Page 1

Responder 1000/1100

Version V 1.0

Servicing Instructions

227 487 20 ENG Revision G

Page 2

GE Medical Systems

Information Technologies Responder 1000/1100 Page 2/38

Service Instructions

──────────────────────────────────────────────────────────────────

Caution:

During repairs/service interventions, observe the protective measures against damage due to ESD.

• GE Medical Systems Information Technologies GmbH is responsible for the effects on safety,

reliability, and performance of the device, only if

− assembly operations, extensions, readjustments, modifications, or repairs are carried out

by GE Medical Systems Information Technologies GmbH or by persons authorized by

GE Medical Systems Information Technologies GmbH,

− the electrical installation of the relevant room complies with the applicable national and

local requirements, and

− the instrument is used in accordance with the instructions for use.

• This manual contains service information, operating instructions are provided in the Operator’s

Manual of the instrument.

• This manual is in conformity with the instrument at printing date.

• All rights are reserved for instruments, circuits, techniques, and names appearing in the manual.

The authorized representative for GE Medical Systems Information Technologies Inc. in Europe

is:

GE Medical Systems Information Technologies GmbH

Munzinger Str. 3

D-79111 Freiburg, Germany

Tel. +49 (0) 7 61 45 43-0

Fax: +49 (0) 7 61 45 43-233

©

2006-2008 General Electric Company. All rights reserved.

227 487 20 Rev G

Page 3

GE Medical Systems

Information Technologies Responder 1000/1100 Page 3/38

Service Instructions

──────────────────────────────────────────────────────────────────

Contents

1 Documentation and nomenclature of GE Medical Systems instrument part Nos....................... 5

1.1 Configuration of Instrument part No..................................................................................... 5

1.2 Configuration of the PCB part No ........................................................................................ 5

1.3 Instrument Status Documentation (nominal status).............................................................. 6

2 General Overview ....................................................................................................................... 7

2.1 Responder 1000...................................................................................................................... 8

2.2 Responder 1100..................................................................................................................... 9

2.3 Block Diagram, total Unit................................................................................................... 10

2.4 Mechanical Structure .......................................................................................................... 11

2.5 Functions............................................................................................................................. 11

3 Interfaces................................................................................................................................... 12

3.1 Internal Interfaces................................................................................................................ 12

3.2 External Interfaces .............................................................................................................. 15

4 Adjustment and Performance Instruction.................................................................................. 16

5 Unit Test Functions................................................................................................................... 18

5.1 General................................................................................................................................ 18

5.2 Test Mode............................................................................................................................ 18

6 Repair Notes.............................................................................................................................. 20

6.1 Safety Notes ........................................................................................................................ 20

6.2 Component Replacement, Battery disposal ....................................................................... 20

7 Troubleshooting ........................................................................................................................ 21

8 Maintenance and Technical Inspection..................................................................................... 22

8.1 Testing Equipment ......................................................................................................... 22

8.2 Technical Inspection ...................................................................................................... 22

8.2.1 Visual Checks................................................................................................................ 22

8.2.2 Function Checks............................................................................................................ 23

8.3 Safety Analysis Test....................................................................................................... 25

8.3.1 General Information...................................................................................................... 25

8.3.2 Measuring of Leakage Current...................................................................................... 25

8.3.3 Enclosure Leakage Current........................................................................................... 26

8.3.4 Patient Leakage Current................................................................................................ 27

9 Technical Description ............................................................................................................... 28

10 Spare Part List..................................................................................................................... 31

11 Schematics........................................................................................................................... 38

227 487 20 Rev G

Page 4

GE Medical Systems

Information Technologies Responder 1000/1100 Page 4/38

Service Instructions

──────────────────────────────────────────────────────────────────

Revision History

Each page of this manual has the document number followed by a revision letter, located at the

bottom line of the page. This letter identifies the manual update level. The latest letter of the alphabet

corresponds to the most current revision of the document.

The revision history of this manual is summarized below.

Date Revision Comments

1998 - 07 A Initial release

2004 – 01 B ECO 075782

2006 – 06 C ECO 082042

2007 – 05 D ECO 087144

2007 – 12 E ECO 088330

2008 – 06 F ECO091141, Changes on page 33, 34.

Drawing 10116601-D02 rev.L replaced by rev.M

2008 – 12 G ECO093900, Battery disposal added on page 20.

227 487 20 Rev G

Page 5

GE Medical Systems

Information Technologies Responder 1000/1100 Page 5/38

Service Instructions

──────────────────────────────────────────────────────────────────

1 Documentation and nomenclature of GE Medical Systems Information Technologies instrument part Nos

1.1 Configuration of Instrument part No

The instrument part No comprises 8 digits, the first 6 digits determining the instrument type, the

last 2 digits the instrument version. The language is determined by configuration, thus having no

influence on the part No.

E.g. Instrument Type Version

Responder 1000, without battery, 230...240 V 101 166 01

Responder 1100, with battery, 230...240V 101 166 12

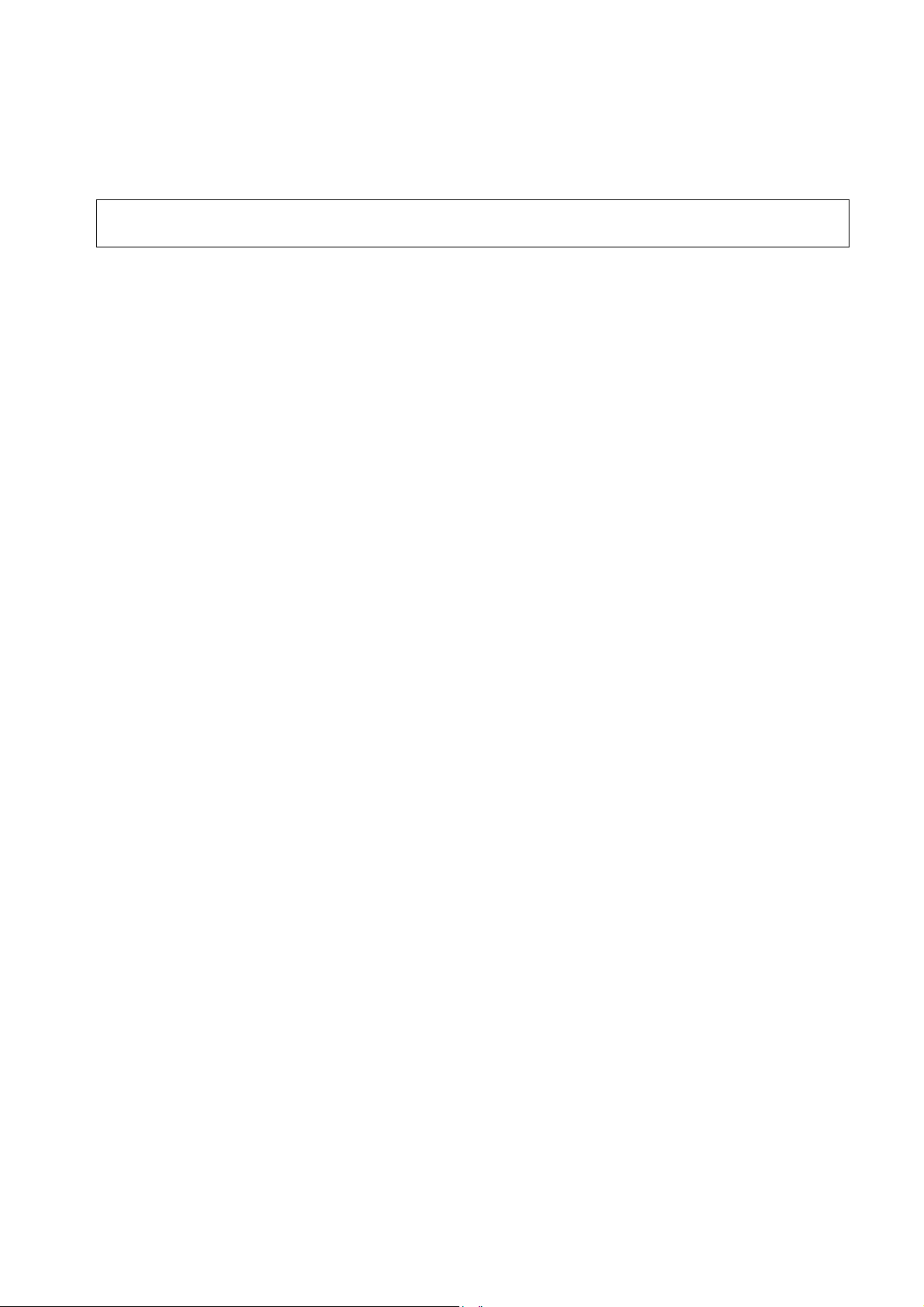

1.2 Configuration of the PCB part No

388 xxx yy Spare part numbers for the operative PCBs.

The instrument documentation, e.g., reference diagrams, circuit diagrams and parts lists are listed

under this part No.

The 388 number is located on the barcode label.

Configuration of the barcode labels:

227 487 20 Rev G

Page 6

GE Medical Systems

Information Technologies Responder 1000/1100 Page 6/38

Service Instructions

──────────────────────────────────────────────────────────────────

303 xxx yy Spare part numbers for PCBs tested especially thoroughly

303 numbers are only given to PCBs where the level of testing applied to 388 PCBs is inadequate for

implementation when servicing in the field, or where only a complete set of PCBs can be replaced in

the field.

In addition to a barcode label (388 number) 303 part Nos also have an additional label with a 303

number and are to be found in the spare parts list under this number.

389 xxx yy Replacement numbers for defective PCBs

Where servicing is required 389 PCBs are available for the replacement of some PCBs. When using a

replacement PCB (389 part No) the defective PCB is to be returned to the Freiburg factory.

Replacement PCB part Nos are included in the spare parts list.

389 PCBs have an additional adhesive label.

1.3 Instrument Status Documentation (nominal status)

Due to the hardware and software combination unambiguous documentation of the instrument

assembly status is necessary, also in the event of repairs.

This documentation comprises the following documents and measures:

Master Record Index (MRI)

This document is a component of this instrument documentation.

This document states the combination of permissible hardware and software for a particular

instrument version. The permissible PCB Index is given in the “Index” column with each update

delivered. Further permissible PCB Indexes are given in the “compatible” column. The PCB

Index can be found in the PCB barcode label.

Product Status Index

This document is created during manufacture. The Product Status Index documents the

hardware/software product status.

227 487 20 Rev G

Page 7

GE Medical Systems

Information Technologies Responder 1000/1100 Page 7/38

Service Instructions

──────────────────────────────────────────────────────────────────

2 General Overview

These service instructions describe both the Responder 1000 as well as the Responder 1100. Unless

a note appears to the contrary, this description applies to both units.

Responder 1000 and Responder 1100 are based on the same hardware platform.

The following versions are available:

101 166 01 Responder 1000, w/o battery, 230...240V~

101 166 02 Responder 1000, w/ battery , 230...240V~

101 166 03 Responder 1000, w/o battery, US, 115...120V~

101 166 04 Responder 1000, w/ battery, US, 115...120V~

101 166 05 Responder 1000, w/o battery, MiniDef III, Esaote 230...240V~

101 166 06 Responder 1000, w/ battery, MiniDef III, Esaote 230...240V~

101 166 07 Responder 1000, w/o battery, 115...120V~

101 166 08 Responder 1000, w/ battery, 115...120V~

101 166 09 Responder 1000, w/o battery, US, 230...240V~

101 166 10 Responder 1000, w/ battery, US, 230...240V~

101 166 11 Responder 1100, w/o battery, 230...240V~

101 166 12 Responder 1100, w/ battery, 230...240V~

101 166 13 Responder 1100, w/o battery, US, 115...120V~

101 166 14 Responder 1100, w/ battery, US, 115...120V~

101 166 15 Responder 1100, w/o battery, MiniDef III, sync, , Esaote 230...240V~

101 166 16 Responder 1100, w/ battery, MiniDef III, sync, , Esaote 230...240V~

101 166 17 Responder 1100, w/o battery, 115...120V~

101 166 18 Responder 1100, w/ battery, 115...120V~

101 166 19 Responder 1100, w/o battery, US, 230...240V~

101 166 20 Responder 1100, w/ battery, US, 230...240V~

101 166 23 Responder 1000, w/o battery, 230...240V~, China

101 166 24 Responder 1000, w/ battery, 230...240V~, China

The hardware consists of the following function blocks:

- PCB Responder 1000/1100

- battery module including PCB battery module

- keypad

- defibrillator electrodes (paddles)

The following function blocks are implemented as PCBs.

- PCB Responder 1000/1100

- PCB battery module

The intended use, the functions available and operation of

Responder 1000/1100 are described in the instructions for use.

227 487 20 Rev G

Page 8

GE Medical Systems

Information Technologies Responder 1000/1100 Page 8/38

Service Instructions

──────────────────────────────────────────────────────────────────

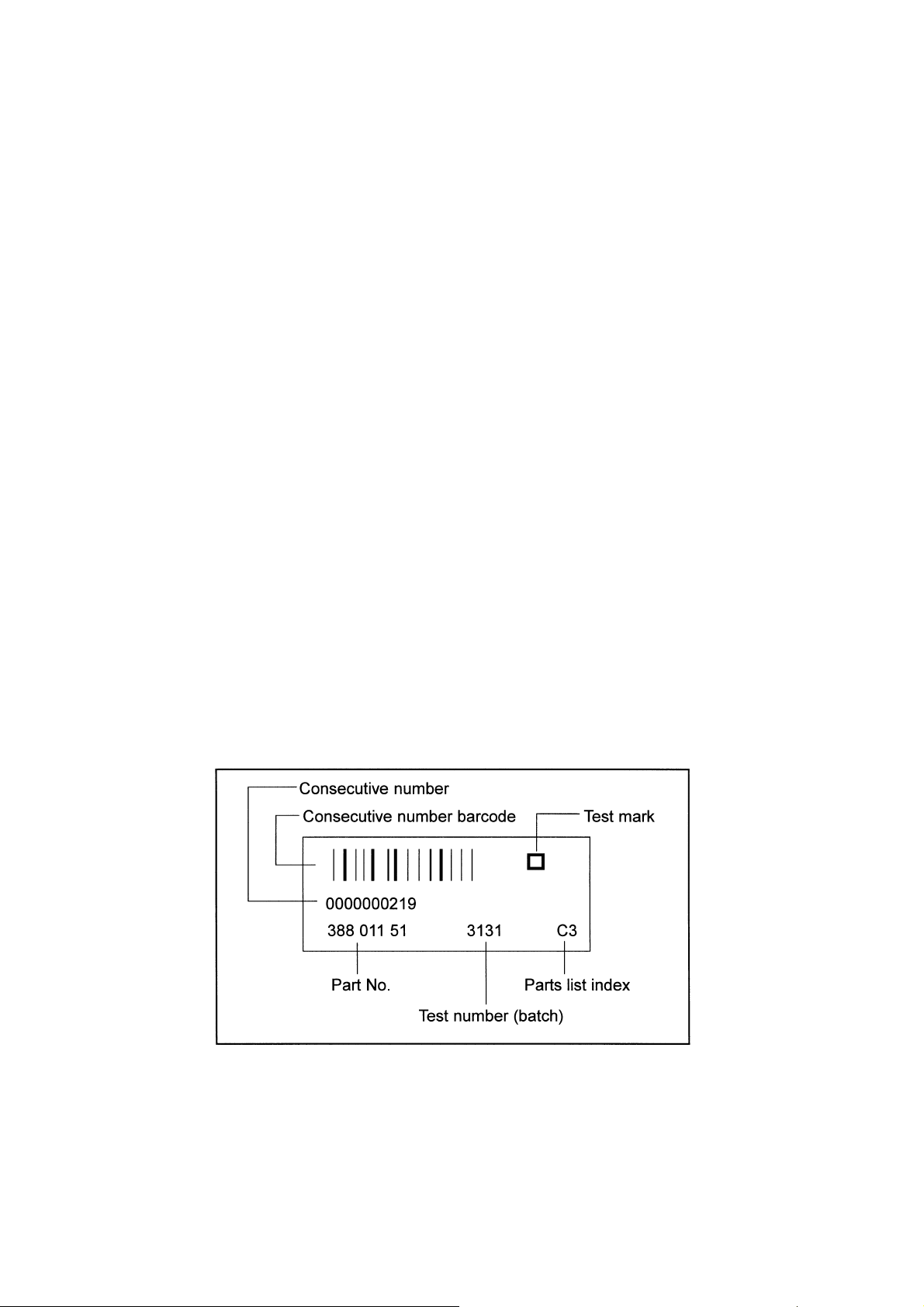

2.1 Responder 1000

1 Button to deliver the shock - together with button 8

2 AC line power indicator

3 Indicator light is green while the battery is charging (line power operation), it is red when the battery

needs charging (battery power operation)

4 Energy selector, On/Off switch

5 Indicators 2 to 360 illuminate when the corresponding energy level has been reached

6 "On" indicator illuminates when the device is On

7 "Service" indicator illuminates when a problem was detected during the automatic self-test

8 Button to initiate defibrillator charging and to deliver the shock - together with button 1

9 Power cord

10 Tube holder for skin prep cream

Explanation of symbols used on the device

Refer to Operator's Manual

Caution, High Voltage

Type CF signal input: highly insulated,

suitable for intracardiac application

battery

Standby mode (line power operation)

227 487 20 Rev G

Page 9

GE Medical Systems

Information Technologies Responder 1000/1100 Page 9/38

Service Instruction

───────────────────────────────────────────────────────────────────

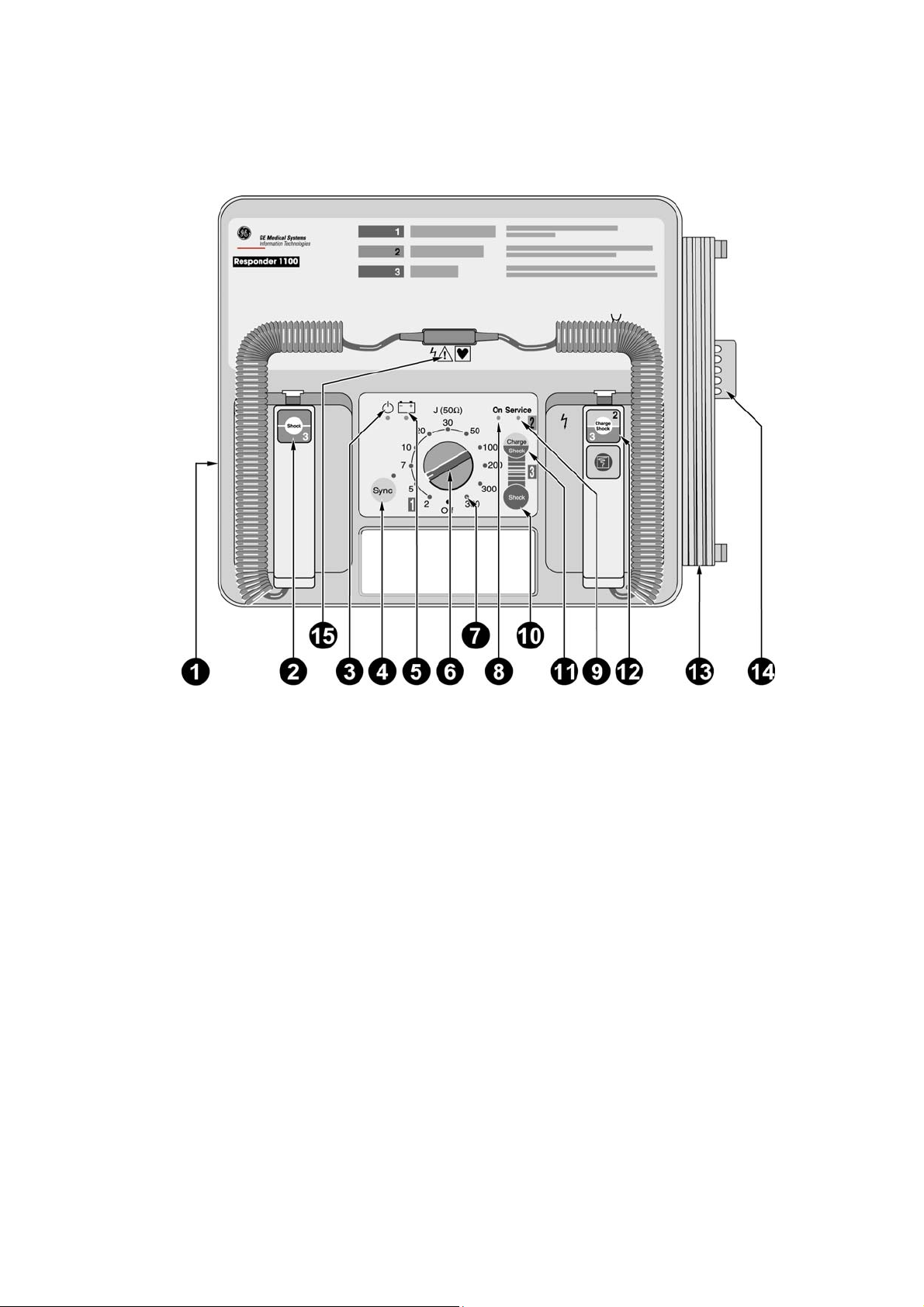

2.2 Responder 1100

1 ECG trigger signal input (synchronized defibrillation)

2 Button to deliver the shock - together with button 12

3 AC line power indicator

4 Button to enable and disable the synchronized defibrillation mode, with indicator (indicator

is illuminated during sync. defibrillation and flashes to the rhythm of the QRS complex)

5 Indicator light is green while the battery is charging (line power operation), it is red when

the battery needs charging (battery power operation)

6 Energy selector, On/Off switch

7 Indicators 2 to 360 illuminate when the corresponding energy level has been reached

8 "On" indicator illuminates when the unit is On

9 "Service" indicator illuminates when a problem was detected during the automatic self-test

10 Button to initiate defibrillator charging and to deliver the shock - together with button 11

when adhesive pads or internal electrodes are used

11 Button to deliver the shock when adhesive pads or internal electrodes are used - together

with button 10

12 Button to initiate defibrillator charging and to deliver the shock - together with button 2

13 Power cord

14 Tube holder for skin prep cream

15 Connector for defibrillation electrodes (turn off the unit before exchanging the electrodes)

227 487 20 Rev G

Page 10

GE Medical Systems

Information Technologies Responder 1000/1100 Page 10/38

Service Instruction

───────────────────────────────────────────────────────────────────

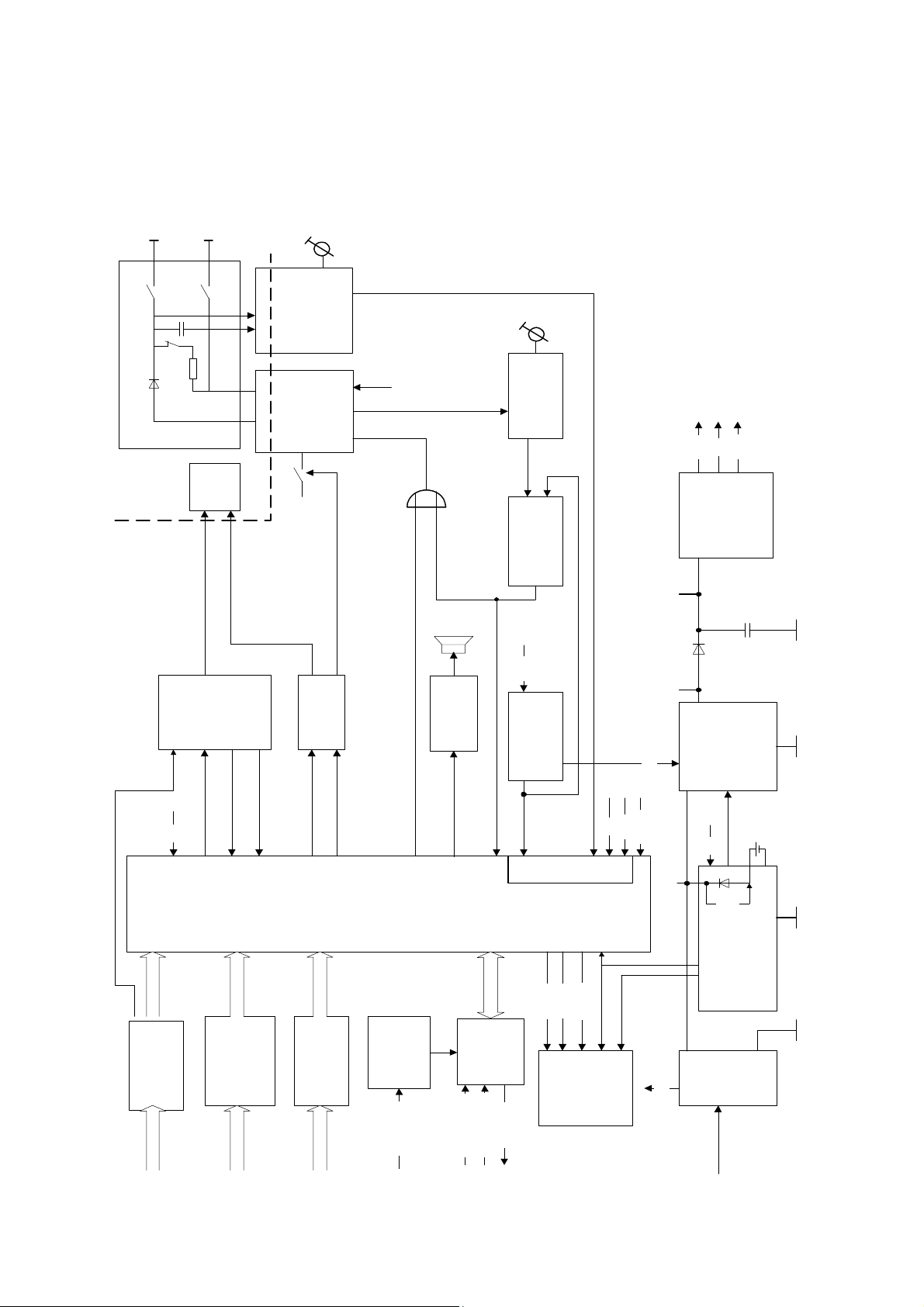

2.3 Block Diagram, total Unit

Defib-

electrodes

relay

shock

HV-Cap

voltage

conversion

relay

disarm

high-voltage part

HV-

relay

HV-

oscillator

Usec1

stop

Uref2

voltage

conversion

oscillator

ready

energy

indication

+12V

Vcc

Uref2

voltage

regulators

5 I/O

Vcc

Vdd

relay

shock

secure

3 I/O

paddlecode

relay

interface

2 I/O

device

control

audio

output

3 I/O

syncsignal

Uref2

energy

selection

serdata

off,2...360 J)

analog inputs

regCLK

serCLK

Vcc

Uref2

!= 0

MReset

Joule

Usec3

Usec2

Usec1

on/off logic

Vcc

Load

battery-

battery

charger

interface

pushbutton

pushbuttons keycode

227 487 20 Rev G

paddle

detection

paddle

model

detection

model varcode

QRS-

trigger

syncECG1V

sync

interface

syncdigital

syncableconn

power

LED

indication

marker

mainsLED

supply

mains

Page 11

GE Medical Systems

Information Technologies Responder 1000/1100 Page 11/38

Service Instruction

───────────────────────────────────────────────────────────────────

2.4 Mechanical Structure

The major mechanical components of the unit are the top and bottom shell. The top shell is the basic

element carrying the following sub-assemblies:

- PCB Responder 1000/1100

- Keypad (only Responder 1100)

The bottom shell holds the battery module and the capacitor which are linked to the PCB Responder

1000/1100 via cables.

The 6-pin inlet plug for connecting the sync-cable is located at the left side of the top shell. It is

linked to the PCB via a cable.

2.5 Functions

The functions follows the Block Diagram of the total unit in chapter 2.3 and the function blocks of

the P plans.

The unit contains following functions:

• power supply

• battery charger (located at PCB battery module)

• on/off logic

• voltage regulators

• device control

• LED indication

• audio output

• high voltage part

• shock relay secure

• relay interface

• HV- oscillator

• energy selection

• voltage conversion HV-Cap

• voltage conversion oscillator

• energy ready indication

227 487 20 Rev G

Page 12

GE Medical Systems

Information Technologies Responder 1000/1100 Page 12/38

Service Instruction

─────────────────────────────────────────────────────────────── ────

3 Interfaces nterfaces

3.1 Internal Interfaces 3.1 Internal Interfaces

Interface signal PCB Responder 1000/1100 Interface signal PCB Responder 1000/1100

connector : BattLoad1 connector : BattLoad1

function: connector to battery module

type: MODUI 6pol

signal name level active I/O meaning

1 Usec1 +18..30V - Output charging voltage

2 GND 0V - - Ground

3 +5V +5V - Output 5V

4 BATTMINIM +5V High Input battery Low signal

5 BATTCHARGE +18..25V - Input battery charge signal

6 BATTLEER - - Input battery empty signal

connector : Sync

function: connector to Sync input.

type: MODUII 6pol

signal name level active I/O meaning

1 ECG1V - Input 1V ECG

2 DIG_GND 0V - - digital Ground

3 SYNEXT L->H Input trigger signal extern monitors

4 MARKOUT High Output marker signal

5 AN_GND 0V - - analog Ground

6 SYNCABLE CMOS Low Input cable detection

connector : HV_Trafo_Pri

function: connector to High Voltage transformer

type: 4,8 x 0,8

signal name level active I/O meaning

2 HV_TRAFO_PRI/2 - - - "passive end" of transformer winding

1 HV_TRAFO_PRI/1 - - - "active end" of transformer winding

connector : HVCapConn

function: connector to High Voltage Capacitor

type: 4,8 x 0,8

signal name level active I/O meaning

- KO_PLUS - + - plus terminal

- KO_NEG - - - minus terminal

connector : KeyConn

function: connector to keypad

227 487 20 Rev G

Page 13

GE Medical Systems

Information Technologies Responder 1000/1100 Page 13/38

Service Instruction

───────────────────────────────────────────────────────────────────

type: TRIO MATE 4pol

signal name level active I/O meaning

1 SHOTAFOL_ +5V Low Input key “shock”

2 CHATAFOL_ +5V Low Input key “charge/shock

3 SYNTAFOL_ +5V Low Input key “sync”

4 GND 0 - Output Ground

connector : PaddConn1

function: connector to “Sternum” Paddle

type: MODU II 4pol

signal name level active I/O meaning

1 SHOTAPAD +5V High Input key “shock” (paddle)

2 VCC +5V - Output VCC

3 PADTYP0 +5V High Input paddle detection

4 PADTYPHE2 analog Input paddle detection (level depends on paddle type)

connector : PaddConn2

function: connector to “Apex” paddle

type: MODU II 4pol

signal name level active I/O meaning

1 NC

2 NC

3 CHATAPAD +5V High Input key charge/shock (paddle)

4 VCC +5V - Output VCC

connector : PaddleHVConn

function: connector to paddles (high voltage)

type: 4,8 x 0,8

signal name level active I/O meaning

7 HV_POS 5kV - Output connection to “Sternum” paddle

8 HV_NEG 0V - Output connection to “Apex” paddle

227 487 20 Rev G

Page 14

GE Medical Systems

Information Technologies Responder 1000/1100 Page 14/38

Service Instruction

───────────────────────────────────────────────────────────────────

Interface signal PCB battery module

connector : BattConn

function: connector to battery

type: soldering connection

signal name level active I/O meaning

1 BAT_PLUS 18V - - battery +

2 BAT_MINUS GND - - battery -

connector : BattLoad2

function: connection to PCB Responder 1000/1100

type: crimp connection terminal mini 2000

signal name level active I/O meaning

1 Usec1 +18..30V - Input charging voltage or battery voltage

2 GND 0V - Input Ground

3 +5V +5V - Input 5V

4 BATTMINIM +5V High Output battery Low signal

5 BATTCHARGE +18..25V High Output battery charge signal

6 BATTLEER - - Output battery empty signal

227 487 20 Rev G

Page 15

GE Medical Systems

Information Technologies Responder 1000/1100 Page 15/38

Service Instruction

───────────────────────────────────────────────────────────────────

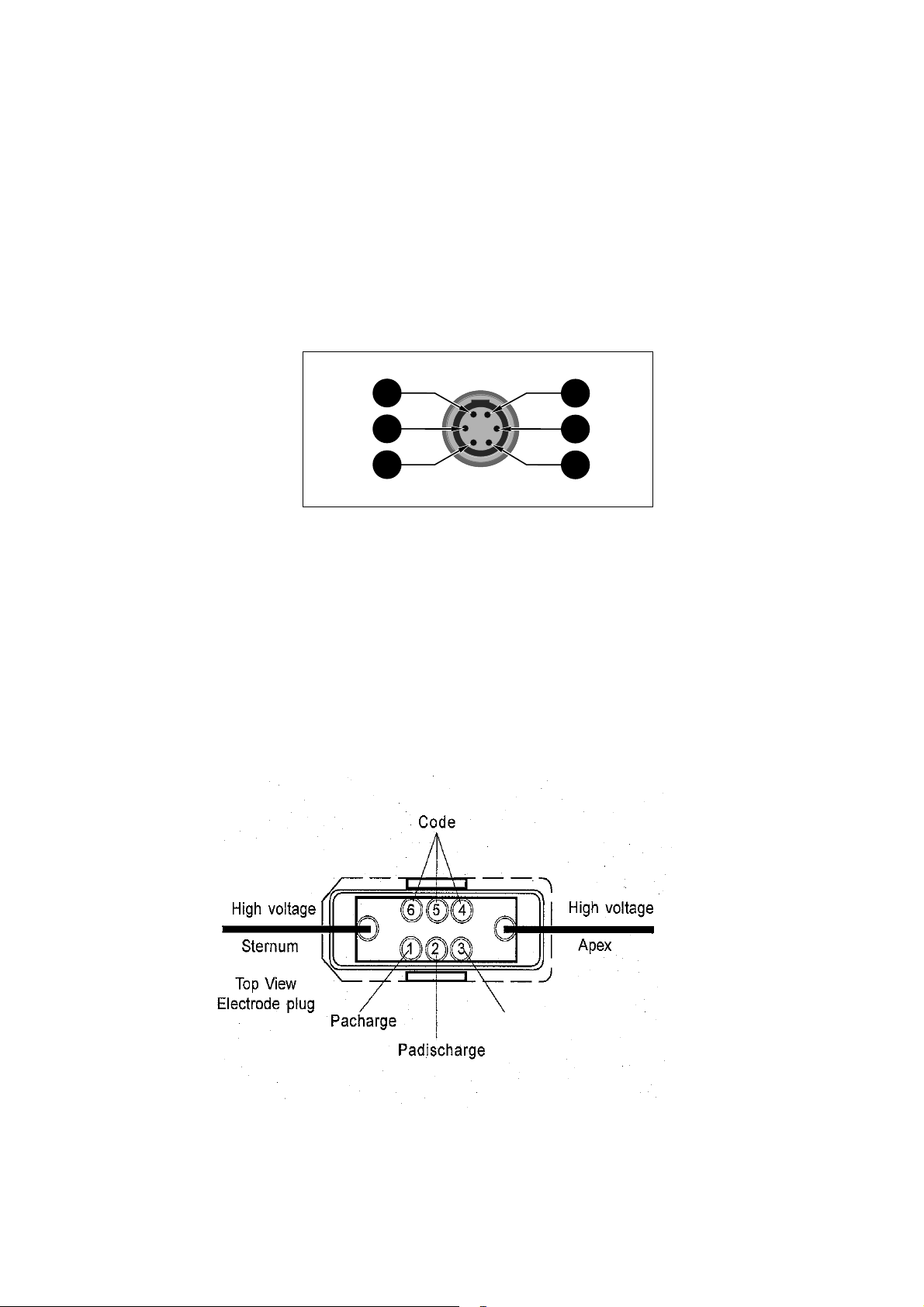

3.2 External Interfaces

Only the Responder 1100 is equipped with external interfaces.

Sync interface

1

2

3

1 1-Volt ECG signal, analog (see chapter 9 Technical Description)

2 Ground, digital

3 SYNC pulse, digital (see chapter 9 Technical Description)

4 Marker, digital

5 Ground, analog

6 SYNC cable detection

Interface for defibrillator electrodes

6

5

4

227 487 20 Rev G

N.C.

Page 16

GE Medical Systems

Information Technologies Responder 1000/1100 Page 16/38

Service Instruction

───────────────────────────────────────────────────────────────────

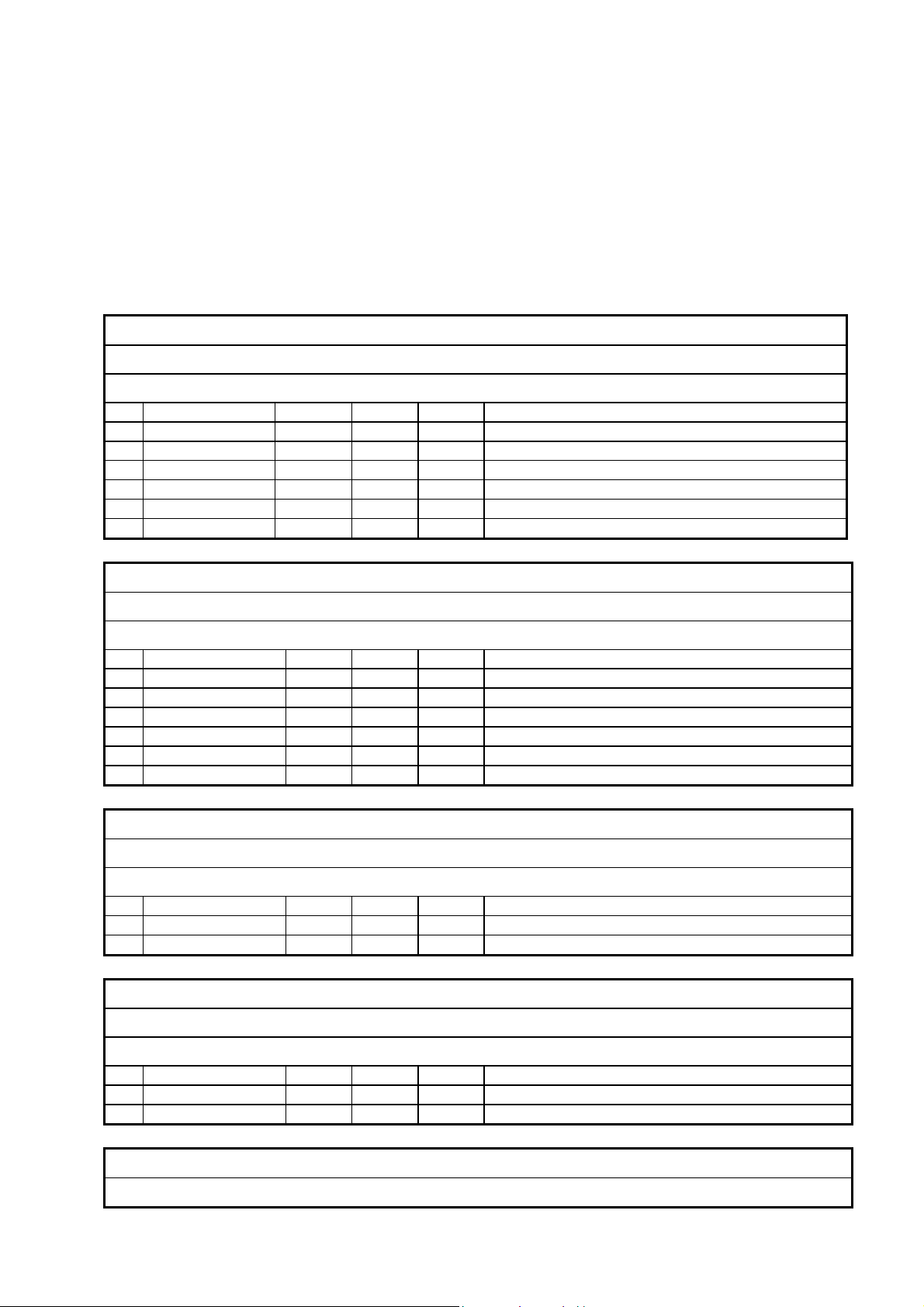

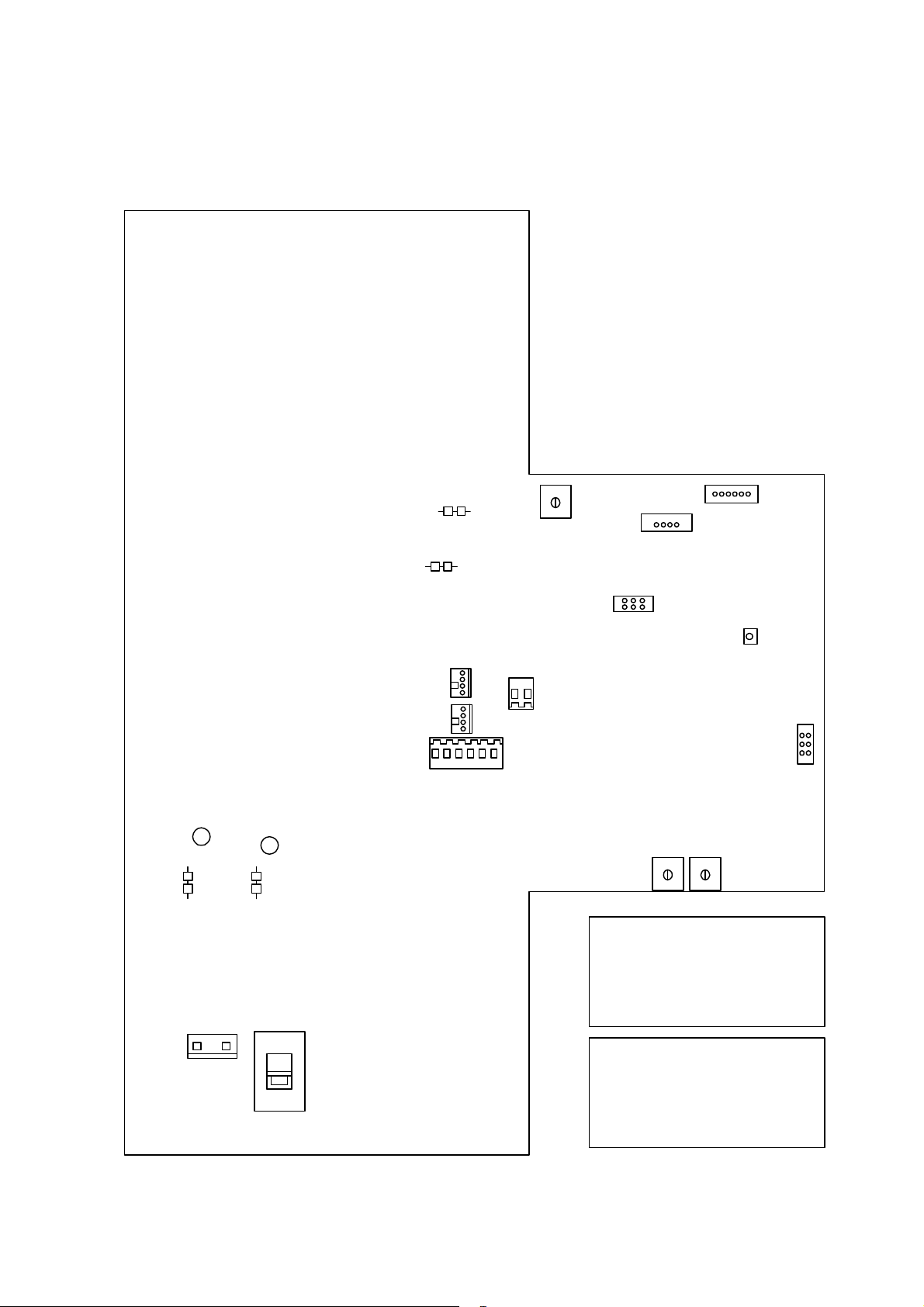

4 Adjustment and Performance Instruction

1

1-2

3-4

1

KEYCONN

5-6

SYNC

KOPOS (+)

R506

KONEG (-)

J2

LED500

HV_TRAFO_PRI

PADCONN2

PADCONN1

BATTLOAD

2

PADDLENEG

1

PADDLEPOS

1

11

1

R502 R503

5-6

3-4

1-2

J3

J2

1-2 must set

3-4 must set

5-6 not set

1

MAINS

230V

J3

227 487 20 Rev G

115V

S500

1-2 not set

3-4 not set

5-6 Test Mode if set

Page 17

GE Medical Systems

Information Technologies Responder 1000/1100 Page 17/38

Service Instruction

───────────────────────────────────────────────────────────────────

Where

(e.g. PCB)

entire unit

entire unit

PCB

Responder

PCB

Responder

PCB

Responder

entire unit

entire unit

What

(e.g. PCB)

check 30s

safety period

check 60s

safety period as

of “energy

reached”

adjust

oscillating

current

adjust energy

adjust charge

monitor LED

check charge

monitor LED’s

check charging

period

What to

measure with?

stopwatch

stopwatch

effective value

(RMS)

Ampere-meter

defibrillatortester

LED 500

all charge

monitor LED’s

stopwatch

Where to

clip to?

---

---

power

supply,

primary side,

(connector

mains)

paddles

---

---

---

Where to

turn

---

---

R 502

R 503

R 506

---

---

How much and

exact?

30 ± 1s until

defibrillator

deactivate charging

40...90 s ± 1s after

the defibrillator is

charged, it must

discharge internally

502...528mA

1004...1056mA

339...381J

as of “energy

reached” set R 506 so

that LED 500 just

lights up and after a

short time (2...3s)

goes out again

all LED’s must light

≤ 12s

What else to note?

remove plug

HV_TRAFO_PRI,

set energy to 2J,

press charge

button

set energy to 2J,

press charge

button

without battery,

charging with

energy set to 300J

U=230VAC,

U=115VAC

set energy to 360J,

trigger defibrillator

before this, the

energy level must

be adjusted with R

503.

set energy to 360J,

press charge

button

set energy to 360J,

press charge

button

without battery,

set energy to 360J,

press charge

button

227 487 20 Rev G

Page 18

GE Medical Systems

Information Technologies Responder 1000/1100 Page 18/38

Service Instruction

───────────────────────────────────────────────────────────────────

5 Unit T est Functions

5.1 General

After power-up and during operation, the Responder 1000/1100 runs automatic self-tests.

After power-up, the device beeps and all LED’s will briefly light up.

When the unit detects a error, the "Service" LED lights up and an acoustic signal sounds.

Every three seconds the unit try’s a new restart and test whether the error still appears.

5.2 Test Mode

The test mode is activated by inserting a jumper on PCB Responder 1000/1100 (J3 5-6). In the test

mode, some LED’s of the energy levels (2J to 30J) will indicate any detected malfunction. The

table below lists all error codes and the corresponding explanations.

If the device detects a error, then:

1.) switch Off the device

2.) insert jumper J3 5-6 (use the jumper J2 3-4 for this test)

3.) switch On the device

After power up, the “Service” LED lights up, an acoustic signal sounds and the error code will

indicated by the LED’s of the energy levels. This mode is active until the device will switched

Off.

227 487 20 Rev G

Page 19

GE Medical Systems

Information Technologies Responder 1000/1100 Page 19/38

Service Instruction

───────────────────────────────────────────────────────────────────

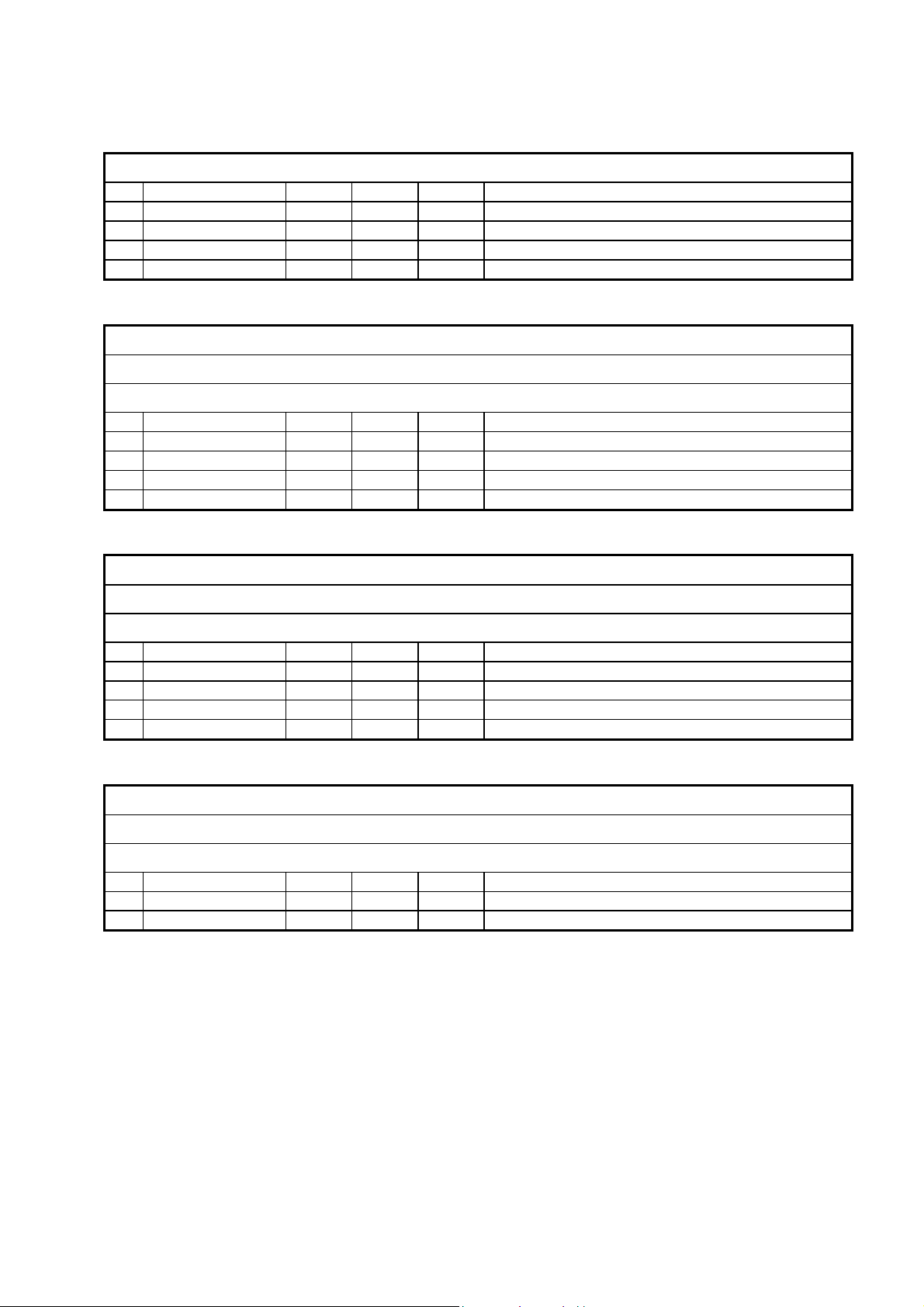

Error codes and the corresponding explanations

LED

30J

LED

20J

LED

10J

LED

7J

LED

5J

LED

2J

Meaning What to do

- - - - - light key error test keypad and paddles

- - - - light - rotary switch error replace PCB

- - - - light light high voltage error replace PCB

- - - light - - disarm error (initialization) replace PCB

- - - light - light disarm error (running time) replace PCB

- - - light light - variant error check jumper J3

- light - - - - device control error (Z501) replace PCB

- light - - - light device control error (Z501) replace PCB

- light - - light - device control error (Z501) replace PCB

- light - - light light device control error (Z501) replace PCB

- light - light - - device control error (Z501) replace PCB

- light - light - light device control error (Z501) replace PCB

- light - light light - device control error (Z501) replace PCB

- light - light light light error high voltage to high check adjustment

- light light - - - rotary switch error replace PCB

- light light - - light device control error (Z501) replace PCB

- light light - light - error shock relay test keypad and paddles

- light light - light light device control error (Z501) replace PCB

light light light - - device control error (Z501) replace PCB

light light light - light signal error “pENROK” replace PCB

light light light light - signal error “pSRELACT” replace PCB

light light light light light device control error (Z501) replace PCB

light - - - - - error voltage Uref2 replace PCB

227 487 20 Rev G

Page 20

GE Medical Systems

Information Technologies Responder 1000/1100 Page 20/38

Service Instruction

───────────────────────────────────────────────────────────────────

6 Repair Notes

6.1 Safety Notes

WARNING !

Shock hazard. Always switch of the unit

and disconnect the power cord before

opening the unit. Do not reconnect the

power cord when the unit is open.

Shock hazard. Before replacing the

primary fuse inside the unit, always

switch off the unit and disconnect the

power cord.

WARNING !

When replacing electronic components, always implement ESD protection.

Return replacement PCBs only in ESD packaging.

Return defective or exhausted batteries to the factory for proper disposal.

6.2 Component Replacement

Opening the unit

Before opening the unit switch the instrument off and disconnect power cord plug. To open the

unit, remove the 7 attachment screws on the base of the unit, place top shell to the left next to the

instrument. When reassembling the unit, make sure that none of the cables are pinched.

Replacing the PCB

The PCB is located in the top shell. With the unit open, first disconnect the plug connections

KOPOS and KONEG to the HV-capacitor. Disconnect the plug connection BATTLOAD

(only if the unit is equipped with battery). Disconnect the plug connection PADDLENEG,

PADDLEPOS, PADCONN1 and PADCONN2 to the paddles. At the Responder 1100

disconnect the remaining plugs to the keypad (plug connection KEYCONN) and to the Sync

input (plug connection SYNC). Then remove the 12 attachment screws.

Replacing the battery module

The battery module is located in the bottom shell. With the unit open, first disconnect the plug

connection BATTLOAD to the PCB. Then remove the 4 attachment screws.

Caution: Use only original GE Medical Systems batteries (see chapter 11, Spare Parts List)

Return defective battery module to the factory for proper disposal.

227 487 20 Rev G

Page 21

GE Medical Systems

Information Technologies Responder 1000/1100 Page 21/38

Service Instruction

───────────────────────────────────────────────────────────────────

7 Troubleshooting

Unit cannot be switched on during line-power operating:

Green LED (AC line power indicator) fails to light up and unit cannot be switched on

- line power cord defective or not connected properly ?

- mains connection on PCB correctly ?

- primary fuse inside the unit defective ?

- input voltage selection (S500) in the correct position ?

if all items above are OK: Î PCB defective

Green LED (AC line power indicator) lights, unit still cannot be switched on

- input voltage selection (S500) in the correct position ?

if all items above are OK: Î PCB defective

Unit cannot be switched on during battery operation:

- battery charged ?

- plug connection BATTLOAD on PCB connected ?

- connect mains cord, green LED (power indicator) and green LED (battery indicator)

must light up and unit can be activated ? If not, see above.

- battery charge activated when connecting the mains cord ?

- After 10 minutes charging, disconnect the mains cord. Can unit be switched on ?

Î battery module defective or battery capacity too low

Battery does not charge:

- green LED (power indicator) and green LED (battery indicator) must light up

- Check connector BATTLOAD to battery module

- Check connection BATTPLUS and BATTMINUS at PCB battery module

if all items above are OK: Î PCB battery module or battery is defective

Error detected during self-test:

If an error is detected during the self-test, the red Service-LED lights and an acoustic signal

sounds. (see chapter 5. Unit Test Functions)

227 487 20 Rev G

Page 22

GE Medical Systems

Information Technologies Responder 1000/1100 Page 22/38

Service Instruction

───────────────────────────────────────────────────────────────────

8 Maintenance and Technical Inspection

8.1 Testing Equipment

defibrillator-tester

standard 1V-ECG signal generator

8.2 Technical Inspection

Caution!

The unit uses high voltage. The inspection should be referred to

independent persons with adequate training and experience.

The Technical inspections must be carried out once every year.

Note!

The following checks and tests must be carried out by personnel who are qualified to maintain this

equipment.

Note:

Check the operational safety and the functional safety of the unit using the following check lists.

They serve the experienced technician to check the appliance. The person carrying out checks and

inspections must be familiar with the operation of the unit as specified in the operating

instructions.

The test items are based on the following measuring and test equipment:

The tests should be carried out with customer´s accessories. This will ensure that any defective

accessories are automatically identified. If measuring and test equipment other than the above is

used, the test items and the tolerance values may have to be modified accordingly.

8.2.1 Visual Checks

Check unit and accessories to make sure that:

- internal fuse comply with the values specified by the manufacturer

- safety notices attached to the unit are readable

- the mechanical condition allows the continued use of the unit

- no pollution reducing the safety standards are found

The defibrillator electrodes as well as handles and holder recesses must be free of any cream

residue. The defibrillator electrodes, power cord and Sync cable should be checked for any visible

external damage to the insulation and strain relief.

227 487 20 Rev G

Page 23

GE Medical Systems

Information Technologies Responder 1000/1100 Page 23/38

Service Instruction

───────────────────────────────────────────────────────────────────

8.2.2 Function Checks

AC line power LED

Connect the unit to mains. The green LED (AC line power indicator) must light up.

Power-up

Switch the unit on with energy selector switch (turn rotary switch to the first position 2J). After

power-up and during operation, the Responder 1000/1100 runs automatic self-tests.

After power-up, the unit beeps and all LED’s will briefly light up. Afterwards the green “OnLED” lights up and the unit is ready. When the unit detects an error, the "Service" LED lights up

and an acoustic signal sounds. Every three seconds the unit try’s a new restart and test whether the

error still appears. (see chapter 6. Unit test functions)

Automatic defibrillator discharge after 60 sec

see chapter 4. Adjustment and Performance Instruction

Adjustment of charge current

see chapter 4. Adjustment and Performance Instruction

Adjustment of the charge monitor LED’s

see chapter 4. Adjustment and Performance Instruction

Adjustment of the energy

see chapter 4. Adjustment and Performance Instruction

Delivered energy

The paddles must be locked at the defibrillator-tester.

Prerequisite for the following test <energy 360 joules in 11 second>

The battery must be fully charged or the instrument must be connected to mains.

Switch instrument on. Switch energy selector to 360 joules. Start energy charge by pressing the

charge/shock key in the electrode handle. Energy must be available after approx. 11 second.

As soon as the charge operation is complete a acoustic signal sounds. Release the defibrillation

pulse with the charge/shock key and the shock key within the next 60 seconds.

Test all energy levels:

Select each energy level and start energy charge every time by pressing the charge/shock key in the

electrode handle. Check that all indicators (LED’s) light up one after the other up to the selected level.

After the device beeps (defibrillator is charged), release the Shock immediately.

The values (tolerance range) for the energy released is given in the table next page.

If an energy adjustment proves necessary, see chapter 4. Adjustment and Performance Instruction.

Energy selected Energy released

227 487 20 Rev G

Page 24

GE Medical Systems

Information Technologies Responder 1000/1100 Page 24/38

Service Instruction

───────────────────────────────────────────────────────────────────

2

5

7

10

20

30

50

100

200

300

360

1-3

4-6

6-8

8-12

18-22

28-32

47-53

93-107

185-215

278-322

333-387

Synchronized defibrillation

Connect the Sync-cable to the defibrillator. Use a standard 1V-ECG signal generator (connected

to Pin 1 and 5) or digital pulse (connected to Pin 3 and 2) to generate signals. Set energy selector

switch to any energy setting. Press the Sync key on the defibrillator. The Sync function should

now be indicated by the Sync LED. As soon as a correct trigger signal is available, the indicator

goes off with each trigger pulse.

The paddles must be locked at the defibrillator-tester. Start energy charge by pressing the

charge/shock key in the electrode handle. As soon as the charge operation is complete a acoustic

signal sounds. Press the charge/shock key and the shock key. Shock release is effected by the Rpeak of the beat. Afterwards, the Sync function is automatically reset.

Battery

Proper maintenance of NiCd batteries is essential and considerably promotes their proper

performance. Routine preventive maintenance should be carried out qualified service technicians

on a regular basis. If batteries are repeatedly partially discharged, the resulting “memory effect”

dramatically reduce the battery capacity. This effect can be efficiently minimized by regular

conditioning. If the capacity of a relatively new battery is drastically reduced, the battery must be

reconditioned by repeated charging and discharging.

Yearly Battery Maintenance (Conditioning) and Checks

1. Charge the battery for min. 14 hours. While charging, the green battery LED must light up.

2. Disconnect the unit from the power line and discharge fully charged battery. To do so,

discharge the battery by defibrillation into the defibrillator-tester.

3. Min. 20 defibrillation at 360 joules must be possible. If less, the battery is too old or

improperly maintained and should be replaced. The red battery LED must light up when

battery is almost discharged.

4. Recharge the battery. This will take 14 hours.

Rechargeable batteries require special maintenance and continued checks to assure their function

in emergency situations. If is normal for batteries of this type to selfdischarge when not in use.

Note : Batteries must be replaced every 3 years.

227 487 20 Rev G

Page 25

GE Medical Systems

Information Technologies Responder 1000/1100 Page 25/38

Service Instruction

───────────────────────────────────────────────────────────────────

8.3 Safety Analysis T est

8.3.1 General Information

The suggested Safety Analysis Test refer to the international Standard IEC 601-1.

The tests are generally performed with Safety Testers, on most of them, the measuring circuits

according IEC 601 are already implemented.

The tests which have to be performed are described generally, for the handling of your Safety

Tester follow the user manual.

The tests may be performed under normal ambient conditions of temperature, humidity and

pressure and with line voltage.

The leakage currents correspond to 110 % of rated voltage for the tested unit. Most Safety Testers

take this into account, otherwise the measured values have to be calculated.

Recommended test equipment

- Safety Tester for measurements according IEC 601.

- Testing connector for the following description.

8.3.2 Measuring of Leakage Current

To proceed the suggested measurements, the unit under test has to be separated from any

interconnection to a system. If the unit is part of a system, extended tests according IEC 601-1-1

have to be performed. The following diagram shows the needed Measuring Circuit [M] for leakage current. The reading in mV corresponds to uA (leakage current). The Safety Testers

generally work with this Measuring Circuit [M] and the displayed values are already converted to

leakage current.

227 487 20 Rev G

Page 26

GE Medical Systems

Information Technologies Responder 1000/1100 Page 26/38

Service Instruction

───────────────────────────────────────────────────────────────────

8.3.3 Enclosure Leakage Current

This test is performed to measure leakage current from chassis to ground during normal conditions

(N.C.) and single fault conditions (S.F.C.).

In any case, the leakage current is measured from any exposed conductive parts to ground, the unit

under test has to be switched on and off.

Connect the unit under test to your Safety Tester.

- During normal conditions (N.C.), referring to the electrical diagram, measurements have to

be done under following conditions:

* Polarity switch Norm and RVS

* GND switch n/a

* S1 closed

- During single fault conditions (S.F.C.), referring to the electrical diagram, the measurements

have to be done under following conditions:

* Polarity switch NORM and RVS

* GND switch n/a

* S1 open

Test has failed if the measured values are greater than:

N.C. S.F.C

100 μA 500 μA

300 μA (U.L. requirements)

Electrical diagram for Enclosure Leakage Current Test

227 487 20 Rev G

Page 27

GE Medical Systems

Information Technologies Responder 1000/1100 Page 27/38

Service Instruction

───────────────────────────────────────────────────────────────────

8.3.4 Patient Leakage Current

This test performs a leakage current test under single fault conditions (S.F.C.) dependent of

domestic power outlet with 115 or 230 V AC as source into the floating inputs.

The following signal have to be tested:

From paddles

In any case, the leakage current is measured from paddles of unit under test, to ground.

For testing the floating input from paddles, the test is measured on each defibrillator paddle.

Connect the unit under test to your Safety Tester.

- Referring to the electrical diagram, measurements have to be done under following conditions

* Polarity switch NORM and RVS

* GND switch GND closed

* S1 closed

Test has failed if the measured values are greater than 100 μA at defibrillator paddles.

Electrical Diagram for Patient Leakage Current Test

For protection of the person, the following values of resistor R may be used:

Type BF 22 kOhm (120 to 130 V)

47 kOhm (220 to 240 V)

Type CF 100 kOhm (220 to 240 V)

227 487 20 Rev G

Page 28

GE Medical Systems

Information Technologies Responder 1000/1100 Page 28/38

Service Instruction

───────────────────────────────────────────────────────────────────

9 Technical Description

The “Technical Description” section describes the technical data of the unit valid at the time

of printing

Operating mode

• Responder 1000, non-synchronized defibrillation

• Responder 1100, non-synchronized and synchronized defibrillation

Energy selection

• Selectable energy levels, energy to be delivered into a 50-ohm external resistance (max.

energy of 50 joules for internal defibrillation by Responder 1100)

2

5

7

10

20

30

50

100

200

300

360 joules

• possible deviation from selected energy less than deviations permitted by IEC regulations

Energy storage

By means of capacitor, capacitor is charged from the power line or from battery.

Typical capacitor charge time to energy level of 360 joules:

• at line voltage or from full charged battery: 11 s

at 90% of line voltage or from partially discharged battery: 12 s (15 s max.)

measured at least 5 minutes after 15 shocks of 360 joules each

• internal safety discharge (see Safety discharge)

• stored energy level indicated by LED's

• "charge done" indicated by buzzer

Defibrillation shock

Capacitor discharge via induction coil (damped serial resonant circuit), pulse shape resembling

sinusoidal halfwave with decay period

• pulse duration for an external resistance of 50 ohms approximately 4.2 ms, measured from

beginning of the pulse to the intersection of the zero line and the inflection point of the trailing

pulse edge

• in synchronized mode the defibrillation shock is released within 25 ms of the R-wave trigger

227 487 20 Rev G

Page 29

GE Medical Systems

Information Technologies Responder 1000/1100 Page 29/38

Service Instruction

───────────────────────────────────────────────────────────────────

Discharge circuit

• serial oscillating circuit with external resistance (patient)

• capacitance 35 µF

• inductance 45 mH

• equivalent resistance 10.7 ohms, in series with external resistance (patient)

Pulse output

isolated , no conductive connection to other parts of the circuit or the enclosure, test voltage

9 kV DC, open-circuit and short-circuit-proof, type CF according to IEC requirements

Safety discharge

Capacitor discharge via internal load resistance:

• when the defibrillation shock is not triggered within 60 s after charging

• when the defibrillation shock is triggered, but the discharge circuit is interrupted, after

approx. 0.2 s

• immediately when reducing or increasing the selected energy during or after charging

• when the selected energy is not reached, after 30 s

• in the event of technical malfunctions

Test features

• LED’s for unit status: line connected, power on and battery charging

• Automatic defibrillator test on power up with LED for error indication

Synchronization (Responder 1100)

In the SYNC mode and in conjunction with a monitor, the unit can be used for synchronized

defibrillation

Synchronization via the SYNC interface can be achieved in two ways:

• by SYNC signal from the monitor (SYNC-pulses) or

• by SYNC signal (analog 1-Volt ECG) derived from the 1V-ECG via QRS-Trigger

With digital SYNC pulses

• Shock release: rising edge

• Input trigger threshold: VIH = +2.2 V (min.)

VIL = +1.8 V (max.)

• Input voltage range (typ.): 0 to +5 V

• Input voltage (max.): +15 V

• Input impedance: 10 KΩ (min)

• Pulse width (min.): >1 ms

With analog "1-Volt ECG"

• Input amplitude (typ.): 1 V (1 V/mV)

• Input voltage range: +/- 4 V

• Input voltage (max.): ±15 V

• Input impedance (min.): 10 KΩ

227 487 20 Rev G

Page 30

GE Medical Systems

Information Technologies Responder 1000/1100 Page 30/38

Service Instruction

───────────────────────────────────────────────────────────────────

Digital marker output

The trigger signal can be checked on the monitor screen. For this purpose, the Responder 1100

supplies a marker signal. Some patient monitors (e.g. Eagle 3000/4000) use this signal to

superimpose the trigger signal on the ECG waveform.)

• output voltage VOH = 3.5V (min.) at 1 mA

VOL = 0.5 V (max.) at 1 mA

• input impedance (min.) 200 Ω nominal

• output current 25 mA (max.)

• pulse width (min.) >100 ms

Power

From the power line, design in compliance with protection class II requirements of IEC 601

Model for rated voltage of 230...240 V

• operating voltage range 207...264 V, 49 to 65 Hz

• rated current 0.5 A

Model for rated voltage of 115...120 V

• operating voltage range 104 to 132 V, 49 to 65 Hz

• rated current 1.0 A

Power for models with built-in rechargeable NiCd battery

• rated voltage 18 V

• rated capacity 600 mAh

• charging time for depleted battery approximately 14 hours, overcharge protection

• battery charging from built-in power supply also during line-power operation

• a new and fully charged battery powers the defibrillator for approximately 25 defibrillation

shocks of 360 joules each (into 50 ohms) (with new, full charged battery at least 25 shocks at

an ambient temperature of 20 °C / 68 °F)

Operational readiness

2 s after power up (incl. Automatic selftest)

Operating position

any

Ambient conditions

• Operation

Temperature between 0 and +40 °C

relative humidity between 10 and 95%, no condensation

atmospheric pressure between 700 and 1060 hPa

• Storage and transport

Temperature between -30 and +60 °C

relative humidity between 10 and 95%, no condensation

atmospheric pressure between 500 to 1060 hPa

227 487 20 Rev G

Page 31

GE Medical Systems

Information Technologies Responder 1000/1100 Page 31/38

Service Instruction

───────────────────────────────────────────────────────────────────

Dimensions

• width 332 mm (13 in.)

• depth 300 mm (11.8 in.)

• height 130 mm (5 in.)

Weight

• model without battery approximately 5.4 kg (11.0 lbs)

• model with battery approximately 5.8 kg (12.8 lbs)

10 Spare Part List Responder 1000 Version’s

Part Number Description

101 166 01 without Battery 230V-240V

101 166 02 with Battery 230V-240V

101 166 03 without Battery 115V-120V US

101 166 04 with Battery 115V-120V US

101 166 05 without Battery 230V-240V MiniDef III, Esaote

101 166 06 with Battery 230V-240V MiniDef III, Esaote

101 166 07 without Battery 115V-120V

101 166 08 with Battery 115V-120V

101 166 09 without Battery 230V-240V US

101 166 10 with Battery 230V-240V US

101 166 23 without Battery 230V-240V China

101 166 24 with Battery 230V-240V China

Responder 1100 Version’s

Part Number Description

101 166 11 without Battery 230V-240V

101 166 12 with Battery 230V-240V

101 166 13 without Battery 115V-120V US

101 166 14 with Battery 115V-120V US

101 166 15 without Battery 230V-240V MiniDef III, sync, Esaote

101 166 16 with Battery 230V-240V MiniDef III, sync, Esaote

101 166 17 without Battery 115V-120V

101 166 18 with Battery 115V-120V

101 166 19 without Battery 230V-240V US

101 166 20 with Battery 230V-240V US

227 487 20 Rev G

Page 32

GE Medical Systems

Information Technologies Responder 1000/1100 Page 32/38

Service Instruction

───────────────────────────────────────────────────────────────────

Operator's Manual Responder 1000

Part Number Description

227 487 01 Operator’s Manual German

227 487 02 Operator’s Manual English

227 487 03 Operator’s Manual French

227 487 04 Operator’s Manual USA

227 487 05 Operator’s Manual Italian

227 487 06 Operator’s Manual Spanish

227 487 07 Operator’s Manual Russian

227 487 08 Operator’s Manual Swedish

227 487 09 Operator’s Manual ESAOTE

227 487 10 Operator’s Manual Portuguese

227 487 16 Operator’s Manual Polish

227 487 17 Operator’s Manual Czech

227 487 21 Operator’s Manual Chinese

2033249-002 Operator’s Manual Estonian

2033249-003 Operator’s Manual Latvian

2033249-004 Operator’s Manual Lithuanian

Operator's Manual Responder 1100

Part Number Description

227 488 01 Operator’s Manual German

227 488 02 Operator’s Manual English

227 488 03 Operator’s Manual French

227 488 04 Operator’s Manual USA

227 488 05 Operator’s Manual Italian

227 488 06 Operator’s Manual Spanish

227 488 07 Operator’s Manual Russian

227 488 08 Operator’s Manual Swedish

227 488 09 Operator’s Manual ESAOTE

227 488 10 Operator’s Manual Portuguese

Service Manual

Part Number Description

227 487 20 Service Manual Responder 1000/1100

227 487 20 Rev G

Page 33

GE Medical Systems

Information Technologies Responder 1000/1100 Page 33/38

Service Instruction

───────────────────────────────────────────────────────────────────

Housing Parts

Part Number Description

432 525 32 Housing upper shell for Responder 1000

432 525 31 Housing upper shell for Responder 1100

432 519 81 snap spring for Defibrillator paddles

432 519 60 Housing lower shell for Responder 1000/1100

924 017 20 Device foot

Label for Housing upper shell Responder 1000 (Logo: GE marquette)

Part Number Description

430 520 12 German

430 520 17 English

430 520 18 French

430 520 23 Italian

430 520 25 Spanish

430 520 27 Russian

430 520 28 Swedish

430 520 32 Portuguese

430 520 99 Chinese

2037488-001 Polish

2037299-001 Lithuanian

2041048-001 Estonian

2041050-001 Hungarian

2041052-001 Latvian

Label for Housing upper shell Responder 1000 REMCO (EP700 Cardioline)

Part Number Description

430 520 51 Italian

Label for Housing upper shell Responder 1000 (Logo: marquette)

Part Number Description

430 520 13 English, U.S. version

Label for Housing upper shell Responder 1000 Minidef PRO (Logo: ESAOTE)

Part Number Description

430 520 14 Italian

227 487 20 Rev G

Page 34

GE Medical Systems

Information Technologies Responder 1000/1100 Page 34/38

Service Instruction

───────────────────────────────────────────────────────────────────

Label for Housing upper shell Responder 1100 (Logo: Marquette Hellige)

Part Number Description

430 520 09 German

430 520 19 English

430 520 20 French

430 520 24 Italian

430 520 26 Spanish

430 520 29 Russian

430 520 30 Swedish

430 520 33 Portuguese

Label for Housing upper shell Responder 1100 (Logo: marquette)

Part Number Description

430 520 20 English, U.S. version

Label for Housing upper shell Responder 1000 Minidef SYC (Logo: ESAOTE)

Part Number Description

430 520 11 Italian

Label for Housing lower shell Responder 1000/1100

Part Number Description

430 520 83 German

430 520 84 English

430 520 85 French

430 520 86 Italian

430 520 87 Spanish

430 520 88 Russian

430 520 89 Swedish

430 520 90 Portuguese

430 520 98 Chinese

430 521 01 Czech

2037489-001 Polish

2037300-001 Lithuanian

2041049-001 Estonian

2041051-001 Hungarian

2041053-001 Latvian

227 487 20 Rev G

Page 35

GE Medical Systems

Information Technologies Responder 1000/1100 Page 35/38

Service Instruction

───────────────────────────────────────────────────────────────────

Label for Housing lower shell Responder 1000

Part Number Description

2027555-001 WEEE label

2034056-020 China RoHS label

Keypad’s

Part Number Description

390 001 79 Keypad for Responder 1000 with Battery

390 001 80 Keypad for Responder 1000 without Battery

390 001 77 Keypad for Responder 1100 with Battery

390 001 78 Keypad for Responder 1100 without Battery

Connector`s

Part Number Description

383 273 86 Sync connector complete wired (Responder 1100)

383 272 24 Wire set for High voltage capacitor

303 446 64 Electrode coupling for Defibrillator paddles (Responder 1100)

Printed circuit board`s

Part Number Description

388 032 79 Spare PCB Responder 1000/1100

389 004 31 Exchange PCB Responder 1000/1100

Battery Part

Part Number Description

205 100 02 Battery Module complete

388 032 80 PCB Battery Module

383 273 72 Wire set Battery Module

504 654 54 Battery holder

929 165 31 Battery chargeable

227 487 20 Rev G

Page 36

GE Medical Systems

Information Technologies Responder 1000/1100 Page 36/38

Service Instruction

───────────────────────────────────────────────────────────────────

Miscellaneous Parts

Part Number Description

903 449 88 High voltage capacitor 35µF

482 035 21 Energy selector button

303 439 42 Mains cable

2031736-001 Power Cord China

217 338 01 Defib electrode Shock Sternum (Responder 1000)

217 338 02 Defib electrode Charge/Shock Apex (Responder 1000)

217 337 01 Defib electrode (Responder 1100)

303 439 96 Contact insert for Defib paddles

384 018 72 Accessories pan complete with housing foot and screw

223 428 01 Sync. cable with open end for Responder 1100

Sync. Cable to different Monitors

Part Number Description

223 428 01 Sync. Cable with open end for Responder 1100

223 428 02 Sync. Cable to Eagle 3000/4000, Solar 8000

223 428 03 Sync. Cable to Eagle 1000

223 428 04 Sync. Cable to Case 8000

Supplies for Responder 1000

Defibrillation external

Part Number Description

303 439 96 Contact plate for Defib electrodes 1pcs

303 439 95 Electrode adapter for children, 1pcs

Consumables

Part Number Description

217 083 05 Electrode cream,10 tubes/cs

217 083 18 Electrode cream,250 ml refill

217 083 14 Electrode cream,51 container

930 115 82 Dispenser,30ml

227 487 20 Rev G

Page 37

GE Medical Systems

Information Technologies Responder 1000/1100 Page 37/38

Service Instruction

───────────────────────────────────────────────────────────────────

Supplies for Responder 1100

Defibrillation external

Part Number Description

217 337 01 Defib electrode, external,

217 337 02 Defib electrode, external,

303 439 96 Contact plate for Defib electrodes, 1pcs

303 439 95 Electrode adapter for children, 1pcs

217 329 01 Defib electrode anterior-posterior

919 202 94 Defibrillator-Pacing electrode, adult, disposable, 1 pair

919 202 95 Defibrillator- Pacing electrode, children, disposable ,1pair

223 383 01 Adapter for 91920294 and 91920295

Defibrillation internal

Part Number Description

217 308 01 Pair of defib electrodes for internal defibrillation (w/o. contact insert)

384 013 19 Contact inserts (2), internal, for adults

384 013 20 Contact inserts (2), internal, for children

384 013 21 Contact inserts (2), internal, for babies

919 202 36 External counter electrode for internal defibrillation

Consumables

Part Number Description

217 083 05 Electrode cream, pkg. of 10 tubes

217 083 18 Electrode cream, 250-ml bottle, refillable

217 083 14 Electrode cream, 51 container

930 115 82 Dispenser pump

227 487 20 Rev G

Page 38

GE Medical Systems

Information Technologies Responder 1000/1100 Page 38/38

Service Instruction

───────────────────────────────────────────────────────────────────

11 Schematics

Circuit Diagrams

Mechanical Drawing Responder 1000 101 166 01/02, 07/08, 23/24

Mechanical Drawing Responder 1000 101 166 03/04, 09/10

Mechanical Drawing Responder 1100 101 166 11/12, 17/18

Mechanical Drawing Responder 1100 101 166 13/14, 19/20

Mechanical Drawing MiniDef III 101 166 15/16

Complete Wiring Diagram Responder 1000 101 166 01,02,05,06,07,08,23,24 Sheet 1

Complete Wiring Diagram Responder 1100 101 166 11...20 Sheet 1

Master Record Index 101 166 .. Sheet 2

PCB Responder 1000/1100 388 032 79 P Sheet 1...6

388 032 79 R Sheet 1...2

PCB Battery Module 388 032 80 P Sheet 1

388 032 80 R Sheet 1

Sync Cable Responder 1100 223 428 01

227 487 20 Rev G

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Diese Tabelle definiert die gültigen Konfigurationen von : Responder 1000 Version 1

This table defines the valid configurations of : Responder 1000 Version 1

Component Part No. Rev. compatible (Service) in Device sw. rel.

Lpl Responder 1000/1100, PCB Responder 1000/1100 388 032 79 L D,E,F,G,H,I,J,K 01,02,05, V1.2

06,07,08,

22,23,24

Ersatzteil-Nr. , Spare Part No. 388 032 79

Austausch Nr. , Replacement No. 389 004 31

Batterie Modul , Battery Module 205 100 02 A 02,04,06,

08,22,24

Lpl Batterie Modul , PCB Battery Module 388 032 80 B 02,04,06,08

22,24

Paddle Defib Shock 217 338 01 D B, C 01,02,05,06,

07,08,22,23,24

Paddle Defib Charge / Shock 217 338 02 D B, C 01,02,05,06,

07,08,22,23,24

Defi Kondensator , Defib Capacitor 903 449 88 A2 A, A1 01,02,05,06,

07,08,22,23,24

Komponente Sachnummer Index kompatibel (Service) in Variante Sw.Rel.

GE Medical Systems IT GmbH

Munzinger Str. 3

D-79111 Freiburg

Master Record Index (MRI)

File Name

10116601-D07_SZ02

Dokument Bezeichnung – Document Description

doc schem dwg SZ02

Dokument Nr. – Document No.

10116601-D07

q 089876 Defib capacitor added 04.12.07 P.Fischer

p 082042 General reworked, Resp.1100 removed 21.06.06 P.Fischer

o 076243 Index von 388 032 79 auf L gesetzt 11.03.04 P.Fischer

n 074451 Index von 388 032 79 auf K gesetzt 19.08.03 P.Fischer

m 072696 Elektroden 217 338 .. von C nach D 14.01.03 B.Deimel

l 071347 Elektrodenpaar..01 v. B n. C,..02 v. C n.D 30.09.02 B.Deimel

Änd.Index

Rev. No.

Blatt Nr. – Page No.

SZ/02

Teil Bezeichnung – Part Description

Responder 1000

ECO No. Änderungsbeschreibung – Change Description Datum-Date Name

MRI

Format

A4

Entworfen-Drawn:

Geprüft-Approved:

Teil Nr. – Part No.

30.06.98 G.Kaltenb.

Electronical

in Agile

101 166 ..

© 1998, 2007 General Electric Company. All rights reserved. / Schutzvermerk nach DIN 34 beachten !

Page 47

Marquette Hellige GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

063764 22.02.00/MSG

REVISIONS

Index

A

Date / Name

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

43367260

Date / Name

18.12.97/BNH

18.12.97/BNH

B. HAGER

388 032 79 - D02

SCHEMATIC

RESPONDER 1000/1100

/home/projects_b/f67260/design

Sheet:

16

of

[1997, 12, 2, 3]

Page 48

Marquette Hellige GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

063764

067395

REVISIONS

Index

A

B

Date / Name

22.02.00/MSG

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

F67260

Date / Name

17.12.97/JFS05.07.01/TYR

17.12.97/JFS

J. SCHULER

388 032 79 - D03

SCHEMATIC

RESPONDER 1000/1100

/home/projects_b/f67260/design/power_supply

Sheet:

62

of

[1997, 12, 12, 6]

Page 49

GE Medical Systems

Information Technologies GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

060448

063764

074451

REVISIONS

Index

A

B

C

Date / Name

23.06.98/MSG

22.02.00/MSG

13.08.03/TYR

A01

DRAWN

APPROVED

ISSUED

D-79111 Freiburg

Munzinger Str. 3

43367260

Date / Name

17.12.97/BNH

17.12.97/BNH

B. HAGER

388 032 79 - D04

SCHEMATIC

RESPONDER 1000/1100

Sheet:

of

36

DATE

DIR

Page 50

Marquette Hellige GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

REVISIONS

Index

A

Date / Name

22.02.00/MSG063764

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

43367260

Date / Name

18.12.97/BNH

18.12.97/BNH

HAGER

388 032 79 - D05

SCHEMATIC

RESPONDER 1000/1100

/home/projects_b/f67260/design/control

Sheet:

64

of

[1997, 12, 8, 2]

Page 51

Marquette Hellige GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

063764

067395

REVISIONS

Date / Name

Index

A

22.02.00/MSG

B

05.07.01/TYR 18.12.97/BNH

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

43367260

Date / Name

18.12.97/BNH

HAGER

388 032 79 - D06

SCHEMATIC

RESPONDER 1000/1100

/home/projects_b/f67260/design/output

Sheet:

6

5

of

[1997, 12, 2, 3]

Page 52

Marquette Hellige GmbH

Not equipped in Version :

x1

38803279

x2

x3

x4

x5

Revision-No

060448

063764

REVISIONS

Index

A

B

Date / Name

23.06.98/MSG

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

43367260

Date / Name

18.12.97/BNH22.02.00/MSG

18.12.97/BNH

B. HAGER

388 032 79 - D07

SCHEMATIC

RESPONDER 1000/1100

/home/projects_b/f67260/design/sync

Sheet:

66

of

[1997, 12, 11, 5]

Page 53

Page 54

Page 55

Marquette Hellige GmbH

Not equipped in Version :

x1

38803280

x2

x3

x4

x5

Revision-No

--

-065687

REVISIONS

Index

--

-A

Date / Name

07.04.98/MNS

15.05.98/MSG

19.10.00/MSG

A03

DRAWN

APPROVED

ISSUED

D-79007 Freiburg

F67261

Date / Name

19.01.98/MSG

19.01.98/JFS

SCHULER

38803280-D04

SCHEMATIC

BATTERY MODULE

Sheet:

11

of

/home/projects_b/f67261/design

[1998, 1, 13, 3]

Page 56

Page 57

Page 58

Page 59

Page 60

GE Medical Systems

Information Technologies, Inc.

8200 West Tower Avenue

Milwaukee, WI 53233 USA

Tel: +1 414 355 5000

1 800 558 5120 (US only)

Fax: +1 414 355 3790

www.gehealthcare.com

GE Medical Systems

Information Technologies, GmbH

Munzinger Straße 3-5

D-79111 Freiburg

Germany

Tel: +49 761 45 43 - 0

Fax: +49 761 45 43 - 233

Asia Headquarters:

GE (China) Co., Ltd.

No1 Huatuo Road,

Zhangjiang Hi-Tech Park Pudong,

Shanghai, P.R.China 201203

Tel: +86 21 38777888

Fax: +86 21 38777402

Loading...

Loading...