Page 1

Electrical Data . . .Electrical Data . . .

Electrical Data . . .

Electrical Data . . .Electrical Data . . .

Switch Ratings - Max Resistive LoadSwitch Ratings - Max Resistive Load

Switch Ratings - Max Resistive Load

Switch Ratings - Max Resistive LoadSwitch Ratings - Max Resistive Load

VAVA

VA

VAVA

1010

10

1010

1515

15

1515

2020

20

2020

This product is suitable for Class I and Class II applications only, per the

requirements of standard EN60730 and any additional specific requirements for

a particular application or medium being sensed. Class I compliance of metal

bodied units requires a ground connection between the metal body and the

earthing system of the installation. Class I compliance of plastic bodied units in

contact with a conductive medium requires that the medium be effectively earthed

so as to provide an earthed barrier between the unit and accessible areas. For

Class III compliance, a supply at safety extra-low voltage (SELV) must be

provided. Please consult the Factory for compliance information on specific part

numbers.

Product must be maintained and installed in strict

accordance with the National Electrical Code and

GEMS product catalog and instruction bulletin. Failure to observe this warning could result in serious

injuries or damages.

An appropriate explosion-proof enclosure or intrinsically safe interface device must be used for hazardous area applications involving such things as

not limited to)

and flammable materials.

Pressure and temperature limitations shown on individual catalog pages and drawings for the specified

flow switches must not be exceeded. These pressures and temperatures take into consideration possible system surge pressures/temperatures and their

frequencies.

Selection of materials for compatibility with the media is critical to the life and operation of GEMS flow

switches. Take care in the proper selection of materials of construction; particularly wetted materials.

ignitable mixtures, combustible dust

VoltsVolts

Volts

VoltsVolts

Important Points!Important Points!

Important Points!

Important Points!Important Points!

(but

Amps ACAmps AC

Amps AC

Amps ACAmps AC

0-500-50

0-50

0-500-50

120120

120

120120

100100

100

100100

0-500-50

0-50

0-500-50

120120

120

120120

240240

240

240240

0-300-30

0-30

0-300-30

120120

120

120120

240240

240

240240

Life expectancy of switch contacts varies with applications. Contact GEMS if life cycle testing is required.

Ambient temperature changes do affect switch set

points, since the specific gravity of a liquid can vary

with temperature.

Flow switches have been designed to resist shock

and vibration; however, shock and vibration should

be minimized.

Liquid media containing particulate and/or debris

should be filtered to ensure proper operation of

GEMS products.

Electrical entries and mounting points may require

liquid/vapor sealing if located in an enclosed tank.

Flow switches must not be field repaired.

Physical damaged sustained by the product may render it unserviceable.

.2.2

.2

.2.2

.08.08

.08

.08.08

N.A.N.A.

N.A.

N.A.N.A.

.3.3

.3

.3.3

.12.12

.12

.12.12

.06.06

.06

.06.06

.4.4

.4

.4.4

.17.17

.17

.17.17

.08.08

.08

.08.08

Amps DC

.13

N.A.

.1

.2

.08

.04

.3

.13

.06

Piston-Type Flow SwitchesPiston-Type Flow Switches

Piston-Type Flow Switches

Piston-Type Flow SwitchesPiston-Type Flow Switches

HPF-920 Series & FS-10798 SeriesHPF-920 Series & FS-10798 Series

HPF-920 Series & FS-10798 Series

HPF-920 Series & FS-10798 SeriesHPF-920 Series & FS-10798 Series

Instruction Bulletin No. 45520Instruction Bulletin No. 45520

Instruction Bulletin No. 45520

Instruction Bulletin No. 45520Instruction Bulletin No. 45520

Installation . . .Installation . . .

Installation . . .

Installation . . .Installation . . .

Install FS-10798 or HPF-920 Series units in piping system using standard pipe

fitting procedures. Be sure to keep thread sealing compound out of unit. Install

so that flow is in proper direction (marked "IN" and "OUT" on housing). Use of 50

micron filtration is recommended.

Dimensional Data . . .Dimensional Data . . .

Dimensional Data . . .

Dimensional Data . . .Dimensional Data . . .

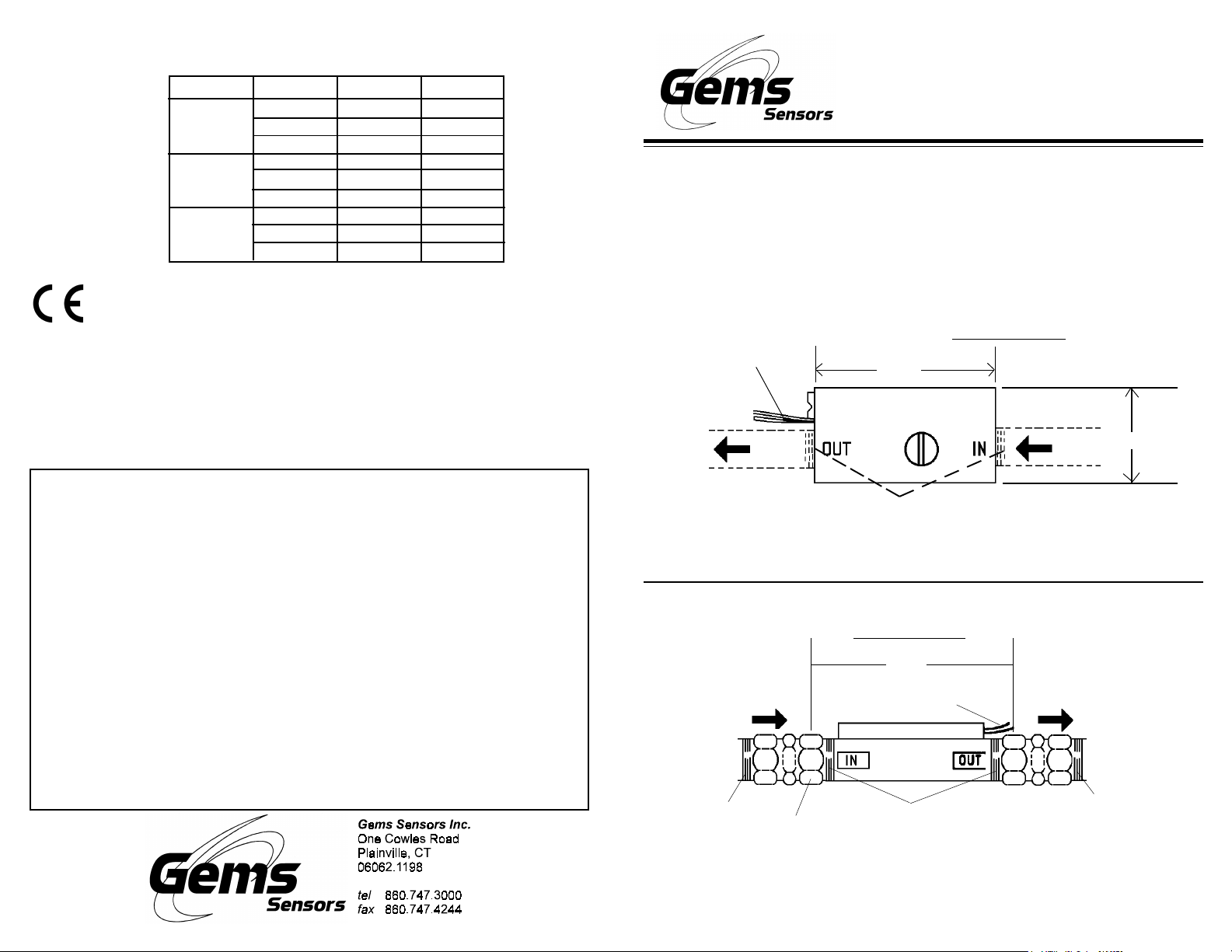

FS-10798 SeriesFS-10798 Series

FS-10798 Series

FS-10798 SeriesFS-10798 Series

Lead Wires

FLOW

Piping System

4-1/8"

1/2" NPT

(Both Ports)

Piping System

FLOW

2"

Unless otherwise specified, units are factory-calibrated in water for in-line

installation; in horizontal position, as shown above.

HPF-920 SeriesHPF-920 Series

HPF-920 Series

HPF-920 SeriesHPF-920 Series

4-5/8"

Piping

System

FLOW

Union

Lead Wires

1/2" NPT

(Both Ports)

FLOW

Piping

System

P/N 45520

Rev. K

Units are factory-calibrated in water on decreasing flow and are installed

in-line, in a horizontal position, as shown above.

Page 2

Specifications . . .Specifications . . .

Specifications . . .

Specifications . . .Specifications . . .

HousingHousing

Housing

HousingHousing

PistonPiston

Piston

PistonPiston

(In Brass Housing)(In Brass Housing)

(In Brass Housing)

MaterialsMaterials

Materials

MaterialsMaterials

Liquid Flow Adjustable Range - WaterLiquid Flow Adjustable Range - Water

Liquid Flow Adjustable Range - Water

Liquid Flow Adjustable Range - WaterLiquid Flow Adjustable Range - Water

PressurePressure

Pressure

PressurePressure

RatingsRatings

Ratings

RatingsRatings

OperatingOperating

Operating

OperatingOperating

TemperaturesTemperatures

Temperatures

TemperaturesTemperatures

RepeatabilityRepeatability

Repeatability

RepeatabilityRepeatability

Set Point DifferentialSet Point Differential

Set Point Differential

Set Point DifferentialSet Point Differential

Set Point Accuracy (Constant Temperature)Set Point Accuracy (Constant Temperature)

Set Point Accuracy (Constant Temperature)

Set Point Accuracy (Constant Temperature)Set Point Accuracy (Constant Temperature)

Air/Gas Flow Adj. Ranges:Air/Gas Flow Adj. Ranges:

Air/Gas Flow Adj. Ranges:

Air/Gas Flow Adj. Ranges:Air/Gas Flow Adj. Ranges:

(Dep. on Oper. Line Pressure)(Dep. on Oper. Line Pressure)

(Dep. on Oper. Line Pressure)

(Dep. on Oper. Line Pressure)(Dep. on Oper. Line Pressure)

Switch (See Electrical Data, Back Page)Switch (See Electrical Data, Back Page)

Switch (See Electrical Data, Back Page)

Switch (See Electrical Data, Back Page)Switch (See Electrical Data, Back Page)

**

*Minimum line pressure for positive actuation.

**

: Temperature changes will slightly affect water or gas flow settings.: Temperature changes will slightly affect water or gas flow settings.

Note

: Temperature changes will slightly affect water or gas flow settings.

: Temperature changes will slightly affect water or gas flow settings.: Temperature changes will slightly affect water or gas flow settings.

Oil settings will vary with viscosity. Oil settings will vary with viscosity.

Oil settings will vary with viscosity.

Oil settings will vary with viscosity. Oil settings will vary with viscosity.

Factory-Set (Standard)Factory-Set (Standard)

Factory-Set (Standard)

Factory-Set (Standard)Factory-Set (Standard)

Lead WiresLead Wires

Lead Wires

Lead WiresLead Wires

Housing and PistonHousing and Piston

Housing and Piston

MaterialsMaterials

Materials

MaterialsMaterials

Operating Pressure, Max.Operating Pressure, Max.

Operating Pressure, Max.

Operating Pressure, Max.Operating Pressure, Max.

Operating TemperatureOperating Temperature

Operating Temperature

Operating TemperatureOperating Temperature

Set Point AccuracySet Point Accuracy

Set Point Accuracy

Set Point AccuracySet Point Accuracy

Set Point DifferentialSet Point Differential

Set Point Differential

Set Point DifferentialSet Point Differential

Switch (See Electrical Data)Switch (See Electrical Data)

Switch (See Electrical Data)

Switch (See Electrical Data)Switch (See Electrical Data)

Lead WiresLead Wires

Lead Wires

Lead WiresLead Wires

Housing and PistonHousing and Piston

Other Wetted PartsOther Wetted Parts

Other Wetted Parts

Other Wetted PartsOther Wetted Parts

(In Brass Housing)(In Brass Housing)

Piston (SS Housing)Piston (SS Housing)

Piston (SS Housing)

Piston (SS Housing)Piston (SS Housing)

Other Wetted PartsOther Wetted Parts

Other Wetted Parts

Other Wetted PartsOther Wetted Parts

OperatingOperating

Operating

OperatingOperating

ProofProof

Proof

ProofProof

BurstBurst

Burst

BurstBurst

With SS or Brass PistonWith SS or Brass Piston

With SS or Brass Piston

With SS or Brass PistonWith SS or Brass Piston

With Polysulfone PistonWith Polysulfone Piston

With Polysulfone Piston

With Polysulfone PistonWith Polysulfone Piston

For 5 PSIG LineFor 5 PSIG Line

For 5 PSIG Line

For 5 PSIG LineFor 5 PSIG Line

For 100 PSIG LineFor 100 PSIG Line

For 100 PSIG Line

For 100 PSIG LineFor 100 PSIG Line

For 5 PSIG Line

For 100 PSIG Line: 3 to 160 SCFM Approx.

HPF-920 UnitsHPF-920 Units

HPF-920 Units

HPF-920 UnitsHPF-920 Units

FS-10798 UnitsFS-10798 Units

FS-10798 Units

FS-10798 UnitsFS-10798 Units

Brass or 316 SS

Polysulfone for Water

Brass for Oil or Air

316 SS

316 SS, Viton, Epoxy

0.5 to 20 GPM

1000 PSIG

2500 PSIG

5000 PSIG

-20o to +300oF(-29oC to +148.9oC)

**

*

**

0oF to +250oF (-17.8oC to +121oC)

No. 18 AWG, 24" L., Polymeric

-20o to +225oF(-29oC to +107.2oC)

1% Max. Deviation

15% Max.

±10% Max.

**

*: 1 to 75 SCFM (Approx.)

**

SPDT, 20 VA

No. 18 AWG, 24" L., Polymeric

Brass

Stainless Steel, Epoxy

1500 PSIG

±20% Max.

20%, Max.

SPST, 20 VA

Note

HPF-920 Series units are calibrated standard in water @+70oF,

on decreasing flow, in horizontal position. Set point accuracy will

change slightly with unit in other calibrated position.

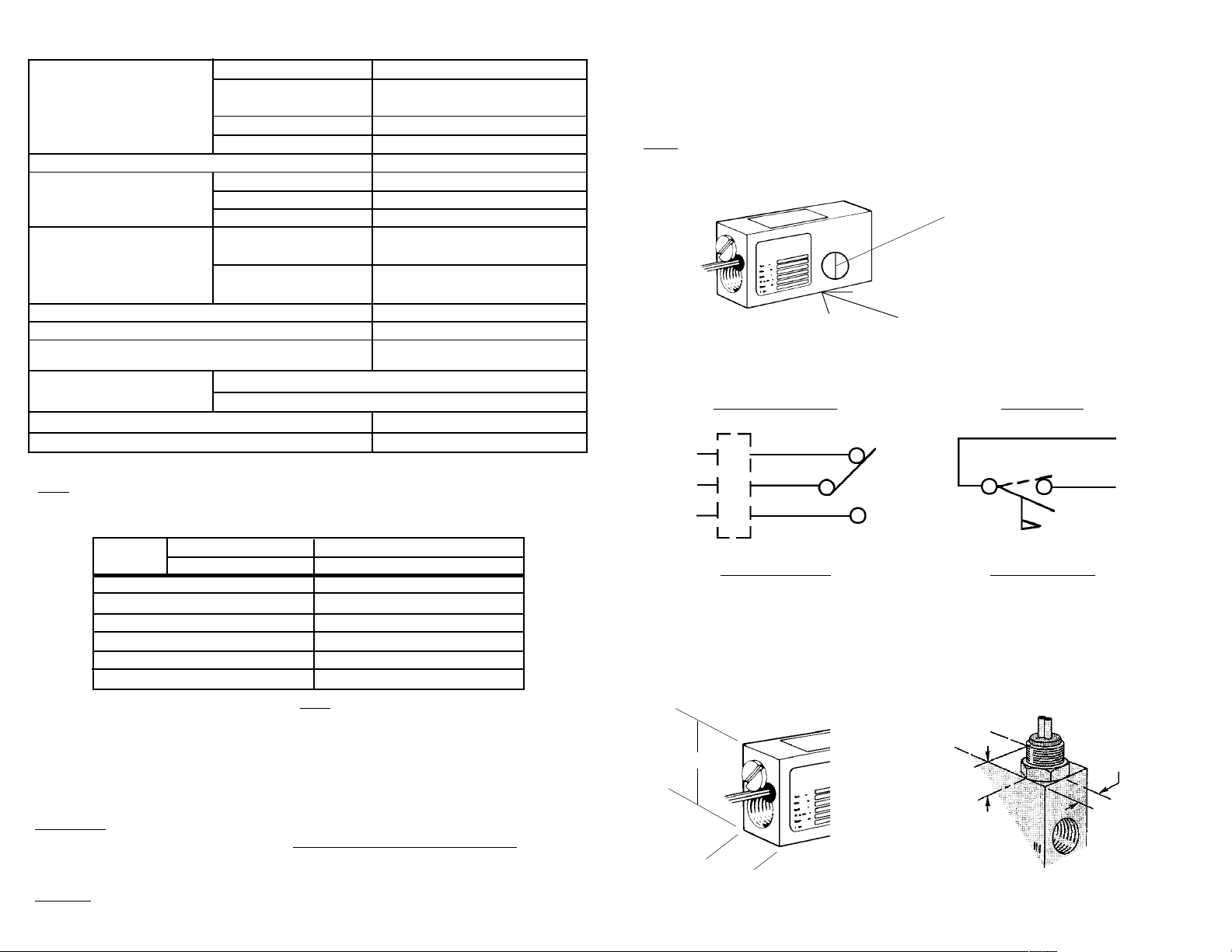

Flow Setting Adjustment: FS-10798 Units . . .Flow Setting Adjustment: FS-10798 Units . . .

Flow Setting Adjustment: FS-10798 Units . . .

Flow Setting Adjustment: FS-10798 Units . . .Flow Setting Adjustment: FS-10798 Units . . .

Standard units are normally supplied with adjustment set at minimum flow adjusting screw slot (and vane within unit) in vertical position, as shown below.

Adjust unit on test stand or installed in system. With liquid (or gas) flow at desired

rate, adjust unit until switch first actuates (opens or closes, as desired).

NoteNote

: Vane is locked at Factory with set screw and must be unlocked prior: Vane is locked at Factory with set screw and must be unlocked prior

Note

: Vane is locked at Factory with set screw and must be unlocked prior

NoteNote

: Vane is locked at Factory with set screw and must be unlocked prior: Vane is locked at Factory with set screw and must be unlocked prior

to any adjustment; then relocked after adjustment has been made.to any adjustment; then relocked after adjustment has been made.

to any adjustment; then relocked after adjustment has been made.

to any adjustment; then relocked after adjustment has been made.to any adjustment; then relocked after adjustment has been made.

Adjustment Screw with Slot in

Minimum Flow Position

Locking Set Screw

Typical Wiring Diagrams . . .Typical Wiring Diagrams . . .

Typical Wiring Diagrams . . .

Typical Wiring Diagrams . . .Typical Wiring Diagrams . . .

3-Pin Receptacle3-Pin Receptacle

3-Pin Receptacle

3-Pin Receptacle3-Pin Receptacle

RedRed

Red

RedRed

AA

A

AA

BlackBlack

Black

BlackBlack

CC

C

CC

OrangeOrange

Orange

OrangeOrange

BB

B

BB

FS-10798 UnitsFS-10798 Units

FS-10798 Units

FS-10798 UnitsFS-10798 Units

Electrical Connection: FS-10798 Units . . .Electrical Connection: FS-10798 Units . . .

Electrical Connection: FS-10798 Units . . .

Electrical Connection: FS-10798 Units . . .Electrical Connection: FS-10798 Units . . .

Lead Wires,Lead Wires,

Lead Wires,

Lead Wires,Lead Wires,

Strain ReliefStrain Relief

Strain Relief

Strain ReliefStrain Relief

2"2"

2"

2"2"

Lead WiresLead Wires

Lead Wires

Lead WiresLead Wires

RedRed

Red

RedRed

RedRed

Red

RedRed

N.O. or N.C.N.O. or N.C.

N.O. or N.C.

N.O. or N.C.N.O. or N.C.

(No Flow)(No Flow)

(No Flow)

(No Flow)(No Flow)

HPF-920 UnitsHPF-920 Units

HPF-920 Units

HPF-920 UnitsHPF-920 Units

1/2" NPT1/2" NPT

1/2" NPT

1/2" NPT1/2" NPT

Conduit ConnectorConduit Connector

Conduit Connector

Conduit ConnectorConduit Connector

**

*

**

1/2"1/2"

1/2"

1/2"1/2"

Maintenance . . .Maintenance . . .

Maintenance . . .

Maintenance . . .Maintenance . . .

FS-10798: FS-10798:

FS-10798:

FS-10798: FS-10798:

the only maintenance normally required.

Occasional cleaning when excessive contamination is present in the liquid is

To disassemble unit for cleaning:To disassemble unit for cleaning:

To disassemble unit for cleaning: With

To disassemble unit for cleaning:To disassemble unit for cleaning:

system shut down and no liquid in piping, remove piston plug from unit. Unit need not

be removed from system.

HPF-920HPF-920

HPF-920

HPF-920HPF-920

: :

Disassembly of HPF-920 Series units is not recommended.Disassembly of HPF-920 Series units is not recommended.

:

Disassembly of HPF-920 Series units is not recommended.

: :

Disassembly of HPF-920 Series units is not recommended.Disassembly of HPF-920 Series units is not recommended.

If mainte-

nance becomes necessary, contact the Factory for assistance.

1-1/4"1-1/4"

1-1/4"

1-1/4"1-1/4"

1-1/16"1-1/16"

1-1/16"

1-1/16"1-1/16"

* Not available with UL or FM approval

Loading...

Loading...