Take

USA

P/N 217952

Rev. -

care in the proper selection of materials of construction;

particularly wetted materials.

Flow sensors have been designed to resist shock and vibration;

however, shock and vibration should be minimized.

Liquid media containing particulate and/or debris should be

filtered to ensure proper operation of GEMS products.

Flow sensors must not be field repaired.

Physical damage sustained by the product may render it

unserviceable.

Gems Sensors Ltd.

Lennox Road

Basingstoke

Hants. RG22 4AW

U.K.

Phone: +44 (0) 1256.320244

Fax: +44 (0) 1256.473680

Loading...

Loading...