Page 1

TM

Page 2

Revision History

The revision letter identifies the document’s update level and changes with every update of the manual.

Part Number and Revision Date Comment

2025653-048A 10/2006 Initial Release

2025653-048B 10/2007 Updated LCD cable routing picture;

Updated from version 2.12 software to

version 2.22; Added safety information

for Hellige test lamp; Added Service

Sticker orderable part number

2025653-048 Revision B Responder™ 2000 Page ii

Page 3

TABLE OF CONTENTS

R

EVISION HISTORY

........................................................................................................................

II

SECTION 1: INTRODUCTION ........................................................................................................8

O

VERVIEW

D

ESCRIPTION

C

ONTROLS AND INDICATORS

G

ENERAL SERVICE INFORMATION

Navigation..............................................................................................................................11

Passwords .............................................................................................................................11

Battery Maintenance..............................................................................................................11

SECTION 2: MAINTENANCE .......................................................................................................12

O

VERVIEW

E

QUIPMENT SETUP

Required Tools ......................................................................................................................13

Procedure ..............................................................................................................................13

Upgrade Software..................................................................................................................14

U

PGRADE PRINTER SOFTWARE

U

PDATE SERIAL AND MODEL NUMBERS

SECTION 3: TROUBLESHOOTING .............................................................................................18

O

VERVIEW

S

AFETY PRECAUTIONS

W

HO SHOULD PERFORM REPAIRS

S

ERVICE/REPLACEMENT PARTS

D

ISPOSAL

R

EPAIR TOOLS AND EQUIPMENT

T

ROUBLESHOOTING GUIDE

General Troubleshooting .......................................................................................................20

No Boot..................................................................................................................................21

Boot, but no Response ..........................................................................................................21

Bad Front Panel LEDs...........................................................................................................22

Buttons do not Work ..............................................................................................................22

Bad Speaker..........................................................................................................................23

Display is Dim, Dark, Fuzzy, or Unreadable .........................................................................23

Printing Problems ..................................................................................................................23

Battery Troubleshooting ........................................................................................................24

SpO2 Not Working.................................................................................................................24

Shock into Paddle Dock Fails................................................................................................24

Shock into Patient Fails .........................................................................................................25

.....................................................................................................................................8

.................................................................................................................................9

.........................................................................................................10

.................................................................................................11

...................................................................................................................................12

......................................................................................................................13

....................................................................................................16

.........................................................................................17

...................................................................................................................................18

.................................................................................................................19

................................................................................................19

....................................................................................................19

....................................................................................................................................19

...................................................................................................20

...........................................................................................................20

A. If the AC Power LED is not lit ..................................................................................................... 21

B. If the AC Power LED is lit ........................................................................................................... 21

A. If the ECG trace is not moving.................................................................................................... 21

B. The Rotary Selection knob works properly ................................................................................. 21

C. The Rotary Selection knob does not work properly .................................................................... 21

A. The Rotary Selection knob does not work properly .................................................................... 22

B. The Rotary Selection knob works properly ................................................................................. 22

A. If the Display is Dim.................................................................................................................... 23

B. If the Display is Dark, Fuzzy, or Unreadable .............................................................................. 23

2025653-048A Page

iii

Page 4

No ECG from Paddles/Pads/Spoons ....................................................................................25

Service Required LED is ON.................................................................................................25

SECTION 4: REPAIR ....................................................................................................................26

O

VERVIEW

R

EQUIRED TOOLS

D

ISASSEMBLY OVERVIEW

H

OW TO REPLACE SPECIFIC COMPONENTS

Capacitors (see page 47) ......................................................................................................28

Therapy Board (see page 46) ...............................................................................................28

SPO2 Board (see page 45) ...................................................................................................29

ECG Board (see page 41) .....................................................................................................29

Display/Main Board/Printer (see page 43) ............................................................................30

Power Supply and Power Control Board (see page 37) .......................................................30

Switches and Fan (see page 37)...........................................................................................30

A

SSEMBLY

Overview................................................................................................................................31

Paddle Latch Assembly.........................................................................................................31

Main Board and Printer Installation .......................................................................................32

Power Control Board and Power Supply Installation ............................................................36

ECG Board Installation ..........................................................................................................40

Display Installation.................................................................................................................42

SPO2 Board Installation .........................................................................................................44

Therapy Board Installation ....................................................................................................45

Capacitor Installation .............................................................................................................46

Rear Cover Installation ..........................................................................................................47

S

ECTION 5: PERFORMANCE VERIFICATION AND SAFETY TESTING

O

VERVIEW

R

EQUIRED EQUIPMENT

P

REVENTIVE MAINTENANCE

A

NNUAL INSPECTION

V

ERIFY OPERATION

Checkout Procedures ............................................................................................................52

M

AINTENANCE MENU REFERENCE

Service Tests.........................................................................................................................54

Device Configuration .............................................................................................................58

Stored Data Management .....................................................................................................58

2025653-048 Revision B Responder™ 2000 Page iv

...................................................................................................................................26

........................................................................................................................27

.............................................................................................................27

...................................................................................28

Main Board...................................................................................................................................... 30

Printer ............................................................................................................................................. 30

...................................................................................................................................31

...................................................50

...................................................................................................................................50

.................................................................................................................51

..........................................................................................................51

....................................................................................................................51

......................................................................................................................52

................................................................................................53

Button Test...................................................................................................................................... 54

Printer Speed Test .......................................................................................................................... 55

Battery Readings............................................................................................................................. 55

Display Test .................................................................................................................................... 56

ECG Lead Test ............................................................................................................................... 56

Temperature Readings ................................................................................................................... 57

Fan Test.......................................................................................................................................... 57

Select Language ............................................................................................................................. 58

Clear Event Logs............................................................................................................................. 58

Clear Service Required Indicator .................................................................................................... 58

Clear Settings Menu Password....................................................................................................... 58

Clear All Stored Data ...................................................................................................................... 58

Page 5

Send Event Logs to PC................................................................................................................... 58

Send/Receive Stored Parameters .................................................................................................. 59

V

ISUAL INSPECTION

O

PERATIONAL TESTS

Initial Power Up .....................................................................................................................60

Maintenance Mode Tests ......................................................................................................61

Verify Serial Communications ............................................................................................... 61

Required Equipment ....................................................................................................................... 61

Procedure ....................................................................................................................................... 61

Defibrillator Tests................................................................................................................... 62

Energy Timeout Test....................................................................................................................... 62

Defibrillator Test Chart.................................................................................................................... 62

Paddles Test................................................................................................................................... 63

Pads Test........................................................................................................................................ 63

Spoons Test.................................................................................................................................... 63

Pacing Test............................................................................................................................64

ECG Tests .............................................................................................................................65

Required Equipment ....................................................................................................................... 65

ECG Connections Test ................................................................................................................... 65

Lead Detection Test........................................................................................................................ 66

ECG Lead Test ............................................................................................................................... 67

Paddles ECG Test .......................................................................................................................... 68

Thermal Printer Operation .....................................................................................................68

Cardioversion Test ................................................................................................................68

SpO2 Operation .....................................................................................................................68

S

AFETY TESTS

Hipot Test ..............................................................................................................................69

Required Equipment ....................................................................................................................... 69

ECG to Serial 4.0 KVAC Test ......................................................................................................... 70

AC Line/Neutral to AC Ground 1.5 KVAC Test ............................................................................... 70

ECG to SpO2 1.5 KVAC Test.......................................................................................................... 70

Apex Test Load to Apex and Sternum 3.0 KVDC Test ................................................................... 71

ECG to Apex and Sternum 3.0 KVDC Test..................................................................................... 71

Apex and Sternum to Service Port 3.0 KVAC Test ......................................................................... 71

Leakage Current Test............................................................................................................72

Required Equipment ....................................................................................................................... 72

Equipment Setup ............................................................................................................................ 72

Test Procedure ............................................................................................................................... 75

A

LTERNATE SAFETY TEST PROCEDURES

Test Equipment .....................................................................................................................75

Leakage Current “Measurement Device” (MD) Characteristics ............................................ 76

Tests......................................................................................................................................76

Visual Inspection............................................................................................................................. 76

Leakage Current ............................................................................................................................. 77

Patient Leakage Current to Ground ......................................................................................80

Patient Leakage Current, Mains on Applied Part (All SIP/SOPs Grounded) ........................83

Insulation Resistance...................................................................................................................... 85

......................................................................................................................60

...................................................................................................................60

.............................................................................................................................69

.......................................................................................75

SECTION 6: PARTS AND ACCESSORIES.................................................................................. 86

O

VERVIEW

K

ITS

A

CCESSORIES

2025653-048 Revision B Responder™ 2000 Page v

...................................................................................................................................86

............................................................................................................................................87

..............................................................................................................................92

Page 6

P

OWER CORDS

............................................................................................................................94

SECTION 7: THEORY OF OPERATION ......................................................................................95

O

VERVIEW

S

YSTEM OVERVIEW

Functions ...............................................................................................................................96

Features ................................................................................................................................96

S

YSTEM INTERCONNECTION BLOCK DIAGRAM

C

OMPONENT DESCRIPTIONS

Main Board ............................................................................................................................98

Therapy Board.......................................................................................................................98

ECG Board ............................................................................................................................98

Power Control Board .............................................................................................................98

SpO2 Board............................................................................................................................98

SECTION 8: SPECIFICATIONS AND SAFETY............................................................................99

O

VERVIEW

S

PECIFICATIONS

P

HYSICAL DIMENSIONS

E

NVIRONMENTAL REQUIREMENTS

Operating Conditions...........................................................................................................102

Storage and Shipping Conditions........................................................................................102

RHYTHM

Detection Rate.....................................................................................................................103

Fine VF ................................................................................................................................103

Asystole ...............................................................................................................................103

Noise Detection ...................................................................................................................103

Non-Committed Shock ........................................................................................................103

Sync Mode...........................................................................................................................104

SVT (Supraventricular Tachycardia) Discriminators ...........................................................104

SVT Rate .............................................................................................................................104

Continuous Monitoring For Shockable Rhythm...................................................................104

Pacemaker Pulse Information .............................................................................................104

STAR

Energy Levels and Patient Impedance................................................................................106

E

LECTROMAGNETIC COMPATIBILITY REQUIREMENTS

Emissions ............................................................................................................................107

Immunity ..............................................................................................................................107

E

NVIRONMENTAL STANDARDS

Shock and Vibration ............................................................................................................108

Storage and Shipping ..........................................................................................................108

E

LECTROMAGNETIC EMISSIONS TABLE

E

LECTROMAGNETIC IMMUNITY TABLE

RF C

C

ONNECTORS

Case ....................................................................................................................................114

2025653-048 Revision B Responder™ 2000 Page vi

...................................................................................................................................95

......................................................................................................................96

................................................................................97

.........................................................................................................98

...................................................................................................................................99

........................................................................................................................100

...............................................................................................................102

...............................................................................................102

X®

ECG A

®

BIPHASIC D

OMMUNICATIONS TABLE

Power Connector – IEC 320 type – AC Power.............................................................................. 114

Paddles/Pads Connector – GE Defibrillator Paddles .................................................................... 114

Paddle Connector ID Codes ......................................................................................................... 115

ECG Connector – GE ECG Connector – Five lead ECG .............................................................. 115

NALYSIS ALGORITHM

EFIBRILLATION WAVEFORM

.....................................................................................................108

.....................................................................................................113

............................................................................................................................114

...................................................................................103

.........................................................................105

....................................................................107

........................................................................................109

..........................................................................................110

Page 7

ECG Cable Identification Encoding............................................................................................... 116

SpO2 Connector – GE SpO2......................................................................................................... 117

Serial Service Connector – DB9-Female ...................................................................................... 117

Paddle Cradles (Test Load) .......................................................................................................... 117

MAIN CPU PCBA ................................................................................................................118

J211 - Power Control Interface to Power Control PCBA ............................................................... 118

J214 – LCD Panel......................................................................................................................... 119

J213 – LCD CCFL Backlight ......................................................................................................... 120

J218 – UI Interface to Power Control PCBA ................................................................................. 121

J216 – SPEAKER ......................................................................................................................... 123

J219 – PRINTER HEAD ............................................................................................................... 123

J220 – PRINTER MOTOR ............................................................................................................ 124

J221 – SpO2 INTERFACE ............................................................................................................ 124

J210 – THERAPY PCBA .............................................................................................................. 125

J212 – ECG PCBA ....................................................................................................................... 125

THERAPY PCBA.................................................................................................................126

J103 - Power Supply..................................................................................................................... 126

J110 – Main CPU PCBA interface ................................................................................................ 126

J109 – Paddles Control Connector ............................................................................................... 127

J101, J102, J108 – Paddles HV Connectors ................................................................................ 127

J104, J105, J106, J107 – Energy Storage Capacitor Connectors ................................................ 128

J126, J127 – Internal Test Load Resistor ..................................................................................... 128

ECG PCBA ..........................................................................................................................128

J412 – Interface to main CPU PCBA ............................................................................................ 128

J423 – Patient ECG Connection ................................................................................................... 129

POWER CONTROL PCBA .................................................................................................129

J315 – Power input from DC power supply................................................................................... 129

J325 – Smart Battery Connector – Data and Power ..................................................................... 129

J303 – Therapy power .................................................................................................................. 130

J311 – Power Control interface from main CPU PCBA................................................................. 130

J318 – UI Features - Interface to main CPU PCBA ...................................................................... 131

J317 – RS-232 SERIAL SERVICE INTERFACE .......................................................................... 132

J323 – FAN................................................................................................................................... 133

J324 – ENCODER “Trim Knob” .................................................................................................... 133

J2 - SpO2 HOST INTERFACE ...................................................................................................... 133

SpO2 PATIENT INTERFACE........................................................................................................ 134

POWER SUPPLY MODULE ...............................................................................................134

TB1 – POWER INPUT.................................................................................................................. 134

POWER OUTPUT ........................................................................................................................ 134

BATTERY ............................................................................................................................135

J325 – Smart Battery Connector – Data and Power ..................................................................... 135

C

ONTACT INFORMATION/CUSTOMER SERVICE

.............................................................................136

2025653-048 Revision B Responder™ 2000 Page vii

Page 8

SECTION 1: Introduction

SECTION 1: Introduction

Overview

This Service manual provides information needed to service the Responder™ 2000. This manual should only be used by

technical personnel trained to service the Responder 2000.

This chapter contains general information for servicing the Responder 2000.

This Service manual assumes familiarity with the controls and basic operation of the Responder 2000. Detailed

information regarding controls, operation, set-up, and regular maintenance procedures are found in the Operator’s

manual. If necessary, review the Operator’s Manual before servicing the Responder 2000.

TOPIC

Description 9

Controls and Indicators 10

General Service Information 11

PAGE

2025653-048 Revision B Responder™ 2000 Page 8

Page 9

SECTION 1: Introduction

Description

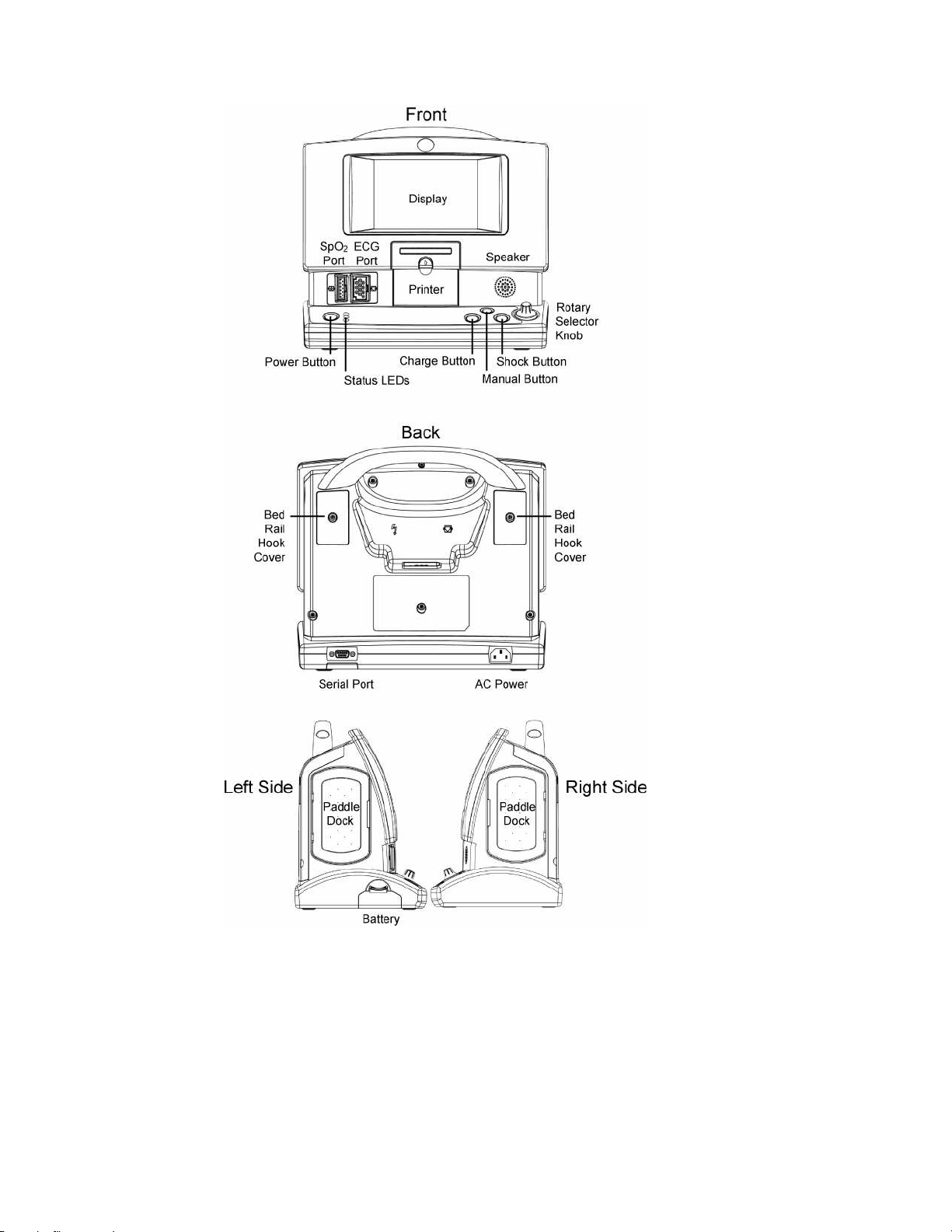

The Responder 2000 is a defibrillator/monitor/pacemaker intended for use by personnel trained in its operation. The

device is lightweight, portable, easy to use and reliable. It incorporates a 320 x 240 transmissive color TFT color display

for wide viewing angles in all light conditions. The device operates using either an AC power supply or internal

rechargeable Li-Ion battery. The device provides continuous ECG monitoring and three types of therapies: defibrillation,

cardioversion and external pacing. Defibrillation can be applied manually or semi-automatically. Pacing therapy can be

either fixed or demand. The device employs patented RHYTHMx

Biphasic waveform delivers impedance-compensated energy ranging from 2-270 Joules. Features and options include

external paddles, spoons, disposable pads, 3- and 5-lead ECG, pulse oximetry (SpO2), built-in 60 mm thermal printer,

internal storage of event history and remote synchronization to bedside monitor.

®

software which provides ECG rhythm analysis. STAR®

2025653-048 Revision B Responder™ 2000 Page 9

Page 10

Controls and Indicators

SECTION 1: Introduction

2025653-048 Revision B Responder™ 2000 Page 10

Page 11

SECTION 1: Introduction

General Service Information

Refer to the Operator’s Manual for setup (and configuration options) required before placing the Responder 2000 into

service.

Navigation

Use the Rotary Selection knob to navigate the Responder 2000 user interface. The Rotary Selection knob is used for:

• Scrolling through menus and sub-menus

• Selecting soft keys

• Setting values

Passwords

The default service password is “HEART1”. See the note under Maintenance Mode Tests in Section 5 (on page 54) for

detailed password instructions.

Battery Maintenance

The Responder 2000 has a rechargeable battery requiring periodic calibration. Calibration consists of a full charge, full

discharge, and full charge of the battery. The cycle may take up to 20 hours to complete.

To calibrate the battery using the optional external charger:

1. Insert the battery into the external charger.

2. Press the calibration button on the battery. The Mode light turns red to indicate calibration in progress.

To stop calibration, press the calibration button again. The Mode light turns green and the battery begins to

charge.

To calibrate the battery without the external charger:

1. Insert the battery into the Responder 2000.

2. Plug the Responder 2000 into an AC outlet.

3. Allow the battery to fully charge.

4. Disconnect the AC power cord and leave on the Responder 2000 until the battery is fully discharged (full

discharge takes about four hours).

5. Reconnect the AC power cord and allow the battery to fully charge.

2025653-048 Revision B Responder™ 2000 Page 11

Page 12

SECTION 2: Maintenance

Overview

Use the following procedures to upgrade the Responder 2000 software:

• Upgrade Software to update one or more software files

• Upgrade Printer Software to upgrade printer software and fonts

TOPIC PAGE

Equipment Setup 13

Upgrade Software 14

Upgrade Printer Software 16

Update Serial and Model Numbers 17

SECTION 2: Maintenance

2025653-048 Revision B Responder™ 2000 Page 12

Page 13

SECTION 2: Maintenance

Equipment Setup

Required Tools

• Serial Cable

• PC (Windows 2000 or XP)

Procedure

1. Plug AC power cord.

Note: When performing a software upgrade, the Responder 2000 must be running on AC power.

2. Connect serial cable between the communications port of the PC and the serial port of the Responder 2000.

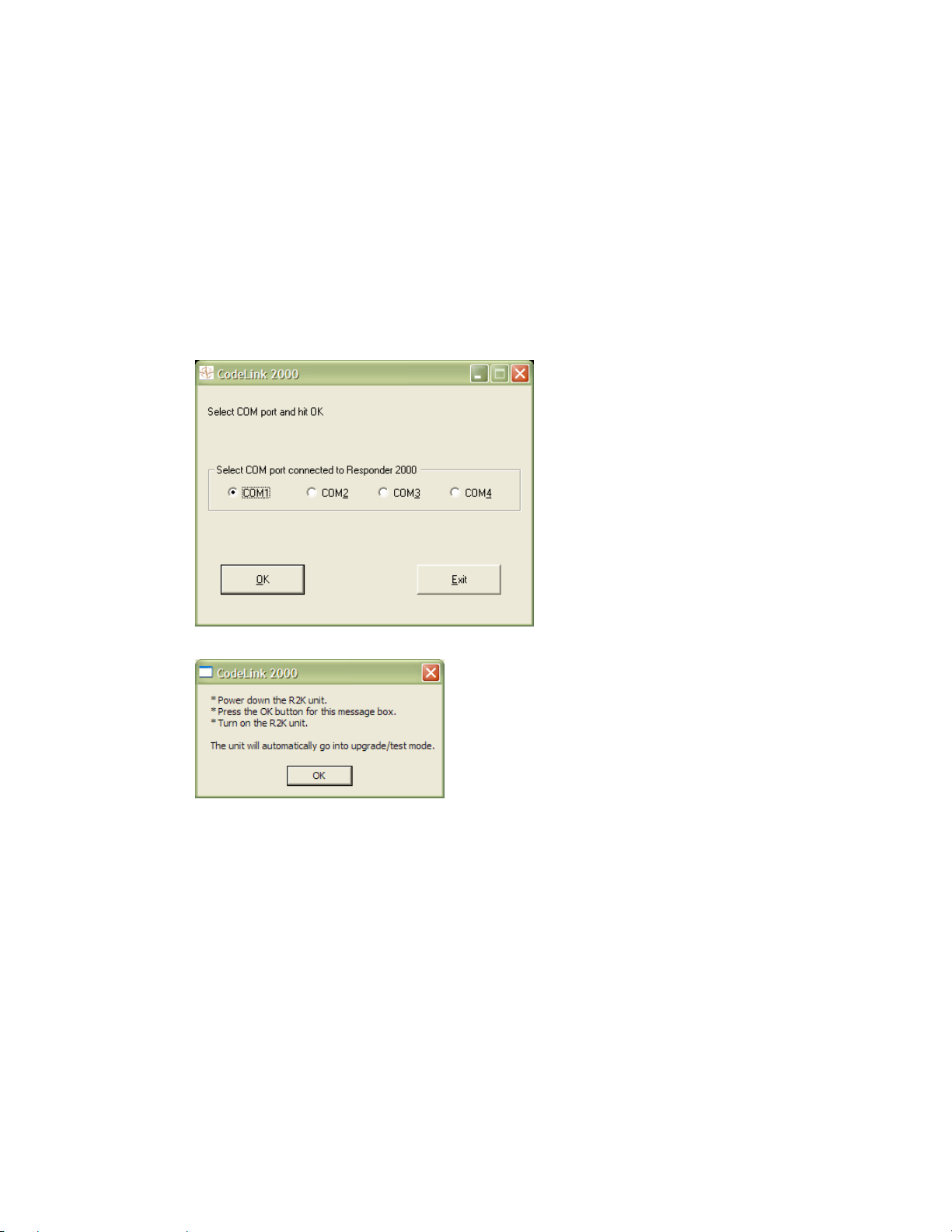

3. At the desktop on the PC, double-click the Responder 2000 Upgrade icon to open the CodeLink 2000 program.

4. Select the appropriate Com port and click OK.

5. Complete the following on-screen instructions and click OK.

2025653-048 Revision B Responder™ 2000 Page 13

Page 14

SECTION 2: Maintenance

Upgrade Software

Caution: Procedure Failure

Do not use this procedure to update the printer files. Updating the printer files incorrectly may cause the printer to fail. Use

the Upgrade Printer Software procedure on page 16.

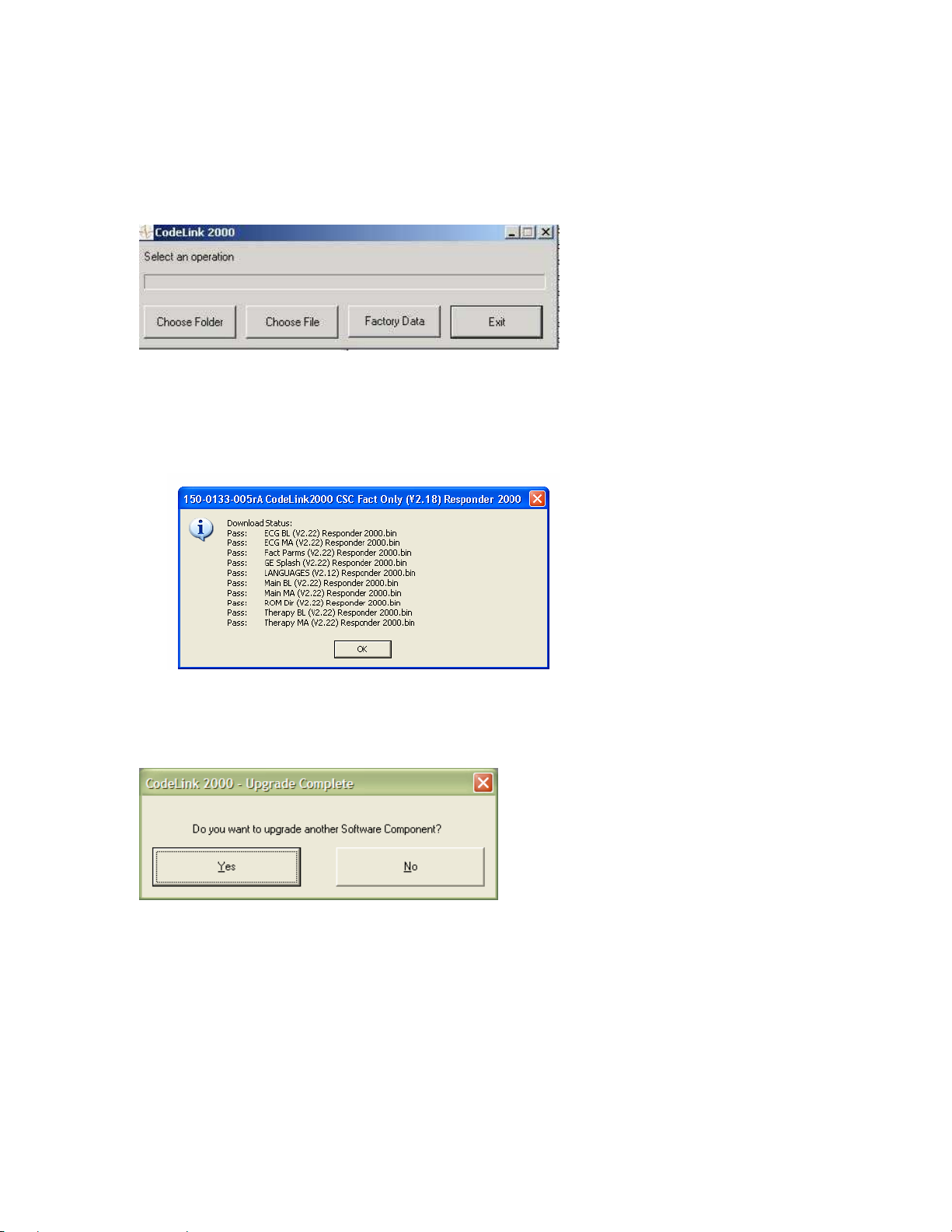

1. Perform the Equipment Setup procedure starting on page 13 until the CodeLink 2000 selection window is

displayed:

2. Click Choose folder to select all the update files in a folder or Choose file to select a single update file.

3. Browse to the folder (or file) to be uploaded and click OK (or Open). While the files are updating, the status of

each file is displayed.

As the files are updated, the Shock button and then the Manual button flash on the Responder 2000. When all

files are updated, a confirmation screen is displayed

4. Verify Pass is displayed for each file and click OK.

Note: If a file fails to update, retry updating the file individually.

The Upgrade Complete Notification is displayed:

5. Click Yes to upgrade more files (and repeat this procedure from step 2) or No to exit.

2025653-048 Revision B Responder™ 2000 Page 14

Page 15

SECTION 2: Maintenance

6. Click Exit.

7. Verify the file upgrade on the Responder 2000.

A text file with the software version numbers is included with the upgrade folder. Compare those software

version numbers to the versions listed on the Responder 2000.

a. Press and hold the Power button for 5 seconds to reboot the Responder 2000.

b. Highlight and click the System Menu.

c. Click About.

d. Click Next to scroll through the version screens. Verify all software versions are updated as listed in the

Version.txt file.

2025653-048 Revision B Responder™ 2000 Page 15

Page 16

SECTION 2: Maintenance

Upgrade Printer Software

When installing the printer software, the files must be upgraded in the following order without reboot:

• printerflash.bin

• printerfont.bin

• printerflash.bin again

Caution: Procedure Failure.

The printer files must be updated without reboot. If the unit is rebooted during the installation, the printer may not work

(the Main Board firmware must then be reinstalled at a repair center).

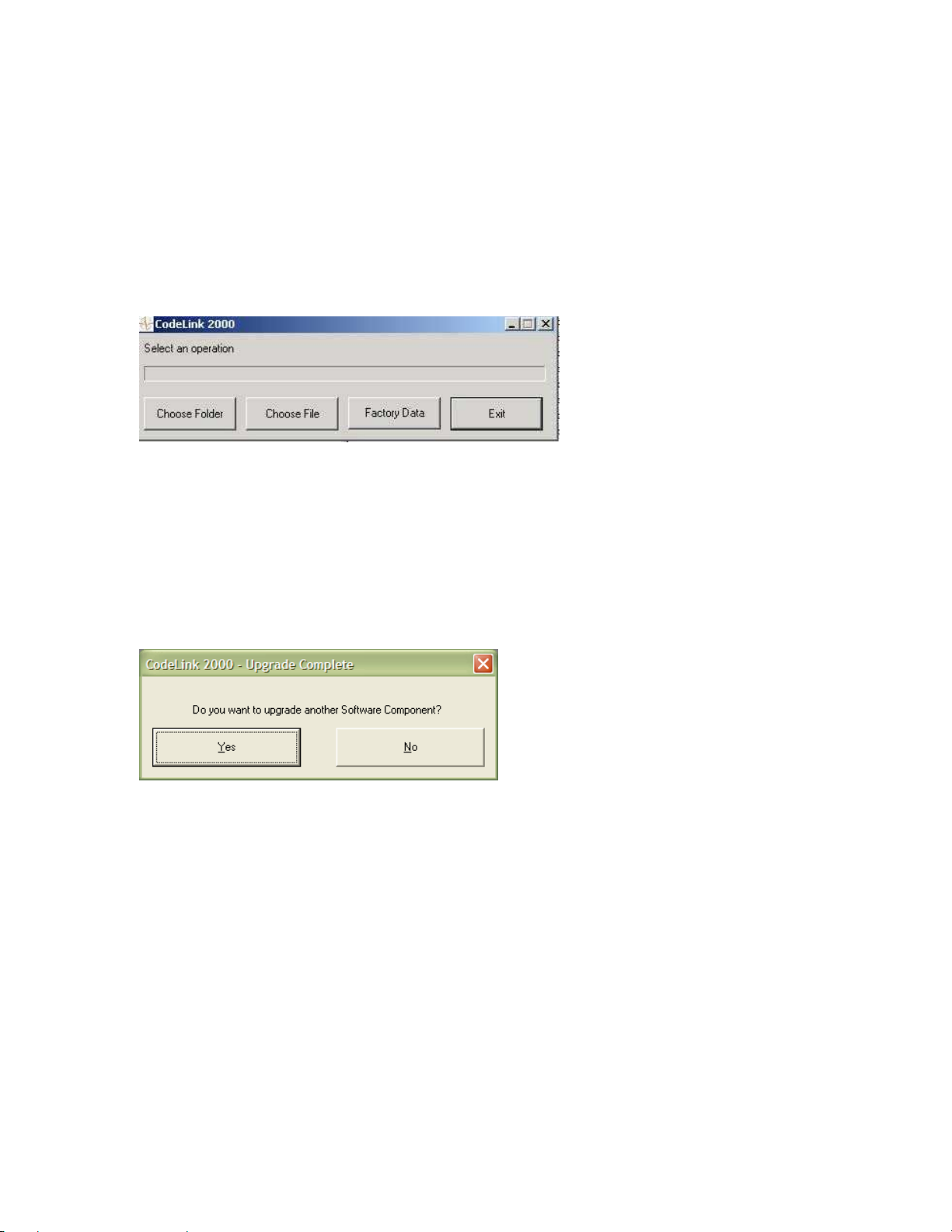

1. Perform the Equipment Setup procedure starting on page 13 until the CodeLink 2000 selection window is

displayed:

2. Click Choose file to select a single update file.

3. Navigate to the Printer folder and select the printerflash.bin file.

4. Click Open. While the file is updating, the status of the file is displayed.

As the file is updated, the Shock button and then the Manual button flash on the Responder 2000.

5. When the file is updated, a confirmation screen is displayed:

6. Verify Pass is displayed for the file and click OK.

Note: If the file fails to update, try updating the file again.

The Upgrade Complete Notification is displayed:

7. Click Yes and repeat this procedure for the printerfont.bin file and then the printerflash.bin again.

8. Click Exit.

9. Verify the file upgrade on the Responder 2000.

a. Press and hold the Power button for 5 seconds to reboot the Responder 2000.

b. Highlight and click the System Menu.

c. Click About.

d. Click Next to scroll through to the printer version screen. Verify the Printer and Font software versions are

updated as listed in the Version.txt file.

2025653-048 Revision B Responder™ 2000 Page 16

Page 17

SECTION 2: Maintenance

Update Serial and Model Numbers

When replacing the Main Board, the Serial and Model numbers must be updated.

1. Before replacing the Main Board, record the Serial and Model numbers from the About screen.

Note: If the Responder 2000 cannot be booted, record the model and serial number from the back panel label.

2. Replace the Main Board.

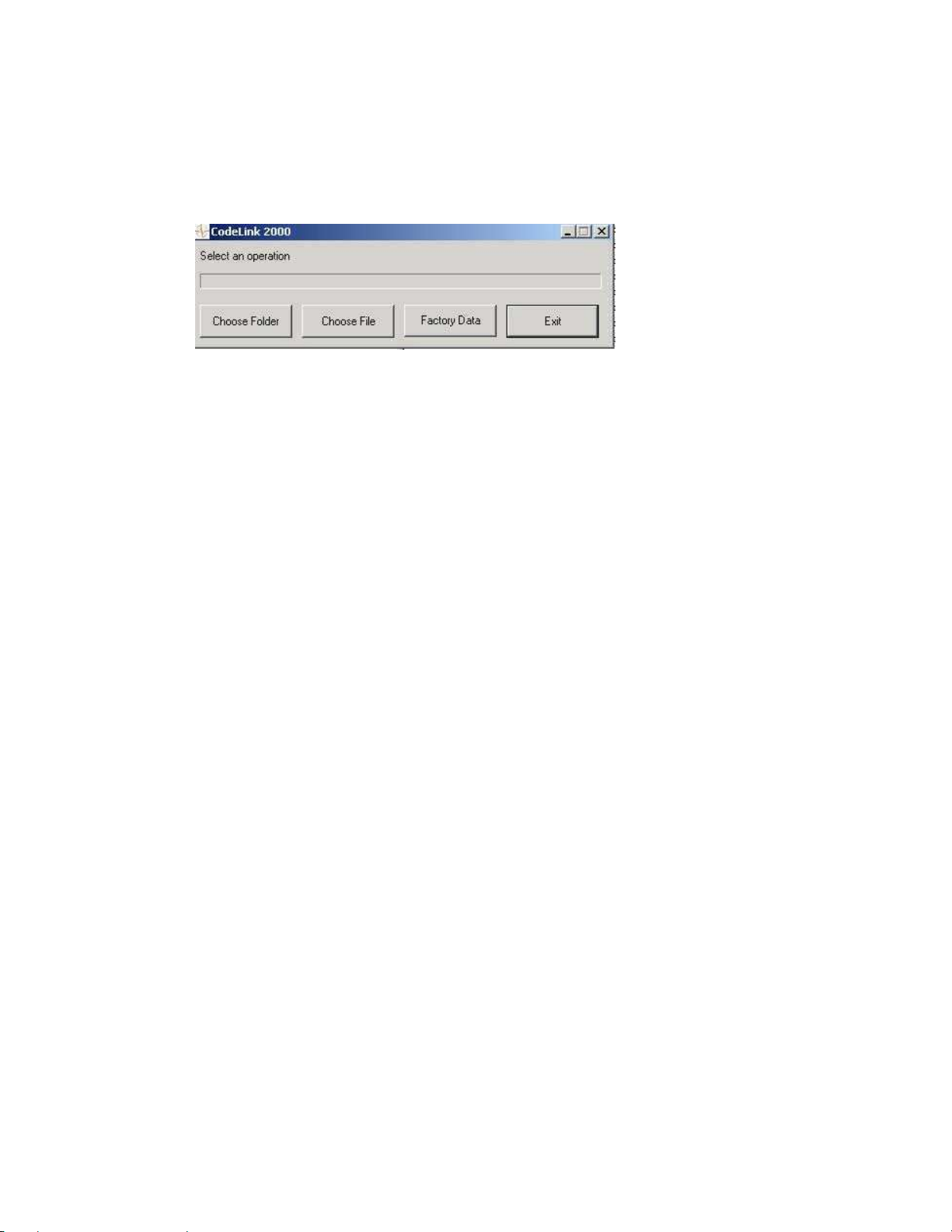

3. Perform the Equipment Setup procedure starting on page 13 until the CodeLink 2000 selection window is

displayed:

4. Click Update Factory Data and enter the previously model and serial numbers.

Note: If the Main Board is not replaced, the fields are not editable.

5. Click OK to accept.

2025653-048 Revision B Responder™ 2000 Page 17

Page 18

SECTION 3: Troubleshooting

SECTION 3: Troubleshooting

Overview

This section describes how to troubleshoot the Responder 2000. These instructions are intended for use only by service

providers who are specifically trained to service the Responder 2000.

TOPIC PAGE

Safety Precautions 19

Who Should Perform Repairs 19

Service/Replacement Parts 19

Disposal 19

Repair Tools and Equipment 20

Troubleshooting Guide 20

2025653-048 Revision B Responder™ 2000 Page 18

Page 19

SECTION 3: Troubleshooting

Safety Precautions

WARNING: Shock Hazard

The Responder 2000 is designed to deliver high-voltage therapeutic shock. Before performing any service on the

equipment, read and follow all safety precautions and instructions in the Operator’s Manual.

WARNING: Shock Hazard or Equipment Damage

Before servicing the Responder 2000, disconnect the AC power cord and remove the battery.

WARNING: Shock Hazard or Equipment Damage

Internal components of the Responder 2000 may still contain high voltages even after the AC power cord and battery are

removed. Before working on any internal component, verify high voltages are not present.

WARNING: Shock Hazard or Equipment Damage

Some service activities require the Responder 2000 to be energized with covers removed. Ensure all personnel and

equipment is clear while the equipment is energized.

WARNING: Biological Contamination

During normal operation, the Responder 2000 may be contaminated by blood, body fluids, or other biological agents.

Always assume the Responder 2000 is contaminated and use appropriate safety procedures until decontamination is

performed. Always decontaminate the Responder 2000 in accordance with hospital or facility procedures before servicing

or returning to service. Refer to the Responder 2000 Operator's Manual for recommended cleaning agents and

instructions

Caution: Electrostatic Damage

Always use a wrist grounding strap and anti-static mat while performing service on any internal components.

Caution: Voiding Product Warranty

Any service performed on the Responder 2000 must be provided by authorized service representatives only.

Unauthorized repair voids the product warranty.

Who Should Perform Repairs

Repair and service of the Responder 2000 must be performed by qualified service technicians trained in safe and proper

servicing of the Responder 2000.

Service/Replacement Parts

For service, please contact your local GE agency. For additional information, please visit our Web site at:

http//www.gehealthcare.com.

Please have the serial and model numbers available when contacting Customer Service. (The serial and model numbers

are located on the back (and on the inside) of the Responder 2000.)

Disposal

Always dispose of the Responder 2000, any unserviceable parts or accessories, or batteries in accordance with any local

disposal regulations for equipment containing electronic parts. Note the following precautions:

WARNING: Shock Hazard

Disposal of the Responder 2000 with the battery inserted presents a potential shock hazard.

WARNING: Environmental Contamination

Disinfect the Responder 2000 appropriately prior to disposal. Also recycle or dispose of the lithium-ion battery in

accordance with applicable local regulations.

WARNING: Fire or explosion hazard

Do not burn or incinerate the battery. Recycle or dispose of the lithium-ion battery in accordance with applicable local

regulations.

Caution: Environmental Contamination

Dispose of the pads or electrodes in accordance with any local disposal regulations.

2025653-048 Revision B Responder™ 2000 Page 19

Page 20

SECTION 3: Troubleshooting

Repair Tools and Equipment

The following tools are needed to perform the procedures in this section.

• TR15 Safety Torx

• TR25 Safety Torx

• Serial cable for software upgrades (with Windows 2000 or XP PC)

• Software upgrade kit

Troubleshooting Guide

General Troubleshooting

Before performing any troubleshooting, check the following:

Ensure all external cables and connections are tight and undamaged.

• If possible, ensure the unit is plugged in to a receptacle with appropriate voltage available (see SECTION 8:

Specifications and Safety for voltage requirements). If no receptacle is available, use a known good, charged

battery to perform any tests.

• Visually inspect the unit for any obvious external damage, including cracks in the display, case, or connectors.

• Ensure all connector pins and sockets are clean, free of debris, and intact.

• Discuss the issues with the operator:

o Have the operator explain and demonstrate the problem.

o Ask about any previous repairs or problems.

o Has the unit been stressed (including extreme heat/cold, submersion, falls, etc.)?

2025653-048 Revision B Responder™ 2000 Page 20

Page 21

SECTION 3: Troubleshooting

No Boot

Use this procedure to troubleshoot the Responder 2000 when plugged into an AC outlet. For battery troubleshooting,

including an operation failure while using the battery, see “Battery Troubleshooting”.

A. If the AC Power LED is not lit

1. Verify power at the AC outlet.

2. Verify AC power available from the AC power cord.

3. Replace power supply.

4. Replace the Power Control Board.

B. If the AC Power LED is lit

1. Check Power button for mechanical operation.

2. Check cables from Power Control Board to Main Board.

3. Ensure cables are properly seated, tight, and undamaged.

4. Replace Power Control Board.

5. Replace Main Board.

Boot, but no Response

Use this procedure to troubleshoot the Responder 2000 when the unit seems to boot up normally (i.e., the Front Panel

LEDs flash and a speaker tone is heard when the Power button is pressed), but does not respond to any subsequent user

input.

A. If the ECG trace is not moving

1. Replace the Main Board.

B. The Rotary Selection knob works properly

1. Check buttons for mechanical operation.

2. Check cables from Power Control Board to Main Board.

Ensure cables are properly seated, tight, and undamaged.

3. Replace Power Control Board.

4. Replace Main Board.

C. The Rotary Selection knob does not work properly

1. Replace Rotary Selection knob.

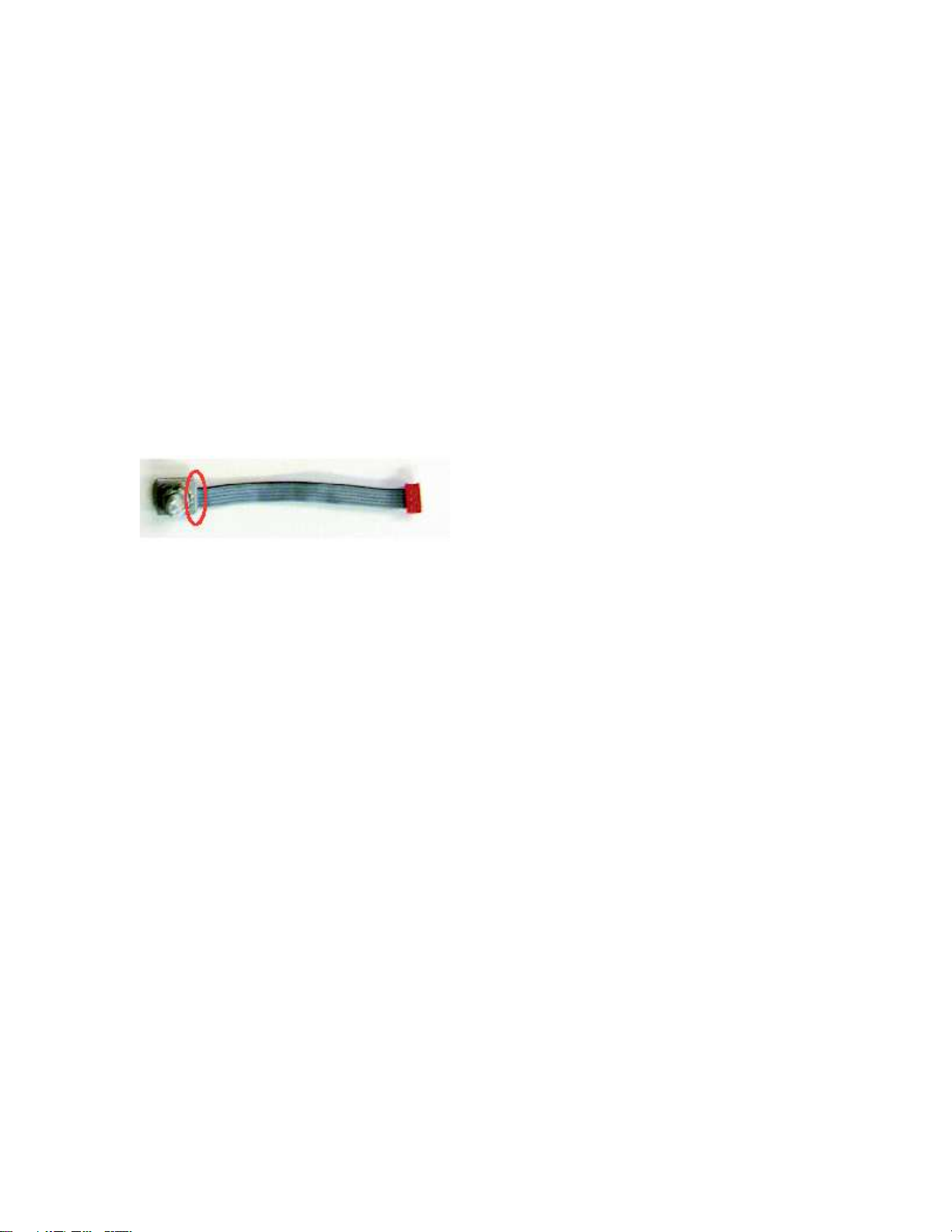

Note: The figure below shows the area where the Rotary Selection knob cable can be easily damaged if flexed

several times or otherwise stressed.

2. Check cables from Power Control Board to Main Board.

Ensure cables are properly seated, tight, and undamaged.

3. Replace Power Control Board.

4. Replace Main Board.

2025653-048 Revision B Responder™ 2000 Page 21

Page 22

SECTION 3: Troubleshooting

Bad Front Panel LEDs

Use this procedure to troubleshoot the Responder 2000 when the Front Panel LEDs are not displaying correctly. Normal

operation is indicated by:

At system boot, all LEDs will flash.

Green AC Power LED is lit when the unit is plugged in.

Yellow Battery Charging LED is lit when the battery is lit when the unit is plugged in and a discharged battery is inserted.

Red Service Required LED should be off.

Blue Manual button LED is lit.

1. Ensure the unit is plugged in and receiving power from the wall outlet.

2. If the battery charge LED is not lit when a battery is inserted, replace the battery with a known good battery.

3. Check cables from Power Control Board to Main Board.

4. Ensure cables are properly seated, tight, and undamaged.

5. Replace Power Control Board.

6. Replace Main Board.

Buttons do not Work

A. The Rotary Selection knob does not work properly

1. Replace Rotary Selection knob.

Note: The figure below shows the area where the Rotary Selection knob cable can be easily damaged if flexed

several times or otherwise stressed.

2. Check cables from Power Control Board to Main Board.

3. Ensure cables are properly seated, tight, and undamaged.

4. Replace Power Control Board.

5. Replace Main Board.

B. The Rotary Selection knob works properly

Perform Button Tests (refer to the Button Test procedure on page 54).

If Manual, Charge, Shock fails:

1. Check cables from Power Control Board to Main Board.

2. Ensure cables are properly seated, tight, and undamaged.

3. Replace Power Control Board.

4. Replace Main Board.

If Paddles, Charge, Shock fails:

1. Replace paddles.

2. Check cable from rear connector to Therapy Board.

3. Check cable between Therapy Board and Main Board.

4. Replace Therapy Board.

5. Replace Main Board.

2025653-048 Revision B Responder™ 2000 Page 22

Page 23

SECTION 3: Troubleshooting

Bad Speaker

Use this procedure to troubleshoot the Responder 2000 when the Speaker is not working correctly.

Note: The Speaker cannot be removed from the Front Panel. If the speaker must be replaced, the entire Front Panel must

be replaced.

Normal operation is indicated by:

At system boot, the speaker sounds a brief tone (listen carefully because the tone is easy to miss in a noisy environment).

When audio indication is enabled in the Settings menu, the speaker should emit loud, non-distorted tones.

1. Check speaker plug and cable.

2. Check speaker resistance. It should be between 4 and 10 ohms.

3. Replace Front Panel.

4. Replace Main Board.

Display is Dim, Dark, Fuzzy, or Unreadable

Normal operation is indicated by:

At system boot, all LEDs will flash.

The speaker sounds a brief tone (listen carefully because the tone is easy to miss in a noisy environment).

Green AC Power LED is lit when the unit is plugged in.

Yellow Battery Charging LED is lit when the unit is plugged in and a partially or fully discharged battery is inserted.

Red Service Required LED should be off.

Blue Manual button LED is lit.

A. If the Display is Dim

1. Check the software setting for display brightness.

2. Check the backlight cable

3. Run display test from the Maintenance menu to verify the display is working and there are no bad pixels.

If these checks are ok, continue with the following steps.

B. If the Display is Dark, Fuzzy, or Unreadable

1. Check the display cable.

2. Replace the Display.

3. Replace the Main Board.

Printing Problems

Note: Check the paper roll to ensure the customer is using approved paper listed in the Accessories list. Non-approved or

generic paper may cause printer damage or failure.

1. Ensure paper roll is in good condition (dry and undamaged).

2. Ensure paper is loaded correctly

3. If the Print icon is not selectable, ensure the printer door is fully closed and the paper is properly inserted.

4. Replace the printer door.

5. Check printer cables.

6. Replace printer.

7. Replace Main Board.

After troubleshooting, always print a test strip (page 55) to ensure proper operation.

2025653-048 Revision B Responder™ 2000 Page 23

Page 24

SECTION 3: Troubleshooting

Battery Troubleshooting

Check battery statistics. Good batteries have a capacity of at least 4500 mAH and will be charging when the Responder

2000 is plugged into an AC outlet.

1. Ensure battery is fully charged.

2. Perform Battery Calibration on page11.

3. Replace the Battery.

4. Replace Power Control Board.

5. Replace Main Board.

SpO2 Not Working

Verify the Responder 2000 has a SpO2 Main Board installed.

Check the About screen. “SpO2 - - - -” indicates a non-SpO

1. Connect the Responder 2000 to a SpO

If the Responder 2000 SpO

display does not agree with the simulator setting, substitute a known good SpO2

2

simulator with the appropriate sensor.

2

Main Board is installed in the unit.

2

sensor.

2. Check SPO

cable.

2

3. Check cable from Front Panel to SPO2 Board.

4. Replace SPO

Board.

2

5. Replace Main Board.

Shock into Paddle Dock Fails

If shocking into the paddle dock does not work or shows high impedance.

Perform a button test for each Paddle.

• If the test fails, replace the Paddle.

• If the test does not fail, connect the Paddles to a simulator and attempt to shock.

If the shock is successful:

1. Check the cables from the Therapy Board to the paddle dock (one on each side).

2. Replace the Therapy Board.

If the shock is unsuccessful:

1. Ensure the paddles are securely paced in the paddle dock.

2. Replace the Paddles.

3. Check the cables between the Rear Panel and the Therapy Board.

4. Check the cable between the Therapy Board and the Main Board.

5. Replace the Therapy Board.

6. Replace the Main Board.

2025653-048 Revision B Responder™ 2000 Page 24

Page 25

SECTION 3: Troubleshooting

Shock into Patient Fails

1. Perform a button test for each Paddle.

If the test fails, replace the Paddle.

If the test does not fail, connect the Paddles/Pads/Spoons to a simulator and attempt to shock.

2. If the shock is successful:

The unit is working correctly. Check patient preparation.

3. If the shock is unsuccessful:

1. Replace the Paddles/Pads/Spoons.

2. Check the cables between the Rear Panel and the Therapy Board.

3. Check the cable between the Therapy Board and the Main Board.

4. Replace the Therapy Board.

5. Replace the Main Board.

No ECG from Paddles/Pads/Spoons

1. Replace the paddles/pads/spoons.

2. Check the cables between the Rear Panel and the Therapy Board.

3. Check the cable between the Therapy Board and the Main Board.

4. Replace the Therapy Board.

5. Replace the Main Board.

Service Required LED is ON

If the Service Required LED is on and the fault has been corrected, perform this procedure to clear the fault.

1. Go to Maintenance > Stored Data Management > Clear Service Required Indicator.

2. Press Accept.

3. Cycle power.

If the fault does not clear, go to History > Event Log to find the fault log entry.

Note: All service required Error codes are displayed in the History with a red exclamation mark.

2025653-048 Revision B Responder™ 2000 Page 25

Page 26

SECTION 4: Repair

SECTION 4: Repair

Overview

This section describes how to assemble and disassemble the Responder 2000. These instructions are intended for use

only by service providers who are specifically trained to service the Responder 2000.

This section is divided into two parts:

How to Replace Specific Components: Provides high-level disassembly steps with references to the assembly steps.

Assembly: Lists production assembly steps applicable to field repair.

TOPIC PAGE

Required Tools 27

Disassembly Overview 27

How to Replace Specific Components 28

Assembly 31

2025653-048 Revision B Responder™ 2000 Page 26

Page 27

SECTION 4: Repair

Required Tools

The following tools are necessary to Assembly/ Disassembly the Responder 2000.

Note: The Security Torx is also known as Tamper Resistant Torx.

T15 Security Torx driver

T25 Security Torx driver

Philips Screwdriver

Tube of Silicone

Disassembly Overview

WARNING: Lethal Shock Hazard.

In the event of equipment failure, the two main capacitors may retain dangerous voltages even if the Responder

2000 is disconnected from AC power and the battery is removed. Normally, the capacitors are discharged when

power is shut off; however, it is possible for equipment damage to prevent the capacitors from discharging

properly.

Always assume the capacitors are fully charged.

Caution: Shock Hazard or Equipment Damage.

Before opening the case, ensure the AC power cord is disconnected and the battery is removed.

Caution: Equipment Damage.

Always wear a grounding wrist strap and use an anti-static mat when handling parts.

Caution: Procedure Failure.

Even though some assembly steps may not be applicable to a specific replacement procedure, all other steps

must be performed in the order listed.

The Responder 2000 has two access points:

Rear Cover: Provides access to Capacitors, Therapy Board, optional SPO2 Board, and ECG Board, and Front Bezel.

Removing the Bezel allows access to the Main Board, Printer, and Display.

Base Cover: Provides access to the Power Supply, Power Control Board, Fan, and Switches.

Note: The Speaker is part of the Front Body Assembly.

2025653-048 Revision B Responder™ 2000 Page 27

Page 28

SECTION 4: Repair

How to Replace Specific Components

Use the following procedures as a guide to replace specific internal components in the Responder 2000. Not all

components are listed. (For example, if the Front Body is damaged and must be replaced, the entire unit must be

disassembled and then reassembled using the more detailed Assembly instructions).

Capacitors (see page 46)

WARNING: Lethal Shock Hazard.

In the event of equipment failure, the two main capacitors may retain dangerous voltages even if the Responder

2000 is disconnected from AC power and the battery is removed. Normally, the capacitors are discharged when

power is shut off; however, it is possible for equipment damage to prevent the capacitors from discharging

properly.

Always assume the capacitors are fully charged.

1. Remove Rear Cover (see Figure 67: Rear Body Installed).

Note: Two cover screws are located under the Bed Hook Covers.

2. Cut tie wraps to free capacitor leads.

3. Disconnect Capacitor leads (see Figure 58: Capacitors Installed) from Therapy Board.

Caution: Equipment Damage.

Carefully note the capacitor lead connection points and double check the lead and jack labels.

Connecting the Capacitors to the wrong jack could cause equipment damage.

4. Reconnect Capacitors. Ensure lead connections are tight.

5. Tie wrap leads and cables. Refer to the assembly instructions for proper cable routing.

6. If necessary replace or reseat rubber tubing along the edge of the Front Body.

7. Replace the Rear Cover. Ensure the cover seats properly—check for gaps or bulges around the entire edge.

Note: One screw is located under the label of the Rear Cover. (See Figure 67: Rear Body Installed)

8. Replace Bed Hook Covers. Check for proper orientation (see Figure 68: Bed Hook Cover

Improperly Installed).

Therapy Board (see page 45)

1. Follow the Capacitor instructions (above) to remove the Capacitors.

2. Disconnect all other leads from the Therapy Board (see Figure 56: Therapy Board Cables Installed).

3. Remove the screws holding the Therapy Board (see Figure 54: Therapy Board Installed).

4. Exchange the board and replace screws.

5. Reconnect all cables and leads.

Caution: Equipment Damage.

Carefully note the capacitor lead connection points and double check the lead and jack labels.

Connecting the Capacitors to the wrong jack could cause equipment damage.

6. Follow the Capacitor instructions (above) to complete the reassembly.

2025653-048 Revision B Responder™ 2000 Page 28

Page 29

SECTION 4: Repair

SPO2 Board (see page 44)

Note: Most SP02 failures are the result of bad sensors. Before replacing the SPO2 Board, be sure to complete the

troubleshooting procedure on page 24 to verify the board is the cause of the fault.

1. Follow the Capacitor and Therapy Board instructions (above) to remove the Capacitors and Therapy Board.

2. Remove the screws holding the SPO2 Board (see Figure 51: SPO2 Board Installed).

3. Lift the SPO2 Board out to disconnect it from the Main Board.

4. Disconnect the SPO2 cable.

5. Exchange the board and reconnect the SPO2 cable.

6. Reconnect the SPO2 Board to the Main Board.

7. Replace the screws.

8. Follow the Therapy Board and Capacitor instructions (above) to replace the Therapy Board and Capacitors.

ECG Board (see page 40)

Note: Most ECG failures are the result of bad cables or sensors. Before replacing the ECG Board, be sure to complete

the troubleshooting procedure on page 25 to verify the board is the cause of the fault.

1. Follow the Capacitor and Therapy Board instructions (above) to remove the Capacitors and Therapy Board.

2. Remove the ECG Board EMI shield.

3. Disconnect the ECG cable (see Figure 41: ECG Cable Installation Detail).

4. Remove the screws holding the ECG Board.

5. Exchange the board and replace the screws.

6. Reconnect the ECG cable.

7. Replace the ECG Board EMI shield.

8. Follow the Therapy Board and Capacitor instructions (above) to replace the Therapy Board and Capacitors.

2025653-048 Revision B Responder™ 2000 Page 29

Page 30

SECTION 4: Repair

Display/Main Board/Printer (see page 42)

1. Follow the Capacitor, Therapy Board, SPO2 Board, and ECG Board instructions (above) to remove the

Capacitors Therapy Board, SPO2 Board, and ECG Board.

2. Remove the screws holding the Front Bezel (see Figure 45: Front Bezel Installed).

3. Remove the screws holding the Display (see Figure 43: LCD Screw Locations).

At this point the Display can be replaced (disconnect Display cables).

If the Main Board or Printer must be replaced, perform the following steps:

Main Board

a. Remove the screws (see Figure 11: Main Board Installed).

b. Disconnect all cables

c. Exchange the Main Board.

d. Reconnect all cables.

e. Replace the screws.

Printer

a. Remove the screws (see Figure 14: Printer Screws).

b. Disconnect the ribbon and Power cables.

c. Exchange the Printer.

d. Reconnect ribbon and Power cables.

Note: Removing the printer bracket may help when connecting the Printer ribbon cable to the Main Board

(see Figure 10: Printer Bracket Removal).

e. Replace the screws.

4. Connect the Display cables.

5. Replace the Display screws.

6. Follow the ECG Board, SPO2 Board, Therapy Board, and Capacitor instructions (above) to replace the ECG

Board, SPO2 Board, Therapy Board, and Capacitor.

Power Supply and Power Control Board (see page 36)

Remove the Base Cover, disconnect all cables, and remove screws.

Note: The Power Supply is held in place only by the two larger Base Cover screws.

Switches and Fan (see page 36)

Remove Base Cover and Power Control Board.

2025653-048 Revision B Responder™ 2000 Page 30

Page 31

SECTION 4: Repair

Assembly

Overview

The following section details the assembly steps starting from a fully disassembled Responder 2000. When replacing a

single board or other component, not all reassembly steps may be applicable.

WARNING: Lethal Shock Hazard.

In the event of equipment failure, the two main capacitors may retain dangerous voltages even if the Responder

2000 is disconnected from AC power and the battery is removed. Normally, the capacitors are discharged when

power is shut off; however, it is possible for equipment damage to prevent the capacitors from discharging

properly.

Always assume the capacitors are fully charged.

Caution: Shock Hazard or Equipment Damage.

Before opening the case, ensure the AC power cord is disconnected and the battery is removed.

Caution: Procedure Failure.

Even though some assembly steps may not be applicable to a specific replacement procedure, all other steps

must be performed in the order listed.

Paddle Latch Assembly

Assembly Step Details

Install Paddle Latch,

three springs, and

Paddle Latch Retainer

(using two Phillips

screws) on each side of

the Front Body.

Note: Ensure the

Paddle Latches are

oriented correctly and

the Paddle Latch notch

fits into the grove on

the Front Body.

Apply Silicone sealant

to the lower half of the

joint between the Front

Body and the Paddle

Latch Retainer.

Note: The seal must be

complete (no gaps).

Figure 1: Front Body Assembly

(Front View)

Figure 2:

Orientation

Figure 3:

Assembled

Latch

Detail

Figure 4:

Silicone

Application

2025653-048 Revision B Responder™ 2000 Page 31

Page 32

Main Board and Printer Installation

Assembly Step Details

Install Ribbon Cables on

Main Board at J210 and

J218.

Note: Ensure the colored

strip on cable into J218 is

visible when board is

oriented as shown.

Note: Ensure cables are

installed correctly as shown

below.

Figure 5: Main Board

Cable Installation Notes

Figure 6 shows the cable

correctly inserted into the

jack.

Figure 7 shows the jack

latch not fully engaged

(latches on both sides must

be fully depressed).

Figure 8 shows the cable

not fully inserted into the

jack.

Figure 6: Good:

Proper Installation

Figure 7: Bad:

Jack Latch not Fully

Engaged

SECTION 4: Repair

Figure 8: Bad:

Cable not Fully

Inserted

Remove the Printer Roller

and connect the printer

cables to J219 and J220.

Note: Ensure the cable and

cable plug are fully inserted

into the cable jacks.

Note: Removing the printer

bracket may help when

connecting the Printer

ribbon cable to the Main

Board.

Note: the following steps detail replacing the entire printer. If the only the printer door is

replaced, see Figure 46 for printer door installation.

Figure 10: Printer Bracket Removal

Figure 9: Printer Connections

2025653-048 Revision B Responder™ 2000 Page 32

Page 33

Assembly Step Details

Place the Main Board and

Printer into the Front

Body.

Tuck the ribbon cables

connected to J210 and

J218 as shown.

Secure the Main Board

with seven Philips screws

and install the copper

Contact Spring as shown.

Note: Ensure the printer

ribbon cable does not twist

during installation.

Turn the assembly over

(support the Printer so the

cable does not twist) and

secure the printer with three

Phillips screws.

Note: Tighten the center

screw first to properly align

the Printer.

Figure 11: Main Board

Installed

Figure 12: Cable

Detail

SECTION 4: Repair

Figure 13: Copper

Contact Spring

Installation Detail

Connect the speaker cable

to Main Board J216.

Figure 14: Printer Screws

Figure 15: Speaker Connection

2025653-048 Revision B Responder™ 2000 Page 33

Page 34

Assembly Step Details

Connect the EGG cable

(and optional SPO2 cable)

to the cable cover.

Secure to the Front Body

assembly with four Phillips

screws

Note: Ensure the heart

symbol is not upside-down.

Insert the Rotary Selection

switch as shown.

Turn over the Front Body

assembly and place the

washer over the encoder

switch.

Tighten the nut and press

on the Rotary Selection

Knob.

Note: When properly

installed, the knob rotates

freely and clicks when

pressed.

Caution: The connection

between the encoder switch

and cable is fragile. Do not

excessively bend or twist

the cable

Figure 16: ECG Cable Cover

Installed

Figure 18: Encoder Switch

SECTION 4: Repair

Figure 17: Correct Orientation

(Rear View)

Apply a 5 mm (3/16 in)

bead of silicone to seal the

joint between the Front

Body and the Lower

Frame (between the two

points as shown).

Note: The seal must be

complete (no gaps).

Figure 19: Lower Frame Silicone Application

2025653-048 Revision B Responder™ 2000 Page 34

Page 35

Assembly Step Details

Connect the CPU Main

Cable to Main Board J211.

Figure 20: CPU Main Cable

SECTION 4: Repair

2025653-048 Revision B Responder™ 2000 Page 35

Page 36

Power Control Board and Power Supply Installation

Assembly Step Details

Pass the three cables

through the holes in the

Lower Frame as shown.

Secure the Lower Frame to

the Front Body with six

Torx security screws.

Figure 21: Lower Frame (Bottom View)

Route the ECG Cable as

shown and pass it back up

into the main compartment.

SECTION 4: Repair

Figure 22: ECG Cable Route through Lower Frame

Install the Fan.

Note: An arrow on the fan

indicates air flow direction.

Ensure the fan blows

upwards into the unit.

Figure 23: Fan Installed

2025653-048 Revision B Responder™ 2000 Page 36

Page 37

Assembly Step Details

Snap the two black

Brackets into place on the

Lower Frame.

Note: Check the Power

Supply green ground wire

to ensure it is properly

soldered on both ends and

is in good condition.

Place the Power Supply on

the Brackets.

Note: The Power Supply is

not secured until the Base

Cover is installed.

Place the AC Cable

Connector into the Lower

Frame as shown.

Note: The single ground pin

must be at the top.

Figure 24: Brackets Installed

SECTION 4: Repair

Figure 25: Power Supply Installed

Insert the Power Button

and Control Button

assemblies into the Lower

Frame.

Pass Therapy Power

Cable into the Lower

Frame as shown. Pull the

slack through, leaving

enough length to connect to

Power Control Board

(installed in the next step).

Figure 26: AC Cable Connector

Figure 28: Power and Control Button Assemblies Installed

Figure 29: Therapy Power Cable

Figure 27: Proper Connector

Orientation

2025653-048 Revision B Responder™ 2000 Page 37

Page 38

Assembly Step Details

Secure the Power Control

Board with five Phillips

screws.

Place the Service

Connector (serial

connector) on the Lower

Frame.

Note: Pin 1 must be at the

top.

Route and connect all

cables as shown.

Note: See the Ribbon

Cable Installation Notes for

proper installation (Figures

6, 7 and 8).

Install the Battery Release

and extension spring.

Note: To help the Battery

Release slide under the

Power Control board,

back off the screws holding

the Power Control board a

turn or two and then

retighten after installation.

Figure 30: Power Control Board Installed

SECTION 4: Repair

Figure 31:

Service Connector

(Correct

Orientation)

Figure 32: Battery Release Installed

If necessary, reinstall

rubber tubing along the

edge of the Lower Frame.

Two lengths are required:

• 705 mm ± 3 mm

(27-3/4 in ± 1/8 in)

• 148 mm ± 2 mm

(5-15/16 in ± 1/16 in)

Note: Do not stretch the

tubing as it is inserted into

the groove.

Note: The gap between the

end of the groove and the

start of the tubing must be 2

mm (1/16 in) or less.

Figure 33: Tubing Properly Installed

Figure 34: Tubing Not Properly

Installed

2025653-048 Revision B Responder™ 2000 Page 38

Page 39

Assembly Step Details

Install the Battery Latch in

the Base Cover.

Apply Silicone to the notch

for the AC power plug.

Figure 35: Battery Latch

Install the Base Cover to

the Lower Frame. Using

five Torx security screws

(white arrows).

Note: Tighten the screws

slowly and evenly to ensure

the rubber tubing is seated

correctly and no wires are

pinched.

When all screws are

tightened, check for any

gaps or bulges in the seal.

Install the two larger Torx

security screws (black

arrows) to hold the Power

Supply in place.

Install the four rubber feet if

necessary.

Figure 37: Base Cover

SECTION 4: Repair

Figure 36: Silicone Applied

If necessary, check the joint

between the Lower Frame

and the Front Body for

gaps in the silicone. Add

more silicone if necessary.

Figure 38: Front Body and Lower Frame Joint

(with Correctly Applied Silicone)

2025653-048 Revision B Responder™ 2000 Page 39

Page 40

ECG Board Installation

Assembly Step Details

Install the ECG Insulator in

the Front Body.

Figure 39: ECG Insulator Installed

Install the ECG Board to

the Front Body by

connecting J412 on the

ECG Board to J212 on the

Main Board.

Install the seven Phillips

screws to hold the ECG

Board in place.

SECTION 4: Repair

Figure 40: ECG Board Installed

Connect the ECG cable to

the ECG Board.

• J4231 White

• J4232 Black

• J4233 Red

• J4234 Brown

• J4235 Green

• J4236 Gray

Notes: Gently pull on each

connector to ensure it is

locked in place.

The extra gray connector

will be connected later.

Figure 41: ECG Cable Installation Detail

2025653-048 Revision B Responder™ 2000 Page 40

Page 41

Assembly Step Details

SECTION 4: Repair

Note: The next section details the Front Bezel and Display replacement. That

procedure includes steps to route the ECG cable and install the ECG Shield for the

ECG Board. Even if the Display or Front Bezel is not replaced, those steps must still

be completed (see Figure 47 and Figure 48).

2025653-048 Revision B Responder™ 2000 Page 41

Page 42

Display Installation

Assembly Step Details

If necessary, snap the LCD

into the LCD Retainer.

Connect the LCD ribbon

cable to J214 on the Main

Board.

Note: See the Ribbon

Cable Installation Notes for

proper installation (Figures

6, 7 and 8).

Secure the LCD to the

Front Body with five

Phillips screws (two in front,

three in back).