Page 1

Dash Responder

Version V 1.0

Servicing Instructions

2004768-001 ENG Revision F

Page 2

GE Medical Systems

Information Technologies

Caution:

During repairs/service interventions, observe the protective measures against damage

due to ESD.

• GE Medical Systems Information Technologies GmbH is responsible for the

effects on safety, reliability, and performance of the device, only if

− assembly operations, extensions, readjustments, modifications, or

repairs are carried out by GE Medical Systems Information

Technologies GmbH or by persons authorized by GE Medical

Systems Information Technologies GmbH,

− the electrical installation of the relevant room complies with the

applicable national and local requirements, and

− the instrument is used in accordance with the instructions for use.

• This manual contains service information, operating instructions are provided in

the Operator’s Manual of the instrument.

• This manual is in conformity with the instrument at printing date.

• All rights are reserved for instruments, circuits, techniques, and names appearing in

the manual.

The authorized representative for GE Medical Systems Information Technologies Inc.

in Europe is:

GE Medical Systems

Information Technologies GmbH

Munzinger Str. 3

D-79111 Freiburg, Germany

Tel.+49(0)7614543-0

Fax:+49(0)7614543-233

©

2005 General Electric Company. All rights reserved.

Servicing Manual Dash Responder V1.0 Revision F

Page 2 of 72 2004768-001

Page 3

GE Medical Systems

Information Technologies

1 General Introduction_______________________________________________7

2 General Overview of the Dash Responder ______________________________9

GE Medical Systems Instrument Part Numbers _______________________________9

Configuration of Instrument Part Numbers __________________________________________ 9

Configuration of the PCB Part Numbers ____________________________________________ 9

Instrument status documentation __________________________________________________ 9

Instrument Versions of the Dash Responder __________________________________9

3 General Description_______________________________________________10

Dash Responder Block Diagram ___________________________________________10

Dash Responder Device___________________________________________________10

PCB Analog ____________________________________________________________10

Block Diagram _______________________________________________________________ 10

PCB Digital ____________________________________________________________11

Block Diagram _______________________________________________________________ 11

PCB Power Management _________________________________________________12

Block Diagram _______________________________________________________________ 12

PCB Pacer _____________________________________________________________13

Block Diagram _______________________________________________________________ 13

Battery ________________________________________________________________14

Batteries 2009218-001, 2009219-001 ________________________________________14

Battery conditioning___________________________________________________________ 16

Defective Battery _____________________________________________________________ 17

Battery replacement ___________________________________________________________ 17

4 Service Tool _____________________________________________________18

Software Download Information ___________________________________________18

Installation_____________________________________________________________19

Software Download ______________________________________________________19

Calibration_____________________________________________________________20

Monitor Interface test____________________________________________________21

Installation __________________________________________________________________ 21

Interface Test ________________________________________________________________ 22

5 Service Menu ____________________________________________________23

User configurable settings_________________________________________________23

Structure of the Service Menu _____________________________________________23

6 Replacing PCBs__________________________________________________26

Safety Information for Disassembly ________________________________________26

Disassembly Procedure___________________________________________________26

Opening Unit ________________________________________________________________ 26

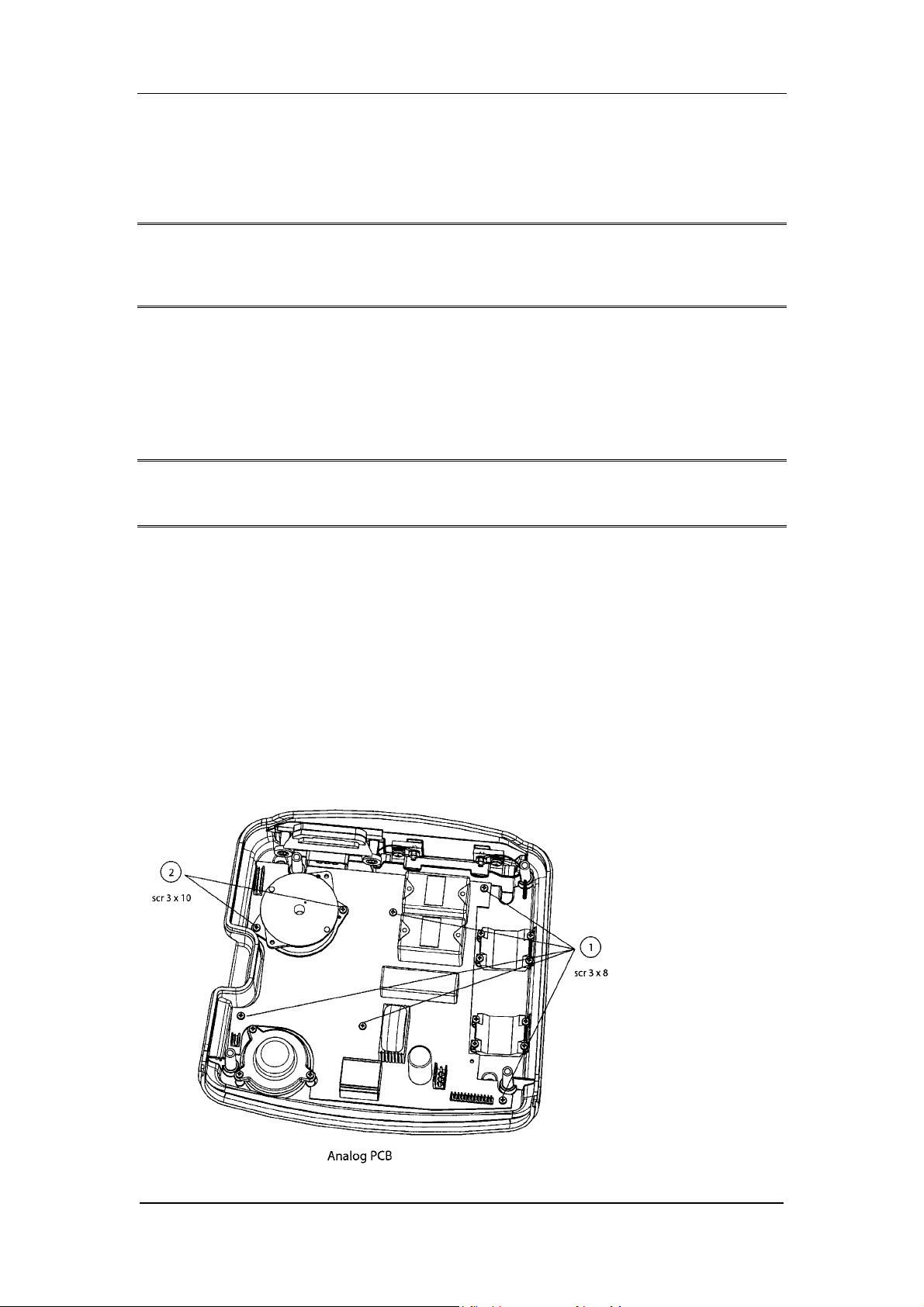

Analog PCB _________________________________________________________________ 26

Digital PCB _________________________________________________________________ 28

Pacer PCB __________________________________________________________________ 29

Power Management PCB / Battery Case ___________________________________________ 30

High-Voltage Capacitor ________________________________________________________ 32

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 3 of 72

Page 4

GE Medical Systems

Information Technologies

7 Troubleshooting Tips______________________________________________33

Electrostatic Discharge (ESD) _____________________________________________33

CMOS Components ___________________________________________________________ 33

Special Components___________________________________________________________ 33

Battery Failure _______________________________________________________________ 34

8 Error Messages and System Information______________________________36

Messages_______________________________________________________________36

Error Numbers _________________________________________________________37

9 Pin Configuration ________________________________________________38

External Connections ____________________________________________________38

Paddle Input Connector ________________________________________________________ 38

Monitor Connector____________________________________________________________ 39

Battery Connector ____________________________________________________________ 40

Internal Connections_____________________________________________________40

Digital P CB _________________________________________________________________ 40

Analog PCB _________________________________________________________________ 47

Power Management PCB _______________________________________________________ 49

Pacer PCB __________________________________________________________________ 49

10 Technical Specification __________________________________________50

Operating Modes________________________________________________________50

Energy Selection ________________________________________________________50

Defibrillator Charging ___________________________________________________50

Defibrillation Shock _____________________________________________________50

Discharge Circuit________________________________________________________51

Defibrillation Pulse Output _______________________________________________51

Safety Discharge ________________________________________________________51

Test Features ___________________________________________________________51

Synchronization_________________________________________________________52

Pacemaker _____________________________________________________________52

Power Supply___________________________________________________________52

Operational Readiness ___________________________________________________52

Operating Position_______________________________________________________52

Type of Protection_______________________________________________________52

Environment ___________________________________________________________52

Operation ___________________________________________________________________ 52

Transport and Storage _________________________________________________________ 53

Dimensions_____________________________________________________________53

Weight ________________________________________________________________53

Environmental Tests _____________________________________________________53

Servicing Manual Dash Responder V1.0 Revision F

Page 4 of 72 2004768-001

Page 5

GE Medical Systems

Information Technologies

11 Maintenance and Technical Inspection _____________________________54

Schedule _______________________________________________________________54

Manufacturer Responsibility ______________________________________________54

Visual Inspection ________________________________________________________54

General Cleaning________________________________________________________54

Checkout Procedures ____________________________________________________55

Testing Equipment ______________________________________________________55

Performance test ________________________________________________________56

Power up test ________________________________________________________________ 56

Key Test ____________________________________________________________________ 56

Display Test _________________________________________________________________ 57

Detection of internal Electrodes__________________________________________________ 57

Discharge and speaker test ______________________________________________________ 57

Pacemaker test _______________________________________________________________ 58

Defib Function Test and Pacer Option Test _________________________________________ 59

Battery conditioning te st _______________________________________________________ 59

12 Electrical Safety Tests ___________________________________________61

Patient (Sink) Leakage Current Test________________________________________62

13 Spare Parts List ________________________________________________64

14 Master Record Index (see Appendix) _______________________________69

15 Circuit Diagrams (see Appendix)___________________________________71

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 5 of 72

Page 6

GE Medical Systems

Information Technologies

REFERENCES

Reference Document Title

[UM] User Manual for Dash Responder Version 1.0 Rev. A (2002853-002-A)

[Lang] Languages of Dash Responder Version 1

Revision History

This manual is subject to the GE Medical Systems Information Technologies change order service. The

revision code, a letter that follows the document part number, changes with every update of the manual.

The initial version of the manual has the letter A.

Part No. Revision Code Date Comment

2004768-001 V 0.1 2001-03 Draft

2004768-001 Rev. A 2001-05 Release A

2004768-001 Rev. B 2001-07 ECO 067557

2004768-001 Rev C 2001-09 ECO 067925

2004768-001 Rev D 2002-12 ECO 070336

2004768-001 Rev E 2004-01 ECO 075782

2004768-001 Rev F 2005-05 ECO 080823

Servicing Manual Dash Responder V1.0 Revision F

Page 6 of 72 2004768-001

Page 7

GE Medical Systems

Information Technologies

1 General Introduction

The Dash Responder is a lightweight, portable defibrillator which must be connected to a Dash 2000 or

Dash 3000/4000 patient monitor for operation.

The Dash Responder is available with or without transcutaneous pacer.

The Dash Responder is powered from a rechargeable battery which is inserted into t he device. A new

fully charged batter y provides power for approx. 60 shocks with 360 J each or for approx. 5 hours of

pacemaker operation at an average pulse rate and pacer output (75 ppm, 100 mA).

The Dash Responder will not operate unless equipped with the battery.

The battery charges automatically when the system (patient monitor and Dash Responder) is connected

to the power line and both devices are not turned on. When the devices are on, the battery will charge

only when the Dash Responder does not require the full energy for operation the patient monitor is able

to deliver.

The Dash 3000/4000 also charges the defibrillator battery when disconnected from power line. A

separate, optional charging unit (ASU 3000) is available for battery charging.

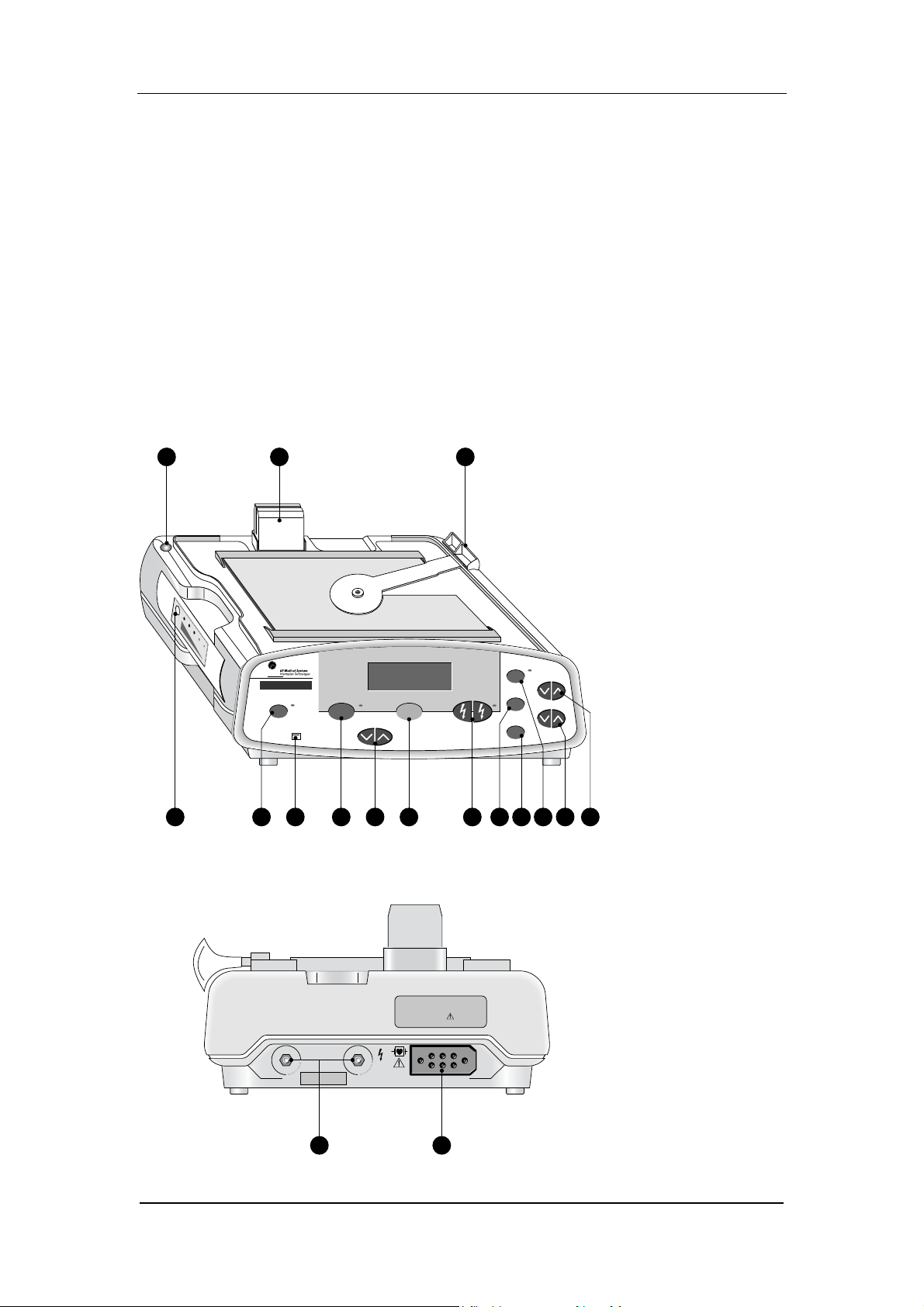

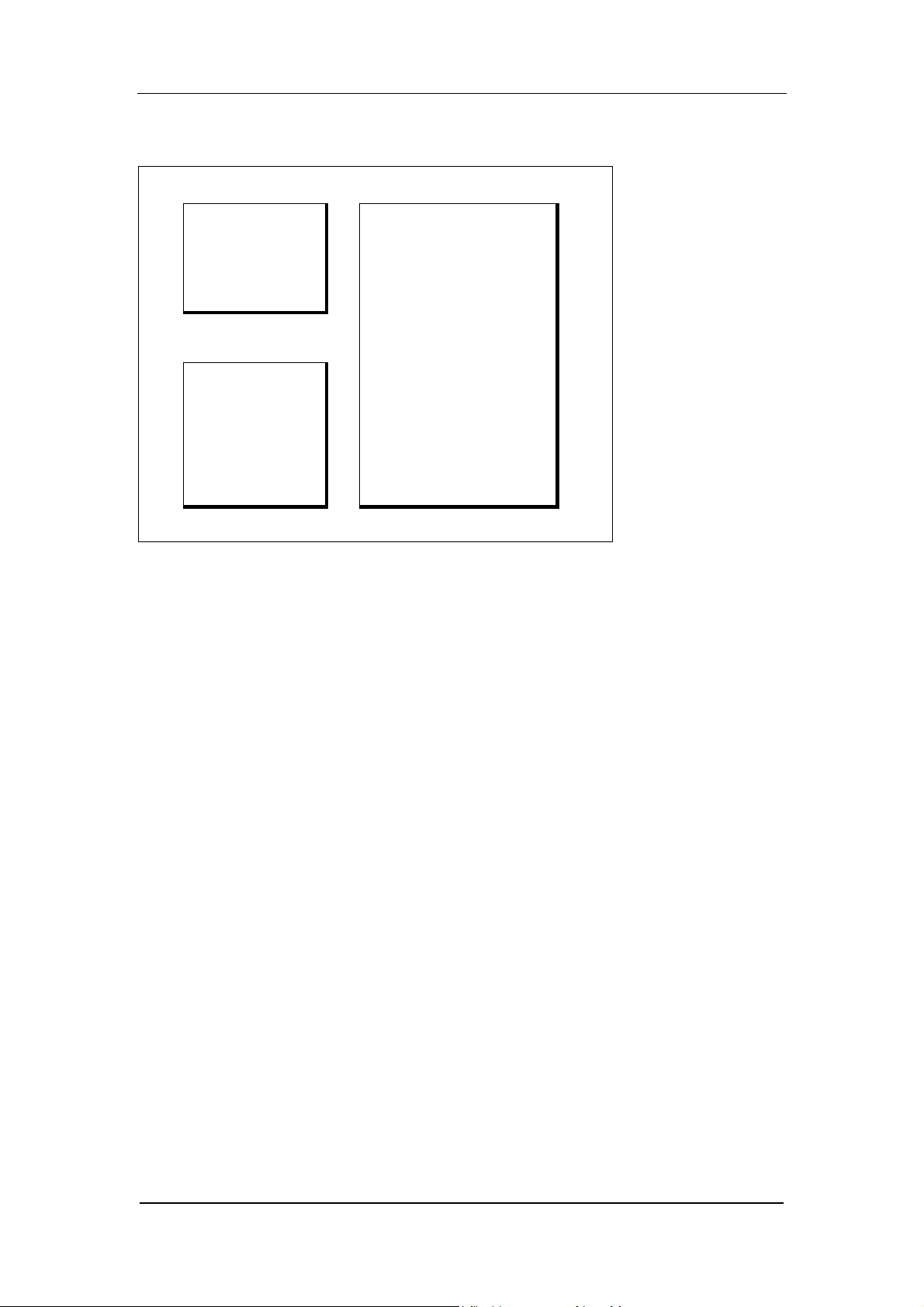

1 2 3

T

e

s

t

Pacer On/Off

Dash Responder

transport defibrillator

Sync.

On/Off Charge

123

Energy Select J (50

Shock

Ω

)Charging Status

Pacer Mode

Pacer Pause

Rate (ppm)

Output (mA)

4 1211109876 135 1514

GE Medical Systems

Information Technologies

D-79111 Freiburg

Munzinger Str. 3

Dash Responder

CAUTION

Defib Test 50 Ω

Refer to equipment

manual before

connencting to these connectors

16 17

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 7 of 72

Page 8

GE Medical Systems

Information Technologies

1 Button to unlock batter y for removal

2 Monitor connector

3 Locking lever

4 Battery with "Test" button and charge level indication

5

Sync. button with indicator to enable and disable the synchronized operating mode (when the

synchronized mode is enabled, the indicator is illuminated and goes off with each sync pulse)

6 Charging Status indicator

solid yellow: battery charging

solid green: battery charged

blinking yellow: charging error (replace battery)

flashing green: battery conditioning program active

7

On/Off button to turn the defibrillator on and off (indicator is illuminated when the device is

turned on)

8

9

10

Energy Select buttons to select the defibrillation energy

Charge button to initiate defibrillator charging

Shock buttons to release the s hock when adhesive or internal electrodes are connected (both

buttons must be pressed simultaneously);

the indicator lights up when the defibrillator is charged

11

12

13

Pacer Mode button to select the pacer operating mode (fixed rate, demand)

Pacer Pause button to suspend delivery of pacer pulses (without changing the pacer settings)

Pacer On/Off button with indicator to turn the pacemaker on and off (when the pacemaker is

enabled, the indicator is illuminated and goes off with each delivered pacer pulse)

14

15

Output (mA) button to change the pacer output current

Rate (ppm) button to change the pacer rate

16 Contacts for test discharge (possible only with adapter lead for adhesive defibrillation pads)

17 Connector for exchange of the defibrillation electrodes (switch off the device before exchanging

the electrodes!)

Servicing Manual Dash Responder V1.0 Revision F

Page 8 of 72 2004768-001

Page 9

GE Medical Systems

Information Technologies

2 General Overview of the Dash Responder

GE Medical Systems Instrument Part Numbers

Configuration of Instrument Part Numbers

The instrument part number comprises of ten digits, the first seven digits determine the instrument type

and the last three—separated by a hyphen—the instrument version.

The user language is determined by configuration, thus is no part of the instrument number.

Configuration of the PCB Part Numbers

The number of the PCB is listed on the barcode label. The label can be seen on the PCB without

dismounting.

As some PCBs need additional tests before they get delivered as field replacement boards, this boards

and assemblies were given separate spare part numbers.

Therefore were special field replacement spare parts are available this need to be ordered (see Spare

Parts List on page 64).

The affiliated documentation, e.g. reference diagrams, circuit diagrams and parts lists are listed under

the part number of the PCB part number.

Instrument status documentation

Due to hardware and software combination, unambiguous documentation of the instrument assembly

status is necessary also in event o f repairs.

Master Record Index

2002550-013

The master record index lists the valid configurations for the Dash Responder. Numbers for all

permissible components of t he device are listed. Spare part numbers are provided where available.

Instrument Versions of the Dash Responder

CAT No Description

2002550-001 DASH RESPONDER, MANUAL

2002550-002 DASH RESPONDER, MANUAL, PACER

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 9 of 72

Page 10

GE Medical Systems

Information Technologies

3 General Description

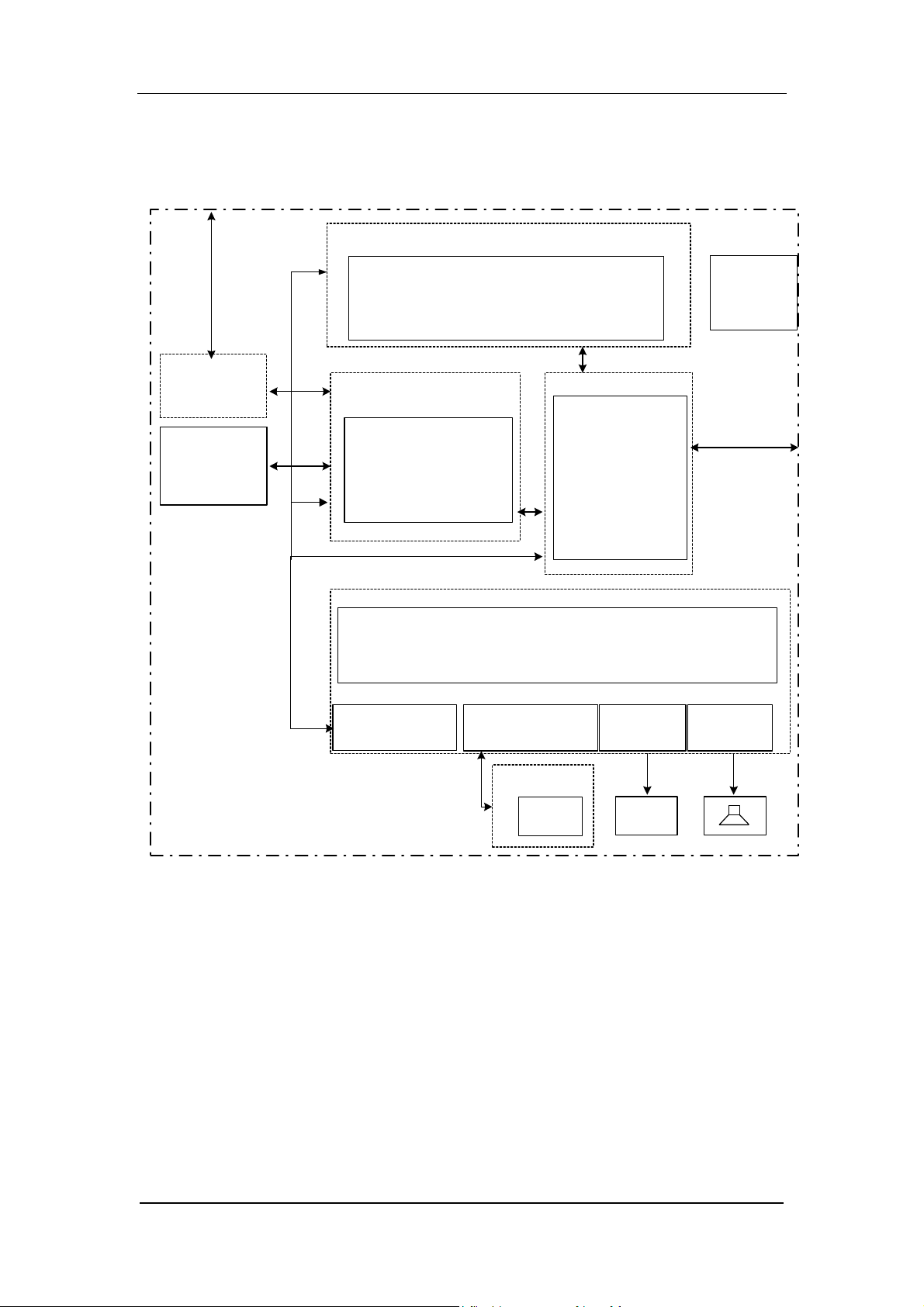

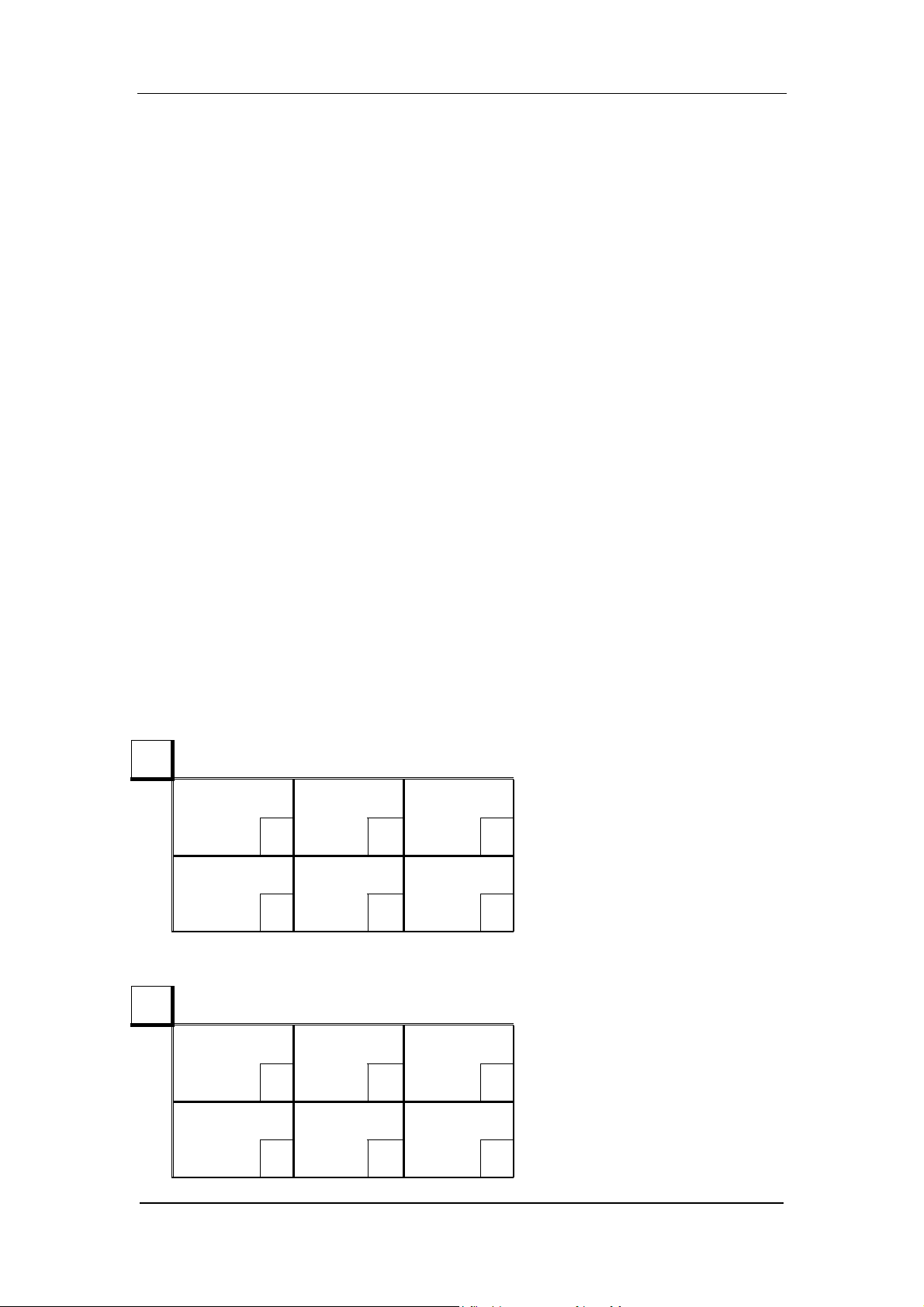

Dash Responder Block Diagram

from / to

Monitor

PCB

Monitor

Interface

Battery

PCB Pacer (device-variant)

Pace Control

Security

PCB Battery

Managemet

Battery Managm.Control

Charger

Deep Discharge Protection

Power switches

On/Off Circuit

PCB Digital

Device- Control,

FLASH, SRAM, EEPROM,

DC/DC- Converter

PCB Analog

HV Generation

HV Control

Paddle Interface

Shock Form

EnergyMeasurement

Pacer Interface

Security

Test

Discharge

50 Ohm

from / to

Paddles

Module Interface

Keypad Interface

Display-

Interface

Sound-

Interface

PCB Keypad

Keypad

Display

Dash Responder Device

PCB Analog

Block Diagram

The PCB Analog provides the following functions:

• Charging of the High-Voltage Capacitor.

The PIC-controllers initiate the charging of the high voltage capacitor to a voltage provided by the

main software on the PCB digital. One PIC supervises the other during the charging to make sure,

the selected voltage will not be exceeded. In the next charging cycle the PICs change place and the

first is supervised by the second.

• Shock delivering and measuring of applied energy.

The PIC-controllers initiate the switching of the relais to deliver the energy to the patient according

Servicing Manual Dash Responder V1.0 Revision F

Page 10 of 72 2004768-001

Page 11

GE Medical Systems

Information Technologies

to a command sequence of the main software. The energy which was delivered to the patient is

measured and the value transfered to the main software.

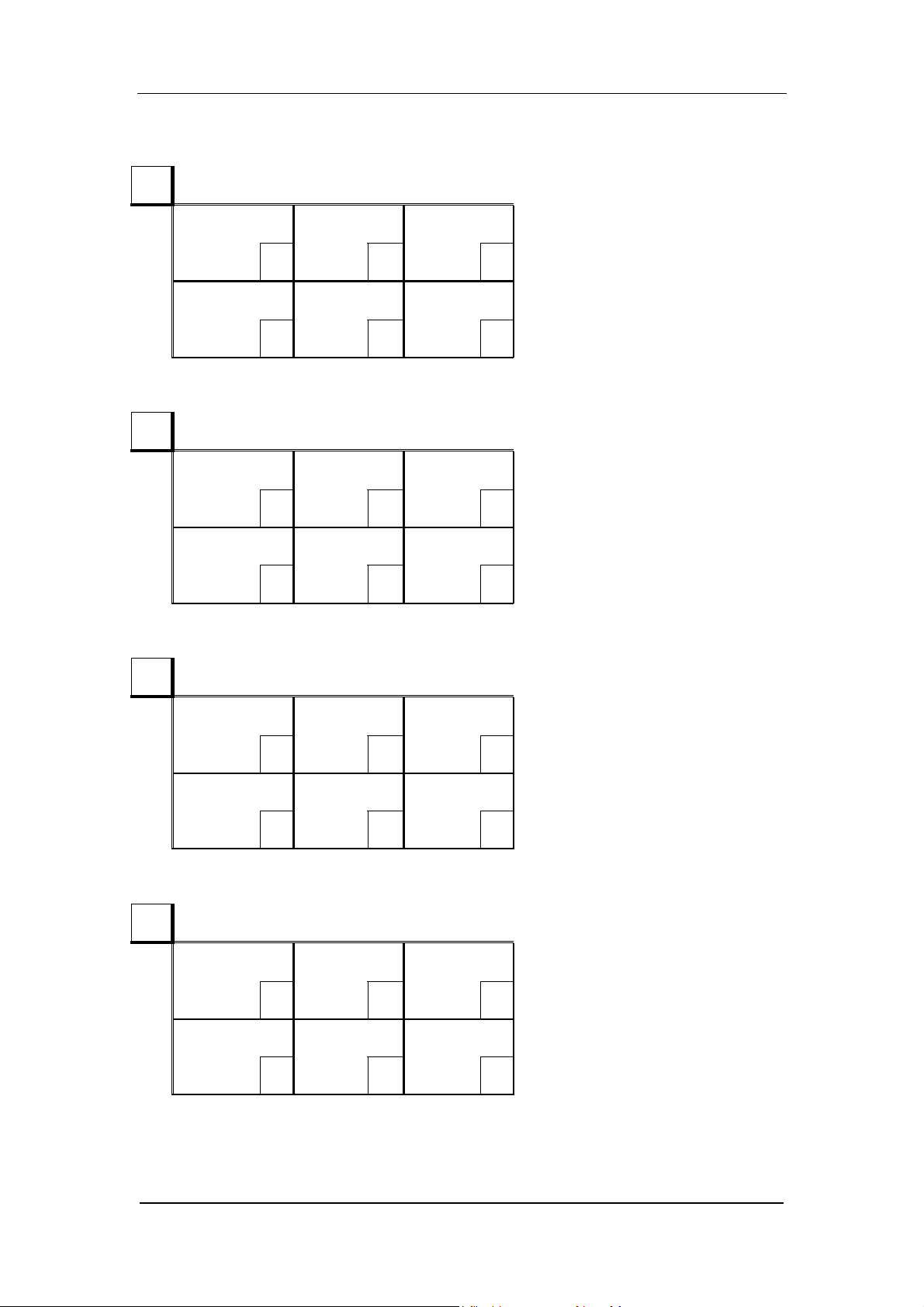

Block Diagram PCB Analog (2002316-001)

Connectors

HV Generation

Shock Control

Paddle Connector Code

Paddle Connector HV

PCB Pacer

HV Capacitor

PCB Power Management

PCB Digital

Speaker

PCB Digital

Block Diagram

The PCB Digital provides the following functions:

• Control of all subsystems (Powermanagement, Analog, Pacer).

• Display

The display is connected to the PCB Digital that contains a graphic controller.

• Keypad

Any pressed keys are decoded by the PCB Digital and the LEDs on the keypad get illuminated

under control of the PCB Digital.

• Sound generation

The alarm sounds are generated and amplified on the PCB Digital by a sound chip.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 11 of 72

Page 12

GE Medical Systems

Information Technologies

Block Diagram LPL Digital

Connectors

Status & Control

I2C-Bus

Display

Keypad

Sound

PCB Powermanagement

PCB Analog

PCB Pacer

(BDM)

Display (piggy back)

Keypad (flex)

PCB Power Management

Block Diagram

The PCB Powermanagement provides following functions:

• Charging and Conditioning (Discharge / Charge-cycle) of the battery

The battery gets charged if it n eeds to be and if energy is provided by a monitor connected to the

Dash Responder. The PCB Powermanagement powers the device and guarantees that every

remaining energy from the monitor is used to charge the battery, but the drawn current does not

exceed the maximum current the monitor is able to deliver.

During the conditioning cycle the battery gets fully depleted and afterwards fully recharged to

regain the optimal energy level.

• Communication with the battery charge level monitoring system which is integrated in the battery

In the service menu the energy level of the battery and the number of conditioning cycles are

given.

• Unregulated P ower supply for subsystems

The Powermanagement regulates the supply voltage to a value that the battery gets charged if

needed and the supply current drawn from the monitor so that the maximum current is not

exceeded.

Servicing Manual Dash Responder V1.0 Revision F

Page 12 of 72 2004768-001

Page 13

GE Medical Systems

Information Technologies

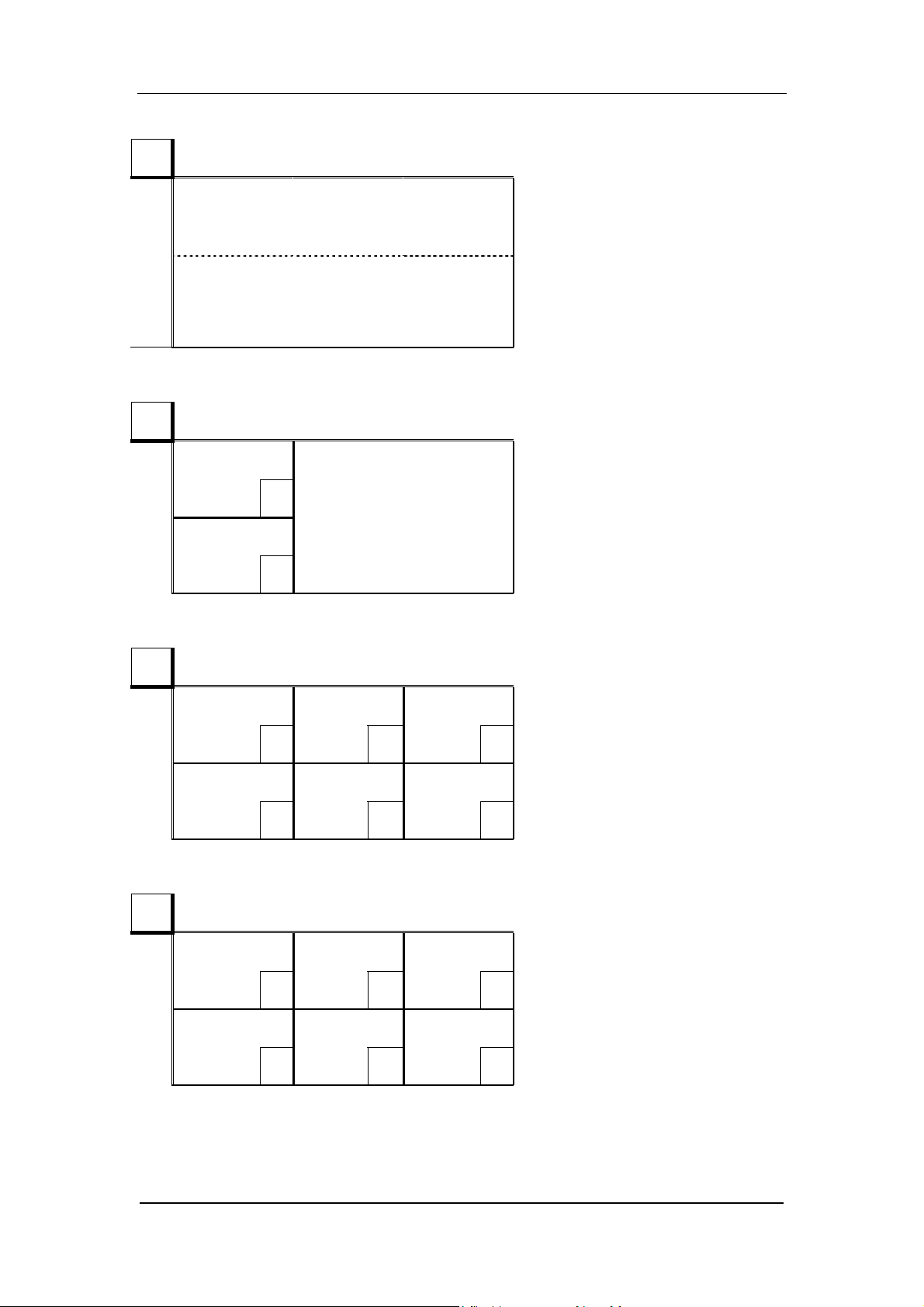

Block Diagram PCB Power Management

Connectors

Power Supply

Battery Charging/

Conditioning

Monitor

PCB Digital

PCB Analog

Battery Case

PCB Pacer

Block Diagram

The PCB Pacer provides following functions:

• Generation of floating HV

The generated voltage level is sufficient to deliver any selected current level to the highest

expectable patient resistance.

• Switched current source for pace pulses

The pace pulse current is regulated by means of a programmable current source.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 13 of 72

Page 14

GE Medical Systems

Information Technologies

Block Diagram PCB Pacer

Connectors

Pulse Generation

Pulse Control

PCB Analog

PCB Digital

Battery

The battery in the Dash Responder is a rechargeable NiCd battery with a charge level of 2000 mAh and

nominal 12 Volt (10 cells).

The battery contains a charge level monitoring system to measure the remaining charge in the battery.

By pressing the key on the battery front the actual charge level can be displayed.

Nevertheless, the displayed charge level provides no information about the quality and usability of the

battery. A worn out battery may still possess its capacity but—as a result of an i ncreased internal

resistance—is only partially operational in the defibrillator. The batteries should be periodically tested

in the ASU 3000.

Batteries 2009219-001

General Information

Rechargeable batteries require special maintenance and continued checks to assure they function in

emergency situations. It is normal for batteries of this type to self-discharge, even when the device is

switched off or in storage.

Furthermore, the battery capacity decreases with age: the storage capacity of older batteries is less than

that of new batteries. By regular maintenance (charging and discharging at regular intervals) the battery

service life can be considerably extended.

Battery type 2009219-001 allows you to determine the charge level and capacity at any time.

Furthermore, the LEDs on these batteries indicate

- the presence of a short-circuit (a distinction is made between a short-circuit in the device

(excessive current drain) and a short-circuit between battery cells),

- a display problem,

- the imminent shut-down of the display to protect the battery from over-discharging.

Servicing Manual Dash Responder V1.0 Revision F

Page 14 of 72 2004768-001

Page 15

GE Medical Systems

Information Technologies

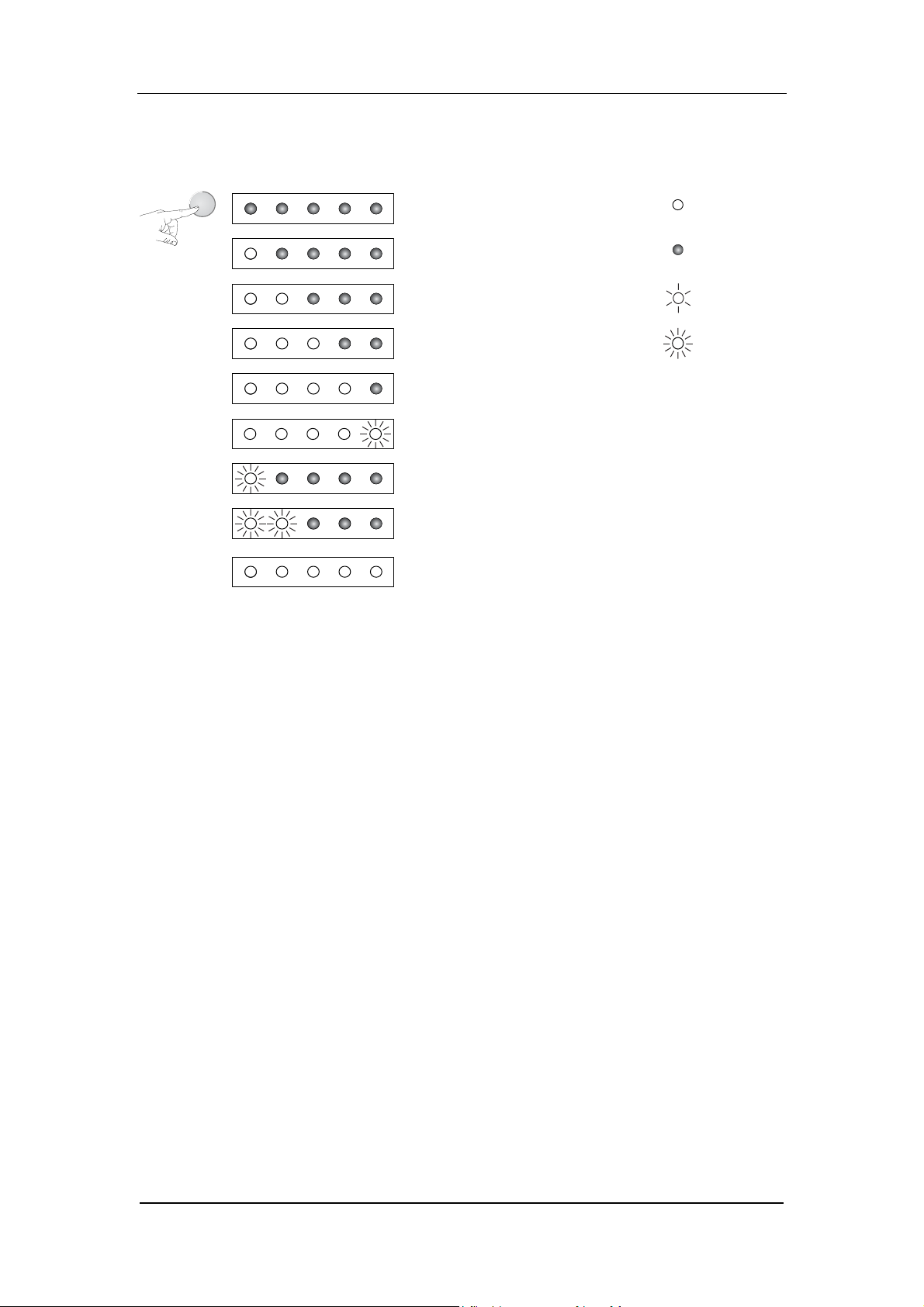

Indication of charge level and capacity

LED charge capacity key to symbols

Test

100 % 100 % LED off

60 ... 80 % 100 % LED on

40 ... 60 % 100 % LED blinking slowly

20 ... 40 % 100 % LED blinking rapidly

6 ... 20 % 100 %

0 ...6 % 100 %

100 % < 80 %

100 % < 60 %

depleted,

display off

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 15 of 72

Page 16

GE Medical Systems

Information Technologies

Indication of short-circuit

LED what it means comment

short-circuit i n the device disconnect battery fro m device

short-circuit of battery cells battery defect, battery cannot be used any more

Fault indication

LED what it means comment

electronics fault perform rese t; if problem persists, battery

Perform reset

cannot be used any more

Test

For a reset, the TEST button needs to be pressed longer than 10 seconds. It is

recommended to perform a reset each time a fault is indicated. If the fault indication

persists, the battery is defective and cannot be used any more.

> 10 s

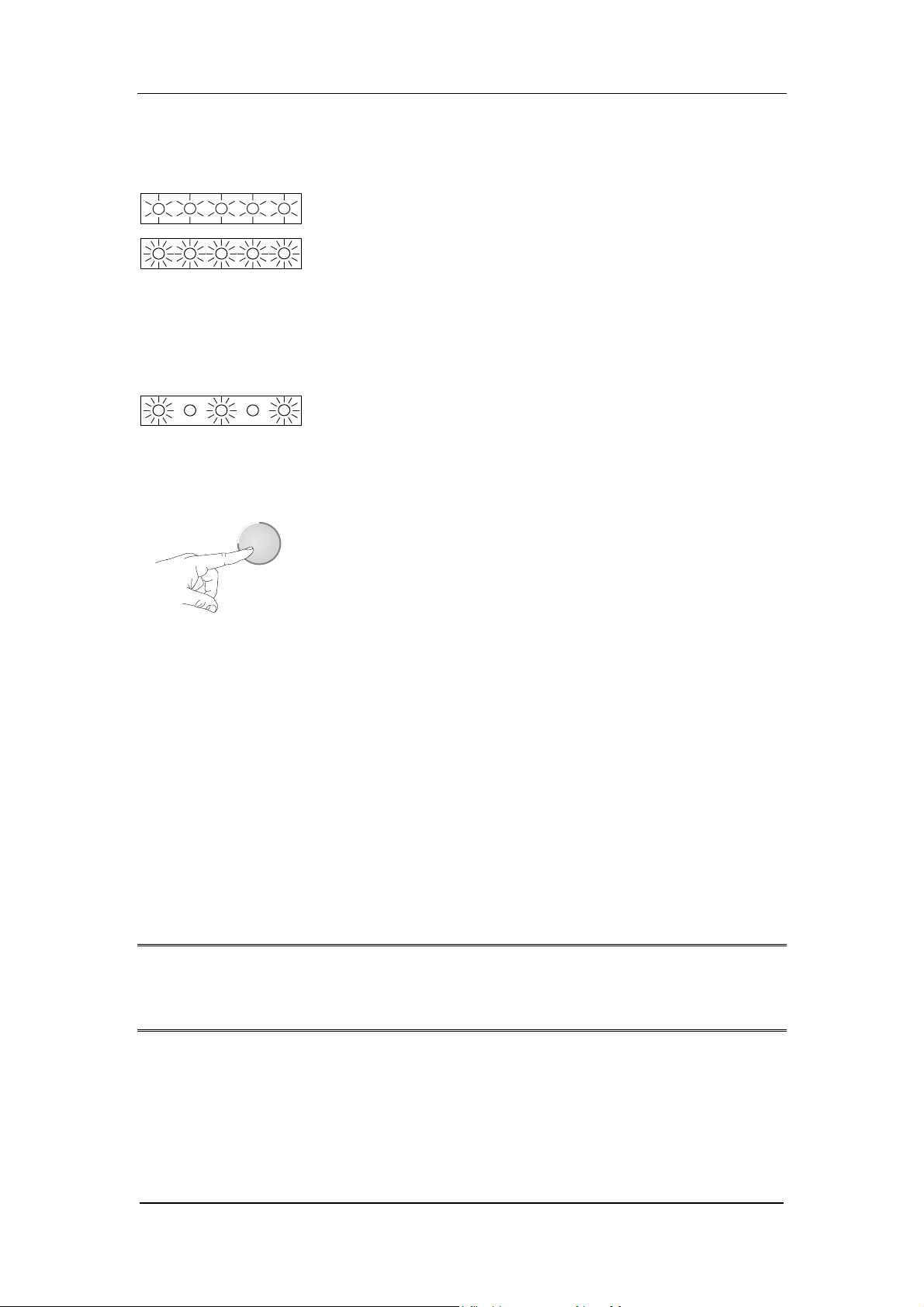

Automatic shut-dow n of the display ( protection from deep discharging)

To protect the battery from deep discharging, the display shuts down automatically. The imminent

shut-down is indicated by running lights, with each of the 5 LEDs blinking in sequence for about 1

second. The display reactivates automatically when the battery is being charged.

Battery conditioning

The battery should be conditioned with the internal battery conditioning program or with the optional

battery charging unit ASU 3000 every month. As t he ASU 3000 is a specially designed battery

charging unit that has a definite conditioning mechanism, it is advisable to use it to condition the

battery. Furthermore the conditioning cycle will last about twenty-one hours if performed in the

defibrillator and only five hours in the ASU 3000.

NOTE

Since the battery will be discharged in the course of the program and the program takes several hours to

complete, a second charged battery must be available to ensure that the defibrillator is ready for use.

The conditioning program can only be run when the defibrillator is connected to the patient monitor

and the monitor, in turn, is connected to the power line.

Start of Conditioning

• Connect the monitor-defibrillator system to the power line.

• Turn the defibrillator on.

Servicing Manual Dash Responder V1.0 Revision F

Page 16 of 72 2004768-001

Page 17

GE Medical Systems

Information Technologies

• Display the main setup menu by simultaneously pressing the two E

NERGY SELECT keys (at least 2

seconds).

• Use the E

HARGE key.

C

The S

ERVICE MODE menu appears.

• Select B

NERGY SELECT key to highlight SERVICE MODE and confirm the selection with the

ATT COND with ENERGY SELECT key and confirm with CHARGE key.

You will see the battery conditioning menu.

• Select C

OND START with ENERGY SELECT key and initiate the conditioning program with CHARGE

key.

These are the steps of the conditioning program:

the Dash Responder switches off,

the battery charges (up to about seven hours, depending on the initial energy level), the green

LED blinks, the yellow LED is solid on

the battery discharges (seven hours), the green LED blinks, the yellow LED is off

the battery charges (about seven hours), the green LED blinks, the yellow LED is solid on

The two C

HARGINGSTATUS indicators signal the steps of the conditioning program:

green LED yellow LED conditioning program step

blinks on battery charging

blinks off battery discharging

blinks blinks charging error (defective

battery)

In the course of the program you can display the battery conditioning menu at any time to view the

battery status or to stop the program.

• Turn on the defibrillator to display the battery conditioning menu.

The battery status is not updated automatically when the battery conditioning menu is displayed; for

displaying a new status leave and enter again the conditioning menu.

Defective Battery

As soon as the battery quality (“F/NEW”) drops to 60% or less, the battery must be replaced by a new

one.

Battery replacement

NiCd batteries have a limited service life time as their storage capacity deteriorates with age. For this

reason, the battery must be replaced every 2 years.

Note

Disposal Notice: Should this product (battery) become damaged beyond repair, or for some reason

its useful life is considered to be at an end, please observe all local, state, and federal regulation that

relate to the disposal of products that contain lead, batteries, plastics, etc.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 17 of 72

Page 18

GE Medical Systems

Information Technologies

4 Service Tool

This Service Tool is suitable for testing of the Dash Responder and Dash Monitor separately, further

for software download and calibration of the Dash Responder.

Software Download Information

The product software for the Dash Responder can be loaded into the flash memory by means of a PC or

laptop. This requires the Dash Responder Service kit, a complete set for download, calibration and test.

The kit (2006861-001) can be ordered from GE Medical Systems, please contact your local distributor;

it includes

1. software diskette,

2. DRST-Box (2005378-001) for adaptation,

3. DCpower supply (2000300-001),

4. PC cable assembly (223 362 03).

Additional you need

• power cord for the power supply

• PC/laptop with

• Microsoft Windows 95 / 98 / NT / Windows 2000 or W indows Millennium.

• RS-232C serial port (COM).

• 3.5-inch floppy drive

When updating to a newer software version, please order the corresponding User Manual separately.

(see Spare Parts List on page 64)

Servicing Manual Dash Responder V1.0 Revision F

Page 18 of 72 2004768-001

Page 19

GE Medical Systems

Information Technologies

For authorized dealers (password required) the software download can be carried out via the following

Internet address:

http://213.164.65.40/octodata/osmh21.nsf/$start/homepage

Important servicing information:

1. Before loading a new software write down the actua l device, defib and pacer setup (see User

configurable settings on page 23).

2. After replacing any of the PCBs’, energy calibration has to be done. (For more details see Section

Calibration on page 20).

Installation

1. Create a directory on your hard disk (e.g., stools) and copy the service program 'drst.exe'

into this directory as well as the software file(s) (*.hex) for the p roduct software.

2. Attach the DRST-Box to the Dash Responder instead of a Dash Monitor.

3. Connect the power supply and the serial cable to the DRST-Box. The other end of the serial cable

should fit into a free COM-port of your PC. You may need a standard 9pin/25pin adapter if the PC

has a 25-pin socket COM.

4. The application software for the Dash Responder comes on a separate floppy disk.

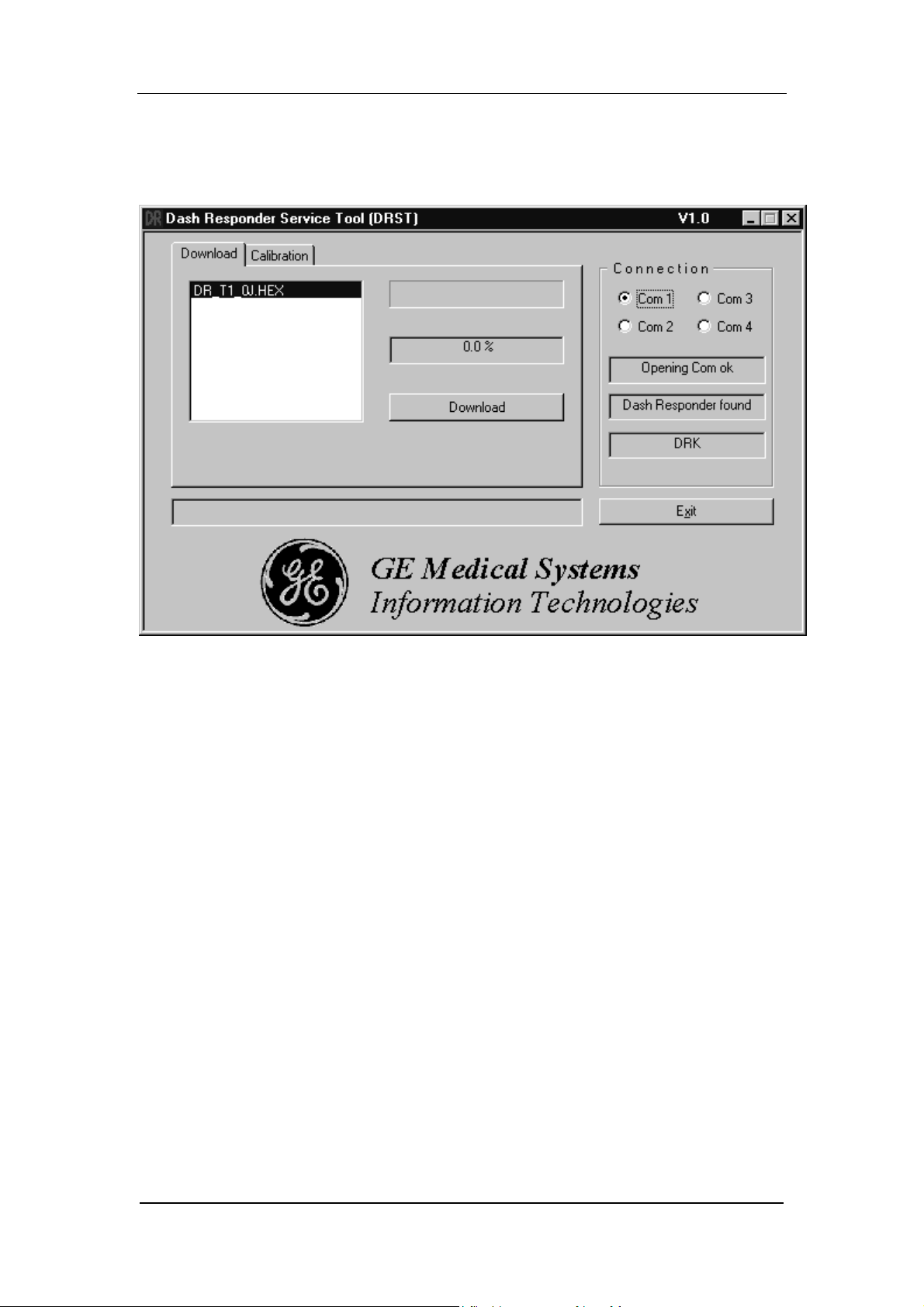

Software Download

1. The product software must be available in the same directory as 'DRST.exe'.

2. Check at the DRST-Box that

• the LED P

• the Switch '9-18V' is ON.

3. Read out all user specific setup and write it down (see User configurable settings on page 23).

Start the Bootloader following these steps

• Switch off the defib

• Hold down the C

• Press and release the O

• Release the C

LED are blinking alternately.

• Start 'DRST.exe' on the PC and select the serial interface (COM 1…4) you chose to

connect the Das h Responder. If the connection is correct, ‘R

4. Nowselect the desired software in the download window (*.hex) and click on ‘D

After successful installation of the software (duration about 3 minutes), the message ‘E

DOWNLOAD

5. Enter the previous setup (see User configurable settings on page 23).

ERIPRESENT is ON and

HARGE and left SHOCK key simultaneously.

N/OFF key.

HARGE and the left SHOCK keys simultaneously when the SYNC LED and SHOCK

ESPONDER FOUND’ is displayed.

OWNLOAD’.

ND

’ appears in the bottom line of the service tool window. The Dash Responder restarts.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 19 of 72

Page 20

GE Medical Systems

Information Technologies

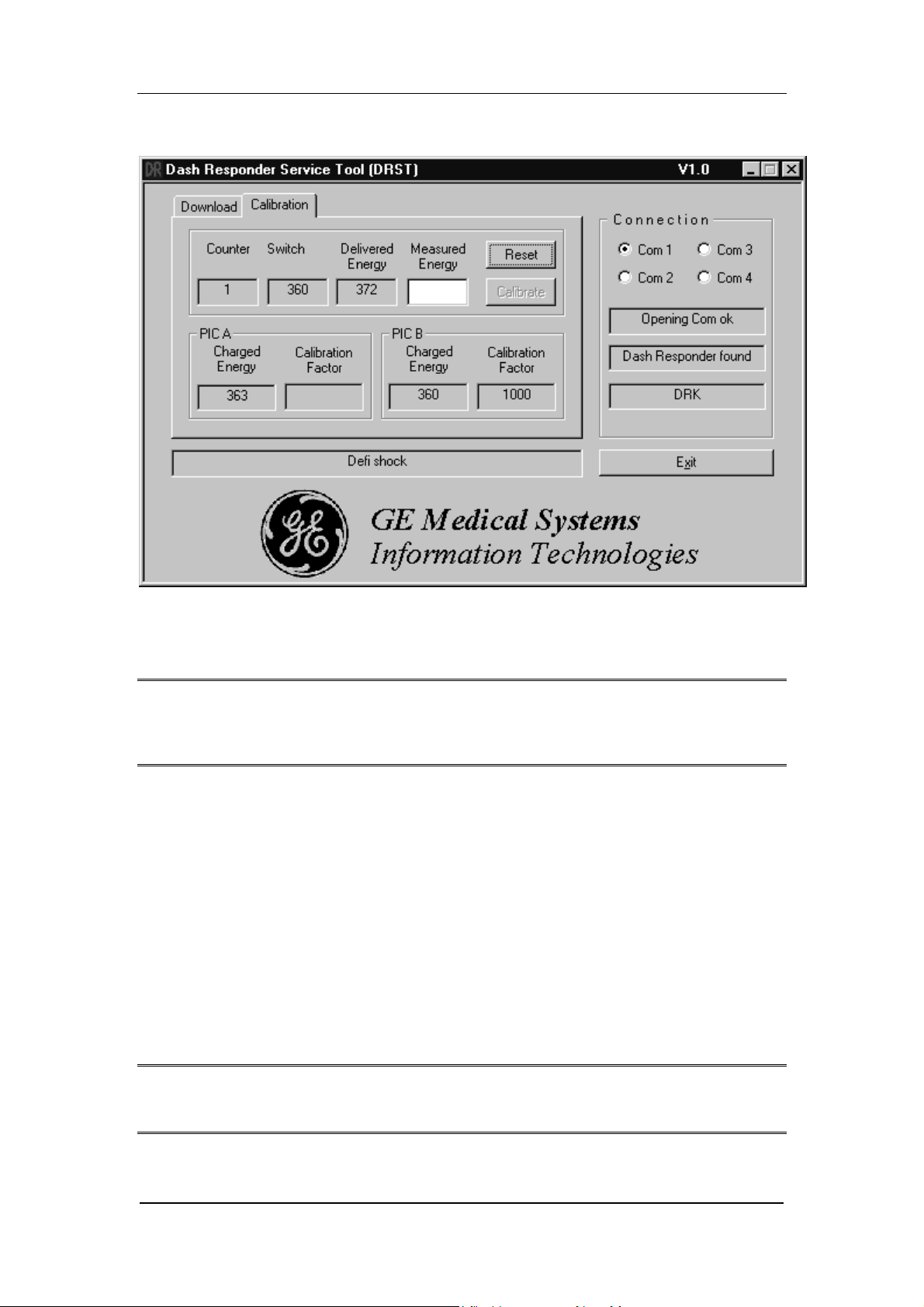

Calibration

The accuracy of the shock energy measurement needs to be checked on a regular basis (see

Maintenance and Technical Inspection on page 54) and after any replacements of PCBs or update of

the software.

CAUTION

No more than 16 shocks can be applied without a pause of about 15 minutes afterwards to avoid

overheating of the device!

Check the current calibration first:

Apply two shocks with each 50 J, 100 J and 360 J to a calibrated defibtester (e.g. DNI Nevada Inc.). If

any of the delivered energy values deviates for more than ± 5% from the chosen value calibration is

required.

The calibration p rocedure requires

• Dash Responder Service kit (2006861-001)

• PC/Laptop

• calibrated defibtester with energy display (e.g. DNI Nevada Inc.)

• hard paddles or the adapter cable for the adhesive paddles which are suitable for the used

defibtester.

NOTE

The charge level of the battery should be sufficient for several shocks.

The following steps describe how to calibrate the Dash Responder

Servicing Manual Dash Responder V1.0 Revision F

Page 20 of 72 2004768-001

Page 21

GE Medical Systems

(

)

Information Technologies

1. Connect the DRST-Box to the Dash Responder and the PC (COM 1 - 4).

Check at the DRST-Box that

• the LED 'P

ERIPRESENT'isONand

• the Switch '9-18V' is OFF for software version V 1.0

• the Switch '9-18 V' is ON for software version V1.01 and higher versions

2. Switch ON the defib.

Enter MAIN MENU by pressing both E

S

ERVICE MODE -> SERVICE TOOLS -> CALIBR.

NERGY SELECTkeys simultaneously for 2 sec. Select

3. Start the program 'DRST.exe' on the PC, select the 'Calibration' sheet and the serial interface

you chose to connect the Dash Responder. If the connection is correct, ‘D

ASH RESPONDER FOUND’

is displayed.

4. Now deliver a 360 J shock into the defibtester.

It is important to shock immediately after charging (sound indicator)!

5. Read the measured energy value from t he defibtester, calculate

_360

_

valuenew

=

+

valueenergyJ

2

and enter the calculated new_value into the window ‘MEASURED ENERGY’nexttothe

‘C

ALIBRATE’keyandclickonthe‘CALIBRATE’ key. The message ‘WAITING FOR SECOND SHOCK’

appears.

6. The 2

nd

shock is now delivered to the defibtester, then the energy calculated as above has to be

entered into the window ‘M

by the Dash Responder by clicking on the ‘C

EASURED ENERGY’nexttothe‘CALIBRATE’ key. This value is adopted

ALIBRATE’ key. The message ‘START CALIBRATION’

appears for approx. 1 seconds followed by the message ‘E

ND CALIBRATION’.

7. Exit S

ERVICE MODE:

Select E

XIT CALIBR ->MAIN MENU

IMPORTANT NOTE

Select SAVE &EXIT if you want to save the calibration values or

E

XIT for not changing the calibration.

8. Restart the defib with the ON/OFF key.

CAUTION

If calibration should not be possible (defibrillator does not charge up) due to an incorrect entry

(message ‘I

NCORRECT CALIBRATION FACTOR ...’ occurs), press the reset button and repeat the

calibration.

Evaluate the results of the calibration with energy levels of 50 J, 100 J and 360 J.. The accuracy levels

that must be gained are listed in the table Accuracy of Shock Energy on page 57.

Monitor Interface test

The Monitor Interface can be tested without a Monitor (if not available or not read y) using the service

tool kit Dash and a PC/Laptop (see Software Download Information on page 18).

Installation

1. Create a directory on your hard disk and copy the service program 'DRTest.exe' into this

directory.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 21 of 72

Page 22

GE Medical Systems

Information Technologies

2. Attach the DRST-Box to the Dash Responder instead of a Dash Monitor.

3. Connect the power supply and the serial cable to the DRST-Box. The other end of the serial cable

should fit into a free COM-port of your PC. You may need a standard 9pin/25pin adapter if the PC

has a 25-pin socket COM.

Interface Test

Switch off the Dash Responder.

• Start the test by executing 'DRTest.exe'.

Follow the steps in the instruction window.

NOTE

The pushbuttons 'MONITOR POWER'and'START COMMUNICATION TEST' are on the right side of the

window.

Servicing Manual Dash Responder V1.0 Revision F

Page 22 of 72 2004768-001

Page 23

GE Medical Systems

Information Technologies

5 Service Menu

The SERVICE MENU can be reached by pressing the ENERGY SELECT keys simultaneously for at least

two seconds.

User configurable settings

Some settings of the Dash Responder are configurable to meet the user’s requirements. The settings

can be made in the Service Menu and comprise following values:

• Volume of the alarm sound

S

ERVICE MODE /DEVICE SETUP /ALARM <LOW |MEDIUM |HIGH>

• Automatic shutdown

S

ERVICE MODE /DEVICE SETUP /SHUTD <ON |OFF>

• User Language

S

ERVICE MODE /DEVICE SETUP /LANGUAGE <ENGLISH |DEUTSCH |…>

• Autosequence of defib shocks

ERVICE MODE /DEFIB SETUP /LEVEL1 <150 J | 200J | 300 J | 360 J>

S

S

ERVICE MODE /DEFIB SETUP /LEVEL2 <150 J | 200J | 300 J | 360 J>

S

ERVICE MODE /DEFIB SETUP /LEVEL3 <150 J | 200J | 300 J | 360 J>

• Pacer Rate

ERVICE MODE /PACER SETUP /RATE < 30 … 200 PPM>

S

Component Test

Service Mode / Comp Test

Keyboard Test

S

ERVICE MODE /COMP TEST /KEY TEST

Press the keys for at least one second

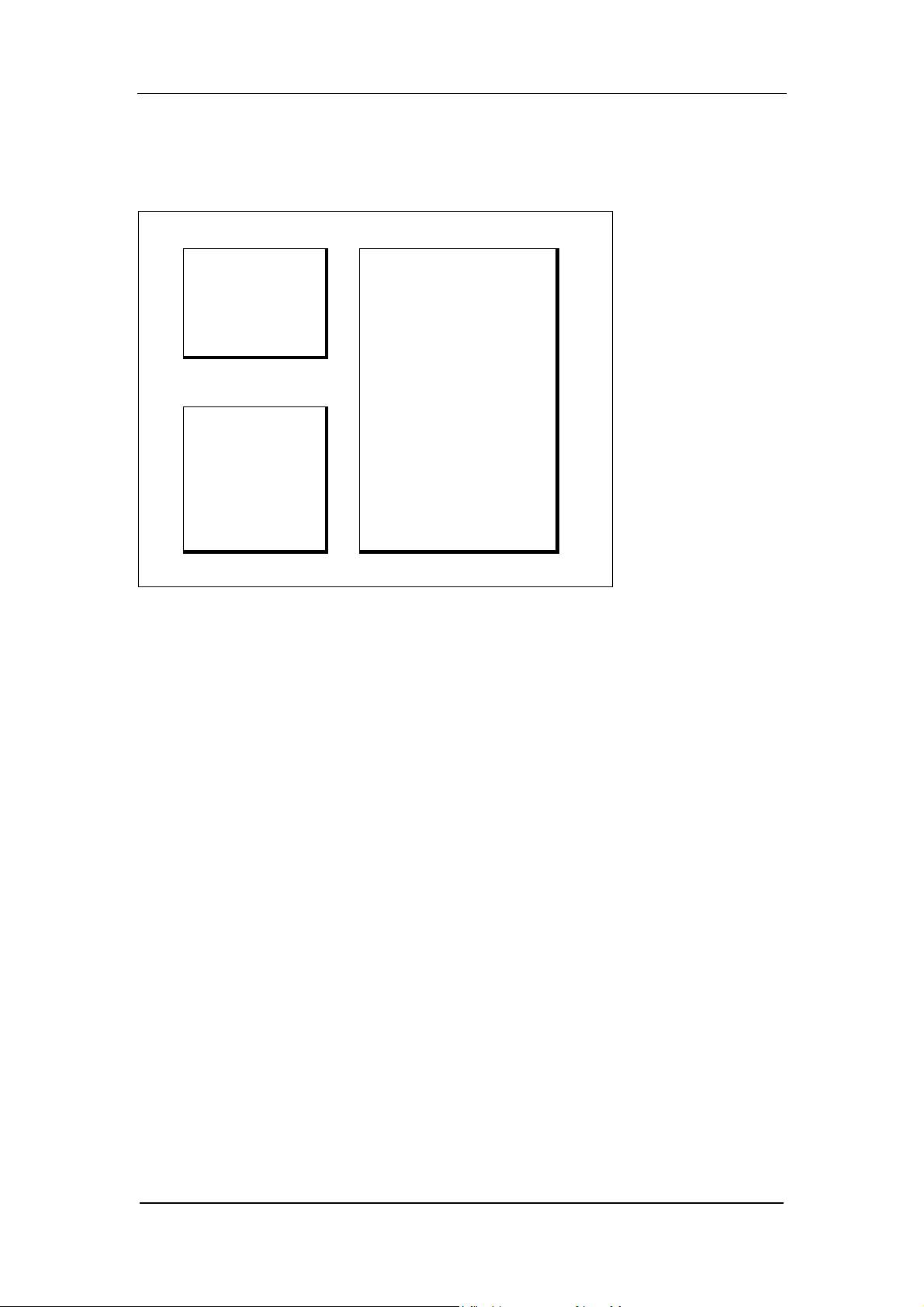

Structure of the Service Menu

Main Service Menu

1

DEVICE

SETUP

2

SERVICE

MODE

5

Device Setup

EFIB

D

SETUP

P

SETUP

3

E

XIT SAVE &

E

ACER

4

XIT

2

MAIN

MENU

SHUTD

<OFF>

ISPLAY

D

SETUP

1

L

ANG

UAGE

6

LARM

A

<LOW>

F

ACT

SETT

7

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 23 of 72

Page 24

GE Medical Systems

Information Technologies

Defib Autosequence Setup

3

MAIN

MENU

1

LEVEL1

<200J>

Pacer Setup

4

MAIN

MENU

Service Mode

5

MAIN

MENU

1

1

LEVEL2

<200J>

ATE:

R

<60PPM>

LEVEL3

<360J>

BATT

COND

S

ERVICE

TOOLS

8

C

OMP

TEST

9

10

Display Setup

6

MAIN

MENU

CKLIT:

B

∇ ∆

CONTR:

∇ ∆

1

PREV

MENU

2

Servicing Manual Dash Responder V1.0 Revision F

Page 24 of 72 2004768-001

Page 25

GE Medical Systems

Information Technologies

Language Setup

7

∆

∇

Battery Conditioning

8

E

NGLISH

DEUTSCH

FRANÇAIS

NEDERLANDS

ITALIANO

ESPAÑOL

SVENSKA

MAIN

MENU

COND

START

Service Tools

9

MAIN

MENU

PREV

MENU

Component Test

FULL <2346mAh>

R

EM <2240mAh>

F/N

1

D

OWNLD

EW <122%>

C

OND <1>

S/W

ALIBR

C

1

5

10

MAIN

MENU

LCD

TEST

K

EY

TEST

1

PREV

MENU

RO

P

FILE

5

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 25 of 72

Page 26

GE Medical Systems

Information Technologies

6 Replacing PCBs

Safety Information for Disassembly

Please observe the following safety information when disassembling the defibrillator.

All PCBs contain semiconductors which must be protected from electrostatic discharge. When

working on open devices and when handling PCBs, it is important to observe ESD safety precautions.

Please read also the paragraph Electrostatic Discharge (ESD) on page 33. It is especially important

that service personnel always establish contact between the PCB and ground before touching a

component.

Use the following ESD protection guidelines when working on an open defibrillator or when handling

PCBs.

• Use an ESD protective underlay connected to a non-fused earth conductor potential.

• Connect yourself to the ESD protective underlay via an armband.

• Use an ESD protective travel bag to transport PCBs.

The following tools may be required for disassembling the unit:

• Goose-necked tweezers

• Phillips Screwdriver, Type “Phillips-recess” sizes 0, 1 and 2

• Swivel wrench 7 mm for hexagonal spacers

• ESD packaging for PCBs

• ESD underlay with armband

NOTE

The Checkout Procedures and Electrical Safety Tests must be performed each time the device has been

opened, a circuit board is removed or replaced.

Disassembly Procedure

Before any service interventions, turn off the device and remove the battery.

Opening Unit

To open the unit, do the following:

• Lay the defibrillator upside down on a clean, level surface (ESD pad) which is placed on a soft

material.

• Undo the 4 buried screws on the bottom beneath the feet of the device to dismount the upper and

the lower shell of the case.

• Turn the device upright again and lift off the upper shell of the case. This can be done by lifting

the shell at the back by a small amount and pull it to the front until the front shell disconnects from

the lower shell. Then turn the upper shell to the right and thereby open the device.

• Disconnect the connectors of the Analog PCB and the Pacer PCB.

Analog PCB

Disassembling

• Disconnect the two connectors to the paddle connector on the rear of the unit. One connector

(PC/) is located at the left side of the air coil (L506) the other one (SHOCK_P/, SHOCK_M/) is

Servicing Manual Dash Responder V1.0 Revision F

Page 26 of 72 2004768-001

Page 27

GE Medical Systems

Information Technologies

located at the right side of the coil.

SHOCK_P/ and SHOCK_M/ should first be lifted with a goose-necked tweezers to loosen them

and afterwards disconnected.

• Disconnect the connectors to the HV-Capacitor.

CAUTION

Short circuit the capacitor as long as it is not in use, because it can show up a lethal voltage after a

certain amount of time if not short circuited.

• Cut the two cable ties that fix the HV-Capacitor and remove the Capacitor.

• Undo the seven screws on the Analog PCB. Remember that the two screws that mount the air coil

are a little bit longer than the others.

• Remove the Analog PCB and put in a ESD packing.

CAUTION

Don’t handle the Analog PCB on the air coil (L506), otherwise its thin wires could break.

Reassembling

• To reassemble the Analog PCB follow the steps mentioned in the assembling description in

reverse order.

• Remember the two screws fixing the air coil are a little bit longer than the other five that fix the

PCB.

• When reassembling the HV-Capacitor make sure the insulation foil is properly placed. The foil has

to be wrapped around the capacitor so that the joint is located in the middle of the lower side of the

capacitor.

• Fasten the capacitor on the bracket with two cable ties (360mm * 7,5mm).

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 27 of 72

Page 28

GE Medical Systems

Information Technologies

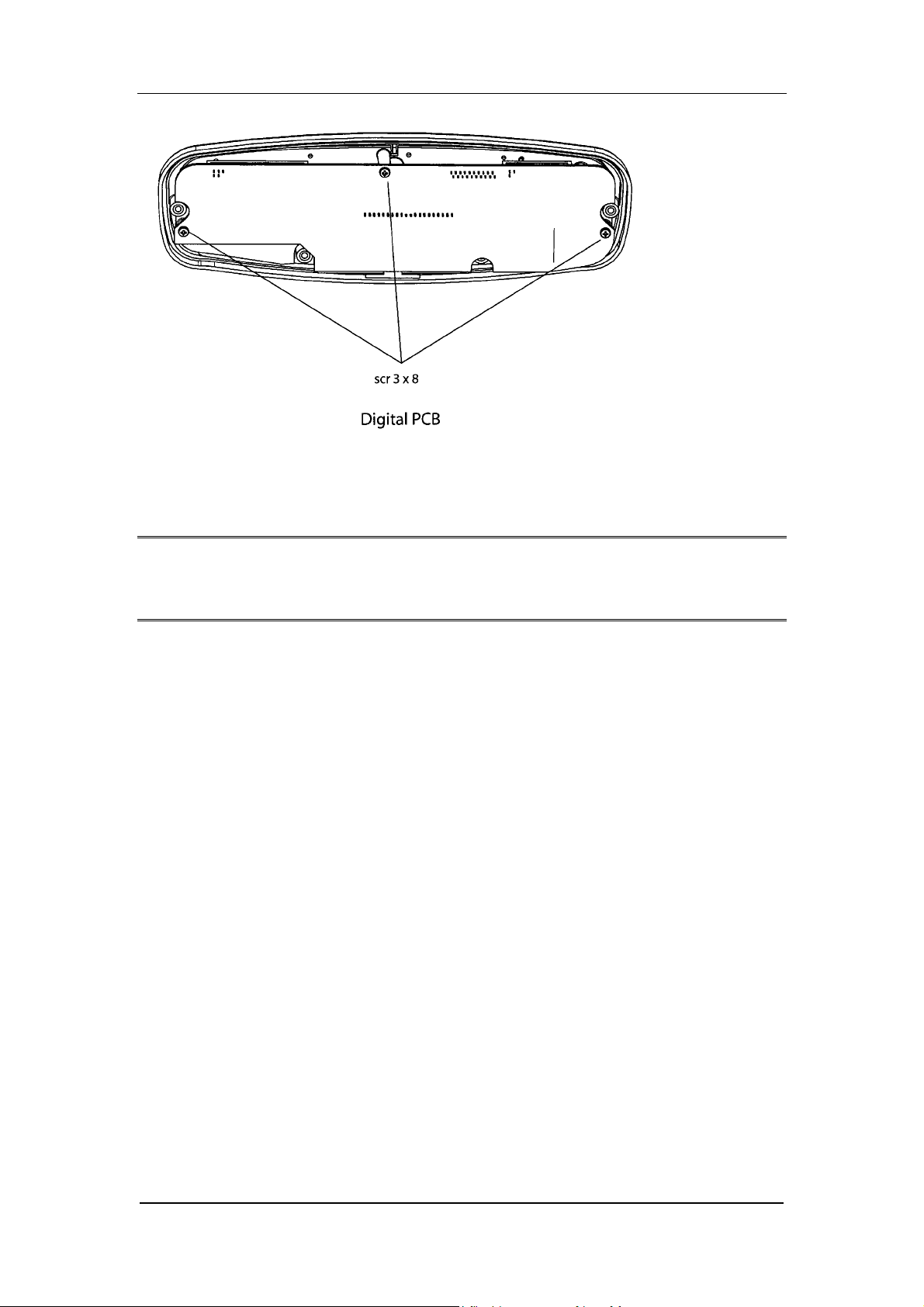

Digital PCB

Disassembling

NOTE

The Power Management PCB / Battery Case and the Pacer PCB have to be removed before removing

the Digital PCB (see disassembly procedure for Power Management PCB / Battery Case on page 30

and disassembly procedure for Pacer PCB on page 29). Otherwise no access to all screws is possible.

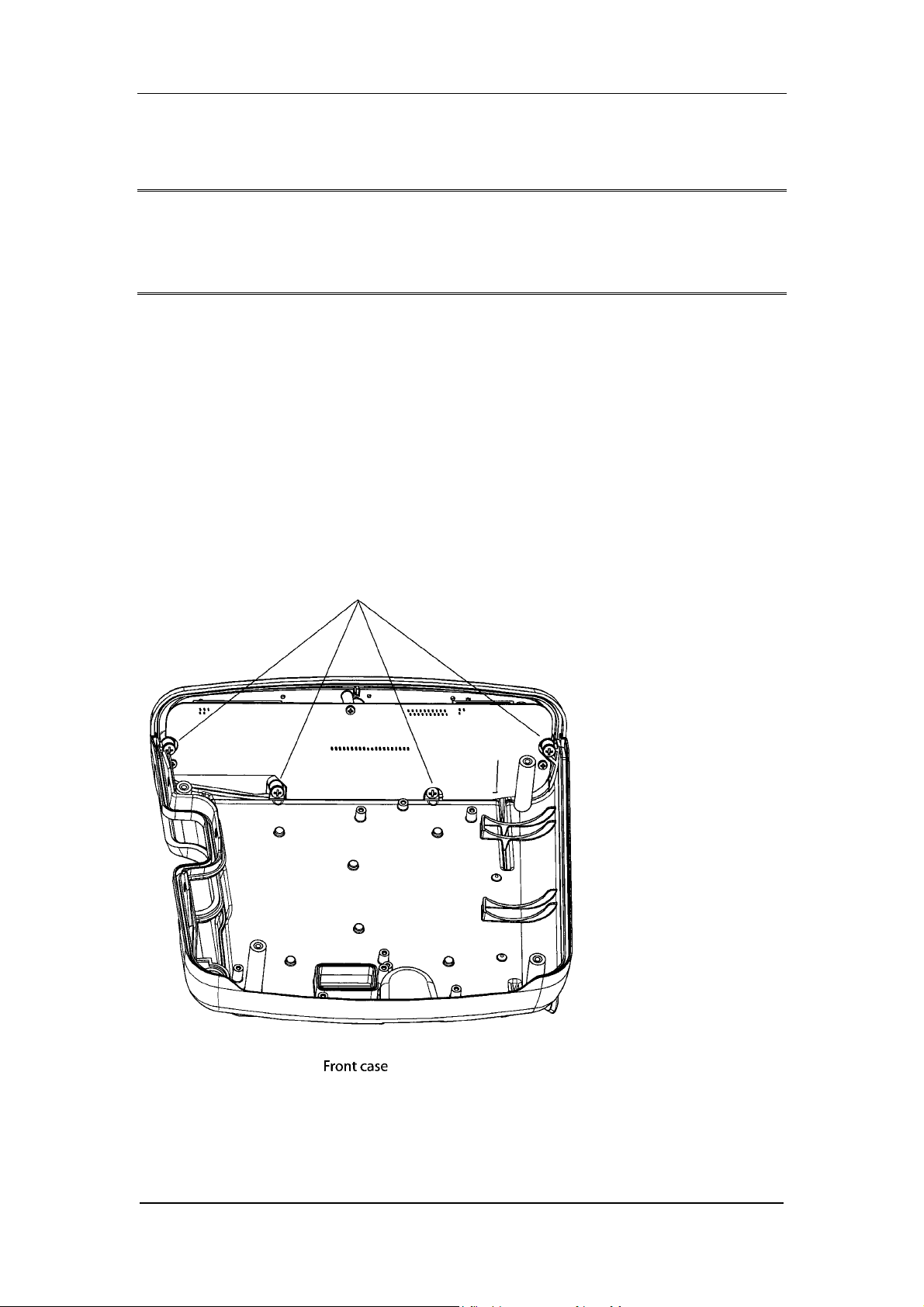

• Undo the big screws to dismount the front from the upper case shell.

• Disconnect the flex flat cable to the keypad. Be careful not to crack the flex cable!

• Undo the screw of the Digital PCB to remove the PCB.

• The display can be removed from the Digital PCB and replaced by a new one.

Reassembling

• Connect the Digital PCB with the front case shell by inserting the pins of the display connector in

the socket on the Digital PCB. Be careful not to bend any of the pins.

• FixthePCBwithitsthreescrews.

• Connect the flex flat cable to the keypad. This can best be done with a goose-necked tweezers.

Make sure to fasten the actuator properly.

Servicing Manual Dash Responder V1.0 Revision F

Page 28 of 72 2004768-001

Page 29

GE Medical Systems

Information Technologies

Pacer PCB

Disassembling

CAUTION

Wait a few minutes before dismounting the Pacer after it has been in use, because it can hold a harmful

voltage for several minutes.

• Disconnect all connectors to the Pacer PCB.

• Undo the two screws that fix the Pacer PCB to the upper case shell.

• Undo the two screws that fix the Power Management PCB to the upper case shell near the Pacer

PCB.

• Undo the two screws that fix the battery case as well as the Pacer PCB to the case shell.

• Lift up the battery case from the upper shell of the case and pull out the Pacer PCB under the

battery case.

Reassembling

• First remove the four screws that fix the battery case / Power Management PCB to the upper case

shell on the back of the battery case.

• Loosen the scre w that fix the battery case to the upper case shell that is located beneath the unlock

button of the battery. This screw also fixes the EMC-foil of the Power Management PCB to the

upper case shell.

• Reach into the battery case with one hand and lift it at its back so that the Pacer PCB can be

pushed under the bolts of the battery case.

• Mount the Pacer PCB with the screws to the upper case shell.

• Remount and fasten the screws of the Power Management PCB.

• Connect the flat ribbon cable from Digital PCB to Pacer PCB.

• Make sure the flex flat cable of the monitor connector receptacle didn’t get loose during mounting

the Pacer PCB. Reconnect and fasten it if necessary.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 29 of 72

Page 30

GE Medical Systems

Information Technologies

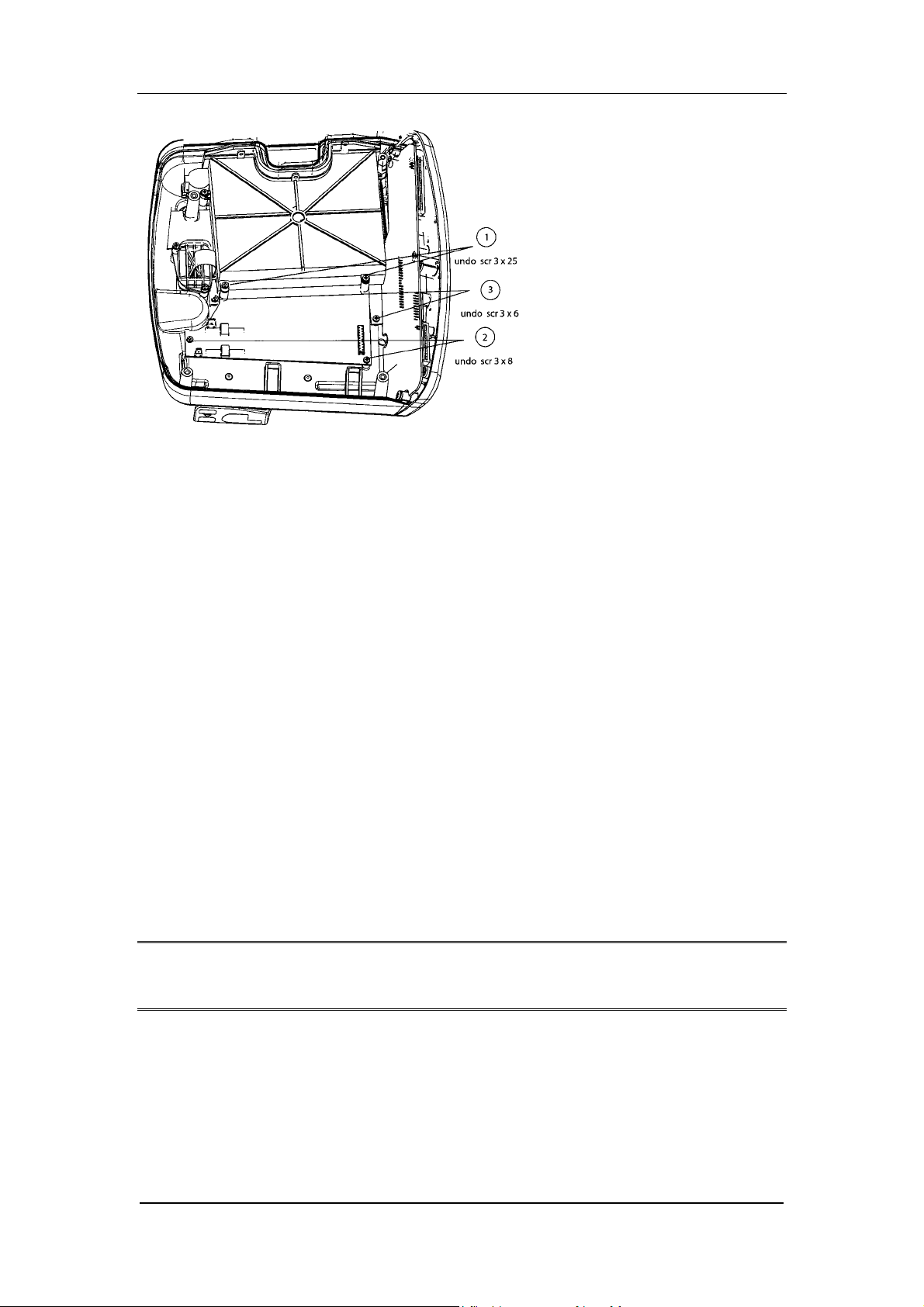

Power Management PCB / Battery Case

Disassembling

• To dismount the Power Management PCB the monitor connector receptacle must b e removed first.

• Carefully disconnect the flat flex cable to the monitor connector. The flat flex cable is locked in

the socket. Loose this actuator by lifting it on both sides with a goose-necked t weezers.

Don’t bend the cable to avoid cracks in the wires!

• Undo the screw that fix the monitor connector receptacle to the upper case s hell.

Carefully remember the orientation o f the flat flex cable versus the receptacle. Pay attention to the

orientation of the contacts on the flex flat cable in regard of the socket on the Power Management

PCB. The contacts are located on the side which is opposite to the battery case. In this orientation

the cable must be reassembled later.

• Remove the monitor connector receptacle.

• Disconnect the cable to the Analog PCB and the flat ribbon cable to the Digital PCB.

• Undo the screws of the battery case and the hexagonal threaded bolt. Undo the three countersunk

screws on the front of the battery case.

Remember the different lengths of the screws.

• Remove the whole battery case with the Power Management PCB mounted on it.

• The Power Management PCB can not be removed from the battery case. The spare part consists of

the Power Management PCB mounted on a new battery case.

Reassembling

NOTE

Before reassembling the Power Management PCB the Digital PCB should be reassembled.

• To reassemble the Power Management PCB the monitor connector receptacle has to be

reassembled first.

Servicing Manual Dash Responder V1.0 Revision F

Page 30 of 72 2004768-001

Page 31

GE Medical Systems

Information Technologies

• Put the receptacle through the hole in the upper case shell. Make sure that the orientation of the

receptacle is right. The flex flat cable has to protrude out of the rubber part of the receptacle on the

side located to the back of the upper case shell. Regard the notch in the joint between the rubber

part of the receptacle and the (outer) plastic part. This notch has to be located to the back side of

the upper case shell. Fix the monitor connector receptacle with the screws.

• The flat flex cable should be placed in the socket on the P ower Management PCB before

reassembling the Power Management PCB to the device.

Make sure that the flex flat cable is inserted completely and perpendicular to the socket. Secure it

by fasten the actuator.

• Carefully push the battery case into its place in the upper case shell. Make sure the rubber seal

around the opening of the battery case gets located in the frame properly. Be careful that the flex

flat cable doesn’t get cracked.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 31 of 72

Page 32

GE Medical Systems

Information Technologies

High-Voltage Capacitor

Disassembling

CAUTION

Short circuit the capacitor as long as it is not in use, because it can show up a lethal voltage after a

certain amount of time if not short circuited.

• Make sure that the HV-Capacitor contains no energy. If you are in doubt, that the discharging

circuit could not work properly, measure the voltage on the capacitor with an appropriate voltage

meter. Discharge the capacitor if necessary by means of resistors of about 60kOhms/10 W.

After 30 seconds capacitor is completely discharged.

• Cut the two cable ties that fix the HV-Capacitor and remove the Capacitor.

• Lift the capacitor of its sockets and remove the cap that cover the connector terminals at the top

and the cap that covers the bottom of the capacitor.

• Disconnect the connectors from the capacitor.

• Remove the plastic insulation foil.

• Short-circuit the terminals of the capacitor by an appropriate blank wire. (Hint: Use the wire that

short-circuits the replacement capacitor for this purpose.)

Reassembling

• Remove the short-circuit wire on the terminals of the replacement capacitor.

• Wrap the insulation foil around the capacitor so that the edge of the foil is placed in the middle of

the side of the negative (‘-‘) terminal of the capacitor and the end of the foil coincides with the

bottom of the capacitor.

• Put the cap on the bottom of the capacitor.

• Connect the wires to the capacitor; use the inner terminals. Beware the polarity!

• Put the cap on the top of the capacitor to cover the connection terminals.

• Thread new cable ties in the sockets for the capacitor.

• Put the capacitor on the sockets in the Dash Responder and fix it with the cable ties.

CAUTION

Check that the Dash Responder is loaded with minimum Software Version 1.01

Servicing Manual Dash Responder V1.0 Revision F

Page 32 of 72 2004768-001

Page 33

GE Medical Systems

Information Technologies

7 Troubleshooting Tips

Electrostatic Discharge (ESD)

CMOS Components

The defibrillator makes extensive use of CMOS components because they are more immune to noise

and consume less power than standard TTL or NMOS components. However, CMOS components are

inherently more susceptible to electrostatic discharge ( ESD) damage than other types of semiconductor

materials. ESD damage, causing a weakening or complete breakdown of p-n junctions within

multilayer semiconductor substrates, can range from slight degradation to catastrophic failure. Slight

degradation usually results in intermittent failure of the affected component catastrophic failure results

in rendering the affected component permanently unusable. Although CMOS components may be

more sensitive to ESD, all semiconductor devices are susceptible to ESD damage.

All external connector inputs and outputs of the defibrillator are designed with protection from ESD

damage. Ho wever, if the defibrillator requires service, exposed components and assemblies contained

within are susceptible to ESD damage. This includes human hands, non-ESD protected work stations

and/or improperly grounded test equipment.

The following guidelines help make a service workstation more resistant to the ESD damage:

• Discharge any static charge you may have built up before handling semiconductors or assemblies

containing semiconductors.

• A grounded, antistatic wristband (3M part number 2046 or equivalent) or heel strap should be

worn at all times while handling or repairing assemblies containing semiconductors.

• Use properly grounded soldering and test equipment.

• Use a static-free work surface (3M part number 8210 or equivalent) while handling or working on

assemblies containing semiconductors.

• Do not remove semiconductors or assemblies containing semiconductors from antistatic containers

(Velo-stat bags) u ntil absolutely necessary.

• Make sure power to an assembly is turned off before re moving or inserting a se miconductor.

• Do not slide semiconductors or electrical/electronic assemblies across any surface.

• Do not touch semiconductor leads unless absolutely necessary.

Semiconductors and electrical/electronic assemblies should be stored only in antistatic bags or boxes.

These guidelines may not guarantee a 100% static-free workstation, but can greatly reduce the potential

for failure of any electrical/electronic assemblies being serviced.

Special Components

Surface mounted devices are used to aid in miniaturizing the electrical/electronic assemblies within the

defibrillator.

Surface mounted integrated circuits have legs that are soldered to rectangular pads on the surface of the

printed circuit board (PCB), versus pin-through devices having legs that are made to be inserted into

solder fillets protruding completely through a PCB. Surface mounted integrated circuits (ICs, SMD,

PLCC) may have legs on either two or four sides of the IC. Another surface mounted technology are

Ball Grid Array ICs (BGA) using soldering balls as electrical connections on the bottom of the

components.

Surface mounted resistors, capacitors, and diodes have conductive parts acting as legs that are directly

soldered to the PCB.

WARNING

Surface mounted components were not designed to b e removed or replaced using standard soldering

equipment. Removal of surface mounted components using a conventional soldering iron can

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 33 of 72

Page 34

GE Medical Systems

Information Technologies

potentially destroy the PCB. Only soldering workstations specifically designed for surface mount

technology may be used to remove and replace these type of components.

Battery Failure

Error Message: Battery Required

The Battery can not be detected by t he defibrillator or is not properly inserted.

Check the battery contacts and the contacts of the battery case of the defibrillator.

Error Message: Battery Low

The battery is depleted to a remaining charge le vel of at least 5 Shocks with 360 J each. The battery

can be charged in the defibrillator if a monitor is connected which, in turn, is connected to mains

power. Another way to charge the battery is b y the optional battery charging unit ASU 3000.

Charge level and battery status

The actual charge level and the “health” condition of the battery can be checked in the Setup Menu.

(S

ERVICE MODE /BATT COND).

The indication of the “F

it is fully charged.

The indication of the “R

The indication of the quotient “F/N

maximal chargeable amount of energy that this battery can hold compared with the nominal capacity of

a typical, already used battery. Therefore this indication can read a number greater than 100% because

a new battery has a capacity higher than the nominal value.

A battery with less than 60% “F/N

conditioning on page 16.

ULL” charge level in mAh gives the maximum charge level of the battery when

EM”chargelevelinmAhgivestheactualchargelevelofthebattery.

EW” gives a hint of the “health status” of the battery as it states the

EW” charge level must be replaced. See also chapter Battery

Charging Status Indicator

The ChargingStatus Indicators are:

• solid yellow while the battery is being charged

• solid green when the battery is charged

• blinking yellow when there is a charging problem

In case of a charging problem most probably the battery is defect and must be replaced.

Fault/Symptom Analysis

This information is provided for the benefit of service tec hnicians responsible for the maintenance and

repair of the monitor. The symptoms covered in this part of the Troubleshooting section represent only

a selected number of faults that you may encounter and by no means are intended to cover ever y

possible failure that may occur.

A systematic approach to the diagnosis of problems as well as a general understanding of the architecture, both hardware and software, of the defibrillator are essential to ensure successful troubleshooting of this device. The manufacturer recommends formal service training before repairs are

attempted on the defibrillator. The Service Tips listed below combined with formal training should

provide the service technician with skills necessary to service and repair a defibrillator, in the event of a

malfunction.

Servicing Manual Dash Responder V1.0 Revision F

Page 34 of 72 2004768-001

Page 35

GE Medical Systems

Information Technologies

Fault Reason Solution

The message ERROR <#>

occurs during selftest

Charging Status LED is not

illuminated when Monitor is

connected to the defibrillator

An error was detected during

test of internal parts of the

device.

No power supply provided from

monitor to defibrillator.

Consider the table of error

numbers on page 37 to get an

idea of the error cause. Try to

resolve the error or replace the

PCB

Connect the monitor to mains

power line.

Check if the monitor is properly

placed on top of the defibrillator

and the lever is engaged.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 35 of 72

Page 36

GE Medical Systems

Information Technologies

8 Error Messages and System Information

Messages

Overall Device

Message Explanation

SHUTDOWN message before the device switches off auto-

matically

BATTERY REQUIRED no battery inserted

DEVICE ERROR <#>

S

WITCH OFF

TRY AGAIN

Defibrillator

Message Explanation

APPLY ELECTRODES electrodes disconnected

BATTERY LOW Battery is partly depleted, 5 shocks with 360 J

CONNECT DEFIBELECTRODES no defibrillation electrode connector plugged into

ENERGY HIGH The charged energy is higher than the chosen

ENERGY LOW The charged energy didn’t reach the chosen level;

LEADSFAIL/NO SYNC ECG lead failure at monitor, synchronized

NO COMM/NO SYNC No communication with monitor, synchronized

NO MONITOR/NO SYNC monitor not ready, synchronized defibrillation not

Internal Device error, device should not be u sed.

Error number is a hint to the cause of the error.

ForErrornumbersseepage37

each can still be triggered

the device

level; shock possible with the charged energy

shock possible with the charged energy

defibrillation not possible

defibrillation not possible

possible

TELEMETRY/NO SYNC patient monitor receives ECG via telemetry; due

to the long delay, this signal is not suitable for

synchronization (Combo mode)

Pacemaker

Message Explanation

APPLY ELECTRODES excessive contact impedance at the defibrillation

electrodes

PACER ACTIVE user tries to turn off the defibrillator while

pacemaker is still in operation

PACER ERROR internal pacemaker problem

PADS REQUIRED no pads are applied when pacemaker is turned on

Servicing Manual Dash Responder V1.0 Revision F

Page 36 of 72 2004768-001

Page 37

GE Medical Systems

Information Technologies

Error Numbers

Error numbers displayed after device was switched on.

Error

Number

1 Unresolved exception in program

2 Internal RAM

3 External RAM

4 Keyboard; key pressed during device start

5 Bootloader Flash RAM

6 Program code Flash RAM

7 EEPROM

11 Failure of Internal Discharge; Caution: Risk of

high voltage on HV-Capacitor

12 Failure of high voltage control (PIC problem)

Explanation

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 37 of 72

Page 38

GE Medical Systems

Information Technologies

9 Pin Configuration

External Connections

Paddle Input Connector

Paddle Connector

Name Description I/O-Type Level

PC4 Paddle coding I 5V L 1

GND Ground - 0V - 2

PC6 Paddle coding I 5V L 3

HP_CHARGE Charge key on external paddle I 5V L 4

HP_DISCHARGE

PC5 Paddle coding I 5V L 6

HV STERNUM Shock_P O 5000V H 7

HV APEX Shock_M O 5000V H 8

The following table shows the connections internal in the different paddle types that provide the coding

of the type. Shown are the connections that exist between two pins in each case.

For example softpaddles are coded via a connection between pin PC/4 and PC/5. Internal electrodes

without spoons are coded via a connection from PC/5 to PC/6 and a connection either directly or via

resistor (4.75 kiloohms) from PC/4 to PC/5.

PC/3 PC/4 PC/5 PC/6

|_______| Softpaddles 919 202 94/95

Discharge key on external

paddle

no paddles

(223 383 01)

I5V

active

L5

Pin

Nr.

|_(4k75)_| |______| internal electrodes

(without spoons) (217 308 01)

|______| paddle pair for external defibrillation with operating keys

(d)/(e) (217 333 01/02)

|_______| electrodes anterior/posterior (217 329 01)

|_(4k75)_| internal spoons with operating keys

|_____________| (not available yet)

Servicing Manual Dash Responder V1.0 Revision F

Page 38 of 72 2004768-001

Page 39

GE Medical Systems

Information Technologies

Monitor Connector

Described in the following table are the signals that are used by the Dash Responder; additional signal

on the "Dash Hardware Peripheral Expansion Interface", which are not used for the Dash Responder

are shaded.

DASH MONITOR HARDWARE INTERFACE

Name Description I/O-Type Level

GND Ground - 0V - 1

+9TO18VM

Switched +9-18V

PER_MARKER_O

UT

PER_ENET_PRES

ENT*

PER_ENET_TXD-

PER_ENET_RXD-

PER_ENET_TXD+

PER_ENET_RXD+

PER_AUTOPORT

_ID_RXD

PER_PRESENT_

PER_PRESENT*

PER_ASYNC_RX

D

PER_ASYNC_TX

D

PACER_BLANK_

TC_PACER_BLAN

K*

PER_AUTOPORT

_ID_TXD

PER_AUTOPORT

_RXD

PER_AUTOPORT

_TXD

SWITCHED +5V power supply from Monitor I +5V - 17

GND Ground - 0V - 18

Power Supply from Monitor I +9...18V

Sync pulse to Defibrillator I TTL

By this signal the Monitor

switches the Ethernet lines of

the docking station.

switched Ethernet Transmit

line -

switched Ethernet Receive line

switched Ethernet Transmit

line +

switched Ethernet Receive line

+

Autoport ID receive O TTL

This outport must be switched

to GND, then the monitor

switches the power supply to

the defib

Asynchronous communication

transmit to Monitor (Idle State

is HI, Startbit is LOW)

Asynchronous communication

transmit to defib (Idle State is

HI, Startbit is LOW)

Signal tells the monitor that an

pacemaker pulse was delivered.

Autoport ID transmit I TTL

Receive data from peripheral O TTL

Transmit data to peripheral I TTL

O 0V

I TTL

O TTL

I TTL

O TTL

OTTL

OTTL

ITTL

OTTL

active

-2

H3

L 4

- 5

- 6

- 7

- 8

- 9

L10

L11

L12

L13

- 14

- 15

- 16

Pin

Nr.

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 39 of 72

Page 40

GE Medical Systems

Information Technologies

Battery Connector

BATTERY HARDWARE INTERFACE

Name Description I/O-Type Level active Pin

+12VBAT Supply Voltage from Nickel

Cadmium Battery Pack

BAT_CONN_ Battery-Pack present

(Connection to GND)

BQ_DQ Data/Controlbus from Battery-

Pack

BATT_EMPTY Battery-Pack empty (FET to

GND is switched on, as long as

the Battery voltage is greater

than 10 V)

GND Ground - 0V - 8, 9, 10

-

I

I/O

I

+12Vnom - 1, 2, 3

OC L 7

TTL L 5

OC H 4

Internal Connections

Digital PCB

Nr.

Analog PCB

Connector Name DEFI/

Interface PCB Analog to PCB Digital / Connector DEFI

Name Description I/O Level Active Pin

VCC Supply Voltage - +5V - 1

GND Ground - 0V - 2

SDA I²C- Datasignal I/O TTL - 3

GND Ground - 0V - 4

SCL I²C-Clocksignal I/O TTL - 5

GND Ground - 0V - 6

KB_CHARGE Keyboard key line CHARGE O TTL H 7

GND Ground - 0V - 8

KB_DISCHARGE Keyboard key line SHOCK O TTL H 9

GND Ground - 0V - 10

HP_CHARGE Hardpaddle key line CHARGE I TTL H 11

GND Ground - 0V - 12

HP_DISCHARGE Hardpaddle key line SHOCK I TTL H 13

GND Ground - 0V - 14

EN_ SHOCKA Enable Defishock to PIC_A O TTL H 15

Servicing Manual Dash Responder V1.0 Revision F

Page 40 of 72 2004768-001

Page 41

GE Medical Systems

Information Technologies

Interface PCB Analog to PCB Digital / Connector DEFI

Name Description I/O Level Active Pin

GND Ground - 0V - 16

EN_SHOCKB Enable Defishock to PIC_B O TTL H 17

(code) n. c. 18

A_DATA Request line from PIC_A I TTL H 19

GND Ground - 0V - 20

B_DATA Request line from PIC_B I TTL H 21

GND Ground - 0V - 22

DEFI_RESET Reset O TTL H 23

GND Ground - 0V - 24

SPEAKER1 Speaker line 1 - - - 25

SPEAKER2 Speaker line 2 - - - 26

Display Interface

Connector Name DISPLAY/

Interface Display to PCB Digital

Name Description I/O Level active Pin

GND Ground - 0V - 1

VCC Power supply for Logic Circuit - +5V - 2

V0 Power supply for LCD - +1V to –

5V

ADR0 L=Instruction, H=Data I TTL H 4

CS_DISPL1_ Chip Select1 I TTL L 5

CS_DISPL2_ Chip Select2 I TTL L 6

DISPL_EN Display Enable I TTL H 7

PWM_DISPCLK External Clock (2kHz) I TTL - 8

R/W_ Read/Write_ I TTL H/L 9

-3

IO_DAT0 Data Bus0 I/O TTL - 10

IO_DAT1 Data Bus1 I/O TTL - 11

IO_DAT2 Data Bus2 I/O TTL - 12

IO_DAT3 Data Bus3 I/O TTL - 13

IO_DAT4 Data Bus4 I/O TTL - 14

IO_DAT5 Data Bus5 I/O TTL - 15

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 41 of 72

Page 42

GE Medical Systems

Information Technologies

Interface Display to PCB Digital

Name Description I/O Level active Pin

IO_DAT6 Data Bus6 I/O TTL - 16

IO_DAT7 Data Bus7 I/O TTL - 17

CPLD_RESET_ Reset I TTL L 18

VLED1 Power supply for LED Anode - +5V - 19

VLED2 Power supply for LED Cathode - 0 to +5V - 20

Keypad Interface

Connector Name KEYPAD/

Interface Keypad to PCB Digital

Name Description I/O Level Active PIN-

Nr.

KB_SEL0_ Matrix-Send line 0 O TTL L 10

KB_SEL1_ Matrix-Send line 1 O TTL L 9

KBSEL2_ Matrix-Send line 2 O TTL L 15

KBSEL3_ Matrix-Send line 3 (not used) O TTL L 13

KB_IN0_ Matrix-Receive line 0 I TTL L 12

KB_IN1_ Matrix- Receive line 1 I TTL L 8

KB_IN2_ Matrix- Receive line 2 I TTL L 11

KB_IN3_ Matrix- Receive line 3 I TTL L 14

KB_POWER_ON_ Key POWER ON ICMOS

+18V

KB_CHARGE_UB Key CHARGE I+5VH3

KB_DISCHARGE1

_UB

POWER_ON_LED O +5V H 20

BATT_GN_LED Green LED is illuminated if

Key SHOCK1I+5VH7

O+5VH1

Battery full (LED connected to

GND)

L19

BATT_YE_LED Yellow LED is illuminated

when Battery is being charged,

it blinks yellow when battery

charging function is defect or

disturbed (LED is connected to

GND)

Servicing Manual Dash Responder V1.0 Revision F

Page 42 of 72 2004768-001

O+5VH2

Page 43

GE Medical Systems

Information Technologies

Interface Keypad to PCB Digital

Name Description I/O Level Active PIN-

Nr.

SYNC_LED_ LED is illuminated in Sync

Mode and blinks during each

Sync pulse

CHARGED_LED_ LED is illuminated when

selected energy has been

charged

PACER_ON_LED_ LED is illuminated when Pacer

Mode active and blinks on eac h

delivered pace pulse

KB_DISCHARGE2

_UB

VCC Supply Voltage - +5V 4

GND Ground - 0V 18

Key SHOCK2O+5VH6

O+5VL16

O+5VL17

O+5VL5

Pacer PCB

Connector name PACER/

Interface PCB Pacer to PCB Digital

Name Description I/O Level Active Pin

VCCP switched power supply from

Dash 2000/3000/4000 for

voltage generation of pace

pulse

GNDP Ground for VCCP - 0V - 2

VCCP switched power supply from

Dash 2000/3000/4000 for

voltage generation of pace

pulse

GNDP Ground for VCCP - 0V - 4

VCC power supply - +5V - 5

GND Ground for VCC - 0V - 6

PHASE_A_ clock for HV-Generator I H/L L 7

GND Ground for VCC - 0V - 8

PHASE_B_ clock for HV-Generator I H/L L 9

GND Ground for VCC - 0V - 10

- +9...18V - 1

- +9...18V - 3

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 43 of 72

Page 44

GE Medical Systems

Information Technologies

Interface PCB Pacer to PCB Digital

Name Description I/O Level Active Pin

PACE_RESET_ Pacer- Reset I H/L L 11

GND Ground for VCC - 0V - 12

PACE_ACKN_ Pace-pulse- acknowledge O H/L L 13

GND Ground for VCC - 0V - 14

PACE_TXD UART Send line O H/L H 15

GND Ground for VCC - 0V - 16

PACE_RXD UART Receive line I H/L H 17

GND Ground for VCC - 0V - 18

PACE_IMP Pace-pulse I H/L H 19

GND Ground for VCC - 0V - 18

Power Management

Connector Name BATTMAN/

Interface PCB Battery Management to PCB Digital

Name Description I/O Level Active Pin

BATT_GN_LED Charging Status- LED. Green

LED is solid on, when battery

is charged.

BATT_YE_LED ChargingStatus- LED. Yellow

LED is solid on, when battery

(NiCd) is being charged. If the

yellow LED blinks the battery

charging is erroneous.

GND Ground - 0V - 3

KB_POWER_ON_ Keypad Power On O 18V-

I+5VH1

CMOS

H2

L4

GND Ground - 0V - 5

POWER_ON_KEY Level shifted Power On signal I TTL H 6

GND Ground - 0V - 7

POWER_OFF_ Supply switch controlled by the

processor

GND Ground - 0V - 9

Servicing Manual Dash Responder V1.0 Revision F

Page 44 of 72 2004768-001

OTTLL8

Page 45

GE Medical Systems

Information Technologies

Interface PCB Battery Management to PCB Digital

Name Description I/O Level Active Pin

BATTMAN_RESETReset Powermanagement O TTL H 10

GND Ground - 0V - 11

BATT_TXD UART send line O TTL - 12

GND Ground - 0V - 13

BATT_RXD UART receive line I TTL - 14

GND Ground - 0V - 15

SYNC_ Sync-Signal for Cardioversion I TTL L 16

GND Ground - 0V - 17

MARKER_ Marker out signal for Monitor O TTL L 18

GND Ground - 0V - 19

PACER_BLANK Pace-inhibit signal for monitor

(during reset and defib

switched off: low). Inverted

outside of the Device-Control

GND Ground - 0V - 21

PER_ASYNC_TXDAsynchronous communication

transmit

GND Ground - 0V - 23

PER_ASYNC_RXDAsynchronous communication

receive

GND Ground - 0V - 25

VCC Power supply +5V for PCB

Power Management

GNDD Ground for VCCD - 0V - 27

VCCD unregulated Power S upply for

PCB Digital

GNDD Ground for VCCD - 0V - 29

OTTLH20

ITTL-22

OTTL-24

-+5V-26

- +8V...+18

V

-28

VCCD unregulated Power S upply for

PCB Digital

GNDP Ground for VCCP - 0V - 31

VCCP unregulated Power Supply for

PCB PACER

GNDP Ground for VCCP - 0V - 33

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 45 of 72

- +8V...+18

V

- +8V...+18

V

-30

-32

Page 46

GE Medical Systems

Information Technologies

Interface PCB Battery Management to PCB Digital

Name Description I/O Level Active Pin

VCCP unregulated Power Supply for

PCB PACER

- +8V...+18

V

-34

Smart Media Card

Connector Name SMARTCARD/

Interface Smart Media Card to PCB Digital

Name Description I/O Level Active Pin

GND Ground - 0V - 1

SMC_CLE Command Latch Enable I TTL H 2

SMC_ALE Address Latch Enable I TTL H 3

SMC_WE_ Write Enable I TTL L 4

SMC_WP_ Write Protect I TTL L 5

SMCDAT_0 Data, Command, Status Port I/O TTL - 6

SMCDAT_1 Data, Command, Status Port I/O TTL - 7

SMCDAT_2 Data, Command, Status Port I/O TTL - 8

SMCDAT_3 Data, Command, Status Port I/O TTL - 9

GND Ground - 0V - 10

GND Ground - 0V - 11

VCC +3,3V Power s upply - +3,3V - 12

SMCDAT_4 Data, Command, Status Port I/O TTL - 13

SMCDAT_5 Data, Command, Status Port I/O TTL - 14

SMCDAT_6 Data, Command, Status Port I/O TTL - 15

SMCDAT_7 Data, Command, Status Port I/O TTL - 16

LVD Low Voltage Detect 17

GND Ground - 0V - 18

SMC_RB_ Ready/Busy_ O TTL H/L 19

SMC_RE_ Read Enable I TTL L 20

SMC_CE_ Chip Enable I TTL L 21

VCC +3,3V power supply - +3,3V - 22

GND Ground - 0V - 23

SMC_ABSENT Card Detect O TTL H 24

Servicing Manual Dash Responder V1.0 Revision F

Page 46 of 72 2004768-001

Page 47

GE Medical Systems

Information Technologies

Analog PCB

Digital PCB

Connector Name DEFI/

(see description Analog PCB, page 40)

HV Capacitor

Connector Name KO_P/ and KO_M/

Interface Analog PCB to HV Capacitor

Name Description I/O Level

(measured

versus

GND)

KO_P High Voltage + (floating) - +2500V - (single)

KO_M HighVoltage - (floating) - -2500V - (single)

Active Pin

Pacer PCB

Connector Name PACE_P/ and PACE_M/

Interface Analog PCB to Pacer PCB

Name Description I/O Level

(measured

versus

GND)

PACE_P High Voltage + (floating) - max

+200V

during

pace

(+2500V

during

shock)

Active Pin

-(single)

PACE_M High Voltage - (floating) - max

-200V

during

pace

(-2500V

during

shock)

Revision F Servicing Manual Dash Responder V1.0

2004768-001 Page 47 of 72

-(single)

Page 48

GE Medical Systems

Information Technologies

Paddle Connector