Page 1

DMS-478

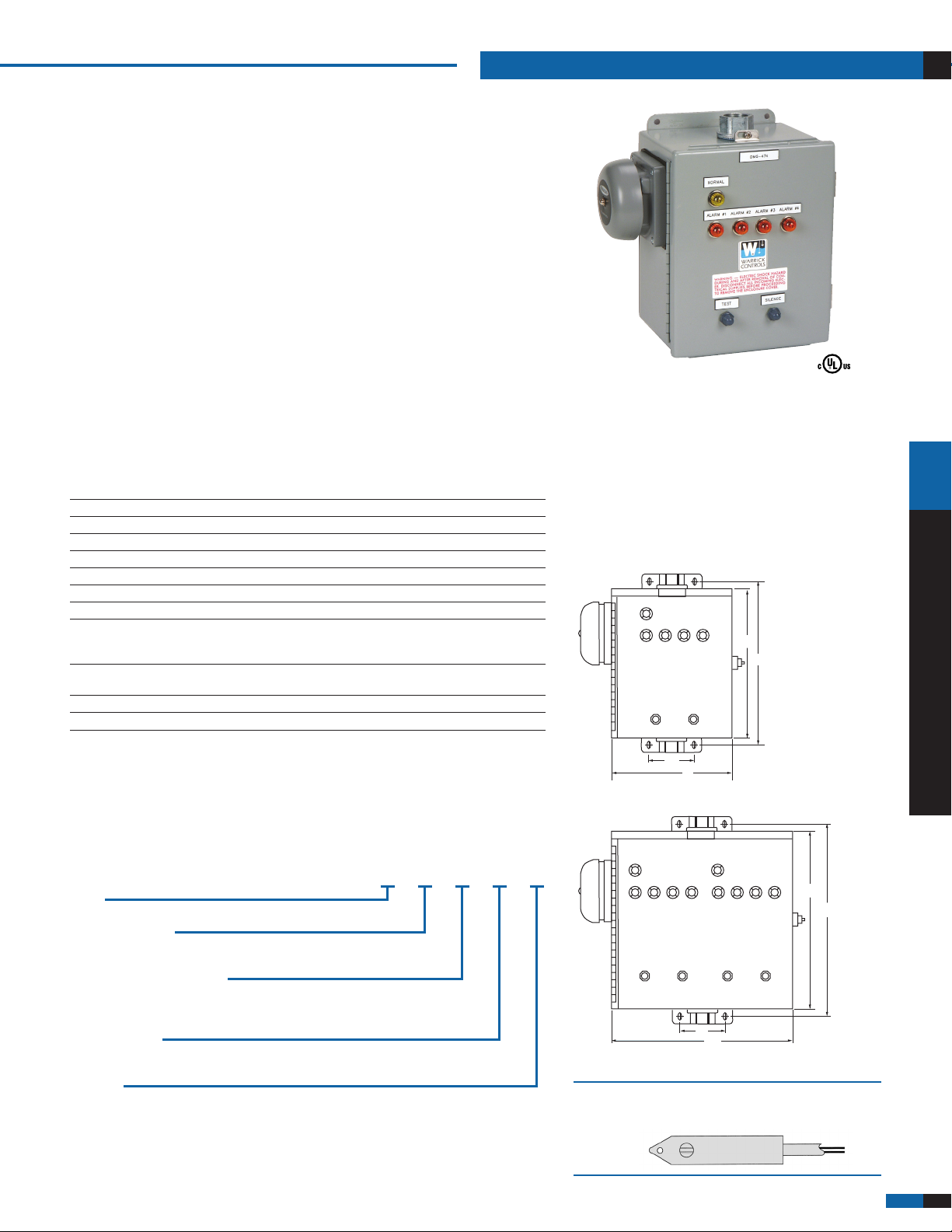

NORMAL

1 234

10˝

11

˝

8˝

3˝

TEST

SILENCE

DMS-478

NORMAL NORMAL

12341234

12˝

13

˝

12˝

3˝

TEST

SILENCE

TEST

SILENCE

DMS 470/570 Series

Leak Detection Systems

for UST and AST Storage Tanks

Low Cost

U.L. Approved Intrinsically Safe

Easily Maintained

Audio/Visual Alarm

The DMS 470/570 monitoring systems are ideal for a number of UST and AST

monitoring applications. The DMS 470 includes an audible bell while the DMS 570

uses a piezoelectric horn. Applications include vapor monitoring of monitoring wells

surrounding single wall tanks, high/low product level alarms, vapor sensors for single

wall piping and piping sump sensors for double wall piping.

Auxiliary Contacts

Auxiliary alarm contacts are also available for interfacing to remote alarms,

computers, tank gauging systems, phone dialers, etc.

Specifications

Contact Design SPDT (1 form C), one normally open, one normally closed

Contact Rating 120 VAC or 30 VAC, 10A, 1/3 h.p.

Sensitivity Range 0-50,000 ohms max. specific resistance

Remote Alarm Contact Terminals; 7 N.C., 8 com, 9 N.O.

Primary Voltage 120 VAC (+10%/-15%) 60 Hz

Probe Voltage Nominal 12 VAC @ 6ma RMS

Optional Auxiliary Contacts One relay contact per channel

Optional “Check”

Push Button Board* Terminals: Size four (4) pan head screw with a clamping plate;

will accept up to 14 AWG.

Enclosure Type NEMA 3R; optional NEMA 4, Weather-proof;

optional NEMA 4X, Fiberglass

Temperature -40°F to +150°F (-40°C to +65.5°C)

Approval U.L. Listed (U.L. 913) E120178

*For media discrimination in-storage tank

pANEl CONTROlS AND AlARmS

Applications

Above Ground Fuel Storage Tanks (AST)

• LeakDetection • Overll

• Rell

Underground Fuel Storage Tanks (UST)

• HighLevelAlarm • LeakDetection

• PipingSumps • MonitoringWell

Dimensions

4 Channel

How to Order

Use the Bold characters from the chart below to construct a product code. One set of

auxiliary contacts is standard with every four (4) channels supplied. A common test

button is standard for every four (4) channels supplied. The fuel/water check buttons

listed below are used to distinguish water or hydrocarbon when three wire sensors are

used. Each sensor or detection point requires its own channel.

DMS XX X X X XX

Series

47 audible bell; 57 piezoelectric horn

Number of Channels

1 1 Channel; 2 2 Channels; 3 3 Channels; 4 4 Channels;

8 8 Channels; 12 12 Channels; 16 16 Channels;

Fuel/Water Check Push Buttons

A No Check Buttons; B Check Buttons, 4; C Check Buttons, 8;

D Check Buttons, 12; F Check Button, 1;

G Check Buttons, 2; H Check Buttons, 3

Auxiliary Contacts

1 None; 2 Aux. Contacts, 4; 3 Aux. Contacts, 8; 4 Aux. Contacts, 12;

6 Aux. Contact, 1; 7 Aux. Contacts, 2; 8 Aux. Contacts, 3

Enclosure

N4 NEMA 4 option; N4XFG NEMA 4X fiberglass option

Visit www.GemsSensors.com for most current information.

8 Channel

See Our Interstitial Tank Monitoring Products

on page A-22.

WARRICK CONDUCTIVITY SENSORS

E-3 1

Loading...

Loading...