Page 1

Electrical Data . . .Electrical Data . . .

Electrical Data . . .

Electrical Data . . .Electrical Data . . .

Standard snap-action switch is a 20VA, SPST,

Typical Wiring DiagramsTypical Wiring Diagrams

Typical Wiring Diagrams

Typical Wiring DiagramsTypical Wiring Diagrams

hermetically sealed,magnetically actuated,

make-and-break type. Normally open or normally closed operation is selectable by inverting floats on unit stem. A level station with

SPDT 3-wire switch is available as a separate

SPST Switch N.O. or N.C. (Dry).SPST Switch N.O. or N.C. (Dry).

SPST Switch N.O. or N.C. (Dry).

component if required.

Switch Ratings . . . Max. Resistive LoadSwitch Ratings . . . Max. Resistive Load

Switch Ratings . . . Max. Resistive Load

Switch Ratings . . . Max. Resistive LoadSwitch Ratings . . . Max. Resistive Load

VA Volts Amps AC Amps DC

0-30

120

20

240

Product must be maintained and installed in strict accordance with the National

Electrical Code and GEMS product catalog and instruction bulletin. Failure to observe

this warning could result in serious injuries or damages.

An appropriate explosion-proof enclosure or intrinsically safe interface device must be

used for hazardous area applications involving such things as

mixtures, combustible dust and flammable materials.

Pressure and temperature limitations shown on individual catalog pages and drawings

for the specified level switches must not be exceeded. These pressures and temperatures take into consideration possible system surge pressures/temperatures and their

frequencies.

Selection of materials for compatibility with the media is critical to the life and

operation of GEMS level switches. Take care in the proper selection of materials of

construction; particularly wetted materials.

Life expectancy of switch contacts varies with applications. Contact GEMS if life

cycle testing is required.

Ambient temperature changes do affect switch set points, since the specific gravity of

a liquid can vary with temperature.

Level switches have been designed to resist shock and vibration; however, shock and

vibration should be minimized.

Liquid media containing particulate and/or debris should be filtered to ensure proper

operation of GEMS products.

Electrical entries and mounting points may require liquid/vapor sealing if located in an

enclosed tank.

Level switches must not be field repaired.

Physical damaged sustained by the product may render it unserviceable.

.4

.17

.08

.3

.13

.06

Important Points!Important Points!

Important Points!

Important Points!Important Points!

SPST Switch N.O. or N.C. (Dry).SPST Switch N.O. or N.C. (Dry).

Selectable by Inverting Float.Selectable by Inverting Float.

Selectable by Inverting Float.

Selectable by Inverting Float.Selectable by Inverting Float.

Black

Yellow

Red

SPDT Switch in N.C. (Dry) PositionSPDT Switch in N.C. (Dry) Position

SPDT Switch in N.C. (Dry) Position

SPDT Switch in N.C. (Dry) PositionSPDT Switch in N.C. (Dry) Position

(but not limited to)

P/N 72946

Rev. L

Com.

N.C.

N.O.

ignitable

Fabri-Level Switch KitFabri-Level Switch Kit

Fabri-Level Switch Kit

Fabri-Level Switch KitFabri-Level Switch Kit

Instruction Bulletin No. 72946Instruction Bulletin No. 72946

Instruction Bulletin No. 72946

Instruction Bulletin No. 72946Instruction Bulletin No. 72946

Fabri-Level Kits contain all components

for complete assembly of a 1- or 2station level switch unit for pipe-plug

mounting in your tank.

Each kit contains: 1 Tube Connector, 1 Mounting

Plug, 2 Level Stations (Switch, Tube,

Float), 2 Extension Tubes, 1 Tube End

Fitting, 3 Tube Unions.

Specifications . . .Specifications . . .

Specifications . . .

Specifications . . .Specifications . . .

Conduit Thread: 1/2" NPT-F

Tube/Fitting Size: 1/2" O.D.

Max. No. Levels per Stem: 6

Mounting Attitude: Vertical ±

30

o

Fitting Ferrule:

Buna N Floats: Nylon

Stainless Floats: 316 Stainless Steel

N.O. or N.C. operation of the SPST switch is selectable by inverting the float(s) on the

unit stem.

are not reversible.are not reversible.

are not reversible. Two 10" lengths of tube are furnished to space level stations as

are not reversible.are not reversible.

Note: SPDT circuits must have "N.O." toward lead wires. SPDT floatsNote: SPDT circuits must have "N.O." toward lead wires. SPDT floats

Note: SPDT circuits must have "N.O." toward lead wires. SPDT floats

Note: SPDT circuits must have "N.O." toward lead wires. SPDT floatsNote: SPDT circuits must have "N.O." toward lead wires. SPDT floats

desired.

SwitchSwitch

Switch

SwitchSwitch

SPST

20 VA

MaterialMaterial

Material

MaterialMaterial

Brass Fittings,

Buna N Floats

316 SS Fittings,

Buna N Floats

All 316 SS

Oper. Temp.Oper. Temp.

WaterWater

Water

WaterWater

To 180

(82.2°C)

o

F

(-40°C to

OilOil

Oil

OilOil

-40°F to

+230oF

+110°C)

-40°F to +275oF

(-40°C to +135°C)

Min.Min.

Min.

Min.Min.

Sp. Gr.Sp. Gr.

Sp. Gr.

Sp. Gr.Sp. Gr.

.55

.75

.75

55

.80

Pres.Pres.

Pres.

Pres.Pres.

(Max.PSI)(Max.PSI)

(Max.PSI)

(Max.PSI)(Max.PSI)

150

750

Mtg.Mtg.

Mtg.

Mtg.Mtg.

NPTNPT

NPT

NPTNPT

2"

1-1/4"

1-1/4"

2"

2"

PartPart

Part

PartPart

NumberNumber

Number

NumberNumber

24576

26128

26130

26675

24577

Oper. Temp.Oper. Temp.

Oper. Temp.

This product is suitable for Class I and Class II applications only, per the

requirements of standard EN60730 and any additional specific requirements

for a particular application or medium being sensed. Class I compliance of

metal bodied units requires a ground connection between the metal body and

the earthing system of the installation. Class I compliance of plastic bodied

units in contact with a conductive medium requires that the medium be

effectively earthed so as to provide an earthed barrier between the unit and

accessible areas. For Class III compliance, a supply at safety extra-low

voltage (SELV) must be provided. Please consult the Factory for compliance

information on specific part numbers.

Installation and Maintenance . . .Installation and Maintenance . . .

Installation and Maintenance . . .

Installation and Maintenance . . .Installation and Maintenance . . .

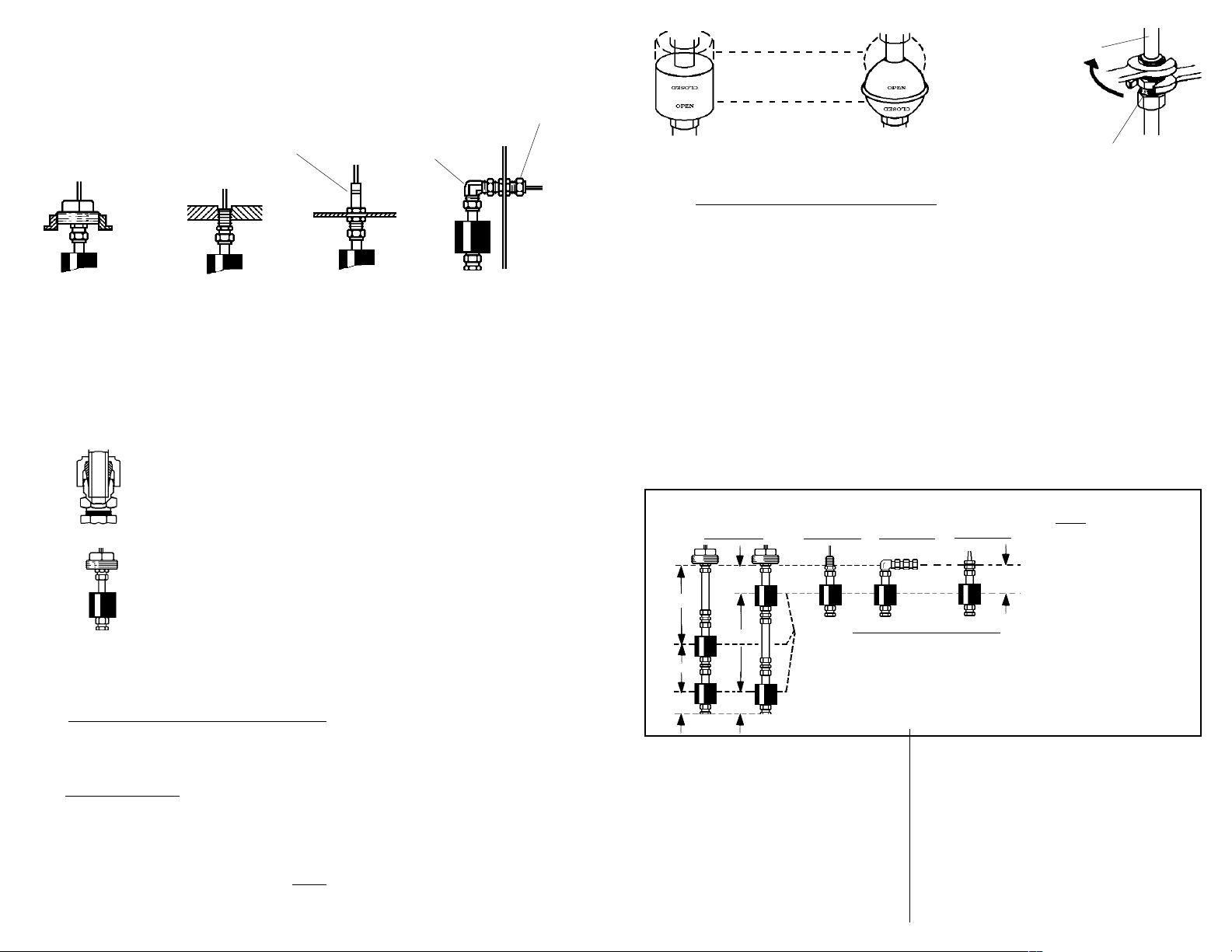

Installation can be from top, bottom or side of tank, as shown below. Usually

installed as nearly vertical as possible, units will operate reliably as much as 30o

from the vertical. Only two wrenches are needed to assemble. From one to six

level stations may be spaced as desired on a single unit. You merely follow

“Assembly Instructions”“Assembly Instructions”

“Assembly Instructions”, install in tank, connect electrical leads and your “tailor-

“Assembly Instructions”“Assembly Instructions”

made” unit is ready for use . . . in any media compatible with Brass and Buna N or

316 Stainless Steel - the two material options available.

Page 2

Installation and Maintenance (Cont.)Installation and Maintenance (Cont.)

Installation and Maintenance (Cont.)

Installation and Maintenance (Cont.)Installation and Maintenance (Cont.)

Maintenance requirements are minimal and usually limited to occasional clean-up of

scum or scale accumulation.

Mounting Methods . . .Mounting Methods . . .

Mounting Methods . . .

Mounting Methods . . .Mounting Methods . . .

1.

Adapter

2.

Elbow

3.

Adapter

4.

1. 1-1/4" or 2" NPT pipe plug. Top or bottom mount, boss or thickwall tank.

Permits unit insertion from outside.

2. 3/8" NPT-M tube connector. Top or bottom mount from inside. Boss or

thickwall tank.

3, 4. Top-mount through sheet metal cover, or with 90o elbow for mounting unit

from inside of tank.

Pressure-type fittingsPressure-type fittings

Pressure-type fittings form positive seal. Tube cannot turn,

Pressure-type fittingsPressure-type fittings

wires cannot twist during tightening. Nylon ferrule for brass

units, SS ferrule for stainless units. 13/16" and 7/8" HEX

fittings.

Closed

Position

Open

Position

Buna NBuna N

Buna N

Buna NBuna N

FloatFloat

Float

FloatFloat

Coupling Components TogetherCoupling Components Together

c/

Coupling Components Together: Insert tubes to limit in fittings and

Coupling Components TogetherCoupling Components Together

316 SS316 SS

316 SS

316 SS316 SS

FloatFloat

Float

FloatFloat

Tube Inserted To Stop

1-1/4" to 1-1/2"

Turns Beyond

"Finger-tight"

Union

tighten “finger-tight”. After checking entire unit, wrench-tighten as

illustrated.

first, then check level locations and switch operation (N.O. or N.C.) first, then check level locations and switch operation (N.O. or N.C.)

first, then check level locations and switch operation (N.O. or N.C.)

first, then check level locations and switch operation (N.O. or N.C.) first, then check level locations and switch operation (N.O. or N.C.)

before final tightening. before final tightening.

before final tightening.

before final tightening. before final tightening.

Install Unit in Tank:Install Unit in Tank:

2.

Install Unit in Tank: Fabri-Level units with 1 1/4" or 2" NPT mounting

Install Unit in Tank:Install Unit in Tank:

Important: Always assemble entire unit “finger-tight”Important: Always assemble entire unit “finger-tight”

Important: Always assemble entire unit “finger-tight”

Important: Always assemble entire unit “finger-tight”Important: Always assemble entire unit “finger-tight”

plugs are installed through a boss or tapped hole from outside of tank.

Units with alternate mountings are installed from the inside.

Electrical Leads: Electrical Leads:

3.

Electrical Leads: Leads are readily identified for connection; i.e., switch

Electrical Leads: Electrical Leads:

leads nearest mounting end of unit project the farthest, etc.

See “Switch Ratings” before connecting power to Fabri-Level unit. See “Switch Ratings” before connecting power to Fabri-Level unit.

See “Switch Ratings” before connecting power to Fabri-Level unit.

See “Switch Ratings” before connecting power to Fabri-Level unit. See “Switch Ratings” before connecting power to Fabri-Level unit.

Actuation Level Dimensional Data . . .Actuation Level Dimensional Data . . .

Actuation Level Dimensional Data . . .

Actuation Level Dimensional Data . . .Actuation Level Dimensional Data . . .

Bulkhead

Plug

Mounted

Connector

Mounted

Side

Mounted

Adaptor

Mounted

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

NoteNote

Note:

NoteNote

Buna N floats shown.

2" NPT mounting plug 2" NPT mounting plug

2" NPT mounting plug permits entire unit to be inserted in tank

2" NPT mounting plug 2" NPT mounting plug

from outside. 1/2" NPT-F provides direct electrical conduit

connection. A 1-1/4" NPT mounting plug is also available.

Assembly Instructions . . .Assembly Instructions . . .

Assembly Instructions . . .

Assembly Instructions . . .Assembly Instructions . . .

1. Assemble unit,

a/ a/

Extension Tubes (When Required):Extension Tubes (When Required):

a/

Extension Tubes (When Required):

a/ a/

Extension Tubes (When Required):Extension Tubes (When Required):

observing the following sketches and information.

Cut to proper length. Tubes 36"

long are available as components, or use any 1/2" tubing of suitable

non-magnetic material.

b/ b/

Level Stations: Level Stations:

b/

Level Stations: Assemble floats on switch tubes for desired switch

b/ b/

Level Stations: Level Stations:

operation, as shown. Feed level station wires through switch tubes of

each level station, toward mounting plug.

normally open (dry) position. To reverse operation, invertnormally open (dry) position. To reverse operation, invert

normally open (dry) position. To reverse operation, invert

normally open (dry) position. To reverse operation, invertnormally open (dry) position. To reverse operation, invert

floats. floats.

floats. (See next page)

floats. floats.

SPDT circuits must have "N.O." towards lead wire end of switch tube.SPDT circuits must have "N.O." towards lead wire end of switch tube.

SPDT circuits must have "N.O." towards lead wire end of switch tube.

SPDT circuits must have "N.O." towards lead wire end of switch tube.SPDT circuits must have "N.O." towards lead wire end of switch tube.

SPDT floats are not reversible.SPDT floats are not reversible.

SPDT floats are not reversible.

SPDT floats are not reversible.SPDT floats are not reversible.

NoteNote

Note

NoteNote

Note: Floats are shown in Note: Floats are shown in

Note: Floats are shown in

Note: Floats are shown in Note: Floats are shown in

D

A

B

C

E

For Units with Buna N Floats . . .For Units with Buna N Floats . . .

For Units with Buna N Floats . . .

For Units with Buna N Floats . . .For Units with Buna N Floats . . .

A. Min. with tube extension: 4-3/4"

Cut tube to length: "A" minus 2-7/8"

B. Min. with tube extension: 6-5/16"

Cut tube to length: "B" minus 4-15/16"

C. 4-1/4": Closest that levels can be.

D. 2-5/8": Highest possible level.

E. 2-1/8": Lowest possible level.

F. 2-7/8": Minus tank wall thickness.

E

Switch Actuation Levels

F

When two or more extension tubes are coupled together for greater length,

assemble coupling unions

before cutting to length per

"A" or "B" (In illustration at

left).

For Units with 316 Stainless Floats . . .For Units with 316 Stainless Floats . . .

For Units with 316 Stainless Floats . . .

For Units with 316 Stainless Floats . . .For Units with 316 Stainless Floats . . .

A. Min. with tube extension: 4-1/2"

Cut tube to length: "A" minus 2-5/8"

B. Min. with tube extension: 6-5/8"

Cut tube to length: "B" minus 4-11/16"

C. 4-1/2": Closest that levels can be.

D. 2-3/8": Highest possible level.

E. 2-5/8": Lowest possible level.

F. 2-5/8": Minus tank wall thickness.

Loading...

Loading...