Page 1

Instruction Bulletin No. 205476

Flow Rate GPM

In-Line Flow Switches

FS-480 Series

Installation

All NPT threads should be installed using a suitable thread sealant (Teflon

tape or Permatex “No more Leaks”). Sealant must be kept out of unit

during installation. Ten diameters of straight run piping are recommended

upstream and downstream of the flow sensor.

The FS-480 end fitting is threaded to the body at assembly and torqued to

25 Ft. Lbs. If disassembly from a system is required, it is advisable to hold

the end fitting hex with a wrench to prevent sensor disassembly. If the

sensor should become disassembled as a result of uninstalling, retorque

the end fitting to 25 Ft. Lbs.

Specifications

Wetted Materials

Housing

Piston

Spring

O-Ring

Oper. Pressure, Max.

Operating Temperature

Required Filtration

Set Point Accuracy

Set Point Differential

Switch, See “Switch Ratings”

Inlet / Outlet

Electrical Termination

Stainless Steel

PPS Composite/Epoxy

316 Stainless Steel

Fluorocarbon

1000 PSI

-20°F to +275°F (120°C), (-28.8°C to +135°C)

100 Micron or Better

±20%, Maximum

20% Maximum

SPST , 20 VA

1/2” Tube, 1/2” & 3/4” NPT Male

No. 22 AWG, 24” to 26” PVC Cable

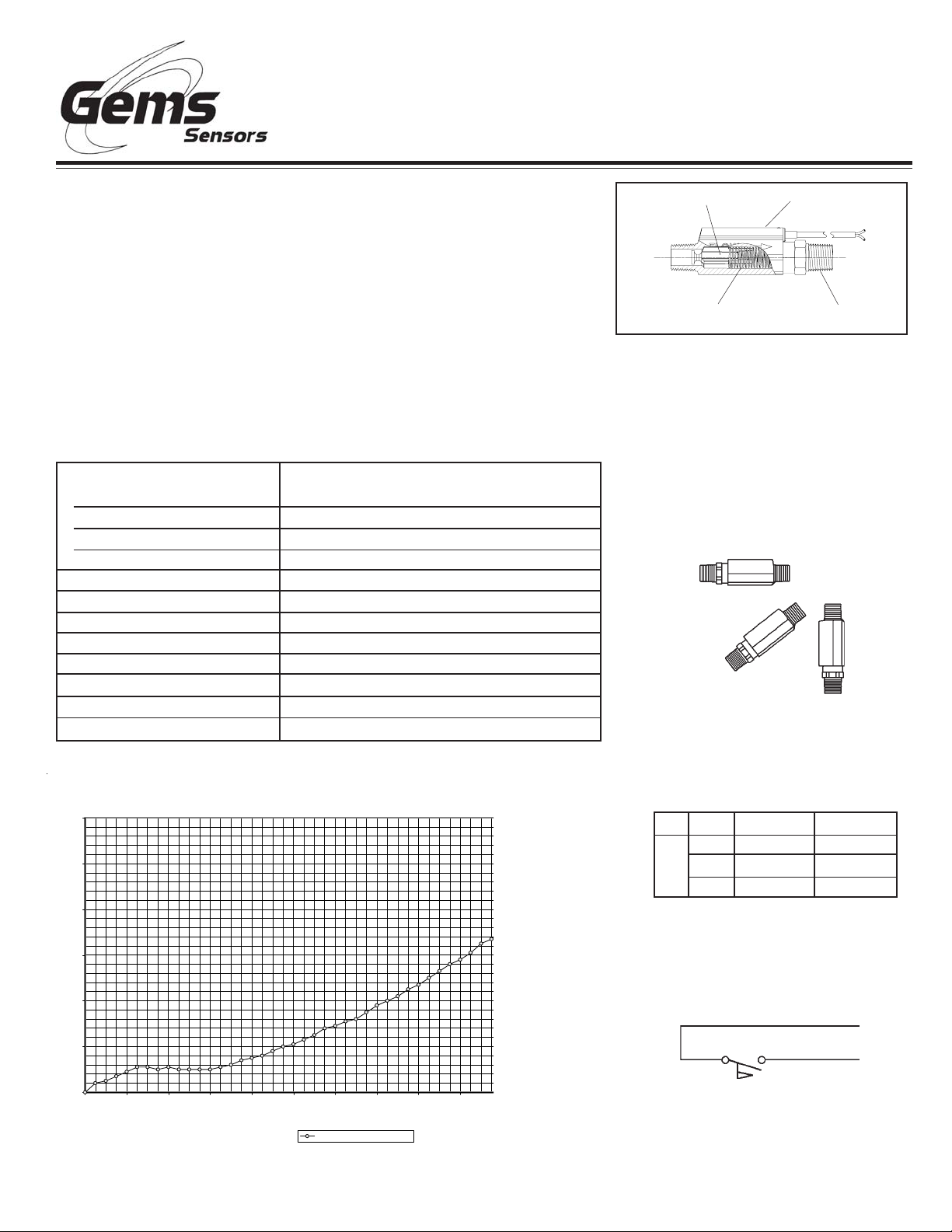

Piston

Inlet

Spring

Body

Outlet

End Fitting

FS-480 Flow Switches Can be Mounted

In Various Positions

Flow settings are based on a vertical

position (inlet port down), using water at

+70°F on increasing flow. Some variation

in set point actuation will occur in other

mounting orientations.

PSID Gems FS 480, 1GPM Setpoint

12

10

8

6

PSID

4

2

0

0123456789

Gems FS-480 P/N 204711

Switch Ratings

Max. Resistive Load

VA

20

Volts

0-30

120

240

Amps AC

.17

.08

Wiring Diagram

Normally Open

.4

Amps DC

.3

.13

.06

Page 2

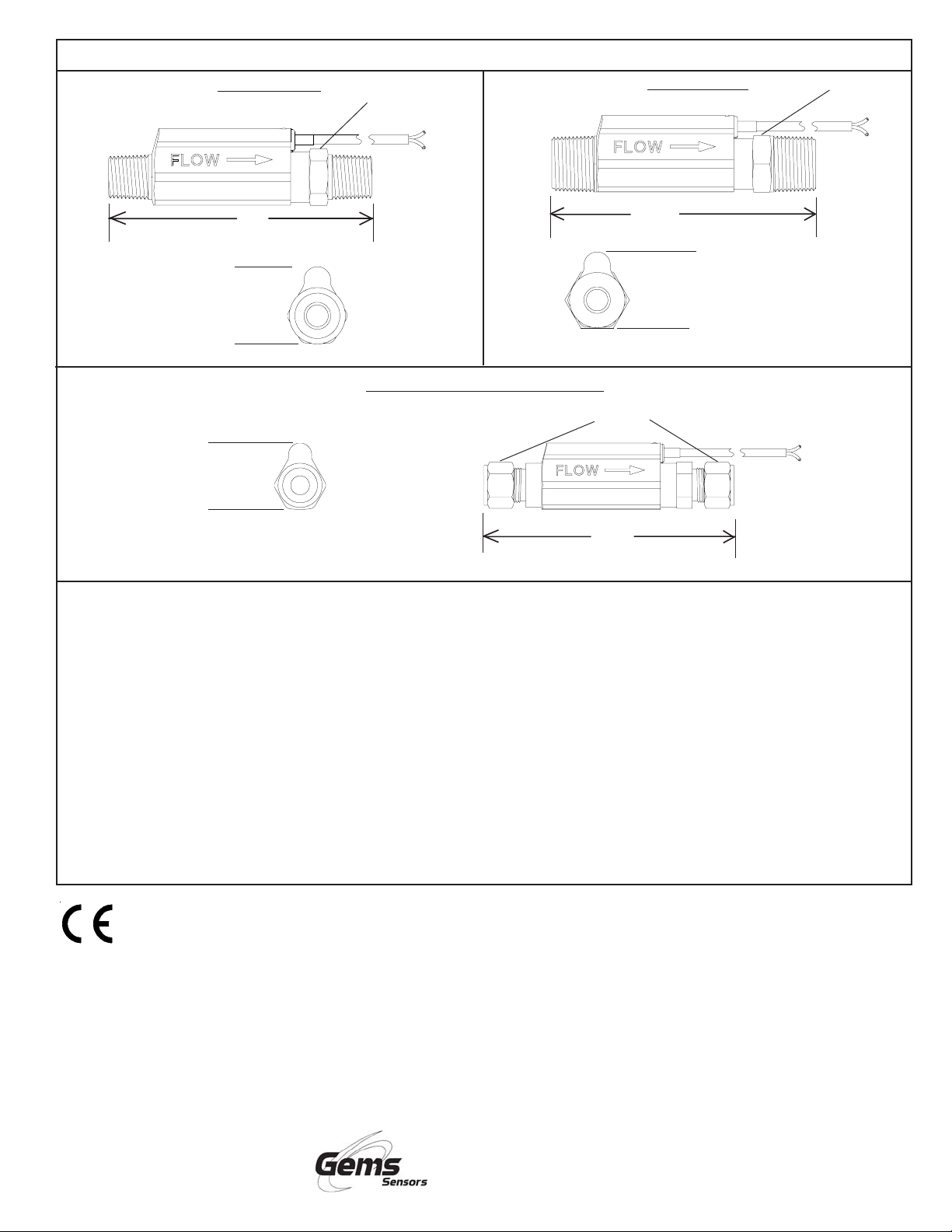

Dimensions

1/2” NPT Ports

4.94”

(125 mm)

↑

1.50”

(38 mm)

↓

↑

1.50”

(38 mm)

↓

7/8” HEX

1/2” Tube End Compression Fitting

(137 mm)

(126 mm)

7/8” HEX

5.4”

3/4” NPT Ports

4.95”

↑

1.50”

(38 mm)

↓

1 1/16” HEX

Important Points:

• Gems products must be maintained and installed in strict accor-

dance with the National Electrical Code and the applicable Gems

product instruction Bulletin that covers installation, operation and

proper maintenance. Failure to observe this information may result

in serious injury or damages.

• For hazardous area applications involving such things as, but not

limited to, ignitable mixtures, combustible dust and flammable

materials, use an appropriate explosionproof enclosure or intrinsi cally safe interface device.

• Please adhere to the pressure and temperature limitations shown

throughout this catalog for our level and flow sensors. These

limitations must not be exceeded. These pressures and tempera tures take into consideration possible system surge pressures/

temperatures and their frequencies.

• Selection of materials for compatibility with the media is critical to

the life and operation of Gems products. Take care in the proper

selection of materials of construction, testing is required.

This product is suitable for Class I and Class II applications only, per the requirements of standard EN60730 and any additional specific

requirements for a particular application or medium being sensed. Class I compliance of metal bodied units requires a ground connection

between the metal body and the earthing system of the installation. Class I compliance of plastic bodied units in contact with a conductive

medium requires that the medium be effectively earthed so as to provide an earthed barrier between the unit and accessible areas. For

Class III compliance, a supply at safety extra-low voltage (SELV) must be provided. Please consult the Factory for compliance information

on specific part numbers.

• NSF-approved sensors are made of materials approved for potable

water applications according to Standard 61.

• Stainless steel is generally regarded as safe by NSF and FDA.

• Life expectancy of switch contacts varies with application. Contact

Gems if life cycle testing is required.

• Ambient temperature changes do affect switch set points, since the

gravity of a liquid can vary with temperature.

• Our sensors have been designed to resist shock and vibration.

However, shock and vibration should be minimized.

• Filter liquid media containing particulate and/or debris to ensure the

proper operation of our products.

• Electrical entries and mounting points in an enclosed tank may

require liquid/vapor sealing.

• Our sensors must not be field-repaired.

• Physical damage sustained by product may render it unserviceable.

Return Policy

Returns are accepted on stock items up to 30 days from date of order. You must contact our Returns Department for a Return Authorization

(RA) number. Return the goods - freight prepaid - in the original container and include original packing slip. C. O. D. returns are not

accepted. Gems reserves the right to apply restocking charges.

Tel: 860-793-4357

Fax: 860-793-4563

Gems Sensors Inc.

One Cowles Road

Plainville, CT 06062-1198

Toll-Free: 1-800-378-1600

Loading...

Loading...