SERVICING

Commissioning

Gas conversion

Maintenance

Operating faults

Options

Parts lists

T

E

C

H

N

I

C

A

L

THI 10-50 C

THI 10-35 SEP

I

N

S

T

R

U

C

T

I

High technology heating

O

N

S

T30.36295.02

CONTENT

I - COMMISSIONING ................................................................................................................................. 4

1 - PROTECTION OF THE INSTALLATION............................................................................................... 4

1.1 - Bionibal ...................................................................................................................................... 4

1.2 - Bionibagel .................................................................................................................................. 4

1.3 - Products equivalent to Bionibal or Bionibagel ........................................................................... 4

2 - FILLING THE INSTALLATION WITH WATER ...................................................................................... 5

3 - GAS SUPPLY ........................................................................................................................................ 5

4 - FLOW RATE OF THE SEP VERSION .................................................................................................. 5

5 - SETTING THE MAXIMUM POWER IN HEATING MODE..................................................................... 5

6 - VERIFICATIONS PRIOR TO COMMISSIONING .................................................................................. 6

7 - USER INFORMATION........................................................................................................................... 6

8 - COMMISSIONING ................................................................................................................................. 6

9 - FLAME SETTING .................................................................................................................................. 8

10 - COMBUSTION PRODUCT CHECKING................................................................................................ 8

11 - ASSEMBLING THE COVER.................................................................................................................. 8

II - GAS CONVERSION .............................................................................................................................. 9

1 - GAS CONVERSION (THI 10-50 C ONLY) ............................................................................................ 9

1.1 - Conversion from Natural Gas to Propane ................................................................................. 9

1.2 - Conversion from Propane to Natural gas .................................................................................. 9

2 - GAS/CO2/CO/NOX FLOW CONTROL AND SERVICE PRESSURE CONTROL ............................... 10

2.1 - Surveillance procedure ............................................................................................................ 11

2.2 - Setting table ............................................................................................................................. 12

III - MAINTENANCE .................................................................................................................................. 13

1 - SERVICING THE FAN AND THE BURNER........................................................................................ 13

2 - SERVICING THE HEAT EXCHANGER OF THE BOILER SHELL...................................................... 14

3 - CHECKING ACCESSORIES ............................................................................................................... 14

4 - EXPANSION VESSEL PRE-INFLATION PRESSURE CHECK .......................................................... 15

5 - COMBUSTION PRODUCT CONDUITS (FLUE) ................................................................................. 15

6 - DRAINING ........................................................................................................................................... 15

7 - SENSOR RESISTANCES ................................................................................................................... 16

8 - PRESSURE SENSOR......................................................................................................................... 16

IV - OPERATING FAULTS ........................................................................................................................ 17

1 - OPERATING FAULTS LIST ................................................................................................................ 17

2 - MAINTENANCE................................................................................................................................... 19

2.1 - Maintenance alarm .................................................................................................................. 19

2.2 - Maintenance code ................................................................................................................... 19

2.3 - Coding of maintenance alarms ................................................................................................ 19

2.4 - General activation of maintenance alarms .............................................................................. 19

2.5 - Activation of the individual maintenance alarm ....................................................................... 20

2.6 - Acknowledgement of maintenance alarms .............................................................................. 20

2.7 - Resetting the maintenance alarms .......................................................................................... 20

- 2 -

CONTENT

V - OPTIONS ............................................................................................................................................. 21

1 - SET-UP TAKING ROOM TEMPERATURE INTO ACCOUNT (REG 73) ............................................ 21

2 - CLIP-IN LPB KIT (REG 130)............................................................................................................... 21

3 - SECONDARY CIRCUIT CLIP-IN KIT ................................................................................................. 21

4 - DOUBLE CIRCUIT KIT (REG 125) - (THI 10-35 SEP) ........................................................................ 22

5 - DOUBLE CIRCUIT KIT (REG 146) - (THI 10-50 C)............................................................................. 22

6 - PROGRAMMABLE RELAY CLIP-IN KIT (REG 127)........................................................................... 22

7 - PROGRAMMABLE RELAY CLIP-IN KIT (WITHOUT SENSOR) (REG 134) ...................................... 23

8 - CONTROL UNIT ZHTI 46 (REG 129).................................................................................................. 23

9 - CONTROL UNIT ZHTI 47 (REG 128).................................................................................................. 23

10 - SOLAR HEATING CONTROL KIT (REG 152) .................................................................................... 24

11 - DHW SENSOR KIT.............................................................................................................................. 24

12 - SELECTOR VALVE KIT FOR CONNECTING THI..C/BS ................................................................... 24

13 - TIMER KIT ........................................................................................................................................... 25

14 - BS TYPE DOMESTIC HOT WATER PRODUCTION SYSTEM .......................................................... 25

15 - BIONIBAL/BIONIBAGEL...................................................................................................................... 26

16 - CONDENSATE LIFT PUMP ................................................................................................................ 26

VI - PARTS LISTS ...................................................................................................................................... 27

- 3 -

I - COMMISSIONING

1 - PROTECTION OF THE INSTALLATION

Note : Our technical personnel, who will visit when the boiler has been installed to arrange for its final

commissioning and calibration, do not perform the role of inspector and/or approval officer for

the system. Its compliance with standards and instructions remains the exclusive responsibility

of the installation company.

Geminox insists the use of the following heating system water conditioning products:

- BIONIBAL corrosion inhibitor (or equivalent products),

- BIONIBAGEL antifreeze and corrosion inhibitor (or equivalent products).

!

BIONIBAL

1.1 - Bionibal 1.2 - Bionibagel

is a biocide, traceable corrosion inhibitor

specially designed to protect multi-metal heating circuits.

Through its efficient means of acting against all types of corrosion and all types of bacteria, BIONIBAL:

- Prevents the formation of rust and metallic slud-

ge,

- Prevents the formation of algae and bacteria

sludge,

- Also suitable for under-floor heating systems,

- Prevents hydrogen build up,

- Contains an internal marker so that doses can be

easily controlled.

BIONIBAL DOSAGE:

- Without under-floor heating: or connection using

reinforced polyethylene type pipes:

1% (0.5 l of BIONIBAL for 50 l of water).

- With under-floor heating or radiators connected in

reinforced polyethylene type pipes:

2% (1 l of BIONIBAL for 50 l of water).

BIONIBAGEL

BAL.

Antifreeze, with glycol monopropylene base, corrosion inhibitor, biocide, traceable.

In addition to the characteristics of BIONIBAL, it protects the installation from frost for residences that

are not inhabited all the year round or that are in the

coldest regions.

BIONIBAGEL DOSAGE:

The number of litres of BIONIBAGEL to put in the

circuit depends on the volume of your installation

and the extreme temperature of your region.

Protection

limit

temperature

- 5°C 7 15 22 30

- 10°C 12 25 37 50

- 15°C 17 35 50 70

- 20°C 20 40 60 80

- 30°C 22 45 67 90

1.3 - Products equivalent to Bionibal or

is the antifreeze version of BIONI-

Installation capacity (litres)

50 100 150 200

Bionibagel

Scrupulously

plementation of the manufacturer's products.

refer to the recommended use and im-

Important warning

Bionibal or Bionibagel must only be put in a clean installation that has been checked. It is therefore imperative to fill the entire system one or more times with clean water as required. In

!

some cases, the system may need washing by a suitable product:

Example:

- In a new installation: To detect any leaks and eliminate any traces of welding, weld solder

or other residues.

- On an old installation: To eliminate any trace of sludge and other products in the radiators,

under-floor heating system and the boiler.

Bionibal or Bionibagel will not clean dirt or corrosion left behind from the installation, it is not

sufficient to believe that adding our chemicals will clean the system. The system should be

clean and then our chemicals will keep it clean.

- 4 -

2 - FILLING THE INSTALLATION WITH WATER

THi 10-50 heat input depending on PHzMax setting (parameter 541 QAA73)

10

15

20

25

30

35

40

45

50

10 20 30 40 50 60 70

PHzMax %

Heat input kW

THRi10-50 PHz ,,

COMMISSIONING

- The installation will have to be rinsed before the

boiler is filled with water.

- To ensure proper boiler bleeding during the installation’s filling stage:

• Filling the DHW tank for the THI 10-50 C mo-

dels + DHW production system:

. Fill the tank with water by using the safety

control box of the installation, taking care to

open a hot water tap,

. After filling, check that the tank access flap

is tightened correctly.

• Filling the installation :

. Open the heating flow/return isolation val-

ves,

3 - GAS SUPPLY

- Open the gas cock (item. 2, fig. 43 to fig. 45 page 41 to page 42- chapter IV - INSTALLATION

- SERVICING MANUAL).

- Carefully bleed the gas piping. If the installation is

new, the bleed evacuates the air that is contained

in the piping so that the boiler has an adequate

fuel.

The presence of air in the gas prevents the ignition of the burner and leads to safety shut-down

by the flame monitoring unit.

. Open the cold water inlet valve,

. Fill the installation slowly (to make degas-

sing easier) by using the valve of the filling

system,

. check the leaktightness of the circuit,

. Bleed the entire installation, particularly the

radiators. Continue to fill the system until a

pressure of approximately 1.5 bar is rea-

ched,

To read the pressure:

1) Switch on the boiler

2) Press the info key twice

3) The value of the pressure is shown on the display

. turn off the filling valve.

This is the case both with a natural gas and a

LPG new installation. With a LPG installation the

storage tank must also be bled properly before

commissioning.

The external discharge of the gas

bleed must be carried out with all ne-

!

cessary safety measures.

- Check the tightness of the connectors and the airtightness of the gas circuit using a foaming product or a water column pressure gauge.

4 - FLOW RATE OF THE SEP VERSION

THI 10-35 SEP is equipped with a flow limiter to pro- vide 16 l/min at 2.5 bars.

5 - SETTING THE MAXIMUM POWER IN HEATING MODE

The maximum power of the boiler in heating mode

can be limited. This operation requires modification

of the PHz parameter in the boiler's LMU management unit.

Access to the PHz parameter is possible via the

QAA 73 ambient temperature sensor (line 541).

The PHz value should be selected by following the

diagram below. Adapting the boiler's maximum heating power to the maximum power of the installation

helps avoid heavy loads during reheating phases

and thus reduces the maximum sound output of the

boiler.

Fig. 1

- 5 -

6 - VERIFICATIONS PRIOR TO COMMISSIONING

COMMISSIONING

- Ensure that the installation has been issued with

a certificate of conformity granted by an approved

organisation (according to the installation standards),

- Check that the boiler is adequately adapted to the

gas used and that there are no gas leaks.

- Check that the boiler is filled with water and under

pressure (1.5 bar) and there are no leaks,

Never let the pressure drop below 1

bar.

!

- Check that the electrical connections of the boiler

are correct: 230 V, 50 Hz, earth connection compliant, polarities correct,

7 - USER INFORMATION

The heating engineer must inform the user about

the unit’s operating mode. In particular the user

must be informed about the function and the opera-

- Check that the combustion products outlet is correctly assembled, that there are no leaks and no

obstruction,

- Check that the heating system ventilations are

not obstructed,

- Check that the condensate siphons of the flues

are filled with water,

- Check that the condensate outlet is connected

properly and there are no leaks.

- Check the system is totally cleaned and had been

cleaned and flushed in accordance with BS 7593.

Failure to do this may invalidate the warranty.

tion of the safety systems and the need for regular

servicing by a qualified person.

8 - COMMISSIONING

- Check that all the water stop valves and the gas

cock are open,

- Activate the boiler’s external electrical circuitbreaker,

- Press button (14) to ON (Button illuminated).

Fig. 2

13

11

14

0

13

• The following references will appear one after

the other on the boiler control panel display

(13),

°C

bar

10

Reset

Info

j

When starting up the boiler, the LMU management

unit recognises all the accessories connected (sensors, mixing valve, pumps, etc.) and automatically

checks the values and settings according to the type

of installation.

If a problem occurs, the LED “alarm signal” (11) is

on (red):

• Press RESET (10) to reset the boiler,

• If the alarm persists, consult the list of operating faults in chapter IV - OPERATING

FAULTS - page 17 - SERVICING MANUAL.

0

1

8

-

I

H

T

For this example, this means that it is the version 3.00 of the LMU management unit and

version 1.01 of the control interface.

- 6 -

COMMISSIONING

Display Description Consequences according to type of installation

4

auto

Function

FUN-01-0

auto

Function

FUN-02-0

auto

Function

FUN-03-0

auto

Function

FUN-04-0

“Function” key (1) gives access to 3 operating

modes by pressing:

1

- auto mode: LED (4) on

- winter mode: LED (5) on

- summer mode: LED (4) and (5) off

5

LED (5) on / LED (4) off: Winter mode

The boiler provides heating and domestic hot

water

LED (4 and 5) off: Summer mode

The boiler provides domestic hot water only

LED (4 and 5) on: Auto winter mode

The boiler provides heating and domestic hot

water

- Basic boiler model (without outside sensor and room

sensor)

• Auto mode is inaccessible

. The heating and hot water temperatures are set

manually by using the boiler potentiometers.

- Boiler with outside sensor only

• Auto mode is not activated,

. Heating operates continually except if there is a

request for hot water,

. The hot water temperature is set manually on the

boiler potentiometer.

- Boiler with outside sensor and room sensor

• The heating and hot water temperatures are set via

the room sensor QAA73.

- Basic boiler model (without outside sensor and room

sensor)

• Auto mode is inaccessible

. The hot water temperature is set manually by

using the boiler potentiometers.

- Boiler with outside sensor only

• Auto mode is not activated,

. The hot water temperature is set manually on the

boiler potentiometer.

- Boiler with outside sensor and room sensor

• The hot water temperature Is set via the room sensor

QAA73.

Auto mode is active:

- Boiler with outside sensor only

• The heating starts up automatically and only when

the average outside temperature computed by the

LMU is below 19°C.

• The hot water temperature is set manually on the boi-

ler potentiometer.

- Boiler with outside sensor and room sensor

• The heating starts up automatically and only when

the average outside temperature computed by the

LMU is below 19°C.

• The heating and hot water temperatures are set via

the room sensor QAA73.

- 7 -

COMMISSIONING

Display Description Consequences according to type of installation

LED (4) on / LED (5) off: Auto summer mode

The boiler provides domestic hot water only

auto

Function

FUN-05-0

Auto mode is active:

- Boiler with outside sensor only

• The heating stops automatically and only when the

average outside temperature computed by the LMU

is below 19°C.

• The hot water temperature is set manually on the boi-

ler potentiometer.

- Boiler with outside sensor and room sensor

• The heating stops automatically and only when the

average outside temperature computed by the LMU

is below 19°C.

• The hot water temperatures are set via the room sen-

sor QAA73.

9 - FLAME SETTING

- After switching the boiler on:

- Check the flame control by disconnecting the ionizing electrode:

10- COMBUSTION PRODUCT CHECKING

The boiler is preset in the factory to operate with natural gas H (G20).

If the gas type is changes at the first commissioning,

check the combustion products according to the

11 - ASSEMBLING THE COVER

After the commissioning and performing all the

checks, put back the front panel of the boiler.

- fit the front panel (G) to the frame of the boiler and

support it with the two latch (F),

- connect the terminal of the earth wire (O) positioned in the boiler to the tab on the front panel (G),

- shut the front panel using the two latch (F) on the

top of the boiler,

- lock the 4 latches (F) using the 4 screws (E).

- The boiler goes into safety mode after two ignition

attempts (display and

)

procedure described in section 2 - page 4 chapter IV - OPERATING FAULTS - page 17 SERVICING MANUAL.

Fig. 3

E

F

E

F

O

G

THI-131-0

G

- 8 -

II - GAS CONVERSION

Check that the boiler is properly adapted to the gas

used, otherwise change the gas.

1 - GAS CONVERSION (THI 10-50 C ONLY)

This operation must be carried out by a

qualified person equipped with a cali-

!

brated combustion analyser.

Prior to any servicing cut the electrical and gas supplies.

The boiler is preset in the factory for natural gas H

Fig. 4

PL

K

Pi

2

V

Po

1

9

8

5

10

(G20) 20 mbar.

When changing the gas, the "gas setting" label that

is in the gas conversion set must be fixed on the inside of the boiler so as to indicate the new setting.

Check the gas circuit for leak tightness after each intervention on the boiler.

1) Gas unit

4

67

3

2) Gas pipe

3) Flange Burner/fan

4) Burner

5) Air/Gas servo-control

6) Brass air reducer

7) Fan

THI-36-0

8) Flat seal

9) Gas reducer

10) Gas reducer o-ring

1.1 - Conversion from Natural Gas to Propane

- Conversion to propane (G31) requires the gas

conversion set (ref : V07.31651)

- Refer to the installation instructions of the gas

conversion set

1.2 - Conversion from Propane to Natural gas

Air inlet of burner :

- Gently separate the fan (7) from the burner (4) at

the level of the flange (3),

- Take off the air reducer (6) into the air inlet sleeve

of the burner,

- Gently refit the fan (7) together with its joint to the

burner flange (3).

Gas valve outlet:

- Remove the nut securing the gas tube (2) to the

gas valve (1),

- Take off the propane gas reducer (9) and o-ring

(10) at the outlet of the gas valve (1),

- Fit the gas tube/gas valve assembly and check

that the flat joint (8) is fitted correctly,

- Check that between the gas tube (2) and gas valve (1) is gas-tight (burner on) by using a foaming

product,

- Check the CO2/CO rate (refer setting table

section 2.2 - page 12 - chapter II - GAS CONVERSION - SERVICING MANUAL).

- 9 -

GAS CONVERSION

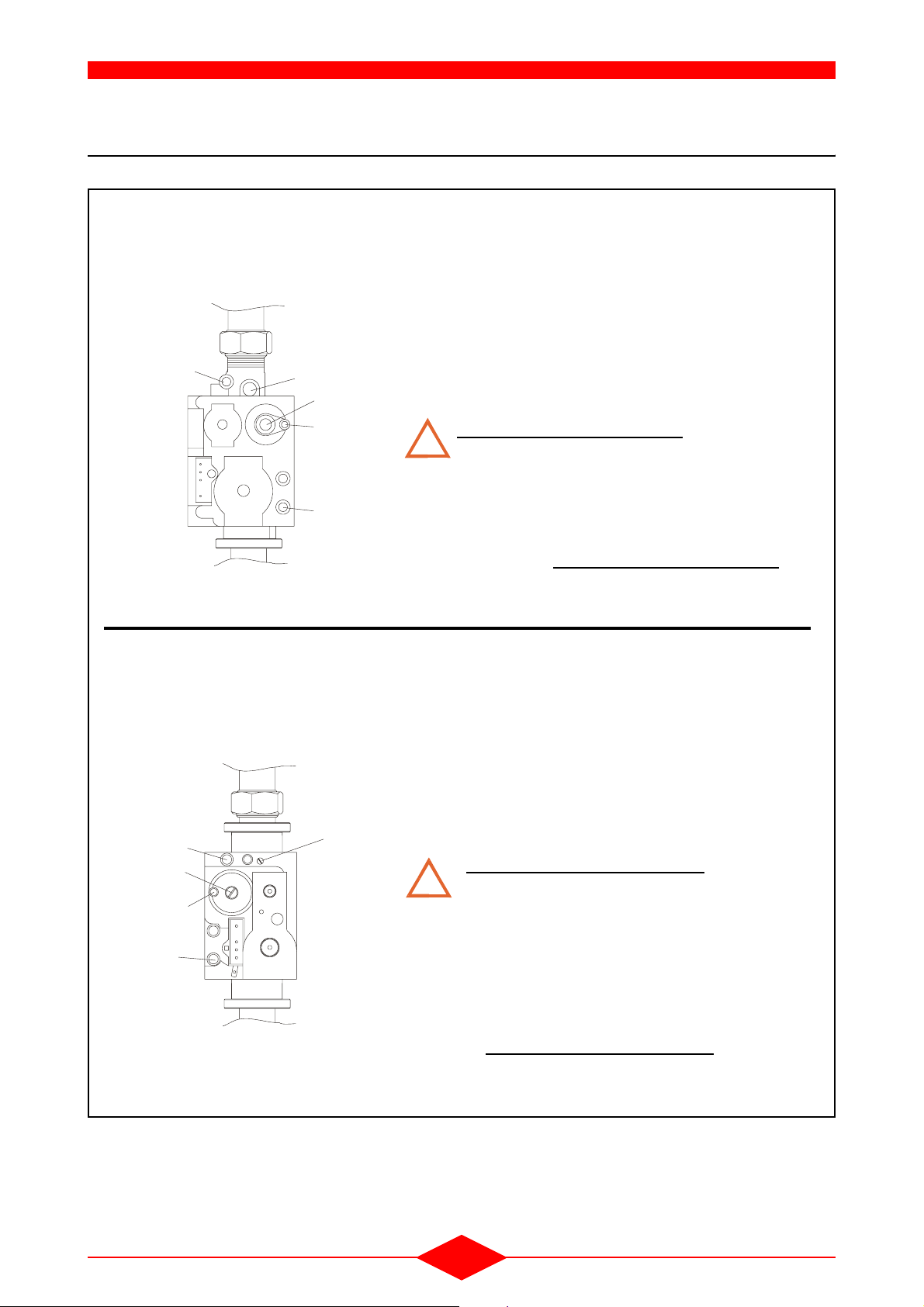

1

2- GAS/CO2/CO/NOX FLOW CONTROL AND SERVICE PRESSURE CONTROL

Fig. 5 Pi = Network gas pressure

Natural gas H (G20) : 20 mbar,

GAS VALVE

SIEMENS/LANDIS

ref : VGU87A0236

Propane (G31) : 37 mbar.

P

= Outlet gas pressure to the burner.

o

PL = Air pressure control (fan/gas valve)

V = Adjust the slope of the characteristic of the air/gas ratio only

when the burner is at high rate. This setting is carried out in

the factory for natural gas type H (G20). This means that the

Po

V

K

PL

pressure Po can be changed to obtain the required gas flow

(section 2.2 - page 12 - chapter II - GAS CONVERSION SERVICING MANUAL).

Screw to increase the gas flow

!

K = Adjust the parallel shift of the characteristic of the air/gas ratio

only when the burner is at low rate. This screw is pre-set in

ZEM-54-0

Pi

the factory. Its setting must not be normally modified even for

changing gas. If however an adjustment is required, it may be

carried out with a low scale pressure gauge 0-10 mmCE, and

a CO2, CO analyser. Screw to increase the gas flow

.

P_OUT

P_IN

GAS VALVE

SIT

ref : 848 SIGMA

2

PL

P_IN =Network gas pressure

Natural gas H (G20) : 20 mbar,

Propane (G31) : 37 mbar.

P_OUT = Outlet gas pressure to the burner.

PL = Air pressure control (fan/gas valve)

1 = Adjust the slope of the characteristic of the air/gas ratio only

when the burner is at high rate. This setting is carried out in

the factory for natural gas type H (G20). This means that the

pressure "P_OUT" can be changed to obtain the required gas

flow . (section 2.2 - page 12 - chapter II - GAS CONVERSION - SERVICING MANUAL).

Screw to descrease the gas flow

!

2 = Adjust the parallel shift of the characteristic of the air/gas ratio

only when the burner is at low rate. This screw is pre-set in

the factory. Its setting must not be normally modified even for

changing gas. If however an adjustment is required, it may be

carried out with a low scale pressure gauge 0-10 mmCE, and

a CO2, CO analyser

To modify the setting, if it is required, take off the protection

screw, and screw to increase the gas flow

justments are realized, reset the protection screw.

. When the ad-

- 10 -

GAS CONVERSION

Fig. 6

23

THI-126-0

23

chimney flue:

B

23

- Combustion control is carried out after making a

hole on the combustion product outlet system ex-

ternal and directly at the boiler outlet (with the boiler unit assembled). This opening must be closed

again after checking.

• the burner switches to the minimum rate,

-Check the CO

/CO ratio (see setting table

2

section 2.2 - page 12 - chapter II - GAS CONVERSION - SERVICING MANUAL),

- If necessary:

• adjust screw K or 2 (fig. 5 - page 10 - SERVICING MANUAL) (tightening and untightening

increases and decreases gas flow).

Before starting the minimum rate setting (V or 1 and K or 2 screws), wait for

!

a stable CO

/CO analyser read-out.

2

Repeat switching from the minimum

THI-130-0

rate to the maximum rate several times

to ensure that the setting has been

done properly.

- to return to normal operation, press on the sweep

key (rep. 6) for 3 seconds then release it.

Note:

- Remember to reposition the d.h.w. potentiometer

(3) to its initial value to return to the required

d.h.w. setting.

C

- C33 balanced flue:

13

- Combustion control is carried out through the

opening (23) provided for this purpose after the

cap is removed. This opening must be closed

again after checking.

2.1 - Surveillance procedure

- To commission the burner:

• Activate the regulator shut-down function - ser-

vice key (6) (section 3.11 - page 19 chapter III - OPERATION - INSTALLATION

MANUAL) :

. the code flashes on the dis-

play screen (13),

- Gradually position the d.h.w. potentiometer (3) to

the maximum on the right:

• the burner switches to max. rate,

- Gradually move the V or 1 adjustment screw of

the gas unit (fig. 5 - page 10 - SERVICING MANUAL) to obtain a stable flame.

-Check the CO

/CO ratio (see setting table

2

section 2.2 - page 12 - chapter II - GAS CONVERSION - SERVICING MANUAL),

- Set the d.h.w. potentiometer (3) to the maximum

on the left:

- 11 -

GAS CONVERSION

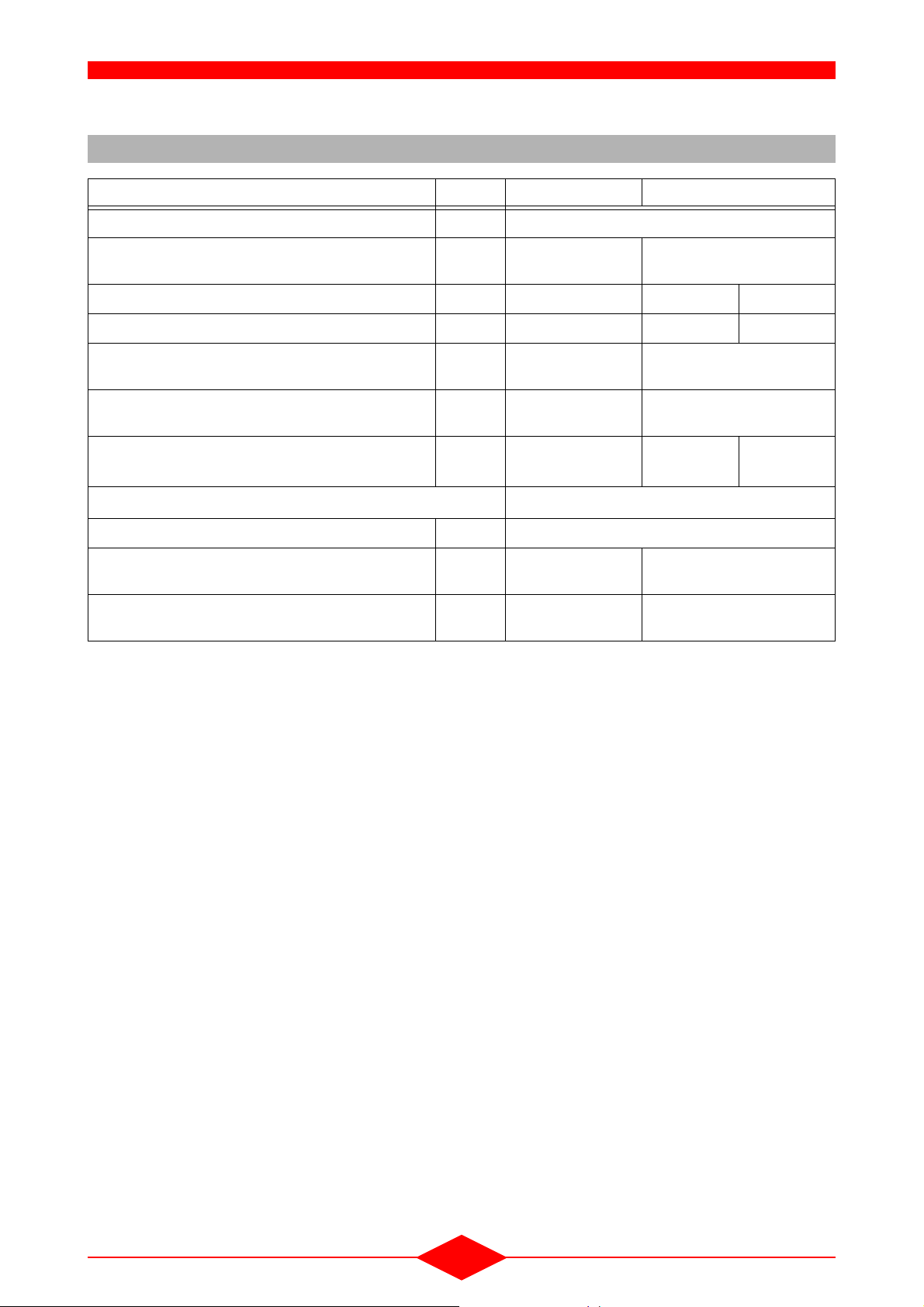

2.2 - Setting table

Models THI 10-50 THI 10-35 SEP

Burner type X07.36237

Heat output 30/50 °C

60/80 °C

Heat input kW 10,0/50,0 10,0/35,0 10,0/50,0

∅ Gas reducer Nat. gas H

Propane

∅ Air reducer Nat. gas H

Propane

Gas flow (15 °C 1013 mbar)

Gas pressure P

Air pressure servo-system (PL) Pa 40/630

CO

Emission Nat. gas H

2

CO Emission Nat. gas H

/ P_OUT (Gas unit to burner)

o

Nat. gas H

Propane

Propane

Propane

kW

kW

mm

mm

mm

mm

3

m

/h

kg/h

mbar 0,25/2,4

%

%

ppm

ppm

10,7/52,6

9,7/48,7

Heating Heating D.H.W

-

6,40

-

31

1,06/5,29

0,78/3,88

8,0-8,5/9,0-9,5

10,0-10,5/10,5-11,0

0/20

0/40

1,06/3,70

10,7/36,0

9,7/33,1

-

-

-

-

1,06/5,29

-

8,0-8,5/9,0-9,5

-

0/20

-

-

- Combustion product evacuation outlet back pressure: 0 mmCE.

- P

/ P_OUT = Gas pressure at the gas valve re-

o

gulator outlet.

- PL = Servo-system air pressure (Fan/gas unit).

- The Po

/ P_OUT and PL values may be more or

less high according to whether back pressure is

greater or smaller.

- 12 -

III - MAINTENANCE

The annual inspection of the boiler and of the combustion product outlet is compulsory and validates

the warranty. It must be carried out by a qualified

person.

Spare parts must be ordered by using the references listed in chapter VI - PARTS LISTS - page 27 SERVICING MANUAL, and specifying the type and

serial number of each part.

Before any servicing, cut the power

supply. Close the gas inlet of the boiler

!

and the isolation valves if required.

If the boiler is removed, provide a port

at the end of the gas piping.

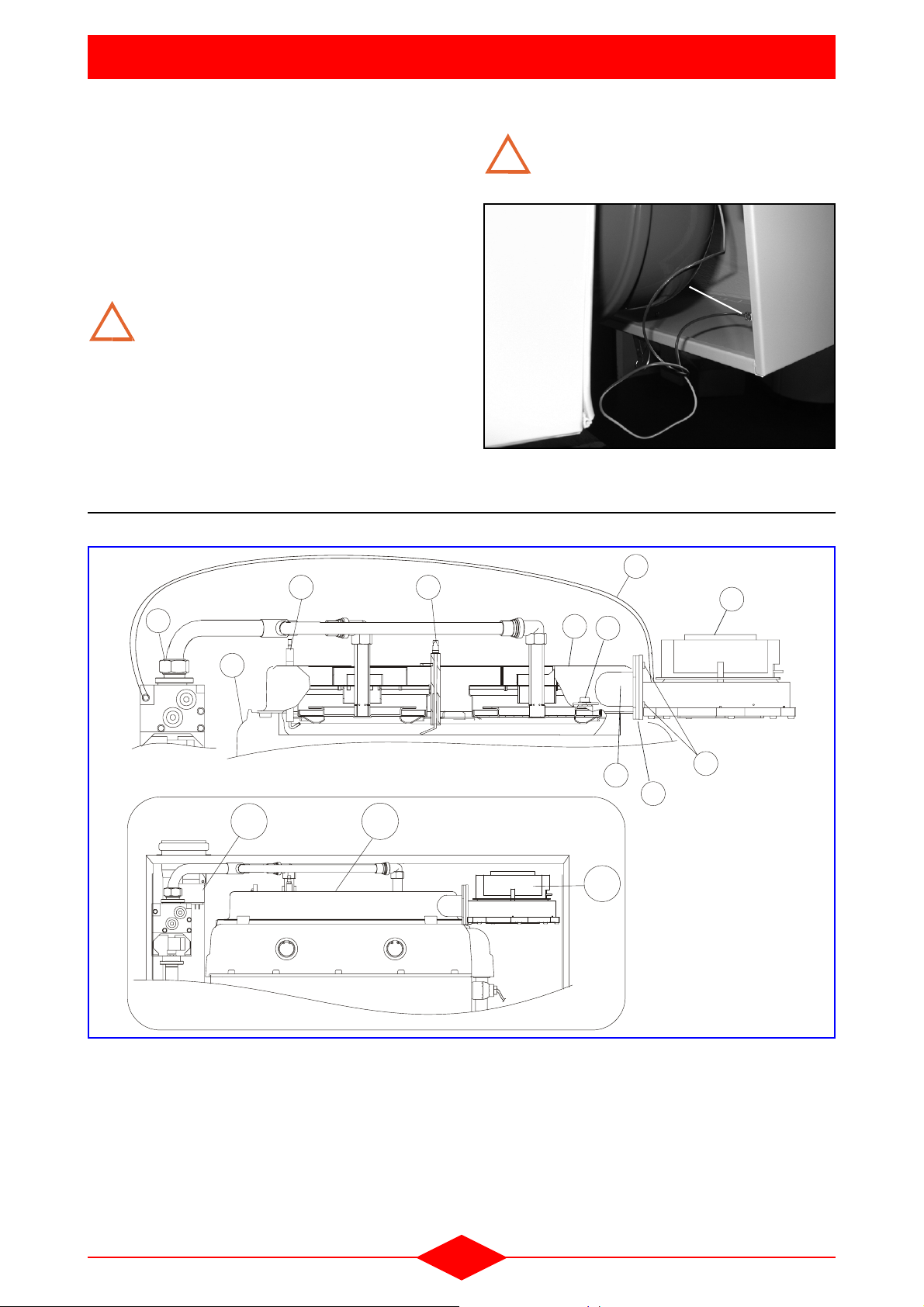

1 - SERVICING THE FAN AND THE BURNER

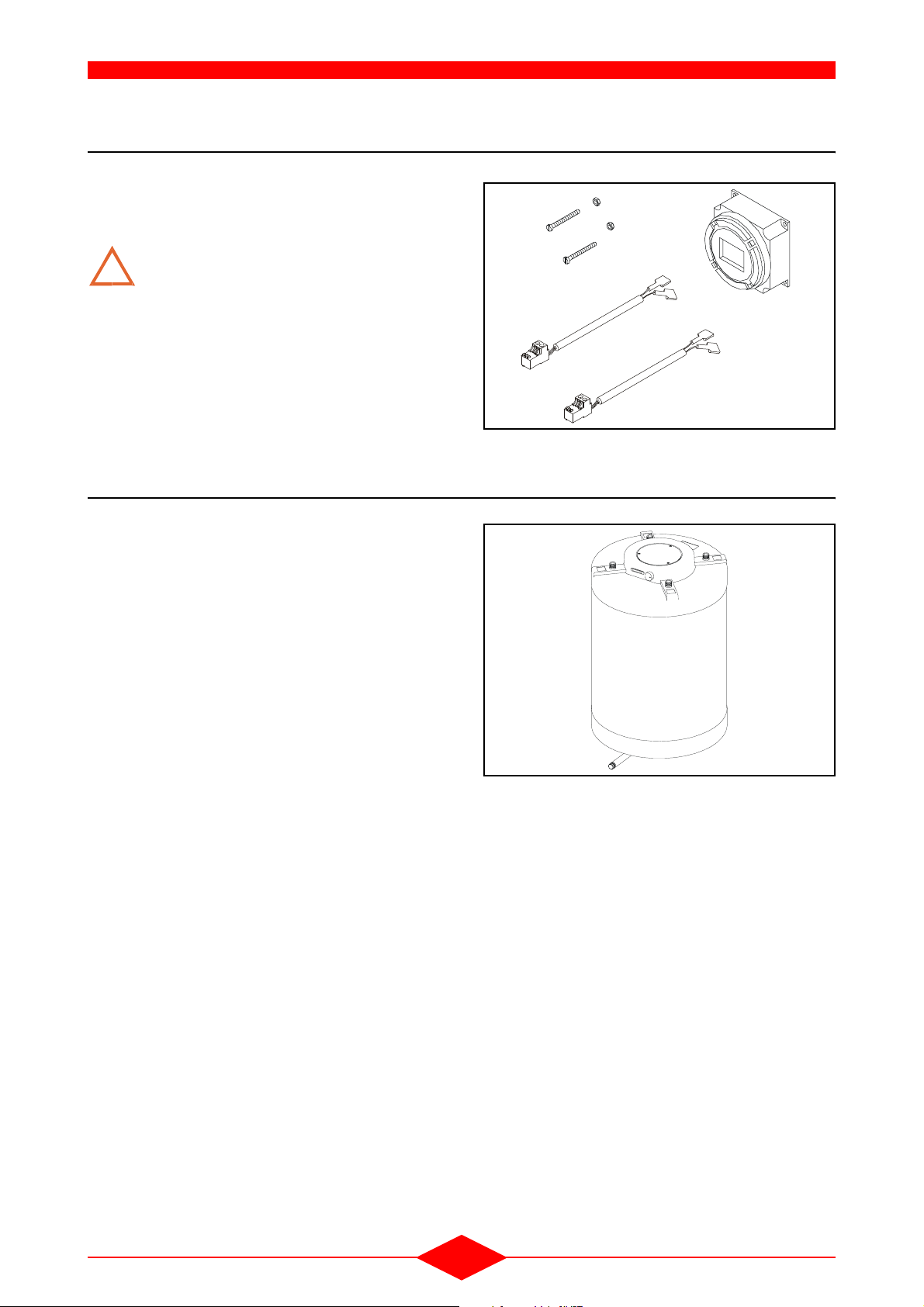

Fig. 7

23

9

Remove the front panel (item G) from

the boiler and disconnect the earth wire

!

(item O).

O

B

7

4

5

G

8

A

Check the state of the ventilator and the burner and

clean them if necessary (following their service instructions).

4

THI-97-0

6

10

1

7

- 13 -

MAINTENANCE

Disassembling the burner/fan unit:

- Disconnect the electrical connections of the burner/fan unit:

• remove the 2 terminals of the cables connect-

ing the ignition electrode (item. 3) to the ignition transformer (rep. A,

• removal the terminal of the cable connecting

the ionization electrode (item. 2) to the X2-05

terminal of the control panel,

• removal at the fan (item. 7):

. of the connector of the power cable from the

fan,

. of the connector of the PWM signal from the

fan,

- disconnect the air/gas control (item B) from the

gas valve

Disassembling the fan:

- Unscrew the four screws (1) fixing the fan (7) to

the burner’s air sleeve (6),

- Clean the fan (item. 7) using a domestic vacuum

cleaner by placing the suction device over the air

inlet and outlet successively.

Cleaning the burner:

- Unscrew the four screws fixing (5) the burner (4)

to the boiler shell (8),

- Disassemble the nut (9),

- Clean the burner (4) using a domestic vacuum

cleaner by placing the suction device over the air

inlet and the gas inlet successively,

- Check the ignition electrodes (3) and the ionisation electrodes (2).

Fig. 8

3

39

2.25

ZEM-31-0-5-25

2

40

20

≈

When reassembly the burner/fan unit:

- Replace the seal at the nut (item. 9) and check

the airtightness of the gas,

- when refitting the fan on the burner :

• check the correct positioning of the fan/burner

gasket (item. 10),

• check the airtightness of the gasket and repla-

ce it if necessary.

- check airtightness at the burner and boiler shell

levels,

2 - SERVICING THE HEAT EXCHANGER OF THE BOILER SHELL

- The heat exchanger must be cleaned once the

burner has been disassembled (section 1 page 13 - chapter III - MAINTENANCE - SERVICING MANUAL).

- Sprinkle the heat exchanger with water. The water is evacuated through the condensate evacuation siphon,

- when reassembling the burner onto the boiler

shell check the correct positioning of the gasket.

3 - CHECKING ACCESSORIES

- Check that the safety and control devices (3 bar

safety valve, air bleed, safety control box, etc.)

are operating properly.

- Clean the condensate drain siphon and then fill it

with water.

- Also check that neither the installation nor the

boiler present any water or fuel leaks (leaks may

produce a risk for safety and shorten the lifespan).

- When it is frequently necessary to add water to

maintain pressure in the installation, even though

no leaks have been discovered, perform an expansion vessel check (section 4 - page 15 chapter III - MAINTENANCE - SERVICING MANUAL).

- 14 -

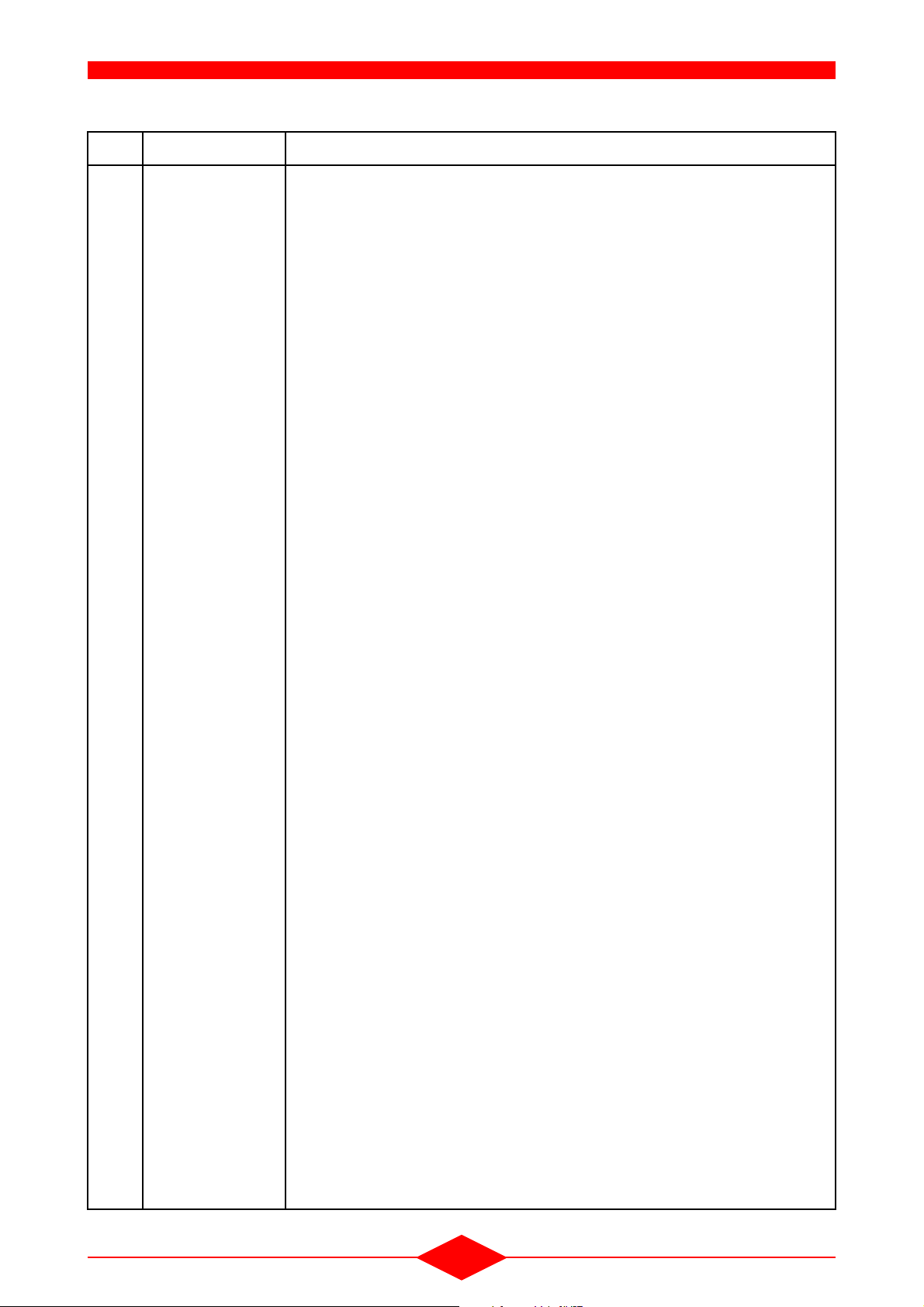

4 - EXPANSION VESSEL PRE-INFLATION PRESSURE CHECK

MAINTENANCE

- Drop the pressure in the heating installation by

opening the drain cock or the safety valve (pressure gauge reading under 0.5 bar).

- Check the pressure in the expansion vessel and

Fig. 9

if necessary bring it back up to pressure, or replace it if the membrane is punctured (water present

in the inflating valve).

- To optimise the efficiency of the vessel:

• adjust its pre-inflation pressure in line with the

installation. It must correspond to the static height of the installation (H) expressed in bars

Water inlet

(height between the highest point of the installation and the expansion vessel, with 10 metres = 1 bar),

• adjust the filling pressure of the installation to a

value of over 0.2 bar above the pre-inflation

Inflating

valve

5 - COMBUSTION PRODUCT CONDUITS (FLUE)

- Check the combustion product evacuation conduit and the air inlet conduit at least once a year

(airtightness of the parts that may be disassembled - conduits not obstructed).

pressure of the vessel (after totally bleeding

the air from the installation).

H

Membrane

Max vessel

volume

Dilated water

volume

Pressure rises

as the air is

compressed

AM4-06-3

6 - DRAINING

- Cut the power supply,

- turn off the gas cock,

- turn off the heating flow/return valves (if they are

fitted),

- connect the drain valve (18) to the sewage system,

- open the drain valve.

Ensure that the air bleed (16) is open, as

soon as the pressure gauge indicates a

!

zero pressure to allow air to enter the

boiler shell.

Fig. 10

16

18

THI-98-0

- 15 -

7 - SENSOR RESISTANCES

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

Input pressure (bar)

100-74-0

Output voltage (Volt)

MAINTENANCE

The resistance of the sensors must be measured

after they have been disconnected from the control

panel.

Resistance values of the sensors

Heating outlet sensor

Temperature

0.00 °C 32624

10.00 °C 19897

15.00 °C 15711

20.00 °C 12493

25.00 °C 10000

30.00 °C 8056

40.00 °C 5324

50.00 °C 3599

60.00 °C 2483

70.00 °C 1748

Boiler return sensor

Flue gas sensor

Resistance values of the sensors

Heating outlet sensor

Temperature

Boiler return sensor

Flue gas sensor

80.00 °C 1252

90.00 °C 912

Resistance values of the sensors

Temperature Outside sensor

-20.00 °C 7578

-15.00 °C 5861

-10.00 °C 4574

-5.00 °C 3600

0.00 °C 2857

5.00 °C 2284

10.00 °C 1840

15.00 °C 1492

20.00 °C 1218

8 - PRESSURE SENSOR

The output voltage on the water pressure sensor is measured between the terminals GND (-) and OUT.

Fig. 11

OUT

GND (-)

IN (+)

100-75-

- 16 -

IV - OPERATING FAULTS

1 - OPERATING FAULTS LIST

Display A0 Description Solution

Outside sensor fault Check that the sensor is correctly fitted and

connected

Boiler sensor 1 fault Check that the sensor is correctly fitted and

connected

Flue gas detector fault Check that the sensor is correctly fitted and

connected

Flow sensor 2 fault Check that the sensor is correctly fitted and

connected

Return sensor 1 fault Check that the sensor is correctly fitted and

connected

Domestic hot water sensor 1 fault Check that the sensor is correctly fitted and

connected

Room device 1 faulty Check the boiler connections

Room device 1 error or radio clock error Check compatibility of the room device or

clock

Water pressure sensor fault Check the connections of the pressure

sensor

Short-circuit on LPB or no voltage Check the wiring

Two identical addresses on the LPB Check the addressing

Loss of data in the EEPROM Change the LMU

Component fault in the LMU Change the LMU

Two master clocks (only one normally),

programming problem

Maintenance alarm Check the maintenance code value, QAA 73

STB (boiler overheating safety) activated Check that shunt X3-01 is present and

Response of the safety thermostat Check whether the installation water flow is

Check parameter 96 of the QAA73 (only one

device can have the message “QAA73”)

setting 726 (section 2 -page 19 - chapter IV OPERATING FAULTS - SERVICING

MANUAL)

whether the installation water flow is sufficient

(circulating pump, isolation valve, etc.)

sufficient (circulating pump, isolation valve,

etc.)

Flue gas alarm displayed (problem of the

flue gas temperature being too high)

Water pressure too high Check and adjust the pressure level if

Water pressure too low Check and adjust the pressure level if

- 17 -

Check whether the boiler is not on thermal

overload or that the exchanger is not clogged

necessary with P < 4 bar

necessary with P > 0.4 bar

OPERATING FAULTS

Display A0 Description Solution

Flame failure while the boiler is operating Check and adjust the gas valve, check the

ionisation electrode and the connections,

possible live-neutral inversion of the

transformer supply

Poor air supply Check the ventilator and the air inlet

Maximum flue gas temperature exceeded Check whether the boiler is not on thermal

overload or that the exchanger is not clogged

Safety device activated Check that shunt X10-03 is present and that

the wires are properly connected

No flame formed after the safety time

period

Segment number or unauthorised

addressing on LPB or LMU

Incompatibility between the LMU and LPB Check the addressing consistency

New LMU configuration Check the b0 internal code

LMU setting error Check the b0 internal code

The boiler is blocked Press Reset to clear the message

Violation of the plausibility criteria (STB

related criteria)

The minimum speed threshold of the fan

is not reached

The maximum speed threshold of the fan

is exceeded

Check that the gas reaches the boiler (Pi),

check the condition of the gas valve, if there

is a major adjustment fault on the gas valve,

check the condition of the transformer,

cables, ignition electrode, ionisation current

value

Check the addressing consistency

Check the value of the criteria related to the

boiler overheating security

Check the wiring of the fan and LMU, ensure

that the fan is turning correctly

Check the mains supply and the fan cable

connections

The service function is active -

The regulator shut-down function is active -

The boiler is in setting mode This appears after one or more settings are

Modem function is active -

"Controlled screed drying" function is

active

Note :

- The last 5 working faults are accessible through

the QAA 73, from LMU version 3.00, lines 728 /

loaded either by the QAA73 or by the PC

TOOL. This means that a reset is necessary

to validate the new setting(s) and for the

boiler to return to normal operating.

-

729 / 730 / 731 / 732. The last saved fault code is

displayed at line 728.

- 18 -

2 - MAINTENANCE

Maintenance alarms can be automatically triggered,

indicating that maintenance jobs are due. The following reasons for maintenance alarms can be delivered:

- Interval of burner hours run since last regular service visit exceeded.

- Interval of the number of startups since last regular service visit exceeded.

- Number of months since last regular service visit

exceeded.

The alarm displayed is always the maintenance

alarm that occurred first.

There is no storage for the maintenance alarms since all pending alarms can be checked at any time

via the counter readings or the relevant parameters.

2.1 - Maintenance alarm

If a maintenance alarm occurs, an error code "105

maintenance" appears on the dipslay of the boiler

and / or room unit.

This code does not give precise information on

maintenance but is only a general maintenance note.

OPERATING FAULTS

2.3 - Coding of maintenance alarms

Internal

Maintenance

alarm

Maintenance

code

– 0 –

105 1 560

105 2 561

105 3 562

error

code

b0

Meaning

No maintenance

alarm

Burner hours run

Startups

Months-service

2.4 - General activation of maintenance alarms

Parameter "WartungsEinstellungen" (QAA 73 setting : 630) permits or suppresses the generation of

maintenance alarms.

The subdivision of parameter "WartungsEinstellungen" by bit is shown in the following table :

These maintenance alarms are a priority lower than

that of the error codes to ensure the error codes prevail.

The maintenance alarm is sent until the enduser has

acknowledged the message or the heating engineer

has rectified the fault.

2.2 - Maintenance code

The maintenance alarm does not provide detailed

information about the reason for the fault. Details

can be displayed using parameter "WartungsCode"

(QAA 73 setting : 726).

Le maintenance code can also be viewed on the display of the boiler (b0).

Bit0

Bit1

1 = general activation of maintenance alarms

1 = single reset of hours run maintenance alarm

Bit2 1 = single reset of startup maintenance alarm

Bit3

alarm

single reset of months- service maintenance

1 =

Bit6 1 = total reset for all maintenance alarms

- 19 -

OPERATING FAULTS

2.5 - Activation of the individual maintenance alarm

Every cause can be individually activated or deactivated by entering the associated limits.

- Burner hours run :

Burner hours run maintenance is activated by

setting parameter "BetrStdWartGrenz" (QAA 73

setting : 625) to a value other than "0".

This value represents the target number of hours

run. When this limit is reached, a maintenance

alarm will be delivered (interval since last service

visit).

- Number of startups:

Startup maintenance is activated by setting parameter "InbetrSetzWartGrenze" (QAA 73 setting :

626) to a value other than "0".

This value represents the target number of star-

tups. When this limit is reached, a maintenance

alarm will be delivered (interval since last service

visit).

- Months (service):

Service maintenance is activated by setting parameter "MonatWartGrenze" (QAA 73 setting :

627) to a value other than "0".

This value represents the target number of

months. When this limit is reached, a maintenance alarm will be delivered (interval since last service unit).

Note :

- The month counter is only active when the device

is connected to power.

2.6 - Acknowledgement of maintenance alarms

The acknowledgement sets the internal error code

"b0" and the fault statut message to "0", but the

maintenance code still gives the precise reason for

the maintenance alarm.

2.6.1 - Acknowledgement via QAA 73

For the parameter "WartungsQuittierung" (QAA 73

setting : 629) (defaut value: 0), to acknowledge the

maintenance alarm the heating engineer (or the enduser) enters the value of "1".

If no repetition is required, all maintenance alarms

after this acknowledgement will be locked, even if

other reasons for maintenance occur. In that case,

parameter "WartungsQuittierung" remains constantly at 1.

2.6.2 - Activation of the repetition after acknowledgement

If required, a timer (duration of repetition) can be

started, that is, the maintenance alarm will reappear

on the display after a certain period of time. An acknowledgement can also be made then. This period

of time starts after each acknowledgement.

The repetition can be set via parameter «WartungsRepetitionsDauer» (QAA 73 setting 633).

Contents of parameter «WartungsRepetitionsDauer» is the desired period of time (in days) until

the maintenance alarm appears again.

If a value other than «0» is entered there, a repetition is made within the entered duration of the repetition time.

During this period of time, no more

maintenance alarms will appear, even if

!

other reasons for maintenance occur.

2.7 - Resetting the maintenance alarms

Resetting can take place at any time, and after acknowledgement or during the repetition sequence.

A reset can be made in 1 of 2 ways:

- Total reset :

Here, all maintenance alarms can be reset at the

same time. If, in parameter «WartungsEinstellungen» (QAA 73 setting 630), «1» is entered, all

maintenance counters will be set to «0» when the

parameter is saved.

The maintenance counters of the hours run, startups and months maintenance alarms will be

newly started.

- Individual resert of a certain maintenance

alarm :

Individual maintenance alarms can also be reset.

In that case, parameter «WartungsEinstellungen» (QAA 73 setting : 630) will again be addressed bit by bit.

There is a bit available for each maintenance

alarm via which this maintenance alarm can be

reset (section 2.4 - page 19 - chapter IV - OPERATING FAULTS - SERVICING MANUAL). It is

thus possible to also reset other reasons for

maintenance although they have not yet occurred.

When resetting the maintenance alarm, the maintenance code and the internal error code (b0) will

automatically also be reset.

Note : Only the QAA 73 can the maintenance alarms

be activated, the reasons for the maintenance alarms be checked and a reset via parameter be made.

- 20 -

V - OPTIONS

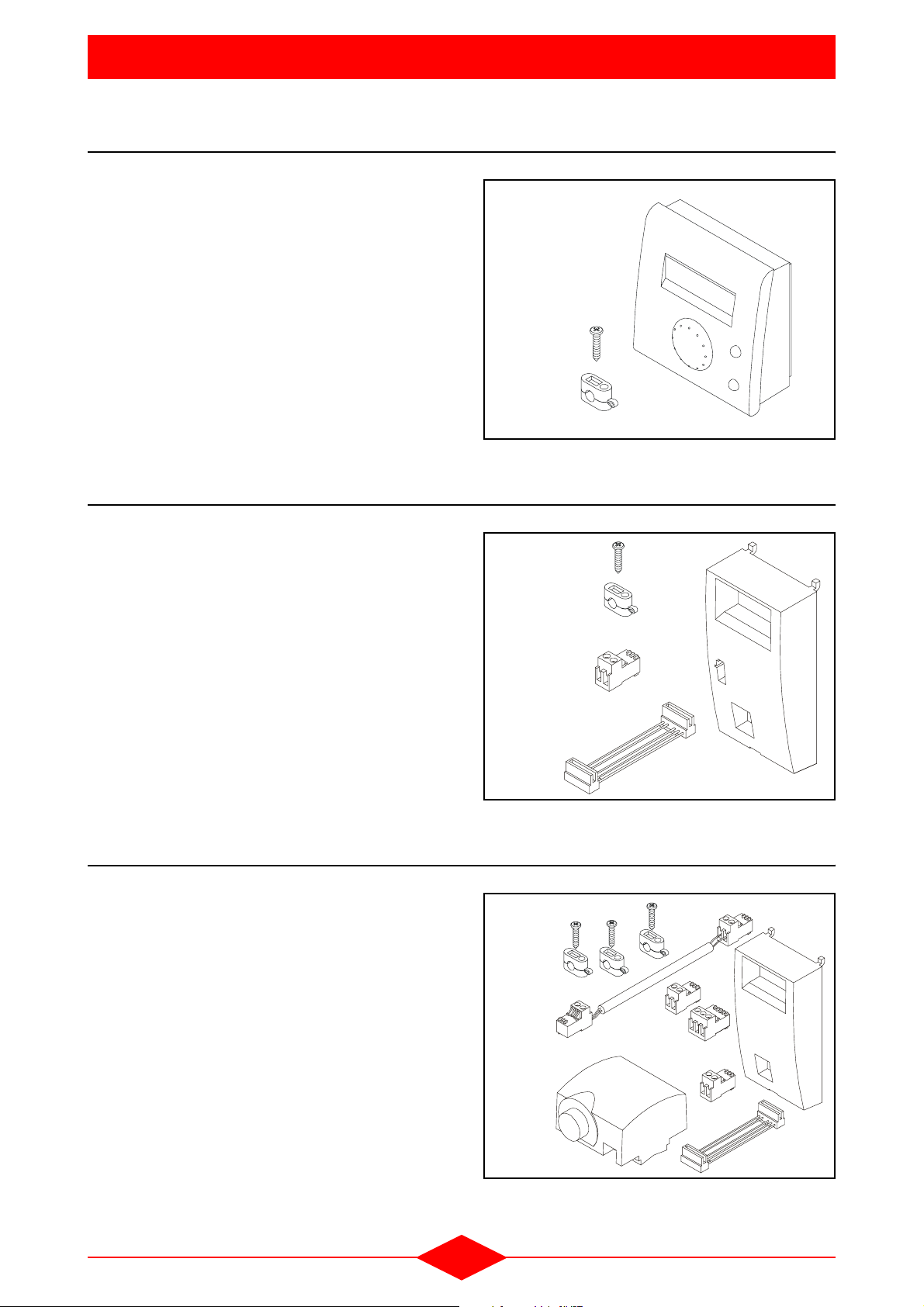

1 - SET-UP TAKING ROOM TEMPERATURE INTO ACCOUNT (REG 73)

The REG 73 is a multifunctional digital room sensor

for one or two heating circuits and for the control of

domestic hot water.

Refer to the kit installation instructions.

2 - CLIP-IN LPB KIT (REG 130)

The LPB communication clip-in kit is used to

connect the LMU control unit to different units or

accessories of the type:

- RVA 46: zone regulator

- RVA 47: cascade regulator

- + others (distance management etc.)

Fig. 12

PDG-REG 73

Fig. 13

Refer to kit installation instructions.

3 - SECONDARY CIRCUIT CLIP-IN KIT

The secondary circuit clip-in kit is used when a

second heating circuit is connected to the boiler. It

allows the communication between the boiler’s LMU

control unit and the various accessories of the

secondary circuit.

Refer to kit installation instructions.

THI-28-0

Fig. 14

- 21 -

0

1

3

-

I

H

T

4 - DOUBLE CIRCUIT KIT (REG 125) - (THI 10-35 SEP)

0

OPTIONS

The double circuit kit is used whenever a second

heating circuit is connected to the boiler:

Fig. 15

- The 2nd circuit clip-in ensures communication

between the boiler's LMU management unit; the

2nd circuit pump control and also the mixing valve motor (accessories supplied with the kit).

Refer to kit installation instructions.

5 - DOUBLE CIRCUIT KIT (REG 146) - (THI 10-50 C)

The double circuit kit is used whenever a second

heating circuit is connected to the boiler:

- The 2nd circuit clip-in ensures communication

between the boiler's LMU management unit; the

2nd circuit pump control and also the mixer valve

motor (accessories supplied with the kit).

- The clip-in relay allowing a 1st circuit pump (Q8CC1) to work in parallel and to regulate the outlet

temperature of the installation.

Fig. 16

0

8

1

-

I

H

T

9

1

-

I

H

T

Refer to kit installation instructions.

6 - PROGRAMMABLE RELAY CLIP-IN KIT (REG 127)

The programmable relay clip-in kit (sensor inlet)

enables:

- a 2nd heating pump to be controlled in parallel

with the boiler pump in the case of operation

using a header.

- with the flow sensor positioned at the outlet of the

header, the heating outlet can be controlled after

the header.

- an external safety gas solenoid to be connected,

- an alarm to be connected.

Refer to kit installation instructions.

Fig. 17

0

1

3

I

H

T

- 22 -

7 - PROGRAMMABLE RELAY CLIP-IN KIT (WITHOUT SENSOR) (REG 134)

OPTIONS

The programmable relay clip-in kit (without sensor)

enables, for example:

- a domestic hot water circulation pump to be controlled,

- an outside gas safety solenoid valve to be connected.

Refer to the assembly instructions for the kit.

8 - CONTROL UNIT ZHTI 46 (REG 129)

The control unit ZHTi 46 enables an additional heating circuit to be controlled. (Required from 3 heating

circuits - refer to technical specifications of the ZHTi

46).

Fig. 18

Fig. 19

0

9

0

1

-

I

H

T

9 - CONTROL UNIT ZHTI 47 (REG 128)

The control unit ZHTi 47 manages 2 cascading boilers.

Note:

- For multiple boiler management, use clip-in kits

LBP (130).

Refer to ZHTi 47 technical specifications.

REG 121

Fig. 20

REG 128

- 23 -

10- SOLAR HEATING CONTROL KIT (REG 152)

OPTIONS

The solar heating control kit is intended for type C

THI boilers that have a solar tank. It is used to control the production of domestic hot water by solar panels.

11 - DHW SENSOR KIT

The DHW sensor kit allows the connection of the domestic hot water sensor to the hot water heater at

the boiler control unit.

Fig. 21

REG-SOL1-0

Fig. 22

Refer to kit installation instructions.

12- SELECTOR VALVE KIT FOR CONNECTING THI..C/BS

The selector valve kit allows the connection of a

central heating only type boiler to a domestic hot

water heater.

Refer to kit installation instructions.

Fig. 23

THI-67-0

THI-37-0

- 24 -

13- TIMER KIT

S

OPTIONS

The timer kit is fitted to the boiler’s control panel and

controls an installation only possessing one heating

Fig. 24

circuit.

Fitting a clip-in to the boiler’s LMU management unit will not work with this ti-

!

mer.

Refer to kit installation instructions.

14- BS TYPE DOMESTIC HOT WATER PRODUCTION SYSTEM

BS domestic hot water production systems can produce hot water when the installation contains a boiler that only operates for heating.

The capacity of the BS systems varies with the model chosen.

- BS 100: 100 litres / BS 200: 200 litres

- BS 150: 150 litres / BS 300: 300 litres

Fig. 25

HOR-01-0

Note:

- The selector valve kit is necessary for connecting

BS systems to ZEM..C boilers.

B

- 25 -

15- BIONIBAL/BIONIBAGEL

OPTIONS

Fig. 26

Fig. 27

BIONIBAGEL 10 litres

BIONIBAL 1 litre

Fig. 28

BIONIBAL 30 litres

16- CONDENSATE LIFT PUMP

The condensate lift pump is used to raise the condensate extraction level for a direct outlet to the exterior. It is used for boilers installed in a basement.

Fig. 29

- 26 -

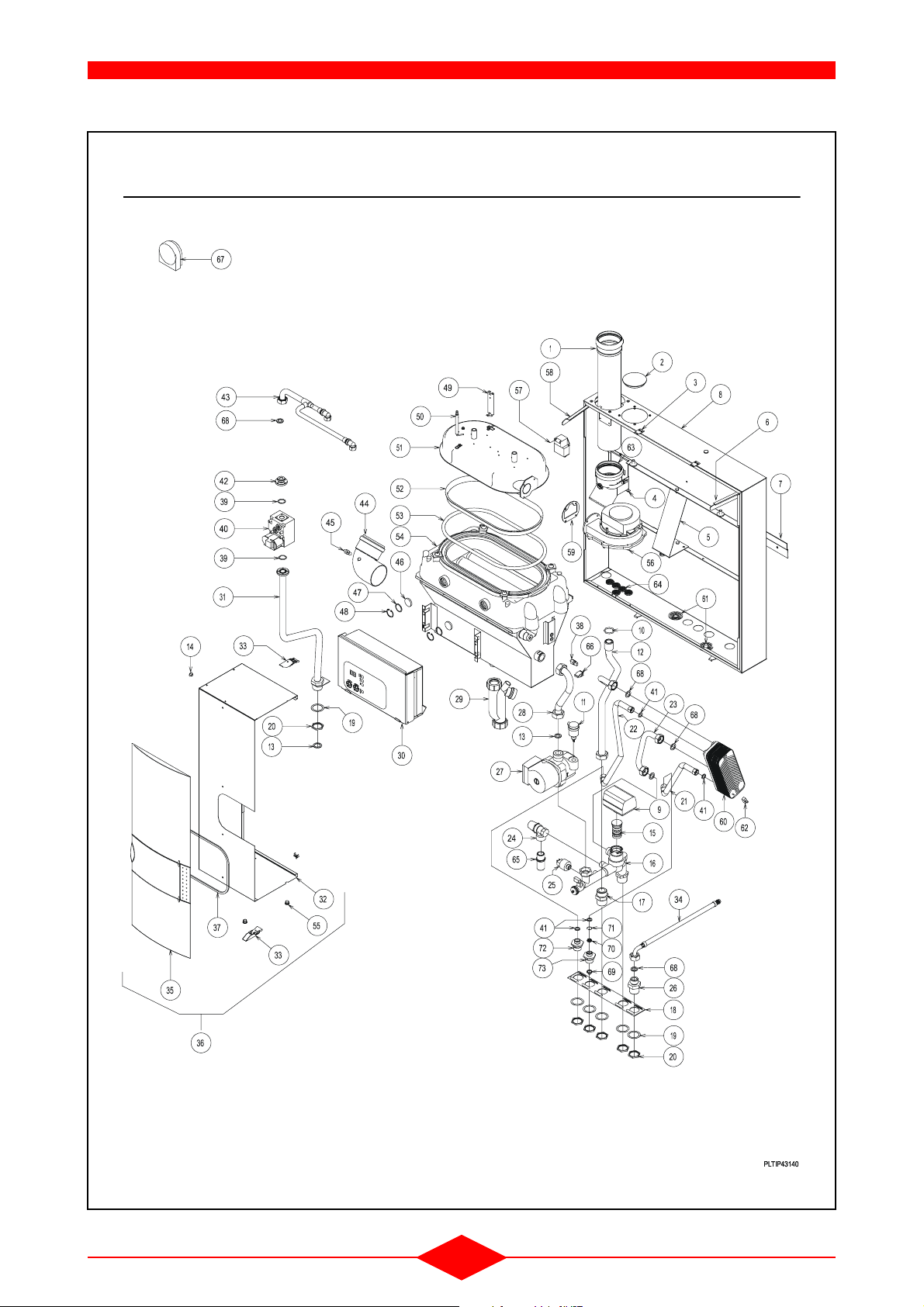

VI - PARTS LISTS

THI 10-50 C

- 27 -

PARTS LISTS

Rep.

1 N40.16810 REDUCED FLUE OUTLET PIPE F75/M80 L360

2 A00.23624 PE CAP N152 BPF 3-1/2

3 Y00.14139 FASTENING HOOK

4 Y00.10807 FIXING SYSTEM FOR FLUE PIPE

5 Y00.13849 BACK STOP PLATE FOR MZ (3355X80,4X1,5)

6 Y00.18233 RIGHT HAND CONSOLE (269,4X25X1,5)

7 V07.31963 WALL FASTENING ; 10-50 MODEL

8 Y90.33470 CHASSIS ; EQUIPPED THI 10-50

9 A00.24109 ORANGE CAP D. 34,7 EZ-16

10 E00.01005 O’ RING DIA DIA 29,32 X 3,6

11 L90.24635 AUTOMATIC AIR VALVE WATTS WITH ISOLATED VALVE

12 U00.19465 HEATING FLOW PIPE GREY THRC

13 E20.03889 SEALING AFM34D 30X21X3

14 W07.32303 OUTSIDE SENSOR .QAC34/101 THRI

15 H30.24159 MESSING CAP 28X52 + 2 O’RING

16 U90.28983 HEATING RETURN UNIT

17 I20.21441 MESSING SEALED CONNECTION "OLIVE" 22/1

18 V00.23999 STOP PLATE FOR HEATING AND DHW

19 V00.21491 PROTECTING RING 1

20 I20.21452 MESSING LOCK NUT 1

21 K50.24473 DRAIN COCK / RETURN UNIT

22 E00.24496 SEALING / O’RING INT. D. 39,45

23 L40.24495 STAINLESS STEEL FILTER / HEATING RETURN

24 L50.35152 PRESSURE SENSOR HUBA TYPE 505.91540

24 V90.35156 REPLACEMENT SET OF IMIT SENSOR BY HUBA SENSOR

25 L90.24178 SAFETY VALVE

26 L20.31471 SENSOR T7335D1024B

27 L30.33738 CIRCULATING PUMP GRUNDFOS UPS15-70/130 AO S3

28 U00.19252 SUMP INLET THRC/S GREY

29 A20.23655 SIPHONIC TRAP WITH PIPE 650 MM

30 W07.31562 CONTROL BOX PROGRAMMED THRI/THI 10-50C (DT)

31 U07.31500 GAS INLET; EQUIPPED; 1/10 - 5/25 MODEL

32 Y90.35965 WHITE COVER THRI S/10-50C

33 T25.31875 FIXING PART; UPPER COVER

34 E20.03890 SEALING AFM34 D 24X17X3

35 H20.32834 FRONTPANEL GREY

36 Y07.32843 COVER + FRONTPANEL

37 V07.32114 RING FOR BOILER COVER L685

38 L20.31470 SENSOR TASSERON NTC SENSOR M5 TSA-TYPE

39 L10.10607 HONEYWELL O’RING 22 X 2,5

40 V90.33616 WIRED SIT GAS VALVE SET

40 V90.37322 GAS VALVE SIEMENS VGU 87

41 I20.31604 GAS REDUCER

42 L10.33774 FLANGE G 3/4" FOR SIT VALVE

43 U07.31563 GAS INLET; COMPLETE BURNER ; 10-50C MODEL

44 U07.31498 90° ELBOW ; D.80 DRILLED

45 L20.31496 SENSOR TASSERON NTC SENSOR D10X20 10K

46 T20.00582 SIGHTGLASS PYREX D.30X5

47 B59.00692 STAINLESS STEEL WASHER 30,4X25,5X0,3

48 T40.01051 INSIDE CIRCLIPS D.30 YELLOW BICHROMATE

49 L00.16673 IGNITION ELECTRODE SHORT 74,5 AV CABLE

50 L00.12950 IONISATION PROBE (SHORT 20)

51 X00.24278 BURNER SET NG/LPG FOR THR 10-50 C

52 X00.32003 BURNER RING; REMOVABLE

53 F00.26573 GLASS BRAID RING D. 12 LG. 1070

Reference

Description

- 28 -

PARTS LISTS

Rep.

54 V07.33783 STAINLESS STEEL BOILER SHELL THRI/THI/THISION10-50

55 A00.03141 COLORLESS PLASTIC CAP

56 C50.31464 FAN MVL-EBM RG 128/1300-3612

57 C90.31466 IGNITION TRANSFORMER ANSTOSS ZAG 2XV 01/10

58 Y00.18234 LEFT HAND CONSOLE (269,4X25X1,5)

59 E20.35446 RING FOR THE FAN

60 I20.22440 MESSING AIR REDUCER D. 310 LP 16 (POUR REGLAGE PROPANE G 31)

61 E20.23654 EXTENSIBLE SEALING D. 18 / RED SILICONE

62 E00.03424 NITRILE O’RING D. 8 X 2 80 SHORE

63 U00.20366 ELBOW D. 80 45°

64 C91.03071 WIRE CARRIER

65 I20.13579 BRASS NIPPLE MAL3/4-MAL3/4(LONG)

66 A00.19059 PLASTIC STOPPER MAL 9 WHITE

* A00.28827 PLASTIC CAP MALE 1/4

* C09.31469 CABLE WITH RECTIFIER VDU GAS VALVE

* C09.33608 CABLE 0.960.401+CONNECT. GAS VALVE SIT 848 SIGMA

* E00.10822 EPDM LIP SEAL D. 80 75 SHORE

* E10.12503 EPDM STICKING SEAL PIPE 6/9 LENGTH 18

* E20.24399 GASKET DN 80; BLACK FOR PART NUMBER U00.12053 AND U00.20366

* I30.31973 STOP TECHNYL D.20X19

* U00.03505 FIXING BRACKET FOR BURNER MZ/THR

* U00.08190 VERSILIC PIPE 6X10 LENGTH 800MM

* U00.18996 FLEXIBLE PIPE 4X8 LG 800 MM GAS UNIT

* V00.24191 MOUNTING KEY; HONEYWELL

* V07.31651 GAS CONVERSION SET GN/GP

* X00.05193 FIXING BRACKET FOR IONISATION PROBE

* X90.30472 IGNITION ANGLE WITH SCREW

Reference

Description

- 29 -

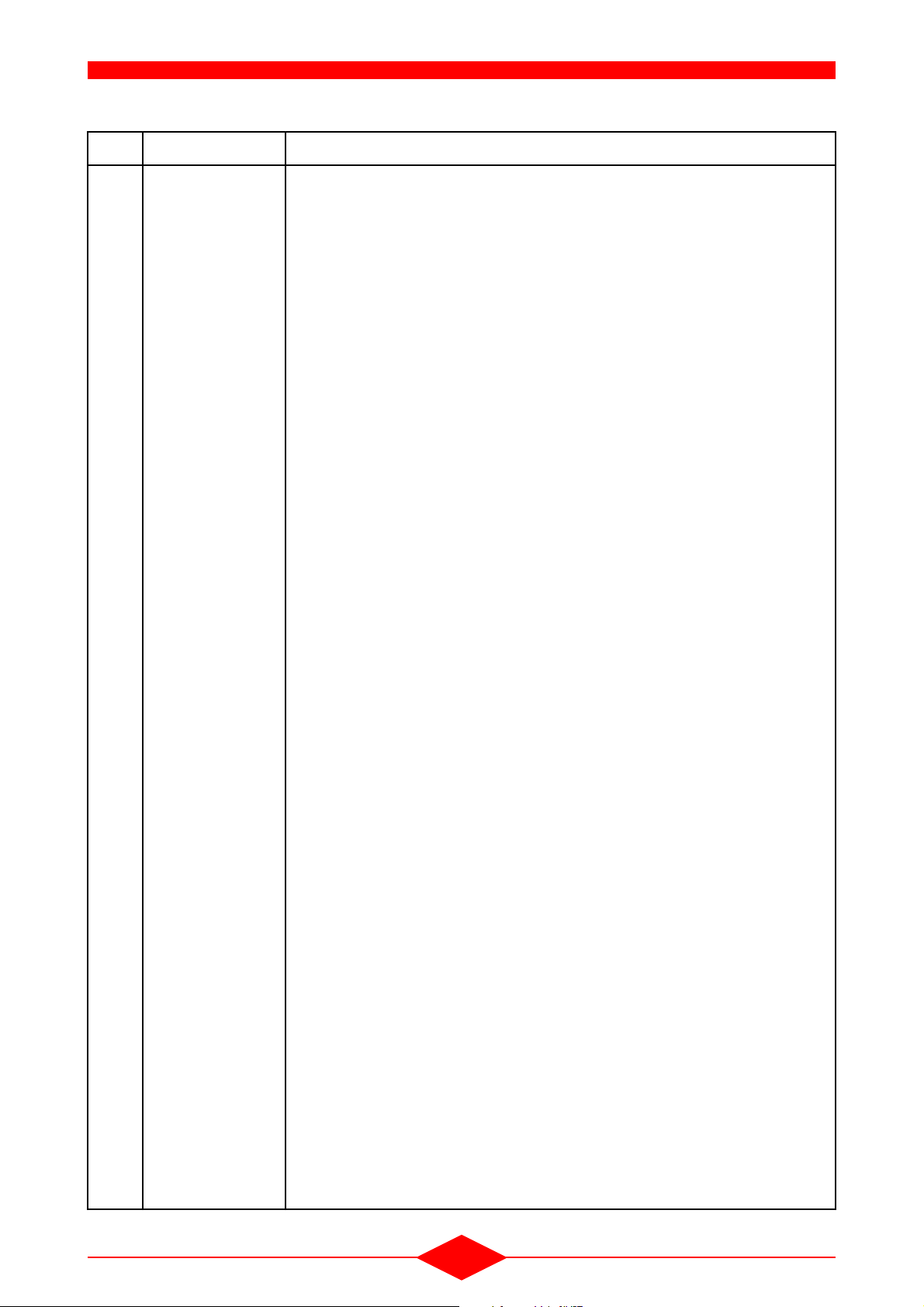

THI 10-35 SEP

PARTS LISTS

- 30 -

PARTS LISTS

Rep.

1 N40.10637 PP. PIPE D.80 LENGTH 445

2 A00.23624 PE CAP N152 BPF 3-1/2

3 Y00.14139 FASTENING HOOK

4 Y00.10807 FIXING SYSTEM FOR FLUE PIPE

5 Y00.13849 BACK STOP PLATE FOR MZ (3355X80,4X1,5)

6 Y00.18233 RIGHT HAND CONSOLE (269,4X25X1,5)

7 V07.31963 WALL FASTENING ; 10-50 MODEL

8 Y90.33470 CHASSIS ; EQUIPPED THI 10-50

9 W07.31704 MOTOR; SELECTIVE VALVE WITH CABLE

10 E00.01005 O’ RING DIA DIA 29,32 X 3,6

11 L90.24635 AUTOMATIC AIR VALVE WATTS WITH ISOLATED VALVE

12 U07.34049 HEATING FLOW; GREY; THRI SEP

13 E20.03889 SEALING AFM34D 30X21X3

14 A00.19059 PLASTIC STOPPER MAL 9 WHITE

15 V90.33015 SELECTOR VALVE KIT

16 U90.28983 HEATING RETURN UNIT

17 I20.21441 MESSING SEALED CONNECTION "OLIVE" 22/1

18 V00.23999 STOP PLATE FOR HEATING AND DHW

19 V00.21491 PROTECTING RING 1

20 I20.21452 MESSING LOCK NUT 1

21 O00.32983 RIGHT FLEXIBLE PIPE NU 1/2 LG 350

22 O00.32984 RIGHT FLEXIBLE PIPE NU 1/2 LG 550

23 U07.32871 PRIMARY OUTLET PIPE

24 L50.35152 PRESSURE SENSOR HUBA TYPE 505.91540

24 V90.35156 REPLACEMENT SET OF IMIT SENSOR BY HUBA SENSOR

25 L90.24178 SAFETY VALVE

26 I20.33459 CONNECTION 1’’ -3/4’’

27 L30.33738 CIRCULATING PUMP GRUNDFOS UPS15-70/130 AO S3

28 U00.19252 SUMP INLET THRC/S GREY

29 A20.23655 SIPHONIC TRAP WITH PIPE 650 MM

30 W07.36930 CONTROL BOX ; WIRED ; PROGRAMMED

31 U07.31500 GAS INLET; EQUIPPED; 1/10 - 5/25 MODEL

32 Y90.35965 WHITE COVER THRI S/10-50C

33 T25.31875 FIXING PART; UPPER COVER

34 O00.20679 STAINLESS STEEL FLEXIBLE PIPE MALE 1/4 WITH ELBOW

35 H20.32834 FRONTPANEL GREY

36 Y07.32843 COVER + FRONTPANEL

37 V07.32114 RING FOR BOILER COVER L685

38 L20.31470 SENSOR TASSERON NTC SENSOR M5 TSA-TYPE

39 L10.10607 HONEYWELL O’RING 22 X 2,5

40 V90.33616 WIRED SIT GAS VALVE SET

41 E20.06892 SEAL AFM34 D. 18,6 X 12 2 MM THICKNESS

42 L10.33774 FLANGE G 3/4" FOR SIT VALVE

43 U07.31563 GAS INLET; COMPLETE BURNER ; 10-50C MODEL

44 U07.31498 90° ELBOW ; D.80 DRILLED

45 L20.31496 SENSOR TASSERON NTC SENSOR D10X20 10K

46 T20.00582 SIGHTGLASS PYREX D.30X5

47 B59.00692 STAINLESS STEEL WASHER 30,4X25,5X0,3

48 T40.01051 INSIDE CIRCLIPS D.30 YELLOW BICHROMATE

49 L00.16673 IGNITION ELECTRODE SHORT 74,5 AV CABLE

50 L00.12950 IONISATION PROBE (SHORT 20)

51 X00.24278 BURNER SET NG/LPG FOR THR 10-50 C

52 X00.32003 BURNER RING; REMOVABLE

53 F00.26573 GLASS BRAID RING D. 12 LG. 1070

54 V07.33783 STAINLESS STEEL BOILER SHELL THRI/THI/THISION10-50

Reference

Designation

- 31 -

PARTS LISTS

Rep.

55 A00.03141 COLORLESS PLASTIC CAP

56 C50.31464 FAN MVL-EBM RG 128/1300-3612

57 C90.31466 IGNITION TRANSFORMER ANSTOSS ZAG 2XV 01/10

58 Y00.18234 LEFT HAND CONSOLE (269,4X25X1,5)

59 E20.35446 RING FOR THE FAN

60 I20.22440 MESSING AIR REDUCER D. 310 LP 16 (POUR REGLAGE PROPANE G 31)

60 V07.35762 PLATE HEAT EXCHANGER 35KW

61 E20.23654 EXTENSIBLE SEALING D. 18 / RED SILICONE

62 L20.32178 SURFACE TEMP. SENSOR T7335D1073B

63 U00.20366 ELBOW D. 80 45°

64 C91.03071 WIRE CARRIER

65 I20.13579 BRASS NIPPLE MAL3/4-MAL3/4(LONG)

66 L20.31471 SENSOR T7335D1024B

67 W07.32303 OUTSIDE SENSOR .QAC34/101 THRI

68 E20.03890 SEALING AFM34 D 24X17X3

69 L40.32888 DOMESTICCOLDWATERFILTERSTAINLESSSTEEL D. 18,5 EXT

70 L50.35756 FLOW LIMITER 16 L / MN

71 T40.32887 COPPER SEALING D.16 INT

72 K20.23797 3/4"-1/2 " CONNECTION ; BRASS

73 K20.32885 CONNECTION ; BRASS 3/4-1/2

74 I20.33459 CONNECTION 1’’ -3/4’’

* A00.28827 PLASTIC CAP MALE 1/4

* C09.33608 CABLE 0.960.401+CONNECT. GAS VALVE SIT 848 SIGMA

* E00.10822 EPDM LIP SEAL D. 80 75 SHORE

* E10.12503 EPDM STICKING SEAL PIPE 6/9 LENGTH 18

* E20.03901 SEALING QUALITY AFM34 D.11X4X3

* E20.24399 GASKET DN 80; BLACK POUR LES RÉFÉRENCES (U00.12053) ET (U00.20366)

* I30.31973 STOP TECHNYL D.20X19

* U00.03505 FIXING BRACKET FOR BURNER MZ/THR

* U00.08190 VERSILIC PIPE 6X10 LENGTH 800MM

* U00.18996 FLEXIBLE PIPE 4X8 LG 800 MM GAS UNIT

* V00.24191 MOUNTING KEY; HONEYWELL

* X00.05193 FIXING BRACKET FOR IONISATION PROBE

* X90.30472 IGNITION ANGLE WITH SCREW

Reference

Designation

- 32 -

CONTROL BOX

PARTS LISTS

- 33 -

PARTS LISTS

Rep.

1 H20.31449 CONTROL BUTTON

2 Y07.31525 CONTROL PANEL + STICKER

3 W07.31892 INTERFACE; EQUIPPED; AGU2.303A136

4 L20.31476 COMMUNICATION MODULE CLIP-IN LPB (VOIR OPTION W07.30832)

4 L20.31477 MODULE CIRCUIT 2 CLIP-IN (VOIR OPTION W07.30833)

4 L20.31499 SUB-MODULE RELAIS CLIP-IN AGU2.511A109 (VOIR OPTION W07.30515)

5 L20.36214 ELECTRONIC CONTROL UNIT LMU64.010D136 V3.03

6 A90.27098 CABLE GRIP D=6,5 MM BLACK

6 C91.38454 CABLE FASTENING TWIST LOCK

7 Y07.31507 ELECTR. BOX

8 C19.32006 SCREW EARTH CONNECTION

9 C20.12490 TIGHT CAP FOR SWITCH

10 C20.12487 BIPOLAR SWITCH; BLACK/LIGHTNING/GREEN

11 L25.17432 TIMER GRASSLIN 230 V FM - DIGI20

* C09.31469 CABLE WITH RECTIFIER VDU GAS VALVE

* C09.33608 CABLE 0.960.401+CONNECT. GAS VALVE SIT 848 SIGMA

* C09.37989 IONISATION CABLE Ø 2,5 LG 1020 MM

* C09.37989 IONISATION CABLE Ø 2,5 LG 1020 MM

* C90.31497 COVER KEY-TOP 4X4 THISION

* W07.31478 WIRING OF THE CONTROL BOX

* W07.31479 WIRING OF THE CONTROL BOX; 10-50 MODEL

* W07.31492 CONNECTING CABLE LG LMU64/AGU2

* W07.31508 ELECTR. CONTROL BOX + WIRING 2-13 THISION

* W07.31542 ELECTRICAL TERMINAL BOX

* W07.31558 ELECTR. CONTROL PANEL + WIRING 0,9-9 THISION

* W07.31562 CONTROL BOX PROGRAMMED THRI/THI 10-50C (DT)

* W07.32380 CONTROL BOX ; WIRED ; PROGRAMMED THI 5-25 S DT

* W07.32381 CONTROL BOX ; WIRED ; PROGRAMMED THI 2-13 M 75 DT

* W07.32382 CONTROL BOX; WIRED; PROGRAMMED THI 5-25 M75 DT

* W07.32899 CONTROL BOX ; WIRED ; PROGRAMMED THRI5-25SEP(DT)

* W07.32995 WIRING - TIMER THRI

* W07.34114 WIRED PROGRAMMED BOX THI 5-25/28 SEP GB/DK

* W07.34211 CONTROL BOX, PROGRAMMED, WIRED

* W07.34228 WIRED, PROGRAMM. CONTROL BOX THRI 5-25 M75H DC

* W07.34974 PROGRAMMED ; CONTROL BOX WIRING

* W07.35261 CONTROL BOX ; PROGRAMMED WIRING THI 2-17

* W07.35314 PROGRAMMED CONTROL BOX ; WIRING 2-17 B120

* W07.35319 PROGRAMMED CONTROL BOX ; WIRING 2-17 B120 DC

* W07.36535 WIRED & PROGRAMMED CONTROL BOX THI 5-25 B120 GB

* W07.36536 WIRED & PROGRAMMED CONTROL BOX THI 5-25 B120 DC

* W07.36930 CONTROL BOX ; WIRED ; PROGRAMMED

* W07.37986 SUPPLY CABLE 230V THRI

* W07.37991 CABLE TRANSFORMER+MASS THRI BURNER

* W07.37992 SWITCH CABLE THRI

* W07.37995 FAN CABLE THRI

* W07.37996 FAN CABLE THRI

* W07.37998 MASS CABLE THRI COVER

* W07.38000 SENSORS CONNECTION THRI

* W07.38001 CABLE PWM FOR THRI FAN

* W07.38002 FAN PWM CABLE THRI 10-50C

* W07.38004 SENSORS CONNECTION THRI 10-50 C

* W07.38379 FAN CABLE THRI/THISION/THI 10-50

* W09.37943 WIRING DHW SENSOR ZEM B120/SEP/M50

Reference

Designation

- 34 -

Loading...

Loading...