I

NSTALLATION

L

INEAR

D

ISPLACEMENT

MANUAL

T

RANSDUCERS

955A BRIK

GEN III Analog LDT

Series 956

955 Series

Includes 955A

Programming & Maintenance

Instructions Plus Accessory Guide

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Introduction

The 955A BRIK Gen III is an accurate programmable, autotuning, non-contact, linear displacement transducer in an

economical, low profile package. The transducer utilizes our

field proven magnetostrictive technology to give absolute

position, repeatable to .006% of the programmable sensing

distance. The streamlined anodized aluminum extrusion houses

the sensing element and electronics. The magnet moves over

the sensing element that determines the position and converts

it to an analog output. It can be ordered with a 0 to 10 VDC or 4

to 20mA output.

The 955A BRIK Gen III has a few truly unique features. One

feature is the LDT’s auto-tuning capability, the ability to sense

a magnet other than the standard slide magnet and adjust its

signal strength accordingly. Another feature is that the analog

output is programmable over the entire active stroke length. The

active stroke area of the LDT lies between the Null and Dead

zones.

LED Colors

Green: Magnet is present and within the active programmed

range. Red: Fault, the LDT has lost its signal from the magnet

or the magnet has moved into the Null or Dead zone. Yellow:

The magnet is out of the programmed ZERO to SPAN range.

Note 1: ZERO or SPAN can be adjusted individually

without setting the other. Note 2: ZERO = 0V on 0 to 10 VDC

units and 4mA on 4 to 20mA units.

Setting Zero & Span Positions

The 955A is programmable over the entire active stroke length

of the LDT. Keep in mind that there is a 3” Null area at the

connector end of the LDT and a 2.0” Dead area at the other

end of the LDT that the magnet must stay out of at all times.

The diagnostic LED can aid you in the setup of the Zero and

Span. A green or yellow LED means that it is OK to program

the LDT in this area, a red LED means that the LDT cannot be

programmed in this area.

There is a diagnostic LED located at the connector end of the

probe that remains green while a good magnet signal is present

and when the magnet is in the programmed stroke area. The

LED turns yellow when the magnet is out of the programmed

active range, but still within the active stroke area. The LED

turns red and the output goes to 0 volts on voltage output units,

or 4mA on current output units when there is no magnet present

or when the magnet is out of the sensing area. The unit can

easily be changed in the field from a 0 - 10VDC to a 10 - 0VDC

or 4 - 20mA to a 20 - 4mA .

Mounting

The transducer can be mounted vertically or horizontally using

SD0522000 mounting brackets. The mounting brackets slide

in the grooves on the lower part of the extrusion and clamp

down when tightened. It is recommended to use one mounting

bracket on each end and every three feet between.

Ferro-magnetic material, which is material readily magnetized,

should be placed no closer than .25” from the sensing surface

of the LDT.

Floating Magnet Assembly

When using the Floating Magnet assembly SD0522100, the

magnet should be installed within 3/8” of the sensing surface.

The magnet assembly should also be installed in such a

manner that it remains an even distance from the aluminum

extrusion throughout the entire stroke. Improperly installed

magnets can result in output signal non-linearity.

To set the ZERO and SPAN position for the probe

follow these steps.

1. Power up the probe in normal operating mode (i.e. “PRGM”

pin floating),

2. Place magnet assembly where ZERO is to be located, but

within the active region of probe,

3. Momentarily short “PRGM” pin (pin 2) to ground (pin 3),

4. Place magnet assembly where SPAN is to be located, but

within the active region of the probe,

5. Momentarily short “PRGM” pin (pin 2) to V+ (pin 1).

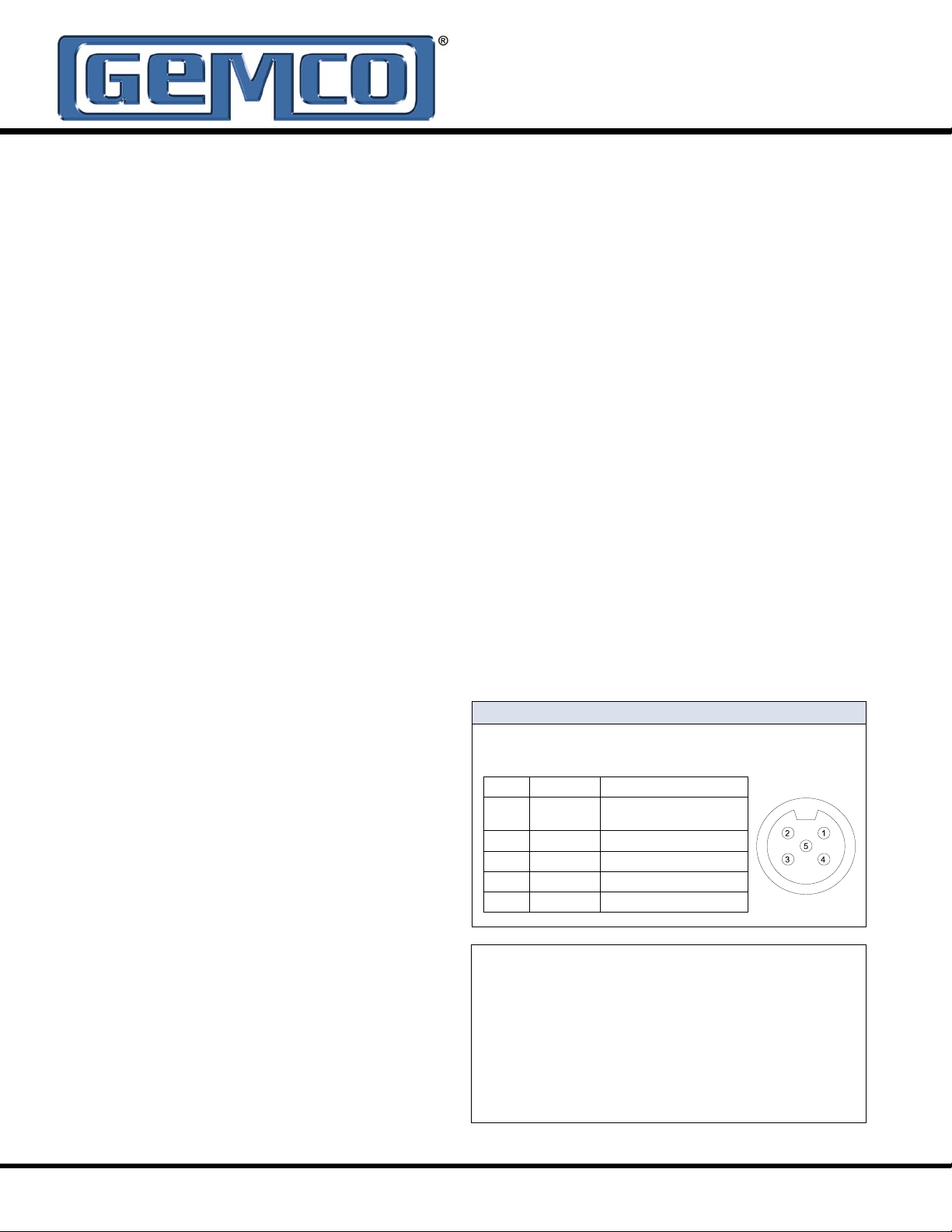

Wiring Diagram 955A Only

Euro Connector (Micro 12 mm single keyway)

Note: Refer to your specific model number and application

manual for the correct wire diagram and pin location.

Pin # Wire Color Function

1 Brown Customer Supplied Power

(+VDC)

2 White Program Input

3 Blue Power Supply Common

4 Black Position Output

5 Gray Analog Output Common

AMETEK Automation & Process Technologies has checked

the accuracy of this manual at the time it was approved

for printing. However, this manual may not provide all

possible ways of installing and maintaining the LDT. Any

errors found in this manual or additional possibilities to

the installation and maintenance of the LDT will be added

in subsequent editions. Any comments you have for the

improvement of this manual are welcomed. AMETEK

reserves the right to revise and redistribute the entire

contents or selected pages of this manual. All rights to the

contents of this manual are reserved by AMETEK.

Specifications

Input Voltage 13.5 to 30 VDC

Current Draw 2.5 Watts Maximum,

Output 0 to 10 VDC

Resolution

Internal

Analog Output

Non-Linearity +/- 0.05% of Stroke

Repeatbility +/- 0.006% of Full Stroke

Update

40” or less

41” to 100”

101” to 150”

151” to 180”

Operating Temperature -20° to 70° C

Span Length 5” to 180”

Null Zone 3.00”

Dead Zone 2.00”

LED Green = Power is applied and magnet is present.

Connector Standard 5 Pin Micro

Approvals CE

Enclosure IP67, Optional IP68

Specifications are subject to change without notice.

120 mA @ 15 VDC Typical

10 to 0 VDC

4 to 20 mA

20 to 4 mA

0.001”

16 Bit (1 part in 65,535)

1mS (Stroke Lengths 40” - 50”)

2mS (Stroke Lengths 41” - 100”)

3mS (Stroke Legnths 101” - 150”)

4mS (Stroke Lengths 151” - 180”)

Red = Fault, magnet is in the Dead Zone or lost

Yellow = Out of the active programmed range

12mm Euro Connector

Specifications are based on a typical 36” LDT.

Dimensions

Floating Magnet Assembly (SD0522100)

Sensing Surface

NOTE: The north pole of the magnet should be pointed towards the probe.

Mounting brackets (SD0522000) slide in the grooves on the side of the

extruded housing. When tightened down with fastening hardware the

mounting brackets clamp the unit into place. It is recommended to use

one mounting bracket on each end and every three feet between.

A standard female swivel mounting arm is provided with the slide magnet

assembly. For extensions and other options contact the factory.

S

N

Accessories

Item Part Number

Slide Magnet SD0521800

Float Magnet SD0522100

Mounting Foot SD0522000

6 Ft. Cable 949019L6

12 Ft. Cable 949019L12

6 Ft. Cable; Right Angle Connector 949020L6

12 Ft. Cable; Right Angle Connector 949020L12

Part Numbering

955A

955A BRIK

with Analog

Output

Output

V0 = 0 to 10 VDC

V1 = 10 to 0 VDC

C4 = 4 to 20mA

C2 = 20 to 4mA

XX

XXXX

Stroke Length

Insert stroke in inches

to 0.1 inch. Enter as

a four-place number.

Valid lengths are 0050

to 1800. Example:

12.0 inch probe stroke

is entered as 0120.

convert a metric stroke

in millimeters, multiply

millimeter value by

0.03937 to arrive at inch

value.

To

X

Options

X = None

A standard 12 mm 5 pin micro connector is used. Straight mating

cables can be ordered in a 6’ length (949019L6), or 12’ length

(949019L12). If space is a consideration a right angle connector is

also available, (949020L6 or 949020L12).

* WARNING: do not use cord sets with LED’s

Differential Input

Power +

Supply

_

Customer Supplied Power (Brown)

Power Supply Common (Blue)

Program Input (White)

955A

LDT

Single Ended Input

Power +

Supply

_

Customer Supplied Power (Brown)

Power Supply Common

Program Input

(White)

955A

LDT

Note: 955A-C is current sourcing, which allows the current to flow from the LDT into

the user’s equipment.

Position Output (Black)

Position Common (Gray)

Position Output (Black)

(Blue)

+ Input

- Input

+ Input

Common

Loading...

Loading...