Page 1

Piston-Type Flow Switches

Series FS-925/926 & FS-927/930

Instruction Bulletin No. 72949

Installation . . .

Unless otherwise specified at time of purchase, units are calibrated in a vertical position, with lead wires up.

Install unit in piping system, using standard pipe fitting procedures. Hold inlet fitting with wrench at installation

to prevent fitting torque accumulation. Be sure to keep thread sealing compound out of unit. Make sure that

flow is in proper direction - marked "IN" and "OUT" on housing. See wiring diagrams for electrical connections.

CAUTION: See "Switch Ratings" before connecting power.

Important Points!

Product must be maintained and installed in strict accordance with the National Electrical Code and Gems

product catalog and instruction bulletin. Failure to observe this warning could result in serious injuries or

damages.

An appropriate explosion-proof enclosure or intrinsically

safe interface device must be used for hazardous area

applications involving such things as (but not limited to)

ignitable mixtures, combustible dust and flammable materials.

*** Warning: To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing.

Pressure and temperature limitations shown on individual

catalog pages and drawings for the specified flow switches

must not be exceeded. These pressures and temperatures take into consideration possible system surge pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is

critical to the life and operation of GEMS flow switches.

Take care in the proper selection of materials of construction; particularly wetted materials.

Life expectancy of switch contacts varies with applications. Contact GEMS if life cycle testing is required.

Ambient temperature changes do affect switch set

points, since the specific gravity of a liquid can vary with

temperature.

Flow switches have been designed to resist shock and

vibration; however, shock and vibration should be minimized.

Liquid media containing particulate and/or debris

should be filtered to ensure proper operation of GEMS

products.

Electrical entries and mounting points may require liquid/vapor sealing if located in an enclosed tank.

Flow switches must not be field repaired.

Physical damage sustained by the product may render it unserviceable.

CAUTION: Flow settings for FS-920 series switches are normally calibrated using water** @ +70°F on

increasing flow. If unit will be used to monitor liquids other than water, gas or air, Factory should have been

consulted at time of purchase for special calibration. All air/gas units are factory-calibrated using a special

piston. Water-calibrated units are not recommended for air/gas applications.

**

Note: Flow settings for FS-930 Viscosity Compensating type switches are calibrated in a vertical position

(lead wires up) with 300 SSU oil. Set points will be maintained within 20% of settings in a liquid viscosity

range of 40 to 2,000 SSU.

Specifications . . .

FS-925/FS-926 FS-930 FS-927

Wetted Materials

Housing

Piston

Brass Housing

Stainless Steel Housing

Spring

O-Ring

Other Wetted Parts

Pressure Rating

Operating

Proof

Burst

Operating Temperature

Brass or SS Piston

Polysulfone Piston

Repeatability

Set Point Accuracy

Set Point Differential

Switch*

Inlet/Outlet Ports

Electrical Termination

Brass or 316 SS

Polysulfone/Water - Brass/Oil or Air

316 SS

®

Viton

Epoxy

1000 PSIG

2500 PSIG

5000 PSIG

-20°F to +300°F

-20°F to +225°F

1% Maximum Deviation

±10%

15% Max.(FS-925) - 20% (FS-926)

SPDT, 20 VA

1/4" NPT

No. 18 AWG, 24" L., Polymeric Lead Wires

316 SS

Brass

Brass

15%, Max.

Brass

Brass

N/A

N/A

N/A

SS

1000 PSIG,Max.

-20°F to +200°F-20°F to +300°F

N/A

N/A

±15%

20% Max.

SPST, 20 VA

1/4" NPT

No. 18 AWG, 24" L.,

PVC Lead Wires

P/N 72949

Rev. P

Page 2

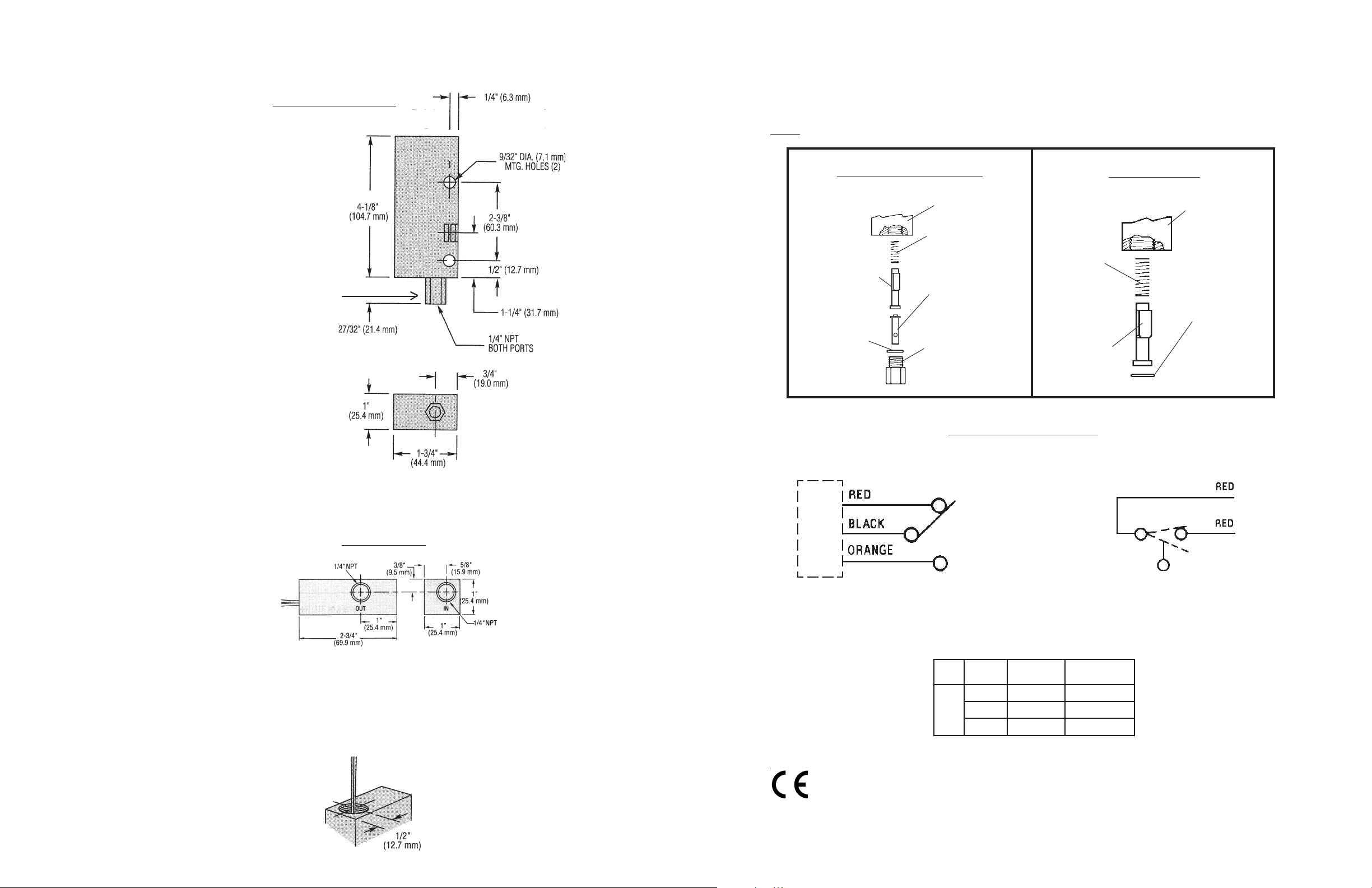

Dimensions . . .

FS-925/926/930 Series

Maintenance . . .

Accumulation of foreign debris should periodically be removed from these switches. Occasional "wipe-

down" cleaning when excessive contamination is present is all that is normally required. To clean: Remove

unit from system and disassemble as shown below. Clean all parts, reassemble and reinstall unit.

Note: 50 micron filtration is recommended.

For FS-926 the inlet fitting it torqued at the factory. Hold

fitting hex with wrench at installation to prevent additional

accumulation torque which could cause sensor malfunction.

(FS-925/FS-930)

(FS-926) 1-9/32" (32.5mm)

FS-925/926/930 Series

Housing

Spring

Piston

O-Ring

FS-925, FS-926, FS-930 Series

Low Flow Piston

(FS-926 ONLY)

Inlet

Fitting

Typical Wiring Diagrams

FS-927 Series

Housing

Spring

Retainer

Ring

Piston

FS-927 Series

FS-927 Series

Electrical Connection

(1/2" NPT Conduit)

A

C

B

Pin Connections for

Units with MS Receptacle

Switch Ratings

Max. Resistive Load

VA20Volts

0-30

120

240

This product is suitable for Class I and Class II applications only, per the requirements of standard EN60730 and any

additional specific requirements for a particular application or medium being sensed. Class I compliance of metal

bodied units requires a ground connection between the metal body and the earthing system of the installation. Class

I compliance of plastic bodied units in contact with a conductive medium requires that the medium be effectively

earthed so as to provide an earthed barrier between the unit and accessible areas. For Class III compliance, a supply

at safety extra-low voltage (SELV) must be provided. Please consult the Factory for compliance information on

specific part numbers.

Amps AC

.4

.17

.08

Amps DC

.3

.13

.06

Loading...

Loading...