Page 1

Form 222B

Sheet P/N 100205-1

Rev. F

Warrick Dual Function Control

®

Installation and Operation Bulletin

This bulletin should be used by experienced personnel as a guide to the installation of Dual Function Controls. Selection or

installation of equipment should always be accompanied by competent technical assistance. We encourage you to contact

Gems Sensors or a representative if further information is required.

Specifications

Control Design: Open-board design (no housing)

Contact Design:

Limit Control - 1 SPDT (1 form C), dry contacts

Level Control - 1 SPDT (1 form C), dry contacts

Contact Ratings: 10A @120/220/240-VAC resistive (120°F),

1A @ 120, 208/240,240 resistive (150°F), 1/3 Hp @ 120,

208/240, 240 VAC

Contact Life: Mechanical - 5 million operations

Electrical - 100,000 operations minimum at rated load

Supply Voltage: 24, 120, 220, or 240 VAC models,+10%/-15%,

50/60 Hz. 208/240 Model: 187V Min to 242V Max, VAC 50/60

Hz

Power Consumption: 24/120/208/220/240-VAC with both

relays energized ~ 4.4 VA.

Secondary Circuit: 2.3 VAC RMS voltage on probes,

< 1 milliampere source capability.

Sensitivity: Factory programmed to 4.7K, 10K, 26K, 50K, or

100K Ohms

Operating Ambient Temperature Range: -40°F to +150°F

(-40°C to +65°C)

Terminals: Probe connections 3/16" male quick connects, Line

and Power connections 1/4" male quick connects

Time Delays: Standard, 0.5 seconds rising level, LLCO probe,

3 seconds lowering level.

Listings: Entire control carries U.L. Limit Control Listing (UL-

353) for supply voltages of 120-VAC and below.

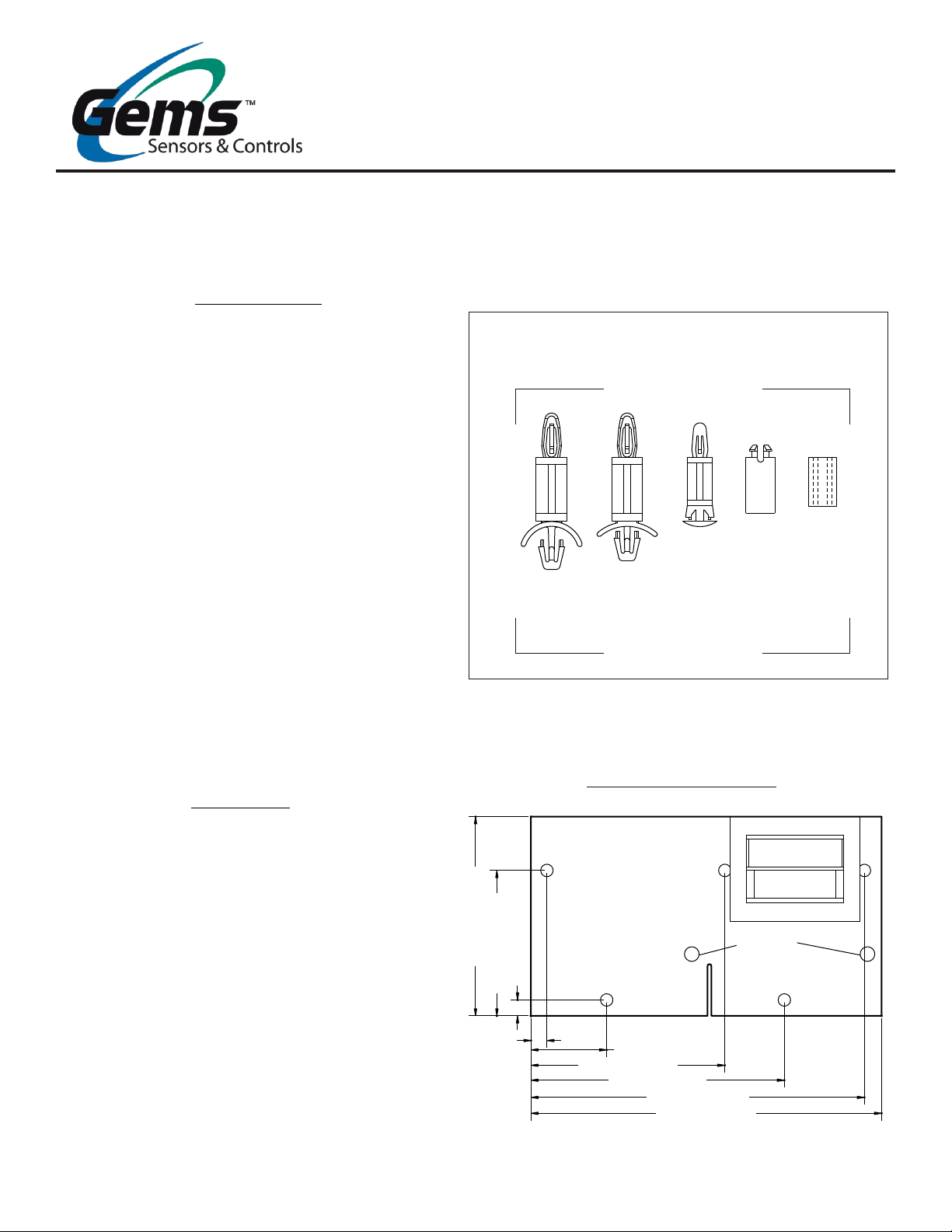

Standoff Options

There are 5 standoff styles offered by Gems to

connect circuit boards to panels.

PCB Mount Side

1/8”

Panel

1/16”

Panel

Retrofit

Standoff

Panel Mount Side

Circuit

Board

Standoff

Standoff

Screw

Mount

Installation

1. Drill five 0.187” holes in customer supplied back plate

using stick on template supplied with control.

Standard standoffs are designed for back plate

thickness of 0.062 (1/16"). Standoffs are available for

back plates of 0.125 (1/8") nominal thickness. If

retrofit plate standoffs are used, drill 5 (five) 0.250 dia.

Holes in proper locations.

2. Install five standoffs into back plate. Install two

support standoffs into circuit board. CAUTION: Be

careful not to bend or flex the circuit board during

installation as this can damage the control. Do not

push down on transformer or relays during installation.

Install circuit board onto standoffs by gently pushing

down on circuit board at board edges near standoff

locations until board is fully seated. See sketch for

proper installation. Install control in appropriate

enclosure.

3. Wire controls per wiring diagram, following N.E.C. and

local codes. Use appropriately sized spade terminals.

mm]

]

m

.5

3

6m

[ 0

"

0 6

0

.5

" [46.3

2

5

2

.8

1

0.200" [5.08mm]

Dimensional Drawing

m

m ]

8

5.0

[

"

00

2

0.

0.950" [24.13mm]

2.433" [61.80mm]

3.180" [80.77mm]

4.185" [106.30mm]

4.400" [111.76mm]

Support

Standoff

Locations

Page 2

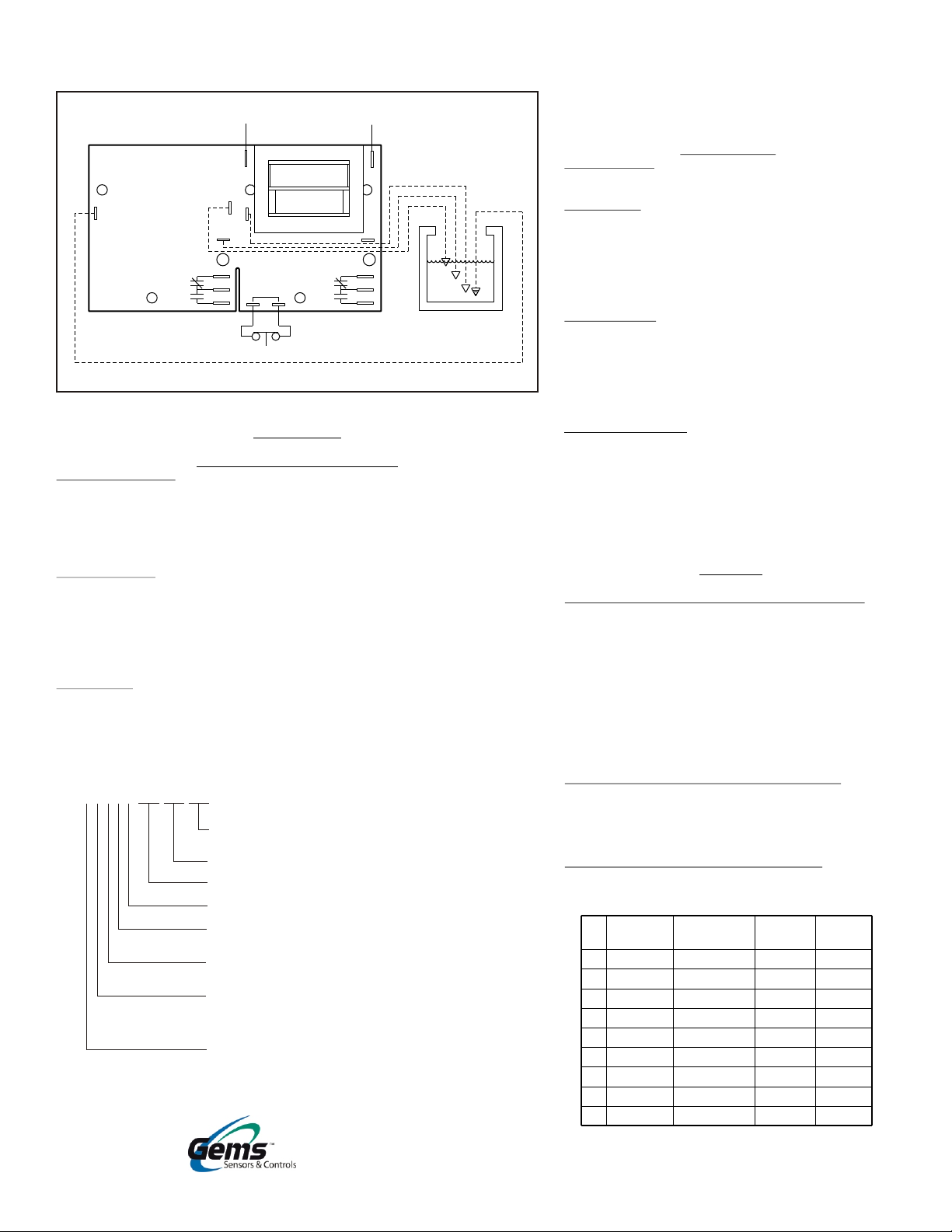

Wiring Diagram

L1

AC Power

L2

Second before control energizes. This function can be wired

for single level service by using only the H terminal.

L1

LLCO

G

Note: For single level service, only High Probe is required

H

L

FILL RELAY

NC

COM

RESET SW.

NO

RESET/TEST Switch Optional

L2

LLCO Probe

Low Probe

High Probe

G

LLCO RELAY

NC

COM

NO

IF METALLIC, TANK MAY BE USED

INSTEAD OF REFERENCE PROBE

Reference Probe

Operation

AUTOMATIC RESET (Reset Switch terminals not wired) When the liquid rises to the

electrode on terminal LLCO, the control energizes, changing state of the load contacts.

(LED will be lit) The control remains energized until the liquid level recedes below

electrode on terminal LLCO. The control then de-energizes, (LED will not be lit) returning

load contacts to original state. Unless otherwise specified, there is a three second time

delay on decreasing level. Liquid must be below probe on terminal LLCO for a full three

seconds before control de-energizes.

MANUAL RESET (Normally closed pushbutton installed across reset terminals) When

the liquid rises to the electrode on terminal LLCO, the control will remain de-energized until

the pushbutton is depressed. Upon Reset Swtich activation, the control will energize, (LED

will be lit) changing the state of the contacts. The control remains energized until the liquid

level recedes below electrode on terminal LLCO. The control then de-energizes, (LED will

not be lit) returning load contacts to their original state. Unless otherwise specified, there is

a three second time delay on decreasing level. Liquid must be below probe on terminal

LLCO for full three seconds before control de-energizes.

H-L Function: When the liquid rises to the electrode on terminal H, the associated

relay energizes, changing the state of the load contacts. (LED will be lit). The relay

remains energized until the liquid level recedes below electrode on terminal L. The

associated relay then de-energizes, (LED will not be lit) returning load contacts to

original state. Unless otherwise specified, there is a one half second time delay on

increasing level. Liquid must be in contact with probe on terminal H for a full half-

DF XXXXX XX XX XX

DIRECT MODE BOTH FUNCTIONS

Time Delay: (Decreasing Level) LLCO level function 3 sec.

Standard.

Time Delay: (Decreasing Level) H-L level function 1-20 sec.

Time Delay: (Increasing Level) H-L level function 1-20 sec.

Optional Character: see Chart

Enclosure: 0-none, 1-NEMA 1, 4-NEMA 4, 7-NEMA 7, 12-

NEMA

Standoff Style: A-1/16” panel, B-1/8” panel, C-screw

mount, D-retrofit

Supply Voltage: 1-120VAC (+10%/-15%), 2-240VAC

(+10%/-15%), 3-24VAC (+10%/-15%), 5-220VAC (+10%/15%), 8-208/240VAC (187 to 242 VAC Absolute Range)

Mode/Sensitivity: LLCO, H/L-Direct A-4.7K, B-10K, C-26K,

D-50K, E-100K --- LLCO, H/L-Inverse K-4.7K, L-10K, M-

26K, N-50K, P-100K

Gems Sensors Inc.

One Cowles Road

Plainville, CT 06062-1198

Tel: 860.793.4579

LLCO Function: LLCO always functions in direct mode

INVERSE MODE

only see above for operation.

H-L Function: Associated relay energizes with power,

(LED will be lit) changing the state of the load contacts.

When the liquid rises to the electrode on terminal H,

relay de-energizes, returning load contacts to shelf

the

state. (LED will not be lit). The associated relay remains

de-energized until the liquid level recedes below electrode

on terminal L. The relay then energizes.

TEST FEATURE

Allows LLCO circuit to be tested without the need to drop the

water level in the boiler to create a dry probe condition.

Holding down the reset button for 3 seconds will allow the

LLCO circuit to trip, simulating a dry probe. The controller will

return to normal operation once the reset button is pressed a

second time.

LED Status Indicator In normal operation, the LED on the

control will either be on or off depending on the controller

state. On-board microprocessors continuously monitor for

fault conditions. In the event a fault is detected, the LED

will blink a pattern indicating the fault type. If you

experience an inoperable control and the LED is blinking,

attempt to leave the control in the blinking state and

contact the factory for assistance.

Options

Manual Reset with optional Power Outage Feature: The

Power Outage option, used in conjunction with the Manual

Reset option, eliminates the need for a manual reset in the

event of a power outage during normal boiler operation.

With the Power Outage option, if there is a loss of power

with liquid present on the LLCO probe, the control will selfreset (energize) IF liquid is still present on the LLCO probe

at the time when power is re-established. If the control did

not have liquid on the LLCO probe at the time of the power

outage, or if there is no liquid present at the time power is

re-established, the control will de-energize and remain so

until liquid again rises to the LLCO probe and the Manual

Reset pushbutton is depressed.

Time Delays associated with terminals H and L : With

time delay on increasing level, the liquid must be in contact

with the high electrode for the full duration of the time delay

before control will operate. With delay on decreasing level,

the liquid must be below the low electrode for the full

duration of the time delay before control will operate.

Time Delays associated with terminal LLCO: 3 Second

time delay on decreasing level is standard.

D

G

J

K

L

R

S

T

W

Reset

Function

x

x

x

x

x

x

x

x

N.C.

Pushbutton

x

x

Power

Outage

x

x

x

x

Retrofit

Plate

x

x

x

x

x

Loading...

Loading...