Page 1

Over 30 years experience in bakery business make Gemini a reliable partner for satisfying all

of your individual wishes.

Together with Gemini’s resources from our international partners Gemini’s technical and

engineering personnel can develop new ideas and concepts to meet your bakery’s needs.

Take profit of it!

Since 1972

Muffin / Cake

Batter Depositors

Creative Technology and Service for the Baking Industry

Gemini Bakery Equipment Company

9990 Gantry Road

Philadelphia, PA 19115—1002

(215) 673-3520 Fax: (215) 673-3944

sales@geminibe.com

www.geminibe.com

Item No. Gem-C2500257 August

Page 2

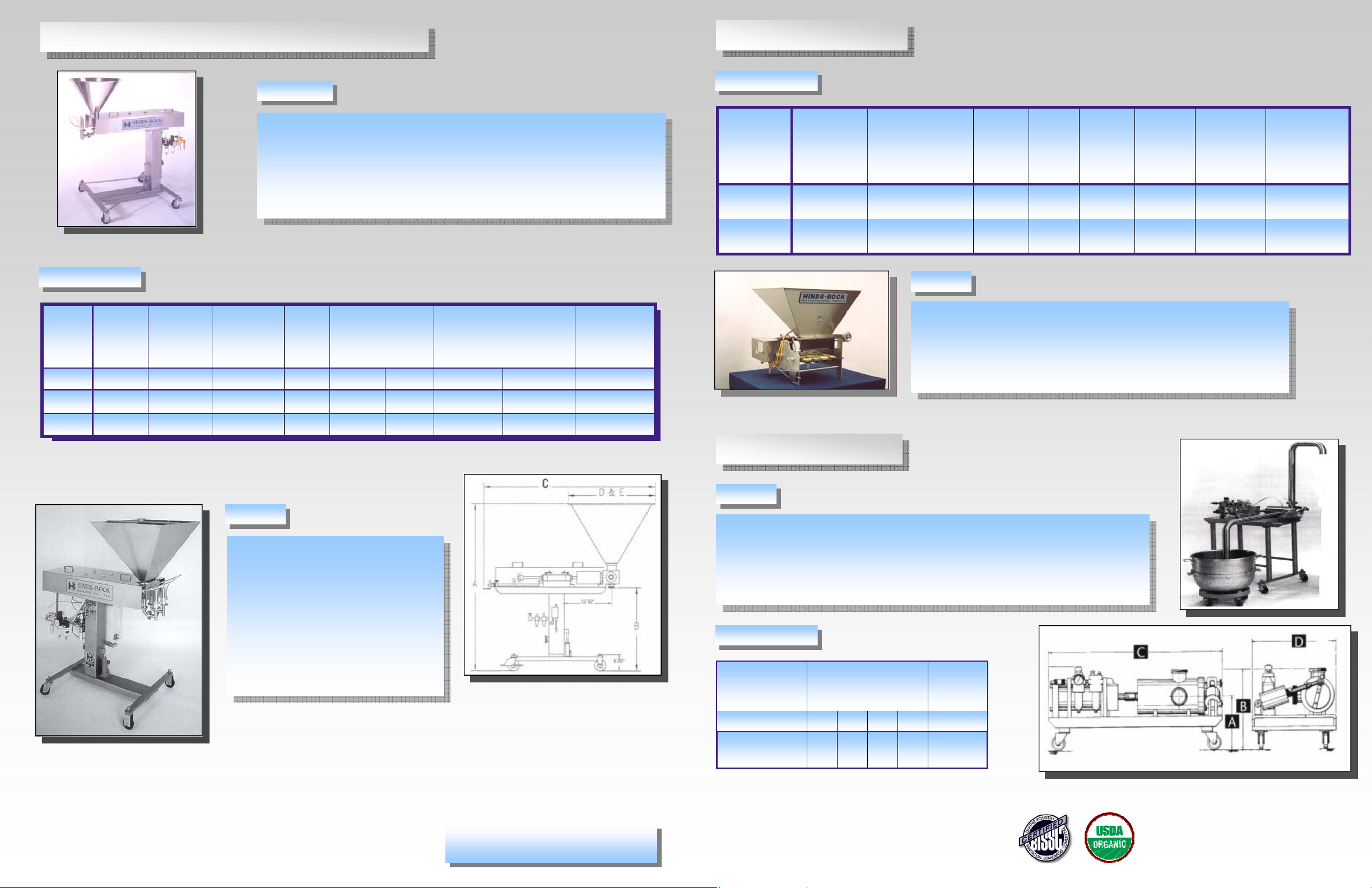

SP-64 Single & 2P-64 Dual Piston Models

Tabletop Depositors

Features

• Air powered - consult factory for compressed air requirements

• 14 inches of height adjustment

• Looking swivel casters

• Stainless steel construction with all contact parts of food-approved

materials

• Fills from fractions of an ounce to 64 ounces per piston with

change cylinders

Technical Data

Model No. of

pistons

(D) (E) volts Hz

SP-64 1 59” - 74” 33.5” - 43” 53” 25.75” N/A 115 60 4-6

Total-

Height

(A)

inches

Height to

Hopper

(B)

inches

Width

(C)

inches

Hopper Width

inches

Electrical

Air re-

quirements

@ 80 psi*

CFM

Technical Data

Model No. of

pistons

NT Series 3 or 4 35 1/2” 36” 36 1/4” 28 18 1/2” -

WT Series 4, 5, 6 or 7 35 1/2” 36” 44 1/4” 39 26 1/2” -

Deposit Weight

range

(for each piston

combination)

oz.

2-8

2-8

Benefits

• High productivity speeds payback

• High versatility increases utilization

• Gentle depositing improves product quality

• Short, unrestricted flow path and large port openings provide

gentle handling of delicate particulates

• Accurate scaling reduces costs

Height

inches

Length

inches

Hopper

Width

inches

* approx. CFM, contact us for exact CFM requirements

Hopper

Capacity

gallons

Pan

Width

inches

11”

18”

Air requirements @ 80

psi

CFM

8

8

2P-64 2 62”- 70” 35” - 43” 53” 25.75” 32.25” 115 60 6-8

* approx. CFM, contact us for exact CFM requirements

Benefits

• Improved quality when

depositing large, delicate

particulates damage free

• Reduced costs with accurate filling/depositing into trays, bottles,

cans, pouches, or targeted onto

product

• Improved payback with

versatility

• Ease of maintenance and

operation

P-64 Transfer Pump

Benefits

• Capable of handling products with large particulates with very little

product degradation or shearing of the pieces

• Pump comes apart in under a minute for ease of sanitation and

maintenance

• Manufactured of high quality stainless steel and designed for 3 shift a

day production

Technical Data

Max.

GPM

25 2.5” 10” 18” 36” 18” Air/

Port

Size

inches

A B C D

Dimensions

inches

Power

hydraulic

In an effort to consistently upgrade our products,

we reserve the right to change specifications and

dimensions without notice.

Loading...

Loading...