Page 1

Paddle-Type Flow Switches

FS-550 Series

Instruction Bulletin No. 45521

Before Installing Unit . . .

Paddle length establishes approximate actuation setting of flow switch. Cut off paddle at proper pipe size mark on paddle for

system pipe line size and the desired flow setting (See charts on back). For flow setting other than standard, cut off paddle at

intermediate point.

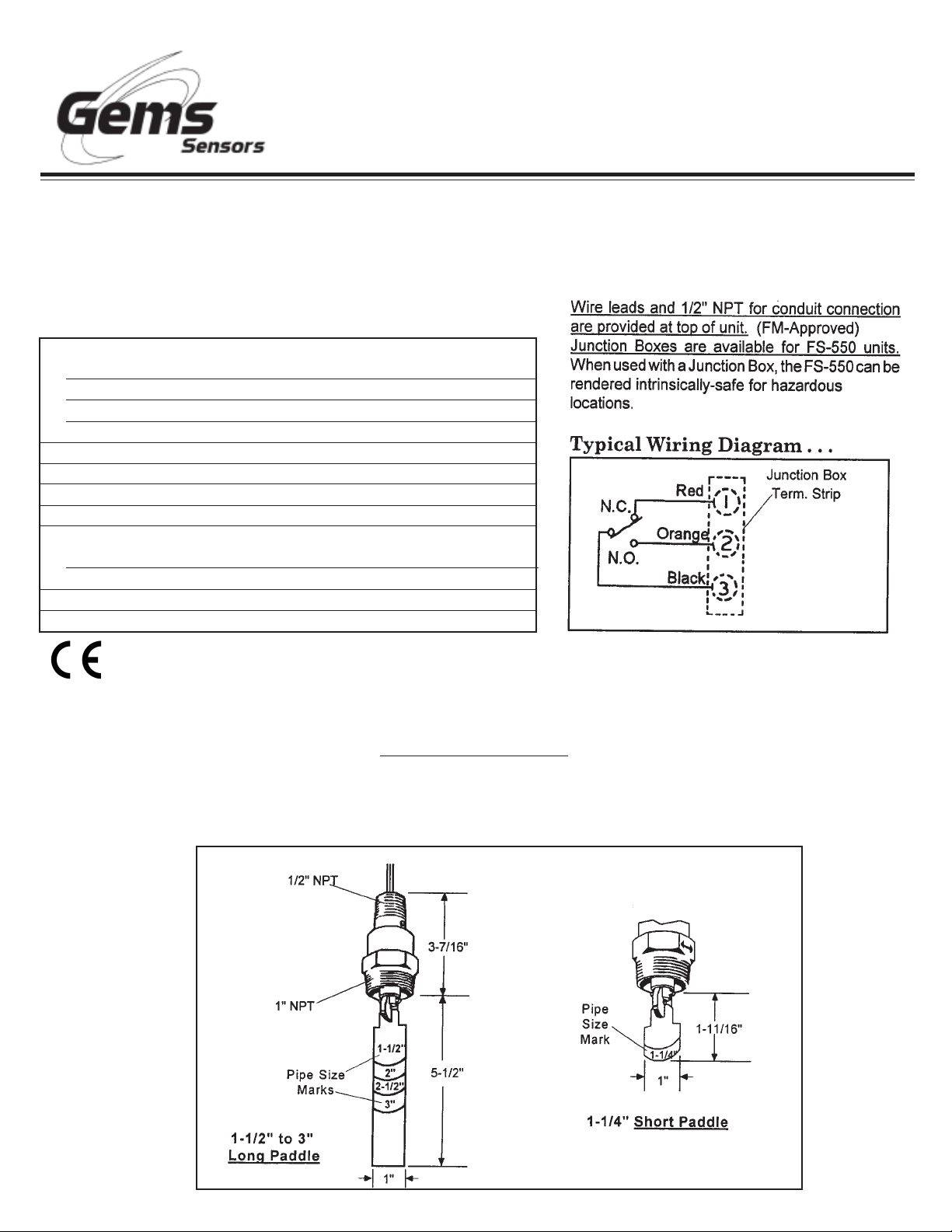

Electrical Connection . . .

Specifications . . .

Wetted Materials:

Housing

Paddle

Spring

Other Wetted Parts

Operating Pressure, Max.

Pressure Drop

Operating Temperature

Set Point Accuracy

Switch:

Standard

Uniflow

Repeatability

Electrical Termination

This product is suitable for Class I and Class II applications only, per the requirements of standard EN60730 and any additional specific

requirements for a particular application or medium being sensed. Class I compliance of metal bodied units requires a ground connection

between the metal body and the earthing system of the installation. Class I compliance of plastic bodied units in contact with a conductive

medium requires that the medium be effectively earthed so as to provide an earthed barrier between the unit and accessible areas.

For Class III compliance, a supply at safety extra-low voltage (SELV) must be provided. Please consult the Factory for compliance

Brass or 316 SS

302 SS

316 SS

Ceramic & Teflon

2000 PSIG

3 PSIG, Max.

-30°F to +300°F (-34.4°C to +148.9°C)

±25%

SPDT, 20 VA

SPST, 20 VA

±5%

No. 18 AWG, 24" L., Polymeric Lead Wires

European Pressure Directive

The product is designed and manufactured in accordance with Sound Engineering Practice as defined by the Pressure Equipment Directive

97/23/EC. This product must not be used as a “safety accessory” as defined by the Pressure Equipment Directive, Article 1, Paragraph 2.1.3.

The presence of a CE Mark on the unit does not relate to the Pressure Equipment Directive.

- Dimensions -

Page 2

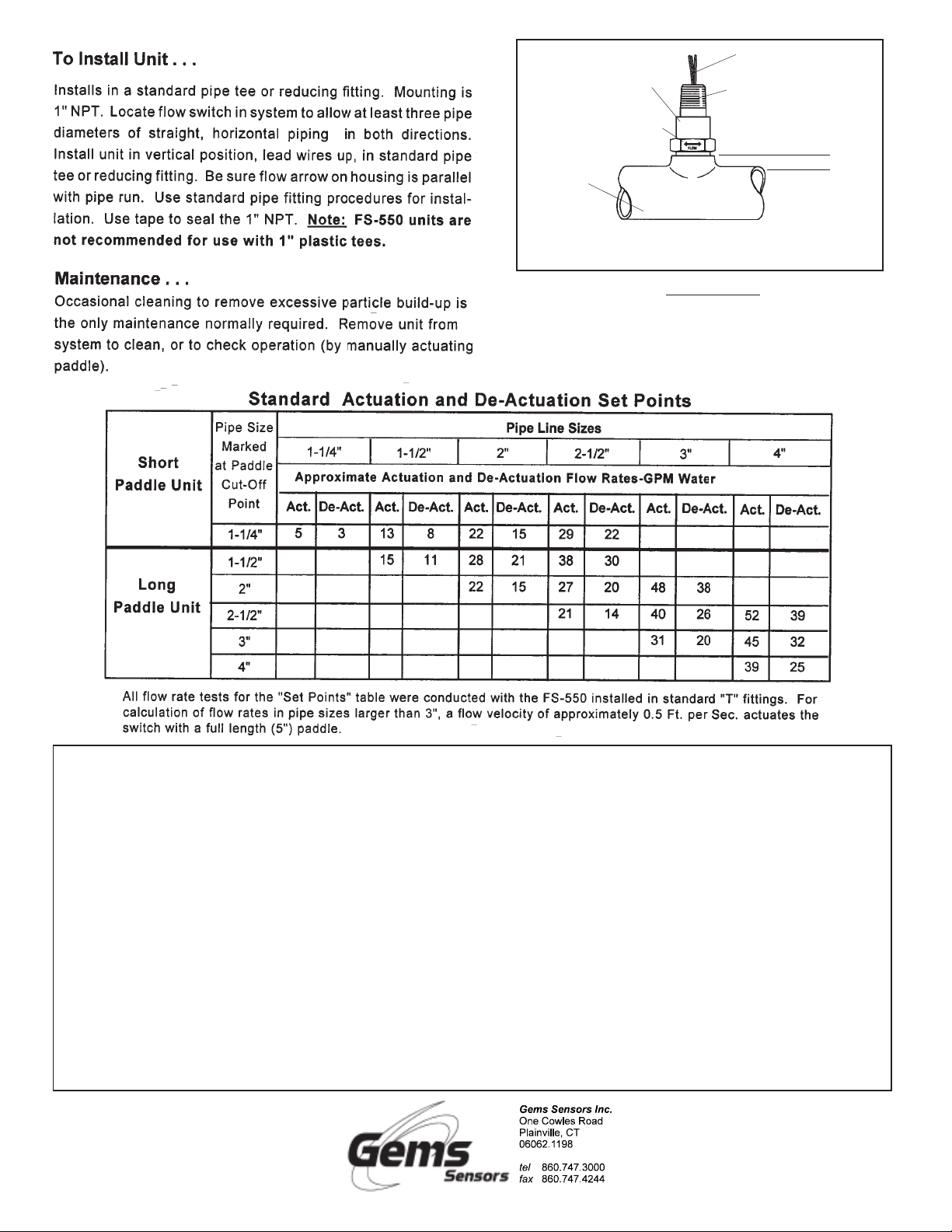

Lead Wires

Flow Switch

Flow Arrow

Reducing

Fitting in

Piping System

Paddle-Type Flow Switches Install in

Reducing Fitting or Standard Pipe Tee.

Important Note

Recommended pipe is Sched. 40. Dimensions shown must be

maintained to allow for full paddle swing when standard NPT

tolerances are met.

Maximum height of boss from pipe or tee I.D. is .66" For proper

operation of switch, do not exceed .66".

1/2" NPT

Nom. 1" NPT boss

.66" Max from Pipe I.D.

↓

↑

Important Points!

Product must be maintained and installed in strict accordance with

the National Electrical Code and GEMS product catalog and instruction bulletin. Failure to observe this warning could result in serious

injuries or damages.

An appropriate explosion-proof enclosure or intrinsically safe interface device must be used for hazardous area applications involving

such things as (but not limited to) ignitable mixtures, combustible

dust and flammable materials.

*** Warning: To prevent ignition of flammable or combustible

atmospheres, disconnect power before servicing.

Pressure and temperature limitations shown on individual catalog pages

and drawings for the specified flow switches must not be exceeded.

These pressures and temperatures take into consideration possible

system surge pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical to the

life and operation of GEMS flow switches. Take care in the proper

selection of materials of construction; particularly wetted materials.

P/N 45521

Rev. T

Life expectancy of switch contacts varies with applications. Contact

GEMS if life cycle testing is required.

Ambient temperature changes do affect switch set points, since the

specific gravity of a liquid can vary with temperature.

Flow switches have been designed to resist shock and vibration;

however, shock and vibration should be minimized.

Liquid media containing particulate and/or debris should be filtered

to ensure proper operation of GEMS products.

Electrical entries and mounting points may require liquid/vapor sealing if located in an enclosed tank.

Flow switches must not be field repaired.

Physical damaged sustained by the product may render it unser-

viceable.

Loading...

Loading...