Page 1

Return Policy

Returns are accepted on stock items up to 30 days from date of order. You must contact

our Returns Department for a Return Authorization (RA) number. Return the goods - freight

prepaid - in the original container and include original packing slip. C. O. D. returns are not

accepted. Gems reserves the right to apply restocking charges.

Tel: 860-793-4357

Fax: 860-793-4563

This product complies with EN61326 Electrical Equipment for Measurement, Control

and Laboratory use - EMC Requirements for Minimum Requirements and Industrial

Locations. Special caution should be taken to meet EN61000-4-5 Surge Immunity if any

of the following conditions apply to the installation: The product is installed outside; the

cable is greater than 30 meters in length. In order to meet the Surge Immunity

requirements, the following conditions must be followed during installation:

1. Shielded cable must be used, and the shield must be tied to earth ground (not power

supply ground) on at least one end of the cable shield/drain wire. The shield must be

maintained all the way from sensor to the power supply.

2. If unshielded cable is used, an earth grounded metal conduit can be used to replace

the shielded cable.

3. For the sensor with metal body or enclosure the body/enclosure must be grounded

to earth. If a protective metal housing is used, the metal housing should be grounded

to earth.

4. If a protective plastic housing is used, the housing must be able to withstand at least

2 kV from the housing to earth ground.

Important Points

• Product must be maintained and installed in strict accordance with the National Electrical Code and the

product catalog and instruction bulletin. Failure to observe this warning could result in serious injuries or

damages.

• An appropriate explosion-proof enclosure or intrinsically safe interface device must be used for hazardous

area applications involving such things as (but not limited to) ignitable mixtures, combustible dust and

flammable materials.

• Pressure and temperature limitations shown on individual catalog pages and drawings for the specified

sensors must not be exceeded. These pressures and temperatures take into consideration possible

system surge pressures/temperatures and their frequencies.

• Selection of materials for compatibility with the media is critical to the life and operation of these sensors.

Take care in the proper selection of materials of construction; particularly wetted materials.

• Life expectancy of switch contacts varies with applications.

• Ambient temperature changes do affect switch set points, since the specific gravity of a liquid can vary

with temperature.

• The sensors have been designed to resist shock and vibration; however, shock and vibration should be

minimized.

• Liquid media containing particulate and/or debris should be filtered to ensure proper operation of these

products.

• Electrical entries and mounting points may require liquid/vapor sealing if located in an enclosed tank.

• Sensors must not be field repaired.

• Physical damage sustained by the product may render it unserviceable.

P/N 179348

Rev. D

All Teflon

®

Electro-Optic Level Switches

ELS-1100TFE Series

Instruction Bulletin No. 179348

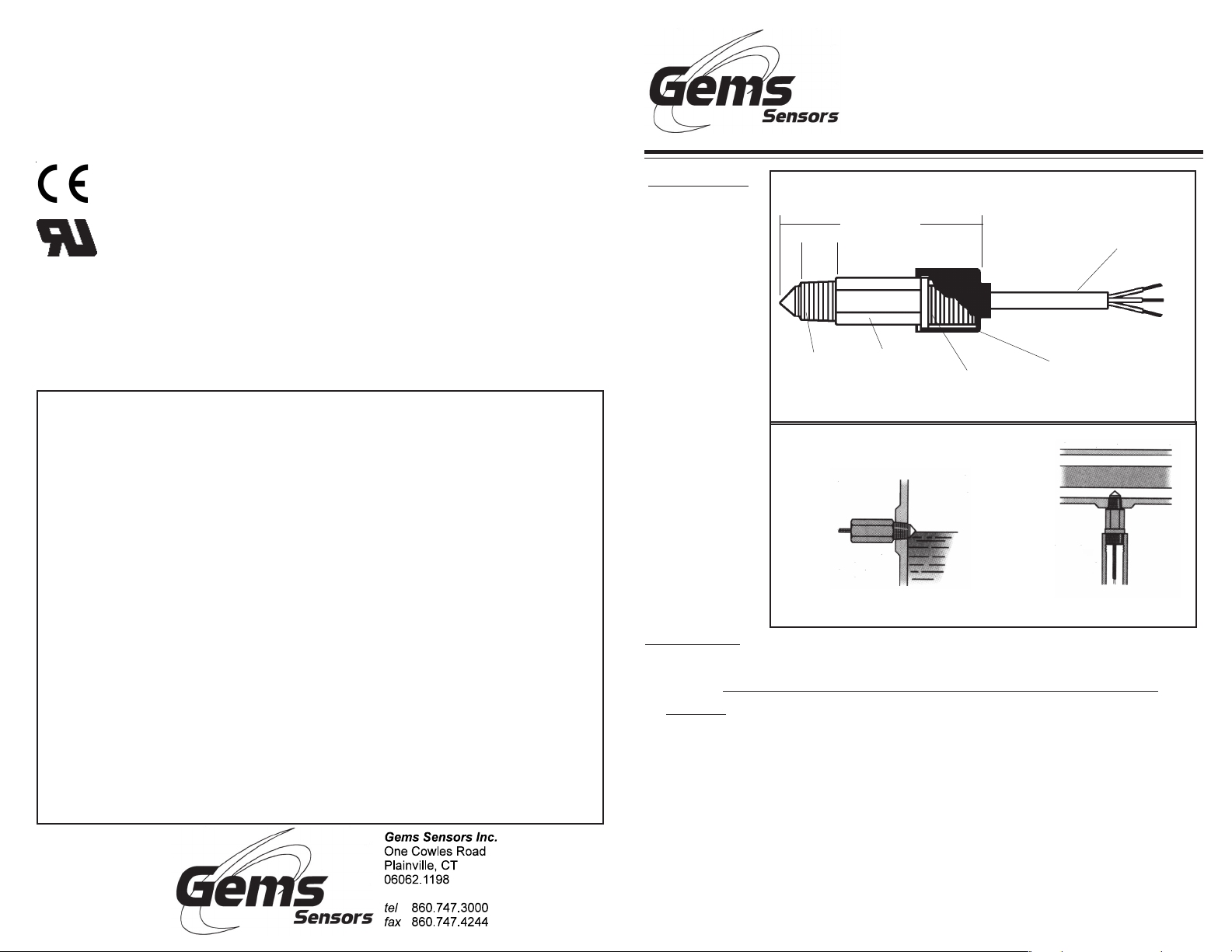

Dimensions

2-1/2” REF .

.50”

←→

REF

1/4”

NPT REF .

5/8”

HEX REF .

3/8” NPT

Conduit

Connection

Optional

Hypalon® Boot,

Cable Seal

Typical Applications

Intermediate Liquid

Level Sensing

ELS-1100 Series;

3/8” Conduit Model

Pipe Leak Detection

Installation

1. Use Teflon (TFE) thread tape or Permatex #80725 plastic pipe sealant to seal

thread. Caution: Pipe sealant must not come in contact with prism

surface.

2. Thread sensor into tank wall and tighten by hand. Further tighten an additional

one to two threads past hand-tightness. (Avoid overtightening, as this may

damage threads.

3. Sensor may be installed in horizontal or vertical positions, only.

4. CAUTION: Do not install sensor close to infrared sources or

incandescent light.

5. Prism surface must be at least 2" from any reflective surfaces.

6. Connect 10 - 28 VDC power to red lead; return (-) to black lead.

7. Output Configuration: See Fig. 1, Fig. 2 and Fig. 3.

Cable,

TFE Jacket

Page 2

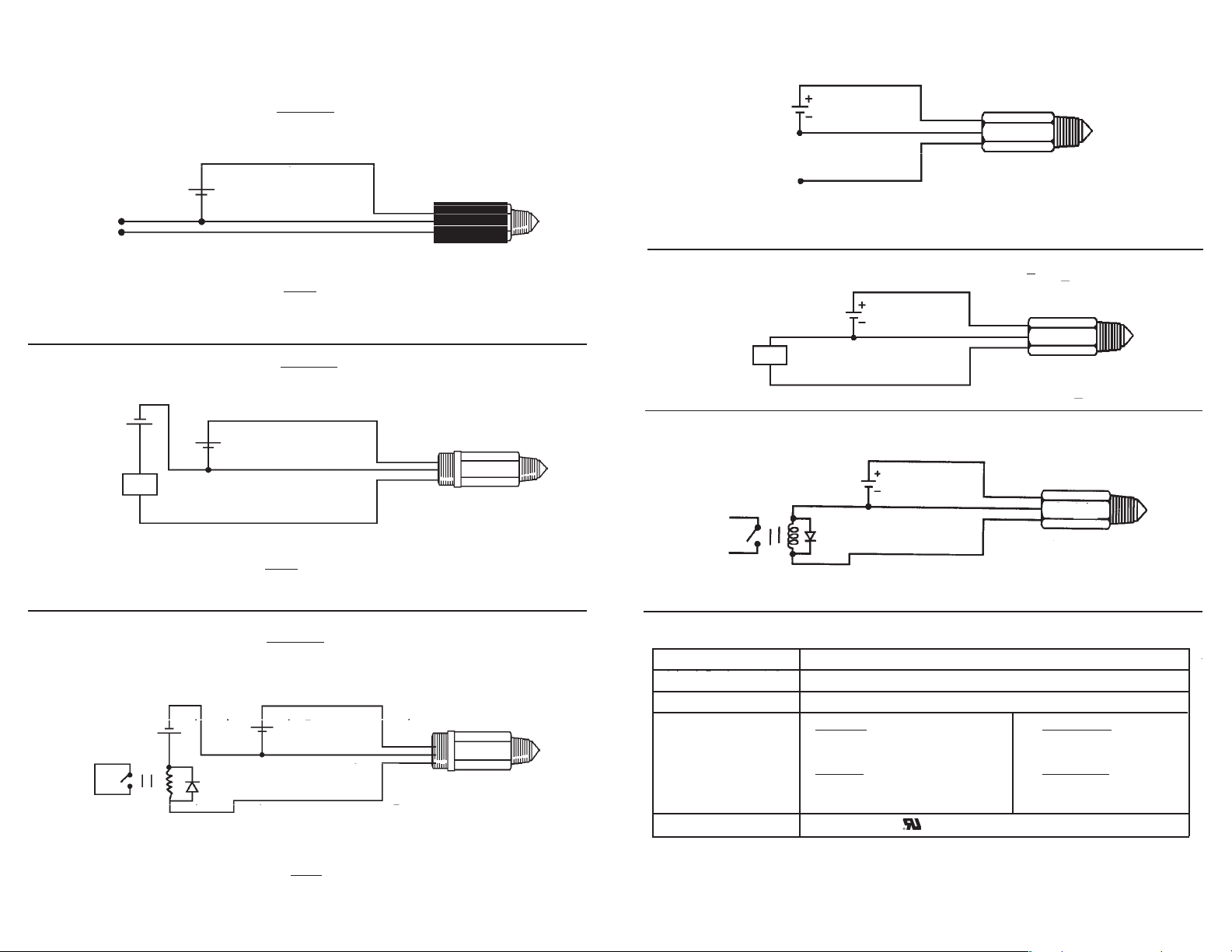

Typical Wiring Diagrams

- Current Sink -

Figure 1

TTL/CMOS Output

Red

+

_

Black

White

Output

10-28 VDC

*

*Note

For 5 volt CMOS: No pull-up resistor needed. For higher

voltage (15 V CMOS), a pull-up resistor is required on output.

Figure 2

External Load

V

Load

_

+

10-28

VDC

+

_

Red

Black

White

SENSOR

SENSOR

Typical Wiring Diagrams

- Current Source -

- Figure 1 -

10 - 28 VDC

Supply

Sourcing Output*

* Maximum Sourcing Output: 40mA @ 30V Max.

For 5 volt CMOS: No pull-down resistor needed. For higher

voltage (15 V CMOS), a pull-down resistor is required on output.

10 - 28 VDC

Supply

Load

10 - 28 VDC

Supply

Red

Black

White

Switch

- Figure 2 -

External Load

Red

Black

White

Max. Spec. = 40mA @ 30 VDC

- Figure 3 -

Relay Output

Red

Black

Switch

Switch

*Note

Maximum Spec. = 40mA sink @ 30 VDC

Figure 3

Relay Output

_

V

10-28

+

VDC

+

_

Red

Black

White

*Note

Inductive loads must be diode suppressed.

SENSOR

White

Max. Spec. = 40mA @ 30 VDC

Inductive loads must be diode suppressed.

Specifications

Material All Teflon Construction

Temperature Ranges 0°F to 176°F (-17.8°C to 80°C)

Pressure Range 0 - 150 psi

Outputs Wet Sink Wet Source: Water

Media: Water Output: 28 V (Max)

Output (White): Low (OV)

Dry Sink Dry Source: Air

Media: Air Output: 28 V (Max)

Output (White): Low (OV)

Approvals Units Labelled U.L.File E108913 CE EN61326

Maintenance

Sensor may require a periodic cleaning of prism surface. A mild

detergent may be used to clean prism surface.

Loading...

Loading...