Page 1

QUICK START GUIDE

Below are the basic steps for installing the transceiver. Detailed instructions are given in “Installation

Steps” on page 6 of this guide.

1. Mount the transceiver (see

Figure 6

or

Figure 7

for mounting dimensions)

2. Install and connect the antenna system to the radio

• Use only good quality, low loss coaxial cable. Keep the feedline as short as possible.

• Preset directional antennas in the direction of desired transmission/reception.

3. Apply DC power to the radio (10–16 Vdc @ 2 A minimum)

• Measure the voltage source before connection.

• Observe proper polarity.

• Connect power to the power connector.

4. Set the radio’s basic configuration with a terminal (PC or HHT) connected to

the

INTERFACE

• Pin 23 of the INTERFACE port must be grounded to place the radio in the control and programming

mode. (See Figure 12 on page 16 for a cable wiring diagram.)

• Set the transmit frequency (

• Set the receive frequency (

• Set the network address (

• Set/verify the data rate using the

“TRANSCEIVER PROGRAMMING” on page 14 for command details.)

port

TX xxx.xxx

RX xxx.xxx

ADDR xxx

BAUD

).

).

). All radios in a given network must have the same address.

command. The default setting is

BAUD 9600 8N1

. (Refer to

5. Connect the data equipment to the radio’s INTERFACE connector

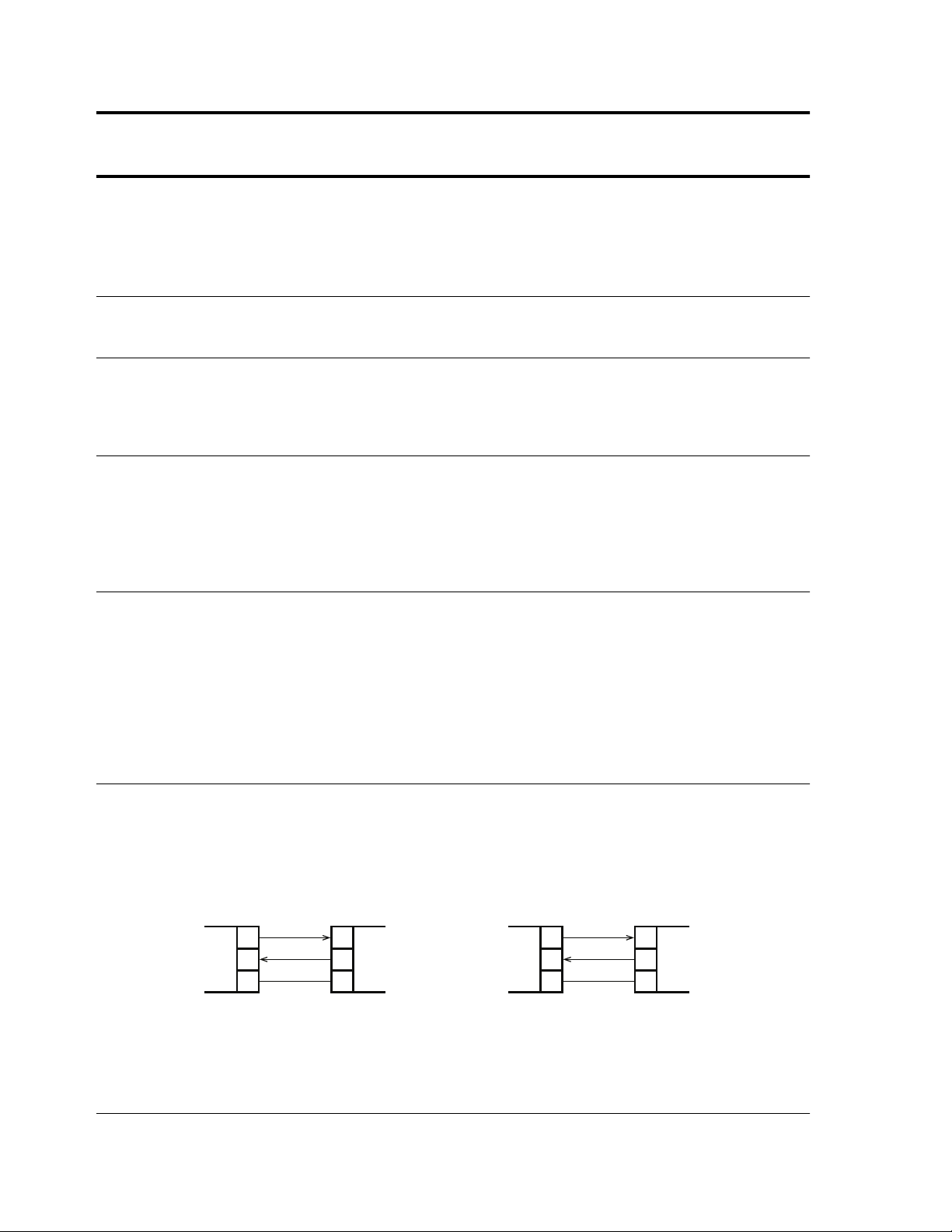

• Connection to the radio must be made with a DB-25 Male connector. Connections for typical systems are shown below.

• Connect only the required pins. Do not use a straight-through RS-232 cable with all pins wired.

• Verify the data equipment is configured as DTE. (By default, the radio is configured as DCE.)

DB-9 to DB-25 ExampleDB-25 to DB-25 Example

DB-25 DB-25

2

TXD

3

RXD

RTU

(DTE)

GND

77

2

TXD

3

RXD

GND

NOTE: Additional connections may be

(DCE)

TRANSCEIVER

needed in some installations.

See Installation for details.

RTU

DB-9 DB-25

2

RXD

3

TXD

(DTE)

GND

57

3

RXD

2

TXD

GND

(DCE)

TRANSCEIVER

6. Verify proper operation by observing the LED display

• See Table 5 on page 13 for a description of the status LEDs.

• Refine directional antenna headings for maximum receive signal strength using the

RSSI

command.

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................................1

1.1 Differences Among Models ..............................................................1

Modem Speeds ..................................................................................2

Frequency Coverage ..........................................................................2

1.2 Applications ......................................................................................2

Point-to-Multipoint, Multiple Address Systems (MAS)........................2

Point-to-Point System.........................................................................3

Switched Carrier Operation................................................................4

Single Frequency (Simplex) Operation...............................................4

1.3 Model Number Codes ......................................................................4

1.4 Accessories ......................................................................................5

2.0 INSTALLATION............................................................................6

2.1 Installation Steps ..............................................................................6

2.2 Mounting the Transceiver .................................................................8

Transceiver Board...............................................................................8

Enclosed Transceiver..........................................................................8

2.3 Antennas and Feedlines ..................................................................9

Antennas ............................................................................................9

Feedlines............................................................................................9

2.4 Power Connection ..........................................................................10

Conservation (Sleep Mode)..............................................................10

2.5 Data Interface Connections ............................................................10

3.0 OPERATION..............................................................................13

3.1 Initial Startup ..................................................................................13

3.2 LED Indicators ................................................................................13

4.0 TRANSCEIVER PROGRAMMING ............................................14

4.1 Radio Programming Methods ........................................................14

PC with Radio Configuration Software..........................................14

À PC in Terminal Mode....................................................................14

à Handheld Terminal (HHT).............................................................14

4.2 PC Connection and Startup ...........................................................14

4.3 Keyboard Commands .....................................................................16

Entering Commands.........................................................................16

Error Messages................................................................................16

4.4 Detailed Command Descriptions ...................................................18

ADDR [NONE | 1–255].....................................................................18

AMASK [0000 0000–FFFF FFFF] ....................................................18

BAUD [xxxxx abc].............................................................................19

CTS [0–255] .....................................................................................19

CTSHOLD [0–60000] .......................................................................19

MDS 05-3624A01, Rev. B OEM Series I/O Guide i

Page 3

DEVICE [DCE | CTS KEY] ...............................................................20

DKEY................................................................................................20

INIT...................................................................................................20

KEY ..................................................................................................21

OWM [XXX...]...................................................................................21

OWN [XXX...]....................................................................................21

PWR [L | M | H].................................................................................21

RSSI and RSSI!................................................................................22

RX [xxx.xxx]......................................................................................22

RXTOT [NONE | 1–255] ...................................................................22

SER..................................................................................................22

SREV................................................................................................22

STAT .................................................................................................22

TOT [1–255 | ON | OFF] ...................................................................23

TX [xxx.xxx]......................................................................................23

5.0 TROUBLESHOOTING...............................................................24

5.1 LED Indicators ................................................................................24

5.2 Event Codes ...................................................................................24

Checking for Alarms—STAT command.............................................24

Major Alarms vs. Minor Alarms.........................................................25

Event Code Definitions.....................................................................25

6.0 TECHNICAL REFERENCE.......................................................26

6.1 OEM Series™ T ransceiv er Specifications ...................................... 26

6.2 Bench Testing Setup ......................................................................27

6.3 Helical Filter Adjustment ................................................................28

6.4 Upgrading the Radio’s Software .....................................................29

Using Radio Configuration Software.................................................30

6.5 dBm-Watts-Volts Conversion Chart ................................................31

7.0 GLOSSARY OF TERMS............................................................32

ii OEM Series I/O Guide MDS 05-3624A01, Rev. B

Page 4

RF Exposure

Separation distances

required for FCC RF

Exposure compliance

Copyright Notice

This Installation and Operation Guide and all software described herein

are protected by copyright: 2001 Microwave Data Systems Inc . All

rights reserved.

Microwave Data Systems Inc. reserves its right to correct any errors and

omissions in this publication.

Antenna Installation Warning

1. All antenna installation and servicing is to be performed by

qualified technical personnel only . When servicing the antenna, or

working at distances closer than those listed below, ensure the

transmitter has been disabled.

Output is measured at the antenna terminal of the transmitter. The

antenna(s) used for this transmitter must be fixed-mounted on

outdoor permanent structures to provide the minimum separation

distances described in this filing for satisfying RF exposure

compliance requirements. When applicable, RF exposure

compliance may need to be addressed at the time of licensing, as

required by the responsible FCC Bureau(s), including antenna

co-location requirements of section 1.1307(b)(3).

2. Typically, the antenna connected to the transmitter is a directional

(high gain) antenna, fixed-mounted on the side or top of a building,

or on a tower. Depending upon the application and the gain of the

antenna, the total composite power could exceed 90 watts EIRP. The

antenna location should be such that only qualified technical personnel can access it, and that under normal operating conditions no

other person can touch the antenna or approach within

the antenna.

2.3 meters

of

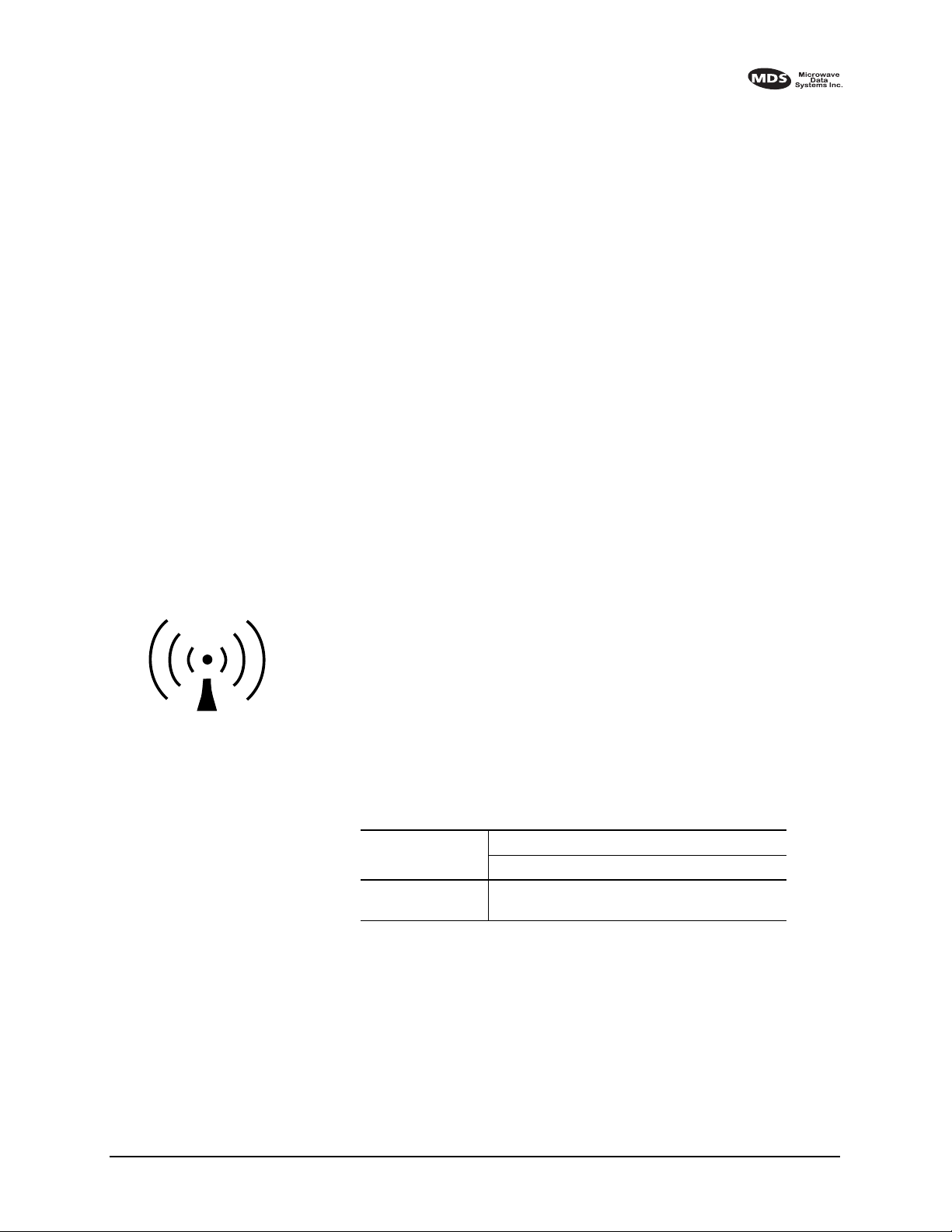

Antenna Gain vs. Recommended Safety Distance

(EL705 OEM 900 Series)

Antenna Gain (EL705 OEMSeries)

0–5 dBi 5–10 dBi 10–18.65 dBi

Minimum RF

Safety Distance

0.53 meter 0.94 meter 2.58 meters

ISO 9001 Registration

Microwave Data Systems adheres to this internationally accepted

quality system standard.

MDS 05-3624A01, Rev. B OEM Series I/O Guide iii

Page 5

MDS Quality Policy Statement

We, the employees of Microwave Data Systems Inc., are committed to

understanding and exceeding our customer’s needs and expectations.

• We appreciate our customer’s patronage. They are our business.

• We promise to serve them and anticipate their needs.

• We are committed to providing solutions that are cost effective,

innovative and reliable, with consistently high levels of quality.

• We are committed to the continuous improvement of all of our

systems and processes, to improve product quality and increase

customer satisfaction.

FM/UL/CSA Notice

This product is available for use in Class I, Division 2, Groups A, B,

C & D Hazardous Locations. Such locations are defined in Article 500

of the National Fire Protection Association (NFPA) publication NFPA

70, otherwise known as the National Electrical Code.

The transceiver has been recognized for use in these hazardous locations

by three independent agencies —Underwriters Laboratories (UL), Factory Mutual Research Corporation (FMRC) and the Canadian Standards

Association (CSA). The UL certification for the transceiver is as a Recognized Component for use in these hazardous locations, in accordance

with UL Standard 1604. The FMRC Approval is in accordance with

FMRC Standard 3611. The CSA Certification is in accordance with

CSA STD C22.2 No. 213-M1987.

FM/UL/CSA Conditions of Approval:

The transceiver is not acceptable as a stand-alone unit for use in the haz-

ardous locations described above. It must either be mounted within

another piece of equipment which is certified for hazardous locations, or

installed within guidelines, or conditions of approval, as set forth by the

approving agencies. These conditions of approval are as follows:

1. The transceiver must be mounted within a separate enclosure which

is suitable for the intended application.

2. The antenna feedline, DC power cable and interface cable must be

routed through conduit in accordance with the National Electrical

Code.

3. Installation, operation and maintenance of the transceiver should be

in accordance with the transceiver's installation manual, and the

National Electrical Code.

4. Tampering or replacement with non-factory components may

adversely affect the safe use of the transceiver in hazardous locations, and may void the approval.

iv OEM Series I/O Guide MDS 05-3624A01, Rev. B

Page 6

5. When installed in a Class I, Div. 2, Groups A, B, C or D hazardous

location, observe the following:

WARNING —EXPLOSION HAZARD—

equipment unless power has been switched off or the area is known

to be non-hazardous.

Refer to Articles 500 through 502 of the National Electrical Code

(NFPA 70) for further information on hazardous locations and approved

Division 2 wiring methods.

Do not disconnect

ESD Notice (Board version only)

To prevent malfunction or damage to this product, which may be caused

by Electrostatic Discharge (ESD), the radio should be properly

grounded at the time of installation. In addition, the installer or maintainer should follow proper ESD precautions, such as touching a bare

metal object to dissapate body charge, prior to touching components or

connecting/disconnecting cables.

Cable Length Recomendation

MDS recommends a maximum cable length of 3.0 meters for DC power

and data connections to this product.

Revision Notice

While every reasonable effort has been made to ensure the accuracy of

this manual, product improvements may result in minor differences

between the manual and the product shipped to you. If you have additional questions or need an exact specification for a product, please contact our Customer Service Team using the information at the back of this

guide. In addition, manual updates can often be found on the MDS Web

site at

www.microwavedata.com

.

MDS 05-3624A01, Rev. B OEM Series I/O Guide v

Page 7

vi OEM Series I/O Guide MDS 05-3624A01, Rev. B

Page 8

1.0 INTRODUCTION

This guide presents installation and operating instructions for the MDS

OEM Series™ of radio transceivers. The radios can be purchased as

compact, modular boards for direct mounting inside remote terminal

units (RTUs), programmable logic controllers (PLCs), automatic

teller/banking machines, or similar equipment. They are also available

as standalone units packaged in their own enclosures (see lower cover

illustration).

Although this manual focuses on the board-level product, the operating

specifications and user connections are identical for both versions of the

radio. Only the visual appearance and mounting details differ between

the two. These differences are explained in the text where necessary.

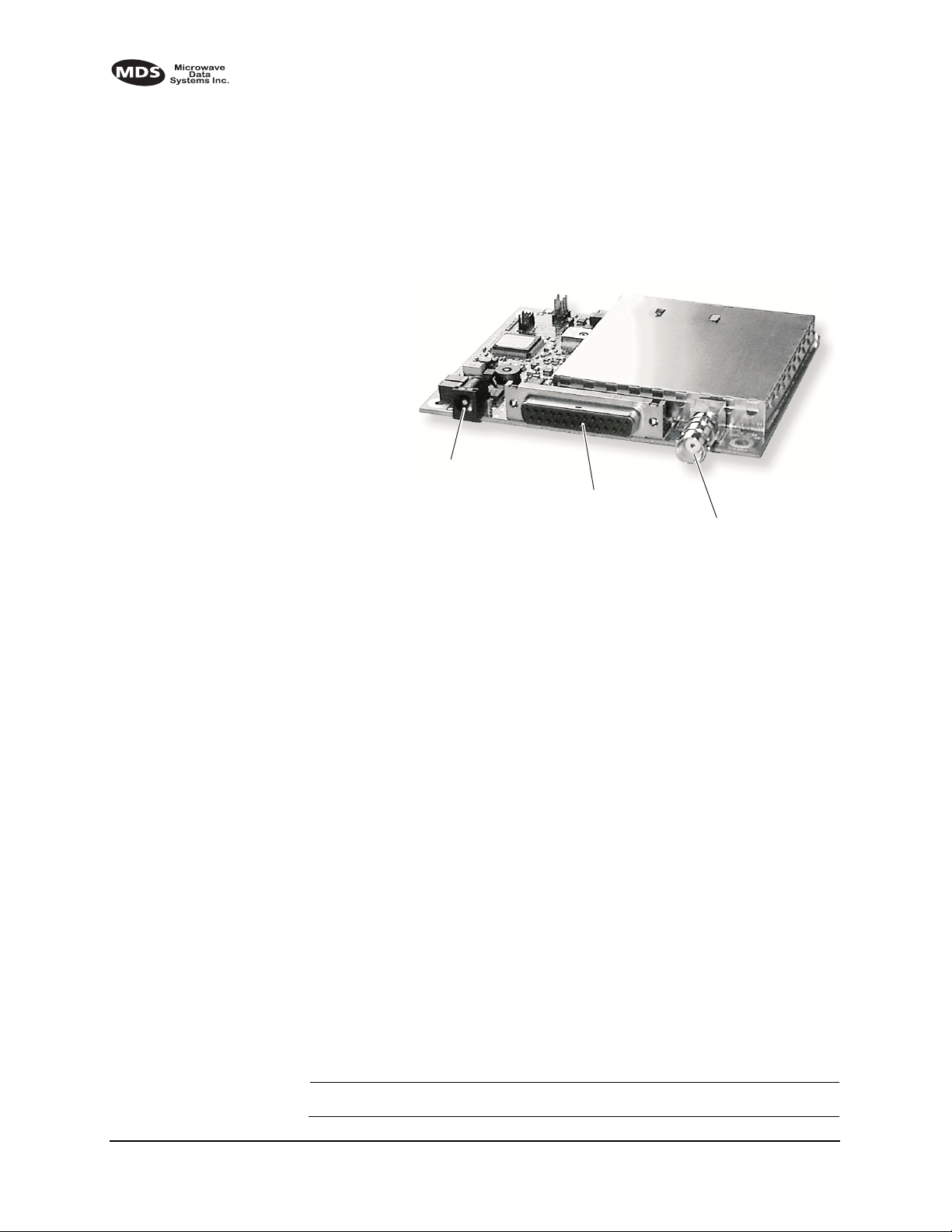

The transceiver (Figure 1) is a data telemetry radio designed to operate

in a point-to-multipoint environment, such as electric utility

Supervisory Control and Data Acquisition (SCADA) and distribution

automation, gas field automation, water and wastewater SCADA, and

on-line transaction processing applications. The radio employs

microprocessor control to provide highly reliable communications, even

under adverse conditions.

MDS OEM Series™ radios use continuous-phase frequency shift

keying (CPFSK) modulation with a 4-level modem.

Invisible place holder

NOTE: FINAL DESIGN WILL EMPLOY

A TWO-PIN, POLARIZED POWER

CONNECTOR.

Figure 1. OEM Series™ Series Data Transceiver

(Board version shown—enclosed unit similar)

1.1 Differences Among Models

All OEM Series™ models are very similar in appearance and

functionality. The major differences are over-the-air modem speed and

frequency coverage.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 1

Page 9

Modem Speeds

Two modem speeds are available in the OEM 900 transceiver—

standard 9600, and an optional 4800 bps. The latter provides 3 dB of

extra receive sensitivity where greater range is required.

Changing the modem speed requires loading different software into the

radio using MDS’ Radio Configuration Software. See

Programming Methods

Frequency Coverage

The OEM 900 Series radio operates in the 900 MHz frequency band.

The exact frequency coverage of each model is listed in the

Specifications chart on Page 26.

NOTE: The radio’s frequency range (band) cannot be set or changed

by the user; it is set at the factory.

on Page 14 for more information.

Radio

1.2 Applications

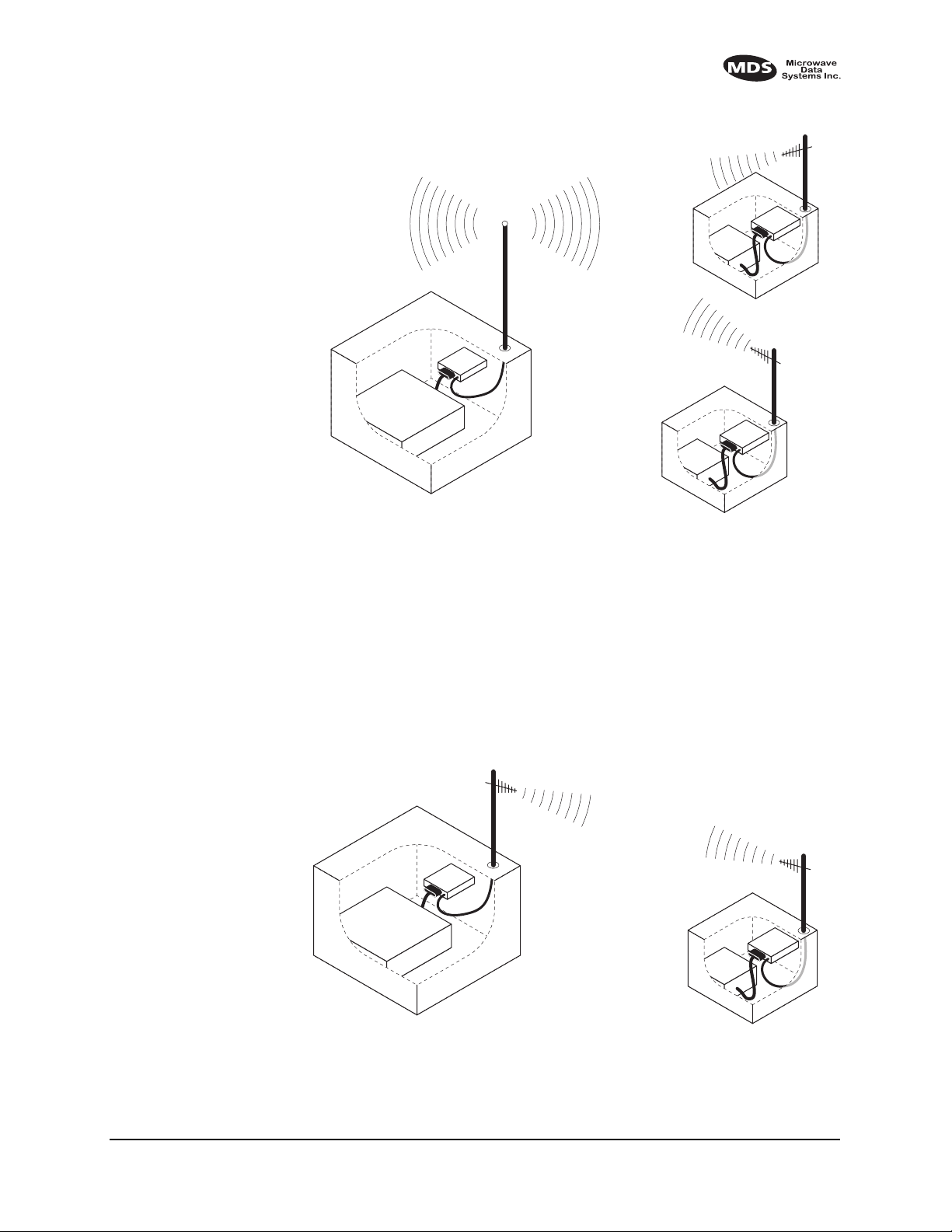

Point-to-Multipoint, Multiple Address Systems (MAS)

Point-to-multipoint (MAS) is the most common application of the

transceiver. It consists of a central master station and several associated

remote units as shown in Figure 2. An MAS network provides

communications between a central host computer and remote terminal

units (RTUs) or other data collection devices. The operation of the radio

system is “transparent” to the computer equipment. That is, the radio

system transports the data in its original form, making no changes to the

data format.

Often, the radio system is used to replace a network of remote monitors

currently linked to a central location by leased telephone lines. At the

central office of such a system, there is usually a large mainframe

computer and some means of switching between individual lines

coming from each remote monitor. In this type of system, there is a

modulator/demodulator (modem) at the main computer and at each

remote site, usually built into the remote monitor itself. Since the cost of

leasing a dedicated-pair telephone line is quite high, radio is frequently

used as an alternative communication medium.

2 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 10

Invisible place holder

radio

REMOTE

radio

REMOTE

COMPUTER

HOST

radio

MASTER

STATION

RTU

RTU

Figure 2. MAS Point-to-Multipoint Network

(Two remote stations shown—four or more are typically used)

Point-to-Point System

Where permitted, the transceiver may also be used in a point-to-point

arrangement. A point-to-point system consists of just two radios—one

serving as a master and the other as a remote—as shown in Figure 3. It

provides a simplex or half-duplex communications link for the transfer

of data between two locations.

Invisible place holder

radio

COMPUTER

HOST

RTU

MASTER

STATION

Figure 3. Typical Point-to-Point Link

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 3

radio

REMOTE

Page 11

Switched Carrier Operation

Switched Carrier operation is a half-duplex mode where the master

station transmitter is keyed to send data and unkeyed to receive. MDS

OEM Series™ radios operate in switched carrier mode and are keyed

when data is present.

NOTE: MDS OEM Series™ radios do not support full-duplex

operation (i.e., transmitting and receiving at the same time).

For information on other MDS products that provide this

capability, contact your sales representative.

Single Frequency (Simplex) Operation

Single frequency operation (also known as simplex) is a special case of

switched carrier operation. Single frequency operation is

automatically

selected whenever the transmit and receive frequencies are set to the

same value.

THIS INFORMATION IS

SUBJECT TO

CHANGE.

DO NOT USE FOR

PRODUCT ORDERING.

1.3 Model Number Codes

The radio model number is printed on the PC board or on the radio

enclosure, and provides key information about how the radio was

configured when was shipped from the factory. See Figure 4 for an

explanation of the model number characters.

Invisible place holder

BANDWIDTH

1 = 12.5 kHz Domestic

ENCLOSURE

0 = Without Enclosure

1 = With Enclosure

EL705

BAND SUB-BAND

9 = 900 MHz A = 928–960 MHz

NA

AGENCY

F = FCC/IC

N = None

Figure 4. MDS OEM Series™ Model Number Codes

SAFETY

N = None

E = Class 1, Div. 2 ENTLA

N

MODEM

2 = 4800 BPS

3 = 9600 BPS

4 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 12

1.4 Accessories

The transceiver can be used with one or more of the accessories listed in

Table 1. Contact the factory for ordering information.

Table 1. Optional Accessories

Accessory Description MDS P/N

Hand-Held Terminal

Kit (HHT)

Accessory Power

Adapter

RTU Simulator Assy. Test unit that simulates data from a

DB-9 to DB-25 adapter Used to connect a PC with a 9-pin

Radio Configuration

Software (EL705)

PC Programming

Adapter Kit

Keypad terminal for programming,

diagnostics, and control. Includes

carrying case, cable set and an

instruction booklet. (Accessory Power

Adapter 03-3722A01 required for use

with OEM radios—see below).

DB-25 male-to-female adapter that

attaches to the radio’s DATA

INTERFACE connector. Provides

regulated 10 Vdc for powering an HHT

or other low power accessory. If not

used, accessories could be damaged

by excessive voltage (equal to the

radio’s DC input voltage).

remote terminal unit. Comes with

polling software that runs on a PC.

Used for testing OEM radio operation.

(NOTE: Older MDS RTU Simulators

will

not

work with the OEM radio as

they require a higher input voltage.)

serial port to the radio’s DATA

INTERFACE port.

Radio programming software for use

with a Windows-based PC. This

program is available on 3.5” disks, and

is included on the MDS’ InSite 6.4 (or

higher) CD.

Required when programming the radio

with a personal computer operating in

terminal mode. The adapter asserts

the auto-open signal (ground) on pin

23 of the DATA INTERFACE port. A

scratch-built cable may also be used

for this purpose (see Figure 12 on

Page 16).

02-1501A01

03-3722A01

03-2094A01

01-3683A01

03-3649A01

01-3683A01

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 5

Page 13

2.0 INSTALLATION

There are three main requirements for installing the transceiver—

adequate and stable primary power, a good antenna system, and the

correct data connections between the transceiver and the data device.

Figure 5 shows the external connections for the transceiver.

Invisible place holder

POWER CONNECTOR*

(TIP/RING BARREL TYPE)

DATA INTERFACE

Final model will have a polarized

*

2-pin power connector (plug & cable

assembly included). Red wire is

positive(+); black is negative (-).

CONNECTOR

(DB-25)

ANTENNA

CONNECTOR

(BNC)

Figure 5. External Connections to the Transceiver Board

(Connector locations identical to enclosed radio)

2.1 Installation Steps

Below are the basic steps for installing the transceiver. In many cases,

these steps alone are sufficient to complete the installation. More

detailed explanations appear at the end of these steps.

1. Mount the transceiver to a stable surface using the appropriate

hardware.

2. Install the antenna and antenna feedline for the station. Preset

directional antennas in the desired direction of transmission and

reception.

3. Measure and install the primary power for the radio. The primary

power must be between 10 and 16 Vdc and be capable of supplying

at least 2 Amperes. (This requirement assumes a 5 watt RF output.

Lower current consumption is possible if lower output po wer can be

used in your application—see OEM Series™ Transceiver

Specifications on Page 26 for details.)

NOTE: Use the radio in negative ground systems only.

6 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 14

4. Set the radio configuration. The transceiver is designed for quick

installation with a minimum of software configuration in most cases.

The selections that need to be verified for new installations are:

• Transmit frequency

• Receive frequency

• Transmitter output power

• Network address (factory default is

NONE)

The operating frequencies are not set at the factory unless they are

specified at the time of order. Determine the transmit and receive

frequencies to be used, and follow the steps below to program them.

5. Connect a terminal interface (personal computer or a hand-held

terminal) to the

DATA INTERFACE connector. (See PC Connection

and Startup on Page 14 for details.)

6. Press to receive the ready “>” prompt.

ENTER

a. Set the transmit frequency with the TX xxx.xxx command.

Press after the command.

b. Set the receive frequency with the

Press after the command.

c. Set the network address with the

Press after the command. After programming, the

terminal interface reads

ENTER

RX xxx.xxx command.

ENTER

ADDR xxx command.

ENTER

PROGRAMMED OK to indicate successful

entry.

7. Disconnect the terminal interface from the

DATA INTERFACE

connector.

8. Connect the data equipment to the transceiver’s

DATA INTERFACE

connector. Use only the required pins for the application—do not

use a fully pinned (25 conductor) cable. Basic applications often

require only the use of Pin 2 (Transmitted Data—TXD), Pin 3

(Received Data—RXD), and Pin 7 (Signal Ground).

Additional connections may be required in some installations. Refer

to the complete list of pin functions in Table 3 on Page 11.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 7

Page 15

2.2 Mounting the Transceiver

Transceiver Board

Figure 6 shows the mounting dimensions of the transceiver PC board.

The board should be secured to the mounting surface using the holes

provided at each corner of the assembly. (Fasteners are not supplied.)

Note that the lower left mounting hole in the board is a threaded ferrule.

Invisible place holder

4.53 in.

(11.51 cm)

0.23 in.

(0.58 cm)

3.23 in.

(8.20 cm)

RF

HEATSINK

1” in.

(2.54 cm)

2.5 in.

(6.35 cm)

DATA

PWR

3.73 in.

(9.47 cm)

0.28 in.

(0.71 cm)

HEATSINK HEIGHT: 0.38” (0.97 cm)

4.05 in.

0.28 in.

(0.71 cm)

(10.29 cm)

0.20 in.

(0.51 cm)

Figure 6. Transceiver Mounting Dimensions (Board Version)

Enclosed Transceiver

Figure 7 shows the mounting dimensions of the enclosed transceiver.

Two cutout slots are provided on each side of the enclosure for

mounting screws. (Fasteners are not supplied.)

Invisible place holder

1.75 in.

(4.45 cm)

5.97 in.

(15.14 cm)

6.50 in.

(16.51 cm)

Figure 7. Transceiver Mounting Dimensions (Enclosed Version)

3.25 in.

(8.25 cm)

5.00 in.

(12.70 cm)

8 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 16

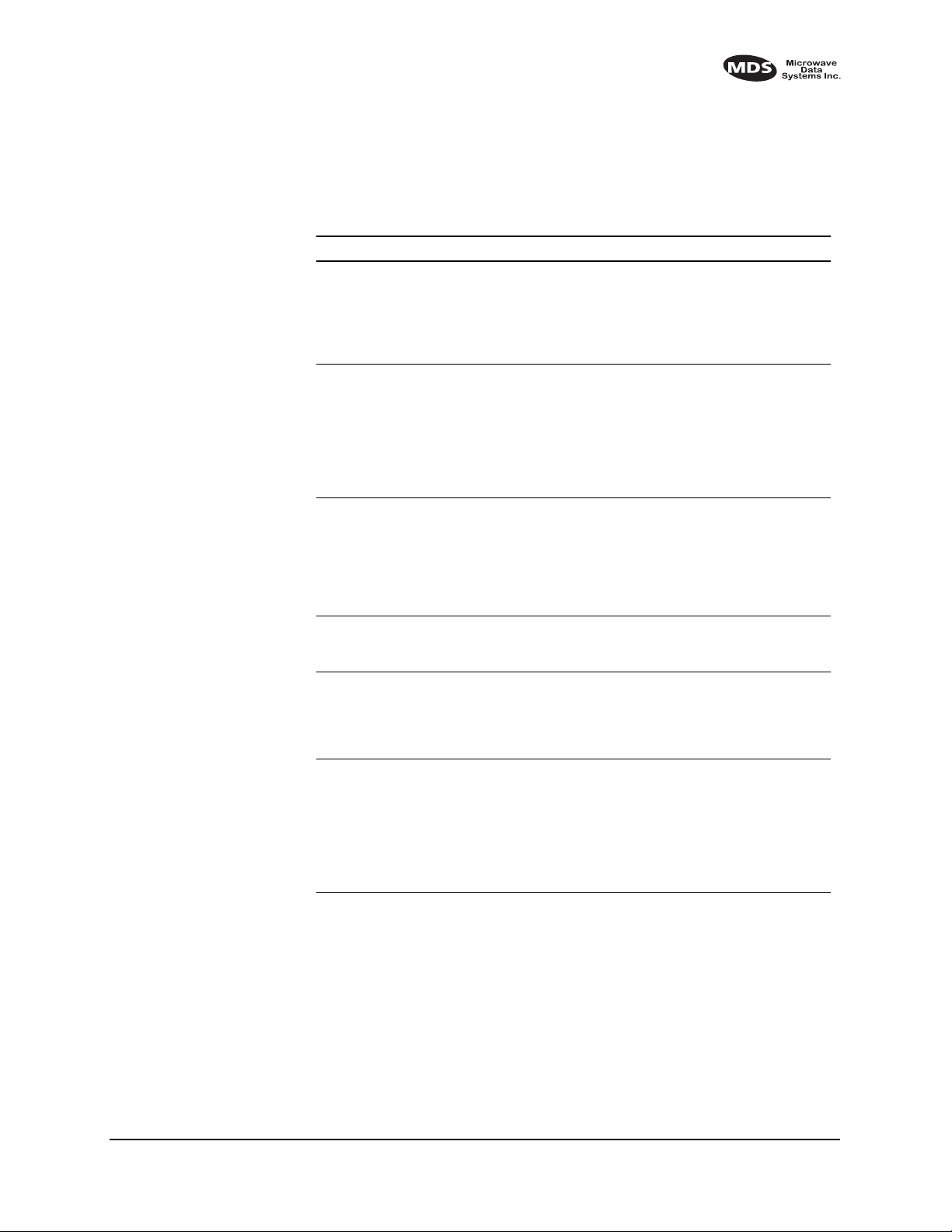

2.3 Antennas and Feedlines

Antennas

The transceiver can be used with a number of antennas. The exact style

depends on the physical size and layout of the radio system. Suitable

antennas are available from several manufacturers, including MDS.

At master stations, omni-directional antennas (Figure 8) are typically

used to provide equal coverage to all remote sites in the network.

Invisible place holder

Figure 8. Typical Omni-directional Antenna for Master Stations

(Shown mounted to mast)

At remote sites, a directional Yagi (Figure 9) or corner reflector antenna

is generally recommended to minimize interference to and from other

users.

Invisible place holder

Figure 9. Typical Yagi Antenna for Remote Sites

Feedlines

The selection of antenna feedline is very important. Poor quality cables

should be avoided as they result in power losses that may reduce the

range and reliability of the radio system.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 9

Page 17

Table 2 shows the losses that occur when using various lengths and

types of cable in the 900 MHz band. Regardless of the type of cable

used, it should be kept as short as possible to minimize signal loss.

Table 2. Length vs. Loss in Coaxial Cables at 900 MHz

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

3 Meters

Cable Type

RG-8A/U 0.85 dB 4.27 dB 8.54 dB 42.70 dB

1/2 inch HELIAX

7/8 inch HELIAX

1-1/4 inch HELIAX

1-5/8 inch HELIAX

(10 Feet)

0.23 dB 1.15 dB 2.29 dB 11.45 dB

0.13 dB 0.64 dB 1.28 dB 6.40 dB

0.10 dB 0.48 dB 0.95 dB 4.75 dB

0.08 dB 0.40 dB 0.80 dB 4.00 dB

15 Meters

(50 Feet)

30 Meters

(100 Feet)

150 Meters

(500 Feet)

2.4 Power Connection

The transceiver can be operated from any well-filtered 10 to 16 Vdc

power source. The power supply must be capable of providing at least 2

Amperes if 5 watt output is planned from the transceiver. Supply the

power to the power connector (see Figure 5 on Page 6).

Do not apply power to the radio through Pin 18 of the DB-25

Interface connector. This pin does not provide over-current input

protection, and is intended only as an auxiliary output for po wering

a low-current (1.0 Amp max.) device, such as an RTU.

NOTE: The radio is designed for use in negative ground systems only.

Conservation (Sleep Mode)

In some installations, such as at solar-powered sites, it may be necessary

to keep the transceiver’s power consumption to an absolute minimum.

This can be accomplished by configuring the data device (RTU, PLC,

etc.) to ground Pin 12 of the

DAT A INTERF ACE connector, which removes

power from the radio. When the ground is removed, the radio is ready

to operate within 75 milliseconds.

2.5 Data Interface Connections

The transceiver’s DATA INTERFACE connector is configured as a DCE

(modem) and is normally connected to an EIA-232 device. The

transceiver supports over-the-air asynchronous data rates up to

19200 bps. Refer to Figure 10 and Table 3 for a detailed description of

each pin on the

DATA INTERFACE connector.

10 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 18

CAUTION

USE

ONLY REQUIRED

PINS

Do not use a 25 wire (fully pinned) cable for connection to the DATA

INTERFACE

connector. Use only the required pins for the application.

Damage may result if improper connections are made. For EIA-232

signaling, typical applications require the use of Pins 2, 3, and 7

only.

Invisible place holder

13

1

25

14

Figure 10. Data Interface Connector Pinouts

(As viewed from the front of the radio)

Table 3. DATA INTERFACE Connector Pinouts

Pin

Number

1--Protective Ground. Connects to ground (negative supply

2INTXD—Transmitted Data. Accepts TX data from the

3 OUT RXD—Received Data. Outputs received data to the

4INRTS—Request-to-Send Input. Causes CTS to go

5 OUT CTS—Clear-to-Send Output. Behavior depends on

6 OUT DSR—Data Set Ready. Active when radio is powered on.

7--Signal Ground. Connects to ground (negative supply

8 OUT DCD—Data Carrier Detect. Active when receiving

11 OUT Receive Audio Output. For test purposes only.

Input/

Output Pin Description

potential) on the radio’s PC board and chassis.

connected device.

connected device.

“high.”

DEVICE command setting:

When DEVICE is set to DCE, this pin follows RTS and will

provide “buffer full” flow control.

When DEVICE is set to CTS KEY, this pin provides a

keyline output when receive data is present.

potential) at radio’s PC board.

data from another OEM Series radio with the same

network address.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 11

Page 19

Table 3. DATA INTERFACE Connector Pinouts (Continued)

Pin

Number

12 -- Sleep Mode. A logic low on this pin removes power from

18 IN/OUT Accessory Power. Unregulated Output. Provides a

19 OUT 5.8 Vdc Regulated Output. Provides a source of

23 IN Auto-Open. A logic low (less than 0.5 volts or ground)

25 OUT Alarm. A logic low (less than 0.5 volts) on this pin indicates

Input/

Output Pin Description

the radio. The radio is ready to operate 75 milliseconds

after the ground is removed.

source of output power for low current (1 Amp max.)

accessories. Excessive drain on this connection causes

the on board fuse (2 ampere) to open. The voltage at this

pin matches the input voltage to the transceiver. Do not

use this pin for powering the radio.

regulated voltage at 100 mA for low power accessories.

on this pin opens the diagnostic channel and disables

normal data operation. A logic high (greater than 4 volts or

open) enables the DATA INTERFACE for normal data

operation.

normal operation. A logic high (greater than 4 volts)

indicates that some alarm condition is present. This pin

can be used as an alarm output, provided the internal

series resistance of 1 kΩ is considered.

12 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 20

3.0 OPERATION

In-service operation of the transceiver is completely automatic. Once

the unit has been properly installed and configured, operator actions are

limited to observing the radio’s LED status indicators for proper

operation.

3.1 Initial Startup

If all parameters are set correctly, operation of the radio can be started

with these steps:

1. Apply DC power to the transceiver.

2. Observe the LED status panel for the proper indications (see

Table 4).

3. If not done earlier, refine the antenna heading of the station to

maximize the received signal strength (RSSI) from the master

station. Use the

to the radio’s

TRANSCEIVER PROGRAMMING.

RSSI command from a terminal interface connected

DATA INTERFACE connector.—See Section 4.0,

3.2 LED Indicators

The transceiver includes four status LEDs visible from the top of the

unit, behind the Data Interface connector (or on the front panel in

enclosed units). Table 4 describes the function of each status LED.

RXDTXDDCDPWR

Table 4. LED Status Indicators

LED Name Description

PWR

(Power)

DCD

(Data Carrier Detect)

RXD

(Receive Data)

TXD

(Transmit Data)

• Continuous—Power is applied to the radio, no problems

detected.

• Rapid flash (five times-per-second)—Fault indication.

• Flashing once every second—Unit is not programmed.

Radio is in Bootloader mode.

Flashing—Indicates another radio (with the same network

address) is transmitting at the radio’s receive frequency.

Receive data is present on DATA INTERFACE connector.

Transmit data is present on DATA INTERFACE connector.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 13

Page 21

4.0 TRANSCEIVER PROGRAMMING

Programming and set-up of the transceiver is performed through the

radio’s

personal computer or a hand-held terminal (HHT). This section contains

a reference chart of commands (Table 5) followed by detailed

descriptions for each entry.

4.1 Radio Programming Methods

➊ PC with Radio Configuration Software

PC-based Radio Configuration software is available for use with the

radio (MDS P/N 03-3649A01). This software is normally supplied on

3.5” disks, but can also be found on the MDS InSite disk (version 6.4 or

higher) under the title of “EL705.” On-line instructions are included

with the configuration software.

NOTE: When using radio configuration software, click on the opening

➋ PC in Terminal Mode

DATA INTERFACE connector with a terminal interface—either a

screen or press a key to activate the program.

A PC may also be used without the Radio Configuration software by

operating it in a basic terminal mode (e.g., HyperTerminal session) and

entering the radio commands listed in Table 5. The terminal

communication parameters must be set to 9600 bps, with 8 data

bits, no parity, and 1 stop bit (8N1).

➌ Handheld Terminal (HHT)

A Hand-Held Terminal kit (MDS P/N 02-1501A01) may be used to

enter the radio commands listed in Table 5. The HHT communication

parameters must be set to 9600 bps, with 8 data bits, no parity, and

1 stop bit (8N1).

4.2 PC Connection and Startup

Follow the steps below to prepare the radio for PC programming. For

information about connecting and setting up a hand-held terminal, refer

to the instructions provided with each HHT kit.:

1. Connect a PC to the radio’s

Figure 11. Pin 23 of the interface cable must be grounded to activate

the control and programming mode. This can be done with a

Programming Adapter (MDS P/N 01-3683A01), or with a

scratch-built cable as shown in Figure 12.

DATA INTERFACE port as shown in

2. Press to obtain the ready “>” prompt.

14 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

ENTER

Page 22

Invisible place holder

Figure 11. Terminal Interface (PC) Connected to the Transceiver

(Pin 23 on cable must be grounded—see Figure 12)

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 15

Page 23

DB-25 MALE

(TO RADIO)

TXD

2

Invisible place holder

DB-9 FEMALE

(TO COMPUTER)

RXD

2

3

RXD

7

GND

23

Diagnostics Open

TXD

GND

3

5

Figure 12. DB-25 to DB-9 Adapter Cable

(For PC control and programming)

4.3 Keyboard Commands

Table 5 is a reference chart of software commands for the transceiver.

Programmable information is shown in brackets [ ] following the

command name. See section 4.4 following the table for detailed

command descriptions.

Entering Commands

To enter a command, type the command, followed by an

keystroke. For programming commands, the command is followed by

SPACE

and the appropriate information or values, then

Error Messages

Listed below are some possible error messages that may be encountered

when using the terminal interface:

ENTER

ENTER

.

UNKNOWN COMMAND—The command was not recognized. Refer to the

command description for command usage information.

INCORRECT ENTRY—The command format or its associated values were

not valid. Refer to the command description for command usage

information.

COMMAND F AILED—The command was unable to successfully complete.

This may indicate an internal software problem.

NOT PROGRAMMED —Software was unable to program the internal radio

memory or the requested item was not programmed.This is a serious

internal radio error. Contact MDS for assistance.

TEXT TOO LONG—Response to OWN or OWM command when too many

characters have been entered. Refer to the command description for

command usage information.

NOT AVAILABLE—The entered command or parameter was valid, but it

referred to a currently unavailable choice. Refer to the command

description for command usage information.

16 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 24

ACCESS DENIED—The command is unavailable to the user. Refer to the

command descriptions for command information.

EEPROM F AILURE— The INIT command was unable to write to EEPROM.

This usually indicates a hardware error. Contact MDS for assistance.

Table 5. Command summary

Command name Function

ADDR [NONE | 1–255]

Details page 18

AMASK [0000

0000–FFFF FFFF]

Details page 18

BAUD [xxxxx abc]

Details page 19

CTS [0–255]

Details page 19

CTSHOLD [0–60000]

Details page 19

DEVICE [DCE | CTS KEY]

Details page 20

DKEY

Details page 20

INIT

Details page 20

KEY

Details page 21

OWM [XXX...]

Details page 21

OWN [XXX...]

Details page 21

Set or display the network address of the radio.

Set or display hex code identifying which events

trigger an alarm.

Set or display the DATA INTERFACE data rate

and format.

Set or display the Clear-to-Send delay in

milliseconds.

Set or display the delay, in milliseconds, at the

end of a CTS line response; CTS Key operation

only.

Set or display the CTS options.

Dekey the radio (transmitter OFF) following a

KEY command.

Set radio parameters to factory defaults.

Key the radio (transmitter ON). Provides a carrier

for testing.

Set or display the owner’s message.

Set or display the owner’s name.

PWR [L | M | H]

Details page 21

RSSI and RSSI!

Details page 22

RX [xxx.xxx]

Details page 22

RXTOT [NONE | 1–255]

Details page 22

SER

Details page 22

SREV

Details page 22

Set or display the transmit power setting.

Display the Received Signal Strength Indication.

Set or display the receive frequency.

Set or display the value of the receive time-out

timer.

Display the radio serial number.

Display the software revision level.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 17

Page 25

Table 5. Command summary (Continued)

Command name Function

STAT

Details page 22

Display the current alarm status.

TOT [1–255 | ON | OFF]

Details page 23

TX [xxx.xxx]

Details page 23

Set or display the time-out timer status and the

timer delay in milliseconds.

Set or display the transmit frequency.

4.4 Detailed Command Descriptions

The only essential commands for most applications are transmit

frequency (

address (

allows you to tailor the transceiver for a specific use or conduct basic

diagnostics on the radio. This section gives more detailed information

for the user commands previously listed in Table 5.

In many cases, the commands shown here can be used in two ways.

First, you can type only the command name to view the currently

programmed data. Secondly, you can set or change the existing data by

typing the command, followed by a space, and then the desired entry. In

the list below, allowable data values, if any, are shown in brackets

following the command name. The separator symbol (|) indicates that

you can enter one of the values in the list.

ADDR [NONE | 1–255]

TX xxx.xxx), receive frequency (RX xxx.xxx), and network

ADDR xxx). However, proper use of the additional commands

The

ADDR command displays or sets the network address of the radio. In

order for all the radios in a network to communicate, their network

addresses must be identical, or set to

the factory with

ADDR set to NONE.)

NONE. (The radio is shipped from

AMASK [0000 0000–FFFF FFFF]

The

AMASK (alarm mask) command displays or sets which events cause

the alarm output signal to be active. Normally, the mask is

FFFF FFFF,

meaning that any of the 32 possible events activate the alarm output

signal. No special configuration is required for typical applications.

Entering the

AMASK command alone displays the current setting of

alarm events in hexadecimal format.

Entering the

AMASK command followed by an eight-digit hexadecimal

number reprograms the specified events to trigger an alarm.

Each bit that is a ‘1’ identifies an associated alarm condition that can

trigger the alarm output status line. Each bit that is a ‘0’ treats the

associated alarm as irrelevant when deciding whether or not to assert the

alarm output status line.

18 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 26

Thus, an eight-digit hexadecimal number can classify up to 32 events as

alarm triggers for the alarm output status line. See Table 6 on Page 25

for a list of the event codes and their hex values. The hex value of the

mask is simply the sum of the hex values of the event codes

corresponding to the alarm triggering events.

BAUD [xxxxx abc]

This command sets (or displays) the communication attributes for the

DATA INTERFACE port.

The first parameter (

xxxxx) is baud rate. Baud rate is specified in

bits-per-second (bps) and must be one of the following speeds: 1200,

2400, 4800, 9600, or 19200.

The second parameter of the

BAUD command (abc) is a three-character

block indicating how the data is formatted:

a = Data bits (7 or 8)

b = Parity (N for None, O for Odd, E for Even)

c = Stop bits (1 or 2)

The factory default setting is 9600 baud, 8 data bits, no parity, 1 start bit,

and 1 stop bit (Example:

9600 8N1).

NOTE: 7N1, 8O2, and 8E2 are invalid communication settings and are

not supported by the transceiver.

CTS [0–255]

The

CTS (clear-to-send) command sets or displays the timer value

associated with the CTS line response. The command parameter ranges

from 0 to 255 milliseconds.

For DCE operation (see

to wait after the RTS line goes high, before the radio asserts CTS. A

DEVICE command), the timer specifies how long

CTS

value of zero asserts the CTS line immediately after the RTS line goes

high.

For CTS Key operation (see

DEVICE command), the timer specifies how

long to wait after asserting the CTS, before data becomes available. A

timer value of zero means that data is available as soon as received

CTSHOLD [0–60000]

For CTS Key operation (see

DEVICE command), the CTSHOLD command

sets or displays the timer value associated with the end of a CTS line

response. The timer value specifies the length of time that CTS remains

active following the last byte from the RXD pin of the

DAT A INTERFACE

port. The time is in milliseconds. The default value is 0, which means

that CTS drops immediately after the last byte.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 19

Page 27

For DCE operation (see DEVICE command), this command has no effect.

The response

CTSHOLD n/a is displayed.

DEVICE [DCE | CTS KEY]

The

DEVICE command sets or displays the device behavior of the radio.

The command parameter is either

DCE or CTS KEY.

The default selection is

DCE. In this mode, CTS goes high following

RTS, subject to the CTS programmable delay time. Hardware flow

control is implemented by signaling the CTS line if data arrives faster

than it can be buffered and transmitted. The transceiver does not require

an RTS/CTS handshake. Data is transmitted whenever there is data to

send.

If

CTS KEY is selected, the CTS line transforms to a Receive Data

indicator (with programmable delays) in order to provide a control line

for use by other devices. The RTS line is ignored. CTS is asserted

immediately following the receipt of RF data, but data is not sent out the

DATA INTERFACE port until the CTS programmable delay time has

expired. (See

CTSHOLD description for the delay available following the

data.)

A typical use of

CTSKEY is to provide a keyline (or RTS signal) for a

half-duplex modem or other radio.

DKEY

This command deactivates the transmitter after it has been keyed with

the

KEY command.

NOTE: The DKEY and KEY commands are not intended for normal

operation. They are tools for field testing and installation.

INIT

The INIT command is used to re-initialize the radio’s operating

parameters to the factory defaults. This may be helpful when trying to

resolve configuration problems that may have resulted from the entry of

one or more improper command settings. Entry of this command allows

you to get back to a known working state. The following changes to the

radio are made when

AMASK is set to FFFF FFFF

•

INIT is entered:

• BAUD is set to 9600 baud, 8 data bits, no parity, and 1 stop bit

(

9600 8N1)

• CTS is set to 0

• CTSHOLD is set to 0

• DEVICE is set to DCE

20 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 28

• PWR is set to H [+37 dBm (5 watts)]

• RXTOT is set to NONE

• TOT is set to OFF

All other commands stay at their previously established settings.

KEY

This command activates the transmitter. The transmitter stays keyed

until either the DKEY command is entered, or the transmitter time-out

timer is enabled and times out. See also the

DKEY and TOT commands.

NOTE: The KEY and DKEY commands are not intended for normal

operation. They are tools for field testing and installation.

OWM [XXX...]

This is a command to display or set an owner’s message. To program

the owner’s message, type

OWM then the message, followed by .

ENTER

The maximum number of characters that can be entered is 30.

To display the owner’s message, type OWM then . The owner’s

ENTER

message appears on the display.

OWN [XXX...]

This is a command to display or set an owner’s name. To program the

owner’s name, type

OWN then the name, followed by . The

ENTER

maximum number of characters that can be entered is 30.

To display the owner’s name, type OWN then . The owner’s

ENTER

name appears on the display.

PWR [L | M | H]

NOTE: This function may not be available, depending on certification

requirements for a particular region.

This command displays or sets the desired RF forward output power

setting of the radio. The

L (low), M (medium), or H (high). The default setting is H. The values of

L, M, and H are:

L = 24 dBm (250 mW)

M = 30 dBm (1 W)

H = 37 dBm (5 W)

PWR command parameter is specified as

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 21

Page 29

RSSI and RSSI!

These commands continuously display the radio’s Received Signal

Strength Indication (RSSI) in dBm units. Incoming signal strengths

from –50 dBm to –120 dBm are displayed.

The

RSSI command causes display of received signal strength, updated

once every second. Press to terminate the display.

ENTER

The RSSI! command displays a one-time reading of the RSSI at the

diagnostic port.

RX [xxx.xxx]

This command sets or displays the radio’s receive frequency in MHz.

The frequency must be an integer multiple of the step size and must be

in the valid range. If the entered frequency is invalid, the terminal

interface displays the message

INCORRECT ENTRY.

NOTE: The frequency must be in the valid range for the sub-band

purchased, and may not be programmed “between” channels.

RXTOT [NONE | 1–255]

The

RXTOT command sets or displays the receive time-out timer value in

minutes. This timer triggers an alarm (event 12) if data is not detected

within the specified time.

Entering the

value in minutes. Entering the

ranging from 1 to 255 resets the timer in minutes. Entering the

command with the parameter

RXTOT command without a parameter displays the timer

RXTOT command with a parameter

RXTOT

NONE disables the timer.

SER

This command displays the radio’s serial number as recorded at the

factory.

SREV

This command displays the software revision level of the transceiver

firmware.

STAT

This command displays the current alarm status of the transceiver.

If no alarms exist, the message

NO ALARMS PRESENT appears at the top

of the terminal display.

22 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 30

If an alarm does exist, a two-digit code (00–31) is displayed and the

alarm is identified as

MAJOR or MINOR. A brief description of the alarm

code is also given. Detailed descriptions of event codes are provided in

Table 6 on Page 25.

If more than one alarm exists, the word

the screen and additional alarms are viewed by pressing the

MORE appears at the bottom of

ENTER

key. Alarms are displayed in ascending order, major alarms before

minor ones.

TOT [1–255 | ON | OFF]

This command sets or displays the transmitter time-out timer value

(1–255 seconds), as well as the timer status (

ON or OFF). The command

parameter can be either the timer value or the status, but not both. The

parameter

ON enables the timer; OFF disables the timer.

If the timer is on, and the radio remains keyed for a longer duration than

the

TOT value, the transmitter is automatically unkeyed. When this

happens, the radio must be commanded back to an unkeyed state before

a new keying command is accepted.

By default the timer is

ON and set to 30 seconds.

TX [xxx.xxx]

This command sets or displays the radio’s transmit frequency in MHz.

The frequency must be an integer multiple of the step size and must be

in the valid range. If the entered frequency is invalid, the terminal

interface displays the message

INCORRECT ENTRY.

NOTE: The frequency must be in the valid range for the sub-band

purchased, and may not be programmed “between” channels.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 23

Page 31

5.0 TROUBLESHOOTING

Successful troubleshooting of the radio system is not difficult, but it

requires a logical approach. It is best to begin troubleshooting at the

master station, as the rest of the system depends on the master for

polling commands. If the master station has problems, the operation of

the entire network can be compromised.

It is good practice to start by checking the simple things. For proper

operation, all radios in the network must meet these basic requirements:

• Adequate and stable primary power.

• Secure connections (RF, data, and power).

• An efficient and properly aligned antenna system with a good

received signal strength (at least –90 dBm). It is possible for a

system to operate with weaker signals, but reliability may be

degraded.

• Proper programming of the transceiver’s operating parameters

(see Section 4.0, TRANSCEIVER PROGRAMMING).

• The correct interface between the transceiver and the connected

data equipment (correct cable wiring, proper data format, timing,

etc.).

5.1 LED Indicators

The LED status indicators are an important troubleshooting tool and

should be checked whenever a problem is suspected. Table 4 on Page 13

describes the function of each status LED.

5.2 Event Codes

When an alarm condition exists, the transceiver creates a code that can

be read on a terminal connected to the

codes can be very helpful in resolving many system difficulties. Table 6

lists the definitions of the event codes.

Checking for Alarms—STAT command

To check for alarms, enter

exist, the message

NO ALARMS PRESENT appears at the top of the display.

If an alarm does exist, the

STAT on the terminal interface. If no alarms

STAT command displays a two-digit alarm

code (00–31) and the event is identified as a Major or Minor Alarm. A

brief description of the alarm is also given.

DATA INTERFACE port. These

If more than one alarm exists, the word

the screen. To view additional alarms, press .

24 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

MORE appears at the bottom of

ENTER

Page 32

Major Alarms vs. Minor Alarms

Major Alarms—report serious conditions that generally indicate a

hardware failure, or other abnormal conditions that prevent (or seriously

degrade) further operation of the transceiver. Major alarms generally

indicate the need for factory repair. Contact MDS for further assistance.

Minor Alarms—report conditions that, under most circumstances do

not prevent transceiver operation. These include out-of-tolerance

conditions, baud rate mismatches, etc. The cause of these alarms should

be investigated and corrected to prevent possible system failure.

Event Code Definitions

Table 6 contains a listing of the event codes that may be reported by the

transceiver.

Table 6. Event Codes

Event

Code Hex Value

00 0000 0000 -- No alarms present. No Alarms Present

1–3 -- -- Not used. --

04 0800 0000 Major One or both of the internal programmable

5–7 -- -- Not used. --

08 0080 0000 Major The system is reporting that it has not been

09 -- -- Not used. -10 0020 0000 Major The internal microcontroller was unable to properly

11 -- -- Not used. -12 0008 0000 Major Receiver time-out. No data received within the

13 0004 0000 Major Transmitter time-out. The radio was keyed for a

14–16 -- -- Not used. --

17 0000 4000 Minor A data parity fault has been detected on the DATA

18 0000 2000 Minor A data framing error has been detected on the

19–30 -- -- Not used. --

Event

Class Description STATUS Message

synthesizer loops is reporting an out-of-lock

condition.

calibrated. Factory calibration is required for proper

radio operation.

program the system to the appropriate EEPROM

defaults. A hardware problem may exist.

specified receiver time-out time.

duration exceeding the time-out timer setting. (This

alarm clears the next time the radio keys.)

INTERFACE connector. This usually indicates a

parity setting mismatch between the radio and the

RTU.

DATA INTERFACE connector. This may indicate a

baud rate mismatch between the radio and the

RTU.

Synthesizer

Out-of-Lock

Radio Not Calibrated

EEPROM Write Failure

Receiver time-out

Transmitter time-out

Data Parity Error

Data Framing Error

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 25

Page 33

6.0 TECHNICAL REFERENCE

6.1 OEM Series™ Transceiver Specifications

MODELS

MDS OEM Series™ 900: Licensed 900 MHz Transceiver

RADIO TYPE

Synthesized, half duplex, 12.5 kHz channel spacing, split frequency, or simplex

ENVIRONMENTAL

Temperature Range: –30 to +60 degrees C

Humidity: 0 to 95% at 40 degrees C

Board Dimensions: 4.53″ W x 0.75″ H x 3.73″ D

Enclosed Dimensions: 6.5″ W x 1.75″ H x 5.00″ D

Weight: (Board version) 4.5 oz. (0.13 kg)

RF Connector: BNC

Enclosure Type (if furnished): Aluminum

TRANSMITTER

11.51 cm W x 1.90 cm H x 9.47 cm D

16.51 cm W x 4.45 cm H x 12.70 cm D

(Enclosed version) 1 lb. (0.45 kg)

Frequency Ranges (900 MHz): 928 to 960 MHz

Frequency Increments: 6.25 kHz (Standard)

Modulation Type: 4 level CPFSK

Carrier Power: 250 mW, 1 W, 5 W programmable

Duty Cycle: 50% (100% with additional heatsinking)

Output Impedance: 50 ohms

Frequency Stability: 1.5 ppm, –30 to +60 degrees C

Channel Spacing: 12.5 kHz

Spurious and Harmonics: –60 dBc

Time-out Timer: 1 to 255 seconds

Transmitter Keying: On data

Key-up Time: 2 ms

5 kHz (Special)

(+24 DBM, +30 dBM, +37 dBm)

26 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 34

RECEIVER

Type: Double conversion superheterodyne

Frequency Ranges (900 MHz): 928 to 960 MHz

Frequency Increments: 6.25 kHz (Standard)

Frequency Stability: 1.5 ppm, –30 to +60 degrees C

Spurious and Image Rejection: –70 dB

Sensitivity: 12 dB Sinad @ –116 dBm

Data Performance: 1 x 10

Intermodulation Rejection: –70 dB minimum

Selectivity: 50 dB typical at adjacent channel (EIA)

Bandwidth: 12.5 kHz

(45 MHz and 450 MHz IF)

5 kHz (Special)

-6

@ –108 dBm (9600 bps)

-6

1 x 10

@ –111 dBm (4600 bps)

DATA INTERFACE

RS-232 through DB-25 Connector

Baud Rates at Interface Port: 1200, 2400, 4800, 9600, and 19200* bps

Over-the-Air Data Rate: 9600 bps

Data Latency: < 20 ms typical

4800 bps

DIAGNOSTICS

Self Test: Yes

Local RS-232 RSSI and Setup: Yes

4 LED Display: PWR, DCD, TXD, and RXD

PRIMARY POWER

Voltage: 10 to 16 Vdc through a 5.5 mm pin plug or 2-pin

RX Current at 13.8 Vdc (typical): 75 mA

TX Current at 13.8 Vdc (typical): 1.75 A @ high power (5W)

Circuit Protection: 2 amp fuse, surface mount

Reverse Polarity Protection: Diode across primary input

* At 19200 bps, the radio operates in a buffered mode, storing 50 characters at a time.

MDS connector

700 mA @ medium power (1W)

400 mA @ low power (250 mW)

6.2 Bench Testing Setup

Figure 13 shows a sample test setup that can be used to verify the basic

operation of transceivers in a shop setting. The test can be performed

with any number of remote radios by using a power divider with the

required number of output connections.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 27

Page 35

The RTU simulator (MDS Part No. 03-2094A01) is a microcontroller

that emulates a remote terminal unit operating at 1200, 2400, 4800, or

9600 bps. Custom software is supplied with the RTU simulator that

allows continuous polling of remote radios using an IBM-compatible

personal computer. The software reports the number of polls sent, polls

received, and the number of errors detected.

NOTE: It is very important to use attenuation between all units in the

test setup. The amount of attenuation required depends on the

number of units being tested and the desired signal strength

(RSSI) at each transceiver during the test.

A maximum level of -50 dBm is recommended at each

transceiver, because the radio’s RSSI reporting will not be

accurate above this level. In no case should a signal stronger

than +10 dBm be applied to any transceiver in the test setup,

or damage may result.

Invisible place holder

COMPUTER RUNNING MDS

POLL.EXE PROGRAM

RTU SIMULATORS

(SEE TEXT)

REMOTE

RADIO

REMOTE

MASTER STATION

POWER ATTENUATORS

• Fixed or adjustable

• 2W minimum rating

RADIO

REMOTE

RADIO

POWER DIVIDER

NON-RADIATING ATTENUATOR

• Install on any unused divider ports

• 2W minimum rating

REMOTE

RADIO

Figure 13. Typical setup for bench testing of radios

6.3 Helical Filter Adjustment

If the operating frequency of the radio is changed more than 10 MHz,

the helical filters should be adjusted for maximum received signal

strength (RSSI). If adjustment is required, follow these steps:

1. For enclosed units, remove the top cover from the transceiver by

loosening the eight screws and lifting straight up.

2. Carefully remove the shield cover from the PC board.

3. Locate the helical filters. See Figure 14.

28 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 36

4. Apply a steady signal to the radio at the programmed receive

frequency (–80 dBm level recommended; no stronger than –60

dBm). This can be done with a signal generator or an over-the-air

signal.

5. Measure the radio’s RSSI using a terminal interface. See

Section 4.0, TRANSCEIVER PROGRAMMING on Page 14.

6. With a non-metallic tool, carefully adjust each section of the helical

filter for maximum RSSI. Repeat several times to work out any

interactions. Re-install the cover to the transceiver.

Invisible place holder

HELICAL

ADJUSTMENTS

HELICAL

ADJUSTMENTS

Figure 14. Helical Filter Location

(Shield cover removed)

6.4 Upgrading the Radio’s Software

From time to time, new product features or software maintenance files

become available from MDS. This section describes the steps necessary

to install new software into the transceiver using a PC connected to the

radio’s

When software upgrades become available, they can be obtained on the

MDS Web site at www.microwavedata.com, or you can contact MDS

to request radio software.

NOTE: Software upgrades are distributed as ASCII files with a “.S28”

DATA INTERFACE port.

extension. These files use the Motorola S-record format.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 29

Page 37

Using Radio Configuration Software

If you already have software that you wish to download into the

transceiver, Radio Configuration Software (MDS P/N 03-3649A01)

may be used to perform the installation. (This software is referred to as

“EL705” on the InSite 6.4 or higher CD.) To use this method, proceed

as follows:

1. Connect a PC to the radio’s

DATA INTERFACE port via a DB-9 to

DB-25 adapter (MDS P/N 01-3683A01 or equivalent). If desired, an

adapter cable may be constructed from scratch using the wiring

diagram shown in Figure 15.

Invisible place holder

DB-25 MALE

(TO RADIO)

TXD

2

RXD

3

GND

7

Figure 15. DB-25 to DB-9 Adapter Cable

DB-9 FEMALE

(TO COMPUTER)

RXD

2

TXD

3

GND

5

2. Run the Radio Configuration software. (Click on the opening screen

or press a key to activate the program.)

3. Under the

SYSTEM menu, select RADIO SOFTWARE UPGRADE.

Follow the prompts and online instructions to locate the desired

software and complete the upgrade. The radio’s

PWR LED flashes

rapidly to confirm that a download is in progress. The download

takes about two minutes.

NOTE: If a software download fails, the radio is left unprogrammed

and inoperative. This is indicated by the PWR LED flashing

slowly (1 second on, 1 second off). This condition is only

likely if a power failure occurred to the computer or radio

during the downloading process. The download can be

attempted again when the fault has been corrected.

30 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 38

6.5 dBm-Watts-Volts Conversion Chart

Table 7 is provided as a convenience for determining the equivalent

wattage or voltage of an RF power expressed in dBm.

Table 7. dBm-Watts-Volts Conversion—for 50 Ohm Systems

dBm V Po

+53 100.0 200W

+50 70.7 100W

+49 64.0 80W

+48 58.0 64W

+47 50.0 50W

+46 44.5 40W

+45 40.0 32W

+44 32.5 25W

+43 32.0 20W

+42 28.0 16W

+41 26.2 12.5W

+40 22.5 10W

+39 20.0 8W

+38 18.0 6.4W

+37 16.0 5W

+36 14.1 4W

+35 12.5 3.2W

+34 11.5 2.5W

+33 10.0 2W

+32 9.0 1.6W

+31 8.0 1.25W

+30 7.10 1.0W

+29 6.40 800mW

+28 5.80 640mW

+27 5.00 500mW

+26 4.45 400mW

+25 4.00 320mW

+24 3.55 250mW

+23 3.20 200mW

+22 2.80 160mW

+21 2.52 125mW

+20 2.25 100mW

+19 2.00 80mW

+18 1.80 64mW

+17 1.60 50mW

+16 1.41 40mW

+15 1.25 32mW

+14 1.15 25mW

+13 1.00 20mW

+12 .90 16mW

+11 .80 12.5mW

+10 .71 10mW

+9 .64 8mW

+8 .58 6.4mW

+7 .500 5mW

+6 .445 4mW

+5 .400 3.2mW

+4 .355 2.5mW

+3 .320 2.0mW

+2 .280 1.6mW

+1 .252 1.25mW

dBm V Po

0 .225 1.0mW

-1 .200 .80mW

-2 .180 .64mW

-3 .160 .50mW

-4 .141 .40mW

-5 .125 .32mW

-6 .115 .25mW

-7 .100 .20mW

-8 .090 .16mW

-9 .080 .125mW

-10 .071 .10mW

-11 .064

-12 .058

-13 .050

-14 .045

-15 .040

-16 .0355

dBm mV Po

-17 31.5

-18 28.5

-19 25.1

-20 22.5 .01mW

-21 20.0

-22 17.9

-23 15.9

-24 14.1

-25 12.8

-26 11.5

-27 10.0

-28 8.9

-29 8.0

-30 7.1 .001mW

-31 6.25

-32 5.8

-33 5.0

-34 4.5

-35 4.0

-36 3.5

-37 3.2

-38 2.85

-39 2.5

-40 2.25 .1µW

-41 2.0

-42 1.8

-43 1.6

-44 1.4

-45 1.25

-46 1.18

-47 1.00

-48 0.90

dBm mV Po

-49 0.80

-50 0.71 .01µW

-51 0.64

-52 0.57

-53 0.50

-54 0.45

-55 0.40

-56 0.351

-57 0.32

-58 0.286

-59 0.251

-60 0.225 .001µW

-61 0.200

-62 0.180

-63 0.160

-64 0.141

dBm µV Po

-65 128

-66 115

-67 100

-68 90

-69 80

-70 71 .1nW

-71 65

-72 58

-73 50

-74 45

-75 40

-76 35

-77 32

-78 29

-79 25

-80 22.5 .01nW

-81 20.0

-82 18.0

-83 16.0

-84 11.1

-85 12.9

-86 11.5

-87 10.0

-88 9.0

-89 8.0

-90 7.1 .001nW

-91 6.1

-92 5.75

-93 5.0

-94 4.5

-95 4.0

-96 3.51

-97 3.2

dBm µV Po

-98 2.9

-99 2.51

-100 2.25 .1pW

-101 2.0

-102 1.8

-103 1.6

-104 1.41

-105 1.27

-106 1.18

dBm nV Po

-107 1000

-108 900

-109 800

-110 710 .01pW

-111 640

-112 580

-113 500

-114 450

-115 400

-116 355

-117 325

-118 285

-119 251

-120 225 .001pW

-121 200

-122 180

-123 160

-124 141

-125 128

-126 117

-127 100

-128 90

-129 80 .1ƒW

-130 71

-131 61

-132 58

-133 50

-134 45

-135 40

-136 35

-137 33

-138 29

-139 25

-140 23 .01ƒW

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 31

Page 39

7.0 GLOSSARY OF TERMS

If you are new to digital radio systems, some of the terms used in this

guide may be unfamiliar. The following glossary explains many of these

terms and is helpful in understanding the operation of the transceiver.

Antenna System Gain—A figure, normally expressed in dB,

representing the power increase resulting from the use of a gain-type

antenna. System losses (from the feedline and coaxial connectors, for

example) are subtracted from this figure to calculate the total antenna

system gain.

Bit—The smallest unit of digital data, often represented by a one or a

zero. Eight bits (plus start, stop, and parity bits) usually comprise a byte.

Bits-per-second—See BPS.

BPS—Bits-per-second. A measure of the information transfer rate of

digital data across a communication channel.

Byte—A string of digital data usually made up of eight data bits and

start, stop and parity bits.

Data Circuit-terminating Equipment—See DCE.

Data Communications Equipment—See DCE.

Data Terminal Equipment—See DTE.

dBi—Decibels referenced to an “ideal” isotropic radiator in free space.

Frequently used to express antenna gain.

dBm—Decibels referenced to one milliwatt. An absolute unit used to

measure signal power, as in transmitter power output, or received signal

strength.

DCE—Data Circuit-terminating Equipment (or Data Communications

Equipment). In data communications terminology, this is the “modem”

side of a computer-to-modem connection. The MDS OEM Series™ is a

DCE device.

Decibel (dB)—A measure computed from the ratio between two signal

levels. Frequently used to express the gain (or loss) of a system.

DTE—Data Terminal Equipment. A device that provides data in the

form of digital signals at its output. Connects to the DCE device.

32 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 40

Fade Margin—The greatest tolerable reduction in average received

signal strength that is anticipated under most conditions. Provides an

allowance for reduced signal strength due to multipath, slight antenna

movement, or changing atmospheric losses. A fade margin of 20 is

usually sufficient in most systems.

Hardware Flow Control—A transceiver feature used to prevent data

buffer overruns when handling high-speed data from the RTU or PLC.

When the buffer approaches overflow, the radio drops the clear-to-send

(CTS) line, which instructs the RTU or PLC to delay further

transmission until CTS again returns to the high state.

Host Computer—The computer installed at the master station site,

which controls the collection of data from one or more remote sites.

Latency—The delay (usually expressed in milliseconds) between when

data is applied to TXD (Pin 2) at one radio, until it appears at RXD

(Pin 3) at the other radio.

MAS—Multiple Address System. A radio system where a central

master station communicates with several remote stations for the

purpose of gathering telemetry data.

Master (Station)—Radio which is connected to the host computer. It is

the point at which polling enters the network.

Multiple Address System—See MAS.

PLC—Programmable Logic Controller. A dedicated microprocessor

configured for a specific application with discrete inputs and outputs. It

can serve as a host or as an RTU.

Point-to-Multipoint System—A radio communications network or

system designed with a central control station that exchanges data with

a number of remote locations equipped with terminal equipment.

Poll—A request for data issued from the host computer (or master PLC)

to a remote radio.

Programmable Logic Controller—See PLC.

Received Signal Strength Indication—See RSSI.

Redundant Operation—A station arrangement where two transceivers

and two power supplies are available for operation, with automatic

switchover in case of a failure.

Remote (Station)—A radio in a network that communicates with an

associated master station.

Remote Terminal Unit—See RTU.

MDS 05-3624A01, Rev. B OEM Series™ I/O Guide 33

Page 41

RSSI—Received Signal Strength Indication. A measure, in dBm, of the

strength of the signal received by a radio from an antenna. The radio

must be properly calibrated for the RSSI value to be meaningful.

RTU—Remote Terminal Unit. A data collection device installed at a

remote radio site.

SCADA—Supervisory Control And Data Acquisition. An overall term

for the functions commonly provided through an MAS radio system.

Supervisory Control And Data Acquisition—See SCADA.

34 OEM Series™ I/O Guide MDS 05-3624A01, Rev. B

Page 42

INDEX

A