Mobile Equipment and Stationary Processing

Systems demand absolute accuracy and

reliability in linear position feedback . . .

Regardless.

Innovation, proprietary technology and decades of

experience were the key to the development of our 953

VMAX Linear Displacement Transducer.

We know the manufacturing challenges of today are

extreme, so we designed and built a sensor to meet and

exceed these demands, regardless of the application or

environment.

Introducing the 953 VMAX LDT features:

• High Vibration Resistance to 30 Gs (lab tested)

• High Shock Resistance to 1000 Gs (lab tested)

• Wide Input Power Range of 7 to 30 VDC

(no need to specify different models)

• High Accuracy with High Resolution

• Applications Include All Mobile/Stationary Equipment, or

Both with the Same Sensor

• Sensor Lengths up to 300”

• Durability and Reliability Exceeds Competitive Offerings

• Tri-Color Diagnostic LED Indicator

• Gives Quick Indication on the Status of the LDT

• Very Low Power Consumption, 1 Watt Typical, Allows

Direct Connection to Display and Control Interface

Modules

• Removable Cartridge for Hydraulic Applications

• Digital Output, Start/Stop, Variable Pulse (PWM),

Control Pulse

• SSI (Synchronous Serial Interface), 24, 25 or 26 Bit,

Binary or Gray Code, Position Update

• Analog Output, 0-10 VDC, +/-10 VDC, 0-5 VDC,

+/-5 VDC, 4-20mA

• Contaminant Resistant

• IP68 Rated

• Optional Stainless Steel Cover and Connector

• Multi-Magnet Option (Digital Start/Stop only)

953A/D/SSI VMAX™ LDT

Applications Include

Absolute linear position feedback for equipment and

process automation in extreme applications.

Process Automation

• Steel Mills, Primary and Secondary Metals Processing

that includes Stamping, Roll Forming and Die-Casting

• Hydraulic & Pneumatic Cylinders

• Adaptive Housing Options to Withstand Extreme

Temperatures and Contaminants

(Gemco 950MD units)

Mobile Equipment

• Lumber and Forest Products Processing

• Refuse Collection, Vehicles, Recycling and

Compaction

• Off Road

953

Removable

Cartridge

Stationary Machines

• Sawmill, Plastic, Rubber, Injection Molding, Extrusion

Equipment, Material Handling, Nonwoven, Dancers

and Accumulators

953SSI

Connector

Interface

953D

Connector

Interface

953A

Connector

Interface

Sensor Housing

and Mounting

Hex

Displacement

Dead Band

Null Zone

Enclosure Rating

953SSI

Resolution

953D

Resolution

953A

Resolution

Internal

Output

6 Pin 12mm Euro micro,

Integral cable ass'y, 7 Pin or 8 Pin DIN

6 Pin 12mm Euro micro,

Integral cable ass'y, 6 Pin or 8 Pin DIN

5 Pin 12mm Euro micro,

Integral cable ass'y, 6 Pin or 8 Pin DIN

Body length 3.2”, hex base 1 3/4” dia., 3/4”x16x1”

thread. Aluminum housing standard, stainless

steel optional.

1” to 300"

2.50" (63.5 mm) standard

2.00" (50.8 mm) standard

IP68, IEC 600529

English or Metric Units

Metric: 1, 5, 10, 20 micron (5 micron standard)

English: .00005", .0001", .0005", .001"

Consult Factory for Others.

Controller Dependant

0.00006”

16-Bit

*One watt typical at 1ms interrogation time with no recirculations. Faster interrogation times and/or recirculations increase power consumption.

953A/D/SSI VMAX™ LDT

Specifi cations

Shock

Vibration

953SSI Update Time

953D Update Time

953A Update Time

Guide Tube Pressure

Approvals

Input Voltage

Current Draw

953A Zero & Span

Adjustability

953D Repeatability

953A Repeatability

953SSI Repeatability

953SSI Measured

Variables

NOTE:

Speci cations subject to change and are based on a typical 48” stroke.

1000 Gs (lab tested)

IEC 60068-2-27

30 Gs (lab tested)

IEC 60068-2-6

Measuring

Length 300 750 1000 2000 5000mm

Measurements/

sec.

Controller Dependant

< 2mS Typical

5,000 psi continuous

(10,000 psi spike)

CE (EMC)

7 to 30 VDC

1 watt typical*, 40mA at 24 VDC typical

Factory set at Null & Dead Band locations

Field re-settable at any location within active stroke

Equal to Resolution of Controller

Equal to Resolution

Equal to Output Resolution

Single Magnet Displacement, Consult Factory for

Velocity or Differential Operation

3.7k 3.0k 2.3k 1.2k 0.5k

953SSI Output

953D Output

953A Output

Voltage

Current

953A Current Output

953A Voltage Output

Hysteresis

Non-linearity

Storage Temperature

Operating

Temperature

Head

Guide Tube

Diagnostics

24, 25 or 26 Bit, Binary or Gray Code

(optional parity and error bit),

Position Update

RS = RS422 Start/Stop Pulse

VP = RS422 Variable Pulse (PWM),

Internal/External Interrogation

CP = RS422 Control Pulse

TP = TTL Start/Stop Pulse

0-10 VDC, +/-10 VDC, 0-5 VDC, +/-5 VDC

4-20mA

Max Load Resistance: 500 Ohms

Minimum Load Resistance: 2K Ohm

Output Current: Guaranteed 5mA minimum

Analog Ripple: 1 mV maximum

0.001”

< 0.01% or +/- 0.005”, whichever is greater,

(+/- 0.002 Typical)

-40° to 221° F

(-40° to 105° C)

-40° to 185° F ( -40° to 85° C)

-40° to 221° F (-40° to 105° C)

ri-Color LED beside connector/cable exit,

T

See 'LED Output Summary Table' on page 39

SSI (Synchronous Serial Interface)

Displacement value is encoded into a 24, 25 or 26 Bit

format and transmitted at high speeds. Synchronization

in a closed loop system is made easy. A clock pulse train

953

from a controller is used to gate out sensor data: one bit

of position data is transmitted to the controller per one

clock pulse received by the sensor. The absolute position

data is continually updated by the sensor and converted

by the shift register into serial information. The sensors

fulfi ll all requirements to the SSI standard for absolute

encoders.

S Connector Style

5 or 6 Pin Micro, 12mm Euro

M Connector Style

6 Pin DIN, Fits MTS D60

7 Pin DIN, Fits MTS D70 (for SSI only)

Stainless Steel

Cover and Connector

8 Pin DIN, Fits Balluff S32

B Connector Style

C Connector Style

Integral Cable Assembly

Analog Part Numbering

953A/D/SSI VMAX™ LDT

953A 0120V0 X

V0

V1

V2

V3

V4

V5

V6

V7

C4

C2

Output

0 to 10 VDC

10 to 0 VDC

-10 to 10 VDC

10 to -10 VDC

0 to 5 VDC

5 to 0 VDC

-5 to 5 VDC

5 to -5 VDC

4 to 20mA

20 to 4mA

X

Standard 2 inches.

N_

Insert non-standard Null Zone over 2 inches.

Stroke Length

Insert stroke length to 0.1 inch. Enter as a four-place

number. Example: A 12.0” stroke enters as 0120.

OR

Insert stroke in millimeters to 1mm. Enter as a

four-place number. Example: 305mm stroke entered

as 0305M. Metric length includes metric mounting,

M18x1.5.

Null Zone

Dead Band

X

Standard 2.5 inches.

Insert non-standard Dead

D_

Band over 2.5 inches.

S

C_

M

B

SXX

Connector Option

Standard 5 Pin, 12mm Euro

Integral Cable Assembly. Insert length

in feet. Example: C6 = 6 foot cable.

6 Pin DIN, MTS Style D60

8 Pin DIN, Balluff S32

Options

X

None

Stainless Steel cover and

connector. Only available

S

with connector options S

and C.

SSI Part Numbering

953S 0120 1

Stroke Length

1" to 300". Insert stroke length to 0.1 inch.

Enter as a four-place number. Example: A 12.0”

stroke enters as 0120.

OR

Insert stroke in millimeters to 1mm. Enter as

a four-place number. Example: 305mm stroke

entered as 0305. Metric length includes metric

mounting, M18x1.5.

X

N_

VP

Units

Blank

Inches

Metric Base

M

and Threads

Null Zone

Standard 2 inches.

Insert non-standard Null Zone

over 2 inches.

Dead Band

X

Standard

2.5 inches

Insert non-standard Dead Band

D_

over 2.5 inches.

Connector Option

S

Standard 6 Pin, 12mm Euro

Integral Cable Assembly. Insert length in

C_

feet. Example: C6 = 6 foot cable.

M

7 Pin DIN, MTS Style D70

B

8 Pin DIN, Balluff S32

.

SXX

Data Length

1

2

3

24 Bits

25 Bits

26 Bits

Data Format

Position Update

S

A

F

R

V

B

S

B

Binary

G

Gray

Synchronous

Asynchronous

Direction

Measures Direction Forward

Measures Direction Reverse

Velocity

Resolution

1

2

3

4

5

6

7

8

9

A

B

F

.005mm

.01mm

.05mm

.1mm

.02mm

.002mm

.001mm

.00005"

.0001"

.0005"

.001"

1

X

A

S

X

Options

None

Alarm Bit 25, Parity 26

Stainless Steel cover and

connector. Only available with

connector options S and C.

953

Digital, CP and RS Part Numbering

953A/D/SSI VMAX™ LDT

953D 0120RS

Output

CP

Control Pulse

RS

RS-422 Start/Stop Pulse

Stroke Length

Insert stroke length to 0.1 inch. Enter as a four-place number.

Example: A 12.0” stroke enters as 0120.

OR

Insert stroke in millimeters to 1mm. Enter as a four-place number.

Example: 305mm stroke entered as 0305M. Metric length includes

metric mounting, M18x1.5.

Digital, VP (PWM) Part Numbering

953D 0120VP I

Output

VP

Variable Pulse

953

Insert stroke length to 0.1 inch. Enter as a

four-place number. Example: A 12.0” stroke

enters as 0120.

OR

Insert stroke in millimeters to 1mm. Enter as

a four-place number. Example: 305mm stroke

entered as 0305M. Metric length includes

metric mounting, M18x1.5.

Stroke Length

X

N_

Dead Band

X

Standard

2.5 inches

Insert non-standard Dead Band

D_

over 2.5 inches.

Connector Option

S

Standard 6 Pin, 12mm Euro

Integral Cable Assembly. Insert length

C_

in feet. Example: C6 = 6 foot cable.

M

6 Pin DIN, MTS Style D60

B

8 Pin DIN, Balluff S32

Dead Band

X

Standard

2.5 inches.

Insert non-standard

D_

Dead Band over 2.5

inches.

Null Zone

Standard 2 inches.

Insert non-standard Null

Zone over 2 inches.

Connector Option

S

Standard 6 Pin, 12mm Euro

Integral Cable Assembly. Insert

C_

length in feet.

Example: C6 = 6 foot cable.

M

6 Pin DIN, MTS Style D60

B

8 Pin DIN, Balluff S32

SXX

.

SXX

Options

X

None

Stainless Steel cover and

connector. Only available

S

with connector options S

and C.

001

X

S

X

X

Options

None

Stainless Steel cover and

connector. Only available

with connector options S

and C.

Null Zone

X

Standard 2 inches.

N_

Insert non-standard Null Zone over 2 inches.

NOTE: Metric LDTs cannot be used with standard 950MD housings. Consult

factory.

Interrogation Mode

I

Internal Interrogation

E

External Interrogation

Number of

Recirculations

001

001 (Standard) to 255

953A/D/SSI VMAX™ LDT

953 LED Output Summary

Output 953A 953D 953SSI

Flashing Red Flash memory corrupt Flash memory corrupt Flash memory corrupt

Flashing Red/Green EE memory corrupt EE memory corrupt EE memory corrupt

Flashing Green N/A N/A N/A

Flashing Yellow Communication/programming mode Communication/programming mode Communication/programming mode

Fast Flashing Yellow Programming input held asserted Interrogation input held asserted Clock input held asserted

Solid Red No magnet signal detected No magnet signal detected No magnet signal detected

Green/Red Blip (1s to 0.12s) N/A Max Gain but signal detected and within range Max Gain but signal detected and within range

Solid Green Magnet signal detected and within the

programmed range

Solid Yellow Magnet signal detected outside of the

programmed range

Yellow/Red Blip (1s to 0.12s) N/A N/A SSI clock pulses do not match

Green/Yellow Blip (1s to 0.12s) N/A N/A LDT data not synchronous with controller

Normal probe operation; magnet signal and

interrogation pulse detected

No external interrogation pulse detected No SSI clock pulses detected

Normal probe operation; magnet signal

and SSI clock operational

LDT SSI data length

(if LDT is programmed for synchronous mode)

953

953A/D/SSI VMAX™ LDT

Magnets

Part Number Description

SD0400800 Standard Four Hole Magnet

SD0480900 Standard Four Hole Magnet, Stainless Steel

SD0403900 Aluminum Split Magnet

SD0411201 Large Split Magnet, Stainless Steel

SD0411200 Large Split Magnet, Standard

SD0410300 Cylinder Magnet, Standard

SD0410301 Cylinder Magnet, Te on Coated

M0750500 Non-Ferrous Spacer for Split Magnet

M0822400 Non-Ferrous Spacer for Four Hole Magnet

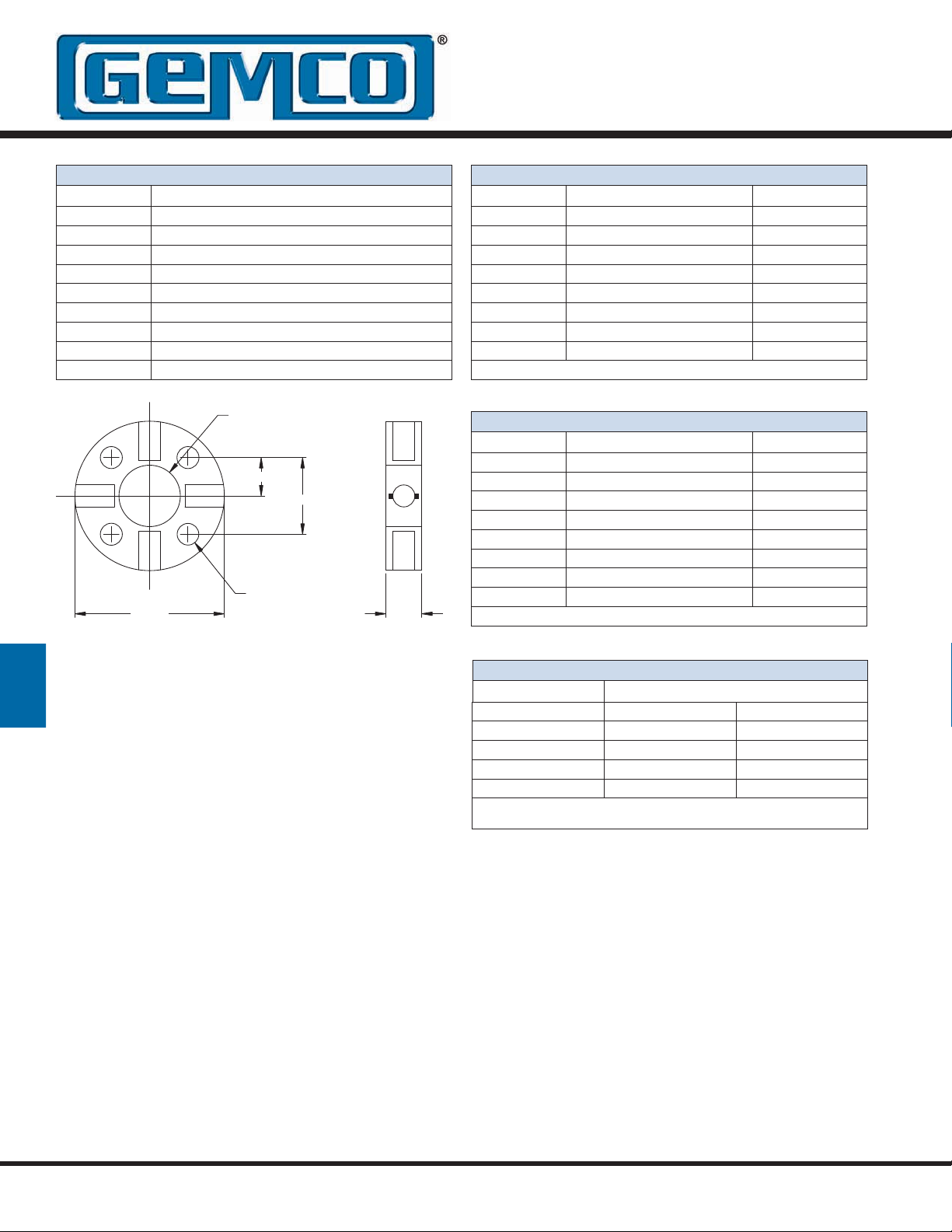

S

S

N

N

N

N

S

1.29

.53

.331 TYP.

S

.662 TYP.

.187

4 PLACES

.31

953A Accessories

Part Number Description Use With Connector

949011L6 6 Foot, 5 Pin, Straight, 12mm Euro Cable S

949011L12 12 Foot, 5 Pin, Straight, 12mm Euro Cable S

949012L6 6 Foot, 5 Pin, Right Angle, 12mm Euro Cable S

949012L12 12 Foot, 5 Pin, Right Angle, 12mm Euro Cable S

SD0553200LXX 6 Pin DIN M

SD0553300LXX 8 Pin DIN Voltage B

SD0553400LXX 8 Pin DIN Current B

SD0400800 Standard 4 Hole Magnet All

Consult factory for complete accessory offerings. XX = Length in Feet.

953D/953SSI Accessories

Part Number Description Use With Connector

949029L6 6 Foot, 6 Pin, Straight, 12mm Euro Cable S

S

949029L12 12 Foot, 6 Pin, Straight, 12mm Euro Cable S

949030L6 6 Foot, 6 Pin, Right Angle, 12mm Euro Cable S

949030L12 12 Foot, 6 Pin, Right Angle, 12mm Euro Cable S

SD0554500LXX 6 Pin DIN (953D) M

SD0558500LXX 7 Pin DIN (953SSI) M

SD0554600LXX 8 Pin DIN B

SD0400800 Standard 4 Hole Magnet All

Consult factory for complete accessory offerings. XX = Length in Feet.

953

Standard 4 Hole Magnet

Standard P/N: SD0400800

Stainless Steel P/N: SD0480900

SSI Cable Length Limits

Baud Rate Max. Cable or Bus Length

1 MBd 10 ft. 3 m

400 kBd 160 ft. 50 m

300 kBd 320 ft. 100 m

200 kBd 650 ft. 200 m

100 kBd 1300 ft. 400 m

NOTE: The maximum cable length recommendation is 10 meters or 33 feet. Longer cables are available, but

extra care must be taken while handling and installing.

Loading...

Loading...