Application

Gemco’s Rotary Limit Switches are primarily used for machine tools,

handling devices, and rotary operators where motion is expressed in

shaft rotation. The primary purpose of the switch is to control the

intermediate or end limits of a linear or rotary motion. The switch is

often used as a safety device to protect against accidental damage to

equipment.

Description

Quality parts make each Rotary Limit Switch highly dependable.

• The 1/2” input shaft (includes Woodruff Key) drives a bronze gear

which rotates the cam block. The cam block houses independently

adjustable cams that actuate the precision type snap action

switches.

• Each switch can be provided with one to four single pole, double

throw switches or a maximum of two double pole, double throw

switches for versatility of control circuits.

• No minimum speed is specified because snap action contacts are

used. Maximum rated speed of the worm shaft is 1000 RPM and

can be rotated clockwise or counterclockwise.

• Gemco’s Rotary Limit Switch offers the broadest range of standard

gear selections of any switch available. Standard ratios range from

5:1 through 5333.3:1.

• Max. Operating Temperature 180°F

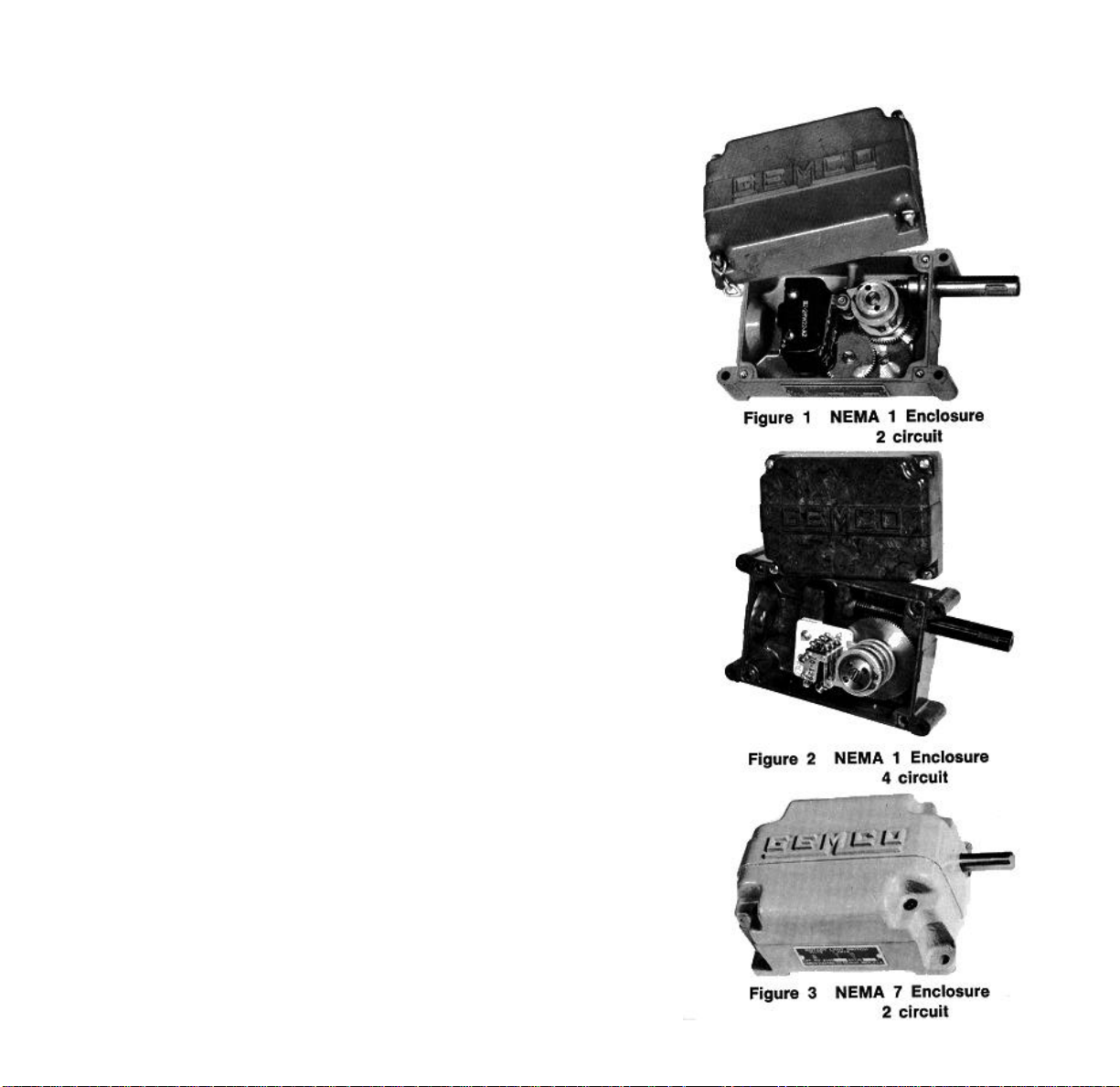

Enclosures

NEMA Type 1 and 12 (General Purpose) enclosures are molded from

FIBRALLOY® a special fiber glass material that is resistant to acids,

alcohols, hydro carbons and heat. A tight fitting synthetic gasket

prevents the entrance of oil and coolants. External mounting holes

enable switch mounting without internal interference. (See Figures 1

and 2.)

NEMA Type 4 (Watertight) enclosures are made of cast aluminum;

cast iron or cast bronze enclosures can be provided upon request.

NEMA Type 7 & 9 (Hazardous Location) enclosures are designed to

meet the requirements of the National Electrical Code for Class 1,

Group D, and Class 2.

Groups E, F & G. The enclosures are made of

cast aluminum; cast iron or bronze enclosures

can be provided upon request. (See Figure 3.)

Rotary Limit Switches

often pays for itself by eliminating cost of stampings

When the cam rotates, the switches "E" and "F" are actuated and the contacts

check these advantages.... worm gear type

The GEMCO Rotary Limit Switch

• reduces hazards to inexperienced users.

• removes danger of terminal shorting from water,

corrosion, or accidental shorting from other metal

objects because of its insulating properties.

• enclosures are made of FIBRALLOY® -- an electrical

insulator.

The GEMCO Rotary Limit Switch.

• reduces design time.

• reduces machine work on special cams and gears

for different operating ratios.

• cams are all standard regardless of ratios.

• offers special cams upon request.

The GEMCO Rotary Limit Switch.

•

and machined bushings in linkages.

• reduces assembly time.

Mounting

The switch may be mounted in any convenient position. An "L" shaped mounting bracket which permits innumerable

mounting positions for all enclosures, can be supplied upon request.

Adjustment

• Front cam "A"actuates switch "F";

rear cam "0" actuates switch "E".

• Both switches "E" and "F" have

independent adjustable cams.

• To adjust cam "A" loosen Allen

Screw "B".

• To adjust cam "0" loosen Allen

Screw "C".

change from the normally closed to open position and normally open to the

closed position.

worm gear type

.....plus a broad range of application

mechanical presses

Both die and press, worth thousands

the cost of the Gemco Rotary Limit

Switch, are safely protected when the

connecting rod length is adjusted.

loaders

You can control travel of

pushers, grabs, and other

reciprocating parts

handlers directly from

drive shafts.

One or more open and close

limits on pipe line, pumping

station and machinery valves

are accurately controlled with

Gemco Rotary Limit

Switches.

door operators

The Gemco Rotary Limit Switch is mounted on

the drive unit, with gear take-off from the main

drive shaft. Much wiring is eliminated. Cam

accuracy maintains door closing to practical limits.

valves

handling fixtures

Assures accurate movement

and placement of parts, plus

control of mechanical

clamping in welding,

induction heating or

machining fixtures.

hoists

Gemco switches on this line of hoists

protect power unit from damage by

controlling critical upper and lower limit.

windows

Gemco Rotary Limit Switches

are used for window

operators in skylights and

monitors, for central station

control.

motor operated valves

packaging machinery

tapping heads

elevating mechanisms

pipe threading machines

index tables

transformer tap changers

conveyors

Max Speed — 1000 RPM worm gear type

Input

Shaft

Rev.

Cam

Block

Rev.

5

10

20

30

40

50

60

80

100

150

250

300

500

600

1000

2000

4000

53333

Input

Shaft

Rev.

Cam

Block

Rev.

5

10

20

30

40

50

60

80

100

150

250

300

500

600

1000

2000

4000

5333.3

NEMA 1* & 12

Encl.

Catalog No. Catalog No. Catalog No. Max.

1 2000-1B

2000-38B

2000-2B

1 2000-3B

2000-4B

2000-5B

1 2000-6B

2000-7B

2000-8B

1 2000-129B

2000-28B

2000-130B

1 2000-29B

2000-131B

2000-30B

1 2000-292B

2000-279B

2000-281B

NEMA 1* & 12

Encl.

Catalog No. Catalog No. Catalog No. Max.

1 2000-137B

2000-138B

2000-25B

1 2000-47B

2000-139B

2000-73B

1 2000-75B

2000-77B

2000-43B

1 2000-1130B

2000-140B

2000-1133B

1 2000-141B

2000-1136B

2000-142B

1 2000-1139B

2000-1142B

2000-1145B

NEMA 4 Encl.

(1)

2000-98

2000-39B

2000-10B

2000-11B

2000-12B

2000-13B

2000-14B

2000-15B

2000-16B

2000-132B

2000-31B

2000-133B

2000-32B

2000-134B

2000-33B

2000-299B

2000-127B

2000-157B

NEMA 4 Encl.

(1)

2000-145B

2000-146B

2000-147B

2000-148B

2000-149B

2000-1508

2000-151B

2000-152B

2000-153B

2000-1131B

2000-154B

2000-1134B

2000-155B

2000-1137B

2000-156B

2000-1140B

2000-1143B

2000-1146B

NEMA 7 Encl.

(1)

2000-17B

2000-40B

2000-18B

2000-198

2000-20B

2000-21B

2000-22B

2000-23B

2000-24B

2000-135B

2000-34B

2000-136B

2000-35B

2000-43B

2000-36B

2000-291B

2000-128B

2000-158B

NEMA 7 Encl.

(1)

2000-159B

2000-160B

2000-161B

2000-60B

2000-1628

2000-163B

2000-164B

2000-165B

2000-166B

2000-1132B

2000-167B

2000-1135B

2000-168B

2000-1138B

2000-169B

2000-1141B

2000-1144B

2000-1147B

Input Shaft

Turns****

Setting

4 1/2

9 1/4

18

28

37

46

58

77

94

135

230

265

460

555

920

Consult

Factory

Input Shaft

Turns****

Setting

4 3/4

9 1/4

19

28 1/2

37 3/4

46 3/4

58

75

95

135

237

265

460

555

920

Consult

Factory

To

Reset

1/16

18

1/8

1/4

1/4

1/4

1 1/2

3/4

3/4

4

6

6 1/2

15 1/4

16

29

To

Reset

1/8

1/4

1/2

1/2

3/4

3/4

1 1/2

1 3/4

2

4

6

61 1/2

15 1/4

16

29

Input

Shaft

Rev.

Cam

Block

Rev.

5

10

20

30

40

60

80

100

150

250

300

500

600

1000

2000

4000

5333.3

Input

Shaft

Rev.

Cam

Block

Rev.

NEMA 1* & 12

Encl.

Catalog No. Catalog No. Catalog No. Max.

1 2000-174B

2000-175B

2000-176B

1 2000 177B

2000 178B

2000 179B

1 2000-180B

2000-181B

2000-182B

1 2000-170B

2000-183B

2000-187B

1 2000 184B

2000-1100B

2000-185B

1 2000-1103B

2000-1106B

2000-1109B

NEMA 1* & 12

Encl.

Catalog No. Catalog No. Catalog No. Max.

*Switch capacities: 125V. - 15 amps. AC., 1/2 amp. D.C.

15 amps. AC.. 1/4 amp. D.C.

460V. 15 amps. AC.

**Switch capacities: 125 or 250V. AC. - 10 amps.

125V. D.C. - 1/2 amp.

250V. D.C. - 1/4 amp.

(1) — For Cast Iron or Bronze Enclosure Contact Factory.

5

10

20

30

40

50

60

80

100

150

250

300

500

600

1000

2000

4000

5333.3

1 2000-89B

2000-90B

2000-91B

1 2000-92B

2000-93B

2000 94B

1 2000-95B

2000-96B

2000-97B

1 2000-1112B

2000-98B

2000-1115B

1 2000-99B

2000-1118B

2000-100B

1 2000-1121B

2000-1124B

2000-1127B

NEMA 4 Encl.

(1)

NEMA 7 Encl.

(1)

Input Shaft

Turns****

To

2000-188B

2000-189B

2000-190B

2000-191B

2000 192B

2000 193B

2000-194B

2000-195B

2000-196B

2000-171B

2000-197B

2000-300B

2000 198B

2000-1101B

2000-199B

2000-104B

2000-1107B

2000-11108

NEMA 4 Encl.

(1)

2000-263B

2000-264B

2000-265B

2000-266B

2000 267B

2000 268B

2000-269B

2000-270B

2000-271B

2000-186B

2000-272B

2000-301B

2000 273B

2000-1102B

2000-274B

2000-1105B

2000-1108B

2000-1111B

NEMA 7 Encl.

(1)

Setting

4 3/4

9 1/2

19 1/4

28 1/2

38

47

57 12

76 3/4

96 1/4

135

234

265

460

555

920

Input Shaft

Reset

1/16

116

1/8

1/4

1/2

1/2

12

12

1 12

4

2

6 1/2

7

16

10

Consult

Factory

Turns****

To

Setting

2000-101B

2000-102B

2000-103B

2000-104B

2000-105B

2000 106B

2000-107B

2000-1 088

2000-109B

2000-1113B

2000-110B

2000-1116B

2000-111B

2000-1119B

2000-112B

2000-1122B

2000-1125B

2000-1128B

***Switch capacities: 250V.

Mechanical rating - 20 million cycles

Electrical rating - 125V. AC. - 10 amps. resistive load.

250V. AC. - 10 amps. resistive load

30V. D.C. - 7 amps. inductive load

****Figures are based on a switch using a standard 25' cam:

maximum setting between limits.

2000-113B

2000-114B

2000-115B

2000-1 1 6B

2000-117B

2000-118B

2000-119B

2000-1 20B

2000-121B

2000-1114B

2000-122B

2000-1117B

2000-123B

2000-1120B

2000-124B

2000-1123B

2000-1 126B

2000-1129B

434

9 12

19 14

28 1/2

36

47

57 1/2

76 3/4

96 1/4

135

234

265

460

555

920

Reset

1/16

1/16

18

1

12

1 2

1/2

1/2

1 1/2

4

2

61/2

7

16

10

Consult

Factory

worm gear type

not listed, can be furnished on special order. When ordering, please

recommend the most suitable Gemco Rotary Limit Switch for your needs. Custom designed switches are

Special Cams*

Cam**

Part No.

S-55-A Standard 25° or 335°

S-68-A Special 540° or 306°

S-84-A Special 75° or 285°

S-69-A Special 90° or 270°

S-85-A Special 105° or 255°

S-86-A Special 135° or 225°

S-87-A Special 150° or 210°

S-70-A Special 180°

S-71-A Special 240° or 120°

S-127-A Special 360° Blank Cam

*Special cams

Ordering

When ordering desired switch, specify:

1. Catalog Number

3. Desired Gear Ratio

2. Number of Cams

4. Type of Enclosure

Example: If a four circuit standard enclosure, 5:1, is required with four 900 cams, order Catalog No.

2000-89 with four Part No. S-69-A Cams. See Special Cam Chart above.

specify cam angle.

Period for which switch contacts

are opened or closed

In selecting a gear ratio, maximum accuracy and ease of adjustment are more easily obtained if full

travel of drive equals, or is less than maximum setting between limits.

Example: If 90 revolutions of a window drive opens a window, a gear ratio of 100:1 should be selected.

Design Service

Gemco Design Engineers will be pleased to assist in the solution of any special control problems and to

available to specifications.

spur gear type

Superior Design and

Operating Features

Rotary Limit Switches

Application spur gear type

GEMCO's Spur Gear Type Rotary Limit Switch is used in applications

requiring ratios below 3:1 and 1:3 for controlling the end and/or

intermediate limits of reciprocating or rotary motion. This device

extends the present line of Gemco Rotary Limit Switches by providing

ultra-sensitive control for small increments of motion.

Many beneficial features include:

• Control of motor-operated valves, dampers and hopper gates used

in pipe lines, ventilating equipment and material handling systems.

• Improved environmental conditions for longer switch life.

• Smaller space requirements.

• Material and labor savings of reduced drilling, tapping, piping, and

wiring.

• Economies afforded when Gemco units are applied for many short

travel end limit uses instead of conventional lever operated limit

switches actuated by cams or dogs.

• Unique mounting which permit these switches to be installed in

convenient mounting positions. Mounting holes are provided for either

direct or sprocket drive applications in three different positions.

Description

The basic switch units are actuated by independently adjustable

cams which are driven by the input shaft. All cams are mounted on a

common block, which is directly coupled or geared to the drive shaft.

• Ratios

Standard geared ratios between the input shaft and cam block are

1:1, 1/2:1, 1/3:1, 2:1, and 3:1. The 1:1 ratio may be supplied with a

potenti-ometer gear coupled to the input shaft with ratios of 1:1, 1:2

and 1:3.

• Long Life Switches

Each enclosure can accommodate from two to four S.P.D.T.

switches. All switches are provided with silver to silver

contacts for reliability along with screw type terminals,

Figure 5 Sketch showing:

• independent adjustable cams A-D

• switches E-F

• Allen screws B-C for cam adjustment

Mounting

Unique mounting features permit these switches to be

installed in any of three different positions. Mount-ing holes

are provided for either direct or sprocket drive applications.

Adjustment

• Top cam ‘A' actuates switch ‘F'; bottom cam ‘D' actuates

switch ‘E'.

• Adjustment of cam ‘A' is independent of cam ‘D'.

• To adjust cam ‘A', loosen cam locking screw ‘C' and rotate

cam ‘A' until trip point of switch ‘F' is reached.

• To adjust cam ‘D', loosen cam locking screw ‘B' and rotate

cam ‘D' until trip point of switch ‘E' is reached.

When the cams rotate, the switches are actuated and the

contacts change from the normally closed to open position.

(See Figure 5.)

spur gear type

Rotary Limit Switches

Enclosures

NEMA Type 1 and 12 (General Purpose) enclosures consist of a die cast

housing and FIBRALLOY® cover. All mounting holes are external to the

wiring cavity eliminating interference with internal wiring when the switch

is mounted. Captive screws fasten the cover to the die cast housing and

eliminate problems of misplaced screws. (See Figure 6.)

NEMA 4 and 7 enclosures are constructed of aluminum to prevent

corrosion. The NEMA 7 (Hazardous Location) enclosure is available for

use in Class 1, Group D, areas as outlined in the National Electrical

Code. Cast iron enclosures can also be provided on special request. All

units are provided with an attractive red wrinkle finish. (See Figure 7.)

Potentiometer

An optional salient feature of mounting a 2 watt potentiometer within the

enclosure, and gear coupled to the input shaft, is offered. This feature

permits the potentiometer to be used as a remote position indicator or as

a constant output auxiliary control device for open or closed loop

feedback systems. (See Figure 8.)

• Step-up geared ratios between the input shaft and the potentiometer

are available to provide a choice of sensitivity and resolution to meet

most applications.

• The special type potentiometer allows continuous rotation of the drive

and a zero or reference point to be adjusted without removing any gears

or components.

SG Type....

....Rotary Application

• reciprocating motions

Assures accurate movement and placement of parts in

all types of handling and positioning fixtures.

NOTE - Replaces two limit switches and electrical

piping.

Rotary Limit Switches

spur gear type - ROTARY LIMIT SWITCH

Enclosure

Type

NEMA 1 & 12

NEMA 4

(1)

NEMA 7

(1)

Enclosure

Type

NEMA 1 & 12

NEMA 4

NEMA 7

Ordering

When ordering desired switch, specify:

1. Catalog Number

2. Quantity Required

Input

Shaft

Rev.

1

1

1

1

1

1

1

1

1

Input

Shaft

Rev.

Cam

Block

Rev.

Cam

Block

Rev.

1

1/2

1/3

2

3

1

1/2

1/3

2

3

1

1/2

1/3

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

ROTARY LIMIT SWITCH WITH POTENTIOMETER

Pot.

Rev.

1

2

3

1

2

3

1

2

3

(1) Contact Factory for Cast Iron or Bronze Enclosure.

Two Circuit

S. P. D. T.

Symbol A

Catalog

Number

2000-800

2000-801

2000-802

2000-803

2000-804

2000-832

2000-833

2000-834

2000-835

2000-836

2000-864

2000-865

2000-866

2000-867

2000-868

Two Circuit

S. P. D. T.

Symbol A

Catalog

Number

2000-820

2000-821

2000-822

2000-852

2000-853

2000-854

2000-884

2000-885

2000-886

Two Circuit

D. P. D. T.

Symbol B

Catalog

Number

2000-805

2000-806

2000-807

2000-808

2000-809

2000-837

2000-838

2000-839

2000-840

2000-841

2000-869

2000-870

2000-871

2000-872

2000-873

Two Circuit

D. P. D. T.

Symbol B

Catalog

Number

2000-823

2000-824

2000-825

2000-855

2000-856

2000-857

2000-887

2000-888

2000-889

3. Desired Gear Ratio

4. Resistance of Potentiometer (if used)

Three Circuit

S. P. D. T.

Symbol C

Catalog

Number

2000-810

2000-811

2000-812

2000-813

2000-814

2000-842

2000-843

2000-844

2000-845

2000-846

2000-874

2000-875

2000-876

2000-877

2000-878

Three Circuit

S. P. D. T.

Symbol C

Catalog

Number

2000-826

2000-827

2000-828

2000-858

2000-859

2000-860

2000-890

2000-891

2000-892

Four Circuit

S.P. D. T.

Symbol C

Catalog

Number

2000-815

2000-816

2000-817

2000-818

2000-819

2000-847

2000-848

2000-849

2000-850

2000-851

2000-879

2000-880

2000-881

2000-882

2000-883

Four Circuit

S. P. D. T.

Symbol C

Catalog

Number

2000-829

2000-830

2000-831

2000-861

2000-862

2000-863

2000-893

2000-894

2000-895

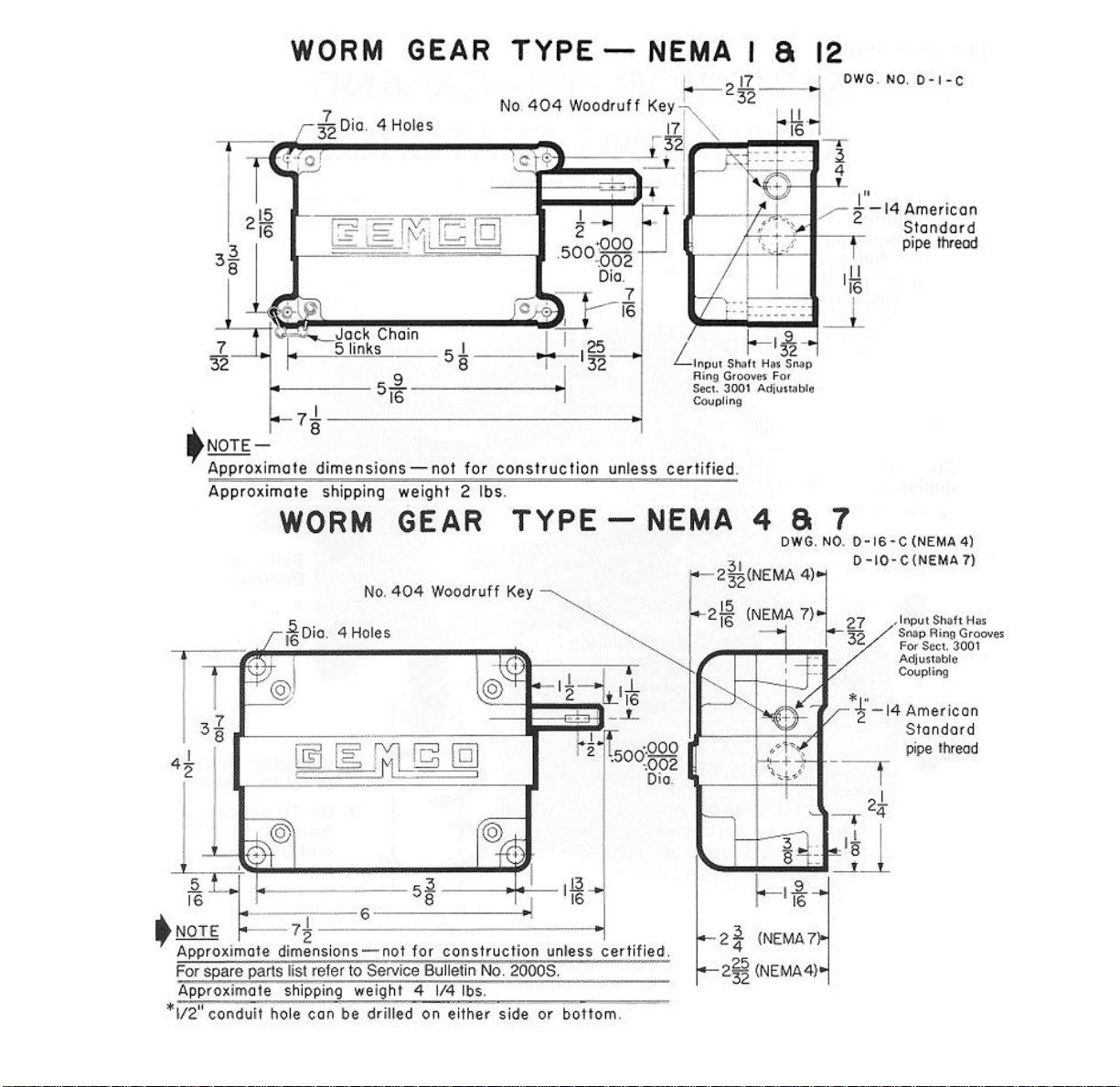

Heavy-Duty Dimensions

Application:

Ruggedly built, GEMCO'S heavy duty Rotary Limit

Switches have gained wide acceptance on

installations such as mechanical press ram

adjustments, press extractors and shuttles which

require dependable trouble free performance.

These installations require a limit switch that will

withstand rapid starting and stopping, shock,

vibration and still successfully control the end or

intermediate limits of such devices. Because of

these demands and the high reliability required,

GEMCO'S heavy-duty Rotary Limit Switch far

exceeds any on the market.

Cams

The input shaft (includes Woodruff Key) drives a bronze gear which rotates the cam block. The cam block houses independently

adjustable cams that actuate the precision type snap action switches.

Input Speed

Maximum rated speed of the input Input Speed shaft is 1800 RPM; can be rotated clockwise or counterclockwise.

Reduction

Ratios

Two Circuit

S.P.D.T. -

Symbol A*

Two Circuit

D.P.D.T. -

Symbol B*

Three Circuit

S.P.D.T. -

Symbol C*

Four Circuit

Symbol C*

S.P.D.T. -

Catalog No. Catalog No. Catalog No. Catalog No.

5:1

7.5:1

Dwg.

No. D-96-C

Dwg.

No. D-85-C

* For switch capacities, see page 13

For Cast Iron or Bronze Enclosure Contact Factory.

10:1

15:1

20:1

30:1

125:1

156.25:1

187.5:1

250:1

312.5: 1

375:1

500:1

625:1

750:1

1000:1

1250:1

1500:1

2000:1

2500:1

3000:1

2000-2000

2000-2001

2000-2002

2000-2003

2000-2004

2000-2005

2000-2024

2000-2025

2000-2026

2000-2027

2000-2028

2000-2029

2000-2030

2000-2031

2000-2032

2000-2033

2000-2034

2000-2035

2000-2036

2000-2037

2000-2038

2000-2006

2000-2007

2000-2008

2000-2009

2000-2010

2000-2011

2000-2039

2000-2040

2000-2041

2000-2042

2000-2043

2000-2044

2000-2045

2000-2046

2000-2047

2000-2048

2000-2049

2000-2050

2000-2051

2000-2052

2000-2053

2000-2012

2000-2013

2000-2014

2000-2015

2000-2016

2000-2017

2000-2054

2000-2055

2000-2056

2000-2057

2000-2058

2000-2059

2000-2060

2000-2061

2000-2062

2000-2063

2000-2064

2000-2065

2000-2066

2000-2067

2000-2068

2000-2018

2000-2019

2000-2020

2000-2021

2000-2022

2000-2023

2000-2069

2000-2070

2000-2071

2000-2072

2000-2073

2000-2074

2000-2075

2000-2076

2000-2077

2000-2078

2000-2079

2000-2080

2000-2081

2000-2082

2000-2083

Heavy-Duty Dimensions

General Purpose Rotary Limit Switches

Featuring:

• S.P.D.T. or D.P.D.T. Industrial Duty Switches With Isolated

Contacts

• Ease of Wiring With Direct Access To All Switch Terminals

• Gear Ratios From 5:1 to 1080:1

• Positive, Independent Cam Settings

• Rugged Duty Die Cast Enclosures

• Large Cover Openings For Ease of Wiring

• NEMA 4 & 5 Oiltight - Watertight - Dusttight

"L" SHAPE BRACKET

When "L" Shape Bracket is purchased, use

CATALOG NUMBER

C-6131-B (2 circuit unit)

C-6132-B (4 circuit unit)

Circuits

2 Circuit Enclosure 4 7/8 4 1/2 2 5/8 4 3/8 5 1/4

4 Circuit Enclosure 6 7/8 5 3 3/8 6 3/8 5 7/32

Dimensions in inches

A B C D E

Includes half inch hub extension.

Lbs.

Boxed

4 1/2

Approximate Dimensions And Shipping Weights For 2 and 4 Circuit Units

Left Hand Extension Shown

3

("L" shape mounting bracket, when purchased separately, is shown in some of the

possible mounting positions by broken lines.)

ELECTRICAL CONTACT RATINGS

Switch

Type

1950-1-B-A-D0 SPDT

1950-4-B-A-D0 DPDT

Contacts Volts

Pilot Duty 35% Power Factor

Make Break

Amps VA Amps VA

110 40 …. 15 …. 15 15 115 0.25 15

220 20 …. 10 …. 15 15 230 0.1 15

440 10 …. 6 …. 15 15 600 …. 15

600 8 …. 5 …. 15 15 …. …. ….

115 30 3450 3 345 10 10 115 0.2 10

230 15 3450 1.5 345 10 10 230 0.1 10

440 7.5 3450 0.75 345 10 10 600 …. 10

575 6 3450 0.6 345 10 10 …. …. ….

Inductive

NOTE: The maximum period for which the switch contacts are opened or closed during one revolution (360°) of the cam

block assembly is 25° or 335°. Multiply the Rotary Limit Switch gear ratio times 25° or 335° to obtain the input shaft rotation

which will yield 25° or 335° of cam block rotation.

AC DC

Continuous

Carrying

Amps

Resistive

75% Power Factor

Make, Break and

Continuous

Carrying Amps

Volts

Inductive Pilot Duty

and Resistive

Make and

Break Amperes

Double Throw

Continuous

Carrying

Amps

Precision rugged duty snap action switches, combined with a

hand or right hand

APPLICATION:

The Type K Rotary Limit Switch is used in applications

requiring ratios from 5:1 to 1080:1 for controlling the end

and/or intermediate limits of a reciprocating or rotary

motion. Two circuit and four circuit assemblies are

available from stock.

The NEMA 4 & 5 enclosure provides a clean environmental condition for the industrial duty snap action

switches. Where motion can be expressed in shaft

rotation either through a roller chain, gear train or direct

coupling, the Type K Rotary Limit Switch makes it

possible to open or close up to four independent circuits

at the desired angular positions.

DESCRIPTION:

wide selection of gear ratios provides reliable electrical

signals as a function of the shaft rotation. No minimum

speed is specified due to the snap action contacts of the

switch. The cam settings and the switch wiring can be easily

accomplished through the full size cover.

With the two circuit assembly, either a left

shaft extension can be supplied. This pro-vides the added

versatility when packaging this assembly in hard-to-get-at

locations.

TYPICAL APPLICATIONS ARE:

• Door Operators

• Hoists

• Valves

• Elevating Jack

Mechanisms

• Tapping Heads

• Packaging

• Machinery

• Conveyors

• Index Tables

• Material Handling Equipment

• Reciprocating Linear Actuators

• Dampers

• End Limits on Machine Tool

Lead Screws

• Shuttles

Industrial Duty Switches

With Isolated Contacts

Contact positions shown are when cams ARE NOT actuating levers.

DESCRIPTION

This rotary limit switch is designed to control the limits of travel of rotating reversing

equipment. The limit switch input shaft is connected to a worm gear. Adjustable self

lubricating nylon roller cams are concentrically mounted to the worm gear. These adjustable

cams actuate the precision limit switches by utilizing a lever assembly.

INSTALLATION

This limit switch may be mounted in any convenient position. when installed this limit switch

will provide long life with a minimum amount of service maintenance.

The following recommendations will prove helpful.

1. Install the limit switch so that the shaft load will not exceed (5) live pounds.

2. A flexible coupling is recommended for all installation other than gear drive

application.

3. Coupling should be employed in a manner that results in a minimum of thrust

loading on the shaft. If switches are mounted with the shaft up or down, some

additional thrust loading resulting from the weight of the shaft plus a very light

coupling is permissible.

4. Whenever possible, a separate support bearing for the drive sprocket should be

used.

5. Permissible speed of the input shaft 2000 R.P.M.

LUBRICATION

This limit switch was lubricated at the factory and should not require lubrication for the life of

the switch.

ADJUSTMENT

Refer to figure 1. The electrical switch units “G” and “H” are shown with the contact positions

assumed when the cams are not actuating the switch units.

When the cam rotates and actuates the switch, the “B” (closed) contact opens and the “A”

(open) contact closes. Each precision switch has (1) one independent adjustable cam.

TO ADJUST SWITCH "G"

1. Loosen Red Set

Screw

2. Turn "D" to Trip "H"

3. Tighten Green Set

Screw

TO ADJUST SWITCH "H"

1. Loosen Blue Set

Screw

2. Turn "C" to Trip "G"

3. Tighten Yellow Set

Screw

WARNING:

LOOSEN CAM SET

SCREW BEFORE

ADJUSTING OR

DAMAGE OF CAMS

WILL OCCUR

Nominal Input

Shaft to Cam

Ratio

5:1

10:1

20:1

30:1

40:1

60:1

80:1

120:1

RENEWAL PARTS

When ordering Renewal Parts give this form No. PF-047, Item No., Description,

Part No., Quantity, and the Complete Unit Number stamped on the label.

Reference FIG. #1 and FIG. #2 above.

ITEM DESCRIPTION PART NUMBER QTY.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Maximum Minimum Over Travel To Reset

4

8-1/2

17

26

35

53

72

108

Case and Shaft assembly

Cam block & Worm Gear assy.

Shim Cam Block (.080 THK.)

Shim Cam Block (.020 THK.)

Shim Cam Block (.016 THK.)

Limit Switch Standard S.P.D.T.

Optional D.P.D.T.

Optional S.M.S.B.

Adjusting Bracket Assembly

Gear and Roller Assembly

Spring, Compression

Lever Assembly

Cover

Cover Gasket

Spacer Center Post

Woodruff Key (#404)

5:1 Ratio

10:1 Ratio

20:1 Ratio

30:1 Ratio

40:1 Ratio

60:1 Ratio

80:1 Ratio

120:1 Ratio

5:1 Ratio

10:1 Ratio

20:1 Ratio

30:1 Ratio

40:1 Ratio

60:1 Ratio

80:1 Ratio

120:1 Ratio

Turns of Input Shaft

1/8

1/4

1/2

1

1

2

2-1/2

3

1/8

1/4

1/2

3/4

1

2

2-1/2

3

PSD-0092400-DN

PSD-0092500-DN

PSD-0092600-DN

PSD-0092700-DN

PSD-0092800-DN

PSD-0092900-DN

PSD-0093000-DN

PSD-0093100-DN

PSD-0093500-DN

PSD-0093600-DN

PSD-0093700-DN

PSD-0093800-DN

PSD-0093900-DN

PSD-0094000-DN

PSD-0094100-DN

PSD-0094200-DN

PS-0003300-A

PS-0000800-A

PS-0003200-A

1950-1-B-A-DO

1950-4-B-A-DO

1950-1408

PSD-0024700-B

PSD-00904-00-A

PM-001 8000-A

PSD-0024500-A

PC-0069200-A

PS-0001 000-A

M-0073000-A

04-56401 9-DN

1/16

1/8

1/4

3/8

1/2

3/4

1

1-1/2

1

....

....

....

....

....

....

....

....

1

....

....

....

....

....

....

....

....

1

1

3

4

....

....

1

4

4

2

1

1

1

1

Contact positions shown are when cams ARE NOT actuating levers.

Nominal

Input Shaft

to Cam Ratio

5:1

10:1

20:1

30:1

40:1

60:1

80:1

120:1

Turns of Input Shaft

Maximum Minimum Over Travel To Reset

4

8-1/2

17

26

35

53

72

108

1/8

1/4

1/2

1

1

2

2-1/2

3

1/8

1/4

1/2

3/4

1

2

2-1/2

3

1/16

1/8

1/4

3/8

1/2

3/4

1

1-1/2

DESCRIPTION

This rotary limit switch is designed to control the limits of travel of rotating reversing

equipment. The limit switch input shaft is connected to a worm gear. Adjustable selflubricating nylon roller cams are concentrically mounted to the worm gear. These

adjustable cams actuate the precision limit switches by utilizing a lever assembly.

INSTALLATION

This limit switch maybe mounted in any convenient position. When installed this limit

switch will provide long life with a minimum amount of service maintenance.

The following recommendations will prove helpful.

1. Install the limit switch so that the shaft load will not exceed (5) live pounds.

2. A flexible coupling is recommended for all installation other than gear drive

application.

3. Coupling should be employed in a manner that results in a minimum of

thrust loading on the shaft. If switches are mounted with the shaft up or

down, some additional thrust loading resulting from the weight of the shaft

plus a very light coupling is permissible.

4. Whenever possible, a separate support bearing for the drive sprocket

should be used.

5. Permissible speed of the input shaft 2000 R.P.M.

LUBRICATION

This limit switch was lubricated at the factory and should not require lubrication for the

life of the switch.

ADJUSTMENT

Refer to figure 1. The electrical switch units “G”, “H' , “L” AND “M” are shown with the

contact positions assumed when the cams ARE NOT actuating the switch units.

When the cam rotates and actuates the switch, the “B” (closed) contact opens and the

“A” (open) contact closes. Each precision switch has (1) one independent adjustable

cam.

TO ADJUST SWITCH "M"

1. Loosen Red Set Screw

2. Turn "K" to Trip "M"

3. Tighten Red Set Screw

TO ADJUST SWITCH "H"

1. Loosen Green Set Screw

2. Turn "D" to Trip "H"

3. Tighten Green Set Screw

WARNING: LOOSEN CAM SET SCREW BEFORE ADJUSTING OR DAMAGE

OF CAMS WILL OCCUR

TO ADJUST SWITCH "L"

1. Loosen Blue Set Screw

2. Turn "J" to Trip "L"

3. Tighten Blue Set Screw

TO ADJUST SWITCH "G"

1. Loosen Yellow Set Screw

2. Turn "C" to Trip "G"

3. Tighten Yellow Set Screw

QTY.

1

....

....

....

....

....

....

....

....

1

....

....

....

....

....

....

....

....

1

1

3

4

....

....

1

4

4

2

1

1

1

1

RENEWAL PARTS

When ordering Renewal Parts give this form No. PF-047, Item No.,

Description, Part No., Quantity, and the Complete Unit Number stamped on

the label. Reference FIG. #1 and FIG. #2 above.

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPTION

Case and Shaft assembly

10:1 Ratio

20:1 Ratio

30:1 Ratio

40:1 Ratio

60:1 Ratio

80:1 Ratio

Cam block & Worm Gear assy.

Shim Cam Block (.080 THK.)

Shim Cam Block (.020 THK.)

Shim Cam Block (.016 THK.)

Limit Switch Standard S.P.D.T.

Optional D.P.D.T.

Optional S.M.S.B.

Adjusting Bracket Assembly

Gear and Roller Assembly

Spring, Compression

Lever Assembly

Cover

Cover Gasket

Spacer Center Post

Woodruff Key (#404)

120:1 Ratio

10:1 Ratio

20:1 Ratio

30:1 Ratio

40:1 Ratio

60:1 Ratio

80:1 Ratio

120:1 Ratio

5:1 Ratio

5:1 Ratio

PART

NUMBER

PSD-0092400-DN

PSD-0092500-DN

PSD-0092600-DN

PSD-0092700-DN

PSD-0092800-DN

PSD-0092900-DN

PSD-0093000-DN

PSD-0093100-DN

PSD-0093500-DN

PSD-0093600-DN

PSD-0093700-DN

PSD-0093800-DN

PSD-0093900-DN

PSD-0094000-DN

PSD-0094100-DN

PSD-0094200-DN

PS-0003300-A

PS-0000800-A

PS-0003200-A

1950-1-B-A-DO

1950-4-B-A-DO

1950-1408

PSD-0024700-B

PSD-00904-00-A

PM-001 8000-A

PSD-0024500-A

PC-0069200-A

PS-0001 000-A

M-0073000-A

04-56401 9-DN

Special Gemco Rotary Limit Switches

Special NEMA 4 Four Circuit Rotary Limit Switch with

To Meet Your Specific Applications

Two Circuit Rotary Limit Switch with a Special Mounting

Bracket and Integral Right Angle Worm Gear for Mounting in

a Power Jack.

Special Two Circuit Open Type Rotary Limit Switch with a

Single Turn Potentiometer.

a Potentiometer for mounting on a rotary valve.

Special Three Circuit Rotary Limit Switch used on a

Mobile Man Lift.

WORM GEAR TYPE

Ratios from 5:1 to 5333.3:1

2 CIRCUIT

WORM GEAR TYPE

Ratios from 5:1 to 1080:1

SPUR GEAR TYPE

Ratios from .5:1 to 3:1

HEAVY DUTY TYPE

Ratios from 5:1 to 3000:1

4 CIRCUIT

WORM GEAR TYPE

Ratios from 5:1 to 1080:1

Loading...

Loading...