Page 1

Solar 7000

Patient Monitor

Solar 7000/8000/SolarView

Patient Monitor

Field Service Manual

414993-001 Revision H

Page 2

NOTE: Due to continuing product innovation, specifications in this

manual are subject to change without notice.

Trademarks

Trademarked names appear throughout this document. Rather than list

the names and entities that own the trademarks or insert a trademark

symbol with each mention of the trademarked name, the publisher states

that it is using the names only for editorial purposes and to the benefit of

the trademark owner with no intention of improperly using that

trademark.

900 SC, ACCUSKETCH, AccuVision, APEX, AQUA-KNOT, ARCHIVIST, Autoseq, BABY

MAC, C Qwik Connect, CardioServ, CardioSmart, CardioSys, CardioWindow, CASE, CD

TELEMETRY, CENTRA, CHART GUARD, CINE 35, CORO, COROLAN,

COROMETRICS, Corometrics Sensor Tip, CRG PLUS, DASH, Digistore, Digital DATAQ,

E for M, EAGLE, Event-Link, FMS 101B, FMS 111, HELLIGE, IMAGE STORE,

INTELLIMOTION, IQA, LASER SXP, MAC, MAC-LAB, MACTRODE, MANAGED USE,

MARQUETTE, MARQUETTE MAC, MARQUETTE MEDICAL SYSTEMS, MARQUETTE

UNITY NETWORK, MARS, MAX, MEDITEL, ME I, MEI in the circle logo, MEMOPORT,

MEMOPORT C, MINISTORE, MINNOWS, Monarch 8000, MULTI-LINK,

MULTISCRIPTOR, MUSE, MUSE CV, Neo-Trak, NEUROSCRIPT, OnlineABG,

OXYMONITOR, Pres-R-Cuff, PRESSURE-SCRIBE, QMI, QS, Quantitative Medicine,

Quantitative Sentinel, RAC RAMS, RSVP, SAM, SEER, SILVERTRACE, SOLAR,

SOLARVIEW, Spectra 400, Spectra-Overview, Spectra-Tel, ST GUARD, TRAM, TRAMNET, TRAM-RAC, TRAMSCOPE, TRIM KNOB, Trimline, UNION STATION, UNITY logo,

UNITY NETWORK, Vari-X, Vari-X Cardiomatic, VariCath, VARIDEX, VAS, and Vision

Care Filter are trademarks of GE Marquette Medical Systems, Inc. registered in the United

States Patent and Trademark Office.

12SL, 15SL, Access, AccuSpeak, ADVANTAGE, BAM, BODYTRODE, Cardiomatic,

CardioSpeak, CD TELEMETRY

Event-Link Cirrus, Event-Link Cumulus, Event-Link Nimbus, HI-RES, ICMMS, IMAGE

VAULT, IMPACT.wf, INT ER-LEAD, IQA, LIFEWATCH, Manag ed Use, MARQUETTE

PRISM, MARQUETTE

CardioWindow, NST PRO, NAUTILUS, O

Prism, QUIK CONNECT V, QUICK CONNECT, QT Guard, SMART-PAC, SMARTLOOK,

Spiral Lok, Sweetheart, UNITY, Universal, Waterfall, and Walkmom are trademarks of GE

Marquette Medical Systems, Inc.

®

®

-LAN, CENTRALSCOPE, Corolation, EDIC, EK-Pro,

RESPONDER, MENTOR, MicroSmart, MMS, MRT, MUSE

SENSOR, Octanet, OMRS, PHi-Res, Premium,

2

GE Marquette Medical Systems, Inc.

8200 W. Tower Ave.

Milwaukee, WI 53223 USA

Tel: 414.355.5000

800.558.5120 (USA only)

Fax: 414.355.3790

Marquette Hellige GmbH

Postfach 60 02 65

D-79032 Freiburg

Germany

Tel: 49.761.45.43.0

Fax: 49.761.45.43.233

© GE Marquette Medical Systems, Inc., 2000. All rights reserved.

T-2 Solar 7000/8000/View Patient Monitor Revision H

414993-001 13 January 2000

Page 3

CONTENTS

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 EQUIPMENT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

What is a Solar 7000/8000 Patient Monitoring System? . . . . . . . . . .2-2

What is the Marquette Unity Network? . . . . . . . . . . . . . . . . . . . . . . . .2-3

What is a Solar 7000 Patient Monitor? . . . . . . . . . . . . . . . . . . . . . . . . 2-4

What is a Solar 8000 Patient Monitor? . . . . . . . . . . . . . . . . . . . . . . . . 2-5

What is a SolarView Remote Display Controller? . . . . . . . . . . . . . . .2-6

What is a Tram-rac Housing? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

What is a DDW? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

What is a PRN 50 Digital Writer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

What is a Remote Control? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

What is a Remote Display? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

What is a Tram-net Hub Assembly? . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

What is a Tram-net Interface? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

What is an Octanet Connectivity Device? . . . . . . . . . . . . . . . . . . . .2-10

What is a TMSS? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Tram-rac Housing Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Marquette Unity Network Connection . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Tram-rac 4A Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Tram-rac 2 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Dual Tram-rac Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Octanet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

DDW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

PRN 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Local/Remote Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Cabling Schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Revision H Solar 7000/8000/View Patient Monitor i

414993-001

Page 4

CONTENTS

Tram-net Interface Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Octanet Connectivity Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

TMSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

For all Solar Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

For Monochrome Solar 8000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

More About Tram-net Communication . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Internal Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Tram-net Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

More About Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Twisted Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Thin-net /Thick-net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Segment and Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

What is Twisted Pair Cabling (10 Base-T)? . . . . . . . . . . . . . . . . . . . 2-44

3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Manufacturer Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Manufacturer Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Cleaning Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cleaning the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cleaning Inside the Solar 7000 Color Monitor . . . . . . . . . . . . . . . . . .3-5

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Wall Receptacle Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Ground (Earth) Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Ground Continuity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Impedance of Protective Earth Connection . . . . . . . . . . . . . . . . . 3-7

Ground (Earth) Wire Leakage Current Tests . . . . . . . . . . . . . . . . . . . 3-9

Enclosure Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Patient (Source) Leakage Current Test . . . . . . . . . . . . . . . . . . . . . .3-13

Patient (Sink) Leakage Current Test

(Mains Voltage on the Applied Part) . . . . . . . . . . . . . . . . . . . . . . . 3-15

Test Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Required Tools/Special Equipment . . . . . . . . . . . . . . . . . . . . . .3-17

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

ii Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 5

CONTENTS

General Monitor Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Solar 7000 Display Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Solar 8000/View Display Check . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Tram-rac Housing Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Tram-net Communication Check . . . . . . . . . . . . . . . . . . . . . . . . 3-21

LAN Network Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Remote Control Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Video/Alarm Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Tram-net Interface Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Octanet Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

PM Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

4 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Troubleshooting Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Terms Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Boot Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cold Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Configured Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Continue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Display On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Protected Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Power Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Service Mode/Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Warm Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Block Theory Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Solar 7000 Color Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Solar 7000 Monochrome Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Solar 8000 Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

SolarView Remote Display Controller . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Block Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Main Processor PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Display Processing Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Remote/Local Display Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Remote Alarm Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Communication Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Low-Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Keycap PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Additional Solar 7000 Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Mono CRT Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Color CRT Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Deflection PCB (Color Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Block Diagram of Internal Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Solar 7000 Color Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Solar 7000 Monochrome Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Solar 8000/View Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Communication Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Revision H Solar 7000/8000/View Patient Monitor iii

414993-001

Page 6

CONTENTS

Async COMM Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

RMT ALM Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Ethernet Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Tram-net Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

RS-232 Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

RMT VID or VID Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Boot Loader Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Change Ethernet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Change IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Set Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Clear Configured Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Country Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Serial Download Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Serial Download Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Serial Download Old Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Service Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Download Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Review Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

Hardware Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

Patient-Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Menu Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Monitor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

Degauss (Solar 7000 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

General Fault Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

First Things to Ask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

AC Line Voltage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

120 VAC, 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

240 VAC, 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

LED Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Troubleshooting Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

5 CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Solar 7000 Color Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Color Display Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Horizontal Frequency Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Color Focus Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Color Cross Hatch Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Color Intensity Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Color Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

CRT Controller PCB Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Gain Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

iv Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 7

CONTENTS

Solar 7000 Color Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Solar 7000 Monochrome Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Monochrome Display Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Special Tools/Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Horizontal Frequency Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Focus Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Cross Hatch Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Intensity Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Solar 7000 Monochrome Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Special Tools/Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Solar 8000/View Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Special Tools/Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

6 CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Configuring a Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Select Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Programming Admit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Programming Patient-Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Programming Care Unit Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Programming Bed Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Selecting Monochrome for Solar 8000/View . . . . . . . . . . . . . . . . . . . 6-7

Programming Display Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

For Solar 8000/View Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

For All Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Programming Line Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Programming Analog Out Levels for the Solar ECG Module . . . . . . .6-8

Programming Graph Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Communication Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Problems? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Updating Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Advanced User Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Programming Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Use Sparingly! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

From BOOT LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

From SERVICE MODE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Revision H Solar 7000/8000/View Patient Monitor v

414993-001

Page 8

CONTENTS

Set Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Set Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Changing Software Feature Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Dial a Lower Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Exchange the EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Changing Remote Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Programming Ethernet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Find Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

From BOOT LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Programming Internet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Ethernet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Internet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Calculate Internet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

From BOOT LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

From SERVICE MODE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Power Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Reviewing Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Accessing Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

What Does an Error Log Contain? . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

What Error Data is Useful? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

What Do Error Codes Mean? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

What Does Severity Imply? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Transferring Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Access the COPY LOGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Select the Care Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Select the Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Select the Error Log Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Copy Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Eject Floppy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Reviewing Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Accessing Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

What Does an Event Log Contain? . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

7 UPPER LEVEL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Solar 7000 Disassembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

PCB Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Opening the Unit for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Main Processor PCB Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Mono CRT Controller or Color Deflection PCB Removal . . . . . . .7-5

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Color CRT Controller PCB Removal . . . . . . . . . . . . . . . . . . . . . . 7-7

Ordering Parts for Solar 7000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Commonly Replaced Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Fuse Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Solar 7000 Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

vi Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 9

CONTENTS

Exploded View (Color) PN 900618-001H . . . . . . . . . . . 7-11

Parts List PN 900618-001H . . . . . . . . . . . .7-14

Exploded View (Mono) PN 900619-001K . . . . . . . . . . . 7-16

Parts List PN 900619-001K . . . . . . . . . . . . 7-19

Revisions to the Solar 7000 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Solar 8000/View Disassembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . 7-23

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

PCB Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

7 UPPER LEVEL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Opening the Unit for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

Main Processor PCB Removal . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26

Ordering Parts for Solar 8000/View . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28

Commonly Replaced Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Fuse Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

Solar 8000/View Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Exploded View PN 900691-001J. . . . . . . . . . . . 7-30

Parts List PN 900691-001M . . . . . . . . . . . .7-31

Revisions to the Solar 8000/View Assembly . . . . . . . . . . . . . . . . . . . . .7-32

Revision H Solar 7000/8000/View Patient Monitor vii

414993-001

Page 10

CONTENTS

viii Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 11

1 INTRODUCTION

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Revision H Solar 7000/8000/View Patient Monitor 1-1

414993-001

Page 12

INTRODUCTION: Manual Information

Manual Information

Revision History

Revision Date Comment

A 28 March 1995 Initial release of this manual.

B 3 October 1995 Added references to Solar 8000 processing unit

C 1 March 1996 Minor corrections

D 15 May 1996 Added references to SolarView remote display controller

E 23 September 1996 Added references to Corometrics TMSS and updated upper assembly

Each page of this manual has a revision letter, located at the bottom of

the page, that identifies its update level. This may be important if you

have different updates to a manual and don’t know which is the most

current.

For the initial release, all pages have the revision letter A. For the first

update of the manual, any changed pages receive the revision letter B.

For the second update, any changed pages receive the revision letter C.

The latest letter of the alphabet added corresponds to the most current

revision. Notice, however, that some pages may skip revision letters, for

example, jump from re vi sion A to re visi on C be caus e they di d not change

in revision B.

Revision History

F 17 June 1998 Added information for revised Service Mode Menu and updated upper

assembly

G 1 September 1999 Removed “Updating Software” from the manual and added UL

information.

H 13 January 2000 Added PRN-50 component to Chapter 2, “Equipment Overview”,

removed references to Corometrics, and updated Chapter 6,

“Configuration” to reflect Reviewing Event Logs.

Manual Purpose

Intended Audience

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipmnet to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary the manual identifies

additional sources of relevant information and technical assistance.

See the operator’s manual for the instructions necessary to operate the

equipment safely in accordance with its function and intended use.

For parts lists and schematic diagrams of the PCB assemblies, order the

Solar 7000/8000/View Monitor Data Manual, PN 414993-007.

This manual is intended for service representatives and technical

personnel who maintain, troubleshoot, or repair this equipment.

1-2 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 13

Safety Information

INTRODUCTION: Safety Information

Responsibility of the Manufacturer

Intended Use

GE Marquette Medical Systems is responsible for the effects of safety,

reliability, and performance only if:

• Assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE Marquette.

• The electrical installation of the relevant room complies with the

requirements of the appropriate regulations.

• The equipment is used in accordance with the instructions for use.

Follow the directives stated below when using this device.

• This device is intended for use under the direct supervision of a

licensed health care practitioner.

• This device is not intended for home use.

• Federal law restricts this device to be sold by or on the order of a

physician.

• Contact GE Marquette Medical Systems for information before

connecting any devices to the equipment that are not recommended

in this manual.

• Parts and accessories used must meet the requirements of the

applicable IEC 601 series safety standards, and/or the system

configuration must meet the requirements of the IEC 60601-1-1

medical electrical systems standard.

• P eriodica lly, and when ever t he int egrit y of the de vice is in d oubt, te st

all functions.

• The use of ACCESSORY equipment not complying with the

equivalent safety requirements of this equipment may lead to a

reduced level of safety of the resulting system. Consideration

relating to the choice shall include:

◆ use of the accessory in the PATIENT VICINITY; and

◆ evidence that the safety certification of the ACCESSORY has

been performed in accordance to the appropriate IEC 60601-1

and/or IEC 60601-1-1 harmonized national standard.

• If the installation of the equipment, in the USA, will use 240V rather

than 120V, the source must be a center-tapped, 240V, single-phase

circuit.

Revision H Solar 7000/8000/View Patient Monitor 1-3

414993-001

Page 14

INTRODUCTION: Safety Information

PRESS

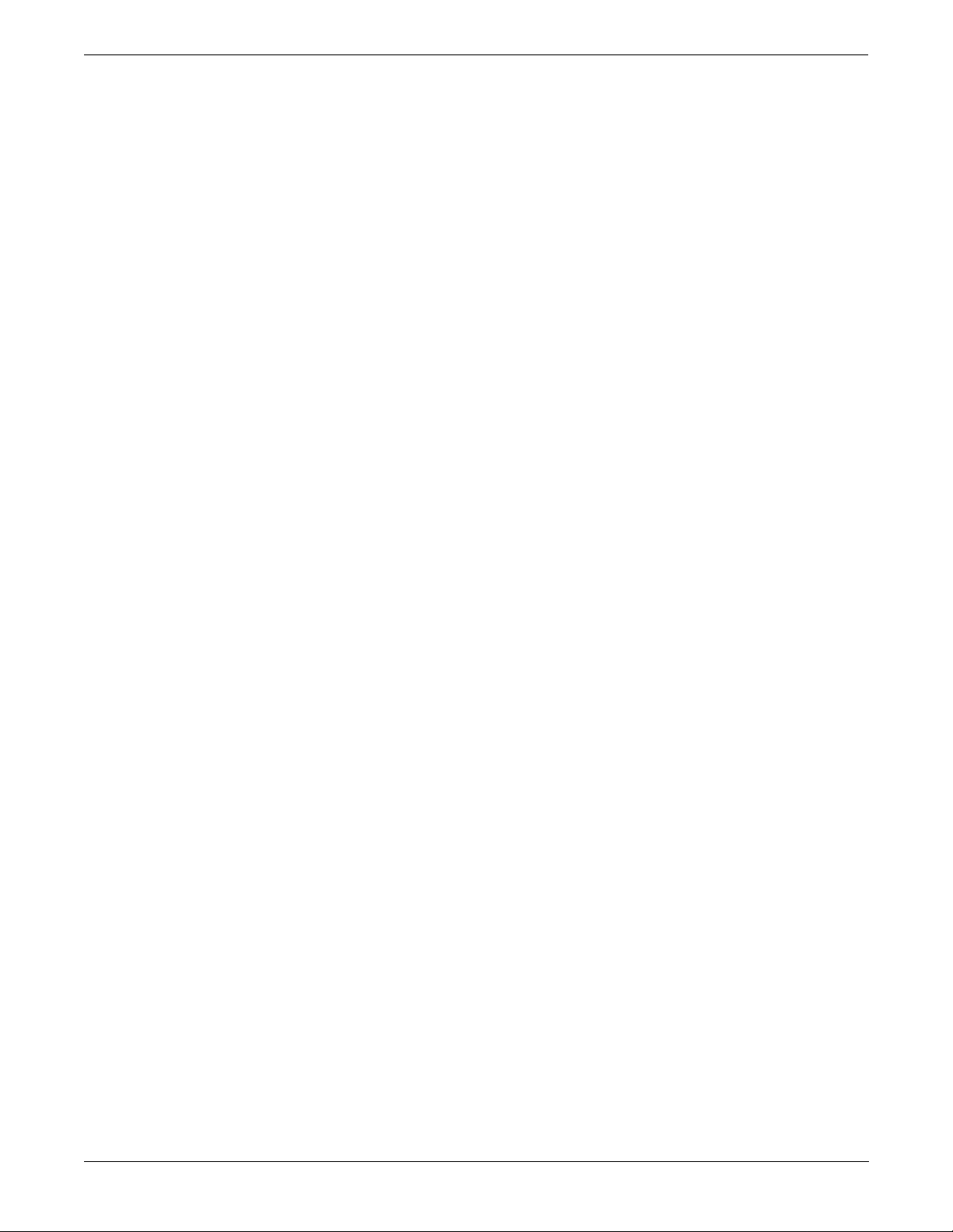

Equipment Symbols

The following symbols appear on the equipment.

NOTE: Some symbols may not appear on all equipment.

ATTENTION: Consult accompanying documents before using the

equipment.

In Europe, this symbol means dangerous or high voltage. In the

United States, this symbol represents the caution notice below:

To reduce the risk of electric shock, do NOT remove cover (or back).

Refer servicing to qualified personnel.

Defibrillator-proof type CF equipment; type CF equipment is

specifically designed for applications where a conductive connection

directly to the heart is established. The paddles indicate the

equipment is defibrillator proof.

Defibrillator-proof type BF equipment; type BF equipment is suitable

for intentional external and internal application to the patient,

excluding direct cardiac application. Type BF equipment is type B

equipment with an F-type isolated (floating) part. The paddles

indicate the equipment is defibrillat or pro o f.

Type B equipment; type B equipment is suitable for intentional

external and internal application to the patient, excluding direct

cardiac application.

Equipotentiality

Alternating current (AC)

Power;

Fuse

Where used, indicates to press to open.

I = ON; O= OFF

Classified by Underwriters Laboratories Inc. with respect to electric

shock, fire, mechanical and other specified hazards, only in

accordance with UL 2601-1, CAN/CSA C22.2 No. 601.1, IEC 60601-1,

and, if required, IEC 60601-2-27, IEC 60601-2-30, IEC 60601-2-34,

IEC 60601-1-1.

1-4 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 15

INTRODUCTION: Safety Information

Warnings, Cautions, and Notes

The terms danger, warning, and caution are used throughout this

manual to point out hazards and to designate a degree or level or

seriousness. Familiarize yourself with their definitions and significance.

Hazard is defined as a source of potential injury to a person.

DANGER indicates an imminent hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or product/property

damage.

NOTE provides application tips or other useful information to assure

that you get the most from your equipment.

Revision H Solar 7000/8000/View Patient Monitor 1-5

414993-001

Page 16

INTRODUCTION: Service Information

Service Information

Service Requirements

Equipment Identification

Follow the service requirements listed below.

• Refer equipment servicing to GE Marquette Medical Systems’

authorized service personnel only.

• Any unauthorized attempt to repair equipment under w arranty voids

that warranty.

• It is the user’s responsibility to report the need for service to GE

Marquette Medical Systems or to one of their authorized agents.

• Failure on the part of the responsible individual, hospital, or

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure and

possible health hazards.

• Regular maintenance, irrespective of usage, is essential to ensure

that the equipment will always be functional when required.

Every GE Marquette Medical Systems device has a unique serial number

for identification. A sample of the information found on a serial number

label is shown below.

D 6 XX 0005 G XX

Month

Manufactured

A = January

B = February

C = March

D = April

E = May

F = June

G = July

H = August

J = September

K = October

L = November

M = December

Warranty

Year

Manufactured

6 = 1996

7 = 1997

8 = 1998

(and so on)

Product Code

Two-character

product

descriptor

1 year.

Product

Sequence

Number

Manufacturing

number (of total

units

manufactured.)

Division

F = Cardiology

G = Monitoring

J = G. W. Labs

Device Character istics

One or 2 letters that further

describe the unit, for

example:

P = prototype not

conforming to marketing

specification

R = refurbished equipment

S = special product

documented under Specials

part numbers

U = upgraded unit

1-6 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 17

2 EQUIPMENT OVERVIEW

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

What is a Solar 7000/8000 Patient Monitoring System? . . . . . . . . . .2-2

What is the Marquette Unity Network? . . . . . . . . . . . . . . . . . . . . . . . .2-3

What is a Solar 7000 Patient Monitor? . . . . . . . . . . . . . . . . . . . . . . . . 2-4

What is a Solar 8000 Patient Monitor? . . . . . . . . . . . . . . . . . . . . . . . . 2-5

What is a SolarView Remote Display Controller? . . . . . . . . . . . . . . .2-6

What is a Tram-rac Housing? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

What is a DDW? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

What is a PRN 50 Digital Writer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

What is a Remote Control? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

What is a Remote Display? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

What is a Tram-net Hub Assembly? . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

What is a Tram-net Interface? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

What is an Octanet Connectivity Device . . . . . . . . . . . . . . . . . . . . .2-10

What is a TMSS? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Tram-rac Housing Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Marquette Unity Network Connection . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Tram-rac 4A Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Tram-rac 2 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Dual Tram-rac Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Octanet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

DDW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

PRN 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Local/Remote Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Cabling Schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Tram-net Interface Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Octanet Connectivity Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

TMSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

For all Solar Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

For Monochrome Solar 8000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

More About Tram-net Communication . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Internal Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Tram-net Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

More About Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Twisted Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Thin-net /Thick-net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Segment and Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

What is Twisted Pair Cabling (10 Base-T) . . . . . . . . . . . . . . . . . . . . 2-44

Revision H Solar 7000/8000/View Patient Monitor 2-1

414993-001

Page 18

EQUIPMENT OVERVIEW: System Components

System Components

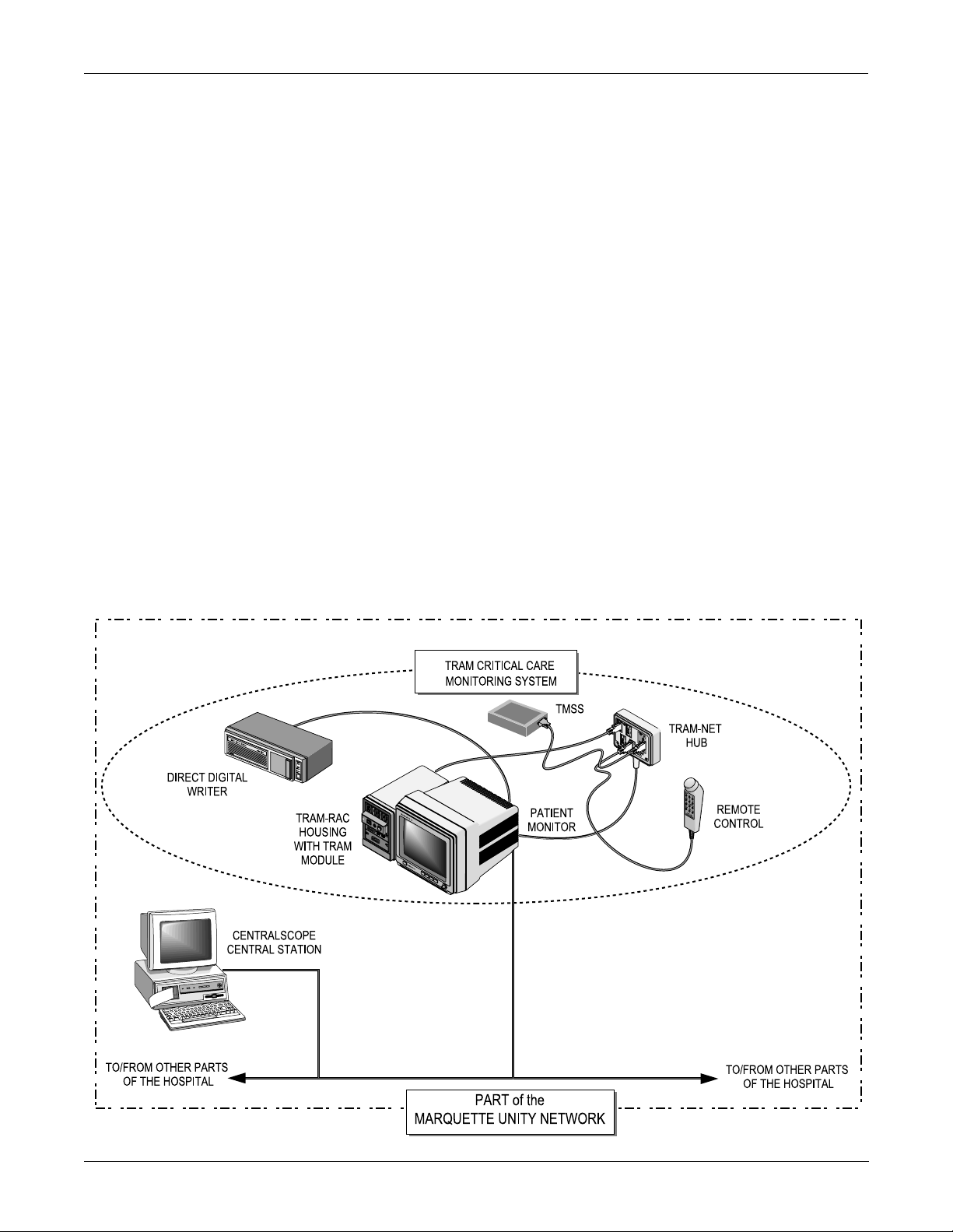

What is a Solar 7000/ 8000 Patient Monitoring System?

The Solar 7000/8000 patient monitoring system is designed to monitor

electrocardiographic, hemodynamic, respiratory, and pulmonary

parameters in the intensive care, coronary care, and operating room

environments of a hospital.

The Solar 7000/8000 patient monitoring system operates with the

Marquette Unity Network or as a system itself. At the patient’s bed, the

Solar 7000/8000 patient monitoring system permits connection of many

peripheral devices from the Solar 7000/8000 monitor.

All Solar 7000/8000 Patient Monitoring Systems include a patient

monitor, at least one patient parameter monitoring module, and one or

more of the following items:

• Tram-rac housing (Tram remote acquisition case),

• DDW (direct digital write r ),

• remote control,

• remote display,

• SolarView remote display, or

• TMSS (Tre nd Memory Storage System)

Shown below is an example of a Solar 7000 patient monitoring system.

2-2 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 19

EQUIPMENT OVERVIEW: System Components

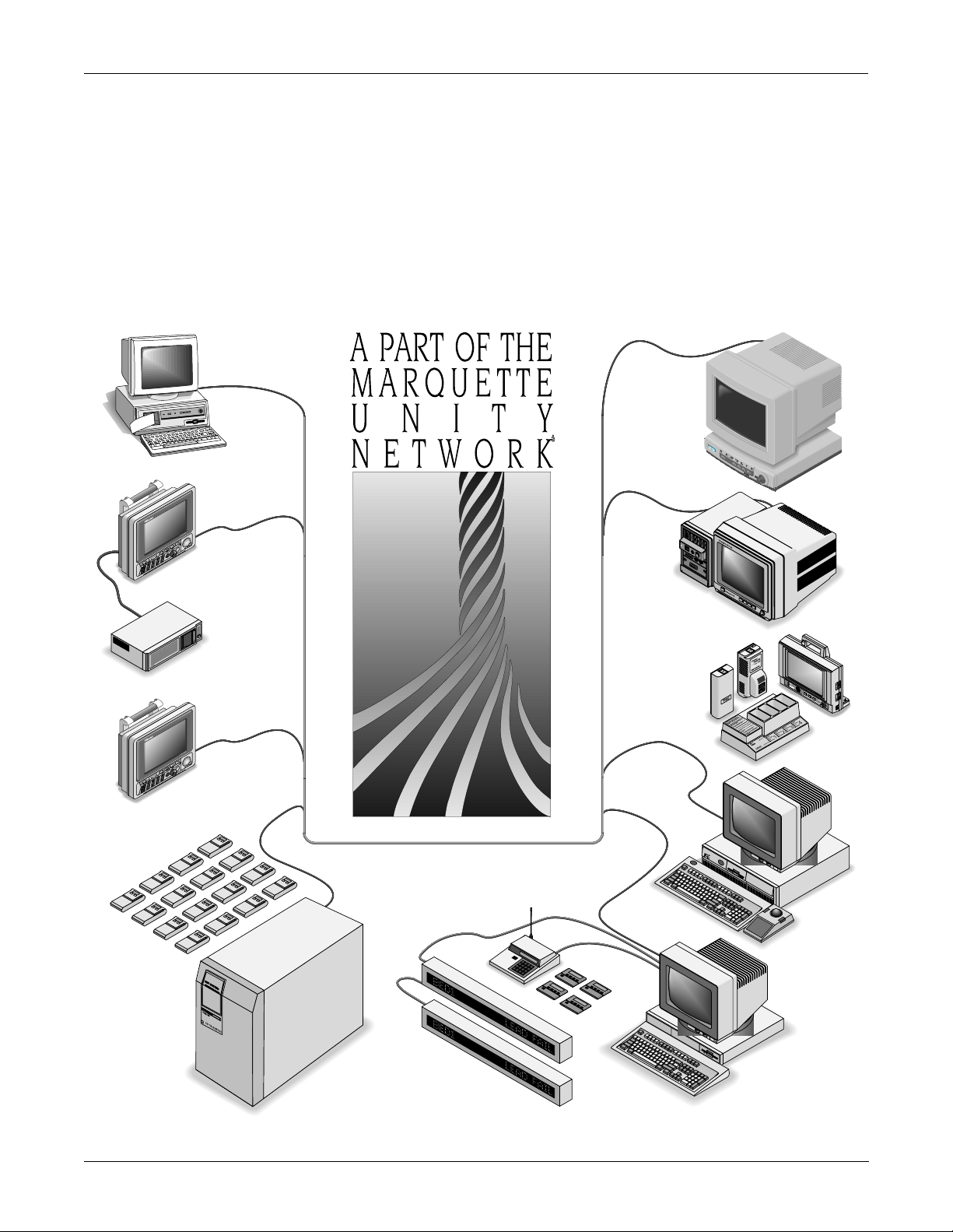

What is the Marquette Unity Network?

The Marquette Unity Network is a comprehensive communication

network which unifies GE Marquette Medical Systems patient

monitoring and data management equipment into an integrated

hospital-wide system. It creates an extended communication system for

efficient information sharing among operating rooms intensive care

units, the emergency room, and other care and diagnostic areas.

Information entered anywhere on the network, via any input device, is

available anywhere else on the network. This is accomplished through

the Ethernet communication hardware in the patient monitor.

An example of part of a Marquette Unity Network is shown bel ow.

Revision H Solar 7000/8000/View Patient Monitor 2-3

414993-001

Page 20

EQUIPMENT OVERVIEW: System Components

What is a Solar 7000 Patient Monitor?

The Solar 7000 patient monitor is the center of the Solar 7000 Patient

Monitoring System. It is an intelligent terminal, containing the display,

all of the user controls, and processors to communicate with patient

monitor peripherals and analyze patient data. It is capable of displaying

up to eight different waveforms at one time. System software may be

updated by a laptop computer at the monitor or through the Marquette

Unity network using a central station.

Shown below is a Solar 7000 patient monitor.

2-4 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 21

EQUIPMENT OVERVIEW: System Components

What is a Solar 8000 Patient Monitor?

The Solar 8000 patient monitor consists of a Solar 8000 processing unit

with a compatible display purchased from GE Marquette Medical

Systems or another vendor. (For details about the GE Marquette display,

refer to the 15-Inch Medical-Grade Color Display Service Manual, pn

414993-056.)

The processing unit is the center of the Solar 8000 Patient Monitoring

system. It provides the user controls, processors to communicate with

various patient monitoring modules contained in a Tram-rac housing,

and analyzes patient data. It is capable of di splaying up to eight diff erent

waveforms at one time on a compatible display. System software may be

updated using a laptop computer connected to the Solar 8000 processing

unit or from a central station on the Marquette Unity Network. Shown

below is a generic display and a Solar 8000 processing unit.

Revision H Solar 7000/8000/View Patient Monitor 2-5

414993-001

Page 22

EQUIPMENT OVERVIEW: System Components

What is a SolarView Remote Display Controller?

A SolarView remote display controller resembles a Solar 8000 processing

unit, but it is not connected to a Tram-rac housing with patient

monitoring modules. It consists of a SolarV iew remote display controller

with a compatible display purchased from GE Marquette Medical

Systems or another vendor. (For details about the GE Marquette display,

refer to the 15-Inch Medical-Grade Color Display Service Manual, pn

414993-056.) The controller is connected to the Marquette Unity network

and may be configured to display any patient waveforms broadcasted on

the network for better visibility as either a remote, full-view display or as

an in-room, telemetry display. System software may be updated using a

laptop computer connected to the SolarView remote display controller or

from a central station on the Marquette Unity Network. Shown below is

a generic display and a SolarView remote display controller.

What is a Tram-rac Housing?

The Tram-rac housing (remote acquisition case) acquires patient data for

the patient monitor. The Tram-rac Housing Service Manual, pn404183-

096, has more information. There are two Tram-rac housings available

for the monitor:

• Tram-rac 2 housing, which holds a single Tram module, and

• Tram-rac 4A housing, which holds a Tram module and two additional

Series 7000 input modules.

Shown below is a Tram-rac 4A housing with a Tram module, Series 7000

BP/dual temperature module, and single Series 7000 BP module

inserted.

2-6 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 23

EQUIPMENT OVERVIEW: System Components

What is a DDW?

What is a PRN 50 Digital Writer?

A Direct Digital Writer (DDW) allows patient data to be printed on a

paper strip. Any parameter or trace that can be monitored at the patient

monitor can also be printed on the DDW. Graphs are initiated

automatically when an alarm has been violated, or they can be initiated

manually at the patient monitor.

A PRN 50 Digital Writer thermally records patient data on a paper strip.

Any parameter or trace that can be monitored on a patient monitor can

be graphed by the writer. Graphs are initiated automatically when an

alarm has been activate d, or they can be initiated manually from a

monitor.

Revision H Solar 7000/8000/View Patient Monitor 2-7

414993-001

Page 24

EQUIPMENT OVERVIEW: System Components

What is a Remote Control?

The remote control duplicates all patient monitor controls on a portable

component with a Trim Knob control. It allows the user to operate the

patient monitor from across a room. The twelve hard keys are configured

for adult, neonatal, or operating room applications. For more details

about the remote control, refer to the Modular Patient Monito r

Accessories Service Manual, pn 404183-150.

What is a Remote Display?

NOTE: An adapter,

pn 405947-002, is

required for cable,

pn 405360-00X, to the

remote display.

A color or monochrome secondary display may be attached directly to the

Solar 7000 patient monitor to display up to eight patient monitor

waveforms for better visibility . It is connected to the video out (RMT VID)

connector at the back of the monitor. F or details about the remote display ,

refer to the Patient Monitor Accessories Service Manual, pn 404183-150.

2-8 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 25

EQUIPMENT OVERVIEW: System Components

What is a Tram-net Hub Assembly?

If a patient monitor is connected to more than one peripheral device, the

Tram-net hub assembly is used. It connects the communication

processing capabilities inside the patient monitor to other equipment,

much like what a multiple outlet power strip does for ac power.

Peripherals can be connected to the Tram-net hub assembly via serial

cabling. The Tram-net hub assembly extends the patient monitor with a

cable of up to 1.3 meters (4 feet) long.

Note that a 25-pin D-type connector at the rear of the patient monitor is

marked TRAM-NET or ASYNC COMM. This connector handles both

Tram-net and async signals. One end of the Tram-net hub assembly

connects to this connector. At the other end of t he Tram-net hub

assembly, the signals are separated into async and four Tram-net

connectors. The 25-pin red color coded connector handles async for

communication only with an async-only. The four 9-pin blue color coded

connectors are for extending the Tram-net network (blue label). More

details about Tram-net communication will be covered later in this

chapter.

Shown below is a Tram-net hub assembly . F or details about the Tram-net

hub assembly, refer to the Modular Patient Monitor Accessories Service

Manual, pn 404183-150.

Revision H Solar 7000/8000/View Patient Monitor 2-9

414993-001

Page 26

EQUIPMENT OVERVIEW: System Components

What is a Tram-net Interface?

The Tram-net interface adapter connects a specific device to the Solar

7000/8000 patient monitoring system using Tram-net communication.

Each adapter is preprogrammed at the factory to interface with a specific

device manufactured by a company other than GE Marquette Medical

Systems. In most cases, the Tram-net interface adapter requires a Tramnet hub to connect with the Tram-net communication network. For more

details about the Tram-net interface adapter, refer to the Modular

Patient Monitor Accessories Service Manual, pn 404183-150.

What is an Octanet Connectivity Device?

The Octanet Connectivity Device acquires digital data from eight

individually isolated serial ports. The data is collected from up to eight of

devices not manufactured by GE Marquette Medical Systems. The

Octanet Connectivity Device processes the patient data from the

peripheral devices and transmits the formatted data to the Solar patient

monitor . For more details about the Octanet Connectivity Device, refer to

the Octanet Connectivity Device Service Manual, pn 418264-003.

2-10 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 27

EQUIPMENT OVERVIEW: System Components

What is a TMSS?

The Trend Memory Storage System (TMSS) is an opt ional device that

stores up to 24 hours of trend data for the CRG Plus display—six hours

at a time. This feature is available with V3 software or later. The stored

CRG data is used in the overall analysis of a patient. Analyzing trend

waveforms permits the ability to view both subtle and dramatic changes

in the patient’s vital signs. It also enables the clinician to correlate

changes of one parameter with respect to ano ther. For more de tails about

the TMSS, refer to the Model 7024 Product Manual, pn 13703AA-000.

Revision H Solar 7000/8000/View Patient Monitor 2-11

414993-001

Page 28

EQUIPMENT OVERVIEW: Technical Specifications

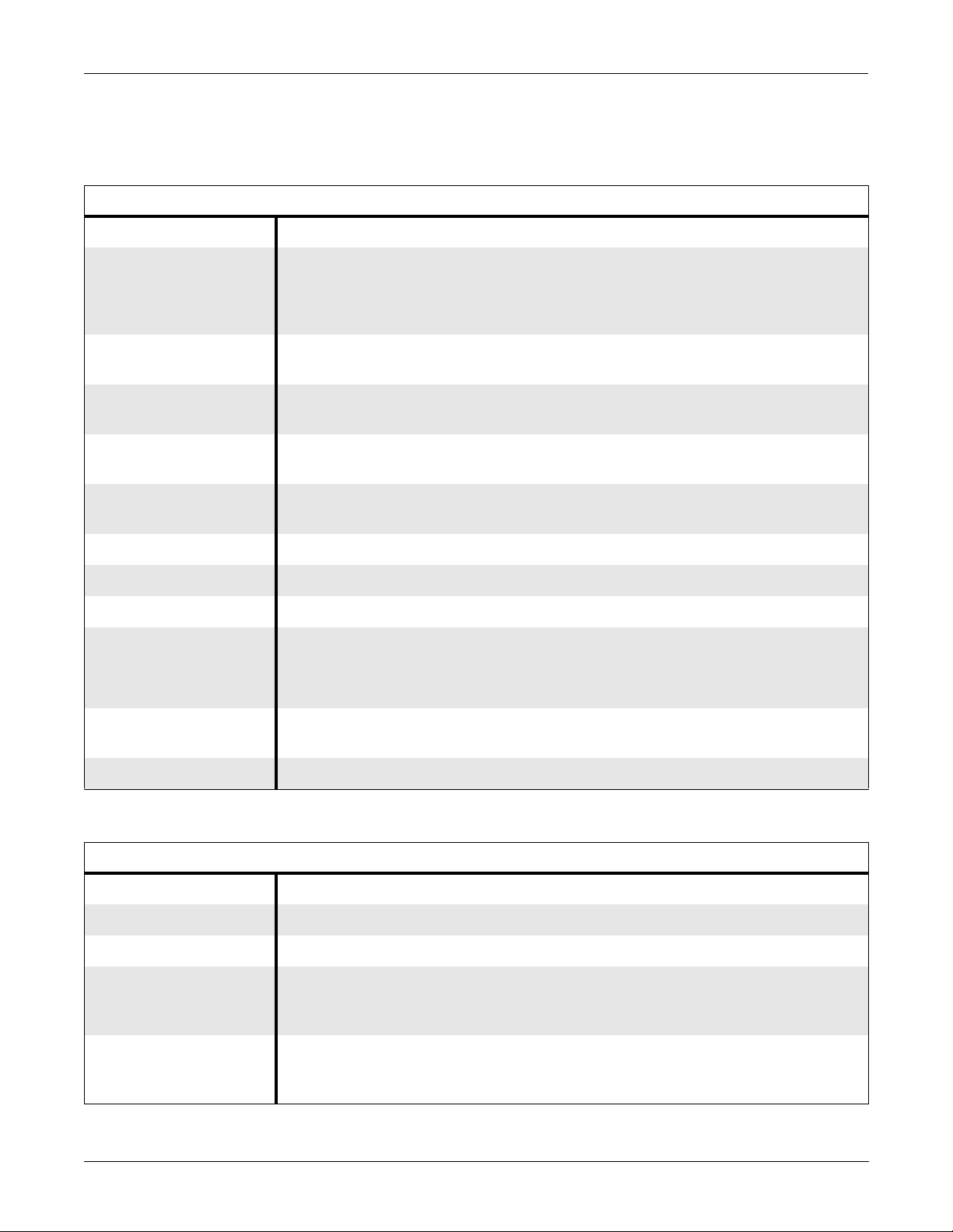

Technical Specifications

Display Specifications

Item Description

Size Solar 7000 Monitor: 12-inch (measured diagonally)

Solar 8000 Processing Unit: Display is ordered separately and may vary.

SolarView Remote Display Controller: Display is ordered separately and

may vary.

Type Solar 7000 Monitor: High-definition Raster scan for waveforms and

alphanumerics

Resolution Solar 7000 Color Monitor: 1024 pixels wide by 512 pixels high

Solar 7000 Monochrome Monitor: 1024 pixels wide by 512 pixels high

Traces Solar 7000 Monitor: Number of traces: 1 to 8

Solar 7000 Monitor: Number of seconds/trace: 6.5 at 25 mm/sec

Phosphor Solar 7000 C olor Monitor: P22

Solar 7000 Monochrome: Monitor: P218

Sweep Speed Solar 7000 Monitor: 25 mm/sec (meets all ANSI/AAMI specifications)

Frequency Response Limited by input response of da ta acquisition device

Linearity Solar 7000 Monitor:1% of picture height

Waveform Display

Options

■ Full

■ Individual

■ CRG Plus

Information Window Display all non-real time information without obstructing the display of

real-time information

Display Organization Prioritized by pa rameter

Processing Specifications

Item Description

Main Processor Motorola MC68EN360, 32-Bit, 25 MHz

Graphics Processor Texas Instrument TMS34010, 16-Bit, 46.7 MHz

Tram-net

Intel 82596CA, 32-Bit, 25 MHz

Communication

Processor

LAN (Ethernet)

Integrated into the Motorola MC68EN360 processor

Communication

Processor

2-12 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 29

EQUIPMENT OVERVIEW: Technical Specifications

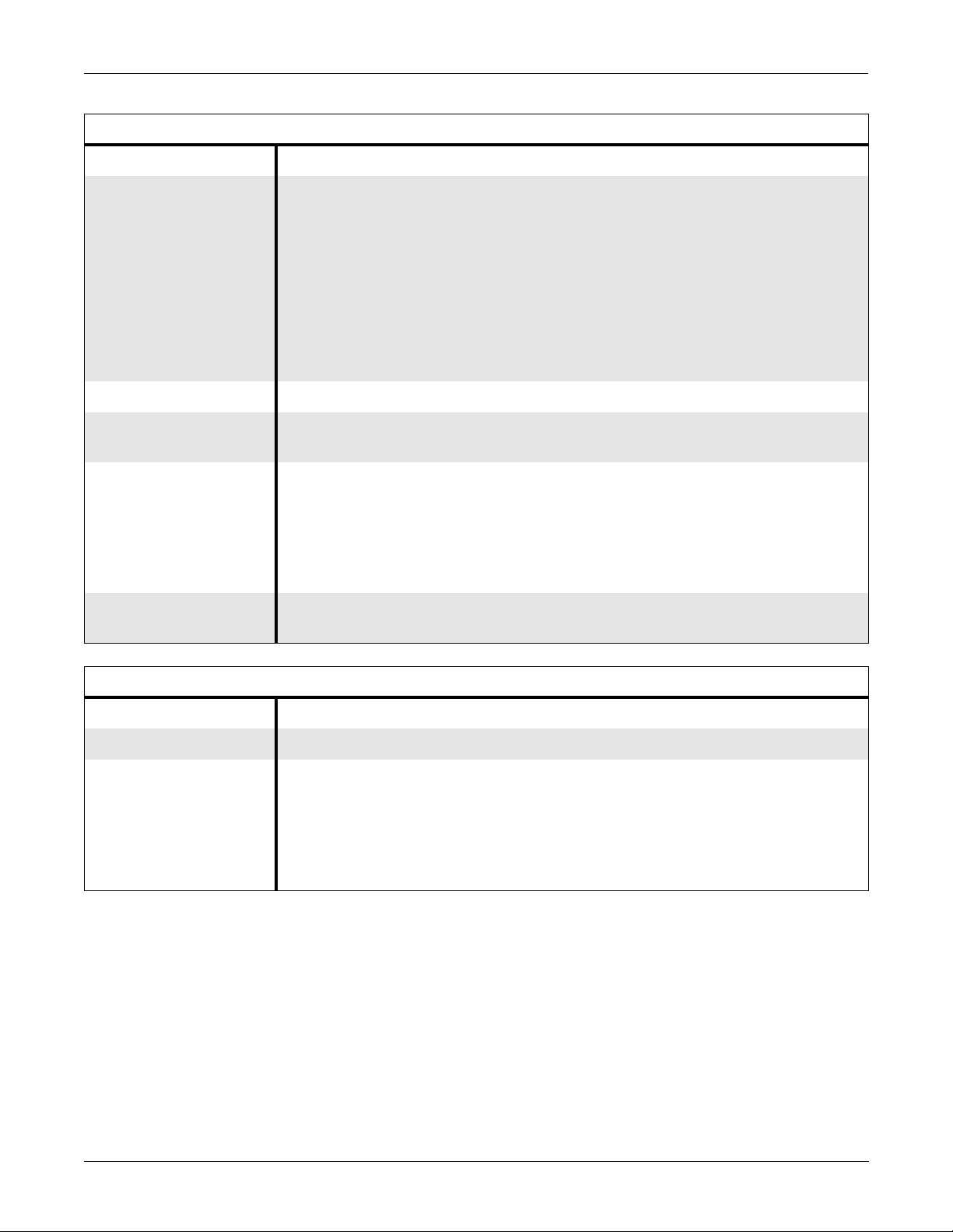

Alarm Specifications

Item Description

Classification Patient status alarms have 4 levels:

■ Crisis

■ Warning

■ Advisory

■ Message

System alarms have 2 levels:

■ Warning

■ Advisory

Alarms Notification Audible and visual, dependent on level

Display of Alarm

All limits are viewable and graphable

Information

Silencing Only current alarm for 1 minute

Alarm pause:

■ 5 minutes in adult ICU mode

■ 3 minutes in neonatal mode

■ 5 minutes, 15 minutes, or permanent alarm pause in OR mode

Continuous Display of

All parameters, one set of limits

Limits

Control Specificat ions

Item Description

Trim Knob Control Single control operation of all display functions

Five Hard Keys

■ Display On/Off

■ Silence Alarm

■ Grap h Go/Stop

■ NBP Go/Stop

■ Zero All

Revision H Solar 7000/8000/View Patient Monitor 2-13

414993-001

Page 30

EQUIPMENT OVERVIEW: Technical Specifications

Environmental Specifications

Item Description

Powe r Requirements Solar 7000 Color Monitor:

■ 110 ± 11 VAC, 50/60-Hz, single phase

■ 120 ± 12 VAC, 50/60-Hz, single phase

■ 220-230 ± 22 VAC, 50/60-Hz, single phase

■ 240 ± 24 VAC, 50/60-Hz, single phase

Solar 7000 Monochrome: Monitor and Solar 8000 Processing Unit

■ 110 ± 20 VAC, 50/60-Hz, single phase

■ 220-230 ± 40 VAC, 50/60-Hz, single phase

Power Consumption Solar 7000 Color Monitor: 200 W (180 W for a Tram-rac housing with power

supply connected)

Solar 7000 Monochrome Monitor: 120 W (100 W for a Tram-rac housing with

power supply connected)

Solar 8000 Processing Unit: 100W (maximum)

SolarView Remote Display Controller: 25W (maximum)

Low Voltage Shutdown Solar 7000 Color Monitor: 88 VAC/106 VAC/196 VAC/214 VAC

Solar 7000 Monochrome Monitor: 85 VAC/170 VAC

Solar 8000 Processing Unit: 90 VAC/190 VAC

SolarView Remote Display Controller: 90 VAC/190 VAC

Cooling Solar 7000 Color Monitor: Forced convection

Solar 7000 Monochrome Monitor and Solar 8000 Processing Unit: Natural

convection

Heat Dissipation Solar 7000 Color Monitor: 680 Btu/hr (200 W)

Solar 7000 Monochrome Monitor: 409 Btu/hr (120 W)

Solar 8000 Processing Unit: 100 Btu/hr (30W)

SolarView Remote Display Controller: 50 Btu/hr (15W)

Operating Conditions

■ Ambient

Temperature

Solar 7000 Monitor: 10°C to 35°C (50°F to 95°F)

Solar 8000 Processing Unit: 10°C to 40°C (50°F to 104°F)

SolarView Remote Display Controller: 10°C to 40°C (50°F to 104°F)

■ Relative Humidity

Solar 7000 Monitor: 15% to 95% (noncondensing)

Solar 8000 Processing Unit: 15% to 95% (noncondensing)

SolarView Remote Display Controller: 15% to 95% (noncondensing)

Storage Conditions

■ Temperature

Solar 7000 Monitor: –10°C to 50°C (14°F to 122°F)

Solar 8000 Processing Unit: –40°C to 70°C (–40F° to °158F)

SolarView Remote Display Controller: –40°C to 70°C (–40F° to °158F)

■ Relative Humidity

Solar 7000 Monitor: 0% to 95% (noncondensing)

Solar 8000 Processing Unit: 15% to 95% (noncondensing)

SolarView Remote Display Controller: 15% to 95% (noncondensing)

2-14 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 31

EQUIPMENT OVERVIEW: Technical Specifications

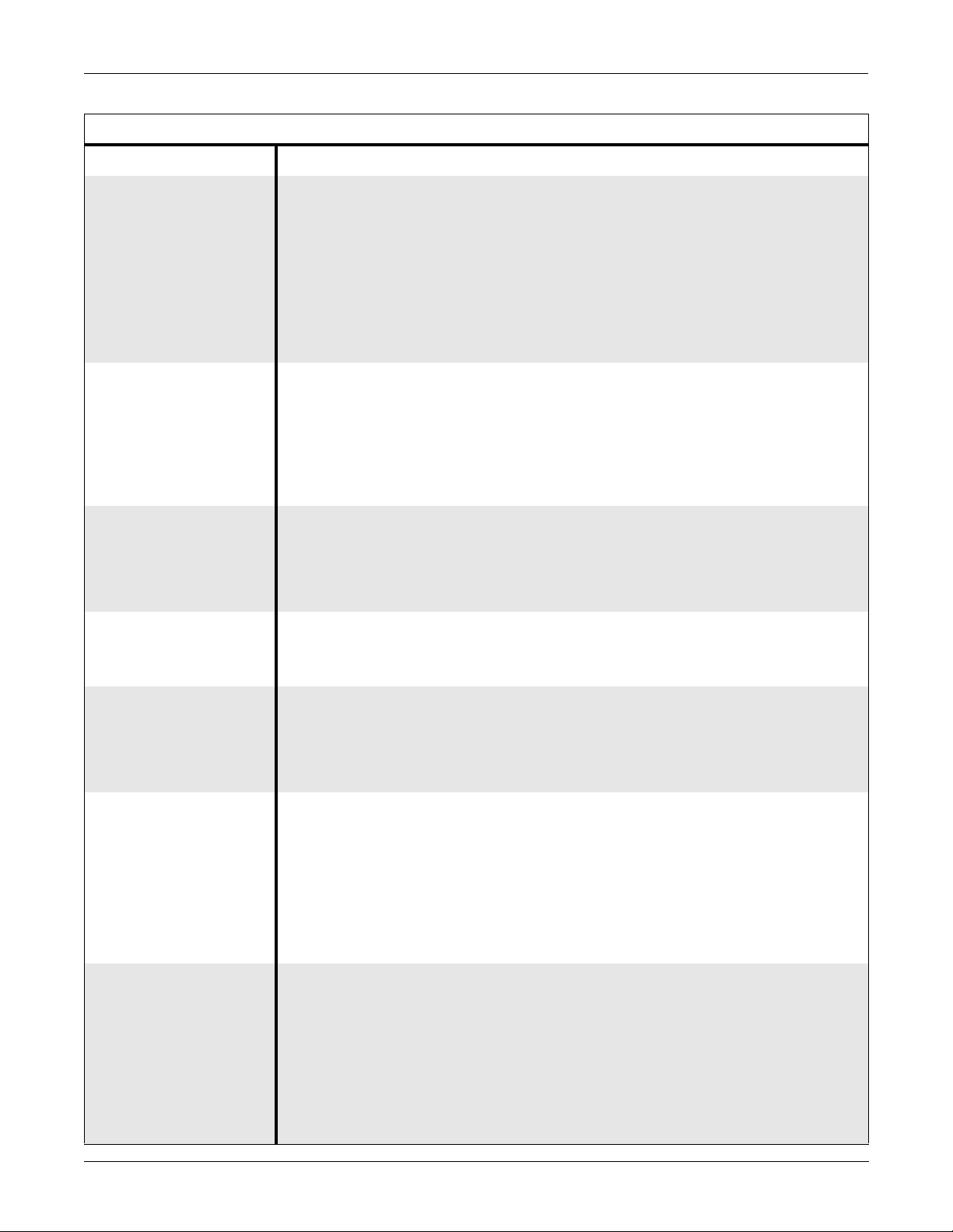

Physical Specifications

Item Description

Height Solar 7000 Monitor: 31.1 cm (12.3 in)

Solar 8000 Processing Unit: 8.1 (3.2 in)

SolarView Remote Display Controller: 8.1 (3.2 in)

Width Solar 7000 Monitor: 33.4 cm (13.5 in)

Solar 8000 Processing Unit: 33.6 cm (13.3 in)

SolarView Remote Display Controller: 33.6 cm (13.3 in)

Depth Solar 7000 Color Monitor: 55.2 cm (21.7 in)

Solar 7000 Monochrome Monitor: 39.9 cm (15.7)

Solar 8000 Processing Unit: 34.9 cm (13.8 in)

SolarView Remote Display Controller: 34.9 cm (13.8 in)

Weight Solar 7000 Color Monitor: 22 kg (48 lb)

Solar 7000 Monochrome Monitor: 13.3 kg (29.4 lb)

Solar 8000 Processing Unit: 5.4 kg (12.0 lb)

SolarView Remote Display Controller: 5.4 kg (12.0 lb)

Minimum Enclosure

Requirements

(Interior)

Height: 10.7 cm (4.2 in)

Width: 38.9 cm (15.3 in)

Depth: 51.8 cm (20.4 in)

Item Description

Safety Standards Solar 7000 Monitor:

■ UL544 Listed

■ UL Listed for CSA C22.2 No. 125

■ IEC 60601-1 Certified

■ CE Marking for the 93/42/EEC Medical Device Directive (Refer to operator’s

manual for CE Marking specifics.)

Solar 8000 Processing Unit and SolarView Remote Display Controller:

■ UL 2601-1 Classified

■ UL Classified for CAN/CSA C22.2 No. 601.1

■ IEC 60601-1 Certified

■ CE Marking for the 93/42/EEC Medical Device Directive (Refer to operator’s

manual for CE Marking specifics.)

Certification

Revision H Solar 7000/8000/View Patient Monitor 2-15

414993-001

Page 32

EQUIPMENT OVERVIEW: Technical Specifications

Classification

Item Description

Type of protection

Class I Equipment

against electrical shock

Degree of protection

Type B Applies Part

against electrical shock

Degree of protection

against harmful ingress

Ordinary Equipment (enclosed equipment without protection against ingress of

water)

of water

Degree of safety of

application in the

Equipment not suitable for use in the presence of a flammabl e anesthetic

mixture with air or with oxygen or nitrous oxide.

presence of a flammable

anesthetic mixture with

air or with oxygen or

nitrous oxide

Method(s) of

Not Applicable

sterilization or

disinfection

recommended by the

manufacturer

Mode of operation Continuous operation

2-16 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 33

EQUIPMENT OVERVIEW: Preparation for Use

Preparation for Use

Power Connection

For the Solar 7000 monitor, connect the power cord to the power supply

inlet and anchor the cord with the restraining clip and screw.

For the Solar 8000 processing unit or SolarView remote display

controller, connect the power cord to the power supply inlet and anchor

the cord with the restraining clip and screw.

Revision H Solar 7000/8000/View Patient Monitor 2-17

414993-001

Page 34

EQUIPMENT OVERVIEW: Preparation for Use

Tram-rac Housing Connection

Marquette Unity Network Connection

If a Tram-rac power supply is used, connect the power cord as shown

below.

For the Solar 7000/8000 monitor or SolarView remote display controller,

connect the Marquette Unity network to the Ethernet connector with kit,

pn 414292-001, as shown below.

1. Remove four jackscrews from

connectors shown.

2. Install two screws from kit to

secure ETHERNET

connector to chassis.

3. Install two screws to connect

transceiver bracket to

transceiver.

4. Use two jackscrews removed

earlier to mount transceiver

and bracket to ETHERNET

connector.

2-18 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 35

EQUIPMENT OVERVIEW: Preparation for Use

Interconnection

The Solar 7000/8000 patient monitor or SolarView remote display

controller has six communication connectors to accomodate your

monitoring system.

• ASYNC COMM connects to a DDW or remote control, or to download

new software. SolarView remote display controller does not use this

function.

• TRAM-NET combines Tram async and the Tram-net network for

communication with many bedside peripherals, i.e. Tram-net hub,

Tram-rac housing, or remote control. SolarView remote display

controller does not use this function.

• ETHERNET is the Marquette Unity Network connection that

provides faster hospital wide communication.

• Remote alarm (RMT ALM) provides relay contact closure for “Leve l

I” alarms to an alarm annunciator.

• For the Solar 7000 monitor, remote display (RMT VID) connects to a

secondary remote display. For the Solar 8000 processing unit or

SolarView remote display controller, video (VID) connects to the local

display.

• RS-232 is for future use.

WARNING

Connect devices solely manufactured by GE Marquette

Medical Systems directly to the Marquette Unity

Network. Contact MMS—Technical Support before

connecting equipment from other manufacturers.

Revision H Solar 7000/8000/View Patient Monitor 2-19

414993-001

Page 36

EQUIPMENT OVERVIEW: Preparation for Use

Tram-rac 4A Housing

Shown below is the connection from the Tram-rac 4A housing to a Solar

monitor with and without a Tram-net hub connection.

Solar 7000 Patient Monitor

Solar 8000 Patient Monitor

2-20 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 37

EQUIPMENT OVERVIEW: Preparation for Use

Tram-rac 2 Housing

Shown below is the connection from the Tram-rac 2 housing to a Solar

monitor with and without a Tram-net hub connection.

Solar 7000 Patient Monitor

Solar 8000 Patient Monitor

Revision H Solar 7000/8000/View Patient Monitor 2-21

414993-001

Page 38

EQUIPMENT OVERVIEW: Preparation for Use

Dual Tram-rac Housings

The Solar patient monitor may support two Tram-rac housings.

The right most Tram-net connector may be connected to the following:

• a monitor or

• a Tram-net hub,

The center Tram-net connector may be connected to the following:

• a remote control or

• to another Tram-rac 4A housing with a power supply.

NOTE: The Tram-rac housing furthest from the monitor must have a

power supply.

Shown below are examples of how to connect dual Tram-rac housings to a

Solar 7000 patient monitor.

2-22 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 39

EQUIPMENT OVERVIEW: Preparation for Use

Shown below are examples of how to connect dual Tram-rac housings to a

Solar 8000 patient monitor.

Revision H Solar 7000/8000/View Patient Monitor 2-23

414993-001

Page 40

EQUIPMENT OVERVIEW: Preparation for Use

Octanet

Shown below is the connection from the Octanet to a Solar monitor with

a Tram-net hub connection.

Solar 7000 Patient Monitor

Solar 8000 Patient Monitor

DDW

The DDW connects between the ASYNC COMM ports of the DDW and

the Solar 7000 or 8000 patient monitor. Due to continuing product

innovation, your DDW may be different from that illustrated below.

2-24 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 41

EQUIPMENT OVERVIEW: Preparation for Use

PRN 50

The PRN 50 Digital W riter conne cts between t he ASYNC COMM ports of

the PRN 50 Digital Writer and the Solar 7000 or 8000 monitor. Shown

below is the connection of the PRN 50 Digital Writer to Solar 7000 or

8000 monitor.

Solar 7000 Patient Monitor

Solar 8000 Patient Monitor

Revision H Solar 7000/8000/View Patient Monitor 2-25

414993-001

Page 42

EQUIPMENT OVERVIEW: Preparation for Use

The PRN 50 Digital Writer connects between AutoPort on the PRN 50

Digital Writer and the TRAM-NET ports of the Solar 7000 or 8000

monitor when using the Octanet. Shown below is the connection of the

PRN 50 Digital Writer to Solar 7000 or 8000 monitor with a Tram-net

hub and Octanet connection.

Solar 7000 Patient Monitor

Solar 8000 Patient Monitor

2-26 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 43

EQUIPMENT OVERVIEW: Preparation for Use

Local/Remote Displays

The Solar 7000 has its own internal local display, but a Solar 8000

system requires a medical-grade display that meets UL and IEC

specifications. If a non-medical computer-grade display is used, an

isolation transformer (or floating power supply) is required regardless if

the computer-grade display meets the leakage current specifications on

its own.

The party assembling or modifying the medical electrical system is

responsible to insure compliance with IEC 601-1-1. Therefore, if GE

Marquette installs a Solar 8000 system with a computer-grade display,

GE Marquette is responsible for meeting the specification. As a result GE

Marquette will only:

• Install medical-grade displays that it recommends, or

• Install computer-grade displays with appropriate isolation

transformers (power conditioners).

NOTE

In an OR or other locations already having an isolated

power system, the use o f an isolat ing transfo rmer (powe r

conditioner) is redundant, and therefore may not be

necessary for patient isolation.

Revision H Solar 7000/8000/View Patient Monitor 2-27

414993-001

Page 44

EQUIPMENT OVERVIEW: Preparation for Use

FPD (Flat Panel Display) Interconnection

To connect a FPD , a medical-g rade power supply is required. Connect the

FPD to the VID 15-pin connector on the Solar 8000 processing unit.

Connect the power supply to the pow er jack of the FPD as shown below.

Connect both po wer cords from both units to the AC outlet.

2-28 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 45

EQUIPMENT OVERVIEW: Preparation for Use

Remote Display Interconnection

Shown below are examples of how to connect a remote display to a Solar

7000 patient monitor.

• Display with D style Connector •

• Display with BNC Connectors •

Revision H Solar 7000/8000/View Patient Monitor 2-29

414993-001

Page 46

EQUIPMENT OVERVIEW: Preparation for Use

Solar 8000 Local and Remote Display Interconnection

Shown below are examples of how to connect a local display to a Solar

8000 patient monitor or SolarView remote display controller.

• Display with D style Connector •

• Display with BNC Connectors •

2-30 Solar 7000/8000/View Patient Monitor Revision H

414993-001

Page 47

EQUIPMENT OVERVIEW: Preparation for Use

Cabling Schemes

Select one of the interconnection schemes described after following the

steps below.

1. Determine which display you have in the left column.

2. Match your display’s connector with the installation required.

3. Determine the distance from the remote display to the monitor.

4. Select the appropriate type of installation.