Page 1

Technical

Publication

Direction: FB091565

Revision 1

GE Medical Systems

GE Medical Systems

Vivid 5 Service Manual

OPERATING DOCUMENTATION

Copyright © 2000 and 2005 by General Electric Company Inc.

All Rights Reserved

Page 2

Page 3

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

LEGAL NOTES

The contents of this publication may not be copied or duplicated in any form, in

whole or in part, without prior written permission of GE Medical Systems.

GE Medical Systems may revise this publication from time to time without written

notice.

TRADEMARKS

All products and their name brands are trademarks of their respective holders.

COPYRIGHTS

All Material Copyright© 2000, 2005 by General Electric Inc. All Rights Reserved

Page i

Page 4

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

This page was intentionally left blank.

Page ii

Page 5

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

IMPORTANT PRECAUTIONS

LANGUAGE

WARNING

AVERTISSEMENT

• THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

• IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER

THAN ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

• DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

• FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO THE SERVICE

PROVIDER, OPERATOR OR PATIENT FROM ELECTRIC SHOCK,

MECHANICAL OR OTHER HAZARDS.

• CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

• SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS UNE AUTRE

LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL INCOMBE DE LE FAIRE

TRADUIRE.

• NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

• LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

WARNUNG

• DIESES KUNDENDIENST-HANDBUCH EXISTIERT NUR IN ENGLISCHER

SPRACHE.

• FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT,

IST ES AUFGABE DES KUNDEN FÜR EINE ENTSPRECHENDE ÜBERSETZUNG

ZU SORGEN.

• VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR DIESES

KUNDENDIENST-HANDBUCH NICHT ZU RATE GEZOGEN UND VERSTANDEN

WURDE.

• WIRD DIESE WARNUNG NICHT BEACHTET, SO KANN ES ZU

VERLETZUNGEN DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER

DES PATIENTEN DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER

SONSTIGE GEFAHREN KOMMEN.

Page iii

Page 6

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

AVISO

ATENÇÃO

• ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

• SI ALGÚN PROVEEDOR DE SERVICIOS AJENO A GEMS SOLICITA UN IDIOMA

QUE NO SEA EL INGLÉS, ES RESPONSABILIDAD DEL CLIENTE OFRECER UN

SERVICIO DE TRADUCCIÓN.

• NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN HABER

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

• LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

PROVEEDOR DE SERVICIOS, EL OPERADOR O EL PACIENTE SUFRAN

LESIONES PROVOCADAS POR CAUSAS ELÉCTRICAS, MECÁNICAS O DE

OTRA NATURALEZA.

• ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA DISPONÍVEL

EM INGLÊS.

• SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE DO CLIENTE FORNECER OS SERVIÇOS DE

TRADUÇÃO.

• NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

• O NÃO CUMPRIMENTO DESTE AVISO PODE POR EM PERIGO A SEGURANÇA

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A‘ CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

AVVERTENZA

• IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE SOLTANTO IN

INGLESE.

• SE UN ADDETTO ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE IL

MANUALE IN UNA LINGUA DIVERSA, IL CLIENTE È TENUTO A PROVVEDERE

DIRETTAMENTE ALLA TRADUZIONE.

• SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

• NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER

FOLGORAZIONE ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

Page iv

Page 7

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Page v

Page 8

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent

write “Damage In Shipment” on ALL copies of the freight or express bill BEFORE

delivery is accepted or “signed for” by a GE representative or hospital receiving

agent. Whether noted or concealed, damage MUST be reported to the carrier

immediately upon discovery, or in any event, within 14 days after receipt, and the

contents and containers held for inspection by the carrier. A transportation

company will not pay a claim for damage if an inspection is not requested within

this 14 day period.

CERTIFIED ELECTRICAL CONTRACTOR STATEMENT - FOR USA ONLY

All electrical Installations that are preliminary to positioning of the equipment at the

site prepared for the equipment shall be performed by licensed electrical

contractors. Other connections between pieces of electrical equipment,

calibrations and testing shall be performed by qualified GE Medical Systems

personnel. In performing all electrical work on these products, GE will use its own

specially trained field engineers. All of GE’s electrical work on these products will

comply with the requirements of the applicable electrical codes.

The purchaser of GE equipment shall only utilize qualified personnel (i.e., GE’s

field engineers, personnel of third-party service companies with equivalent training ,

or licensed electricians) to perform electrical servicing on the equipment.

OMISSIONS & ERRORS

If there are any omissions, errors or suggestions for improving this documen tation,

please contact the GE Healthcare Global Documentation Group with specific

information listing the system type, manual title, part number, revision number,

page number and suggestion details. Mail the information to : Service

Documentation, 4855 W. Electric Ave (EA-53), Milwaukee, WI 53219, USA.

GE Healthcare employees should use the iTrak System to report all documenta tion

errors or omissions.

Page vi

Page 9

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Revision History

REVISION DATE REASON FOR CHANGE

A 8. Aug. 2000 Initial release of manual

1 6. Jun. 2005 Updated with changes since the release of the first version of the manual.

List of Effected Pages

PAGES REVISION PAGES REVISION PAGES REVISION

Title Page 1 5-1 to 5-20 1 Back Cover N/A

i to xx 1 6-1 to 6-22 1

1-1 to 1-14 1 7-1 to 7-22 1

2-1 to 2-10 1 8-1 to 8-86 1

3-1 to 3-4 1 9-1 to 9-41 1

4-1 to 4-4 1 10-1 to 10-24 1

Page vii

Page 10

GE Medical Systems

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

This page was intentionally left blank.

Page viii

Page 11

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1-1 Purpose of Chapter 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1-2 Purpose of Service Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1-2-1 Typical Users of the Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3 Vivid 5 Models Covered by this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3-2 System History - Hardware/Software Versions. . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-1-3-3 Supported Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-1-3-4 How to Turn the Scanner ON and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-1-4 Purpose of Operator Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 1-2

Important Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-1 Conventions Used in Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-2 Standard Hazard Icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Section 1-3

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3-2 Human Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3-3 Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3-4 Temperature Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-5 Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-5-1 Safe Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-6 Dangerous Procedure Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-7 Lockout/Tagout Requirements (For USA Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-8 Returning/Shipping Probes and Repair Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Section 1-4

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-4-1 What is EMC?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-4-2 Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-4-3 Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Section 1-5

Customer Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-5-1 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-5-2 System Manufacture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table of Contents Page ix

Page 12

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 2

Pre Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 2-1

Purpose of Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 2-2

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2-1 Time and Manpower Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2-2 Important VIVID 5 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2-2-1 Physical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2-2-2 Weight without Monitor and Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2-2-3 Acoustic Noise Output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2-3 EMI Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2-4 Purchaser Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Section 2-3

Facility Needs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3-1 Required Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3-2 Desirable Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3-3 Minimal Floor Plan Suggestion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Section 2-4

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-4-1 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-4-2 Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4-3 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4-4 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Section 2-5

Electrical Needs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-5-1 VIVID 5 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-5-2 Site Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-5-3 Site Power Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-5-4 Unit Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page x

Page 13

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 3-1

Purpose of Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 3-2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2-1 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2-2 EMI Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Section 3-3

Receiving and Unpacking the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Section 3-4

Preparing the Unit for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4-1 Check the Unit Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4-1-1 Check Voltage Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4-1-2 Video Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Section 3-5

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-5-1 Electrical Safety Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-5-2 Paperwork. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-5-2-1 User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page xi

Page 14

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 4

Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section 4-1

Purpose of chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section 4-2

General Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2-1 Connect a Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2-2 Power On/Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2-3 Stand By/Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section 4-3

Functional Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3-1 Basic System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3-2 Check of Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 4-4

Mechanical Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-4-1 Check of Wheels/Locks/Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 4-5

Site Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Page xii

Page 15

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 5

Theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 5-1

Purpose of chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 5-2

VIVID 5 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2-1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2-2 Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2-3 Ultrasound Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2-4 Functional Subsystems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2-4-1 Front End (FE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2-4-2 Mid Processors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2-4-3 Display and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2-4-4 Keyboard, I/O and Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Section 5-3

Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3-1 Front End (FE) Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3-2 Mid Processor Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3-3 Display and Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3-4 Keyboard, I/O and Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Section 5-4

Power System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-4-1 AC Power Supply with ON/OFF Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-4-2 AC Power Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-4-3 DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-4-4 3.3V DC/DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-4-5 High Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-4-6 Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-4-7 Front End and Mid. Processors Block Diagram 5-9

5-4-8 Display, Control and Input/Output (I/O) Block Diagram 5-10

5-4-9 Front End Block Diagram 5-11

5-4-10 Mid Processor Block Diagram 5-12

5-4-11 Display Block Diagram 5-13

5-4-12 Internal I/O and External I/O Block Diagram 5-14

5-4-13 Connector Layout of Vivid 5 Internal I/O-2 Board (IIO-2) . . . . . . . . . . . . . . . . . . . . . . 5-15

5-4-14 Signal List, Internal I/O-2 (IIO-2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5-4-15 Connector Layout of Vivid 5 External I/O-2 Board (EIO-2)) . . . . . . . . . . . . . . . . . . . . 5-17

5-4-16 Insulation Diagram, External I/O-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-4-17 Signal Insulation List, External I/O-2 (EIO-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Section 5-5

Video Specifications for VIVID 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5-5-1 PAL Video Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5-5-2 NTSC Video Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Page xiii

Page 16

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 6

Service Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Section 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Section 6-2

Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Section 6-3

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3-1 Setup Menu Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3-2 Date, Time and Hospital Name Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Section 6-4

Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4-1-1 Abstract. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4-2 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-3 Initial Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-3-1 Configuration/Test Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-3-2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-3-3 Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-3-4 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-4 Automatic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-4-1 Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4-5 Front Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-4-5-1 Start of Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-4-5-2 Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-3 LED Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-4 Key Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-5 Rotary Knob Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-6 Paddle Stick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-7 TGC Slide pot. Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-5-8 Trackball Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4-6 Transmit Pulse Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4-7 Transmit Trigger (TXTRIG) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4-8 ATGC Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4-9 High Voltage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4-9-1 HV1 and HV2 Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4-10 DC Voltage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4-10-1 Measuring DC Voltages on the INT I/O Power Connector(s):. . . . . . . . . . . . 6-6

6-4-10-2 Watching LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-4-10-3 Measuring DC Voltages on th e Motherboard.. . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-4-11 Peripheral and I/O Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-11-1 PAL/NTSC Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-11-2 Record and Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-11-3 Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-11-4 Footswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-12 External I/O Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-12-1 Video out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-12-2 S-VHS Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Page xiv

Page 17

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

6-4-12-3 RGBS Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-4-12-4 MAC Interface Test - Stand Alone MAC only . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-12-5 ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-12-6 Phono . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-12-7 Respiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-12-8 Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-13 Integrated Mac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-13-1 Setup Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-13-2 Macintosh with Continuous Capture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-4-13-3 Communication with Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-4-14 Mechanical Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-4-14-1 Checking Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-4-14-2 Checking Monitor Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-4-15 Hardware Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-4-15-1 Screen Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-4-15-2 VCR Recording. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-4-15-3 EchoPac-3D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-4-16 Monitor Setup (Adjust if Necessary, ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-4-16-1 Screen Manager (Main Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-16-2 Pre Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-16-3 Adjust Convergence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-16-4 Geometry and Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-17 Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-17-1 2D Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4-17-2 Doppler Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-4-17-3 Color Flow controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-4-17-4 MPTE Test (PAMPTE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-4-18 M-Mode Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-4-18-1 Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-4-18-2 Color M-mode Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-4-19 Image Quality and Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-4-19-1 2D Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-4-19-2 Doppler Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-4-19-3 Color Flow Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-4-20 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-4-21 Hardware Revision Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Section 6-5

Probe Element Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Section 6-6

Element to Channel Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-6-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-6-2 192 Element Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-6-2-1 Troubleshooting Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6-6-3 128 Element Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6-6-4 96 Element Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

6-6-5 64 Element Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6-6-6 Stand Alone Doppler Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Page xv

Page 18

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 7

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Section 7-1

Minimum Boot Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-1 Minimum Board Configuration for System to Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-1-1 Boards Needed to Boot to the So-called "No-mode" Screen . . . . . . . . . . . . 7-1

7-1-1-2 Boards Needed for 2D Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-1-3 Boards Needed for Any Test Purposes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-1-4 Boards That May be Left Out Without any Special Modifications. . . . . . . . . 7-2

7-1-1-5 Boards That Must be Replaced by a VME Jumpe r When Removed . . . . . . 7-2

7-1-2 Minimum Cable Configuration for System to Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Section 7-2

Faults Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-2-1 Instructions on How to Use This chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-2-2 Fault Classification Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Section 7-3

Start-up Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7-3-1 System Doesn’t Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7-3-2 Start-up Problems, AC Power Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7-3-3 Start-up Problems, DC Power Related (AC Power ok). . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7-3-4 Start-up Problems, System Doesn’t Boot, Possible Hard Disk Problem. . . . . . . . . . . . 7-7

7-3-5 Start-up Problems, System Doesn’t Boot, Possible Board Problem. . . . . . . . . . . . . . . 7-8

Section 7-4

Display Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7-4-1 No Display on Monitor, Monitor Display is Black (System Appears to Have Booted). . 7-9

7-4-2 No Display in the Image Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7-4-3 Data in Image Field Frozen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7-4-4 Only Noise in Image Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Section 7-5

Peripheral Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7-5-1 VCR Related Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Section 7-6

Front Panel Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7-6-1 No Response to Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Section 7-7

Probe Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7-7-1 Probe Recognition and Switching Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Section 7-8

Specific 2D Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7-8-1 “Frozen” Images, Images with Artifacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7-8-2 Noisy Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7-8-3 Poor Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7-8-4 Only Center Part of FLA Probes Image Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Page xvi

Page 19

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Section 7-9

Specific Color Flow Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7-9-1 No Color Flow (2D ok) or Frozen Color Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7-9-2 Noise Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7-9-3 Poor Flow Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Section 7-10

Specific Doppler Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7-10-1 No Doppler (2D ok). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7-10-2 Noisy Doppler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Section 7-11

Analog Traces (ECG, Phono, Pressure, Respiration). . . . . . . . . . . . . . . . 7-21

7-11-1 Unstable ECG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Section 7-12

Misc. Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7-12-1 Fan Related Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Page xvii

Page 20

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 8

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Section 8-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-1-1 Purpose of Chapter 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-1-2 Returning/Shipping Probes and Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-1-3 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Section 8-2

AC Power Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2-2 Tool Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2-3-1 Prepare the system for AC Power Replacement . . . . . . . . . . . . . . . . . . . . . 8-3

8-2-3-2 Remove the AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8-2-3-3 Install the New AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Section 8-3

External I/O Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8-3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8-3-2 Tool requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8-3-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Section 8-4

DC Power Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8-4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8-4-2 Tool requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8-4-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Section 8-5

Front Panel Assembly & Trackball Replacement Procedure . . . . . . . . . . . 8-7

8-5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8-5-2 Tool Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8-5-3 Front Panel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8-5-4 Trackball Replacement Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Section 8-6

QWERTY (Alphanumeric) Keyboard Replacement Description . . . . . . . . . 8-8

Section 8-7

Fan Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8-7-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8-7-2 Tool requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8-7-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Section 8-8

Hard Disk Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8-8-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8-8-2 Tool requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8-8-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Page xviii

Section 8-9

Internal I/O Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Page 21

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

8-9-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8-9-2 Tool requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8-9-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Section 8-10

Monitor Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8-10-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8-10-2 Tool requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8-10-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Section 8-11

Relay Board Assembly, Replacement Procedure . . . . . . . . . . . . . . . . . . . 8-13

8-11-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8-11-2 Tool requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8-11-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Section 8-12

Temperature Sense Board Replacement Procedure . . . . . . . . . . . . . . . . 8-14

8-12-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8-12-2 Tool requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8-12-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Section 8-13

Rear Wheels Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-1 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-2 Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-3 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-4 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-5 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8-13-6 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Section 8-14

Front Wheels Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-1 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-2 Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-3 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-4 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-5 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-14-6 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Section 8-15

Front Bumper Support, Replacement Procedure . . . . . . . . . . . . . . . . . . . 8-17

8-15-1 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-15-2 Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-15-3 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-15-4 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-15-5 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-15-6 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Section 8-16

Macintosh Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-16-1 Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-16-2 Assembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Section 8-17

Page xix

Page 22

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Side Bumper Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8-17-1 Side Bumper Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8-17-2 Side Bumper Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Section 8-18

Software Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

8-18-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

8-18-2 Introduction to Software Re-load or Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-2-1 Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-2-2 Effectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-2-3 Time to Complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-2-4 Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-2-5 EchoPAC Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8-18-3 Preparations Prior to Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

8-18-3-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

8-18-3-2 RS-232C “Non Modem” Connection to a Vivid 5 Scanner . . . . . . . . . . . . . 8-24

8-18-3-4 Laptop with 10 Mbit PC LAN Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

8-18-3-6 Laptop Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

8-18-3-8 Create Work Folder on the Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8-18-3-9 Start the Terminal Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8-18-3-15Record VCR Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

8-18-3-16Record EchoPAC Related Parameters (Supervision ONLY) . . . . . . . . . . . 8-37

8-18-4 Identify the Vivid 5 Scanner’s IP Address and Netmask . . . . . . . . . . . . . . . . . . . . . . . 8-40

8-18-5 Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

8-18-5-1 Start FTP Session. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

8-18-5-3 Erase/Initialize the Scanner’s Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 8-51

8-18-5-6 Transfer User Defined Settings File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-53

8-18-5-8 Close the FTP Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

8-18-6 Unpack the Scanner Software Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-18-6-1 Unpack the System Software File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-18-6-2 Unpack the “svision” File (if needed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-18-6-3 Unpack the User Defined Settings File. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-18-6-4 Reboot the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

8-18-7 Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-7-1 Verify Successful Software Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-7-2 Verify the VCR Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-7-3 Verify the EchoPAC Parameters (Supervision ONLY) . . . . . . . . . . . . . . . . 8-56

8-18-8 Finalizing Software Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-8-1 Close and Disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-9 Complete the Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-9-1 Set Spectrum Caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-9-2 FE Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

8-18-10Functional Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-57

Page xx

Section 8-19

Using a Hummingbird FTP Server for the Software Upgrade . . . . . . . . . . 8-58

8-19-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-58

Section 8-20RS-232C “Non Modem” Connection to a Vivid 5 Scanner . . 8-58

8-20-1 Ethernet Connection to Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-59

8-20-1-1 Laptop with 10 Mbit PC LAN Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-59

8-20-2 Laptop Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-60

8-20-3 Create Directories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-61

Page 23

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

8-20-4 Create Work Folder on the Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-61

8-20-5 Configure and Start the Terminal Program (Hyper Terminal). . . . . . . . . . . . . . . . . . . 8-61

8-20-5-1 Start the Terminal Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-61

8-20-6 Scanner Power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-70

8-20-7 Identify the Vivid 5 Scanner’s IP Address and Netmask. . . . . . . . . . . . . . . . . . . . . . . 8-71

8-20-8 Identify Vivid 5’s Version via the Terminal (optional) . . . . . . . . . . . . . . . . . . . . . . . . . 8-72

8-20-9 Record and Change the Laptop’s Native IP Address . . . . . . . . . . . . . . . . . . . . . . . . . 8-73

8-20-9-1 Exit BlackICE on Laptop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-73

8-20-10Copy Correct Softwar e File s to th e work Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-76

8-20-11Open Command Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-77

8-20-12Verify Change of Laptop IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-78

8-20-13Verify Connection Between Laptop and Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-80

8-20-14Enable Hummingbird FTP Server :. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-81

8-20-15Change BootSequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-83

8-20-16Formatting the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-84

8-20-17Install the New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-85

8-20-18Disable Hummingbird FTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-86

Page xxi

Page 24

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 9

Renewal Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Section 9-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1-1 Purpose of Chapter 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1-2 Equipment Models Covered by this Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Section 9-2

List of Abbrevations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Section 9-3

Parts List Groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Section 9-4

Software Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9-4-1 VIVID 5 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9-4-2 EchoPAC MAC Software and MAC OS (for Internal Macintosh) . . . . . . . . . . . . . . . . . 9-6

9.4.3 EchoPAC 3D for Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Section 9-5

Plastic Parts, Console, Top and Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9-5-1 External Details, Front and Right Side, VIVID 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.5.2 External Details, Rear and Left Side, VIVID 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Section 9-6

Operator Panel Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9-6-1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Section 9-7

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9-7-1 M onitors - Cathode Ray Tube (CRT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.7.2 S5/V5 Monitor Replacement Assembly, FC200537 . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9-7-3 Monitors - Liquid Crystal Display (LCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Section 9-8

Input/Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Section 9-9

PCB Boards - Card Cage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9-9-1 Card Cage’s Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

9.9.2 Front End Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

9.9.3 MID and Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Section 9-10

Power Distribution Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Section 9-11

Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Page xxii

Section 9-12

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Section 9-13

Cables for Vivid 5 Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Section 9-14

Page 25

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Cables for Internal MAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9-14-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9-14-2 Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

9.14.3 ECG Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Section 9-15

Integrated (Internal) Macintosh with EchoPAC . . . . . . . . . . . . . . . . . . . . . 9-30

Section 9-16

Internal Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

9-16-1 Footswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

Section 9-17

External Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

Section 9-18

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9-18-1 CLA Probes, Curved Linear Array Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9-18-2 ECLA Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9-18-3 FLA, Flat Linear Array Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9-18-4 FPA, Flat Phased Array Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.18.5 PAMPTE Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.18.6 Doppler Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

9-18-7 Intraoperative Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

Section 9-19

Service Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

Section 9-20

Other Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

Section 9-21

Product Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

9-21-1 Manuals for Vivid 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

9-21-2 Manuals for EchoPAC (MAC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

9-21-3 Manuals for EchoPAC 3D for Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

Section 9-22

EchoPAC 3D Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

Page xxiii

Page 26

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 10

Care & Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Section 10-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10-1-1 Periodic Maintenance Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10-1-2 Purpose of Chapter 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Section 10-2

Why do Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10-2-1 Keeping Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10-2-2 Quality Assurance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Section 10-3

Maintenance Task Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10-3-1 How often should maintenance tasks be performed?. . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Section 10-4

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10-4-1 Special Tools, Supplies and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Section 10-5

System Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10-5-1 Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10-5-2 Functional Checks (See Also Chapter 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10-5-2-1 System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10-5-2-2 Peripheral/Option Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10-5-3 Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10-5-3-1 Mains Cable Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10-5-4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10-5-4-1 General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10-5-4-2 Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10-5-5 Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10-5-6 Probe Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10-5-6-1 Probe Related Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10-5-6-2 Basic Probe Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10-5-6-3 Basic Probe Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Page xxiv

Section 10-6

Electrical Safety Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10-6-1 Safety Test Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10-6-2 GEMS Leakage Current Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10-6-3 Outlet Test - Wiring Arrangement - USA & Canada . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10-6-4 Grounding Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10-6-4-1 Meter Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

10-6-5 Chassis Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10-6-5-1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10-6-5-2 Generic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10-6-5-3 Data Sheet for Chassis Source Leakage Current. . . . . . . . . . . . . . . . . . . 10-15

10-6-6 Isolated Patient Lead (Source) Leakage–Lead to Ground . . . . . . . . . . . . . . . . . . . . 10-15

10-6-6-1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

10-6-6-2 Generic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10-6-7 Isolated Patient Lead (Source) Leakage–Lead to Lead . . . . . . . . . . . . . . . . . . . . . . 10-16

Page 27

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

10-6-8 Isolated Patient Lead (Sink) Le ak ag e -Is ola tio n T est . . . . . . . . . . . . . . . . . . . . . . . . 10-17

10-6-8-1 Data Sheet for ECG Leakage Current . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

10-6-9 Probe Leakage Current Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

10-6-9-1 Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

10-6-9-2 Generic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

10-6-9-3 No Meter Probe Adapter Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10-6-9-4 Data Sheet for Transducer Source Leakage Current. . . . . . . . . . . . . . . . 10-21

Section 10-7

When There's Too Much Leakage Current... . . . . . . . . . . . . . . . . . . . . . . 10-22

Page xxv

Page 28

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Page xxvi

Page 29

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

Chapter 1

Introduction

Section 1-1

Overview

1-1-1 Purpose of Chapter 1

This section describes important issues related to safely servicing this ultrasound machine. The

service provider must read and understand all the information presented here before installing or

servicing a unit.

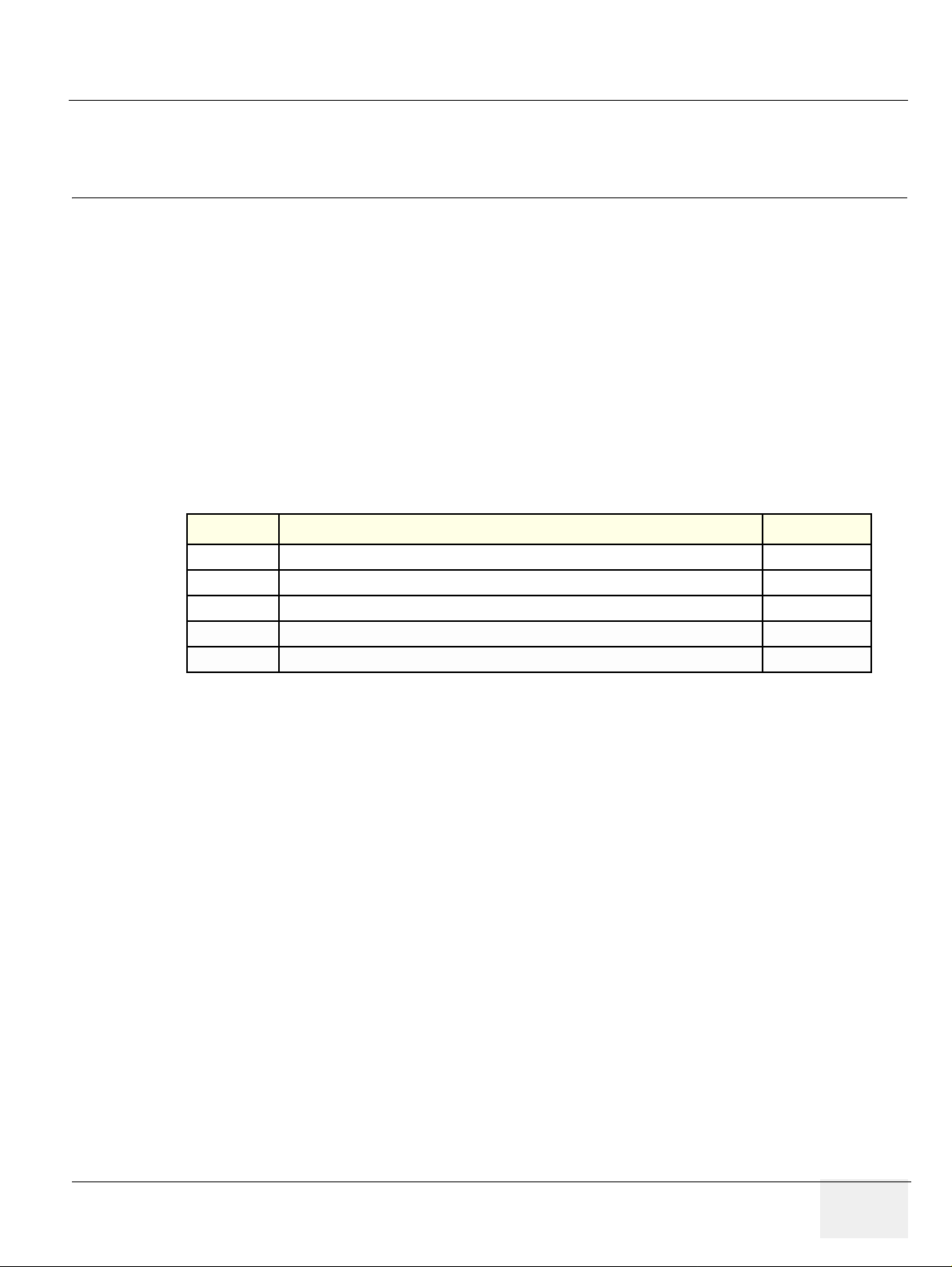

Table 1-1 Contents in Chapter 1

Section Description Page Number

1-1 Overview 1-1 1-2 Important Conventions 1-5 1-3 Safety Considerations 1-7 1-4 Electromagnetic Compatibility (EMC) 1-10 1-5 Customer Assistance 1-12

1-1-2 Purpose of Service Manual

This Service Manual provides installation and service information for the VIVID 5 Ultrasound

Scanning unit and contains the following chapters:

1.) Chapter 1 - Introduction: Contains a content summary and warnings.

2.) Chapter 2 - Pre Installation: Contains any pre-installation requirements for the VIVID 5.

3.) Chapter 3 - Installation: Contains installation procedure with installation checklist.

4.) Chapter 4 - Functional Checks: Contains functional checks that must be performed as part of

the installation, or as required during servicing and periodic maintenance.

5.) Chapter 5 - Theory: Contains block diagrams and functional explanations of the electronics.

6.) Chapter 6 - Service Adjustments: Contains instructions on how to make any available

adjustments to the VIVID 5.

7.) Chapter 7 - Diagnostics: Provides procedures for runn ing and diagnostic or related routines for

the VIVID 5.

8.) Chapter 8 - Replacement Procedures: Provides disassembly procedures and reassembly

procedures for changeable FRUs.

9.) Chapter 9 - Renewal Parts: Contains a complete list of replacement parts for VIVID 5.

10.) Chapter 10 - Care & Maintenance: Provides care and maintenance procedures for VIVID 5.

Page 1 - 1

Page 30

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

1-1-2-1 Typical Users of the Service Manual

• Service Personnel (installation, maintenance, etc.).

• Hospital’s Service Personnel

• Architectural Planners/Installation Planners (some parts of Chapter 2, Pre-Installation)

1-1-3 Vivid 5 Models Covered by this Manual

Table 1-2 VIVID 5 Models Covered in this Manual

GE VINGMED

PART NUMBER

FB000223 VIVID 5 (BT’00) 240V

FB000224 VIVID 5 (BT’00) 110V

FB000225 VIVID 5 (BT’00) 100V

FB000711 VIVID 5 (BT’00) 120V

FB000712 VIVID 5 U with integrated EchoPAC 120V

FB000713 VIVID 5 230V

FB000714 VIVID 5 U with integrated EchoPAC 230V

FB000750 VIVID 5 with NTSC 240V

FB000751 VIVID 5 U with integrated EchoPAC 100V

FB000753 VIVID 5 100V

FB000880 VIVID 5 Pro 240V

FB000890 VIVID 5 Expert 240V

FC000040 VIVID 5 Pro US with integrated EchoPAC 110V

FC000050 VIVID 5 Expert US with integrated EchoPAC 110V

FC000080 VIVID 5 Eur. 230V

DESCRIPTION VOLTAGE

1-1-3-1 Overview

• VIVID 5 is a phased and linear array ultrasound imaging scanner. It also has provisions for

• The unit can be used for:

• VIVID 5 is a digital beam forming unit and can handle up to 192 element linear probes by use

• Signal flow from the Probe Connector Panel to the Front End, then to the Mid Processors and

• System configuration is stored on a hard disk and all necessary software is loaded from the

Page 1 - 2

analog input sources like ECG and phono, and a Doppler probe may be connected and used

too.

- 2D Black and White imaging

- 2D Color Flow

- M-Mode Black and White imaging

- Color M-Mode

- Doppler

- a number of combinations of the above

of multiplexing.

Backend Processor and finally to the monitor and peripherals.

hard disk on power up.

Page 31

GE MEDICAL SYSTEMS

P

ART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

1-1-3-2 System History - Hardware/Software Versions

This procedure describes how to display the system software revision:

1.) Press the SETUP button

2.) Select Configuration & Test

3.) Select SW

Both the system software revision and the revision of the local DSP software will be shown.

Use Table 1-1 to verify the correct/needed revision on each card in the Card Rack.

Note: The Master Control Document (MCD) Revision is printed on a label on the board or module.

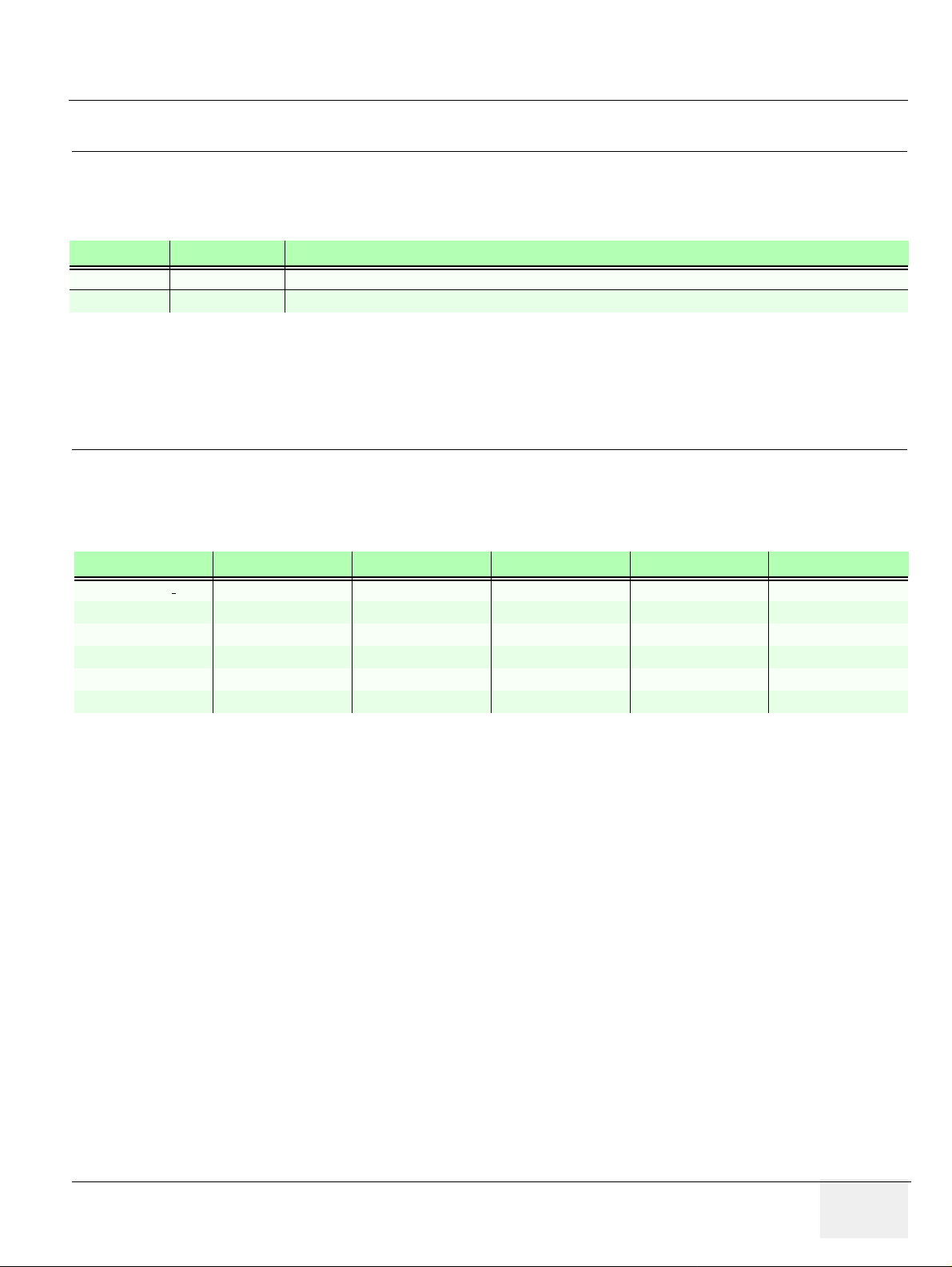

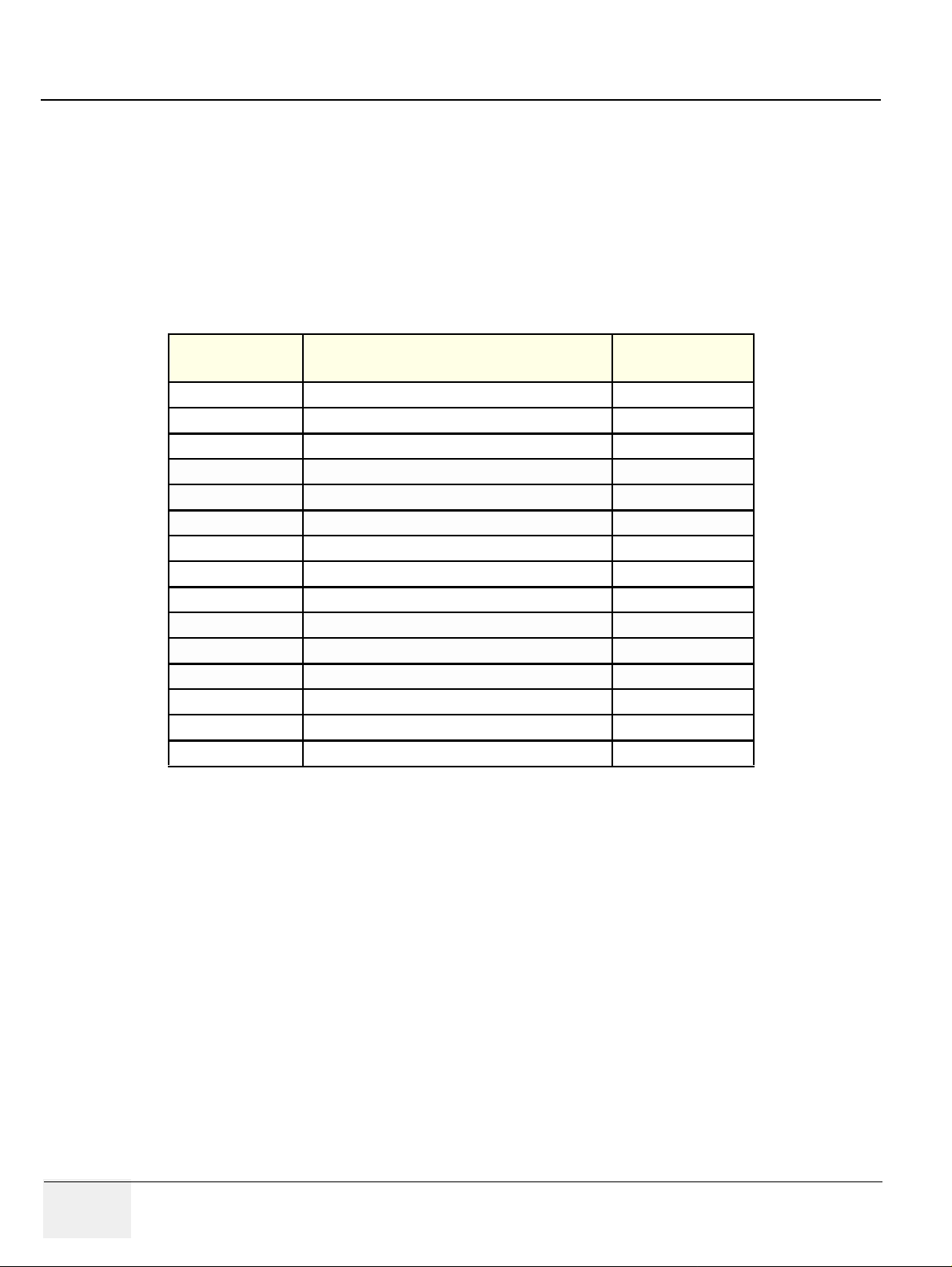

Table 1-1 Required Revisions for Cards and Modules

CARDS AND MODULES

v2.0.6

Latest

Part Number Name

FA200890 RLY-2 A B

FA200799 RLY-PAL-PB2 A A Piggyback, ESD protection. Plugs into FA200890

FB200211 TX128-2 A A

FA200907 RX128-2 A C

FB200191 XD BUS A B

FA200550 BF64-2 A B

FB200900 BF64-3 A E

FB200024 3.3V DC/DC A A

FA200764 FEC A I

FB200140 RFT A D Rev B and Rev C can be interchanged.

FA200026 SDP G K Rev. K includes a noise fix

FA200027 CFP C D

FB200708 CFP-2 A B

FA200572 IMAGE PORT 2 A E

FA200030 GRAPH K M

FB200818 GRAPH B B

FA200029 SCONV I K

066E2700

066E2701

066E2702

FB200005 INT I/O B D

FB200006 EXT I/O B D

FB200196

FA200063 HV POWER F G

FA200107 AC CCTRL D E

FA200191 FP MAIN BOARD-2 R R

Fb200245 FRONT PANEL A C

PATIENT I/O MODULE 2,

CPU

COMPLETE

A A

MCD CommentsMCD

NO MCD REVISION ON THESE BOARDS.

NEW PART NUMBER WAS PULLED FOR EACH CHANGE.

Page 1 - 3

Page 32

GE MEDICAL SYSTEMS

PART NUMBER FB091565, REVISION 1 VIVID 5 SERVICE MANUAL

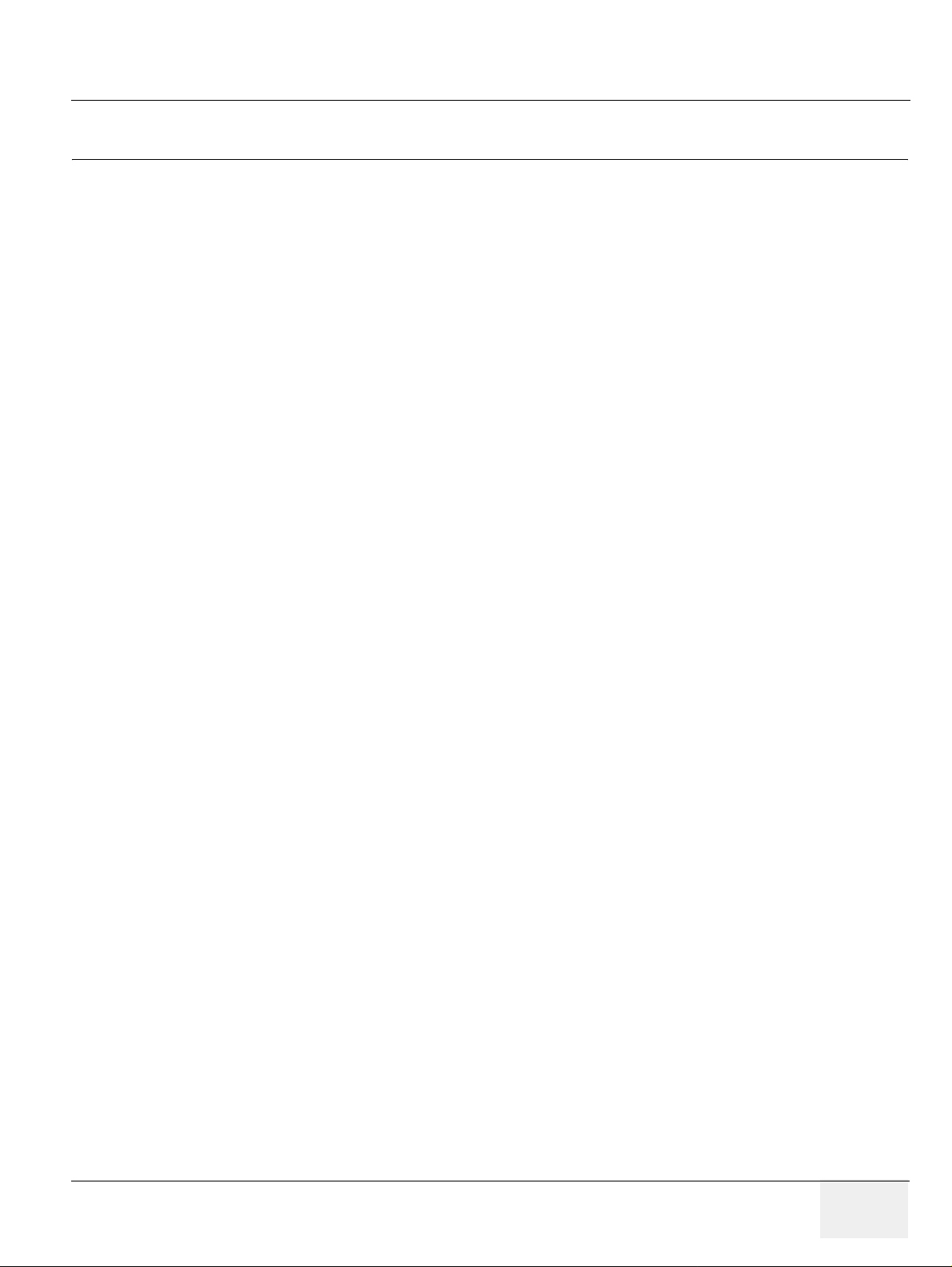

Table 1-1 Required Revisions for Cards and Modules (cont’d)

CARDS AND MODULES

v2.0.6

Part Number Name

FB200246 FRONT PANEL W/LCD4" A D

FB200177 ROTARY & DISPLAY BOARD 4 A A

FA200076 FP AUDIO AMPLIFIER BOARD A E

FB200561

FB200172 MBD A A

FA200248 IV & DP F F

FA200075

FA200034 DC POWER E E

FA200231 AC POWER SUPPLY D D

FA200040

FA200114

QWERTY KEYBOARD

SUBASSY

VME BG/IACK JUMPER (VME

JUMPER)