Page 1

INSTRUCTIONS FOR USE

BEDIENUNGSANLEITUNGEN

MODE D’EMPLOI

ИНСТРУКЦИИ ПО

ЭКСПЛУАТАЦИИ

BLAST CHILLER 3-5-10-15-24 TRAYS

SCHOCKFROSTER 3-5-10-15-24 BEHÄLTERN

CELLULE DE REFROIDISSEMENT 3-5-10-15-24

BACS

БЫСТРЫЙ ОХЛАДИТЕЛЬ НА 3-5-10-15-24

ЛОТКА

Serie “NEW RUNNER”

Control panel version EVXV-805

Версия платы EVXV-805

BCB/03

BCB/05

BCB/10

BCB/15

BCB/24

Manual BCB - N Rev05 05-2015

www.gemm-srl.com

Page 2

BCB_N Rev.05 05-2015 pag. 2

Page 3

INDEX / INHALTSVERZEICHNIS / SOMMAIRE / ОГЛАВЛЕНИЕ

1. GENERAL INFORMATION

6

ALLGEMEINE INFORMATIONEN

41

INFORMATIONS GENERALES

75

ОБЩАЯ ИНФОРМАЦИЯ

109

1.1 – Markings / Kennzeichnungsdaten / Données de marquage / Данные маркировки

1.2 – Declaration of conformity / Konformitätserklärung / Déclaration de conformité / Декларация соответствия

1.3 – Warranty / Garantie / Garantie / Гарантия

1.4 – Service / Kundendienst / Assistance / Техническая поддержка

1.5 – Using and keeping this guide / Benutzung und Aufbewahrung des Handbuchs / Utilisation et conservation du

manuel d’utilisation

1.5.1 – Symbols used in this guide / In diesem Handbuch verwendete Symbole / Symboles utilisés sur ce manuel

d’utilisation / Использование и хранение руководства

1.6 – Description of personnel / Beschreibung des Personals / Description du personnel / Описание персонала

2. DESCRIPTION OF THE APPLIANCE

10

BESCHREIBUNG DER MASCHINE

45

DESCRIPTION DE LA MACHINE

79

ОПИСАНИЕ МАШИНЫ

113

2.1 – Technical data / Technische Daten / Données techniques / Технические характеристики

2.2 – Description and intended use / Beschreibung und vorgesehene Benutzung / Description et utilisation prévue /

Описаниеиназначениечиллера

2.2.1 – Main components / Hauptbestandteile / Composants principaux / Основные компоненты

2.3 – Noise / Geräuschpegel / Bruit / Шум

2.4 – Environmental conditions / Umgebungsbedingungen / Conditions environnementales / Условия окружающей

среды

3. SAFETY

17

SICHERHEIT

51

SECURITE

85

БЕЗОПАСНОСТЬ

120

3.1 – General warnings / Allgemeine Hinweise / Avertissements généraux / Общие предостережения

3.2 – Specific warnings / Spezifiche Hinweise / Avertissement spécifique / Противопоказания к использованию

3.3 – Precautions for use / Gegenanzeigenfür die Benutzung / Contre-indications

3.4 – Protective devices / Schutzvorrichtungen / Dispositifs de protection / Средства защиты

3.5 – Stop functions / Stoppfunktionen / Fonctions d’arrêt / Функции остановки

4. TRANSPORTATION AND HANDLING

21

TRANSPORT UND VERSTELLEN

55

TRANSPORT ET DEPLACEMENT

89

ОБРАЩЕНИЕ

124

4.1 – Transportation / Transport / Transport / Транспортировкачиллера

4.2 – Handling the packaged / Verstellen des verpackten / Déplacement emballée / Перемещениечиллеравупаковке

4.2.1 – Weight and overall size / Gewicht und Außenabmessungen / Poids et encombrement de /

Весигабаритычиллера

4.2.2 – Necessary equipment / Notwendige Hilfsmittel / Moyens nécessaires / Необходимые средства

BCB_N Rev.05 05-2015 pag. 3

Page 4

5. INSTALLATION

23

INSTALLATION

57

INSTALLATION

91

УСТАНОВКА

126

5.1 – Preparation for installation / Vorrüstung für die Installation / Prédispositions nécessaires à l’installation /

Подготовкакустановке

5.2 – Unpacking / Auspacken / Déballage / Извлечение из упаковки

5.2.1 – Necessary equipment / Notwendige Hilfsmittel / Moyens nécessaires / Необходимые средства

5.2.2 – Unpacking procedure / Vorgehen für das Auspacken / Procédure de déballage / Порядок извлечения из

упаковки

5.3 – Handling / Verstellen / Déplacement / Перемещениечиллера

5.3.1 – Necessary equipment / Notwendige Hilfsmittel / Moyens nécessaires / Необходимыесредства

5.3.2 – Procedure for handling the unpacked / Vorgehen für das Verstellen des ausgepackten / Procédure de

déplacement déballée / Прядокперемещениячиллерабезупаковки

5.4 – Assembling / Montage / Montage / Монтаж чиллера

6. SETTING UP

25

INBETRIEBSETZUNG

59

MISE EN MARCHE

93

ВВОД В ЭКСПЛУАТАЦИЮ

128

6.1 – Connections / Anschlüsse / Connexions / Подключение

6.1.1 – Electrical connection / Elektrischer Anschluss / Connexion électrique / Электрическоеподключение

6.2 – Preliminary checks / Vorkontrollen / Contrôles préliminaires / Предварительные проверки

6.2.1 – Adjustments / Einstellungen / Réglages / Регулировка

7. USE

26

BENUTZUNG

60

UTILISATION

94

ИСПОЛЬЗОВАНИЕ

130

7.1 – Intended use / Vorgesehene Benutzung / Utilisation prévue / Назначение

7.2 – Inappropriate use / Nicht vorgesehene Benutzung / Utilisations non prévues / Использование не по назначению

7.3 – Residual risks / Restrisiko / Risque résiduel / Остаточные риски

7.4 – Control panel / Bedienfeld / Panneau de contrôle / Панель управления

7.5 – Controls / Verfahren für die Kontrolle / Procédures de contrôle / Порядок проверки

7.6 – Preparing for use / Verfahren für die Benutzung / Procédures d’utilisation / Порядок использования

7.7 – Soft chilling / Refroidissement rapide positif “soft”

7.7.1 – Setting and Selecting of soft chilling cycle (Soft blast chilling)

Auswahl und Setzen einer weichen Zyklus Kühlen (Schnellkühl zarten)

Sélection et établissement d'un cycle doux (blast chilling délicate)

Выбор и настройка цикла Soft chilling (мягкого охлаждения до положительной температуры)

7.8 – Hard chilling / Réfroidissement rapide positif “hard”

7.8.1 – Setting and Selecting of hard chilling cycle (Hard blast chilling)

Auswahl und Setzen einer Festkühlzyklus (positive chilling schnell)

Sélection et établissement d'un cycle de refroidissement dure (refroidissement rapide positif)

Выбор и настройка цикла Hard chilling (быстрого охлаждения до положительной температуры)

7.9 – Freezing / Surgélation

7.9.1 – Setting and Selecting a of freezing cycle

Auswahl und Einstellung eines Gefrierzyklus (Einfrieren)

Sélection et le réglage d'un cycle de congélation (congélation)

Выбор и настройка цикла Freezing (замораживания)

7.10 – Special functions and uses / / Sonderfunktionen / Utilisations particulières / Специфичные виды использования

7.10.1 – Pre-chilling function / Vorkühlfunktion / Fonction de pré-refroidissement / Функция предварительного

охлаждения

7.10.2 – Defrost / Abtauen / Dégivrage / Размораживание

7.10.3 – Long idle perdios / Stillstand für längere Zeit / Arrêt pendant une longue période / Продолжительные простои

BCB_N Rev.05 05-2015 pag. 4

Page 5

8. MANUTENZIONE

34

MAINTENANCE

68

WARTUNG

102

MAINTENANCE

138

8.1 – Special precautions / Besondere Vorsichtsmaßnahmen / Précautions particulières / Особые меры

предосторожности

8.2 – Routine maintenance / Gewöhnliche Wartung / Maintenance ordinaire / Текущее техническое обслуживание

8.2.1 – Summary table of routine maintenance (table 4) / Zusammenfassende Tabelle der gewöhnlichen

Wartungsarbeiten (Tab. 4) / Tableau récapitulatif des maintenances ordinaires (tab. 4) / Сводная таблица

текущего технического обслуживания (табл. 4)

8.2.2 – Cleaning the cabinet interior / Reinigung des Innenraums / Nettoyage cellule interne / Очистка камеры

внутри

8.2.3 – Cleaning the exterior of the appliance / Außenreinigung des Geräts / Nettoyage partie externe de l’appareil /

Очистка наружной части аппарата

8.2.4 – Cleaning the appliance condenser / Reinigung des Gerätekondensators / Nettoyage condensateur appareil /

Очистка конденсатора аппарата

8.2.5 – Cleaning the core probe / Reinigung der Nadelsonde / Nettoyage de la sonde à cœur / Очистка игольчатого

зонда

8.3 – Extraordinary maintenance / Außergewöhnliche Wartung / Maintenance extraordinaire / Внеплановое

техническое обслуживание

8.4 – Operating anomalies and faults / Alarme und Fehler / Alarmes et erreurs / Сигналы тревоги и ошибки

8.4.1 – Alarms / Alarm / Alarmes / Сигналы тревоги

8.4.2 – Errors / Fehler / erreurs / Ошибки

9. DISASSEMBLY

39

ZERLEGUNG

73

DEMONTAGE

107

ДЕМОНТАЖ

143

10. DISPOSAL

40

VERSCHROTTUNG

74

DEMANTELEMENT

108

УТИЛИЗАЦИЯ

144

10.1 – Method of disposal / Vorgehensweise für die Verschrottung / Mode de démantèlement / Порядок утилизации

11. SPARE PARTS

40

ERSATZTEILE

74

PIECES DE RECHANGE

108

ПРИЛОЖЕНИЯ

144

11.1 – Method for requesting spare parts / Anforderung von Ersatzteilen / Demande de pièces de rechange / Порядок

заказа запасных частей

12. ENCLOSURES

40

ANLAGEN

74

PIECES JOINTES

108

ОБОРУДОВАНИЕ

144

BCB_N Rev.05 05-2015 pag. 5

Page 6

1 – GENERAL INFORMATION

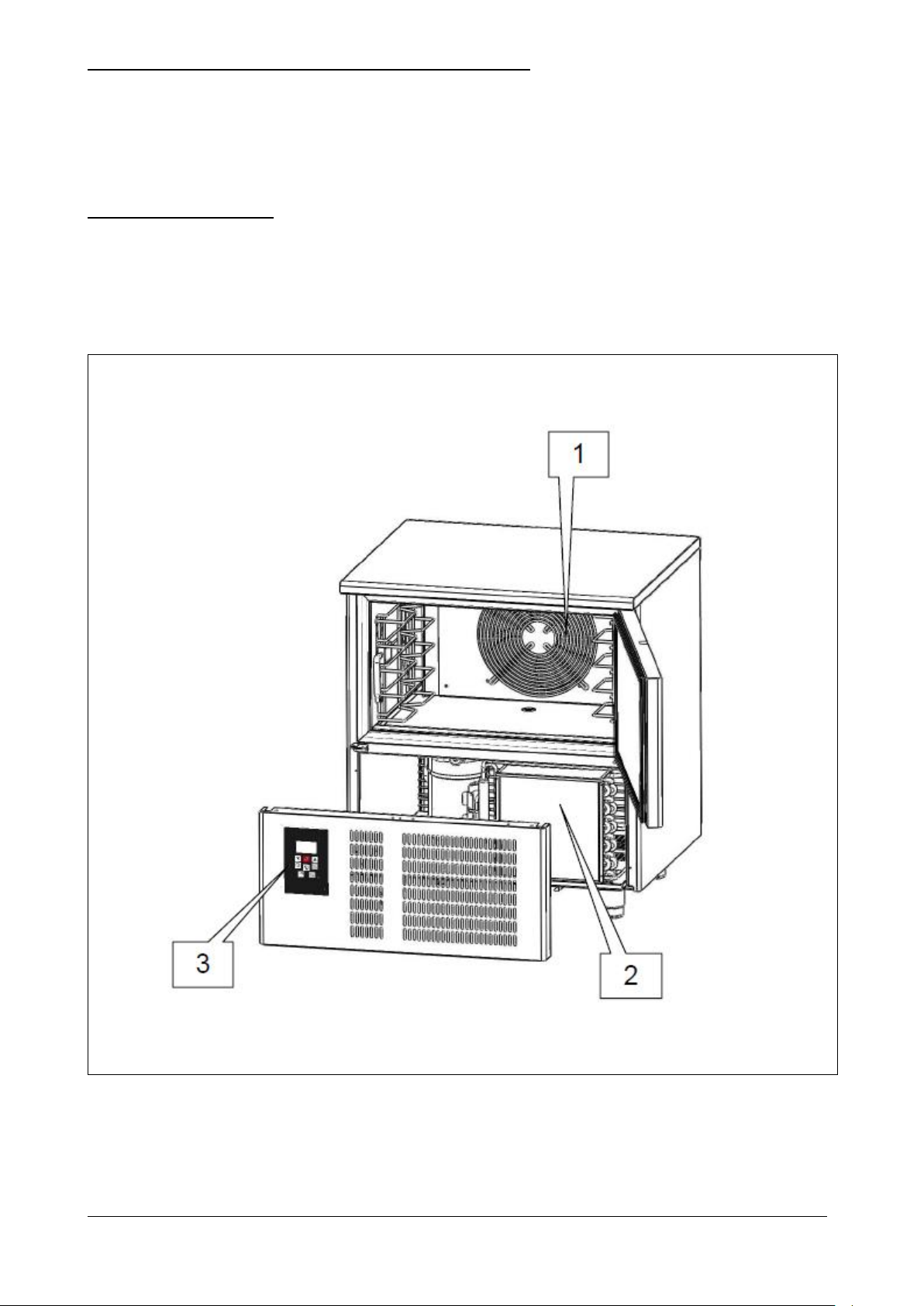

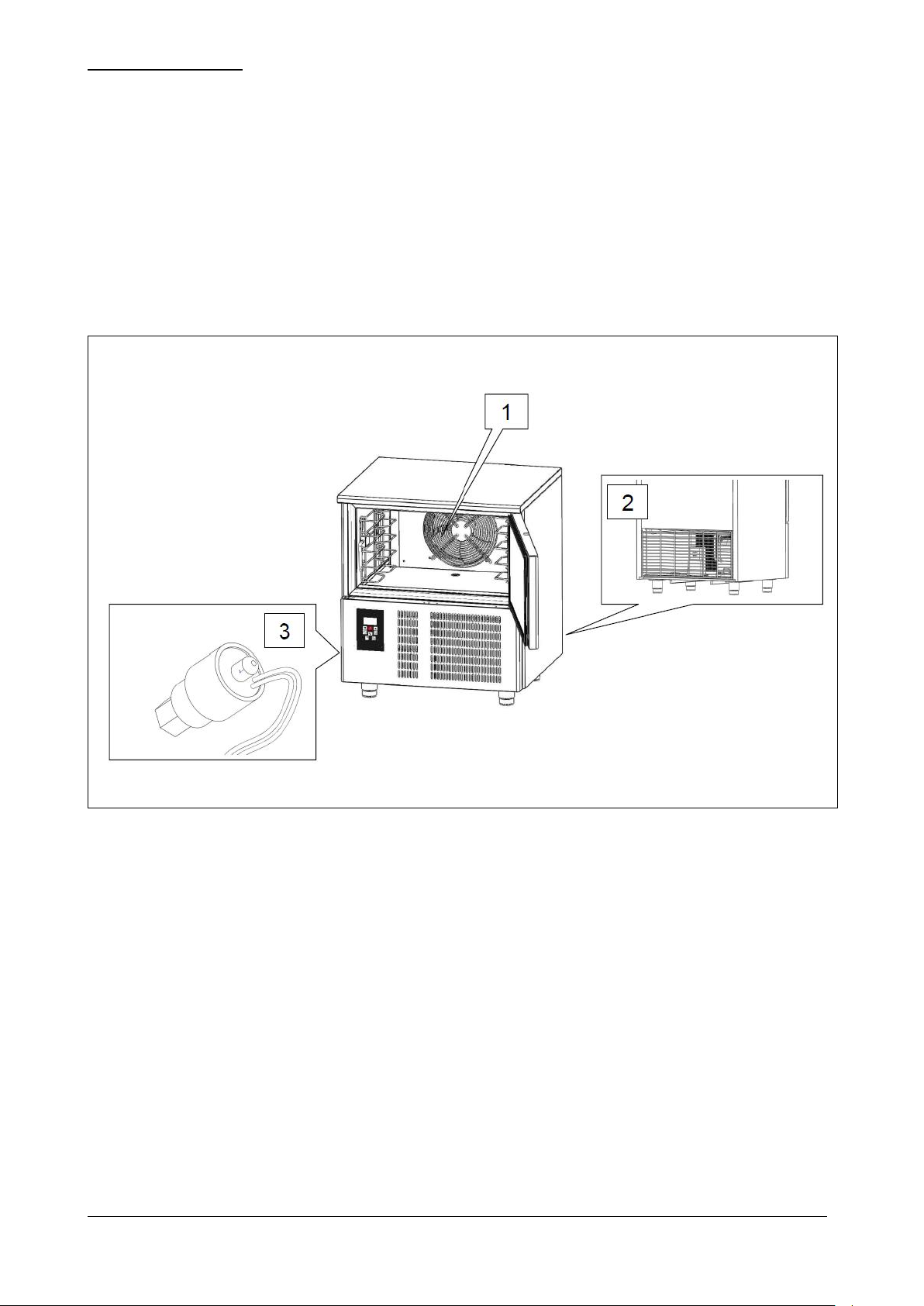

Fig. 1

Thank you for having chosen one of our blast chillers.

Please read this guide very carefully and make sure it is available to those who will install, use and maintain the

equipment.

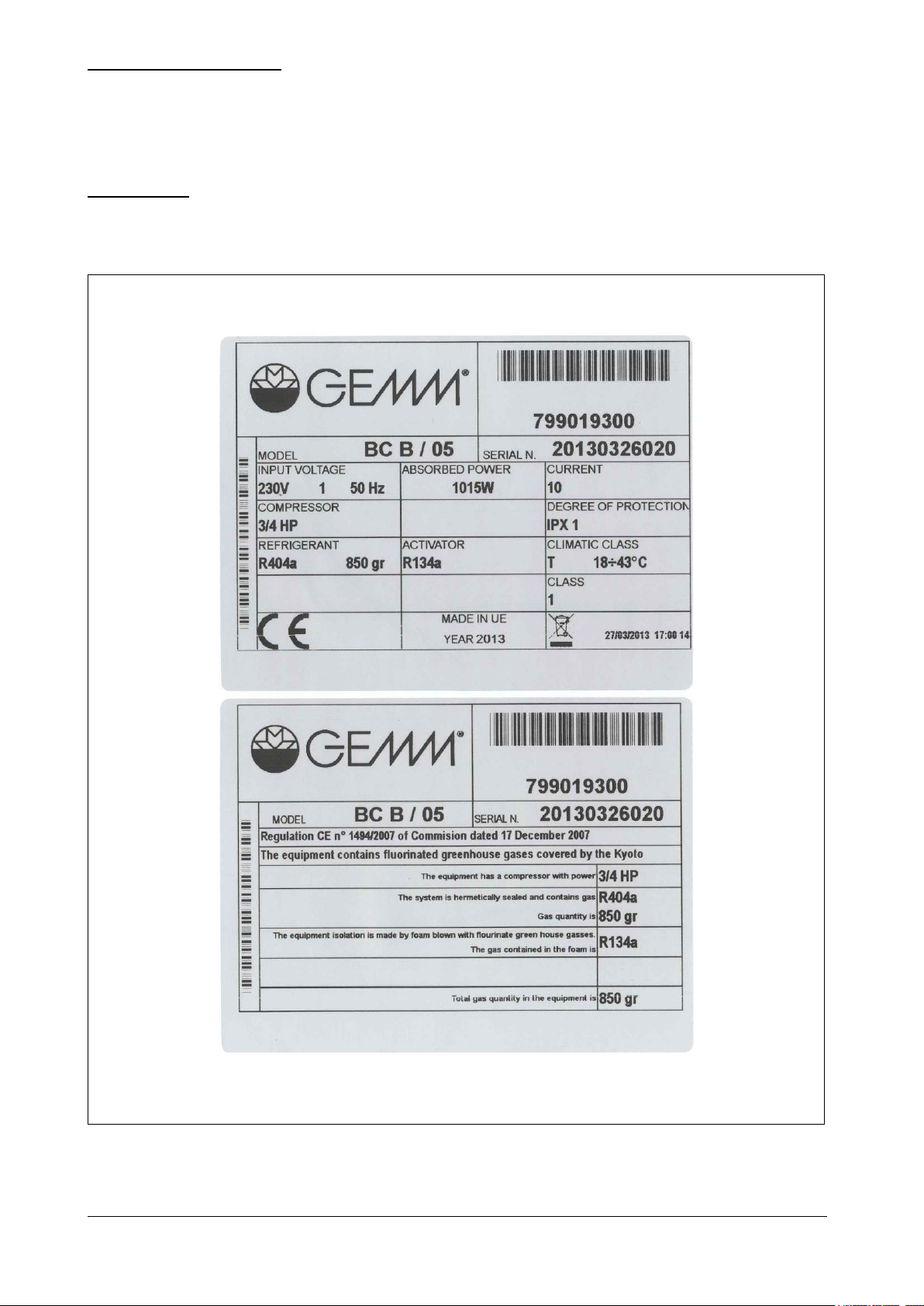

1.1 – MARKING

The ID plates are located on the outside of the appliance, at the bottom of the right side panel towards the front.

Examples are given in Fig. 1 below.

BCB_N Rev.05 05-2015 pag. 6

Page 7

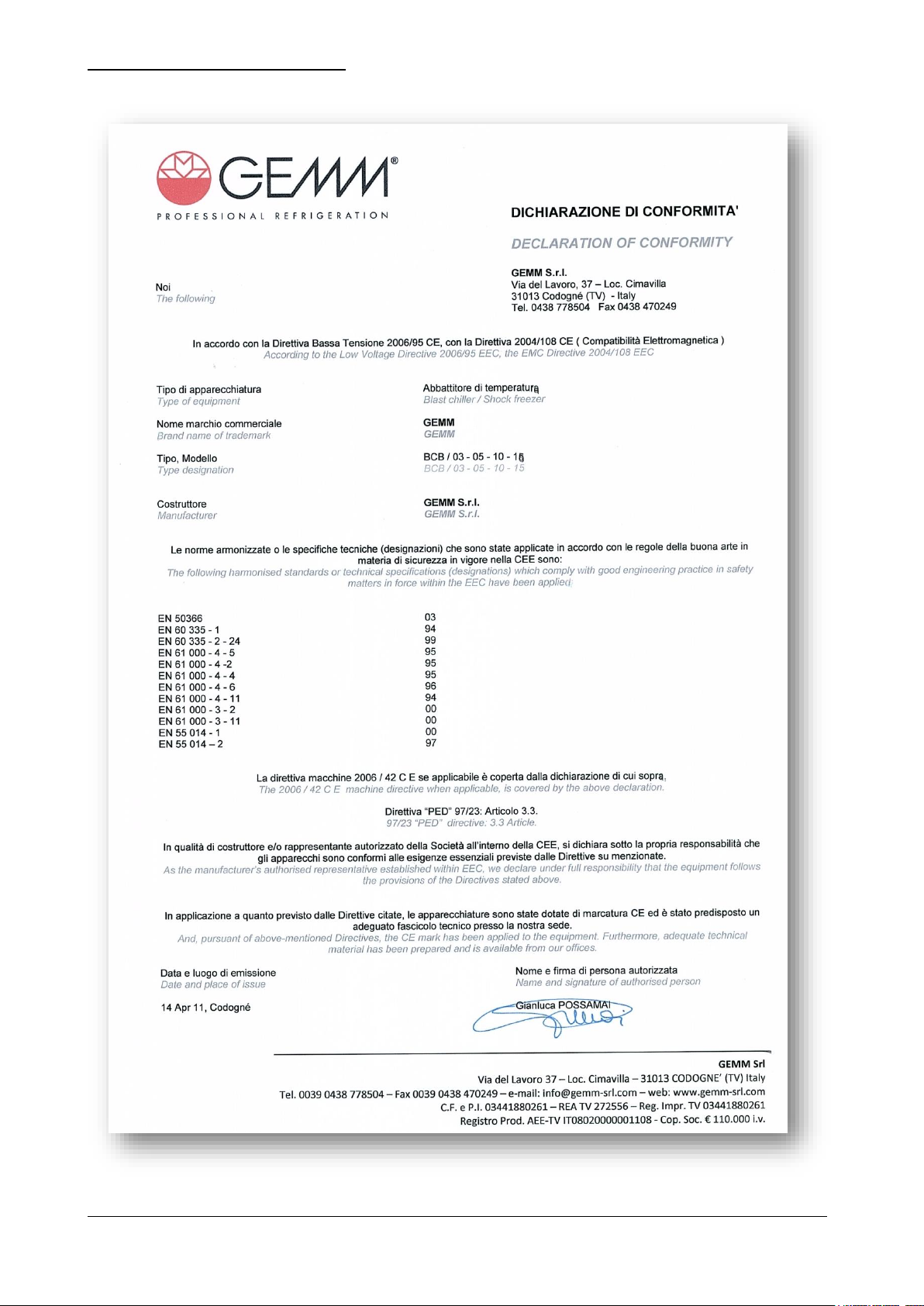

1.2 – DECLARATION OF CONFORMITY

BCB_N Rev.05 05-2015 pag. 7

Page 8

1.3 – WARRANTY

This symbol indicates information and warnings which if not observed could result in damage to the

appliance or jeopardize the safety of personnel.

This symbol indicates information and warnings regarding electrical devices which if not observed could

result in damage to the appliance or jeopardize the safety of personnel.

The warranty covering the various parts of the appliance is valid from the date on the relative delivery note and is as

described in the sales agreement.

The warranty does not cover damage to the appliance caused by:

- transport and/or handling;

- operator errors;

- lack of the maintenance described in this manual;

- faults and/or breakages that cannot be traced to faulty operation of the appliance;

- maintenance operations carried out by unqualified personnel;

- improper use.

1.4 – AFTER-SALES SERVICE

Please contact the manufacturer directly for any needs regarding use, maintenance or ordering of spare parts, and give

the identification details of the appliance to be found on the ID plate.

1.5 – USING AND KEEPING THIS GUIDE

The purpose of this guide is to provide all the necessary information to ensure proper use of the appliance in all safety

and independence.

The guide is divided into sections with paragraphs and sub-paragraphs: the contents page makes it quick and easy to

find any aspect of interest.

The material in this document is provided for information purposes only and may be changed without notice. Although

great care has been taken in preparing the guide, the manufacturer cannot be held liable for damage arising from

errors, omissions or the use made of the information herein.

Keep this guide and all the attached documentation in good condition, legible and complete; keep it near the equipment

in an accessible place known to all operators.

1.5.1 – SYMBOLS USED IN THIS GUIDE

BCB_N Rev.05 05-2015 pag. 8

Page 9

1.6 – DESCRIPTION OF PERSONNEL

Operators must not carry out work reserved for maintenance engineers or specialised

technicians.

The manufacturer accepts no liability for damage arising from failure to observe this rule.

This guide is for the use of operators, authorized installers and maintenance engineers.

- Appliance operator: specialised person who can operate the appliance in normal working conditions by using

the relevant controls. The operator must also be capable of carrying out simple routine maintenance (cleaning,

loading) and starting or resetting the appliance after a power failure.

- Specialised electrician: specialised electrician who has been trained by the manufacturer to work on the

appliance. The specialised electrician must be capable of installing the appliance and operating it in normal

conditions; he/she is qualified to carry out all electrical and mechanical adjustments, maintenance and repairs.

He/she is able to operate with live switchgear and connector blocks.

- Qualified forklift operator: person qualified in handling materials on company premises, holder of a licence for

the use of forklift trucks.

BCB_N Rev.05 05-2015 pag. 9

Page 10

2 – DESCRIPTION OF THE APPLIANCE

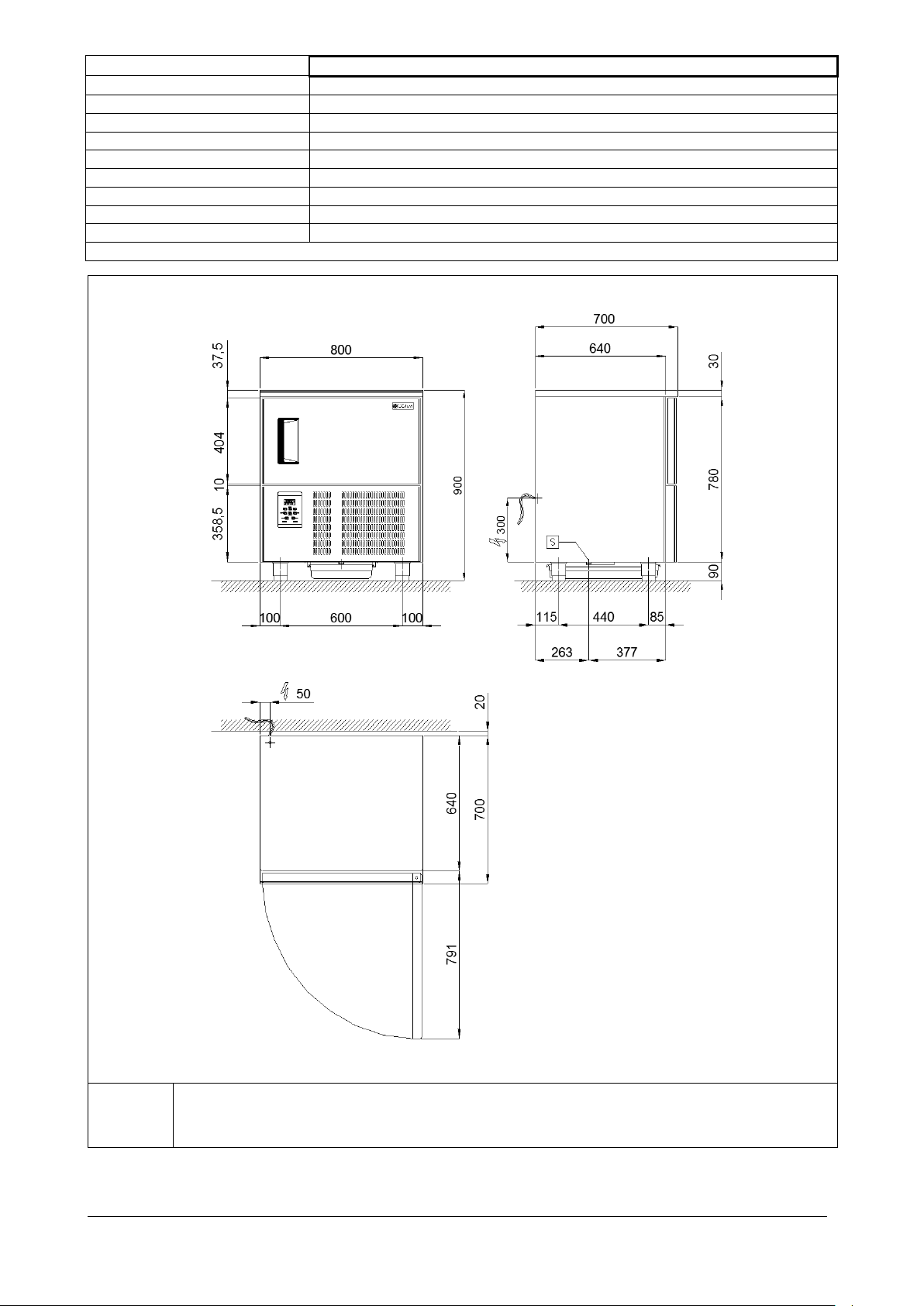

Model

BCB/03

External dimensions

cm

65 x 67 x 67h

Weight

kg

65

Trays

No.

3 GN (cm 53 x 32.5)

Chamber temperature

°C

+ 95 / - 40

Output

kg

10 (+ 65 °C ÷ + 3 °C); 7 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Compressor power

Hp

1/2

Max. absorbed power

W

600

Power supply voltage

Volt 1x230 ~ 50 Hz

Table 1/a

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm2 avec fiche Schuko; L=4000 mm

Fig. 2/a

2.1 –TECHNICAL DATA

BCB_N Rev.05 05-2015 pag. 10

Page 11

Model

BCB/05

External dimensions

cm

80 x 70 x 90h

Weight

kg

92

Trays

No.

5 EN (cm 60 x 40) or 5 GN (cm 53 x 32.5)

Chamber temperature

°C

+ 95 / - 40

Output

kg

15 (+ 65 °C ÷ + 3 °C); 9 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Compressor power

Hp

3/4

Max. absorbed power

W

1100

Power supply voltage

Volt 1x230 ~ 50 Hz

Table 1/b

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm2 avec fiche Schuko; L=4000 mm

Fig. 2/b

BCB_N Rev.05 05-2015 pag. 11

Page 12

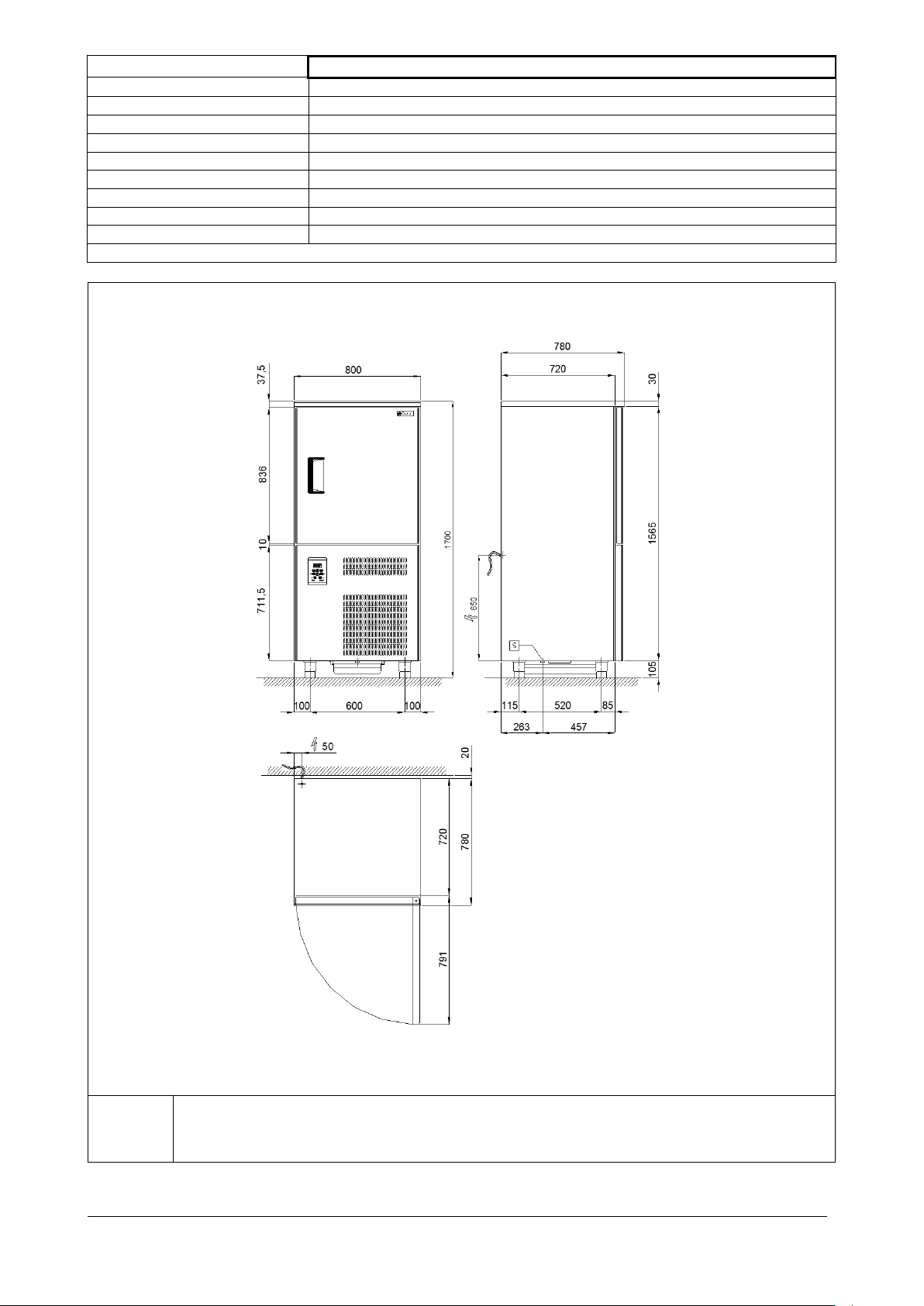

Model

BCB/10

External dimensions

cm

80 x 78 x 170h

Weight

kg

145

Trays

nr

10 EN (cm 60 x 40) or 10 GN (cm 53 x 32,5)

Chamber temperature

°C

+ 95 / - 40

Output

kg

26 (+ 65 °C ÷ + 3 °C); 16 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Compressor power

Hp

1,5

Max. absorbed power

W

1628

Power supply voltage

V. 1x230 ~ 50 Hz

Table 1/c

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Fig. 2/c

BCB_N Rev.05 05-2015 pag. 12

Page 13

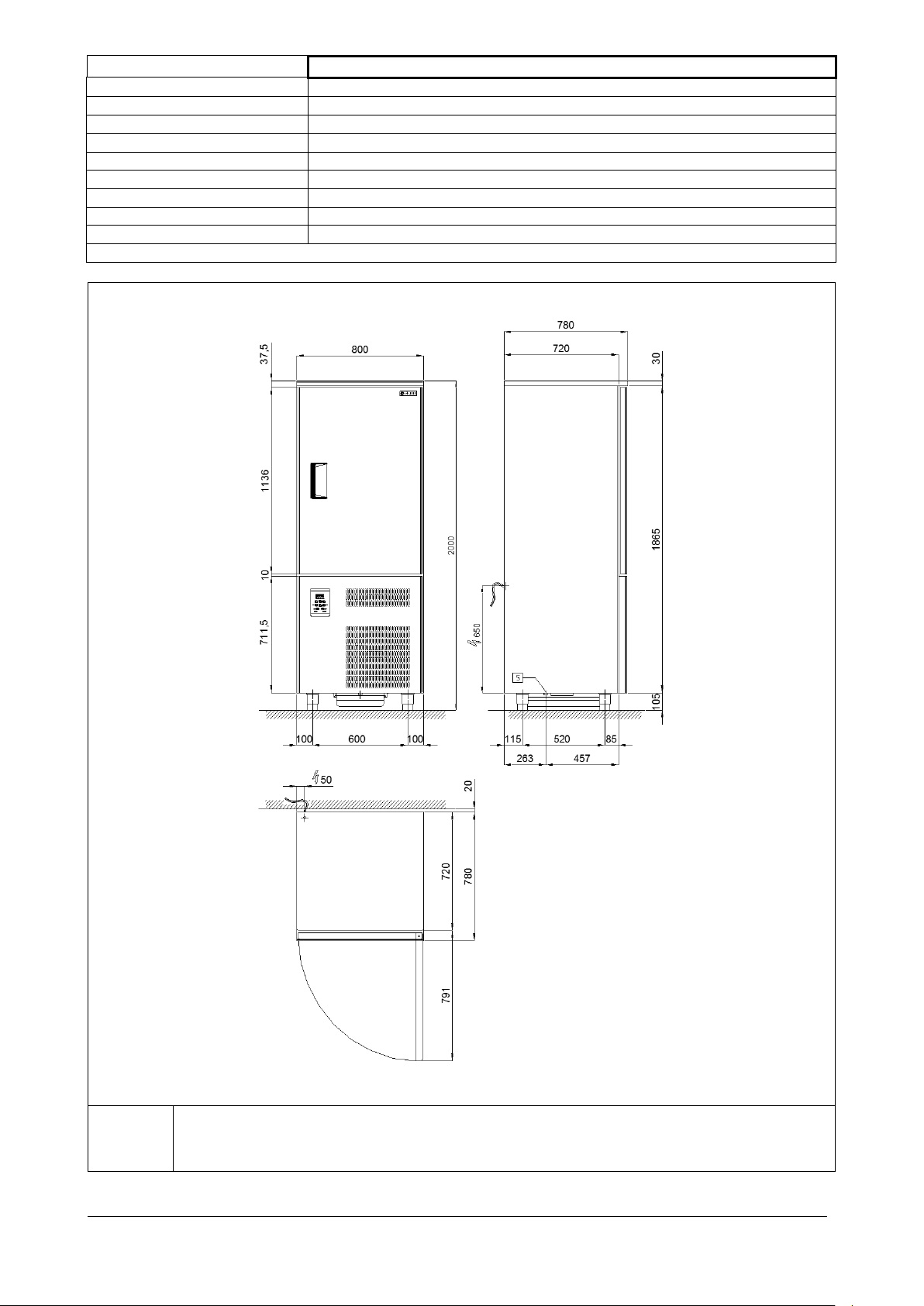

Model

BCB/15

External dimensions

cm

80 x 78 x 200h

Weight

kg

175

Trays

nr

15 EN (cm 60 x 40) or 15 GN (cm 53 x 32,5)

Chamber temperature

°C

+ 95 / - 40

Output

kg

43 (+ 65 °C ÷ + 3 °C); 32 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Compressor power

Hp

3

Max. absorbed power

W

2986

Power supply voltage

Volt 3x400 ~ 50 Hz

Table 1/d

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Fig. 2/d

BCB_N Rev.05 05-2015 pag. 13

Page 14

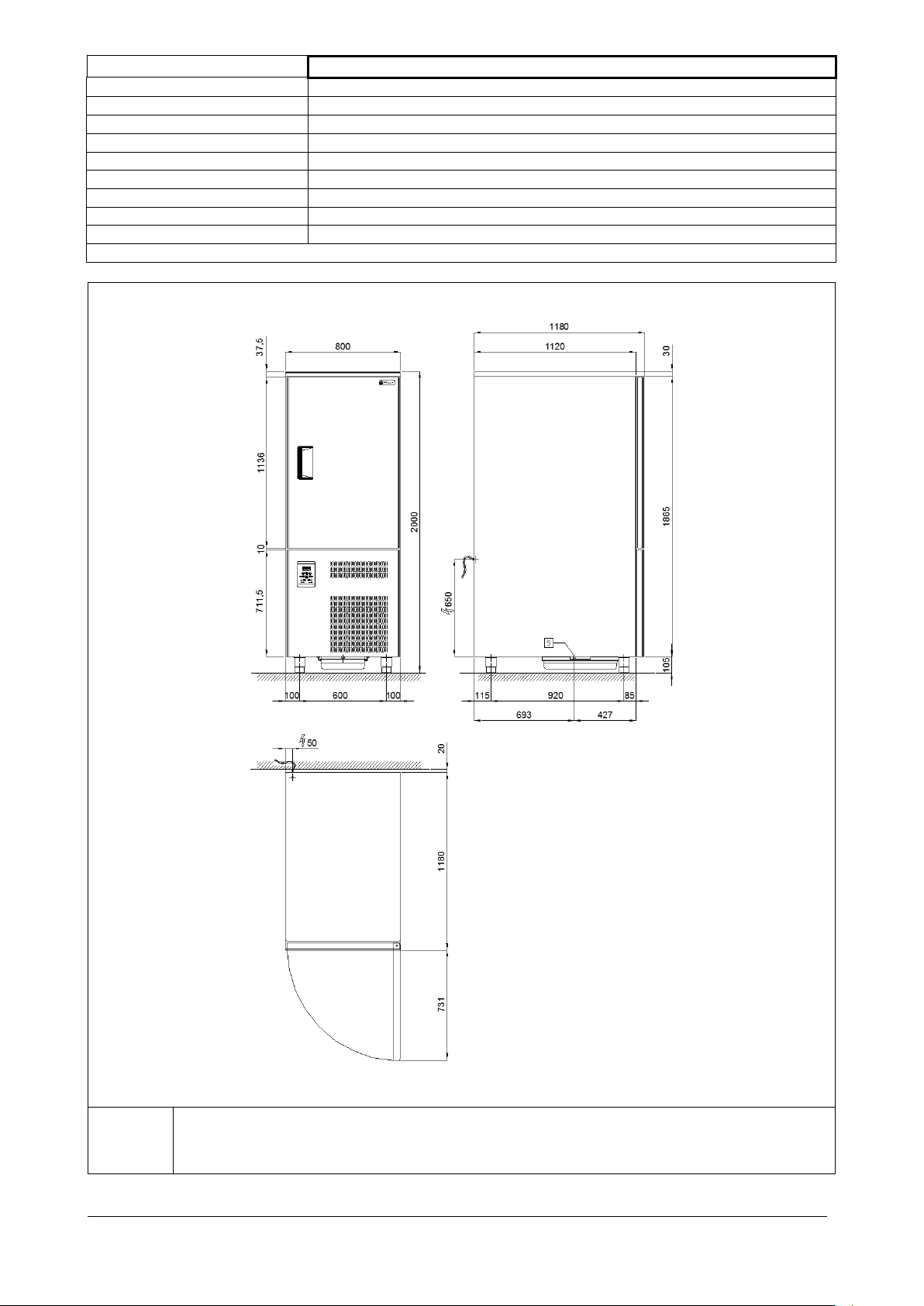

Model

BCB/24

External dimensions

cm

80 x 118 x 200h

Weight

kg

203

Trays

nr

12 EN (cm 60 x 80) or 12 GN 2/1 (cm 53 x 65)

Chamber temperature

°C

+ 95 / - 40

Output

kg

43 (+ 65 °C ÷ + 3 °C); 32 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Compressor power

Hp

3.7

Max. absorbed power

W

4312

Power supply voltage

Volt 3x400 ~ 50 Hz

Table 1/e

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Fig. 2/e

BCB_N Rev.05 05-2015 pag. 14

Page 15

2.2 – DESCRIPTION OF THE BLAST CHILLER AND INTENDED USE

Fig. 3

Blast chillers are appliances with a powerful refrigeration system that can rapidly reduce the core temperature of food.

Ideal for use in kitchens, bakeries and ice cream establishments.

The main work cycles of the appliance are CHILLING and FREEZING. Each cycle has two different end-of-cycle modes

that also correspond to the start of the hold mode: temperature controlled (when the core temperature probe inserted

into the product reaches the set temperature) or time controlled (when the set time expires).

2.2.1 – MAIN COMPONENTS

The appliance comprises the following parts:

body;

condenser unit (ref. 2, fig. 3);

evaporator unit (ref. 1, fig. 3);

control panel (ref. 3, fig. 3)

BCB_N Rev.05 05-2015 pag. 15

Page 16

2.3 – NOISE

Installation site

Bakeries, confectioneries, ice cream makers, and kitchens in general

Relative humidity

< 80% without condensation

Climatic class

“T” + 18 °C ÷ + 43 °C

Table 2

The appliance is designed and built to keep its noise level as low as possible.

2.4 –AMBIENT CONDITIONS

BCB_N Rev.05 05-2015 pag. 16

Page 17

3. – SAFETY

IMPORTANT: before using the appliance read this guide carefully and follow the technical operating

instructions and indications to the letter. The operator must know the position and function of all the

control devices as well as the characteristics of the blast chiller.

The blast chiller complies with current safety laws and regulations, but misuse may cause injury to

persons or damage to property.

At the time of installation all operatives must be suitably trained in accident hazards, operator safety

devices, general accident prevention regulations established by international directives and the current

law in the countries where the appliance is used. The appliance must be started up and used exclusively

by trained staff. The behaviour of operators must in any case scrupulously comply with the accident

prevention regulations in the country where the appliance is used.

Do not remove or deface the plates fitted to the appliance by the manufacturer.

The blast chiller must not be used if the control panel or any other part is damaged.

Do not obstruct the front or rear air vents on the appliance; do not place food to be processed against

the ventilation grilles, air ducts or directly on the cabinet floor.

Promptly report any malfunction.

Use only accessories recommended by the manufacturer.

Do not expose the appliance to rain or sprays of water.

Disconnect the appliance from the electricity supply before carrying out any routine or extraordinary

maintenance which involves opening the control panel/switchboard or disassembling any part of the

blast chiller.

3.1 – GENERAL WARNINGS

The manufacturer is relieved from all liability in the following cases:

failure to carry out scheduled maintenance;

unauthorized alterations or work:

use of other than original spare parts;

failure to observe any part of the contents of this guide;

misuse of the appliance.

Any tampering with or unauthorized replacement of one or more appliance parts or components and use of

other than original accessories and consumables can create a hazard and relieve the manufacturer from any

civil or criminal liability.

If in doubt about appliance operation, refrain from using it and contact the manufacturer.

BCB_N Rev.05 05-2015 pag. 17

Page 18

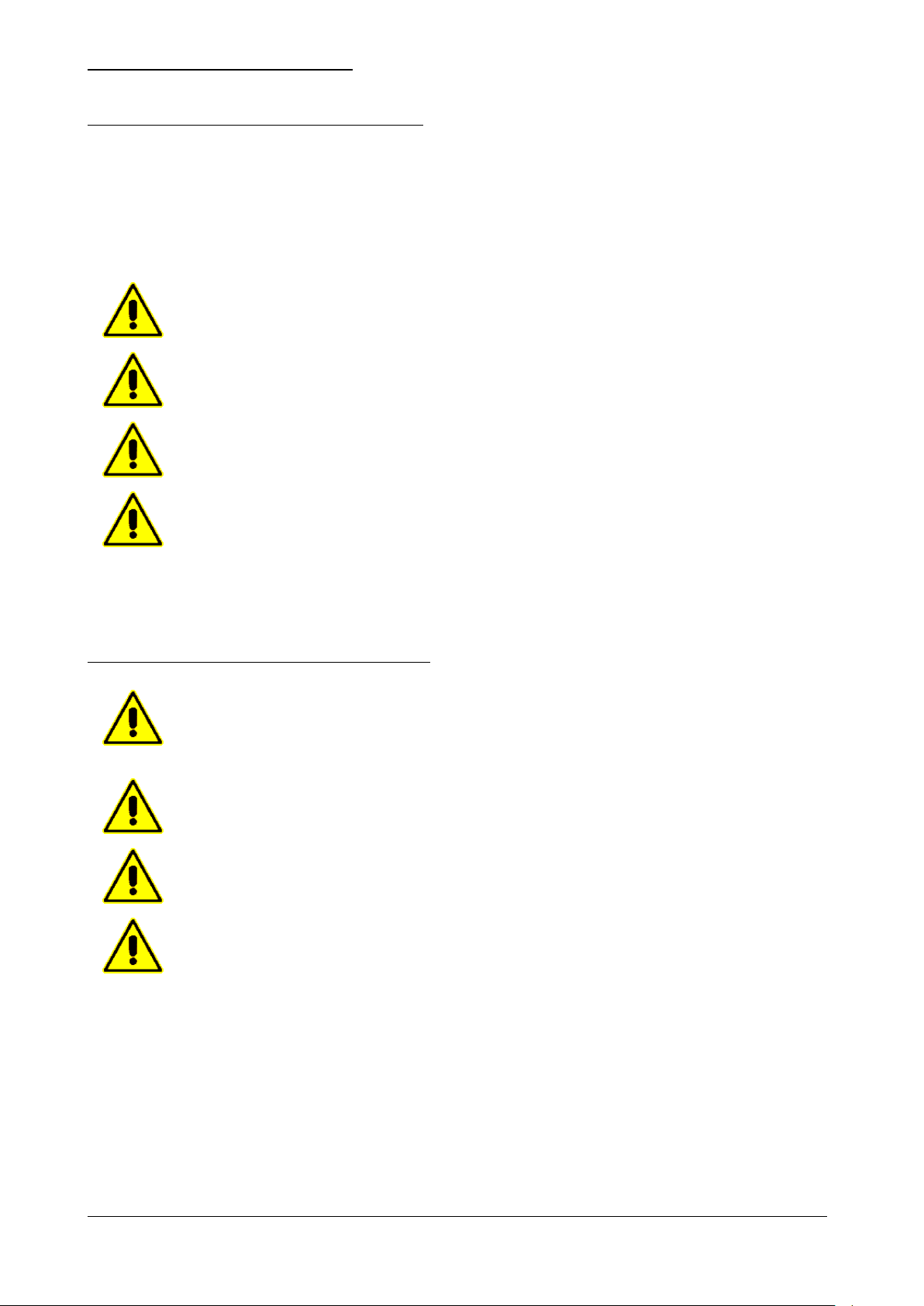

3.2. – PRECAUTIONS FOR USE

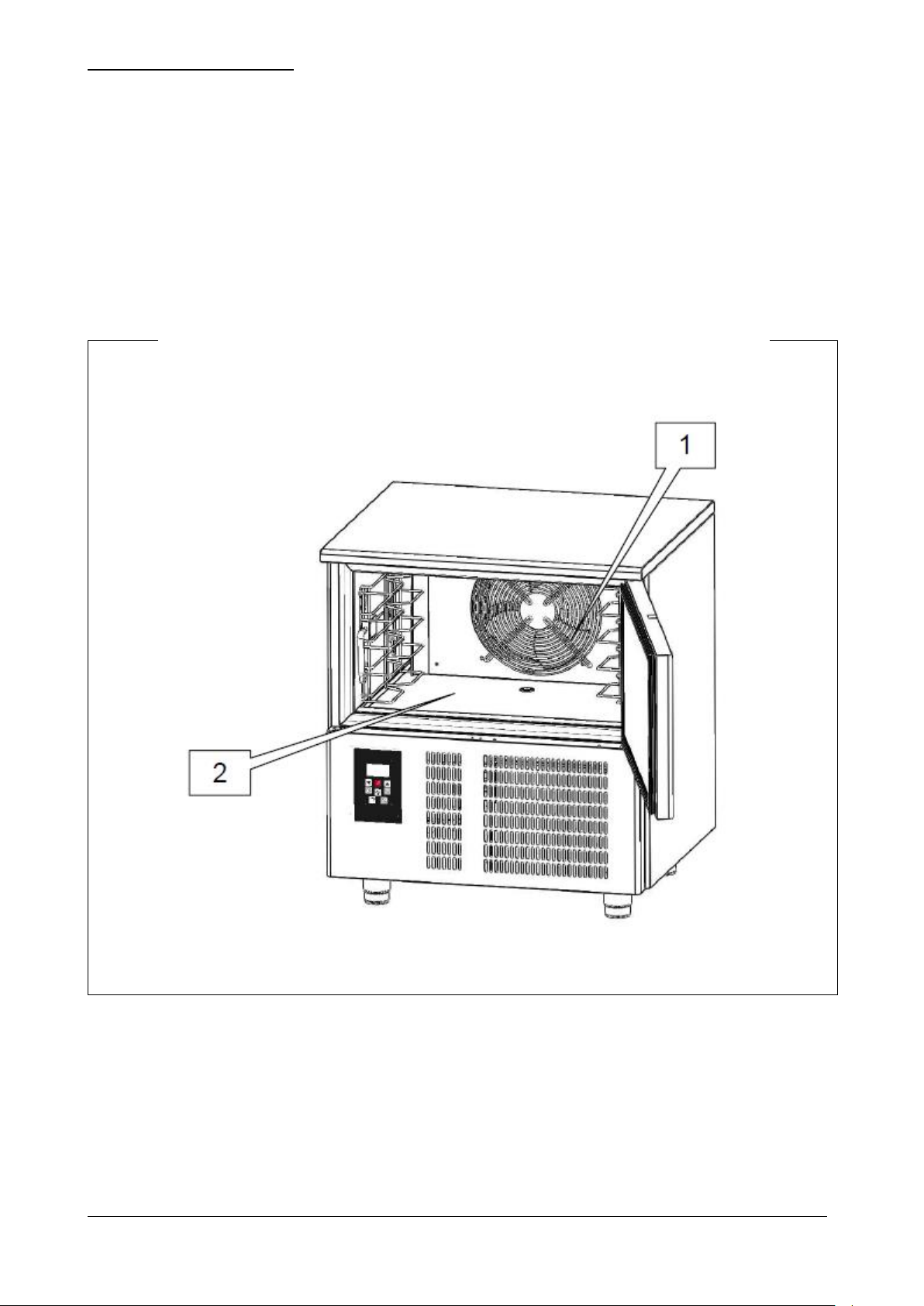

Fig. 4

The blast chiller must not be used:

for purposes other than those given in paragraph 2.2 “Description of the blast chiller and intended use”;

if safety systems are not working;

after incorrect installation;

by untrained personnel;

when maintenance has not been carried out or has been carried out badly;

when other than original spare parts have been used;

with damaged power lead or electrical socket;

with obstructed air ducts (ref. 1 fig. 4);

with the food to be processed placed against the ventilation grilles (ref. 1 fig. 4), air ducts or on the cabinet floor

(ref. 2 fig. 4).

BCB_N Rev.05 05-2015 pag. 18

Page 19

3.3 – SAFETY DEVICES

Fig. 5

Special safety devices on the appliance protect personnel exposed to the hazards inherent in moving parts.

grilles covering the cooling fans (ref. 1 fig. 5);

grilles covering the condenser unit (ref. 2 fig. 5).

The appliance is also provided with devices to protect the food during processing. Below is a list of the safety devices

on the appliance.

Sensor, which detects and signals door opening. If the door remains open for a preset time, the message “ id ”

appears on the display, a sound signal is activated and the compressor switches off.

Sensor (ref. 3 fig. 5), located on the cooling circuit, signals any overheating of the equipment and puts the

appliance in standby mode.

BCB_N Rev.05 05-2015 pag. 19

Page 20

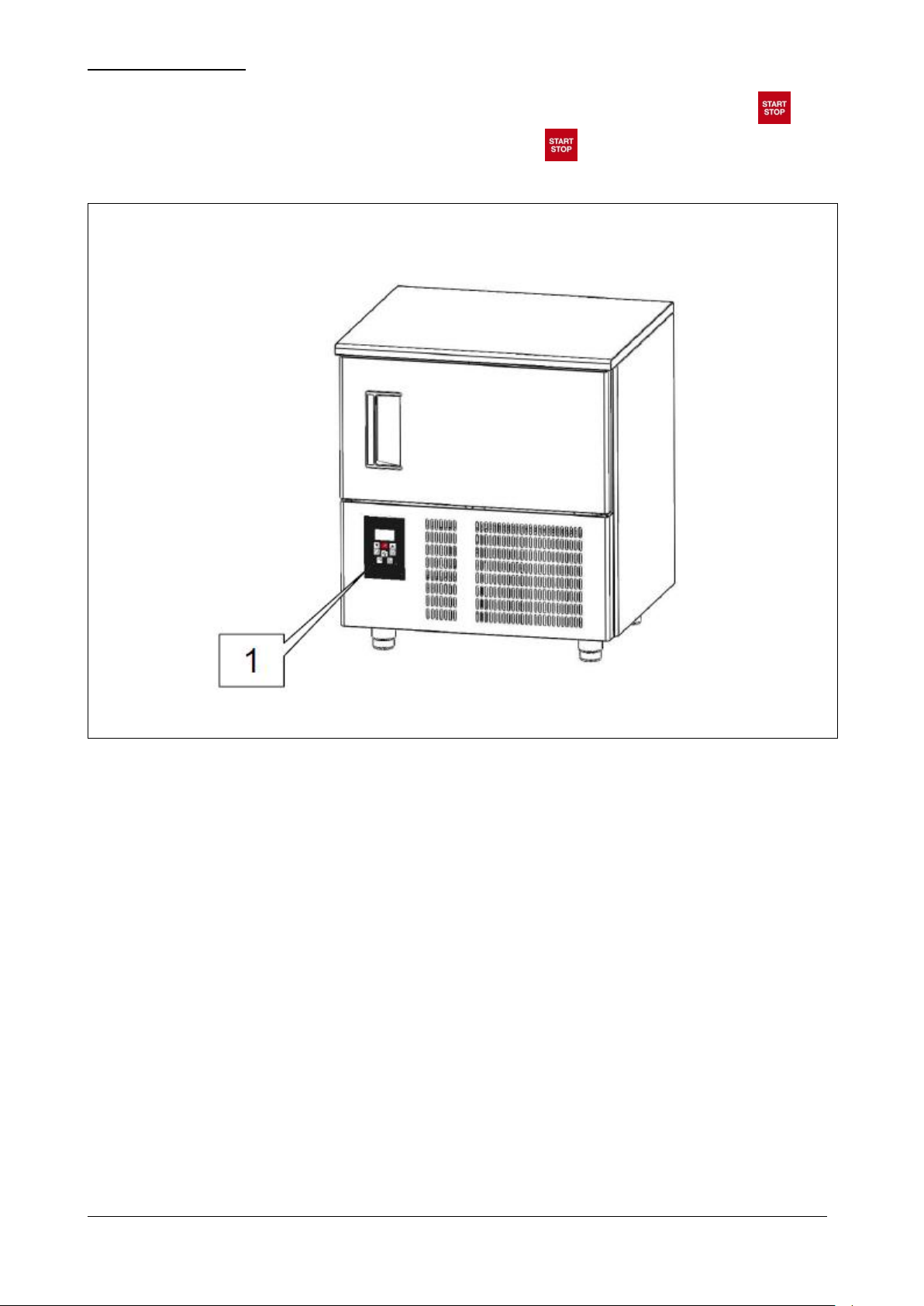

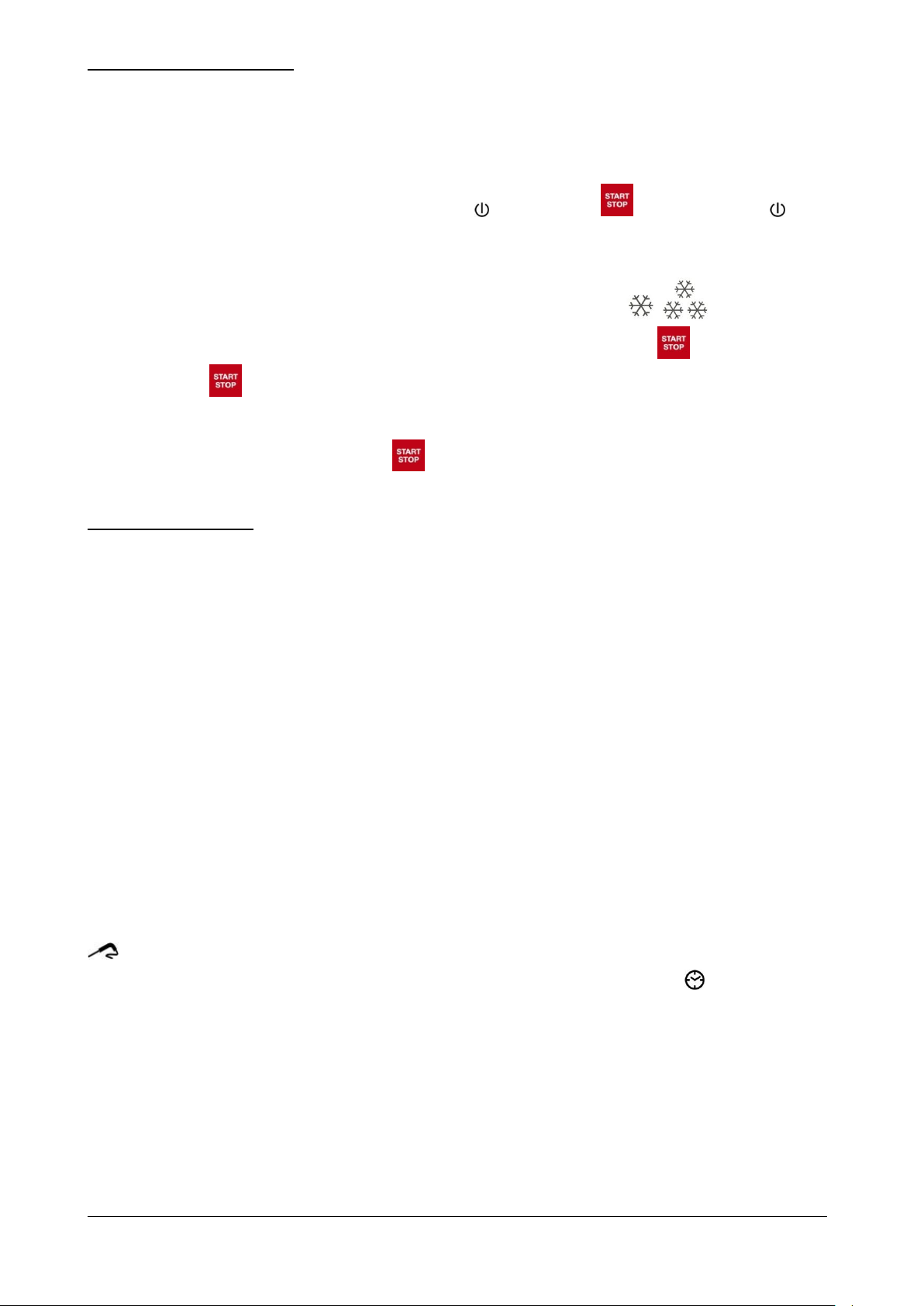

3.4 – STOP FUNCTIONS

Fig. 6

The entire appliance is controlled by an electronic circuit board. The stop function is represented by the button

(ref. 1 fig. 6). Whatever condition the machine is in, holding down the button for 3 seconds cuts out the circuit

board.

BCB_N Rev.05 05-2015 pag. 20

Page 21

4 – TRANSPORTATION AND HANDLING

The appliance must never be overturned.

The pack must be firmly and stably placed on the floor of the means of transport and secured by

appropriate ropes.

Take the utmost care when lifting and positioning the blast chiller so as to avoid serious injury to

persons or damage to property. The manufacturer cannot be held liable if the indications for

lifting and transporting the blast chiller are not observed.

The ambient temperature must never drop below 4°C during transportation.

Take care when lifting and handling the blast chiller; there is the danger of even fatal injury with

loads being moved.

All handling and lifting must be carried out with extreme care, making sure that all personnel,

without exception, are at a safe distance and that no-one is loitering under suspended loads,

whether stationary or moving.

Before starting any movement, check the whole appliance handling area to identify any

dangerous points.

The ambient temperature must never drop below 4°C during transport.

4.1 – TRANSPORTATION OF THE BLAST CHILLER

Suitable packaging for the type, size and weight of the appliance has been used to ensure it is not damaged during

transit and is delivered intact to the purchaser.

The blast chiller must be placed upright on a pallet wrapped in its own cardboard for the entire time it is being

transported.

The blast chiller is handed over to the carrier ready to be handled.

Once the blast chiller has been unpacked, the packaging material must be disposed of or recycled in accordance with

the laws in force in the country where the appliance is being installed.

4.2. – HANDLING THE PACKAGED BLAST CHILLER

AUTHORIZED PERSONNEL

Specialised forklift truck operator.

Personal protective equipment:

- safety shoes;

- safety gloves.

Personnel carrying out such operations must not wear rings, wrist watches, jewellery, loose or unfastened garments,

such as ties, torn garments, scarves, unbuttoned jackets or tunics with open zips, etc. In general, personnel must wear

safety apparel.

BCB_N Rev.05 05-2015 pag. 21

Page 22

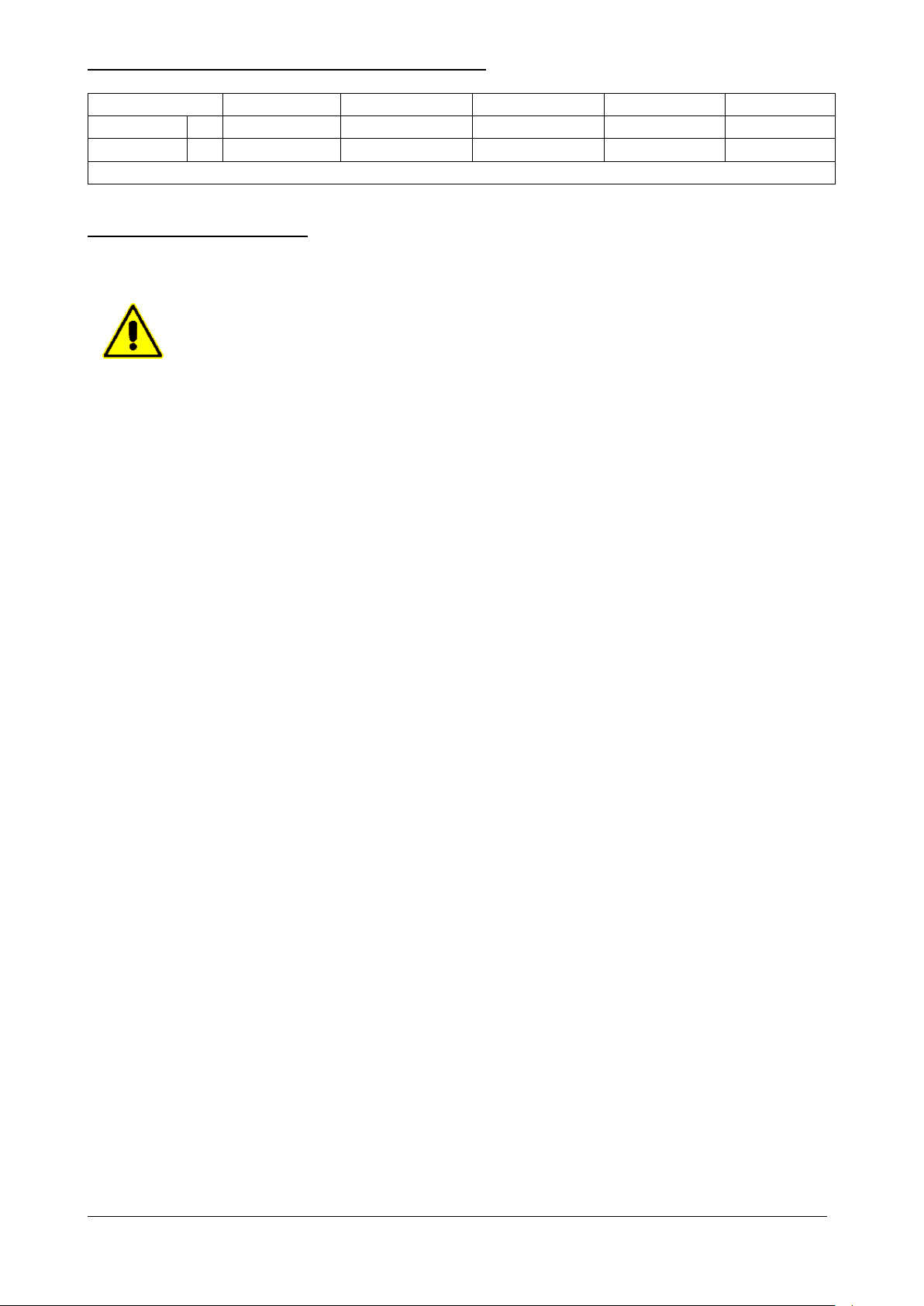

4.2.1 – WEIGHT AND DIMENSIONS OF THE BLAST CHILLER

Model

BCB/03

BCB/05

BCB/10

BCB/15

BCB/24

Dimensions

cm

65x65x67h

80x70x90h

80x78x170h

80x78x200h

80x118x200h

Weight

kg

76

107

166

202

230

Table 3

The use of unsuitable equipment can cause accidents to those involved in the handling or

damage to the appliance.

The manufacturer cannot be held liable for incorrect and non-compliant use of equipment for

lifting, transport and handling.

4.2.2 – NECESSARY EQUIPMENT

- To lift the appliance, use a forklift truck with suitable minimum lifting power.

BCB_N Rev.05 05-2015 pag. 22

Page 23

5 – INSTALLATION

Take every precaution when handling the appliance so as to avoid injury to persons or damage to

property.

Do not start the appliance if there are faults on the control panel or damaged parts.

Check that the packing has not been damaged during transport.

The use of unsuitable equipment can cause accidents to those involved in the handling or

damage to the appliance.

The manufacturer cannot be held liable for incorrect and non-compliant use of equipment for

lifting, transport and handling.

AUTHORIZED PERSONNEL

Specialized electrician.

Personal protective equipment:

safety shoes;

safety gloves.

Personnel carrying out such operations must not wear rings, wrist watches, jewellery, loose or unfastened garments,

such as ties, torn garments, scarves, unbuttoned jackets or tunics with open zips, etc. In general, personnel must wear

safety apparel.

5.1 – PREPARATION FOR INSTALLATION

For installation, prepare an area to work in which is suitable for the size of the appliance (see fig. 2) and the chosen lifting

equipment.

The installation site must be set up with all the cabling and connecting systems required for the appliance to work.

The installation site must satisfy the requirements that will allow the appliance to be used in all safety. The area must

have a solid flat floor providing good support, with a finish that ensures a suitable and safe working place for personnel.

The installation site must have natural or artificial lighting suitable for the work to be carried out (in compliance with

specific regulations).

5.2 – UNPACKING

5.2.1 – NECESSARY EQUIPMENT

Use a forklift truck or equivalent equipment to lift the appliance.

BCB_N Rev.05 05-2015 pag. 23

Page 24

5.2.2 – UNPACKING PROCEDURE

All handling and unpacking must be carried out with extreme care, making sure that all

personnel, without exception, are at a safe distance and that no-one is loitering under

suspended loads, whether stationary or moving.

AFTER INSTALLING THE APPLIANCE, WAIT AT LEAST TWO HOURS BEFORE SWITCHING ON.

The use of unsuitable equipment can cause accidents to those involved in the handling or

damage to the appliance.

The manufacturer cannot be held liable for incorrect and non-compliant use of equipment for

lifting, transport and handling.

All handling and unpacking must be carried out with extreme care, making sure that all

personnel, without exception, are at a safe distance and that no-one is loitering under

suspended loads, whether stationary or moving.

To unpack the appliance, simply remove the cardboard wrapping. Then remove the appliance from the pallet using a

forklift truck, ensuring that the forks are inserted under the appliance and taking care not to damage the two water

tray runners.

5.3 – HANDLING THE BLAST CHILLER

5.3.1 – NECESSARY EQUIPMENT

See paragraph 5.2.1.

5.3.2 – PROCEDURE FOR MOVING THE UNPACKED BLAST CHILLER

To move blast chillers fitted with wheels, release the brakes on the wheels and push, taking care to lock the brakes again

when the appliance is in its final location.

To move blast chillers fitted with feet, lift with a suitable forklift truck; the forks must be inserted under the appliance

taking care not to damage the two water tray runners.

5.4 – ASSEMBLING THE BLAST CHILLER

The blast chiller is delivered to the customer fully assembled.

Remove the water tray from the cabinet and place it under the appliance, sliding it along the runners placed between the

feet.

BCB_N Rev.05 05-2015 pag. 24

Page 25

6 – SETTING UP

AFTER INSTALLING THE APPLIANCE, WAIT AT LEAST TWO HOURS BEFORE SWITCHING ON.

Electrical connection must be carried out by a specialized electrician.

Check that the power supply voltage given on the ID plate corresponds to the mains voltage

available at the installation site.

The electrical system must conform to current wiring regulations; the mains supply must have

an efficient earthing system compliant with the electrical codes and regulations in the country;

this is the responsibility of the customer.

Avoid sharp bends or kinks in the power cord and do not place any object whatsoever on top of

it.

If it is necessary to unplug from the mains supply, first make sure the circuit board is on OFF

on the display.

The manufacturer cannot be held liable for any damage or accidents caused by failure to comply

with these rules and regulations.

Adjustments carried out by unauthorized personnel may damage the appliance and expose the

operator to serious hazards. Adjustments by unauthorized personnel are considered as

tampering with the appliance and as such invalidate the warranty and relieve the manufacturer

from any liability.

6.1 – CONNECTIONS

6.1.1 – ELECTRICAL CONNECTION

ELECTRICAL CONNECTION PROCEDURE

The appliance is supplied by the manufacturer complete with power plug. Simply connect the power plug to a socket at

the installation site; the system must conform to current regulations.

The electricity supply at the installation site must satisfy the following requirements:

Voltage: 230 Vac

Frequency: 50 Hz

6.2 – PRELIMINARY CHECKS

The electrician-installer must instruct the operator on how to use the blast chiller correctly and explain the basic

maintenance to be carried out.

METHOD

The blast chiller must be prepared for initial start-up by a specialised engineer, in the presence of the operator who will

use the appliance so that the operator can acquire a minimum working knowledge to help him/her carry out allowed

routine maintenance and cleaning.

Before switching on the appliance, a series of checks and inspections must be carried out to prevent errors or accidents

during start up.

Check that the appliance has not been damaged during transport.

Check very carefully for any damage to the control panel/switchboard, pushbutton control, wiring and pipes.

Check that all external power sources have been connected properly.

Check that the machine is perfectly level.

6.2.1 – ADJUSTMENTS

BCB_N Rev.05 05-2015 pag. 25

Page 26

7 – USE

AFTER INSTALLING THE APPLIANCE, WAIT AT LEAST TWO HOURS BEFORE SWITCHING ON.

COLD BURN HAZARD

During operation the appliance can reach extremely low temperatures: avoid direct contact with

the internal parts immediately after opening the door.

7.1 – INTENDED USE

Blast chillers are appliances with a powerful refrigeration system that can rapidly reduce the core temperature of food.

Ideal for use in kitchens, bakeries and ice cream establishments.

The main work cycles of the appliance are CHILLING and FREEZING. Each cycle has two different end-of-cycle modes

that also correspond to the start of the hold mode: temperature controlled (when the core temperature probe inserted

into the product reaches the set temperature) or time controlled (when the set time expires).

- SOFT CHILLING. “Delicate” positive chilling (+3°C). Food just out of the oven is brought quickly to a

temperature of 3°C in no more than 90’, thus inhibiting bacterial proliferation and avoiding dehydration of the

cooked food due to evaporation. Food treated in this way can be stored perfectly for 5-7 days without any

alteration to its original qualities.

- HARD CHILLING. “Intense” positive chilling (+3°C). This mode also lasts for a maximum of 90’ and is used

when the food to be chilled is thicker than 2-3 centimetres (i.e. large joints), dense or fatty. The appliance air

temperature varies to accelerate penetration of the cold into the food.

- FREEZING. Shock freezing or freezing (-18°C). This work cycle brings the core temperature of the food to 18°C in less than four hours (240’). The speed of the process prevents large ice crystals from forming, ensuring

that when it is used the thawed food has its original texture, colour and quality.

- HOLDING. At the end of both the chilling and freezing cycles the machine automatically goes to the set holding

temperature.

7.2 – INAPPROPRIATE USE

Blast chillers cannot be used for purposes other than those described in point 7.1. In particular the appliance is not

suitable for storing food for an indefinite period.

7.3 – RESIDUAL RISKS

BCB_N Rev.05 05-2015 pag. 26

Page 27

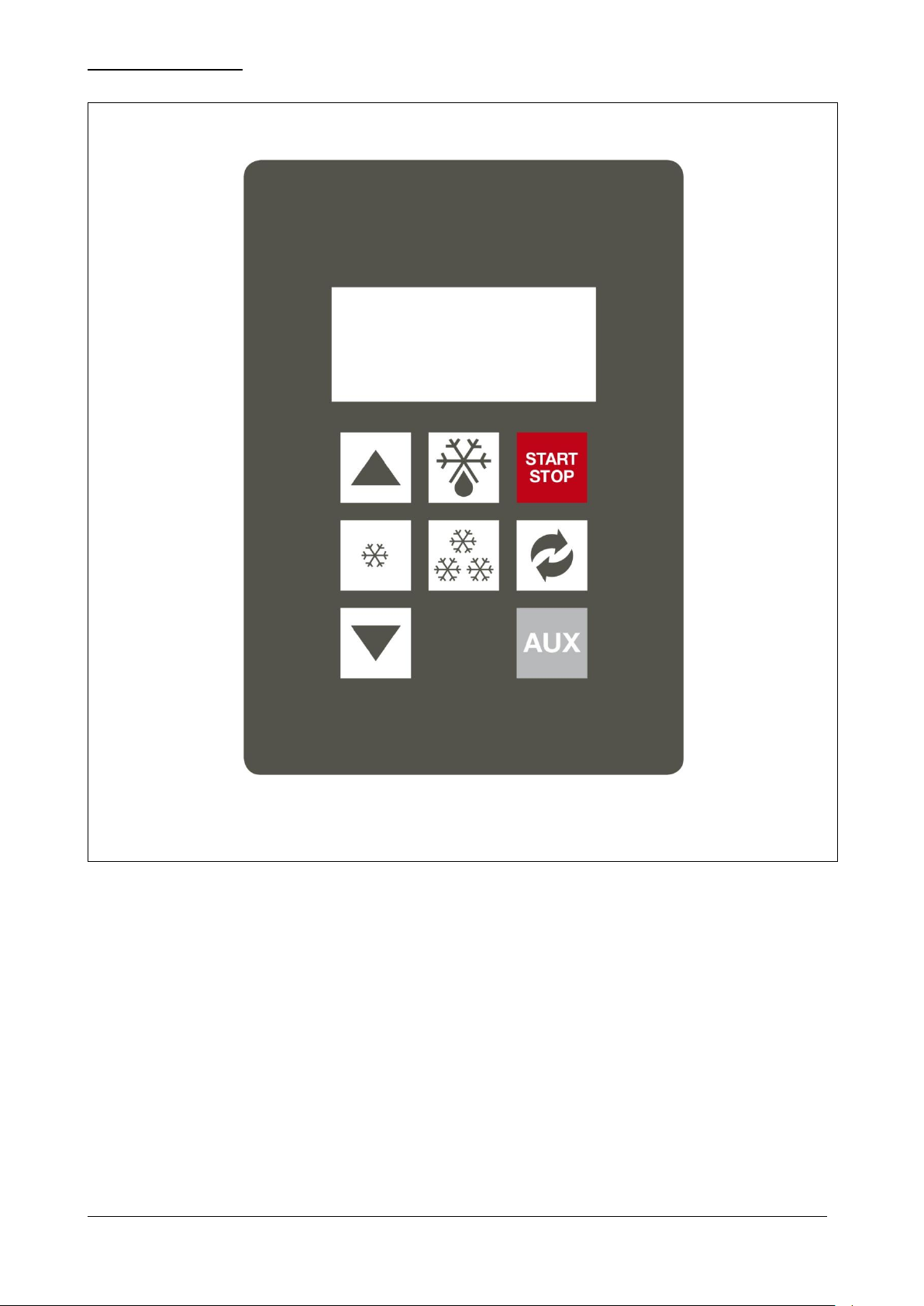

7.4 – CONTROL PANEL

Fig. 7

BCB_N Rev.05 05-2015 pag. 27

Page 28

The buttons on the control panel are as follows:

BUTTON 0/1, START/STOP

When the appliance is OFF (0), press just once to pass to

STANDBY (1). When the appliance is in STANDBY press just

once to START a cycle. When a cycle is in progress, press just

once to STOP. Whatever the appliance status, if the button is

held down for 3 seconds the circuit board is put to OFF.

+ AND - BUTTONS

Used to increase or decrease the value shown on the display.

DEFROST BUTTON

With the appliance in STANDBY or during the storage, press just

once to start a defrost cycle.

CHILLLING BUTTON

With the appliance in STANDBY, press just once to select a

chilling cycle.

Hold the button down for 3 seconds to start the continuous cycle.

HARD/SOFT BUTTON

With the cycle selected, press just once to select the HARD or

SOFT mode.

FREEZING BUTTON

With the appliance in STANDBY, press just once to select a

freezing cycle.

AUXILIARY BUTTON

Press this button to use the accessory, such as UV lamp, warmed

core probe, when installed.

OFF

Only lit when the appliance is OFF, otherwise always off.

CELSIUS

May be lit red or green to show the temperature unit of

measurement.

CHILLING AND FREEZING

Blinking when the relative cycles are in progress; lit during the

subsequent hold cycle.

TEMPERATURE

Lit during a temperature-controlled cycle

TIME

Lit during a time-controlled cycle.

HOLDING

Lit or blinking when in the hold mode.

CONTINUOUS CYCLE

Lit or blinking during the pre-cooling phase, also CONTINUOUS

CYCLE.

The following icons are present on the controller display:

BCB_N Rev.05 05-2015 pag. 28

Page 29

7.5 – CONTROL PROCEDURES

The entire appliance is controlled by an electronic circuit board.

As soon as the appliance is connected to the electricity supply, the whole display lights up for a “lamp-test” lasting a few

seconds, At the end of the lamp test, the display returns to the condition it was in before being switched off. In

particular, if a cycle was in progress at the time, it will re-start from the point at which it was interrupted.

With the circuit board OFF the display is not lit except for the icon. Press the button to turn off the icon on

the display and go into STANDBY mode; the cabinet temperature appears in blue on the display.

Use the controls on the panel, helped by the indications on the display, to activate the various appliance functions.

With the circuit board in STANDBY, pass from one cycle to another by simply pressing , .

With the circuit board in STANDBY and a cycle selected, start the cycle by pressing the (START) button once.

Similarly, press the (STOP) button just once to stop the cycle in progress.

If the buzzer sounds for any reason whatsoever, it may be muted by simply pressing any button.

Whatever the appliance status, holding down the button for 3 seconds puts the circuit board to OFF.

7.6 – USE PROCEDURES

Before using the appliance, the inside of the cabinet should be thoroughly cleaned.

When switching on after installation or if the appliance has not been used for a long time, it is a good rule to let it operate

empty until the set temperature has been reached.

To get the best performance from the blast chiller, arrange the products so that air can circulate properly: do not obstruct

the fan, do not stack trays on top of each other, distribute the load neatly and do not cover the containers with lids or

cling film.

To avoid unwanted changes in the food, do not load the appliance with more than the allowed quantities, do not use

pieces thicker than 50-70 mm and avoid pointlessly opening the door.

Clean and sterilise the core probe before use. The probe must be inserted into the centre of the largest joint or piece,

taking care that the point does not go right through and come into contact with the tray.

To improve the efficiency of either the chill or freeze working cycle, we recommend pre-cooling the cabinet by

switching the appliance on at least 15 min before inserting the product.

When any cycle is selected the electronic circuit board checks the temperatures read by the cabinet sensor and

the core probe to assess correct insertion of the probe (AUTOMATIC probe acknowledgement). This check lasts

just over 2 minutes and then, in accordance with set parameters and provided the probe is properly inserted, a

temperature-controlled cycle starts. In this case the temperature of the core probe will be displayed and the icon

lights up.

A failed test is indicated by activation of the buzzer for one minute, after which the icon will light up on the

display and a time-controlled cycle starts.

BCB_N Rev.05 05-2015 pag. 29

Page 30

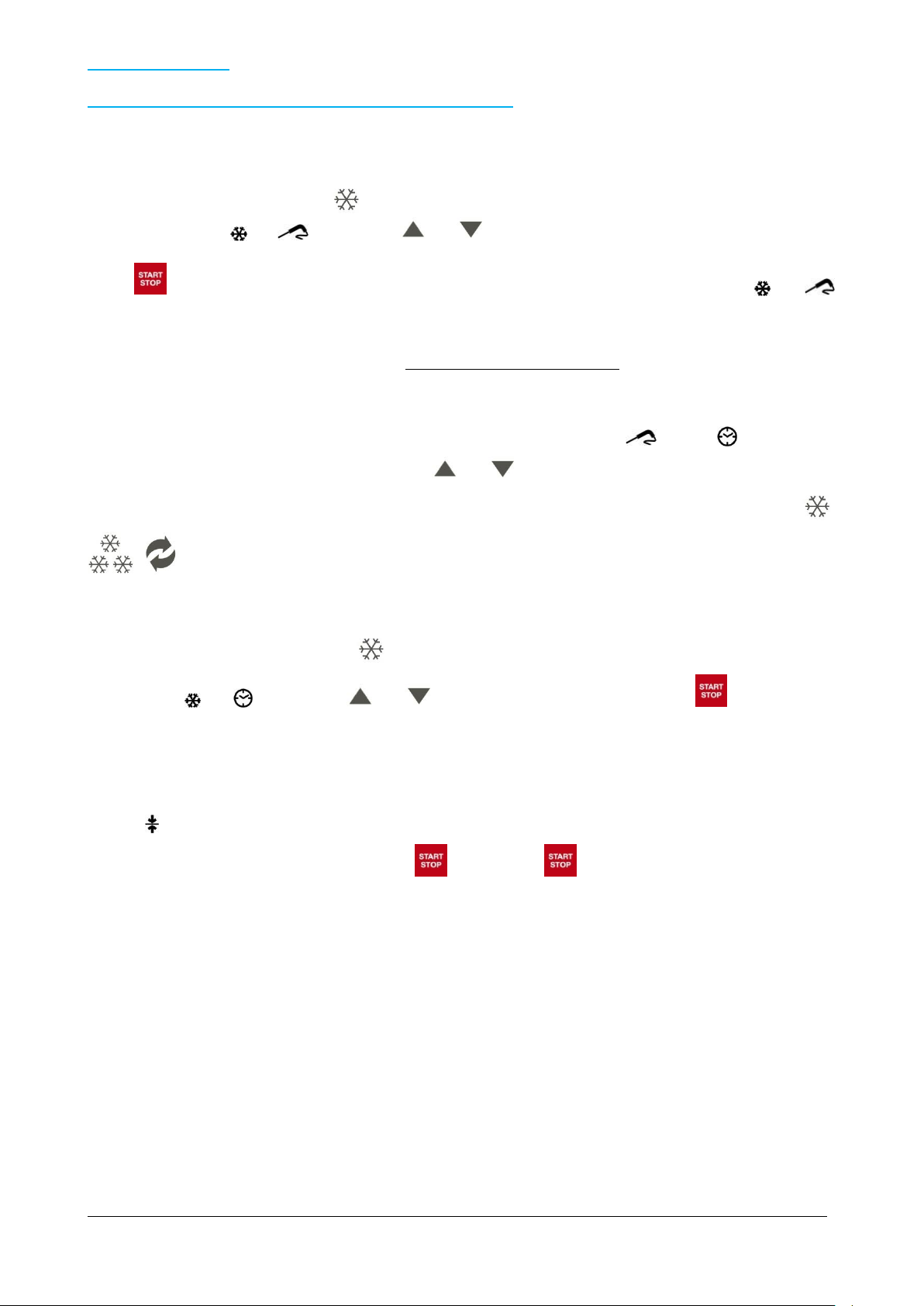

7.7 – SOFT CHILLING

7.7.1 – SELECTING AND SETTING OF SOFT CHILLING CYCLE

Load the appliance suitably with the food to be chilled, insert the core probe correctly into the product for a temperaturecontrolled cycle, and close the door.

With the appliance on STANDBY press : the cabinet set point temperature related to the - 5°C cycle appears on the

display while the icons and blink. Use the and buttons to change this value.

Press (START) to start the cycle: the cabinet temperature appears on the display while the icons and

remain lit. As already explained, once the cycle is confirmed, the device carries out an automatic acknowledgement of

probe insertion (approx. 2 minutes), at the end of which the temperature-controlled cycle (with probe) will be confirmed or

the appliance will pass to the time-controlled cycle. All this is done AUTOMATICALLY.

If the test is passed, the device confirms the temperature-controlled cycle (with probe) and the probe temperature

appears on the display.

If the test is failed, after the buzzer alarm and visual warning given by the blinking icon , the icon appears on the

display and the cycle becomes time controlled. Use the and buttons to change this value.

While the residual time is being displayed, the cabinet temperature may also be displayed by simply pressing the ,

, buttons.

The time-controlled cycle may be selected DIRECTLY, bypassing the automatic probe acknowledgement stage.

With the appliance in STANDBY press the button TWICE: the duration of the cycle, 90 min, appears on the display

while the icons and blink. Use the and buttons to change this value. Then press (START) to start

the cycle.

When the 90’ cycle has elapsed or when the core temperature of +3°C has been reached, the buzzer sounds and the

device automatically starts the hold cycle with +2°C cabinet temperature.

The icon lights up on the display.

The cycle can be interrupted at any time by pressing (STOP): press (START) again to restart the cycle.

BCB_N Rev.05 05-2015 pag. 30

Page 31

7.8 – HARD CHILLING

7.8.1 – SELECTING AND SETTING A HARD CHILLING CYCLE

Load the appliance suitably with the food to be chilled, insert the core probe correctly into the product for a temperaturecontrolled cycle, and close the door.

With the appliance on STANDBY, press : the cabinet set point temperature related to the - 5°C cycle appears on the

display while the icons and blink. Use the and buttons to change this value.

Press the button just once to start the hard cycle. The symbol HARD also starts blinking on the display.

Press (START) to start the cycle: the cabinet temperature appears on the display while the icons and

remain lit. As already explained, once the cycle is confirmed, the device carries out an automatic acknowledgement of

probe insertion (approx. 2 minutes), at the end of which the temperature-controlled cycle (with probe) will be confirmed or

the appliance will pass to the time-controlled cycle. All this is done AUTOMATICALLY.

If the test is passed, the device confirms the temperature-controlled cycle (with probe) and the probe temperature

appears on the display.

If the test is failed, after the buzzer alarm and visual warning given by the blinking icon , the icon appears on the

display and the cycle becomes time controlled. Use the and buttons to change this value.

While the residual time is being displayed, the cabinet temperature may also be displayed by simply pressing the ,

, buttons.

The time-controlled cycle may be selected DIRECTLY, bypassing the automatic probe acknowledgement stage.

With the appliance in STANDBY press the button TWICE: the duration of the cycle, 90 min, appears on the display

while the icons and blink. Use the and buttons to change this value. Then press (START) to start

the cycle.

When the 90’ cycle has elapsed or when the core temperature of +3°C has been reached, the buzzer sounds and the

device automatically starts the hold cycle with +2°C cabinet temperature.

The icon lights up on the display.

The cycle can be interrupted at any time by pressing (STOP): press (START) again to restart the cycle.

BCB_N Rev.05 05-2015 pag. 31

Page 32

7.9 – FREEZING

7.9.1 – SELECTING AND SETTING A FREEZING CYCLE

Load the machine suitably with the food to be frozen, place the core probe into the food and close the door.

With the appliance on STANDBY press : the display will show the set point temperature of the room referred to

- 40°C cycle, in the meantime the icons and flash. Use the and buttons to edit this value.

Press (START) to start the cycle: the display will show the temperature of the room and the icons and

will remain on. As already explained, once confirmed the cycle, the device does an automatic identification of probe’s

insertion (around 2 minutes), at the end of which the cycle will be confirmed or by probe or by time. All this process will

be made AUTOMATICALLY.

If the test has a positive result, the device will confirm the temperature controller cycle (probe) and the display will show

the temperature of the probe.

Otherwise, if the result is negative, after buzzer’s alarm and visual signalling of the flashing icon , the display will

show the icon and the cycle will change in time controlled cycle. Use the and buttons to edit this value.

During the visualization of the residual time, it is possible to change the temperature of the room by pressing the buttons

, , .

You can DIRECTLY select the cycle time, bypassing the automatic stage of probe recognition.

With the appliance on STANDBY press TWICE : the display will show the duration of the cycle 240 min, in the

meantime the icons and flash. Use the and buttons to edit this value. Than press (START) in

order to start the cycle.

Once finish the time relative to 240’ cycle or once reaches the core temperature of -18°C, the device automatically starts

the conservation cycle, -25°C rooms, previously reported by the buzzer’s alarm.

On the display will appear the icon

The cycle can be interrupted at any time by pressing (STOP): press (START) again in order to restart again

the cycle.

BCB_N Rev.05 05-2015 pag. 32

Page 33

7.10 – SPECIAL FUNCTIONS AND USES

7.10.1 – PRE-CHILLING FUNCTION or CONTINUOUS CYCLE

If the temperature of the food to be chilled is very high (above 65°C) it is advisable to pre-chill as follows: press the

button for a few seconds, the appliance starts and the LED starts blinking. Once the set point (-30°C) has been

reached, the LED remains on with fixed light and any cycle may be set and the appliance suitably loaded with the food to

be chilled or frozen. The new set cycle will “overwrite” the continuous cycle, without having to switch off the appliance

first.

The continuous cycle is ideal for ice-cream establishments where working cycles are very frequent

(HARDENING). Only the cabinet temperature and not the time parameter is necessary.

7.10.2 – DEFROST

The appliance evaporator is defrosted by stopping the compressor. Defrost can be carried out in the Automatic or

Manual mode and is shown by the readout “ dEF ” appearing on the display first with fixed light then during dripping with

blinking light.

Automatic defrost can only take place during the hold cycle, at intervals of 6 hours with a maximum duration of 15’ and

an evaporator temperature of +8°C.

Manual defrost can be activated when the machine is in STANDBY and the evaporator temperature does not exceed

+8°C, by pressing . Since the compressor is already off in the STANDBY mode, forced ventilation takes place during

Manual defrost and it is therefore advisable to keep the door open throughout the cycle.

7.10.3 – LONG IDLE PERIODS

Switch the appliance OFF by pressing for three seconds, then unplug.

Clean the appliance thoroughly (see paragraph 8.2) and make sure the door is left open at the end of cleaning and

throughout the period that the appliance is not used.

BCB_N Rev.05 05-2015 pag. 33

Page 34

8 – MAINTENANCE

Contact the manufacturer for any anomaly not described in this guide; also contact the manufacturer

if any doubts arise concerning the maintenance described herein. Maintenance carried out by

unauthorized personnel may damage the appliance and expose the operator to serious hazards.

Maintenance carried out by unauthorized personnel is considered as tampering with the appliance

and as such invalidates the warranty and relieves the manufacturer from any liability.

Switch off the appliance, on the display, and disconnect from the power supply before

carrying out any routine or extraordinary maintenance which involves opening the control

panel/switchboard or disassembling any part of the appliance.

Maintenance carried out on an appliance in which the electrical system is live, may cause

even fatal injury.

Only authorized personnel may deactivate the safety devices so as to guarantee the safety of

persons and prevent damage to the appliance. The safety devices must be correctly activated again

when maintenance is completed.

Unauthorized persons must keep a safe distance from the appliance during maintenance or repairs.

Observe the intervals for making inspections as directed or indicated in this guide.

At the end of maintenance or repairs the appliance may only be started after the specialist engineer

has made sure that:

- all the work has been fully carried out;

- the safety systems are active;

- the appliance is working perfectly;

- no-one is working on the appliance.

Component

Type of work

Timing

Responsibility

Method

Chamber

Cleaning

When needed

Appliance operator

See para. 8.2.2

External part

Cleaning

When needed

Appliance operator

See para. 8.2.3

Condenser

Cleaning

Every 30 days

Appliance operator

See para. 8.2.4

Core probe

Cleaning

Every cycle

Appliance operator

See para. 8.2.5

Table 5

8.1 – SPECIAL PRECAUTIONS

8.2 – ROUTINE MAINTENANCE

8.2.1 – ROUTINE MAINTENANCE TABLE (TABLE 5)

8.2.2 – CLEANING THE CHAMBER INTERIOR

Carry out this operation whenever necessary.

APPLIANCE STATUS:

- ON/OFF button on OFF ( on the display);

- power supply plug disconnected from the mains.

AUTHORIZED PERSONNEL

Appliance operator.

BCB_N Rev.05 05-2015 pag. 34

Page 35

METHOD

Use exclusively water and non-abrasive neutral detergent for cleaning. The use of different

products could damage the surface of the appliance and compromise the quality and healthiness of

the product being processed.

Do not use abrasive sponges.

When cleaning do not use cloths that leave lint.

Do not use water jets to clean the appliance.

Fig. 8

Clean very carefully the internal part of the chamber, the door closure surface (ref. 1 fig. 8) and gasket (ref. 2 fig. 8),

using a non-abrasive sponge soaked in neutral detergent. Rinse with a sponge soaked in water and dry with a clean

cloth.

Proper cleaning of the inside of the appliance prevents the formation of bad odour which could affect the end product

negatively.

BCB_N Rev.05 05-2015 pag. 35

Page 36

8.2.3 – CLEANING THE EXTERIOR OF THE APPLIANCE

Only use water and non-abrasive neutral detergent for cleaning. The use of other products could

damage the surface of the appliance and jeopardise the quality and healthiness of the product being

processed.

Do not use abrasive sponges.

When cleaning do not use cloths that could leave lint.

Clean whenever necessary.

APPLIANCE STATUS:

- ON/OFF button on OFF ( on the display);

- power plug disconnected from the mains supply.

AUTHORIZED PERSONNEL

Appliance operator.

METHOD

Clean the external surfaces of the appliance (steel base and panelling) using a sponge soaked with neutral detergent.

neither of which must be abrasive. Rinse thoroughly using a clean sponge soaked with water and then wipe dry using a

clean cloth.

BCB_N Rev.05 05-2015 pag. 36

Page 37

Fig. 9

The condenser has sharp edges. When carrying out the above work, wear safety gloves, goggles

and face masks.

Do not use direct water jets to clean the appliance.

8.2.4 – CLEANING THE APPLIANCE CONDENSER

Clean once every 30 days.

APPLIANCE STATUS:

- ON/OFF button on OFF ( on the display);

- power plug disconnected from the mains supply.

AUTHORIZED PERSONNEL

Appliance operator.

METHOD

For trouble-free efficient appliance operation, the air-cooled condenser (ref. 1 fig. 9) must be kept clean so that the air

can circulate freely. Cleaning must be carried out once every 30 days. Remove the control panel by loosening the

screws (ref. 2 and 3 fig. 9). Clean with a non-metallic brush to remove all the dust and fluff from the fins. It is advisable

to use a vacuum cleaner so that dust does not float in the air. If there are greasy deposits, remove with a brush soaked

in alcohol. DO NOT SCRAPE THE SURFACES WITH POINTED OR ABRASIVE OBJECTS.

BCB_N Rev.05 05-2015 pag. 37

Page 38

8.2.5 – CLEANING THE CORE PROBE

Fig. 10

Do not tug the probe cable; you may damage it.

The probe has a very sharp pointed tip. Always wear safety gloves and take great care during

cleaning.

Clean at every cycle.

APPLIANCE STATUS:

- ON/OFF button in position “O” (OFF);

AUTHORIZED PERSONNEL

Appliance operator.

METHOD

The core probe (ref. 1 fig. 10) must always be cleaned before a new cycle so as to avoid “contaminating” the product in

any way. Remove any residue using a sponge soaked in neutral detergent. Rinse with plenty of water and apply a

sterilising product.

BCB_N Rev.05 05-2015 pag. 38

Page 39

8.3 – EXTRAORDINARY MAINTENANCE

Contact the manufacturer to disassemble the appliance in any way.

If the appliance needs extraordinary maintenance or if malfunctioning occurs that is not described in this guide, contact

the manufacturer.

8.4 – TROUBLESHOOTING

It is important to remember that whatever the appliance status, pressing the button for 3 seconds switches it OFF.

When any malfunction occurs, the buzzer sounds intermittently and a readout appears in red on the display. Whatever

the reason for the buzzer, it can be muted by pressing any button.

8.4.1– ALARMS

The following alarms could appear on the display:

- “ tiME ” temperature-controlled chilling or freezing not finished within the maximum time limit (HACCP alarm).

This alarm has no direct effect, it will simply be stored.

- “ AL ” low temperature alarm. Whatever the cycle in progress, this alarm has no direct effect.

- “ AH ” high temperature alarm. Whatever the cycle in progress, this alarm has no direct effect.

- “ HP ” high pressure switch alarm. In the STANDBY mode it has no direct effect. If triggered during any work

cycle, it causes the cycle to stop and the appliance goes into STANDBY. The cause of the alarm must be

eliminated, then the appliance switched off by pressing for 3 seconds, after which (START) is

pressed again to restart. This alarm could be caused by a high room temperature (higher than allowed; see

par. 2.4) or a dirty condenser (which must be cleaned as described in par. 8.2.4).

- “ id ” door open alarm. This alarm has no direct effect and will stop as soon as the door is closed properly.

8.4.2– ERRORS

Errors acknowledged by the electronic controller are:

- “ Pr 1 ” cabinet sensor error. In STANDBY it prevents cycle start. In the Chilling or Freezing mode it causes

the cycle to stop and the appliance to go onto STANDBY. If in the Hold mode, the cycle is not stopped but the

compressor operates on a cyclic basis to ensure that cabinet temperature is maintained. Check the sensor

connection and replace the sensor if necessary.

- “ Pr 2 ” core probe error. In STANDBY it prevents the start of a temperature-controlled cycle. In the

temperature-controlled Chilling or Freezing mode, it causes the machine to go into a time-controlled cycle.

During the Hold mode it has no direct effect. Check the probe connection and replace the probe if necessary.

- “ Pr 3 ” evaporator sensor error. In the STANDBY, Chilling or Freezing and Hold mode it has no direct effect.

If defrost is taking place, it will end by time-out.

9 – DISASSEMBLY

BCB_N Rev.05 05-2015 pag. 39

Page 40

10 – DISPOSAL

TAKE CARE: THE APPLIANCE CONTAINS REFRIGERANT GAS THAT MUST BE

CONTROLLED AND RECOVERED ACCORDING TO THE REGULATIONS OF THE COUNTRY IN

WHICH DISPOSAL WILL TAKE PLACE.

Consult the fitter for any disassembly requirements.

10.1 – DISPOSAL METHOD

APPLIANCE STATUS

- electronic circuit board in position “O” (OFF);

- power plug disconnected from the mains supply.

METHOD

The appliance is made of ferrous materials, electronic components and plastics. If it needs to be scrapped, separate the

various components according to the material of which they are made in order to simplify separate waste collection or

possible recycling of parts. The appliance must be disposed of separately from municipal waste.

No special instructions apply to the disassembled appliance. Consign to specialised waste disposal firms or return to the

dealer, if allowed by law (also see “Information to users regarding waste disposal in the European Union” below).

With regard to disposal and scrapping, always consult the laws applicable in the country where the appliance is used

(also see “Information to users regarding waste disposal in the European Union” below).

INFORMATION TO USERS REGARDING WASTE DISPOSAL IN THE EUROPEAN UNION

The symbol of a crossed waste bin on the appliance indicates that at the end of its working life the product must be

collected separately from other waste.

At the end of its working life the user must therefore take the product to a suitable centre for the separate collection of

electronic and electrical waste, or return it to a dealer when purchasing a new appliance of the same type.

Suitable separate waste collection of unwanted appliances and their forwarding to recycling, treatment, recovery and

environmentally friendly disposal makes it possible to avoid potential negative effects on the environment and human

health, and assists recycling and recovery of materials.

Unauthorized disposal of the product by the user is punished by the application of fines established by the countries in

which the appliance is disposed of.

11 – SPARE PARTS

11.1 – ORDERING SPARE PARTS

Contact the manufacturer or authorized dealer to order spare parts.

12 – ENCLOSURES

The appliance comes with the following enclosures:

- Declaration of conformity

- Wiring diagram

- Electrical approval report

- Assessment of vacuum, leakage and gas load for the refrigeration system.

BCB_N Rev.05 05-2015 pag. 40

Page 41

Abb. 1

1 – ALLGEMEINE INFORMATIONEN

Wir danken Ihnen, dass Sie einen unserer Schockkühler/Froster gewählt haben.

Lesen Sie diese Bedienungsanleitungen sorgfältig durch und stellen Sie diese dem Personal zur Verfügung, das für die

Installation, die Bedienung und die Instandhaltung des Geräts zuständig ist.

1.1 – GERÄTEKENNZEICHNUNG

An der Außenseite des Geräts, rechts unten zur Vorderseite hin, befinden sich die Kennschilder des Geräts: in Abb. 1

bringen wir eine Kopie davon.

BCB_N Rev.05 05-2015 pag. 41

Page 42

1.2 – KONFORMITÄTSERKLÄRUNG

BCB_N Rev.05 05-2015 pag. 42

Page 43

1.3 – GARANTIE

Dieses Symbol kennzeichnet Informationen und Hinweise, deren Nichtbeachtung zu Schäden am Gerät

oder Personen führen kann.

Dieses Symbol kennzeichnet elektrische Informationen oder Hinweise, deren Nichtbeachtung zu

Schäden am Gerät oder an Personen führen kann.

Die Garantie auf die Gerätekomponenten gilt ab dem auf dem Lieferschein angegebenen Datum, gemäß den im

Verkaufsvertrag angegebenen Bestimmungen.

Ausgenommen von der Garantie sind Schäden am Gerät, die verursacht werden durch:

- Transport und/oder Handling;

- Fehler des Bedieners;

- nicht laut den Angaben in diesem Handbuch durchgeführte Instandhaltung;

- Defekte und/oder Schäden, die nicht auf Betriebsstörungen des Gerätes beruhen;

- Instandhaltungsarbeiten durch nicht qualifiziertes Personal;

- unsachgemäßen Gebrauch.

1.4 – KUNDENDIENST

Für jede Art von Reparatur, Wartung oder Anforderung von Ersatzteilen wenden Sie sich bitte direkt an den Hersteller,

unter Angabe der auf dem Geräteschild angegebenen Maschinendaten.

1.5 – GEBRAUCH UND AUFBEWAHRUNG DES HANDBUCHS

Dieses Handbuch liefert alle erforderlichen Informationen für die sachgemäße, möglichst autonome und sichere

Bedienung des Gerätes.

Das Handbuch unterteilt sich in Kapitel, Paragraphen und Unterparagraphen: das Inhaltsverzeichnis liefert eine

Übersicht über die einzelnen Kapitel.

Der Inhalt dieser Bedienungsanleitungen dient ausschließlich zur Information und kann ohne Vorankündigung geändert

werden. Obwohl das Handbuch mit äußerster Sorgfalt erstellt wurde, haftet der Hersteller nicht für Schäden auf

Grund von Fehlern oder Unterlassungen und dem Gebrauch der enthaltenen Informationen.

Bewahren Sie das Handbuch samt den Anlagen in gutem und leserlichem Zustand in der Nähe des Gerätes an einem

leicht zugänglichen und allen Bedienern bekannten Ort auf.

1.5.1 – IN DIESEM HANDBUCH ENTHALTENE SYMBOLE

BCB_N Rev.05 05-2015 pag. 43

Page 44

1.6 – BESCHREIBUNG DES PERSONALS

Die Bediener dürfen keine Operationen durchführen, die dem Instandhaltungsdienst oder den

spezialisierten Technikern zustehen.

Der Hersteller haftet nicht für Schäden, die auf Grund der Nichtbeachtung dieses Verbots

entstehen.

Dieses Handbuch wendet sich an die für die Installation und Instandhaltung des Geräts zuständigen Techniker.

- Für die Bedienung des Geräts zuständiges Personal: Spezialisiertes Personal, das in der Lage ist, das

Gerät unter normalen Bedingungen mit Hilfe der vorgesehenen Bedienungselemente zu bedienen. Es muss

ferner in der Lage sein, einfache Instandhaltungsarbeiten (Reinigung, Bestückung), Inbetriebnahme oder

Wiederaufnahme des Betriebs auf Grund eines eventuellen Notstopps durchzuführen.

- Elektrofachmann: Ausgebildeter Elektriker, der die Schulungskurse vom Hersteller besucht hat, die ihm jede

Art von Eingriff am Gerät gestatten. Der Techniker muss in der Lage sein, das Gerät zu installieren, es unter

normalen Bedingungen zu bedienen, einfache Instandhaltungsarbeiten vornehmen, alle elektrischen und

mechanischen Einstellungen, Instandhaltungen und Reparaturen durchführen. Er ist in der Lage, unter

Vorhandensein von Spannung in den elektrischen Schränken und elektrischen Dosen zu arbeiten.

- Gabelstaplertechniker. Geschulter Techniker für das Handling von Material innerhalb eines Betriebes und

ausgestattet mit Führerschein für Gabelstapler.

BCB_N Rev.05 05-2015 pag. 44

Page 45

2 – BESCHREIBUNG DER MASCHINE

Modell

BCB/03

Außenabmessungen

cm

65 x 67 x 67h

Gewicht

kg

65

Backbleche-Kapazität

Anzahl

3 GN (cm 53 x 32,5)

Innentemperatur in der

Kühlzelle

°C

+ 95 / - 40

Leistung

kg

10 (+ 65 °C ÷ + 3 °C); 7 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Kompressorleistung

Hp

1/2

Max. Stromaufnahme

W

600

Netzspannung

Volt 1x230 ~ 50 Hz

Tab. 1/a

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm2 avec fiche Schuko; L=4000 mm

Abb. 2/a

2.1 – TECHNISCHE DATEN

BCB_N Rev.05 05-2015 pag. 45

Page 46

Modell

BCB/05

Außenabmessungen

cm

80 x 70 x 90h

Gewicht

kg

92

Backbleche-Kapazität

Anzahl

5 EN (cm 60 x 40) oder 5 GN (cm 53 x 32,5)

Innentemperatur in der

Kühlzelle

°C

+ 95 / - 40

Leistung

kg

15 (+ 65 °C ÷ + 3 °C); 9 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Kompressorleistung

Hp

3/4

Max. Stromaufnahme

W

1100

Netzspannung

Volt 1x230 ~ 50 Hz

Tab. 1/b

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm2 avec fiche Schuko; L=4000 mm

Abb. 2/b

BCB_N Rev.05 05-2015 pag. 46

Page 47

Modell

BCB/10

Außenabmessungen

cm

80 x 78 x 170h

Gewicht

kg

145

Backbleche-Kapazität

Anzahl

10 EN (cm 60 x 40) oder 10 GN (cm 53 x 32,5)

Innentemperatur in der

Kühlzelle

°C

+ 95 / - 40

Leistung

kg

26 (+ 65 °C ÷ + 3 °C); 16 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Kompressorleistung

Hp

1,5

Max. Stromaufnahme

W

1628

Netzspannung

V. 1x230 ~ 50 Hz

Tab. 1/c

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Abb. 2/c

BCB_N Rev.05 05-2015 pag. 47

Page 48

Modell

BCB/15

Außenabmessungen

cm

80 x 78 x 200h

Gewicht

kg

175

Backbleche-Kapazität

Anzahl

15 EN (cm 60 x 40) oder 15 GN (cm 53 x 32,5)

Innentemperatur in der

Kühlzelle

°C

+ 95 / - 40

Leistung

kg

43 (+ 65 °C ÷ + 3 °C); 32 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Kompressorleistung

Hp

3

Max. Stromaufnahme

W

2986

Netzspannung

Volt 3x400 ~ 50 Hz

Tab. 1/d

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Abb. 2/d

BCB_N Rev.05 05-2015 pag. 48

Page 49

Modell

BCB/24

Außenabmessungen

cm

80 x 118 x 200h

Gewicht

kg

203

Backbleche-Kapazität

Anzahl

12 EN (cm 60 x 80) oder 12 GN 2/1 (cm 53 x 65)

Innentemperatur in der

Kühlzelle

°C

+ 95 / - 40

Leistung

kg

43 (+ 65 °C ÷ + 3 °C); 32 (+ 65 °C ÷ - 18 °C)

Gas

R 404 a

Kompressorleistung

Hp

3.7

Max. Stromaufnahme

W

4312

Netzspannung

Volt 3x400 ~ 50 Hz

Tab. 1/e

R

Alimentazione elettrica: cavo 3x1.5 mm2 completo di spina Schuko; L=4000 mm

Electricity supply: 3x1.5 mm2 wire complete with Schuko plug; L=4000 mm

Elektrischer Stromanschluss: Kabel 3x1,5 mm2 komplett mit Schukostecker; L=4000 mm

Alimentation électrique: câble 3x1.5 mm

2

avec fiche Schuko; L=4000 mm

Abb. 2/e

BCB_N Rev.05 05-2015 pag. 49

Page 50

2.2 – BESCHREIBUNG DES SCHOCKKÜHLERS/FROSTERS UND VORGESEHENER GEBRAUCH

Abb. 3

Installationsort

Bäckereien, Konditoreien, Eisdielen und Küchen im Allgemeinen

Relative Luftfeuchtigkeit

< 80% ohne Kondensation

Klimaklasse

“T” + 18 °C ÷ + 43 °C

Tab. 2

Der Schockkühler/Froster ist ein Gerät mit einem hochleistungsfähigen Kühlsystem, das die Temperatur bis zum Kern

der Lebensmittel hinunter schnell erniedrigt. Das Gerät ist ideal für den Einsatz in Küchen, Konditoreien und Eisdielen.

Die Hauptarbeitszyklen der Maschine sind das Schockkühlen (CHILLING) und Schockfrosten (FREEZING). Jeder Zyklus

sieht zwei unterschiedliche Arten von Zyklusende vor, ab dem die Lagerung beginnt: temperaturgesteuert (Beenden

des Zyklus, wenn der in den Kern des Produkts eingeführte Kerntemperaturfühler die eingegebene Temperatur erreicht

hat) oder zeitgesteuert (Beenden des Zyklus nach Ablauf der eingegebenen Zeit).

2.2.1 – HAUPTKOMPONENTEN

Das Gerät besteht aus folgenden Komponenten:

Gerätegehäuse;

Kondensatoreinheit (Ref. 2, Abb. 3);

Verdampfereinheit (Ref. 1, Abb. 3);

Bedienungsfeld (Ref. 3, Abb. 3)

2.3 – GERÄUSCH

Das Gerät wurde so entwickelt und hergestellt, um den Geräuschpegel auf ein Minimum zu reduzieren.

2.4 – UMWELTBEDINGUNGEN

BCB_N Rev.05 05-2015 pag. 50

Page 51

3. – SICHERHEIT

WICHTIG: Lesen sie vor dem Gebrauch des Geräts dieses Bedienungshandbuch aufmerksam durch

und halten sie sich streng an die technischen Betriebsanleitungen und die darin enthaltenen Angaben.

Der Bediener muss die Position und die Funktionen aller Steuervorrichtungen und Eigenschaften des

Schockkühlers/Frosters kennen.

Der Schockkühler/Froster entspricht den geltenden Sicherheitsnormen. Unsachgemäßer Gebrauch

kann zu Schäden an Personen oder Dingen führen.

Bei der Installation muss das gesamte Personal über die Risiken eines Unfalls, die

Sicherheitseinrichtungen, die allgemeinen Unfallverhütungsvorschriften gemäß den internationalen

Richtlinien und dem im Land des Einsatzes des Geräts geltenden Gesetzen unterrichtet sein. Die

Inbetriebnahme und die Bedienung des Geräts darf ausschließlich von geschultem Personal

durchgeführt werden. Das für die Bedienung zuständige Personal hat sich strengstens an die

Unfallverhütungsvorschriften des Landes zu halten, in dem das Gerät benutzt wird.

Die vom Hersteller am Gerät angebrachten Schilder dürfen nicht entfernt werden.

Der Schockkühler/Froster darf bei Schäden an der Steuertafel oder beschädigten Teilen nicht in Betrieb

gesetzt werden.

Die vorderen und/oder hinteren Luftkanäle des Geräts dürfen nicht verstopft werden; das zu kühlende

Produkt nicht auf die Luftgitter der Belüftungskanäle oder direkt auf den Boden der Kühlzelle legen.

Eventuelle Betriebsstörungen sind rechtzeitig zu melden.

Nur vom Hersteller empfohlenes Zubehör verwenden.

Das Gerät nicht dem Regen oder Wasserstrahlen aussetzen.

Ordentliche und außerordentliche Instandhaltungsarbeiten, bei denen die elektrische Schalttafel

geöffnet oder der Schockkühler/Froster ganz oder teilweise zerlegt werden muss, dürfen erst nach

Unterbrechung der Stromzufuhr zum Gerät vorgenommen werden.

3.1 – ALLGEMEINE HINWEISE

Der Hersteller ist in folgenden Fällen der Haftung enthoben:

Fehlende Durchführung der programmierten Instandhaltungsarbeiten;

Unzulässige Änderungen und/oder Eingriffe:

Verwendung von nicht originalen Ersatzteilen;

Nicht Befolgung der in diesem Handbuch angegebenen Anweisungen;

Unsachgemäßer Gebrauch des Geräts.

Unzulässige Eingriffe oder unzulässiges Auswechseln von Teilen oder Komponenten des Geräts, die

Verwendung von nicht originalem Zubehör und Verbrauchsmaterial kann zu Unfällen führen und entheben den

Hersteller jeder zivil- oder strafrechtlichen Haftung.

Im Falle von Zweifel bezüglich der Betriebsweise des Geräts vor dem Gebrauch den Hersteller kontaktieren.

BCB_N Rev.05 05-2015 pag. 51

Page 52

3.2. – GEGENANZEIGEN FÜR DEN GEBRAUCH

Abb. 4

Der Schockkühler/Froster darf nicht verwendet werden:

für andere Zwecke als die in Kap. 2.2 “Beschreibung des Schockkühlers/Frosters und vorgesehener Gebrauch”

angegebenen;

mit nicht funktionierenden Sicherheitssystemen;

nach einer nicht richtig durchgeführten Installation;

von ungeschultem Personal;

bei nicht oder nicht richtig durchgeführten Instandhaltungsarbeiten;

bei der Verwendung von nicht originalen Ersatzteilen;

bei beschädigtem Netzkabel und/oder beschädigter elektrischer Steckdose;

bei verstopften Luftleitungen (Ref. 1 Abb. 4);

bei auf dem Luftgitter der eventuellen Luftkanäle (Ref.1 Abb.4) oder auf dem Boden der Zelle (Ref.2 Abb.4)

liegenden Produkten.

BCB_N Rev.05 05-2015 pag. 52

Page 53

3.3 – SCHUTZEINRICHTUNGEN

Abb. 5

Die Sicherheit für das Personal, das auf Grund von gefährlichen Teilen in Bewegung möglichen Risiken ausgesetzt ist,

wird durch entsprechende Schutzeinrichtungen auf dem Gerät gewährleistet:

Gitter und Abdeckungen von Kühlventilatoren (Ref. 1 Abb. 5);

Abdeckungsgitter der Kondensatoreinheit (Ref. 2 Abb. 5).

Das Gerät ist auch mit Schutzvorrichtungen für das behandelte Produkt ausgestattet. Nachfolgend eine Liste der

Sicherheitsvorrichtungen auf dem Gerät:

Sensor, der das Öffnen der Tür erfasst und anzeigt. Wenn die Tür für eine eingestellte Zeit geöffnet bleibt,

werden die Meldung “ id ” im Display sowie ein akustisches Signal aktiviert und der Kompressor wird blockiert.

Sensor (Ref. 3 Abb. 5) auf dem Kühlkreislauf, der ggf. Übertemperaturen in der Anlage anzeigt und die

Maschine in den Standby-Modus bringt.

BCB_N Rev.05 05-2015 pag. 53

Page 54

3.4 – STOPPFUNKTIONEN

Abb. 6

Das Gerät wird im Allgemeinen von einem elektronischen Kartenmodul gesteuert. Für die Stoppfunktion steht die Taste

zur Verfügung (Ref. 1 Abb. 6). Wird die Taste 3 Sekunden lang gedrückt, schaltet das Kartenmodul auf

OFF.

BCB_N Rev.05 05-2015 pag. 54

Page 55

4 – TRANSPORT UND HANDLING

Das Gerät darf auf keinen Fall auf dem Kopf gestellt werden.

Das verpackte Gerät muss sicher auf dem Boden des LKW positioniert und mit Hilfe von

geeigneten Drahtseilen befestigt werden.

Während des Hebens und Positionierens des Schockkühlers/Frosters vorsichtig vorgehen, um

Personen- oder Sachschäden, auch schwerwiegende, zu verhindern. Der Hersteller übernimmt

keine Haftung für Schäden, die auf Grund der Nichtbeachtung der angegebenen Vorschriften für

das Heben und den Transport des Geräts entstehen.

Während des Transports darf die Raumtemperatur nicht unter 4°C liegen.

Beim Heben und Handling des Schockkühlers/Frosters vorsichtig vorgehen, um Verletzungen,

auch mit tödlichem Ausgang, zu vermeiden.

Beim Handling und Heben des Geräts ist höchste Vorsicht geboten; das Personal muss sich in

einem angemessenen Sicherheitsabstand vom Gerät und nicht unter der hängenden Last

aufhalten.

Vor dem Beginn der Operationen das gesamte Areal kontrollieren, in dem das Handling

stattfindet, um eventuelle Gefahrenstellen ausfindig zu machen,

Während des Transports darf die Raumtemperatur nicht unter 4°C liegen.

4.1 – TRANSPORT DES SCHOCKKÜHLERS/FROSTERS

Je nach Typ, den Abmessungen und des Gewichts wurde die geeignete Verpackung gewählt, um das Gerät während

des Transports und der Lagerung bis zur Übergabe an den Käufer vor Schäden zu schützen.

Der Schockkühler/Froster muss in den Karton verpackt während des gesamten Transports auf den Füßen auf der

Palette positioniert werden.

Der Schockkühler/Froster wird dem Spediteur transportbereit übergeben.

Das Verpackungsmaterial muss nach dem Auspacken des Schockkühlers/Frosters laut den im jeweiligen

Bestimmungsland des Geräts geltenden Normen entsorgt und/oder wiederverwertet werden.

4.2. – HANDLING DES VERPACKTEN SCHOCKKÜHLERS/FROSTERS

BCB_N Rev.05 05-2015 pag. 55

Page 56

ZUGELASSENES PERSONAL

Modell

BCB/03

BCB/05

BCB/10

BCB/15

BCB/24

Abmessungen

cm

65x65x67h

80x70x90h

80x78x170h

80x78x200h

80x118x200h

Gewicht

kg

76

107

166

202

230

Tab. 3

Der Einsatz von ungeeigneten Einrichtungen kann zu Schäden an dem für das Handling

zuständige Personal und/oder Schäden am Gerät führen.

Der Hersteller lehnt jede Haftung auf Grund von unsachgemäßem und nicht Zweck bestimmtem

Gebrauch von Geräten für das Heben, den Transport und das Handling ab.

Gabelstaplertechniker

Persönliche Schutzausrüstung:

- Schutzschuhe;

- Schutzhandschuhe.

Das für diese Operationen zuständige Personal darf keine Ringe, Armbanduhren, Schmuck, offene oder lose

Kleidungsstücke, wie zum Beispiel Krawatten, zerrissene Kleidung, Schals, offene Jacken oder Blusen mit offenen

Reißverschlüssen, usw. tragen. Das Personal muss Schutzkleidung tragen.

4.2.1 – GEWICHT UND ABMESSUNGEN DES SCHOCKKÜHLERS/FROSTERS

4.2.2 – ERFORDERLICHE MITTEL

- Zum Heben des Gerätes muss ein Hubstapler mit geeigneter Mindesttragfähigkeit verwendet werden.

BCB_N Rev.05 05-2015 pag. 56

Page 57

5 – INSTALLATION

Beim Handling des Geräts vorsichtig vorgehen, um Sach- oder Personenschäden zu vermeiden.

Das Gerät darf bei Fehlern am Bedienungsfeld oder beschädigten Teilen nicht in Betrieb gesetzt

werden.