Page 1

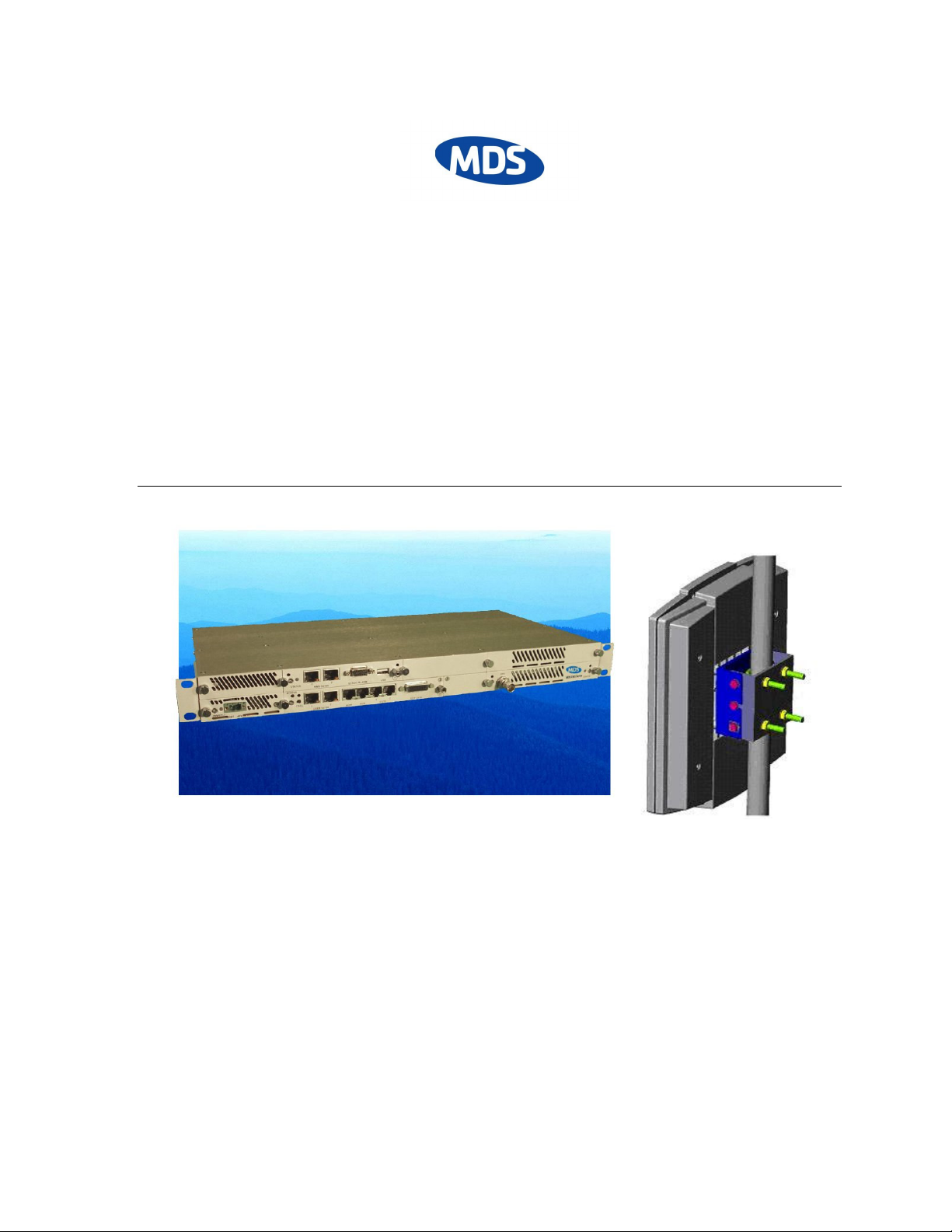

Microwave Data Systems

Digital Radio System

MDS FOUR.9 Series

MDS SIX.4 Series

User Reference and Installation Guide

PRELIMINARY

Part No. 05-4561A01, Rev. A

Date: 9 JUNE 2006

Page 2

Page 3

© 2006 Microwave Data Systems Inc. All Rights Reserved.

This book and the information contained herein is the proprietary and confidential information of

Microwave Data Systems Inc. that is provided by Microwave Data SystemsTM exclusively for

evaluating the purchase of Microwave Data Systems Inc. technology and is protected by copyright

and trade secret laws.

No part of this document may be disclosed, reproduced, or transmitted in any form or by any means,

electronic or mechanical, for any purpose without the express written permission of Microwave Data

Systems Inc.

For permissions, contact Microwave Data Systems Inc. Marketing Group at 1-585-241-5510 or 1-585-

242-8369 (FAX).

Notice of Disclaimer

The information and specifications provided in this document are subject to change without notice.

Microwave Data Systems Inc. reserves the right to make changes in design or components as

progress in engineering and manufacturing may warrant.

The Warranty(s) that accompany Microwave Data Systems Inc., products are set forth in the sales

agreement/contract between Microwave Data Systems Inc. and its customer. Please consult the

sales agreement for the terms and conditions of the Warranty(s) proved by Microwave Data Systems

Inc. To obtain a copy of the Warranty(s), contact your Microwave Data Systems Inc. Sales

Representative at 1-585-241-5510 or 1-585-242-8369 (FAX).

The information provided in this Microwave Data Systems Inc., document is provided “as is” without

warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties

of merchantability, fitness for a particular purpose, or non-infringement. Some jurisdictions do not

allow the exclusion of implied warranties, so the above exclusion may not apply to you.

In no event shall Microwave Data Systems Inc. be liable for any damages whatsoever – including

special, indirect, consequential or incidental damages or damages for loss of profits, revenue, use, or

data whether brought in contract or tort, arising out of or connected with any Microwave Data

Systems Inc., document or the use, reliance upon or performance of any material contained in or

accessed from this Microwave Data Systems Inc. document. Microwave Data Systems’ license

agreement may be provided upon request. Additional Terms and Conditions will be finalized upon

negotiation or a purchase.

The above information shall not be constructed to imply any additional warranties for Microwave Data

Systems Inc. equipment including, but not limited to, warranties of merchantability or fitness for an

intended use.

Trademark Information

Software Defined Indoor UnitTM (SDIDUTM) is a product and trademark of CarrierComm Inc.

JavaTM is a trademark of Sun Microsystems Inc.

Windows® is a registered trademark of Microsoft Corporation

All other brand or product names are trademarks or registered trademarks of their respective

companies or organizations.

Page 4

Table of Contents

1 SAFETY PRECAUTIONS ......................................................................................................................1-1

2 SYSTEM DESCRIPTION .......................................................................................................................2-1

2.1 About This Manual............................................................................................................................2-1

2.2 Introduction .......................................................................................................................................2-1

2.3 System Features ...............................................................................................................................2-5

2.4 Physical Description ........................................................................................................................2-6

2.4.1 Model Types ................................................................................................................................2-6

2.4.2 Options ........................................................................................................................................2-8

2.4.3 Front Panel Indicators .................................................................................................................2-8

2.4.4 Front Panel Connections .............................................................................................................2-9

2.5 System Description ........................................................................................................................2-13

2.6 Consecutive Point Architecture ....................................................................................................2-16

2.7 2 + 0 (East-West) Configuration ....................................................................................................2-18

2.8 1+1 Protection .................................................................................................................................2-19

2.9 1 + 1 Multi-hop Repeater Configuration .......................................................................................2-20

2.10 Data Interfaces ................................................................................................................................2-22

2.11 Power Management ........................................................................................................................2-22

2.12 MDS Digital Radio Series Software and Network Management.................................................2-23

3 INSTALLATION .....................................................................................................................................3-1

3.1 Unpacking..........................................................................................................................................3-1

3.2 Notices ...............................................................................................................................................3-2

3.3 Required Tools..................................................................................................................................3-2

3.3.1 SDIDUTM Tools ............................................................................................................................3-2

3.3.2 ODU Tools...................................................................................................................................3-2

3.4 PRE-INSTALLATION NOTES ...........................................................................................................3-3

3.5 Overview of Installation and Testing Process ...............................................................................3-3

3.6 Site Evaluation ..................................................................................................................................3-5

3.6.1 Preparing for a Site Evaluation....................................................................................................3-6

3.6.2 Site Evaluation Process...............................................................................................................3-7

3.6.3 Critical System Calculations ......................................................................................................3-12

3.6.4 Frequency Plan Determination ..................................................................................................3-13

3.6.5 Antenna Planning ......................................................................................................................3-14

3.6.6 ODU Transmit Power Setup ......................................................................................................3-15

3.6.7 Documenting a Site Evaluation .................................................................................................3-17

3.7 Installation of the Digital Radio Series .........................................................................................3-20

3.7.1 Installing the Software Defined IDUTM.......................................................................................3-20

3.7.2 Installing the ODU .....................................................................................................................3-21

3.7.3 Routing the ODU/ SDIDUTM Interconnect Cable .......................................................................3-23

3.8 Quick Start Guide ...........................................................................................................................3-25

3.8.1 Materials Required ....................................................................................................................3-25

3.8.2 Grounding the ODU...................................................................................................................3-25

Page 5

3.8.3 Grounding the SDIDUTM............................................................................................................3-27

3.8.4 Connecting the SDIDUTM to the PC and Power Source ............................................................3-27

3.8.5 SDIDUTM Configuration..............................................................................................................3-28

3.8.6 ODU Antenna Alignment ...........................................................................................................3-30

3.8.7 Quick Start Settings...................................................................................................................3-31

3.9 Documenting MDS FOUR.9 Series Configuration .......................................................................3-32

4 SUMMARY SPECIFICATIONS..............................................................................................................4-1

5 FRONT PANEL CONNECTORS ...........................................................................................................5-1

5.1 DC Input (Power) Connector............................................................................................................5-1

5.2 Ethernet 100BaseTX Payload Connector 1-2.................................................................................5-1

5.3 SONET Payload Connector..............................................................................................................5-2

5.4 STM-1 Payload Connector ...............................................................................................................5-2

5.5 DS-3/E-3/STS-1 Payload Connector ................................................................................................5-2

5.6 NMS 10/100BaseTX Connector 1-2 .................................................................................................5-3

5.7 Alarm/Serial Port Connector............................................................................................................5-3

5.8 ODU Connector .................................................................................................................................5-4

5.9 T1- Channels 1-2 Connector ............................................................................................................5-4

5.10 T1- Channels 3-16 Connector ..........................................................................................................5-5

5.11 USB ....................................................................................................................................................5-7

5.12 Voice Order Wire...............................................................................................................................5-8

5.13 Data Order Wire ................................................................................................................................5-8

6 APPENDIX .............................................................................................................................................6-1

6.1 Alarm Descriptions ...........................................................................................................................6-1

6.2 Abbreviations & Acronyms............................................................................................................6-14

Page 6

1 Safety Precautions

PLEASE READ THESE SAFETY PRECAUTIONS!

RF Energy Health Hazard—FOUR.9 Series

The radio equipment described in this guide employs radio frequency transmitters. Although the

power level is low, the concentrated energy from a directional antenna may pose a health hazard.

Do not allow people to come closer than 119 cm (47.2 inches) to the front of the antenna while

the transmitter is operating. The antenna must be professionally installed on a fixed-mounted

outdoor permanent structure to provide separation from any other antenna and all persons as

detailed in this manual.

RF Energy Health Hazard—SIX.4 Series

The radio equipment described in this guide employs radio frequency transmitters. Although the

power level is low, the concentrated energy from a directional antenna may pose a health hazard.

Do not allow people to come closer than 3.17 meters (124.80 inches) to the front of the antenna

while the transmitter is operating. The antenna must be professionally installed on a fixed-

mounted outdoor permanent structure to provide separation from any other antenna and all

persons as detailed in this manual.

Protection from Lightning

Article 810 of the US National Electric Department of Energy Handbook 1996 specifies that radio

and television lead-in cables must have adequate surge protection at or near the point of entry to

the building. The code specifies that any shielded cable from an external antenna must have the

shield directly connected to a 10 AWG wire that connects to the building ground electrode.

Warning – This is a Class A product

Warning – This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Warning – Turn off all power before servicing

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 7

User Reference and Installation Guide 1-2

Warning – Turn off all power before servicing this equipment.

Safety Requirements

Safety requirements require a switch be employed between the SDIDU™ external power supply

and the SDIDU™ power supplies.

Proper Disposal

The manufacture of the equipment described herein has required the extraction and use of

natural resources. Improper disposal may contaminate the environment and present a health risk

due to the release of hazardous substances contained within. To avoid dissemination of these

substances into our environment, and to lessen the demand on natural resources, we encourage

you to use the appropriate recycling systems for disposal. These systems will reuse or recycle

most of the materials found in this equipment in a sound way. Please contact Microwave Data

Systems or your supplier for more information on the proper disposal of this equipment.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 8

2 System Description

2.1 About This Manual

This manual is written for those who are involved in the installation and use of the

MDS FOUR.9 Series or MDS SIX.4 Series Digital Radio System, including installation

technicians, site evaluators, project managers, and network engineers. The transceivers are

comprised of a Software Defined Indoor UnitTM (SDIDUTM) and outdoor unit (ODU). The SDIDUTM

is a product and trademark of CarrierComm.

This manual assumes the reader has a basic understanding of how to install hardware, use

Windows based software, and operate test equipment. For the purposes of this manual, the

radios are referred to as the “Digital Radio Series” except where it is necessary to make a

distinction between the models covered or their operating frequency ranges.

2.2 Introduction

The Microwave Data Systems family of digital radios provides high capacity transmission,

flexibility, features, and convenience for wireless communications networks. These radios

represent a new microwave architecture that is designed to address universal applications for

both PDH and SDH platforms. This advanced technology platform provides the flexibility

customers need for their current and future network requirements.

The radio family is based on a common platform used to support a wide range of network

interfaces and configurations. It supports links for 16 x E1/T1, 100BaseTX Ethernet, and DS3/E-3/STS-1 (optional, consult factory for availability). The radio family is spectrum and data rate

scalable, enabling service providers or organizations to trade-off system gain with spectral

efficiency and channel availability for optimal network connectivity. The radio family enables

network operators (mobile and private), government and access service provides to offer a

portfolio of secure, scalable wireless applications for data, video, and Voice over IP (VoIP).

The MDS FOUR.9 Series digital radio family operates in the FCC Public Safety Band of 4.940 to

4.990 GHz, which is generically referred to as the “4.9 GHz band.” It supports three types of user

data payload connectivity as follows:

• 100Base-TX intelligent bridging between two locations without the delay and expense of

installing cable or traditional microwave.

• Scalable Ethernet capability of 25 and 50 Mbps is included. These scalable radios provide

LAN connectivity and offer performance trade-offs between operational bandwidths, data

rates, and distance.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 9

User Reference and Installation Guide 2-2

• 16E1 or T1 for cellular backhaul, enterprise voice applications and voice network redundancy

The MDS SIX.4 Series digital radio family operates in the FCC Fixed Microwave Services band

of 5.925 to 6.425 GHz, which is generically referred to as the “6.4 GHz band.” It supports four

types of user data payload connectivity as follows:

• Gigabit Ethernet intelligent bridging between two locations without the delay and expense of

installing cable or traditional microwave.

• Scalable Ethernet capability of 16 to 131 Mbps is included. These scalable radios provide

LAN connectivity and offer performance trade-offs between operational bandwidths, data

rates, and distance.

• 32 T1 for cellular backhaul, enterprise voice applications and voice network redundancy with

85 Mbps of Ethernet

• SONET (Synchronous Optical Network)

For customers such as cellular carriers requiring backhaul and backbone extension as well

as service providers requiring network redundancy, new Points of Presence (POPs), and last mile

access, the Digital Radio Series is a cost effective alternative to leased lines with carrier-class

quality of performance. The Digital Series radio is a cost effective solution to meet the growing

demand for enterprise Local Area Network (LAN) connectivity between buildings and campuses

as well as service providers requiring reliable products for infrastructure expansion, extending

Metropolitan Area Network (MAN) fiber access, and network redundancy.

The Digital Series includes integrated Network Management functionality and design features that

enable simple commissioning in the field at the customer’s premises. Furthermore, a highlight of

MDS radio products is scalability and the capability to support a ring-type architecture. This ring

or consecutive point radio architecture is “self-healing” in the event of an outage in the link and

automatically re-routes data traffic to ensure that service to the end user is not interrupted.

The Digital Series radio system is composed of a Software Defined Indoor UnitTM (SDIDUTM) and

Outdoor Unit (ODU). It supports 1+0 and 1+1 protection and ring architectures in a single 1 Rack

Unit (1RU) chassis. The modem and power supply functions are supported using easily

replaceable plug-in modules. An additional feature of the SDIDUTM is provision for a second

plug-in modem/IF module to provide repeater or east/west network configurations.

The overall architecture consists of a single 1RU rack mount Software Defined Indoor Unit

(SDIDUTM) with a cable connecting to an Outdoor Unit (ODU) with an external antenna.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 10

User Reference and Installation Guide 2-3

Core Access

Network

Outdoor

Outdoor

Unit

Unit

Outdoor

Unit

Outdoor

Unit

Indoor Unit

Indoor Unit

Outdoor

Unit

Outdoor

Unit

Indoor Unit

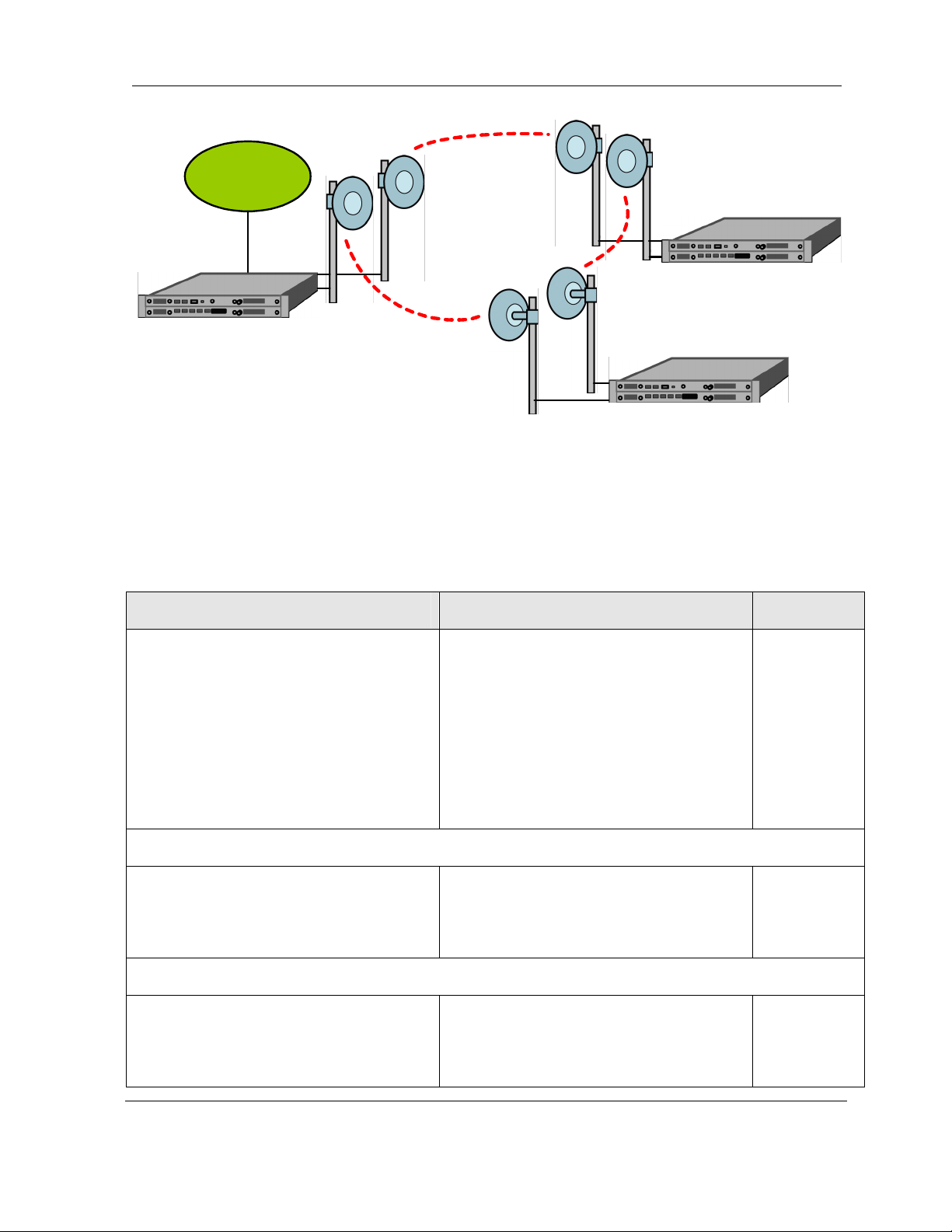

Figure 2-1. MDS Digital Radio Series SDIDUTM and ODU Architecture

Table 2-1 lists key features that Digital Radio Series technology offers to those involved in the

design, deployment and support of broadband fixed wireless networks.

Table 2-1 Key Benefits and Advantages of MDS Digital Radio Series

Benefits Advantages to Providers/Customers Reference

Wireless license-free system (FOUR.9

Fast return on investment.

146H143H2.2 –147H144H2.4

only): ISM bands do not require expensive

license band fees or incur licensing delays.

Wireless licensed system (SIX.4 only):

No interference from other services as this

Lower total cost of total ownership.

Media diversity avoids single points of

failure.

band is licensed to the user.

Wireless connectivity supplements existing

cable (Ethernet).

Easy to install units

Straightforward modular system enables

Fast return on investment.

148H145H3.5

fast deployment and activation.

No monthly leased line fees.

Carrier-class reliability.

Complete support of payload capacity with additional wayside channels

Aggregate capacity beyond basic payload:

Increases available bandwidth of network.

149H146H2.2– 150H147H2.5

FOUR.9 Series—34 Mbps, 50 Mbps or

100 Mbps.

SIX.4 Series—16 to 131 Mbps

Allows customer full use of revenuegenerating payload channel.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 11

User Reference and Installation Guide 2-4

Benefits Advantages to Providers/Customers Reference

Scalable and spectrally efficient system.

Separate networks for radio

overhead/management and user payload.

Ring Architecture

Supports a ring (consecutive point)

configuration, thus creating a self-healing

redundancy that is more reliable than

traditional point-to-point networks.

In the event of an outage, traffic is

automatically rerouted via another part of

the ring without service interruption.

Ring/consecutive point networks can

overcome line-of-sight issues and reach

more buildings than other traditional

wireless networks.

Networks can be expanded by adding

more Digital Radio Series units, or more

rings without interruption of service.

Up to 16 (FOUR.9 Series) or 32 (SIX.4

Series) T1/E1 wayside channels support

extension of PBX connectivity between

buildings without additional leased-line

costs.

Lowers total cost of ownership.

Enables network scalability.

Increases deployment scenarios for initial

deployment as well as network expansion

with reduced line-of-sight issues.

Increases network reliability due to selfhealing redundancy of the network.

Minimizes total cost of ownership and

maintenance of the network.

Allows for mass deployment.

2.6,2.7,2.9

A separate management channel allows

for a dedicated maintenance ring with

connections to each radio on the ring.

Adaptive Power Control

Automatically adjusts transmit power in

discrete increments in response to RF

interference. For EIRP compliance, the

power output is limited to the maximum

established at the time of installation, per

FCC Part 90 (FOUR.9 Series) or 101

(SIX.4 Series) rules.

Comprehensive Link/Network Management Software

A graphical user interface offers security,

configuration, fault, and performance

management via standard craft interfaces.

Suite of SNMP-compatible network

management tools that provide robust

local and remote management capabilities.

Enables dense deployment.

Simplifies deployment and network

management.

Simplifies management of radio network

and minimizes resources as entire network

can be centrally managed from any

location.

Simplifies troubleshooting of single radios,

links, or entire networks.

2.11

2.12

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 12

User Reference and Installation Guide 2-5

Benefits Advantages to Providers/Customers Reference

Simplifies network upgrades with remote

software upgrades.

Allows for mass deployment.

2.3 System Features

Selectable Rates and Interfaces

o Up to 16 (FOUR.9 Series) or 32 (SIX.4 Series) x E1/T1 (wayside channels)

o 100BaseTX/Ethernet: Scalable 25-50 Mbps (FOUR.9 Series) or 16 to 131Mbps

(SIX.4 Series)

o DS-3/E-3/STS-1 (option; consult factory for availability)

Support for multiple configurations

o 1+0, 1+1 protection/diversity

o Hot Standby

o East/West Repeater (2 + 0)

Selectable Spectral Efficiency of 0.8 to 6.25 bits/Hz (FOUR.9 Series) or 5 to 7 bits/Hz

(SIX.4 Series). These figures include FEC and spectral shaping effects.

16 – 64 QAM Modulation (FOUR.9 Series) or 32 – 64 QAM Modulation (SIX.4 Series)

Powerful Trellis Coded Modulation concatenated with Reed-Solomon Error Correction

Built-in Adaptive Equalizer

Support of Voice Orderwire Channels

Peak output power at antenna port (FOUR.9 Series):

o 24.4 dBm at 4.9 GHz (High Power)

o 17.1 dBm at 4.9 GHz (Low Power)

Peak output power at antenna port (SIX.4 Series):

o 26 dBm at 6.4 GHz (High Power)

o 8 dBm at 6.4 GHz (Low Power)

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 13

User Reference and Installation Guide 2-6

Receive Sensitivity: -84 dBm to -72 dBm (depending on data rate/modulation/FEC/ODU)

Adaptive Power Control—Adjusts power output to account for changing path

conditions. Power is limited to the maximum established at the time of installation, per

FCC Part 90.

Built-in Network Management System (NMS)

Consecutive Point ring architecture

Built-in performance statistics

o Built-in Bit Error Rate (BER) performance monitoring

Data encryption of all payload data and T1/E1 wayside channels for Series-100 radios

and Series-50 Ethernet models (Consult factory for availability)

2.4 Physical Description

The following section details the physical features of the Digital Series digital radios

• Model types

• Front panel indicators

• Front panel connections

2.4.1 Model Types

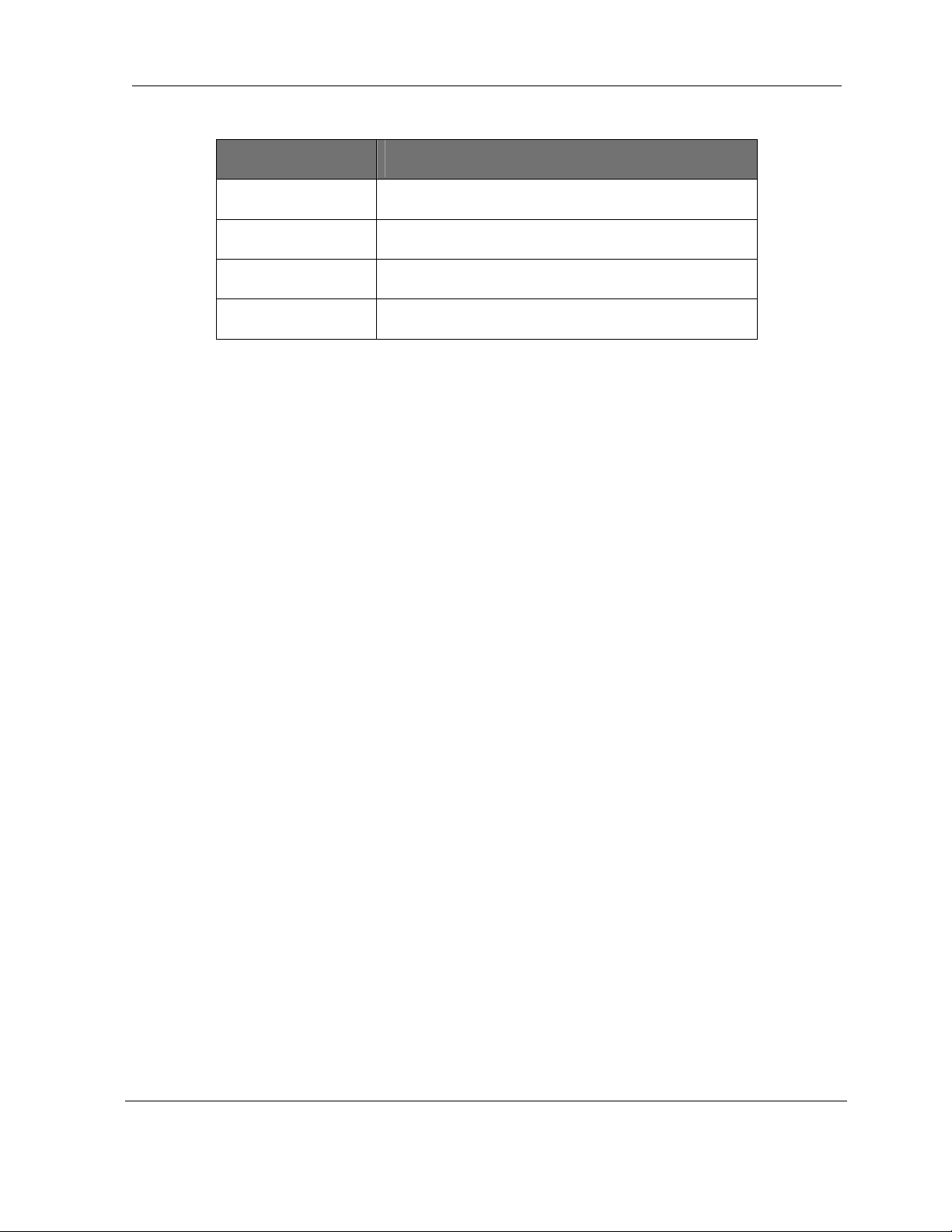

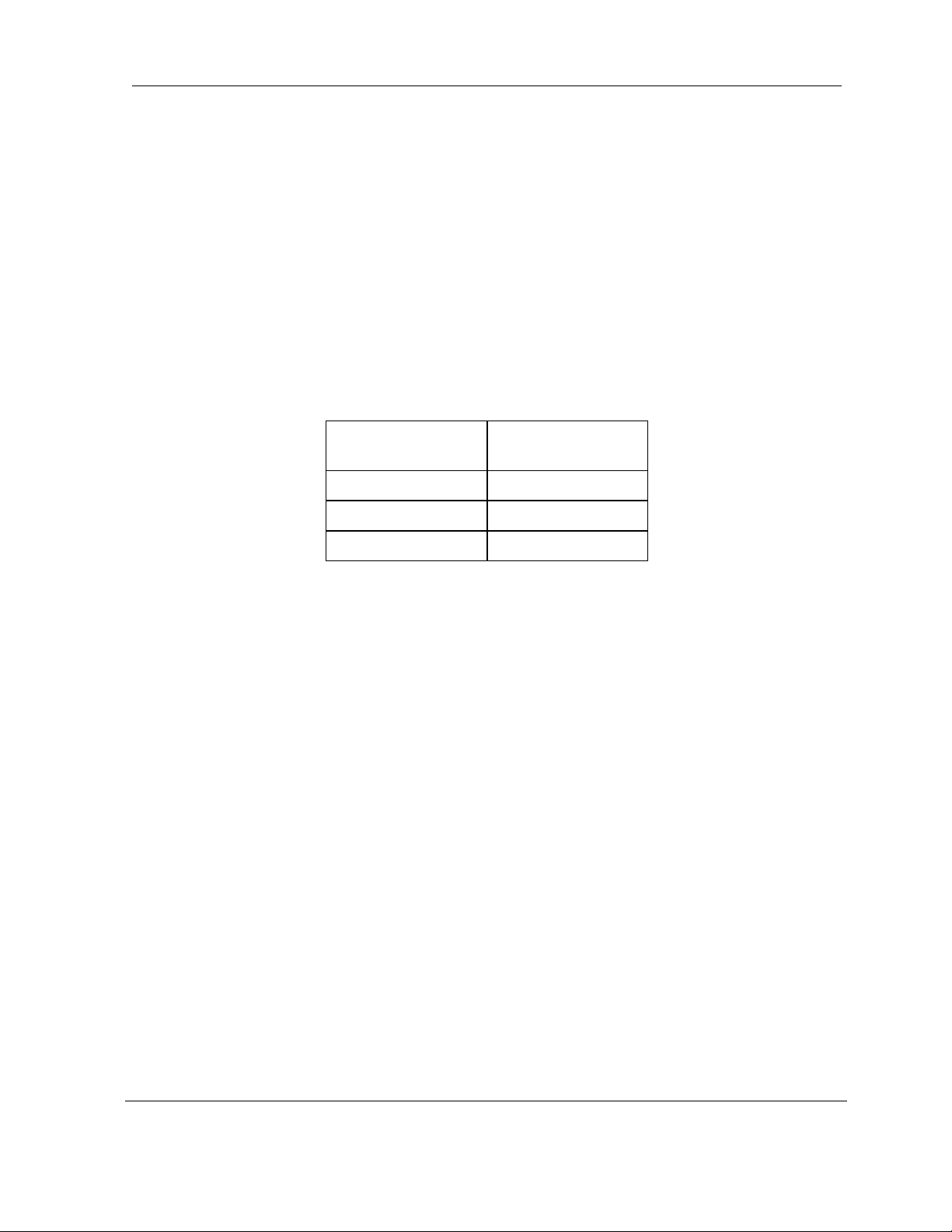

158H155HTable 2-2 lists the radio series according to model number and associated capabilities of throughput,

data interface, and wayside channel. 159H156H

Table 2-3 lists the ODU model numbers.

Table 2-2 MDS Digital Radio Series SDIDUTM Model Types

MODEL NUMBER*

SDIDUxxMNVN

FULL DUPLEX

THROUGHPUT

100 Mbps

Aggregate

(50 Mbps full

duplex)

DATA

INTERFACE

100 BaseTX

WAYSIDE

Two

T1/E1s

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 14

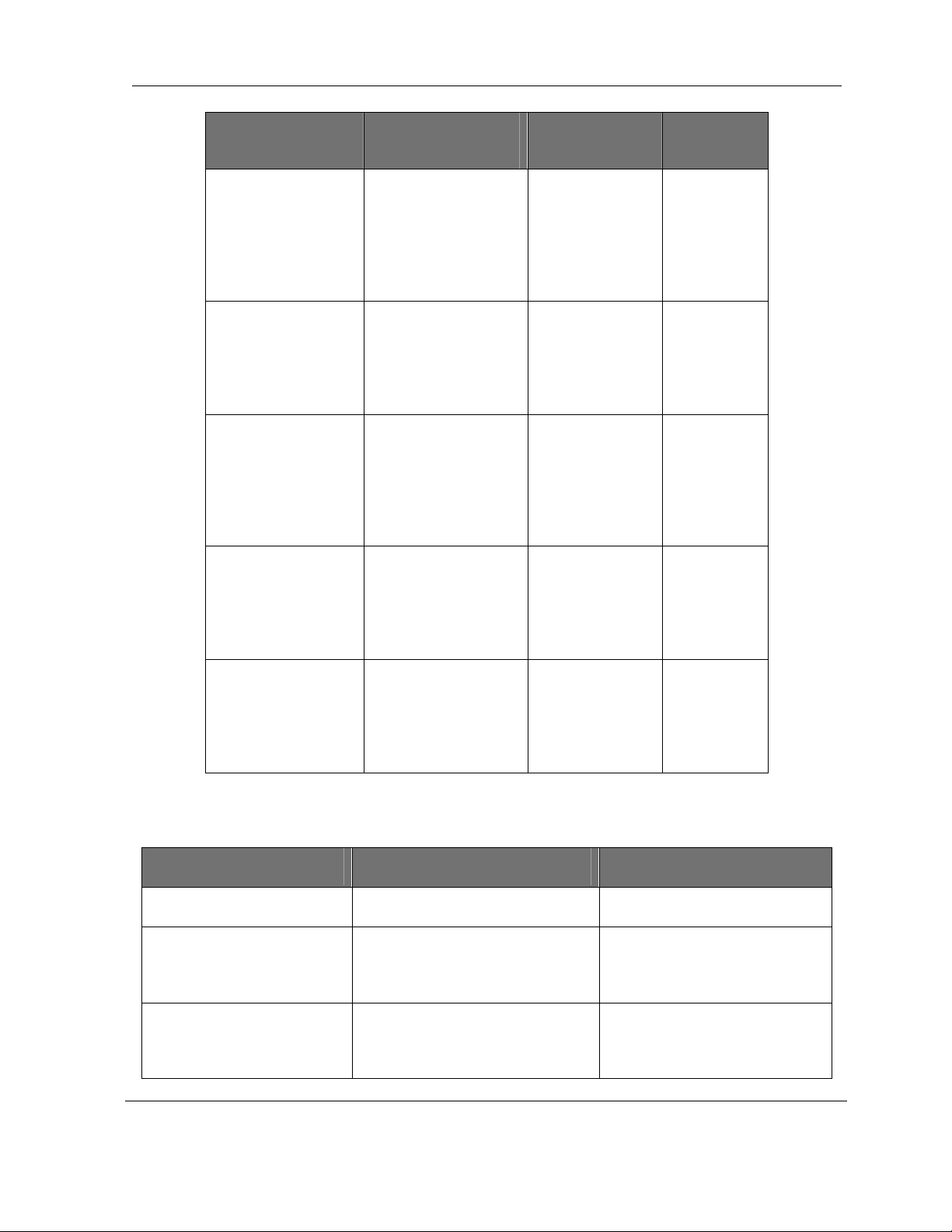

User Reference and Installation Guide 2-7

MODEL NUMBER*

SDIDUxxMPVN 100 Mbps

SDIDUxxMNCN 200 Mbps

SDIDUxxMPCN 200 Mbps

SDIDUxxMNTN 68 Mbps Aggregate

FULL DUPLEX

THROUGHPUT

Aggregate

(50 Mbps full

duplex), 1+1

Protection or 2+0

Aggregate

(100 Mbps full

duplex)

Aggregate

(100 Mbps full

duplex), 1+1

Protection or 2+0

(34 Mbps full

duplex) + scalable

Ethernet

DATA

INTERFACE

100 BaseTX

100 BaseTX

100 BaseTX

1-16xE1/T1

WAYSIDE

Two

T1/E1s

Two

T1/E1s

Two

T1/E1s

Scalable

Ethernet, 2

Mbps

SDIDUxxMPTN 72 Mbps Aggregate

1-16xE1/T1

Scalable

Ethernet, 2

(36 Mbps full

duplex), 1+1

Protection or 2+0

* “xx” changes in accordance with the frequency range of radio; 49 for 4.9 GHz, 64 for 6.4 GHz)

Table 2-3 MDS Digital Radio Series ODU Model Types

PRODUCT NAME MODEL NUMBER ANTENNA

MDS FOUR.9 - ODU49e ODU4900MEP External antenna required

MDS SIX.4 – ODU*

MDS SIX.4 – ODU*

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

Transmit: 5929 – 6110 MHz

Transmit: 6181 – 6362 MHz

ODU6400MLL

Receive: 6181 – 6362 MHz

ODU6400MLH

Receive: 5929 – 6110 MHz

External antenna required

External antenna required

Mbps

05-4561A01, Rev. A

Page 15

User Reference and Installation Guide 2-8

MDS SIX.4 – ODU*

Transmit: 5988 – 6169 MHz

ODU6400MHL

External antenna required

Receive: 6240 – 6421 MHz

MDS SIX.4 – ODU*

ODU6400MHH

Transmit: 6240 – 6421 MHz

External antenna required

Receive: 5988 – 6169 MHz

* To support the FCC Part 101 6.4 GHz band plan, four separate ODUs are required to cover the

frequencies as listed above.

2.4.2 Options

The following items are also available:

• AC/DC power supply

• Data Encryption

• OC-3/STM-1 Mini-IO Module

Please consult the factory for more information.

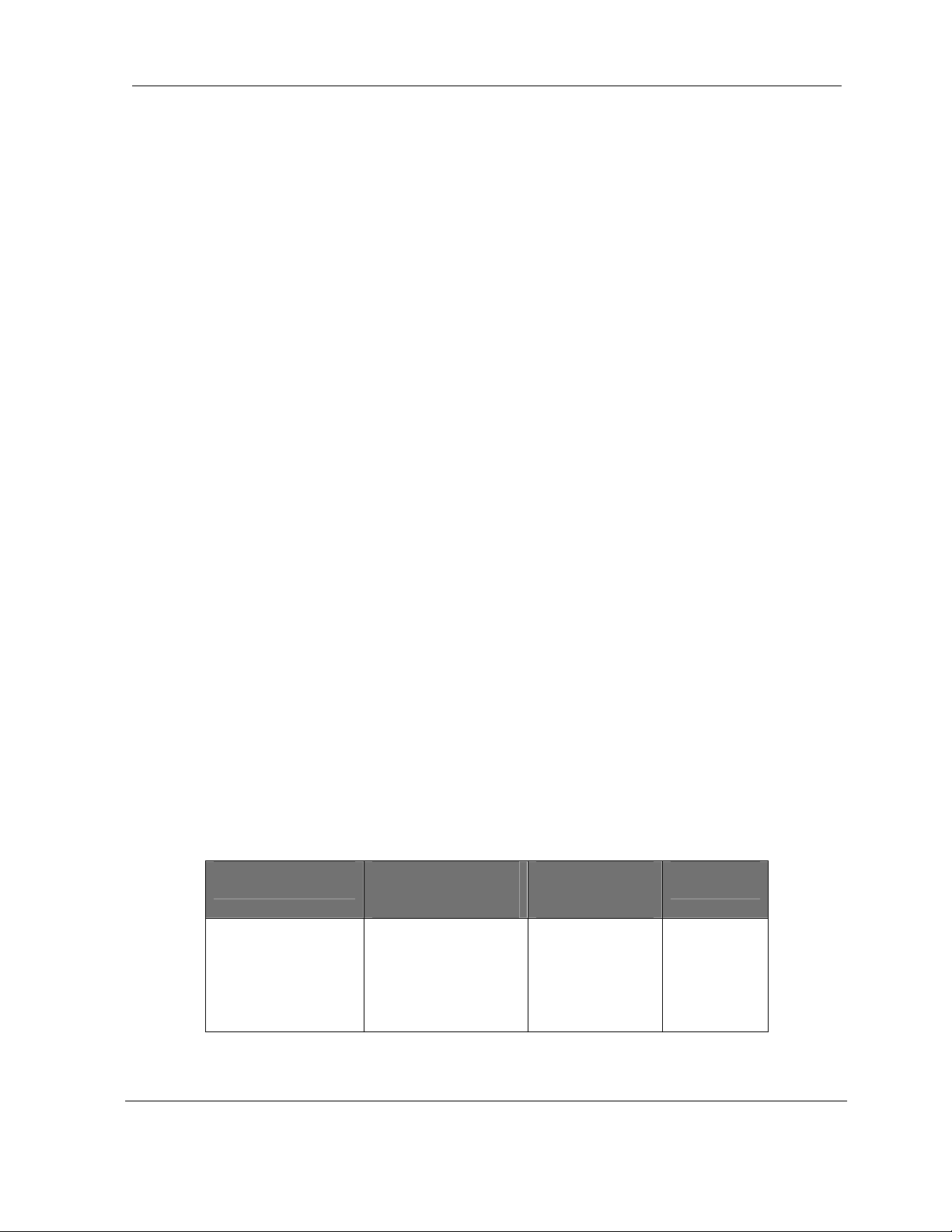

2.4.3 Front Panel Indicators

All models of the Digital Radio Series support a variety of front panel configurations that are

dependent on the network interface and capacity configurations.

160H157HFigure 2-2 provides an example of a 1+0 configuration and the associated LEDs displayed on

the SDIDUTM front panel. The controller, standard I/O, and each modem card have a status LED.

Figure 2-2. Front Panel LEDs: SDIDUTM Configuration for 1+0 Configuration

The modem status LED indicates the modem status as described in Table 2-4.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 16

User Reference and Installation Guide 2-9

Table 2-4. Modem status LED.

LED STATUS

Green

Orange

Flashing Green

Flashing Orange

The controller status LED is the primary front panel indicator of alarms. An alarm is generated

when a specific condition is identified and is cleared when the specified condition is no longer

detected. When an alarm is posted,

1. The controller status LED turns orange for 5 seconds

2. The controller status LED turns off for 5 seconds

3. The controller status LED flashes orange the number of times specified by the first digit of

the alarm code

4. The controller status LED turns off for 3 seconds

5. The controller status LED flashes orange the number of times specified by the second

digit of the alarm code

Standby Locked Link (1+1 Non-Diversity Only)

Active Locked Link

Low SNR

Unlocked

Steps 2 through 5 are repeated for each alarm posted. The entire process is repeated as long as

the alarms are still posted.

The standard I/O and modem status LEDs are set to red when certain alarms are posted. A

complete list of alarms is provided in Appendix 161H158H6.1.

The alarm description is also displayed in the Graphical User Interface (GUI) as described in the

User Interface Reference Manual.

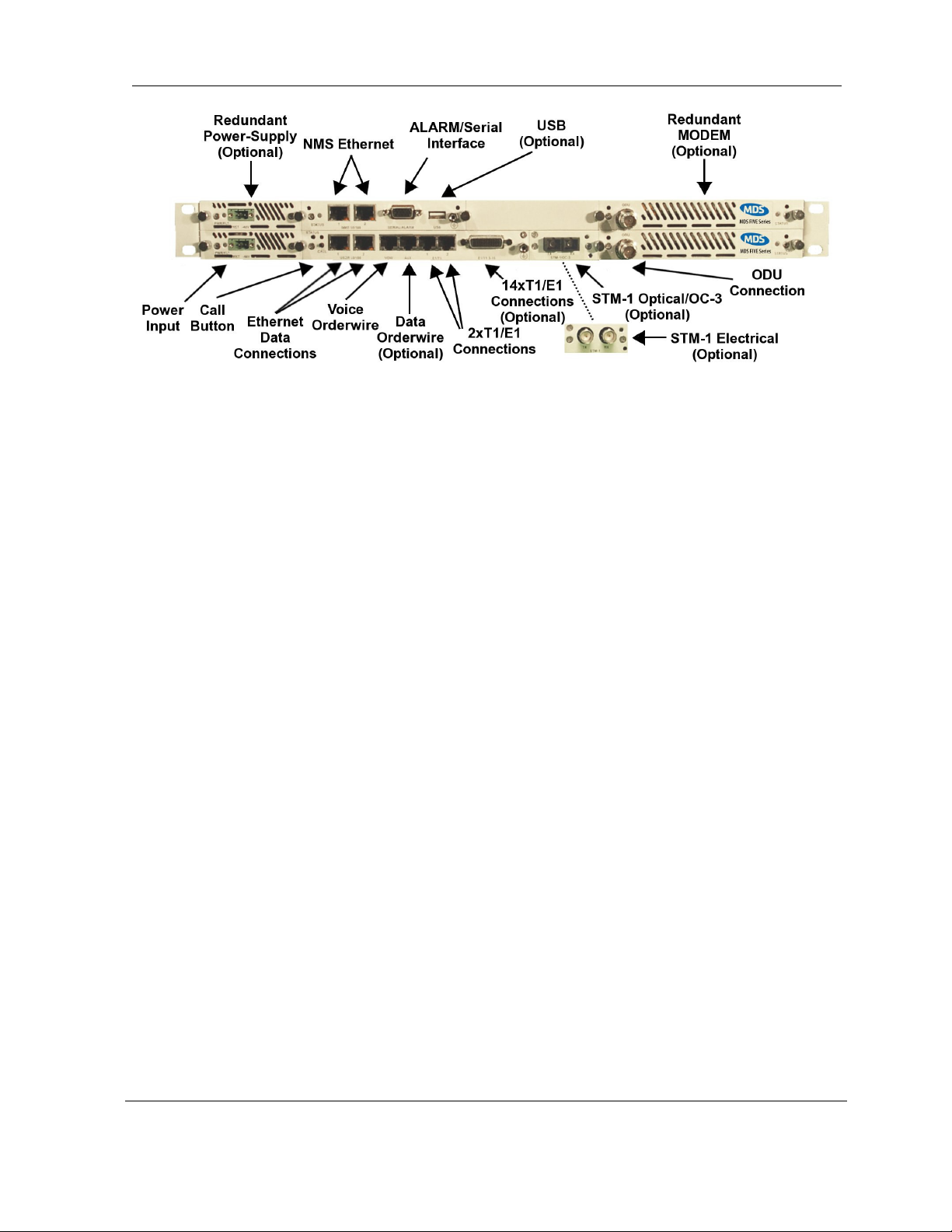

2.4.4 Front Panel Connections

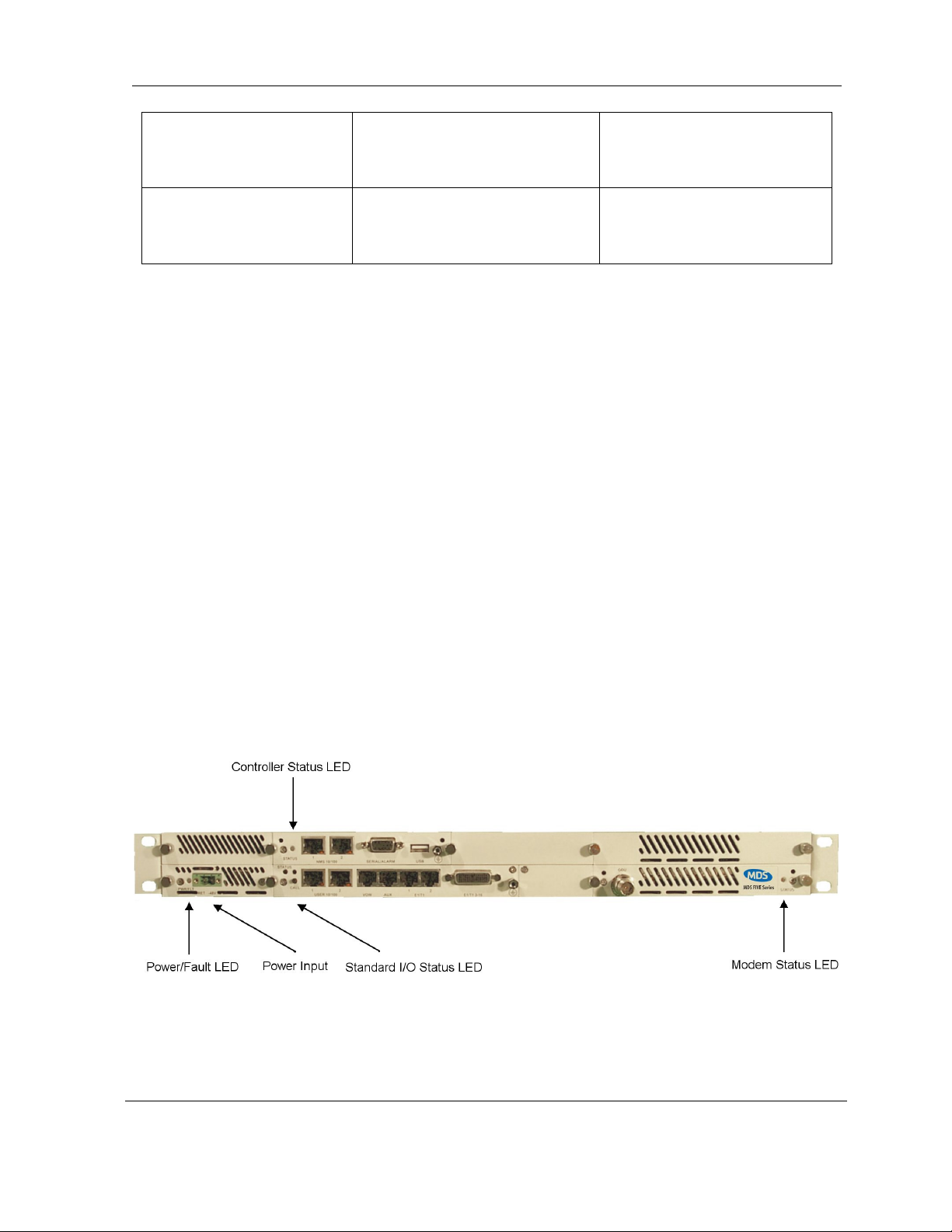

Please refer to the 162H159HFigure 2-3 for an example of the SDIDUTM front panel followed by a

descriptive text of the connections.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 17

User Reference and Installation Guide 2-10

Figure 2-3. Front Panel Connections, 1+1 Protection: SDIDUTM

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 18

User Reference and Installation Guide 2-11

48 V dc, with respect to the unit chassis (ground).

Power Supply Input

DC Input

-48 VDC

-48v (Isolated Input); 2-pin captive power connector. The unit

requires an input of -48 volts dc ±10% at the front panel DC

Input connector. The total required power is dependent on

the option cards and protection configuration (1+0, 1+1). The

SDIDUTM front panel power connector pin numbering is 1

through 2, from left to right, when facing the unit front panel.

Pin 1 is the power supply return and is connected to unit

chassis ground internally. Pin 2 should be supplied with a

nominal A ground-isolated supply may be used, provided it will

tolerate grounding of its most positive output.

The recommended power input is -44 to -52 V dc at 2 Amps

minimum. It is recommended that any power supply used be

able to supply a minimum of 100 Watts to the SDIDUTM.

A mating power cable connector is supplied with the

SDIDUTM. It is a 2-pin plug, 5 mm pitch, manufactured by

Phoenix Contact, P/N 17 86 83 1 (connector type MSTB

2,5/2-STF). This connector has screw clamp terminals that

accommodate 24 AWG to 12 AWG wire. The power cable

wire should be selected to provide the appropriate current

with minimal voltage drop, based on the power supply

voltage and length of cable required. The recommended

wire size for power cables under 10 feet in length supplying

-48 Vdc is 18 AWG.

The SDIDUTM supplies the ODU with all required power via

the ODU/SDIDUTM Interconnect cable. The SDIDUTM does

not have a power on/off switch. When DC power is

connected to the SDIDUTM, the digital radio powers up and is

operational. There can be up to 204 mW of RF power

present at the antenna port (external antenna version). The

antenna should be directed safely when power is applied.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 19

User Reference and Installation Guide 2-12

Alarm/Serial Interface

Alarms/Serial DB-15HD female connector for two Form-C relay alarm

outputs (rated load: 1A @ 24 VDC), two TTL alarm outputs,

four TTL alarm inputs, and Serial Console. The two Form-C

relay alarm outputs can be configured to emulate TTL alarm

outputs.

USB Interface

USB USB connector, optional.

Voice Orderwire Connector

Voice

Orderwire Call

Voice

Call button to alert operator at link-partner SDIDUTM of

incoming Voice-Orderwire call.

RJ-11 modular port connector for voice orderwire interface.

Orderwire

NMS 10/100 Network Management System Connections

NMS 10/100 1 10/100Base-TX RJ-45 modular local port connector for

access to the Network Management System (SNMP) and

GUI.

NMS 10/100 2 10/100BaseTX RJ-45 modular remote port connector for

access to the Network Management System (SNMP). This

port to be used for consecutive point networks.

100/Ethernet Models: Ethernet 100BaseT Connections

USER 10/100 1 100Base-TX RJ-45 modular port connector for the local Fast

Ethernet interface.

USER 10/100 1 100Base-TX RJ-45 modular port connector. This port to be

used for consecutive point networks.

T1 Channels

T1 1-2 Two T1/E1 (RJ-48C) interface connections.

T1 3-16 Fourteen T1/E1 high density interface connector

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 20

User Reference and Installation Guide 2-13

2.5 System Description

The overall digital radio architecture consists of a single 1RU rack mount Software Defined Indoor

UnitTM (SDIDUTM) with a cable connecting to an Outdoor Unit (ODU). The ODU is designed for

use with an external antenna only. This SDIDUTM/ODU architecture is advantageous when

compared to a single IDU with external mount antenna, since supporting a signal from the IDU

rack to the antenna can result in significant signal losses, which would be difficult to avoid without

the use of expensive coaxial cable or a waveguide.

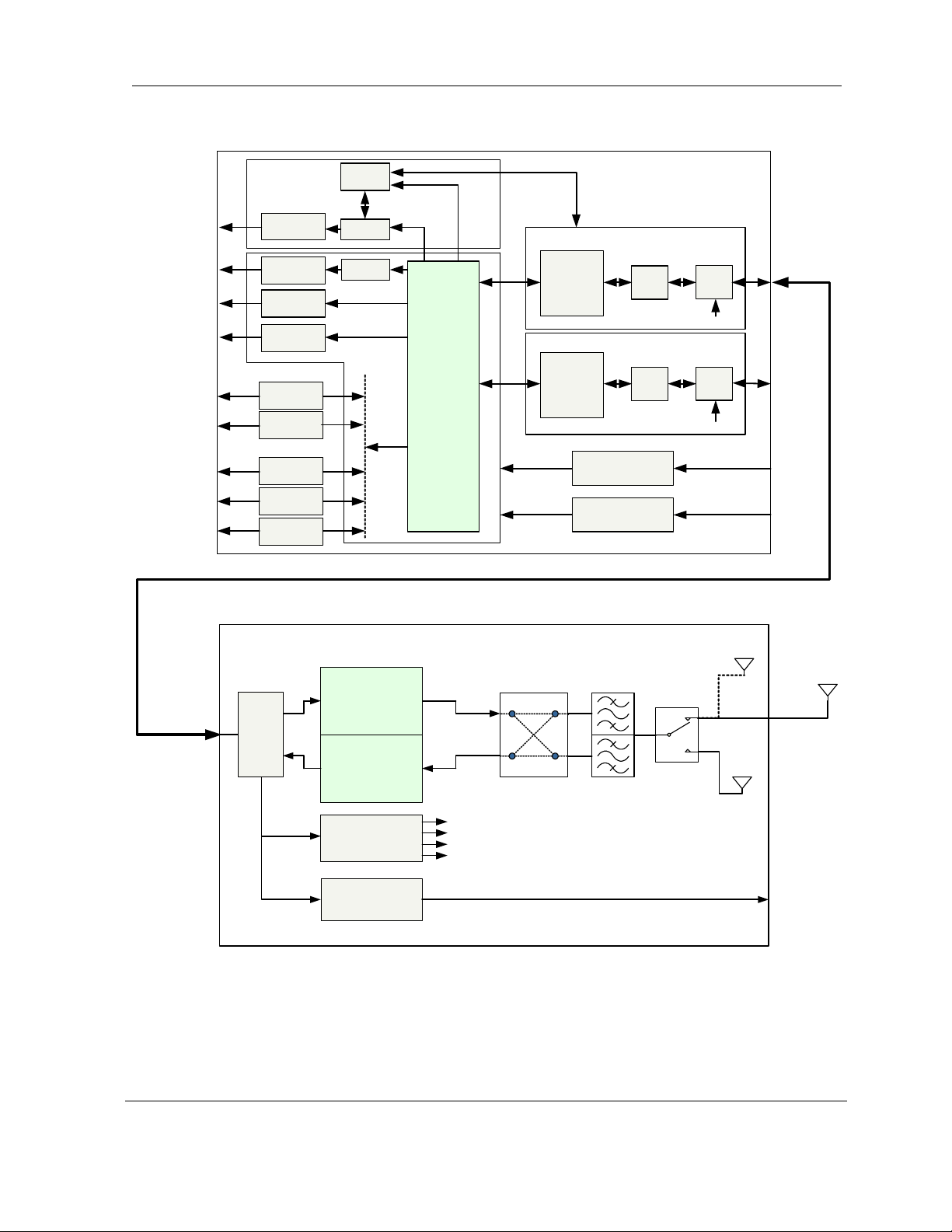

163H160HFigure 2-4 shows the SDIDU

TM

and interfaces from a functional point of view. The functional

partitions for the I/O, Modem/IF, and power supply modules are shown. The SDIDUTM comes

with the standard I/O capability that can be upgraded. In addition, the Modem/IF function is

modular. This allows the addition of a second Modem to support protection or ring architectures.

The power supply is similarly modular.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 21

User Reference and Installation Guide 2-14

IDU

Modem Control

Telemetry

East/Primary Modem

MODEM/

FEC ASIC

West/Secondary Modem

MODEM/

FEC ASIC

Secondary Power

Digital

Digital

Primary Power

Supply

Supply

Multiplexed

Quad

IF

IF

Mux

-48Vdc

Quad

Mux

-48Vdc

IF

Multiplexed

IF

-48Vdc

-48Vdc

2x 100 Mbps

2x 100 Mbps

16x 1.544/2.048

Mbps

155.52 Mbps

4x44.736/34.368/

51.84 Mbps

2x 155.52 Mbps

4x44.736/34.368/

51.84 Mbps

IDU

CONTROLLER

SNMP 2x

100Base-Tx

User 2x

100Base-Tx

16 T1/E1

64 kbps

Voice

Standard I/O Cards

Optional I/O Cards

(Small Slot)

STM-1/OC3

DS-3/ES/

STS-1

Optional I/O Cards

(Large Slot)

2xSTM-1/

OC3

4xDS3/ES/

STS1

Future

CPU

Switch

Switch

Serial

RCH Serial

FRAMER

ODU

Vertical

Antenna

350

TNC

Quad

Mux

MHz

MHz

-48Vdc

5/10

MHz

140

Transmitter

Up-Converter

Receiver

Down-Converter

DC/DC

Converters

Commlink

& Processor

5.3/

5.8

GHz

+10Vdc

+5Vdc

+3Vdc

-5Vdc

Figure 2-4. MDS Digital Radio Series System Block Diagram

The SDIDUTM interfaces with the ODU to receive and provide modulated transmit and receive

waveforms. The SDIDUTM interfaces provide Fast Ethernet 100Base-T connections to the

network. Contact the factory for availability of SONET OC-3 connections. In addition, two E1/T1

channels are provided for PBX extension. SNMP is provided on 10/100BaseT ports.

Transfer

Switch

Duplexer

Diversity

Switch

Internal/

Horizontal

Antenna

BNC

N-type

External

Antenna

RSL

(Received

Signal Level)

Voltage

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 22

User Reference and Installation Guide 2-15

The ODU RF Up/Down Converter card provides the interface to the antenna. The transmit

section up-converts and amplifies the modulated Intermediate Frequency (IF) of 350 MHz from

the IF Processor and provides additional filtering. The receive section down converts the

received signal, provides additional filtering, and outputs an IF of 140 MHz to the IF Processor.

The 64-QAM Modem performs the modulation and demodulation of the payload and forward error

correction using advanced modulation and coding techniques. Using all-digital processing, the

64-QAM Modem uses robust modulation and forward error correction coding to minimize the

number of bit errors and optimize the radio and network performance. The 64-QAM Modem also

scrambles, descrambles and interleaves/de-interleaves the data stream in accordance with

Intelsat standards to ensure modulation efficiency and resilience to sustained burst errors. The

modulation will vary by application, data rate, and frequency spectrum. The highest order

modulation mode supported is 64 Quadrature Amplitude Modulation (QAM). 164H161HTable 2-5

summarizes the TCM/convolutional code rates for each modulation type supported by the MDS

Digital Radio Series.

Table 2-5. MDS Digital Radio Series TCM/Convolutional Code Rates

Modulation Type Available Code

Rates

16-QAM 3/4, 7/8, 11/12

32-QAM 4/5, 9/10

64-QAM 5/6, 11/12

The major functions of the SDIDUTM can be summarized as follows:

• I/O Processing – The SDIDUTM comes with a standard I/O capability that includes support for up to

16xT1/E1 and 2x100Base-TX user payloads, 2x100Base-TX for SNMP, and voice orderwire. In

addition, option cards for DS-3/E3/STS-1, 1-2 x STM-1/OC-3, and 4xDS-3/E3/STS-1 may be

added. The SDIDUTM architecture is flexible and allows for the addition of other I/O types in the

future.

• Switch/Framing – The SDIDUTM includes an Ethernet Switch and a proprietary Framer that are

designed to support 1+1 protection switching, ring architecture routing, and overall network control

functions.

• Network Processor – The SDIDUTM includes a Network Processor that performs SNMP and

Network Management functions.

• Modem/IF – The SDIDUTM Modem performs forward-error-correction (FEC) encoding, PSK/QAM

modulation and demodulation, equalization, and FEC decoding functions. The IF chain provides a

350 MHz carrier, receives a 140 MHz carrier, processes OOK telemetry, and provides –48V

power. Two modems can be used for 1+1 protection or ring architectures.

• Power Supply – The SDIDUTM power supply accepts -48 Vdc and supplies the SDIDUTM and ODU

with power. A second redundant power supply may be added as an optional module.

The Modem Processor and its associated RAM, ROM, and peripherals control the digital and analog

Modem operation. It also provides configuration and control for both the IF and I/O cards. The

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 23

User Reference and Installation Guide 2-16

SDIDUTM interfaces with the ODU to receive and provide modulated transmit and receive

waveforms.

The SDIDUTM also provides the physical interface for the user payload and network management.

In transmit mode, the Framer merges user payload with radio overhead-encapsulated network

management data. This combined data stream is transmitted without any loss of user bandwidth.

In the receive mode, the Framer separates the combined data stream received from the 64-QAM

Modem. The SDIDUTM supports Scalable Ethernet data rates, such as 25 or 50 Mbps via the

100BaseT data interface port. The SDIDUTM provides network management data on 10 Mbps

ports accessible via the 10/100BaseTX port. The Central Processor Unit (CPU) provides the

embedded control and network element functionality of the NMS. The CPU also communicates

with other functions within the SDIDUTM for configuration, control, and status monitoring.

In Ethernet models, the payload of each user Ethernet data packet and all T1 can be encrypted

using an AES encryption algorithm. In addition, the encryption engine is re-seeded with a new,

randomly generated key stream every 10 seconds, in order to provide enhanced security. The

initial key is based off of a pass phrase entered into each Digital Radio Series unit by the network

administrator. Consult factory for the availability of this encryption function.

The power supply converts -48 Vdc to the DC voltage levels required by each component in the

system.

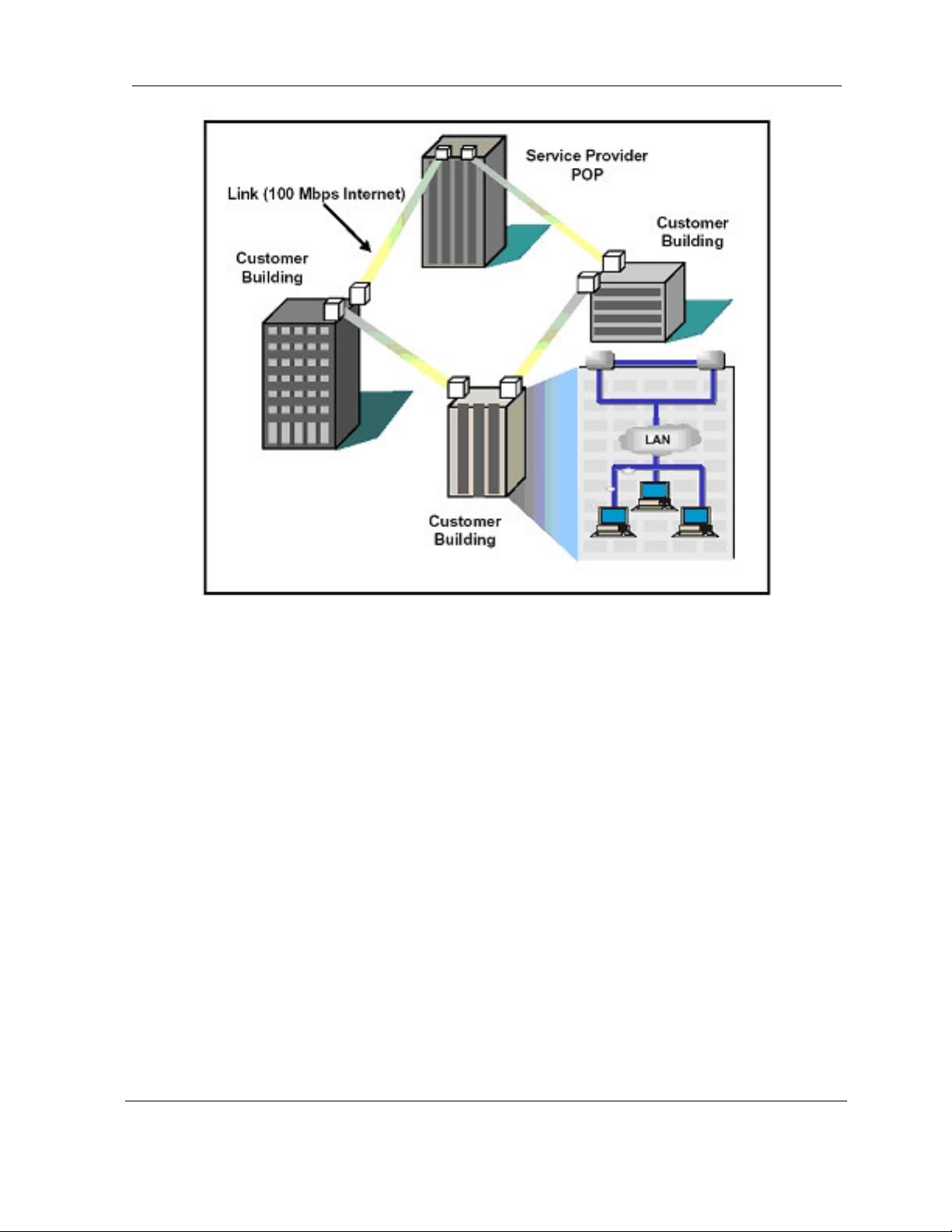

2.6 Consecutive Point Architecture

The consecutive point network architecture of the Digital Radio Series is based upon the proven

SONET/SDH ring. Telecommunications service providers traditionally use the SONET/SDH ring

architecture to implement their access networks. A typical SONET/SDH network consists of the

service provider’s Point of Presence (POP) site and several customer sites with fiber optic cables

connecting these sites in a ring configuration (see 165H162HFigure 2-5). This architecture lets providers

deliver high bandwidth with high availability to their customers.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 24

User Reference and Installation Guide 2-17

Figure 2-5. Ring Configuration.

SONET/SDH rings are inherently self-healing. Each ring has both an active path and a standby

path. Network traffic normally uses the active path. Should one section of the ring fail, the network

will switch to the standby path. Switchover occurs in seconds. There may be a brief delay in

service, but no loss of payload, thus maintaining high levels of network availability.

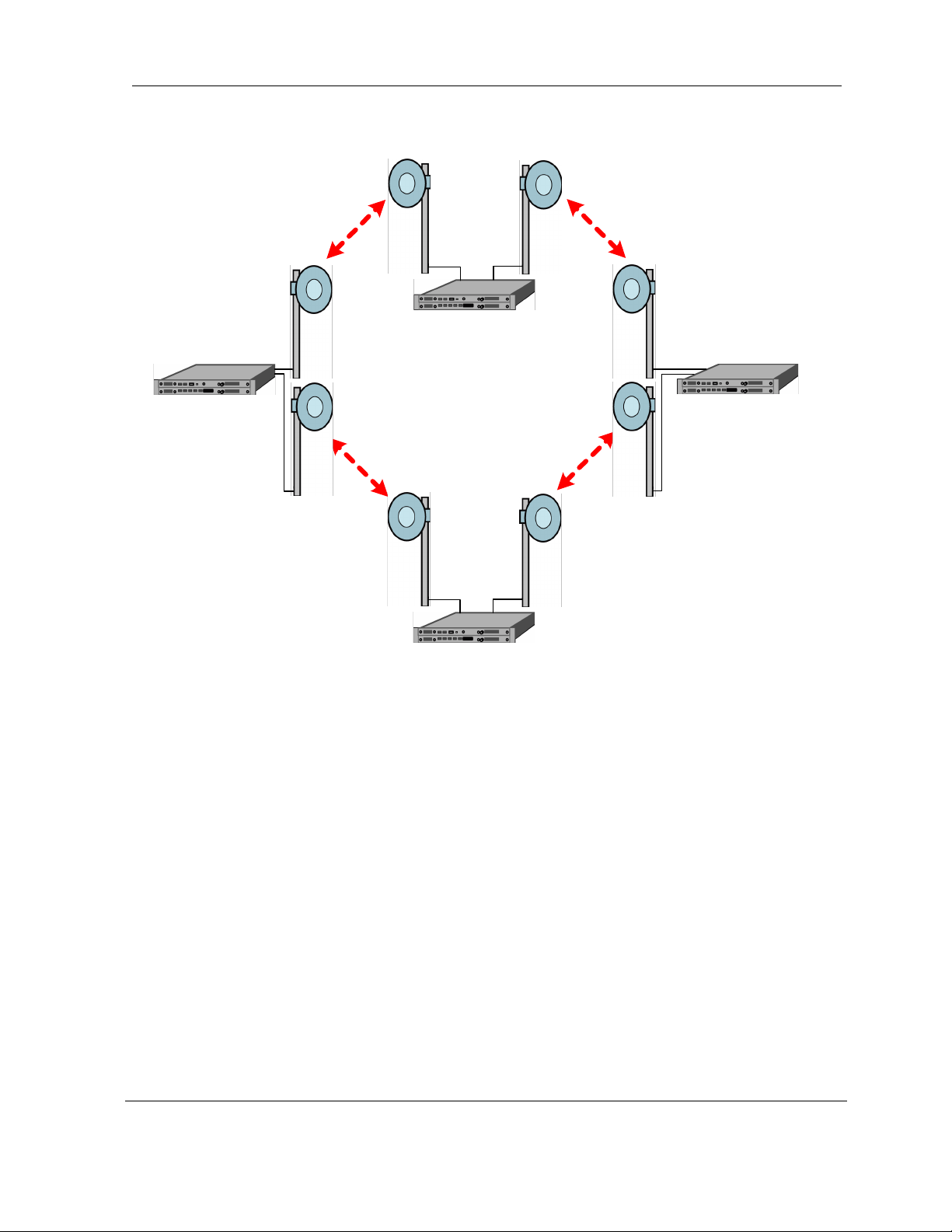

The consecutive point architecture implemented in the Digital Radio family is based on a point-topoint-to-point topology that mimics fiber rings, with broadband wireless links replacing in-ground

fiber cable. A typical consecutive point network consists of a POP and several customer sites

connected using MDS Digital Radio Series units. These units are typically in a building in an

east/west configuration. Using east/west configurations, each unit installed at a customer site is

logically connected to two other units via an over-the-air radio frequency (RF) link to a unit at an

adjacent site.

Each consecutive point network typically starts and ends at a POP. A pattern of wireless links and

in-building connections is repeated at each site until all buildings in the network are connected in

a ring as shown in 166H163HFigure 2-6. . For 2 x 1+0 and 2 x 1+1 nodes payload and NMS connections

need to be jumpered between two SDIDUTMs. For 1 x 2+0 nodes, there is no need for jumpers as

there is a single SDIDUTM. For SDH or SONET payloads, the configuration is similar but an

external add/drop MUX and a second SDH/SONET interface card are required.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 25

User Reference and Installation Guide 2-18

Figure 2-6. Consecutive Point Network

2.7 2 + 0 (East-West) Configuration

The SDIDUTM supports an east/west, or 2+0, configuration that allows a consecutive point

architecture to be achieved with only a single 1 RU chassis at each location. In this configuration

the SDIDUTM contains two modems supplies and may contain two power supplies. One modem

is referred to as the west modem and the other as the east modem. The SDIDUTM is connected

to two ODUs, one broadcasting/receiving in one direction of the ring architecture and the other

broadcasting/receiving in the other as shown in Figure 2-7.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 26

User Reference and Installation Guide 2-19

Connected to

west modem

Connected to

east modem

Connected to

east modem

Connected to

east modem

Connected to

west modem

Connected to

west modem

Connected to

east modem

Connected to

west modem

Figure 2-7. 2+0 (East-West) configuration.

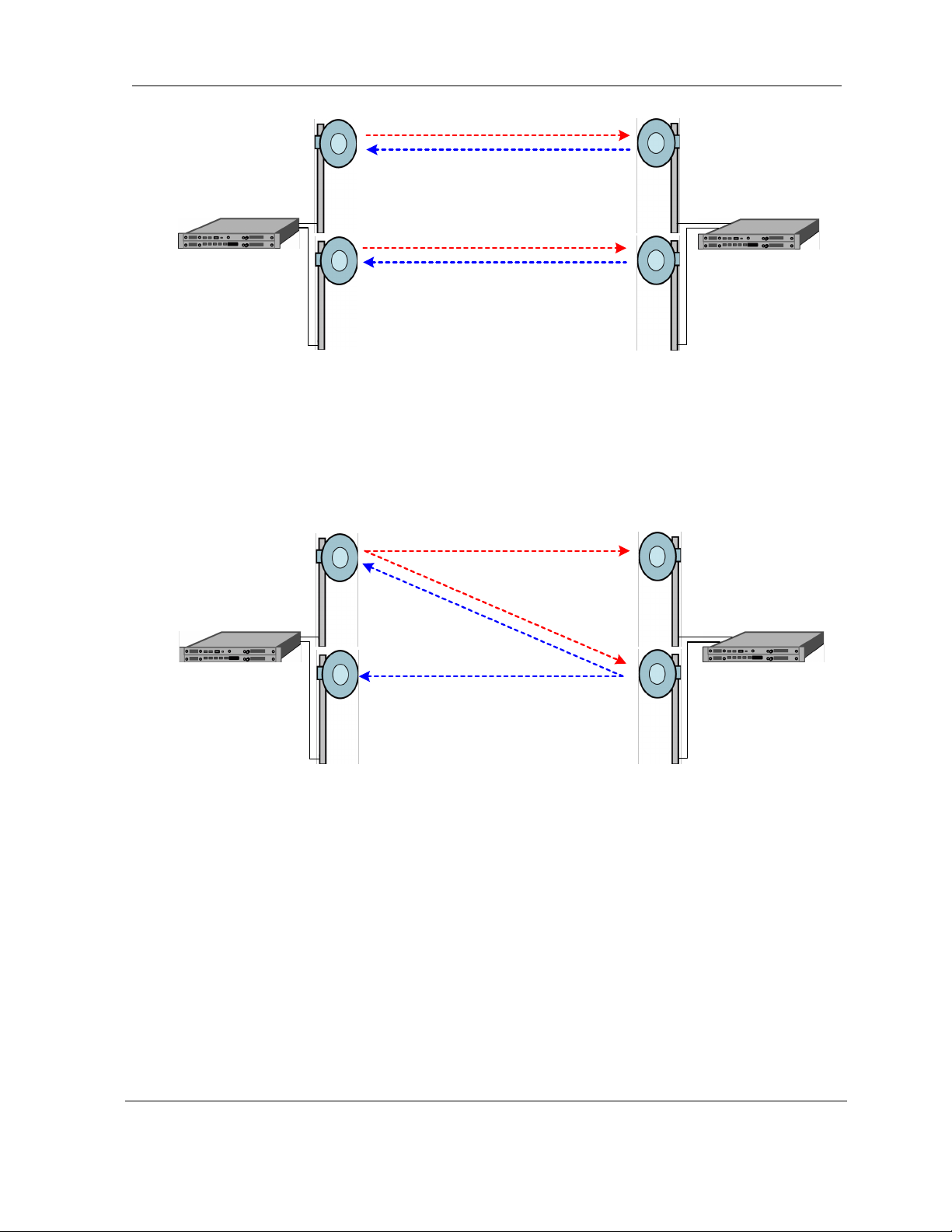

2.8 1+1 Protection

The MDS Digital Radio Series supports 1+1 protection as an option for a critical link. In this

configuration, protection is provided in a single 1 RU chassis. The SDIDUTM contains two power

supplies and two modems. The power supply, ODU, IF/telemetry and modem are protected. The

digital framing and LIUs are not. One modem is referred to as the west modem and the other as

the east modem. 1+1 protection can be run in two modes called diversity and non-diversity.

In diversity mode, the link between each pair of modems is the same, as shown in 168H165HFigure 2-8,

providing complete redundancy. This arrangement requires bandwidth for both links and noninterference between the links, but it provides hitless receive and transmit switching. The

SDIDUTM supports both frequency and spatial diversity. In frequency diversity, two frequencies

are used. In spatial diversity, two non-interfering paths are used. In either case, the proprietary

framer chooses the best, or error-free, data stream and forwards it to the Line Interface Units

(Luis).

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 27

User Reference and Installation Guide 2-20

Connected to

west modem

Connected to

east modem

Figure 2-8. 1+1 protection in diversity mode

169H166HFigure 2-9 shows operation in non-diversity mode. In this mode, one ODU at each location

Connected to

west modem

Connected to

east modem

transmits to both two ODUs at the other location. This mode does not require the extra

bandwidth or interference protection of diversity mode. It provides hitless receive switching and

hot standby. The SDIDUTM automatically switches transmit ODU upon appropriate ODU alarm or

ODU interface error, minimizing transmit outage time.

Connected to

west modem

Connected to

west modem

Connected to

east modem

Connected to

east modem

Figure 2-9. 1+1 protection in non-diversity mode

2.9 1 + 1 Multi-hop Repeater Configuration

The MDS Digital Radio Series supports a 1 + 1 multi-hop repeater configuration with drop/insert

capability as shown in 171H168HFigure 2-10. This configuration provides individual 1 + 1 link protection as

described in section 172H169H2.8, as well as the full-scale protection inherent in the consecutive point

architecture as described in section 173H170H2.6. At each location within the network, data may be

dropped or inserted. Front panel connections for drop/insert capability are shown in 174H171HFigure 2-11.

In this configuration each SDIDUTM contains two power supplies and two modems.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 28

User Reference and Installation Guide 2-21

Protected

Data

drop/insert

Link

drop/insert

Protected

Link

Protected

Link

Data

Data

drop/insert

Protected

Link

Data

drop/insert

Figure 2-10. 1 + 1 Multi-hop Repeater Configuration

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 29

User Reference and Installation Guide 2-22

Figure 2-11. Front Panel connections in 1 + 1 multi-hop repeater configuration

2.10 Data Interfaces

The I/O card has 2x100BaseTX interfaces that can be configured as either primary payload, or

secondary wayside channels. The Over-the-air channel has a data-bandwidth capacity that is set

by the frequency-bandwidth, modulation, and coding. The data-bandwidth may be allocated to

various I/O card interfaces, including STM-1, 2 Mbps per E1, up to 50 Mbps Ethernet, and up to 1

Mbps NMS. Only up to 100 Mbps of data-bandwidth may be allocated for Ethernet data, and the

two I/O card 100BaseTX interfaces will share that 100 Mbps data-bandwidth.

There is also an option mini-I/O card, which provides STM-1 Optical/OC-3 or STM-1 Electrical

interfaces. The optical interface is single mode at 1300 nm. Consult factory for availability of

Mini-IO STM-1/OC-3 Module.

2.11 Power Management

RF power management is a radio design feature that controls the power level (typically expressed

in dBm) of the RF signal received from a transmitter by a receiver. The traditional goal of power

management is to ensure that the RF signal at a receiver is strong enough to maintain the radio

link under changing weather and link conditions.

Traditional power management techniques such as Constant Transmit Power Control (CTPC)

and Automatic Transmit Power Control (ATPC) transmit at a high power level to overcome the

effects of fading and interference. However, these techniques continue to operate at a higher

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 30

User Reference and Installation Guide 2-23

power level than needed to maintain the link in clear weather. Because transmit power remains

high when the weather clears, the level of system interference increases.

Radios operating at high transmit power will interfere with other radios, even if the interfering

source is miles away from the victim. High interference levels can degrade signal quality to the

point that wireless radio links become unreliable and network availability suffers. The traditional

solution to system interference is to increase the distance between radios. However, the resulting

sparse deployment model is inappropriate for metropolitan areas.

In response to the need for a high-density deployment model the MDS Digital Radio Series use a

unique power control technique called AdTPC. AdTPC enables MDS Digital Radio Series units to

transmit at the minimum power level necessary to maintain a link regardless of the prevailing

weather and interference conditions. The MDS Digital Radio Series is designed and

manufactured to not exceed the +23 dBm maximum power allowed. The purpose of power

management is to minimize transmit power level when lower power levels are sufficient. AdTPC

also extends the concept of power management by controlling not only the power (dBm) of the

RF signal, but its quality (signal-to-noise ratio) as well.

In contrast to ATPC, the AdTPC technique dynamically adjusts the output power based on both

the actual strength and quality of the signal. Networked radios constantly monitor receive power

and maintain 10

radio detects when there is a degradation in the received signal level of quality and adjusts the

transmit power level of the far-end unit to correct for it.

-12

BER performance under varying interference and climate conditions. Each

AdTPC provides maximum power in periods of heavy interference and fading and minimum power

when conditions are clear. Minimal transmit power reduces potential for co-channel and adjacent

channel interference with other RF devices in the service area, thereby ensuring maximum

frequency re-use. The resulting benefit is that operators are able to deploy more radios in a

smaller area.

2.12 MDS Digital Radio Series Software and

Network Management

All Digital Radio Series parameters are accessible in three ways:

1. Using a standard web-browser via HTTP to access the built in webserver.

2. Via SNMP using the fully featured MIB, allowing for automation of data collection and

network management.

3. Via a command line client accessible from a terminal client connected to the serial port, or

telnet over the NMS Ethernet.

The GUI, SNMP, and CLI control are discussed in the Digital Radio Series User Interface Manual.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS Digital Radio Series

05-4561A01, Rev. A

Page 31

3 Installation

3.1 Unpacking

The following is a list of possible included items.

Description Quantity

Digital Radio SDIDUTM (1RU chassis) 1

ODU (with hardware) 1

Manual and/or Quick Start Guide 1

ODU

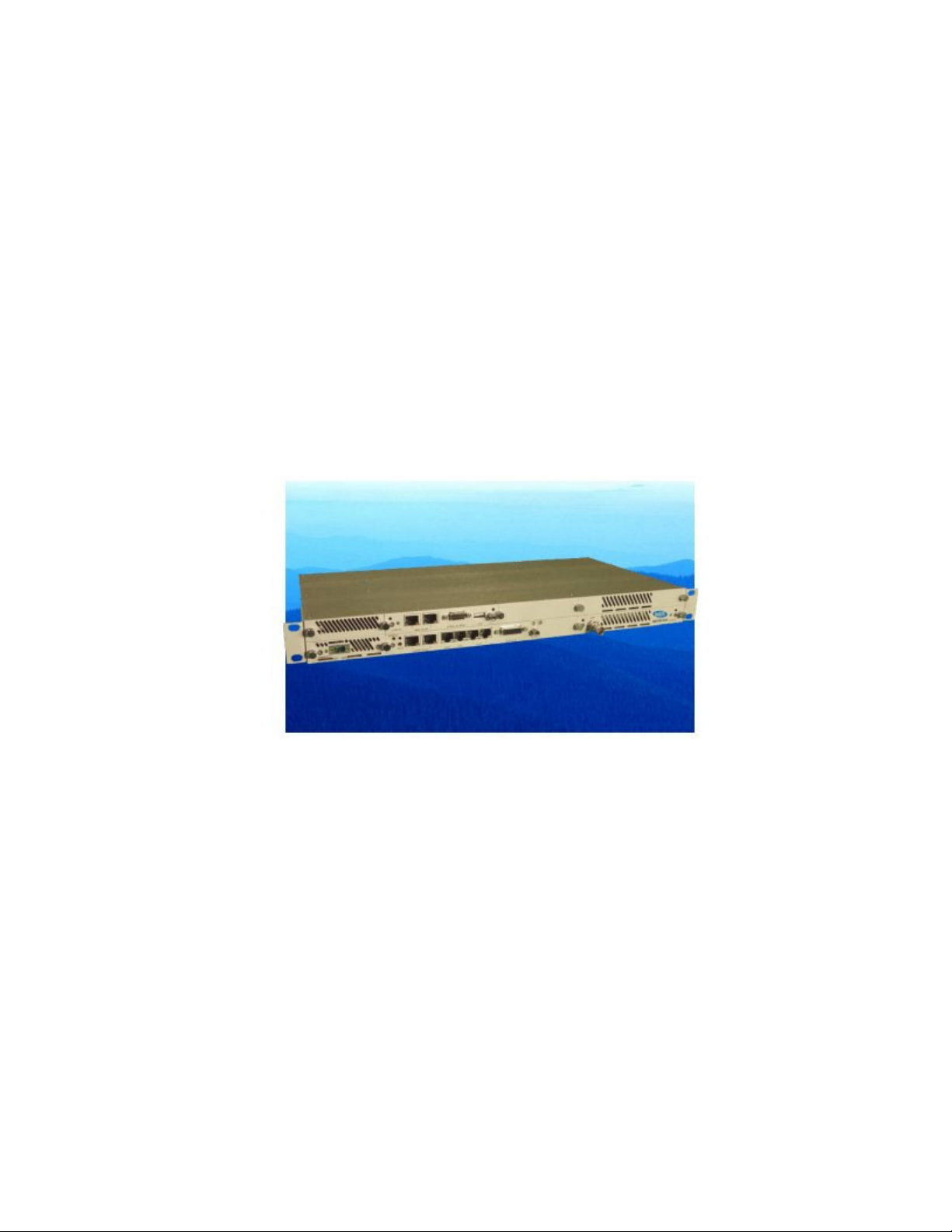

Figure 3-1. MDS Digital Radio Series Components

Be sure to retain the original boxes and packing material in case of return shipping. Inspect all

items for damage and/or loose parts. Contact the shipping company immediately if anything

appears damaged. If any of the listed parts are missing, call the distributor or the factory

immediately to resolve the problem.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

SDIDUTM

05-4561A01, Rev. A

Page 32

User Reference and Installation Guide 3-2

3.2 Notices

CAUTION

DO NOT OPERATE EXTERNAL ANTENNA ODU UNITS WITHOUT AN ANTENNA,

ATTENUATOR, OR LOAD CONNECTED TO THE ANTENNA PORT. DAMAGE MAY OCCUR

TO THE TRANSMITTER DUE TO EXCESSIVE REFLECTED RF ENERGY.

ALWAYS ATTENUATE THE SIGNAL INTO THE RECEIVER ANTENNA PORT TO LESS THAN

–20 dBm. THIS WILL PREVENT OVERLOAD AND POSSIBLE DAMAGE TO THE RECEIVER

MODULE.

WARNING

HIGH VOLTAGE IS PRESENT INSIDE THE ODU and SDIDUTM WHEN THE UNIT IS

PLUGGED IN. TO PREVENT ELECTRICAL SHOCK, UNPLUG THE POWER CABLE

BEFORE SERVICING. UNIT SHOULD BE SERVICED BY QUALIFIED PERSONNEL ONLY.

3.3 Required Tools

The following tools are needed for installation.

3.3.1 SDIDU

• 1/8” Slotted screwdriver for securing power supply connector

• Screwdriver for rack mount assembly. Size and types depends on rack mount screws

(not included).

3.3.2 ODU Tools

• 13 mm or adjustable wrench for ODU bracket mounting bolts

• 17 mm or adjustable wrench for U-Bolt

TM

Tools

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 33

User Reference and Installation Guide 3-3

3.4 PRE-INSTALLATION NOTES

It may be useful to gain familiarity with the MDS Digital Radio Series via back-to-back bench

testing prior to final installation. We highly recommend installation of lightning protectors on the

ODU/SDIDUTM Interconnect Cable to prevent line surges from damaging expensive components.

Back-to-back bench testing prior to final installation is highly recommended in order to gain

familiarity with the product. The following additional equipment is required for back-to-back

testing:

• Low-loss cables, N-male connectors on ODU interfaces.

• Two inline RF attenuators, 30 dB each, rated for ODU frequency.

The SDIDUTM and ODUs must be configured in an operational configuration and set-up as shown

in 175H172HFigure 3-2. When equipment is connected in operational configuration, no errors should be

reported on the front panel.

Ant. Port

ODU - 1

To IDU

SDIDU - 1

TM TM

Figure 3-2. MDS Digital Radio Series Back-to-Back Testing Configuration

30 dB 30 dB

Ant. Port

ODU - 2

SDIDU - 2

3.5 Overview of Installation and Testing

Process

The installation and testing process is accomplished by performing a series of separate, yet

interrelated, procedures, each of which is required for the successful implementation of a

production Digital Radio Series network. These procedures are as follows:

• Site Evaluation: gathering specific information about potential radio installation sites.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 34

User Reference and Installation Guide 3-4

• Cable and Installation: Testing and installing ODU cables and optional interface devices at

installation sites.

• ODU Mounting and Alignment: Mounting ODUs to a pole or wall, performing link alignment

and radio frequency (RF) verification.

• Radio Configuration: Using MDS Series Link Manager software to install network- and sitespecific parameters in the radios.

• Radio Testing: Performing cable continuity checks and RF tests for links, the payload/radio

overhead channel, and the management channel.

The following diagram shows where installation and commissioning resides within the radio

network deployment life cycle, and defines the sequence in which the processes that comprise

installation and commissioning should be performed.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 35

User Reference and Installation Guide 3-5

Network Life Cycle

Customer

Requirements

RF Planning

& Network

Design

Site Selection

& Acquisition

PDH SDH

Installation &

Commissioning

Perform Site

Evaluation

Mount and Align

ODUs

Install Cables

Configure Digital

Software Defined

TM

IDU

Type of

Network?

Operation &

Maintenance

Network

Network

Upgrade &

Expansion

Perform Fast

PDH Network Test

Installation &

Commissioning

Complete

Perform

SDH Network Test

03-01-013b

3.6 Site Evaluation

A site evaluation consists of a series of procedures for gathering specific information about

potential radio locations. This information is critical to the successful design and deployment of a

network.

Site evaluations are required to confirm whether or not a building meets network design

requirements. The main objectives are as follows:

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 36

User Reference and Installation Guide 3-6

• Confirm

• Line of sight for each link

• ODU mounting locations

• Site equipment locations

• Cable routes

• Any other potential RF sources

• Prepare site drawings and record site information

3.6.1 Preparing for a Site Evaluation

The following tools are required to perform a site evaluation:

• RF and network design diagrams (as required)

• Binoculars

• Global positioning system (GPS) or range finder

• Compass

• Measuring tape and/or wheel

• Digital camera

• Area map

• Aerial photograph (if available)

• List of potential installation sites (“targeted buildings”)

The following tasks must be completed prior to performing a site evaluation:

• Prepare the initial network design by performing the following:

• Identify potential buildings by identifying targeted customers (applicable if you’re a service

provider)

• Identify potential links by selecting buildings based on the high probability of line of sight

• Arrange for access with the facility personnel into the buildings, equipment rooms, and

architectural plans to become familiar with the location of all ducts, risers, etc.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 37

User Reference and Installation Guide 3-7

3.6.2 Site Evaluation Process

The following steps must be completed to perform a successful site evaluation. Each step in the

process is detailed in the following subparagraphs:

• Ensure RF Safety compliance: Ensure that appropriate warning signs are properly placed

and posted at the equipment site or access entry. For a complete list of warnings, refer

the Safety Precautions listed at the beginning of this manual.

• Ensure Compliance with Laws, Regulations, Codes, and Agreements: Ensure that any

installation performed as a result of the site evaluation is in full compliance with applicable

federal and local laws, regulations, electrical codes, building codes, and fire codes.

• Establish Radio Line of Sight between radios: The most critical step in conducting a

site evaluation is confirming a clear visual and radio Line of Sight (LOS) between a

near radio and a far radio. If LOS does not exist, another location must be used.

Radios used in a link must have a clear view of each other, or visual “line of sight”.

Binoculars may be used evaluate the path from the desired location of the near radio to

the desired location of the far unit.

To confirm Line of Sight:

- Ensure that no obstructions are close to the transmitting/receiving path. Take into

consideration trees, bridges, construction of new buildings, unexpected aerial traffic,

window washing units, etc.

- Ensure that each ODU can be mounted in the position required to correctly align it

with its link partner.

The radios must also have a clear radio line of sight. If a hard object, such as a mountain

ridge or building, is too close to the signal path, it can damage the radio signal or reduce

its strength. This happens even though the obstacle does not obscure the direct, visual

line of sight. The Fresnel zone for a radio beam is an elliptical area immediately

surrounding the visual path. It varies in thickness depending on the length of the signal

path and the frequency of the signal. The necessary clearance for the Fresnel zone can

be calculated, and it must be taken into account when designing a wireless links.

As shown in the picture above, when a hard object protrudes into the signal path within

the Fresnel zone, knife-edge diffraction can deflect part of the signal and cause it to reach

the receiving antenna slightly later than the direct signal. Since these deflected signals

are out of phase with the direct signal, they can reduce its power or cancel it out

altogether. If trees or other 'soft' objects protrude into the Fresnel zone, they can

attenuate (reduced the strength of) a passing signal. In short, the fact that you can see a

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 38

User Reference and Installation Guide 3-8

location does not mean that you can establish a quality radio link to that location.

Microwave Data Systems provides a link planner spreadsheet that calculates the Fresnel

ratio and helps determine link feasibility. Contact your technical support representative

for a copy of the spreadsheet.

Determine ODU Mounting Requirements: ODUs can be mounted on an antenna mast,

brick, masonry or wall. Refer to detailed installation sections.

• Determine SDIDUTM Installation Location: SDIDUsTM can be installed tabletop or cabinet,

wall mount, or rack mount. The site must provide DC power or an optional AC/DC

converter may be used. Refer to detailed installation sections.

• Document Potential Sources of Co-location Interference: When ODUs are located on a

roof or pole with other transmitters and receivers, an interference analysis may be

required to determine and resolve potential interference issues. The interference analysis

needs to be performed by an RF engineer. The specific information required for each

transmitter and receiver includes the following:

- Transmitting and/or receiving frequency

- Type of antenna

- Distance from ODU (horizontal and vertical)

- Polarity (horizontal or vertical)

- Transmit power level

- Antenna direction

• Measure the Link Distance: The two ways to measure link distance are as follows:

- GPS: record the latitude and longitude for the near and far ODU sites and calculate

the link distance. Record the mapping datum used by the GPS unit and ensure the

same mapping datum is used for all site evaluations in a given network.

- Range finder: measure the link distance (imperial or metric units may be used).

Once the link distance has been measured, verify that the link distance meets the

availability requirements of the link. Microwave Data Systems has created a spreadsheet

tool that calculates the link availability based on the details of the link. The Microsoft Excel

spreadsheet is available on Internet, at http://www.microwavedata.com/, and is shown on

the following page. The following parameters should be entered (items in yellow):

• Operating Frequency: Enter 4900

• Transmit Antenna Gain: Enter the gain of the external antenna.

• Transmit Output Power: Selectable between +5 to +23 dBm in 1 dB steps.

• Receive Antenna Gain: Enter the gain of the external antenna if used.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 39

User Reference and Installation Guide 3-9

• Link Distance: Enter distance in miles or kilometers (must select the correct units: miles or

kilometers)

• Fresnel Clearance Ratio: This is a factor indicating the radio line of sight. A clear radio

line of site has a Fresnel clearance ratio of +0.60. As the curvature of the earth or other

obstacles degrade the radio line of sight, the ratio can drop to –1. A separate spreadsheet

is provided to calculate the appropriate ratio. In this spreadsheet the path length, tower

heights and heights of any obstructions or ridges in the path of the link are entered.

• Climate Factor: Enter 0.1 for dry, 0.25 for average and 0.5 for humid environments

• Terrain Factor: Enter 0.25 for mountainous, 1 for average, and 4 for smooth (water)

• Determine the Length of Interconnect Cable from ODU to SDIDUTM: The primary

consideration for the outdoor interconnect cable from the ODU to SDIDUTM is the distance

and route between the ODU and SDIDUTM. Maximum cable lengths are listed in 176H173HTable

3-1.

Table 3-1. Maximum cable lengths

Cable Type 140 MHz 350 MHz

LMR-200 12.6 20.1 100 m

LMR-300 7.6 12.1 165 m

LMR-400 4.9 7.8 256 m

RG-214 8 13.1 153 m

Belden 7808 8.6 14 143 m

Loss at (dB/100 m)

Maximum

Length*

* Does not account for connector loss.

The link availability, dispersive fade margin and expected signal strength readings are calculated

based on the entered parameters. Maximum link distances based on the antenna and transmitter

power settings are also displayed.

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 40

User Reference and Installation Guide 3-10

Transmitter Output Power (dBm)

1,2

Modem Data

Note1: FCC's definition; negative clearance indicates no optical LOS; range is [-1,…,0.6]; 0.6 is radio LOS condition.

Note2: Accounting for single knife-edge diff raction loss only.

Note3: BER<<1e-6.

Note4: Listed data rates inlcudes 2 E1 Wayside channels, except for 16E1/T1 modes.

Receiver

(dBm)

MDS FIVE series Link Planner: 5.3GHz Availability

Para me ter

Operating Frequency (MHz)

Transmit Antenna Gain (dBi)

Receive Antenna Gain (dBi)

Link Distance

Fresnel Clearance Ratio

Climate Factor

Terrain Factor

Value

5300

3.93

0.60

0.25

23

6

23

miles

1

MDS FIVE serie s Mode

5.3GHz Band

5.3G-25FE1 31.112E+6 30.0 -83 12 -71

5.3G-25FE2 31.112E+6 20.0 -82 11 -71

5.3G-25FE3 31.112E+6 13.3 -82 11 -71

5.3G-50FE1 56.733E+6 30.0 -80 9 -71

5.3G-50FE2 56.733E+6 20.0 -77 6 -71

5.3G-50FE3 56.733E+6 13.3 -72 1 -71

5.3G-100FE1 107.797E+6 30.0 -73 2 -71

5.3G-16E1-2 36.918E+6 20.0 -82 11 -71

5.3G-16T1-2 28.655E+6 20.0 -84 13 -71

5.3G-16E1-3 36.918E+6 13.3 -82 11 -71

5.3G-16T1-3 28.655E+6 13.3 -84 13 -71

MDS FIVE serie s Mode

5.3G-25FE1 QPSK 3/4 -83

5.3G-25FE2 16QAM 3/4 -82

5.3G-25FE3 16QAM 3/4 -82

5.3G-50FE1 16QAM 3/4 -80

5.3G-50FE2 32QAM 4/5 -77

5.3G-50FE3 64QAM 11/12 -72

5.3G-100FE1 32QAM 9/10 -73

5.3G-16E1-2 16QAM 3/4 -82

5.3G-16T1-2 16QAM 3/4 -84

5.3G-16E1-3 16QAM 7/8 -82

5.3G-16T1-3 16QAM 7/8 -84

Rate (Mbps)

Modula tion

and Code

Rate

Channel

Bandwidth

(MHz)

Sensitivity

Receiver

Sensitivity

(dBm)

3

99.9% 99.99% 99.999%

9 5 3

9 5 3

9 5 3

8 5 3

7 4 2

5 3 2

5 3 2

9 5 3

9 6 3

9 5 3

9 6 3

Link Fade

3

Margin (dB)

Max Distance

for Various Availability

ODU RSSI

(dBm)

(miles)

Availa bility

(%)

99.9987

99.9984

99.9984

99.9975

99.9950

99.9845

99.9876

99.9984

99.9990

99.9984

99.9990

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 41

User Reference and Installation Guide 3-11

Clearance ) Zone

1

Obstr uction

Total Earth

Path Leng th (Km) 10

TX Tow er Height (m ) 30

RX Tower Height ( m) 30

Freque ncy (MHz) 5800

Calculated Fre snel Cle arance Ratio 0.48

MDS FIVE series Link Planner: Fresnel Zone Clearance

1st

1st

Distance

Note1: Earth Curvature is based on a spherical Earth model with a nominal radius of 6371Km and a typical K-factor of 1.33.

Optical

from TX

(Km)

Height (m )

0.0 30.0 0.0 30.0 30.0 0.0 0.0 0.0

0.3 30.0 3.5 26.5 27.9 0.1 0.0 0.1

0.5 30.0 5.0 25.0 27.0 0.3 0.0 0.3

0.8 30.0 6.0 24.0 26.4 0.4 0.0 0.4

1.0 30.0 6.8 23.2 25.9 0.5 0.0 0.5

1.3 30.0 7.5 22.5 25.5 0.6 0.0 0.6

1.5 30.0 8.1 21.9 25.1 0.8 0.0 0.8

1.8 30.0 8.6 21.4 24.8 0.8

2.0 30.0 9.1 20.9 24.5 0.9

2.3 30.0 9.5 20.5 24.3 1.0

2.5 30.0 9.8 20.2 24.1 1.1

2.8 30.0 10.1 19.9 23.9 1.2

3.0 30.0 10.4 19.6 23.8 1.2 0.0 1.2

3.3 30.0 10.6 19.4 23.6 1.3 0.0 1.3

3.5 30.0 10.8 19.2 23.5 1.3 0.0 1.3

3.8 30.0 11.0 19.0 23.4 1.4 0.0 1.4

4.0 30.0 11.1 18.9 23.3 1.4

4.3 30.0 11.2 18.8 23.3 1.4 0.0 1.4

4.5 30.0 11.3 18.7 23.2 1.5 0.0 1.5

4.8 30.0 11.3 18.7 23.2 1.5 0.0 1.5

5.0 30.0 11.4 18.6 23.2 1.5 0.0 1.5

5.3 30.0 11.3 18.7 23.2 1.5 0.0 1.5

5.5 30.0 11.3 18.7 23.2 1.5 0.0 1.5

5.8 30.0 11.2 18.8 23.3 1.4 0.0 1.4

6.0 30.0 11.1 18.9 23.3 1.4 0.0 1.4

6.3 30.0 11.0 19.0 23.4 1.4 0.0 1.4

6.5 30.0 10.8 19.2 23.5 1.3

6.8 30.0 10.6 19.4 23.6 1.3 0.0 1.3

7.0 30.0 10.4 19.6 23.8 1.2 0.0 1.2

7.3 30.0 10.1 19.9 23.9 1.2 0.0 1.2

7.5 30.0 9.8 20.2 24.1 1.1 0.0 1.1

7.8 30.0 9.5 20.5 24.3 1.0 0.0 1.0

8.0 30.0 9.1 20.9 24.5 0.9 0.0 0.9

8.3 30.0 8.6 21.4 24.8 0.8 0.0 0.8

8.5 30.0 8.1 21.9 25.1 0.8 0.0 0.8

8.8 30.0 7.5 22.5 25.5 0.6 0.0 0.6

9.0 30.0 6.8 23.2 25.9 0.5 0.0 0.5

9.3 30.0 6.0 24.0 26.4 0.4 0.0 0.4

9.5 30.0 5.0 25.0 27.0 0.3 0.0 0.3

9.8 30.0 3.5 26.5 27.9 0.1 0.0 0.1

10.0 30.0 0.0 30.0 30.0 0.0 0.0 0.0

LOS

Fres nel

Zone

Radius (m )

Fres nel

Zone

Height (m )

Radio LOS (60%

Fres nel

Height (m )

Earth

Curvatur e

(m)

Height (m )

20.0

10.0

10.0

23.0

24.0

10.0

18.5

Ter rain

Height (m )

20.8

10.9

11.0

24.1

25.2

11.4

19.8

Fres nel

Clear ance

Ratio

8.42

6.00

4.95

4.32

3.91

3.61

1.06

2.10

2.00

0.60

0.48

2.76

2.70

2.65

2.60

1.67

2.54

2.53

2.52

2.51

2.52

2.53

2.54

2.57

2.60

0.94

2.70

2.76

2.84

2.94

3.05

3.20

3.38

3.61

3.91

4.32

4.95

6.00

8.42

-

-

Optical LOS 1st Fresnel Radio LOS Earth Curv ature Obstr uctions

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

0.0 2.0 4.0 6.0 8.0 10.0

Di s ta nce (k m)

© 2006 Microwave Data Systems Inc. All Rights Reserved. MDS FOUR.9 Series

05-4561A01, Rev. A

Page 42

User Reference and Installation Guide 3-12