Page 1

Form 159Form 159

Form 159

Form 159Form 159

Sheet P/N 7800447Sheet P/N 7800447

Sheet P/N 7800447

Sheet P/N 7800447Sheet P/N 7800447

RevRev

. C. C

Rev

. C

RevRev

. C. C

®®

®

WW

arrickarrick

W

arrick

WW

arrickarrick

®®

Direct Current Controls Series Direct Current Controls Series

Direct Current Controls Series

Direct Current Controls Series Direct Current Controls Series

Installation and Operation BulletinInstallation and Operation Bulletin

Installation and Operation Bulletin

Installation and Operation BulletinInstallation and Operation Bulletin

This bulletin should be used by experienced personnel as a guide to the installation of Series Direct Current

Controls. Selection or installation of equipment should always be accompanied by competent technical assistance.

We encourage y ou to contact Gems Sensors or its local representative if further information is required.

Installation

1. Remove the plug-in module from the octal base. When plug-module is removed, the pin number identification can

be see on the octal base.

2. Mount the octal socket (base) on a rigid vertical or horizontal surface using two #6 or #8 screws. The controls

should be mounted within an enclosure of proper NEMA integrity.

3. After the base has been mounted, refer to the applicable wiring diagram. Connect the electrodes to the designated

terminals of the socket using #14-#18 AWG wire for interconnecting leads. Be sure that the control is wired in

accordance with the appropriate application drawing.

4. Wire the appropriate load contact in series with the “Hot” lead of the load device. Note: Load current rating must

not exceed the maximum rating of the relay contact.

5. In accordance with the proper wiring diagram, connect the negative side (-) of the power supply to terminal #1 of

the octal socket and the positive side (+) of the supply to terminal #2 of the socket. Verify that the power supply

output voltage correlates to the data label on the control. Caution: Reversal of power supply leads from desig-

nated polarity may damage the internal solid-state circuitry of the control. Verify the correct polarity of the

power supply connections before proceeding to step #6.

6. Plug the DC level control into the octal socket. Numbers at the base of the pins match the numbers on the installed

base. The control is keyed for proper installation; the unit will not plug in if the pins are not properly aligned.

Warrick Controls recommends that you inspect and clean the electrode rods annually.

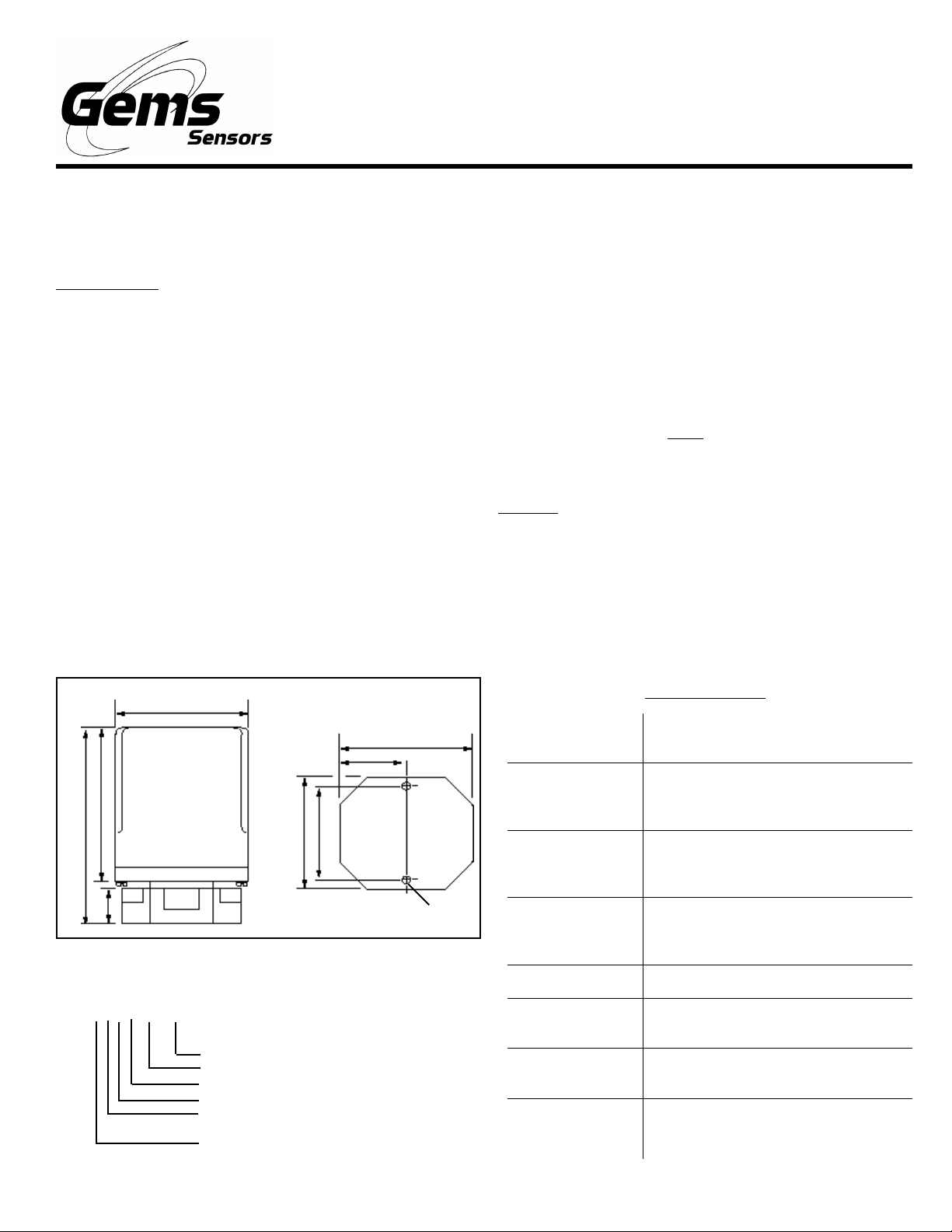

Dimensional Diagram

2-3/8 in

2-5/16 in

1-5/32 in

2-3/4 in

3-1/2 in

5/8 in

2.0 in

1-11/16 in

11/64 in dia

Use copper (60/70° C) wire only. Torque to 20 inch pounds.

DC XXXX XX XXDC XXXX XX XX

DC XXXX XX XX

DC XXXX XX XXDC XXXX XX XX

Time Delay: (decreasing level 1-30 sec)

Time Delay: (increasing level 1-30 sec)

Enclosure:

Mode:

Sensitivity (ohms):

EE

E- 1M

EE

Supply Voltage:

00

0- none,

00

DD

D- direct,

DD

11

1- NEMA 1,

11

II

I- inverse

II

BB

B- 22K,

BB

11

1- 12 VDC,

11

44

4- NEMA 4

44

C C

C- 100K,

C C

22

2- 24 VDC

22

DD

D- 470K,

DD

Contact Design:

Contact Ratings:

Contact Life:

Electronics

Module:

Supply Voltage

Supply Current:

Sensitivity Range:

Temperature

Range:

Specifications

SPDT (1 form C) 1 Normally Open

(N.O.) and 1 Normally Closed (N.C.)

5A @ 30 VDC or 120 VAC, 4A @ 240

VAC resistive, 1/8th Hp 120 VAC, 240

VAC pilot duty code C150

Mechanical - 20 million operations.

Electrical - 100,000 operations minimum @ rated load

Solid-state components epoxy sealed

in a black polystyrene plug-in style

housing

12 or 24 VDC - Negative ground, ±20%

12 VDC Model - Relay de-energized

10mA, Relay energized 40mA

0-1M maximum specific resistance,

ohm factory set

-50° to +150° F

Page 2

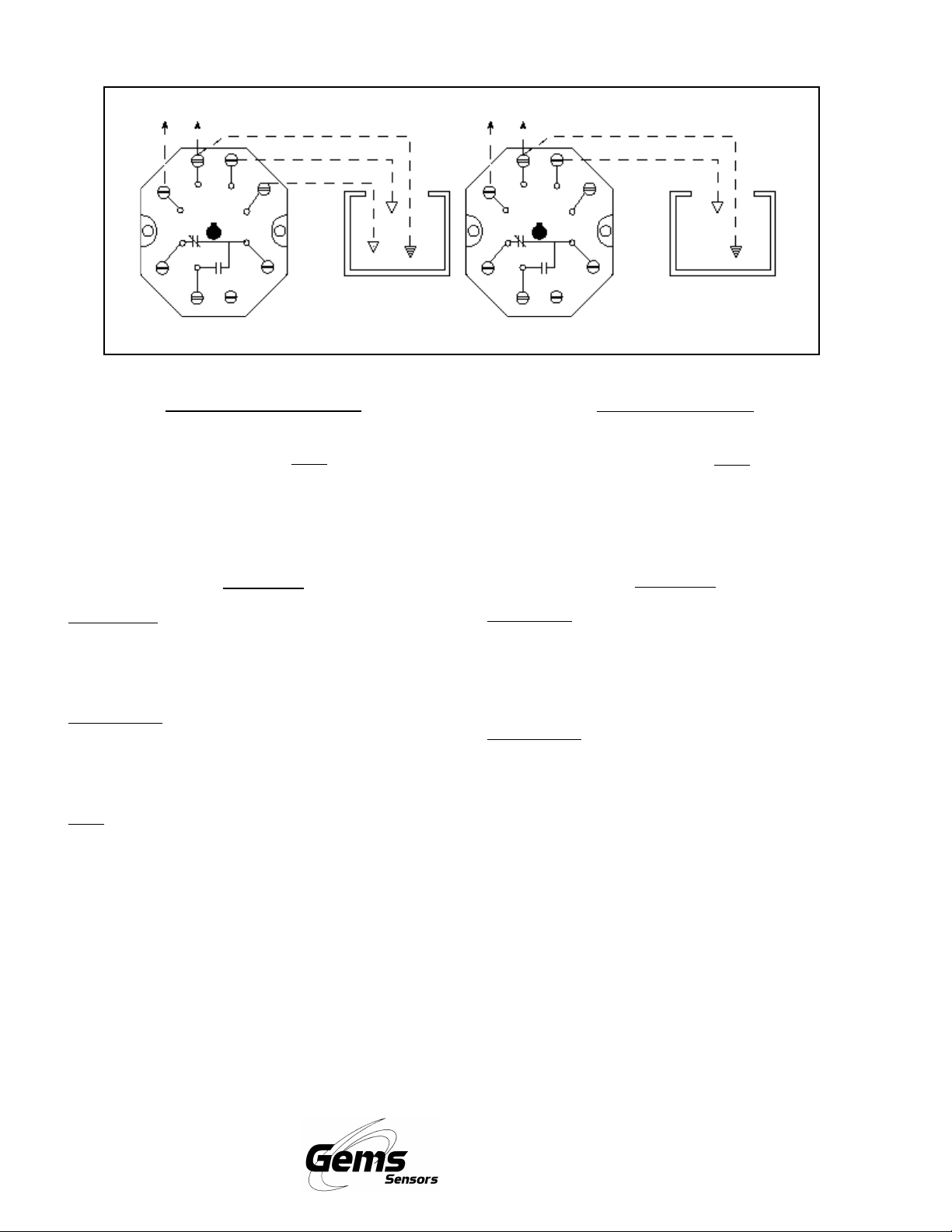

Wiring Diagram

DC Power

Reference Probe

High Probe

H

8

1

2

3

4

NC

NO

Differential Level WDifferential Level W

Differential Level W

Differential Level WDifferential Level W

6

7

Low Probe

L

C

If metallic, tank may

be used instead of

reference probe

iringiring

iring

iringiring

Connect negative side (-) of VDC supply line to terminal #1

and positive (+) side to terminal #2.

Note Note

Note: Check polarity of

Note Note

power connections. Connect terminal #8 (H) to the high

electrode and terminal #7 (L) to the low electrode. Terminal #1

can be grounded to tank if the tank is metallic. When the tank

is not metallic, terminal #1 must be connected to an additional

electrode of length equal to or longer than the longest probe.

DC Power

Reference Probe

High Probe

H

8

1

2

3

4

NC

NO

L

7

6

C

Single Level WSingle Level W

Single Level W

Single Level WSingle Level W

If metallic, tank may

be used instead of

reference probe

iringiring

iring

iringiring

Connect negative side (-) of VDC supply line to terminal #1

and positive side (+) to terminal #2.

Note:Note:

Note: Check polarity of

Note:Note:

power connections. Connect terminal #8 (H) to the electrode. Terminal #1 can be grounded to tank if the tank is

metallic. When the tank is not metallic, terminal #1 must be

connected to an additional electrode of length equal to or

longer than the longest probe.

OperationOperation

Operation

OperationOperation

Direct Mode: Direct Mode:

Direct Mode: The control energizes closing load contact 4-6

Direct Mode: Direct Mode:

and opening load contact 3-6 when the level rises to the short

electrode connected to terminal #8. The control remains

energized until the level recedes below the long electrode

connected to terminal #7.

Inverse Mode:Inverse Mode:

Inverse Mode: The control de-energizes opening load

Inverse Mode:Inverse Mode:

contact 4-6 and closing load contact 3-6 when the level rises

to the short electrode connected to terminal #8. The control

remains de-energized until the level recedes below the long

electrode connected to terminal #7.

Note:Note:

Note: For single level service controls utilizing both increas-

Note:Note:

ing and decreasing time delays, a jumper wire is required

between terminals #7 and 8.

OperationOperation

Operation

OperationOperation

Direct Mode:Direct Mode:

Direct Mode: The control energizes closing load contact 4-

Direct Mode:Direct Mode:

6 and opening contact 3-6 when the level rises to the

electrode connected to terminal #8. The control deenergizes and the contacts return to their de-energized state

when the level recedes below the electrode connected to

terminal #8.

Inverse Mode:Inverse Mode:

Inverse Mode: The control de-energizes opening load

Inverse Mode:Inverse Mode:

contacts 4-6 and closing load contact 3-6 when the level

rises to the electrode connected to terminal #8. The control

energizes and the contacts return to the energized state

when the level recedes below the electrode connected to

terminal #8.

Gems Sensors Inc.

One Cowles Road

Plainville, CT 06062-1198

Tel: 860-793-4579

Fax: 860-793-4580

Loading...

Loading...