INSTALLATION MANUAL

LINEAR DISPLACEMENT TRANSDUCERS

951

™

Quik-Stik

II

Series 956

951 Series

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Preface

This manual is divided into three parts. Part 1 provides instructions

for the electrician on how to install and maintain the Series 951 Linear

Displacement Transducer (LDT). This includes wiring the LDT to

a power supply, an external device for monitoring or control, and/or

an interface device for programming. Part 2 provides programming

procedures and reference material for the programmer. This is necessary

when the LDT is connected to an interface device, such as a PC or

a hand-held programmer. Finally, Part 3 contains three appendixes:

Troubleshooting, Command Summary , and Specifi cations. To further

assist you in this manual, a glossary is also provided at the back.

AMETEK has checked the accuracy of this manual at the time it was

printed. Any comments you may have for the improvement of this

manual are welcomed.

AMETEK reserves the right to revise and redistribute the entire contents

or selected pages of this manual. All rights to the contents of this

manual are reserved by AMETEK.

Contents

Chapter 1: Hardware Overview ...............................................1

1.1 Model Number Code for Analog LDTs ...........................3

1.2 Model Number Code for Digital LDTs ............................4

Chapter 2: Installing the LDT ..................................................6

2.1 Installing the LDT to a Mounting Bracket .......................6

2.2 Installing the LDT to a Hydraulic Cylinder .....................8

Chapter 3: Wiring Connections ..............................................11

3.1 951A-V (Voltage) ...........................................................11

3.2 951A-C1/C2 (Current) ...................................................12

3.3 951CP (Controlled Pulse) ..............................................16

3.4 951VP (Variable Pulse) ..................................................18

3.5 951RS/TP (Start/Stop) ...................................................20

3.6 Communications Connections .......................................23

3.7 Connections to an Interface Device ...............................23

3.8 Hand-held Programmer as Your Interface Device .........24

3.9 Dumb Terminal or PC as Your Interface Device ...........24

Chapter 4: Programming ........................................................26

4.1 Devices Used to Program the LDT ................................27

4.2 Programming through a PC or Dumb Terminal .............27

4.3 Programming through the Hand-held Programmer .......27

4.4 Analog Program Commands Defi ned ............................28

4.5 Digital Program Commands Defi ned .............................39

Appendix A: T roubleshooting .................................................49

Appendix B: Command Summary .........................................52

Appendix C: Specifi cations .....................................................54

Glossary .....................................................................................57

Notes

Chapter 1: Hardware Overview

Chapter 1: Hardware Overview

The Gemco Series 951 QUIK-STIK II is a line of magnetostrictive linear displacement transducers (LDT). Each LDT offers highly accurate position and

optional velocity sensing. The LDT also is built to withstand the most severe

environment conditions. The cornerstone to this new style of LDT is its patented sensing and temperature compensating techniques. The LDT is completely absolute. Power loss will not cause the unit to lose positional information or require re-zeroing. Also, the non-contact design allows this device to be

used in highly repetitive applications without mechanical wear.

NOTE: There are a variety of different types of LDTs that the factory offers.

The model number on you LDT is a record of all the specific

characteristics that make up your unit. This includes what type it is:

analog or digital; its output signal and range; stroke, null, and dead

band length; and type of connector the unit uses. For a translation of

the model number, see pages 3 and 4.

The following is a list of several unique features the QUIK-STIK II provides:

n Each QUIK-STIK II LDT requires a single-ended power

supply. This eliminates the need for a dual-ended power

supply.

n Analog LDTs are completely field programmable for zero

reference, span, voltage type, and polarity. Digital LDTs are

programmable for the number of recirculations, wire speed,

internal or external interrogation, and change of mode (i.e.

controlled pulse to variable pulse, etc.).

n Programming is accomplished through an RS-232 data link.

This eliminates the need for removing the LDTs head cover

which would expose the devices electronics to potential

hazards.

n Programming interface can be accomplished through a

dumb terminal or a PC with a terminal emulator software

package, including PROCOMM PLUS or Terminal for

Windows . A portable hand-held programmer is also

available from the factory.

®

Installation, Maintenance, and Programming Manual

1

Chapter 1: Hardware Overview

n The LDTs serial port can supply position information

directly to computers not set up for analog or digital inputs.

Custom programming and/or protocols are available.

n The onboard microprocessor makes the QUIK-STIK II LDT

the most versatile system available on the market.

2

Installation, Maintenance, and Programming Manual

Chapter 1: Hardware Overview

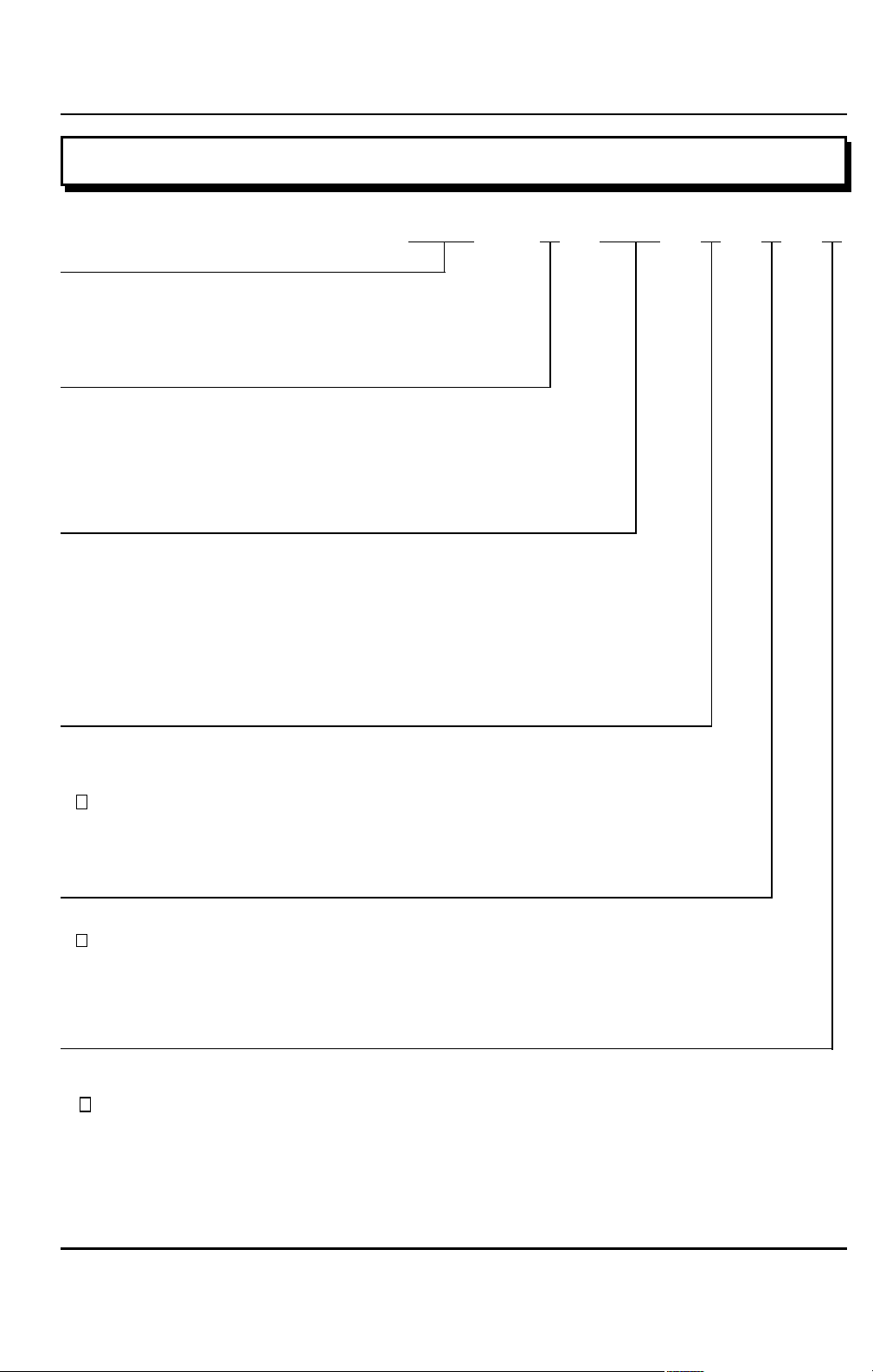

1.1: Model Number Code for Analog LDTs

QUIK-STIK II LDT

951A - V - 0120 - X - X - E

A = Analog

Output Type

V = Voltage

C1 = 4-20 mA Grounded (Sourcing)*

C2 = 4-20 mA Ungrounded (Sinking)

Stroke

Insert stroke in inches to .1. Enter as a four-place

number. For example, 12.0 = 0120.

Millimeter measurements do not contain a decimal

and are followed by the letter M. For Example,

12 mm = 0012M

Null

Null Dimension

X = Standard 1.5 inch Null

N = Insert non-standard Null over 1.5 inches

(Add non-standard portion of Null length to stroke length to calculate list price)

Dead Band

X = Standard Dead Zone of 2.25 inches

D = Insert non-standard Dead Zone over 2.25 inches

(Add non-standard portion of Dead Zone length to stroke length to calculate

list price)

Connector

E = Environmental MS Connector*

C = Potted Pigtail Cable Assembly. Insert pigtail length in feet.

TM

TM

or III)

or III)

TM

or III)

T = Threaded Metal Connector (fits MTS® - RB on Tempo II

Q = Bayonet Style Connector (fits MTS® - RC on Tempo II

M = 1/4 Turn Quick Disconnect (fits MTS® - MS on Tempo II

*Preferred Method

**If option E (Environmental Connector) is selected, mating connector and/or pigtail must be ordered separately.

Installation, Maintenance, and Programming Manual

3

Chapter 1: Hardware Overview

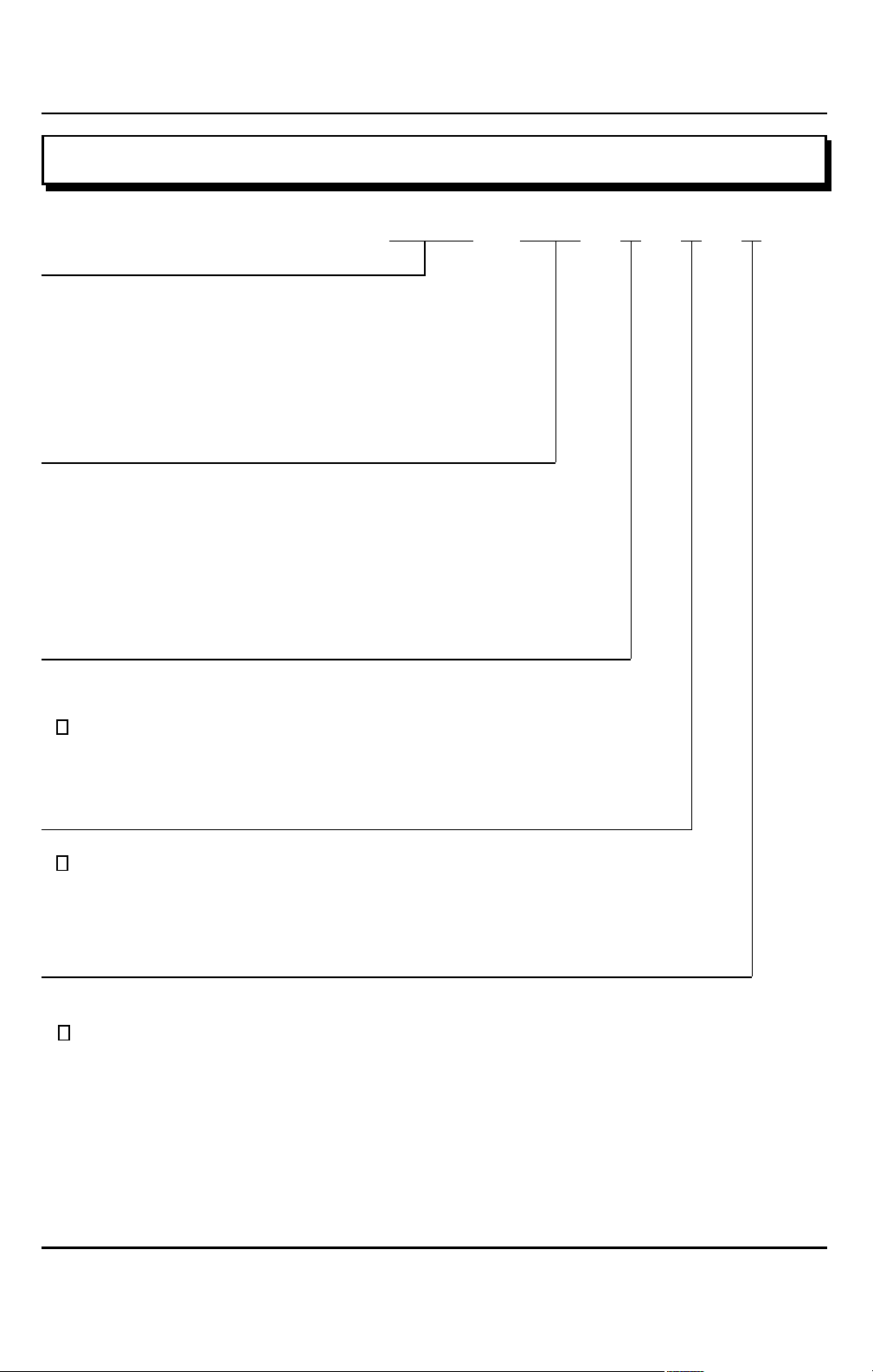

1.2: Model Number Code for Digital LDTs

951CP - 0120 - X - X - E

QUIK-STIK II LDT

CP = Controlled Pulse

VP = Variable Pulse

RS = RS422 Start/Stop Pulse with Interrogation

TP = Start/Stop Pulse

Stroke

Insert stroke in inches to .1. Enter as a four-place

number. For example, 12.0 = 0120.

Millimeter measurements do not contain a decimal

and are followed by the letter M. For Example,

12 mm = 0012M

Null

Null Dimension

X = Standard 1.5 inch Null

N = Insert non-standard Null over 1.5 inches

(Add non-standard portion of Null length to stroke length to calculate list price)

Dead Band

X = Standard Dead Zone of 2.25 inches

D = Insert non-standard Dead Zone over 2.25 inches

(Add non-standard portion of Dead Zone length to stroke length to calculate

list price)

Connector

E = Environmental MS Connector*

C = Potted Pigtail Cable Assembly. Insert pigtail length in feet.

TM

TM

or III)

or III)

TM

T = Threaded Metal Connector (fits MTS® - RB on Tempo II

Q = Bayonet Style Connector (fits MTS® - RC on Tempo II

M = 1/4 Turn Quick Disconnect (fits MTS® - MS on Tempo II

or III)

*If option E (Environmental Connector) is selected, mating connector and/or pigtail must be ordered separately.

4

Installation, Maintenance, and Programming Manual

Chapter 1: Hardware Overview

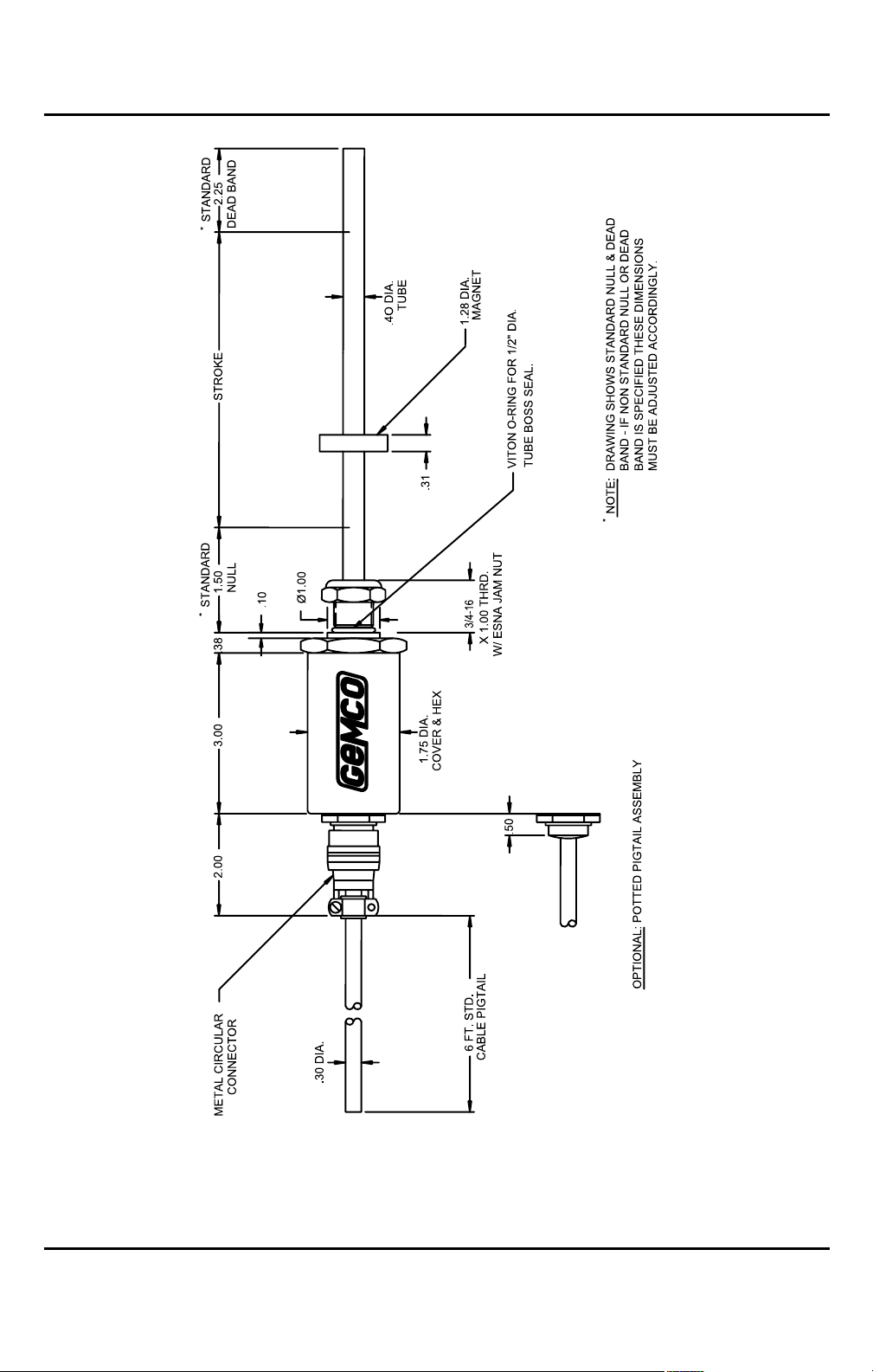

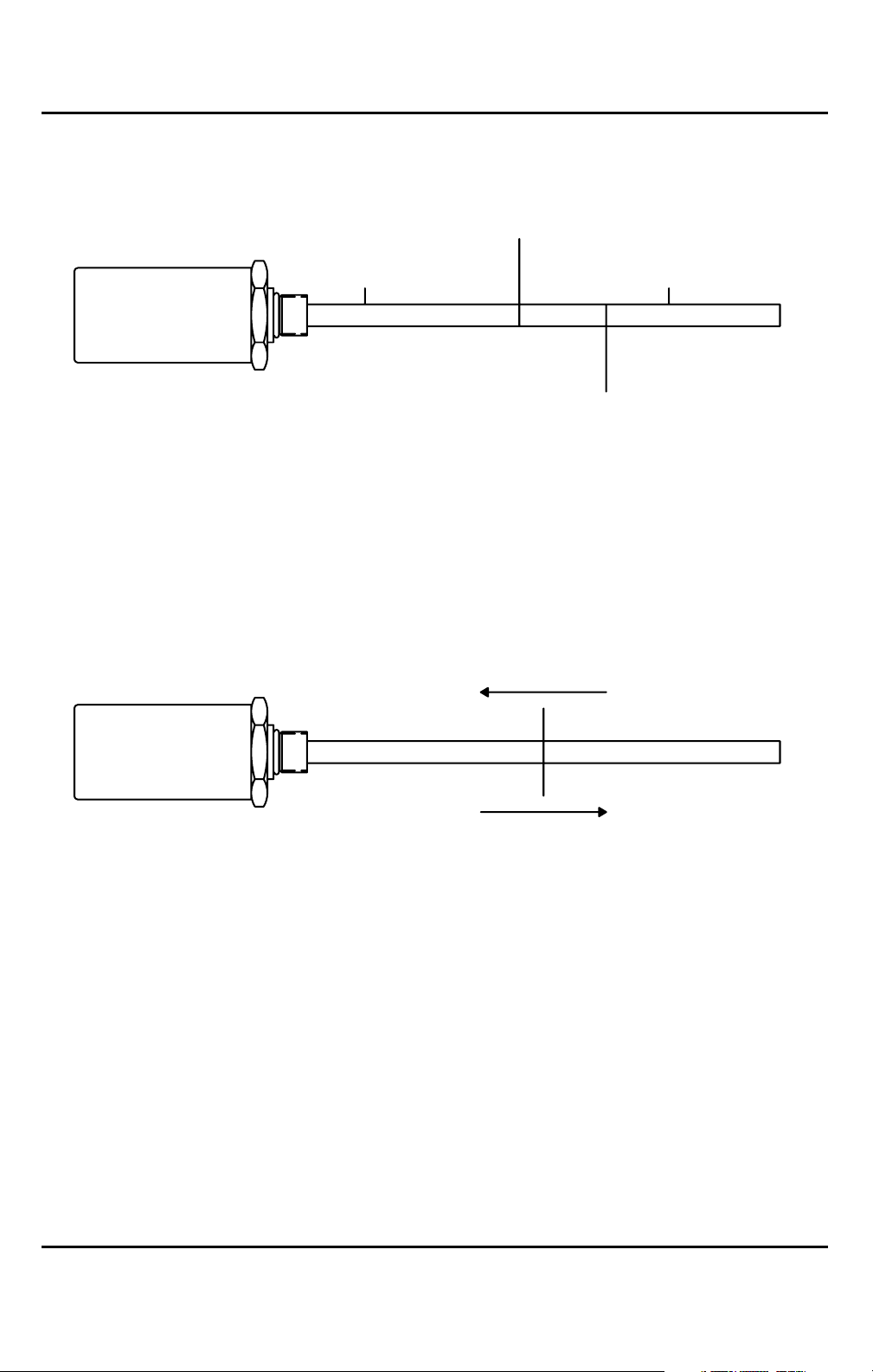

Figure 1-1 Series 951 Linear Displacement Transducer

Installation, Maintenance, and Programming Manual

5

Chapter 2: Installing the LDT

Chapter 2: Installing the LDT

Before installing the LDT, you should consider the following:

n If you are using mounting brackets made of a ferromagnetic

material (a material readily magnetized), they should be

placed no closer than 0.25 into the area of the devices

guide rail.

n To minimize the effects of magnetic flux distortion (which

could cause an inaccurate measurement of the magnets

position), ferromagnetic material should not be placed closer

than 0.25 from the magnet.

2.1: Installing the LDT to a Mounting Bracket

Perform the following steps to install your LDT to a mounting bracket. To

assist you in finding the position of parts that are discussed in this section,

refer to Figure 1-1. If you are installing your LDT into a hydraulic cylinder,

refer to Section 2.2 Installing the LDT into a Hydraulic Cylinder.

1. Unscrew the LDTs jam nut from the threads protruding

from the hex mounting base.

2. Insert the LDTs guide rail into the mounting brackets hole.

Your mounting bracket may contain a 3/4 - 16 UNF - 2B

threaded hole. In this case, you will need to screw the LDT

into this hole using the threads protruding from the hex

mounting base.

3. Once the LDT is in place, screw the jam nut back onto the

threads of the hex mounting base. Use the 1.75 hex

mounting base on the head assembly to tighten the LDT

within the bracket.

WARNING: Do not use the head assembly casing to tighten the LDT within

the bracket. This may damage the LDT and will void your warranty

If the length of your LDTs guide rail is less than 30, ship to the sub-section:

Mounting the Magnet Assembly.

6

Installation, Maintenance, and Programming Manual

Chapter 2: Installing the LDT

Installing Support Brackets

It is recommended that a support bracket be used with LDTs having a guide

rail 30 - 71 in length. Supporting the end of the guide rail will minimize

operational errors and protect against damage due to shock and vibration. If

the length of your LDTs guide rail is 72 or longer, it is recommended that you

use additional support brackets. These additional support brackets must be

made of a non-magnetic material. Because these additional support brackets

will interfere with the magnets movement, a special split-type magnet assembly (part number SD0411200) must be used. To order a split magnet and

support brackets (part number SD0411100), contact factory.

To install a support bracket for a LDT having a guide rail 30 - 71 in length,

perform step 4a. If your guide rail is longer than 71, perform step 4b.

4a. If the support bracket is made of a ferromagnetic material

(material readily magnetized), install the support bracket no

closer than 0.25 from where the guide rails dead band

ends and the area of stroke begins. Continue to the subsection: Mounting the Magnet Assembly.

Install two or more support brackets for an LDT having a guide rail of 72 or

longer in length, perform the following steps:

4b. Install support brackets at increments of 48 throughout the

LDTs guide rail. Support brackets placed within the null

zone and area of stroke or closer than 0.25 to the beginning

of these areas must be made of a non-magnetic material.

Mounting the Magnet Assembly

Before mounting the magnet assembly, you should consider the following:

n Ferromagnetic material should not be placed closer than

0.25 from the LDTs magnet assembly or guide rail. Failure

to do so could cause magnetic flux distortion which would

lead to erratic operations of the magnets position. Materials

with non-magnetic properties, such as brass, copper, aluminum, non-magnetic stainless steel, or plastics, can be in

direct contact with the magnetic assembly and guide rail

without producing any adverse results.

Installation, Maintenance, and Programming Manual

7

Chapter 2: Installing the LDT

n Minimal clearance between the LDTs guide rail and the

magnet assembly is required. Stress between the magnet

and the guide rail can cause flexing of the mounting brackets. This can cause the appearance of excessive hysteresis.

n LDTs using a split magnet assembly must keep the diameter

of the magnet assembly within the guide rail throughout the

complete stroke. The diameter of this magnet assembly

should not be farther than 0.2 away from the guide rail.

Split magnet assemblies outside this range will cause signal

loss.

To install the magnet assembly, perform the following steps:

1. Slide the magnet assembly over the LDT guide rail.

2. Mount the magnet to the non-magnetic, movable portion of

the device being controlled using non-magnetic screws.

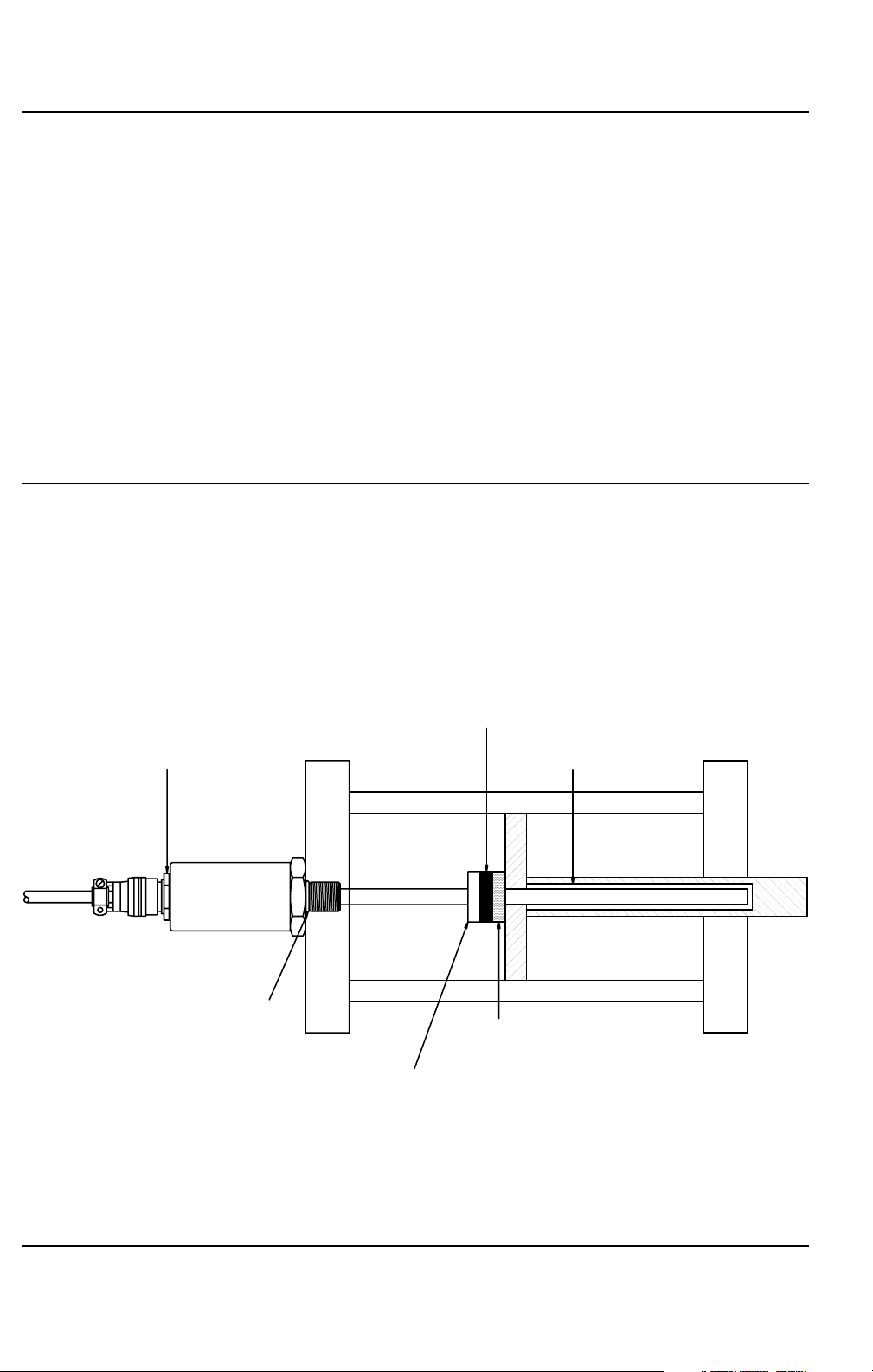

2.2: Installing the LDT to a Hydraulic Cylinder

Before mounting an LDT within a hydraulic cylinder, note the following considerations. Also, to assist you in finding the positions of parts that are discussed in this section, refer to figures 1-1 and 2-1.

n A non-magnetic spacer must be used to separate the magnet

assembly from the head of the piston rod. See Figure 2-1.

n The magnet should not be closer than 1.5 from the base of

the LDTs hex head when the piston rod is fully retracted.

In instances where space restraints exist, it may be required

to countersink the magnet into the piston rod. Two magnets

are available for mounting to the piston rod: the standard

1.29 (in diameter, part number SD0400800) four-hole

magnet and a 1.0 magnet (part number SD0410300) de

signed exclusively for countersunk mounting applications.

The 1.0 magnet must be held captive with a snap ring.

n An O-ring groove is provided at the base of the LDTs mount-

ing hex for pressure sealing. The O-ring seal was designed

to meet Mil-Std-MS33656. Refer to SAE J514 for machining

of mating surfaces.

8

Installation, Maintenance, and Programming Manual

Chapter 2: Installing the LDT

n It is recommended that a chamfered rod bushing be used

with LDTs having a guide rail 60.0 or longer in length. On

applications with guide rails of this length, a chamfered rod

bushing in front of the magnet may be required. This bushing will prevent wear to the aluminum material of the magnet assembly (wear occurs as the piston rod retracts from

extended lengths). This rod bushing should be manufactured from a high wear polymer, such as Teflon

® .

n It is recommended the bore for the cylinder piston rod have

an outside diameter of at least 0.50. It is also recommended that the LDT guide rail and end of guide rail have

an outside diameter of at least 0.40. Use standard practices

for machining and mounting these components. Consult

the cylinder manufacturer for details on applicable SAE or

military specifications.

Before performing the following steps for installing the LDT into a hydraulic

cylinder, you may need to perform machining and mounting tasks on your

hydraulic cylinder. Consult the information and specifications provided by the

cylinder manufacturer before beginning the following steps:

1. Unscrew the LDTs jam nut from the threads protruding

from the hex mounting base.

2. Position the non-magnetic spacer against the piston face,

followed by the magnet and, finally, the chamfered rod

bushing. (If the length of the LDTs guide rail is 60.0 or

longer in length, it is recommended that you use a chamfered rod bushing).

3. Insert non-magnetic screws through the chamfered rod

bushing (if used), magnet, and non-magnetic spacer, and

secure items by tightening screws.

If the leading edge of the magnet will come closer than 1.5

from the base of the LDTs hex head when the piston rod is

fully retracted, you will need to countersink the magnet

assembly into the piston rod. Both the standard 1.29 fourhole magnet assembly (part number SD0400800) and the

1.0 magnet assembly (part number SD0410300) are designed exclusively for countersinking mounting applications.

If you have a 1.0 magnet assembly, you must use a snap

ring to hold it in place, since no mounting holes are in this

magnet.

Installation, Maintenance, and Programming Manual

9

Chapter 2: Installing the LDT

4. Insert the LDTs guide rail into the hole of the hydraulic

cylinders mounting bracket.

You may need to remove a protective covering for the

hydraulic cylinder before inserting the LDT. Also, the

mounting bracket may contain a 3/4-16 UNF - 2B threaded

hole. In this case, you will need to screw the LDT into this

hole using the threads protruding from the LDTs hex

mounting base.

WARNING: Do not use the casing of the head assembly or cable nuts (either a

1 1/6 or 1 3/16 cable nut) to tighten the LDT within the bracket

(see Figure 2-1). This may damage the LDT and will void your

warranty.

At this point, your LDT should now be properly installed inside the hydraulic

cylinder. You now may need to assemble parts of the hydraulic cylinder. For

assistance in this task, refer to the information provided by the cylinder manufacturer.

CABLE NUT

O-RING SEAL

STANDARD 4-HOLE MAGNET

0.5" BORE MINIMUM

MAGNET SPACER

OPTIONAL ROD BUSHING

Figure 2-1 Mounting LDT in Hydraulic Cylinder

10

Installation, Maintenance, and Programming Manual

Chapter 3: Wiring Connections

Chapter 3: Wiring Connections

Once the LDT has been installed, wiring connections can be made. There are

two groups of connections you will need to make, with a third group of connections that is optional. They are as follows:

n Power Supply Connections (including grounding and shield-

ing)

n LDT Output Connections

n Communications Connections (optional)

NOTE: When grounding the LDT, a single earth ground should be connected

to the power supply common (circuit ground). The LDT power supply

common (pin B) should be connected to the power supply common (-)

terminal. Pin C should be connected to the power supply positive

terminal (+). The LDT cable shield should be tied to earth ground at

the power supply. The LDT analog common as well as the RS-232

common should not be connected to earth ground and should be used

for connection to interface devices only. For assistance, refer to your

LDTs wiring drawing in this chapter.

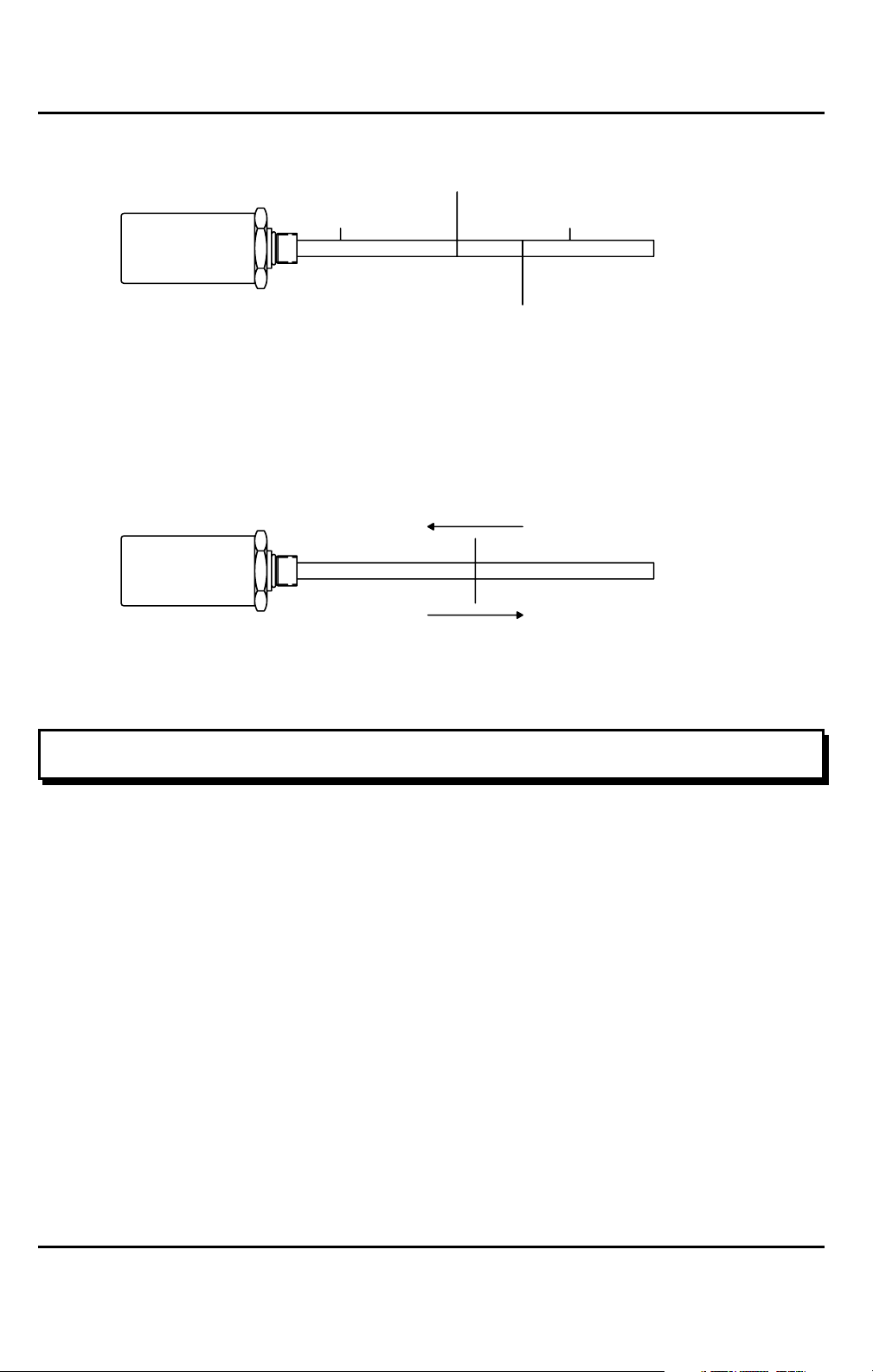

3.1: 951A-V (Voltage)

The 951A-V LDT generates a voltage output based on position. A voltage output based on velocity is optional. (Contact factory if you require a velocity.)

The voltage value of the velocity output will reflect the same voltage levels as

the position output. To understand how position and velocity outputs are

determined for a LDT based on voltage, see Figure 3-1. The parameters contained in this figure are used only as examples. These parameters are fully

programmable. To reconfigure these parameters, see Chapter 4: Programming. Further, note that velocity is typically ordered from the factory. However, LDTs ordered without velocity can be field configured for velocity output.

This is done through velocity setup software that can be provided by the factory.

Both outputs based on position and velocity are referenced to the analog common terminal and should not be referenced to any of the other common terminals. To wire the 951A-V LDT, see Figure 3-4. For proper grounding information, see note at the beginning of this chapter.

Installation, Maintenance, and Programming Manual

11

Chapter 3: Wiring Connections

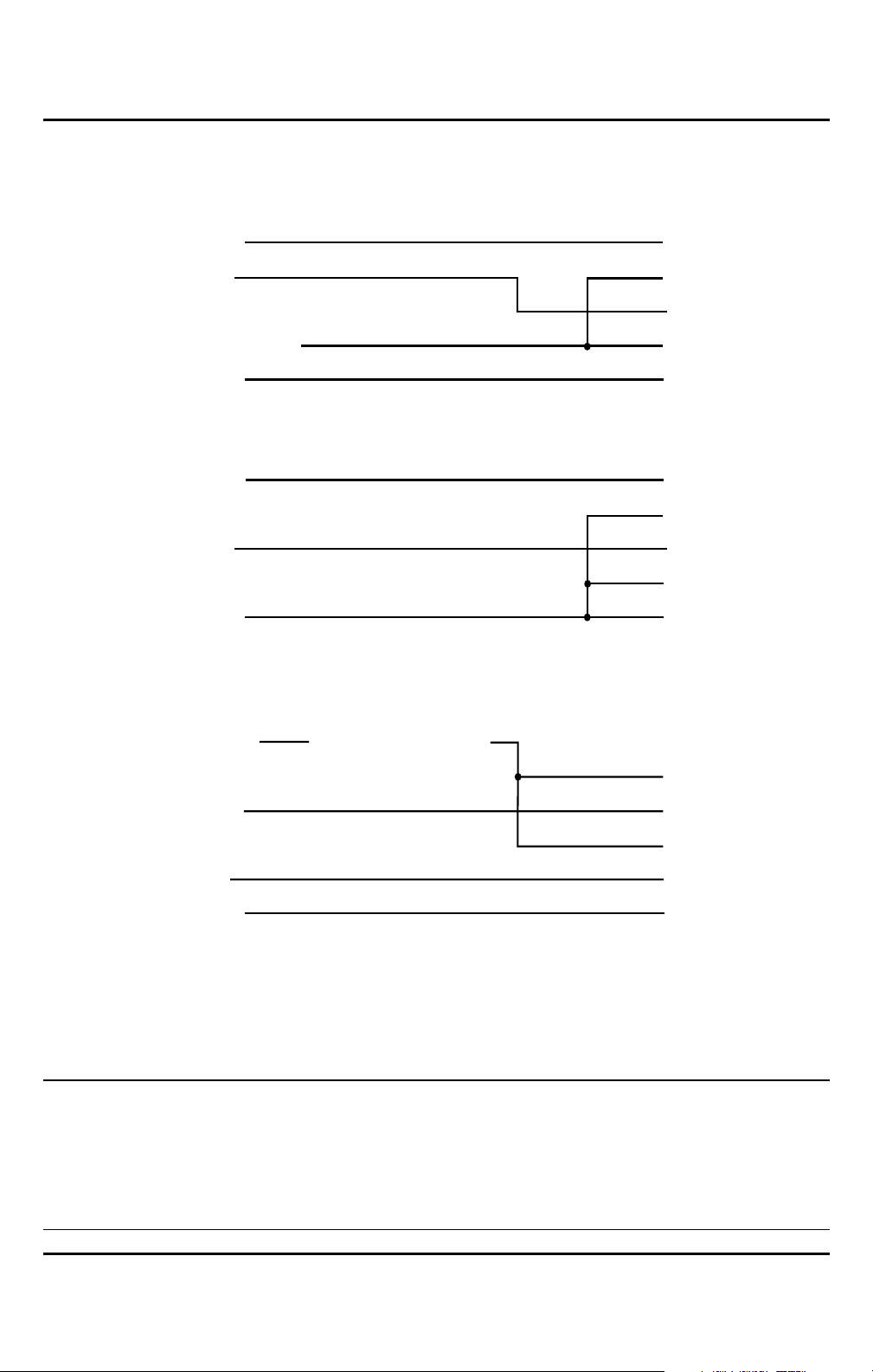

Full Scale Position = -10 to +10 VDC

Full Scale Position = 30" per second

Velocity direction toward tip of rod greater or more positive voltage

Velocity direction toward head generates less voltage

Output Voltage Range = -10 to +10 VDC

Output = -10 VDC when magnet is traveling at 30"/sec.

Output = -5 VDC when magnet is traveling at 15"/sec.

Output = 0 VDC when magnet is in center position

-10 +10

Output = +5 VDC when magnet is at 3/4 position

Output = +10 VDC when magnet is traveling at 30"/sec.

Output = +5 VDC when magnet is traveling at 15"/sec.

Figure 3-1 Examples of Position and Velocity Outputs for the 951A-V

3.2: 951A-C1/C2 (Current)

The 951A-C1/C2 LDT generates a current output based on position. A current

output based on velocity is optional. (Contact factory if you require velocity).

The current value of the velocity output will reflect the same current levels as

the position output. To understand how position and velocity outputs are

determined for an LDT based on current, see Figure 3-2. The parameters

contained in this figure are used only as examples. These parameters are fully

programmable. To reconfigure these parameters, see Chapter 4: Programming. Further, note that velocity is typically ordered from the factory. However, LDTs ordered without velocity can be field configured for velocity output.

This is done through velocity setup software that can be provided by factory.

Both outputs based on position and velocity are referenced to the analog common terminal and should not be referenced to any of the other common terminals. Note that the grounded style (standard) LDT sources the 4 to 20 mA

while the ungrounded style unit sinks the 4 to 20 mA. To wire the 951A-C1/

C2 LDT, see Figure 3-4. For proper grounding information, see note at the

beginning of this chapter.

12

Installation, Maintenance, and Programming Manual

Full Scale Position = 4-20 mA

Output = 12 mA when magnet is in center position

4 mA 20 mA

Output = 16 mA when magnet is at 3/4 position

Full Scale Position = 30" per second

Velocity direction toward tip of rod generates greater current

Velocity direction toward head generates less current

Output Voltage Range = 4-20 mA

Chapter 3: Wiring Connections

Output = 4 mA when magnet is traveling at 30"/sec.

Output = 8 mA when magnet is traveling at 15"/sec.

Output = 20 mA when magnet is traveling at 30"/sec.

Output = 16 mA when magnet is traveling at 15"/sec.

Figure 3-2 Examples of Position and Velocity Outputs for the 951A-C

Installation, Maintenance, and Programming Manual

13

Chapter 3: Wiring Connections

Grounded System

E/Brown/Positoin

F/Blue/Velocity

K/Grey/Analog Common

B/Black/Common

E/Brown/Positoin

F/Blue/Velocity

B/Black/Common

C/Red/Power Input

+Input

-Input

+Input

-Input

Common

-or-

+Input

-Input

+Input

-Input

Common

Ungrounded System

*(Customer Supply) +15 to + 26 VDC

+Input

E/Brown/Position

F/Blue/Velocity

B/Black/Common

*Customer power supply can feed both the LDT and the customer input card.

* NOTE: LDT sinks 4 to 20mA.

-Input

+Input

-Input

Common

Figure 3-3 Current Sourcing and Sinking

NOTE: 951A-C1 is for current sourcing which allows the current to flow from

the LDT into the users equipment. 951A-C2 is for current sinking

which allows the current to flow from the users equipment into the

LDT. Because higher currents can come from the users equipment,

which can cause damage to the LDT, current sourcing is the more

recommended method for current flow. See Figure 3-3.

14

Installation, Maintenance, and Programming Manual

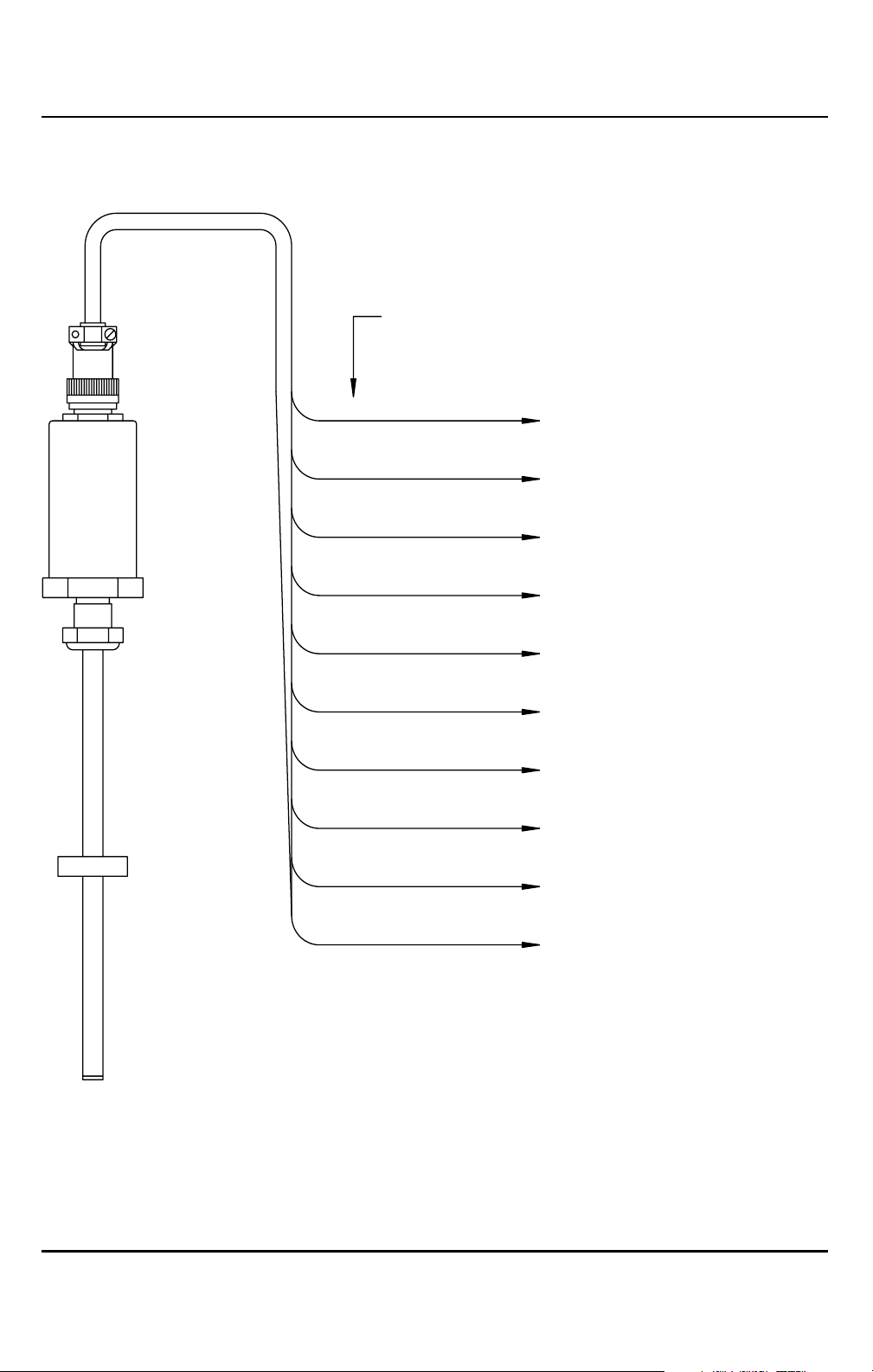

PIN-OUT FOR STANDARD

CIRCULAR CONNECTOR

AT TRANSDUCER HEAD

Chapter 3: Wiring Connections

PIN-B

PIN-C

PIN-K

PIN-E

PIN-F

PIN-A

PIN-G

PIN-D

PIN-H

BLACK

RED

GRAY

BROWN

BLUE

WHITE

ORANGE

GREEN

YELLOW

POWER SUPPLY

COMMON

+15/+26 VDC

POWER INPUT

POSITION/VELOCITY

COMMON

POSITION OUTPUT

VELOCITY OUTPUT

FRAME (NO CONNECTION)

RS232 RXD

RS232 TXD

RS232 COMMON

PIN-J

PURPLE

2nd POWER SUPPLY

COMMON

Figure 3-4 Analog Wiring Drawing

Drawing E0213900

Installation, Maintenance, and Programming Manual

15

Loading...

Loading...