Page 1

TC65 Hardware Interface Description

Strictly confidential / Draft

s

3.11.1 Installing the USB Modem Driver

This section assumes you are familiar with installing and configuring a modem under

Windows 2000 and Windows XP. As both operating systems use multiple methods to access

modem settings this section provides only a brief summary of the most important steps.

Take care that the “usbmodem.inf” file delivered with TC65 is at hand. Connect the USB

cable to the TC65 host application (for example the evaluation board DSB75) and the PC.

Windows detects TC65 as a new USB modem, opens the

reports that it is searching for the “Siemens AG WM USB Modem” driver. Follow the

instructions on the screen and specify the path where the “usbmodem.inf” file is located.

Windows will copy the required software to your computer and configure the modem by

assigning a free COM port. If you are already using more than one COM port then the next

free one will be allocated. Click

Notes for Windows 2000 only:

• During the installation procedure you will be prompted for the “usbser.sys” driver. Make

sure the file is present before you start installing the above inf file.

The “usbser.sys” file is not delivered as a single file, but must be extracted from a

Windows 2000 cabinet file. This is either the file “driver.cab” located in the “I386” folder of

the original Windows 2000 CD or a later cabinet file inside the Service Pack. SP4 for

example includes the “sp4.cab” file which can be found in its “I386” folder. The

“usbser.sys” driver from the Service Pack has priority over one provided with the

standard Windows 2000 install CD.

• It is necessary to restart Windows 2000 to make the changes take effect.

Finish to complete the installation.

Found New Hardware Wizard and

TC65_HD_V00.450 Page 49 of 96 20.04.2005

Page 2

TC65 Hardware Interface Description

Strictly confidential / Draft

You can find the “Siemens AG WM

USB Modem” listed under

Panel

| Phone and Modem Options |

Modems.

Troubleshooting for installation problems

If Windows fails to

assign the next free

COM port to TC65 and,

for example, allocates a

COM port already used

by another modem you

can manually select a

free port as follows:

Open the Windows

Device Manager, select

the installed “Siemens

AG WM USB Modem”,

click

Properties, select

the

Advanced tab and

click

settings

listbox

Number

port. To make the

changes take effect

disconnect and reconnect the USB cable.

If not yet successful,

also restart Windows.

Advanced Port

. From the

COM Port

choose a free

Control

s

TC65_HD_V00.450 Page 50 of 96 20.04.2005

Page 3

TC65 Hardware Interface Description

Strictly confidential / Draft

s

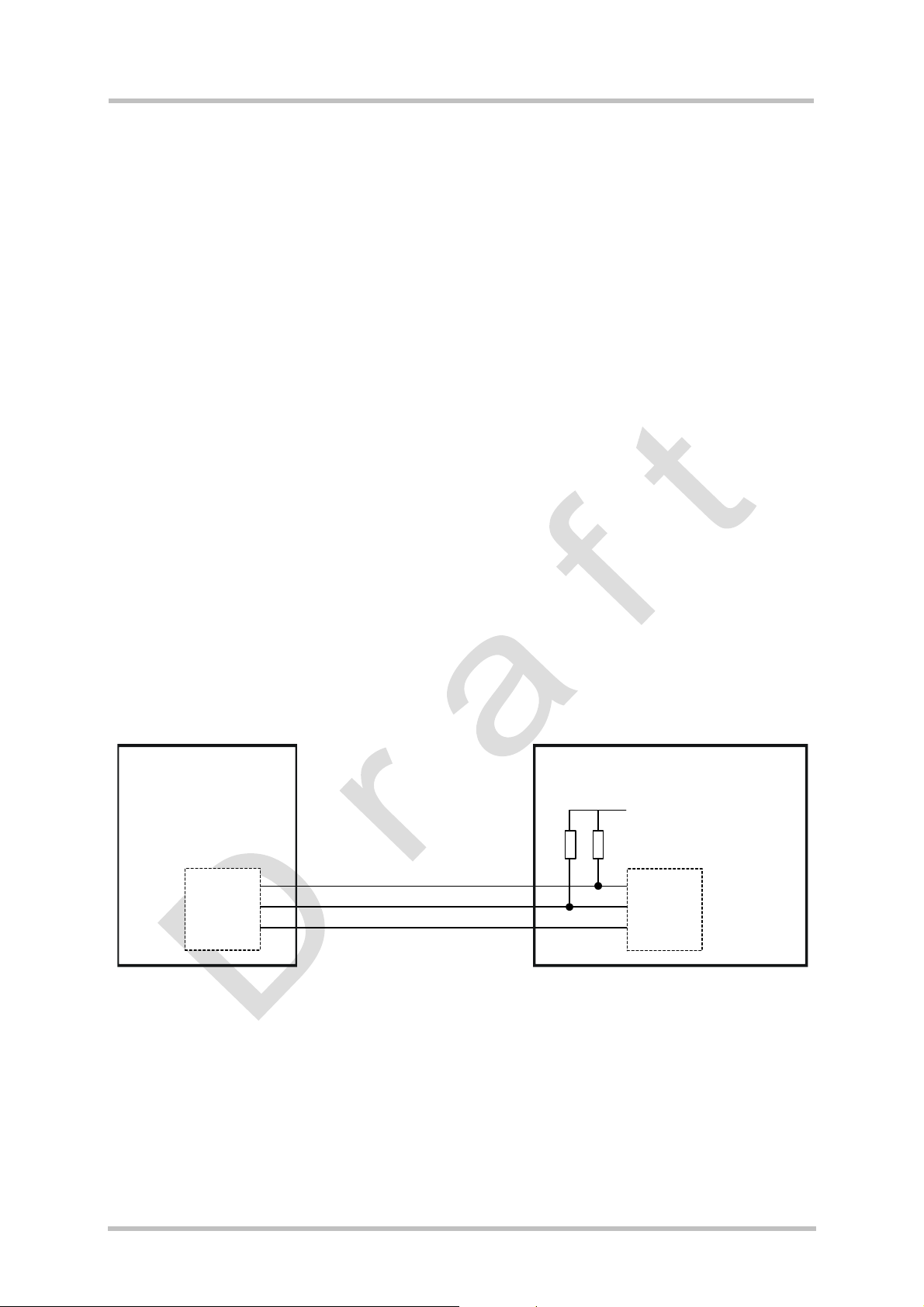

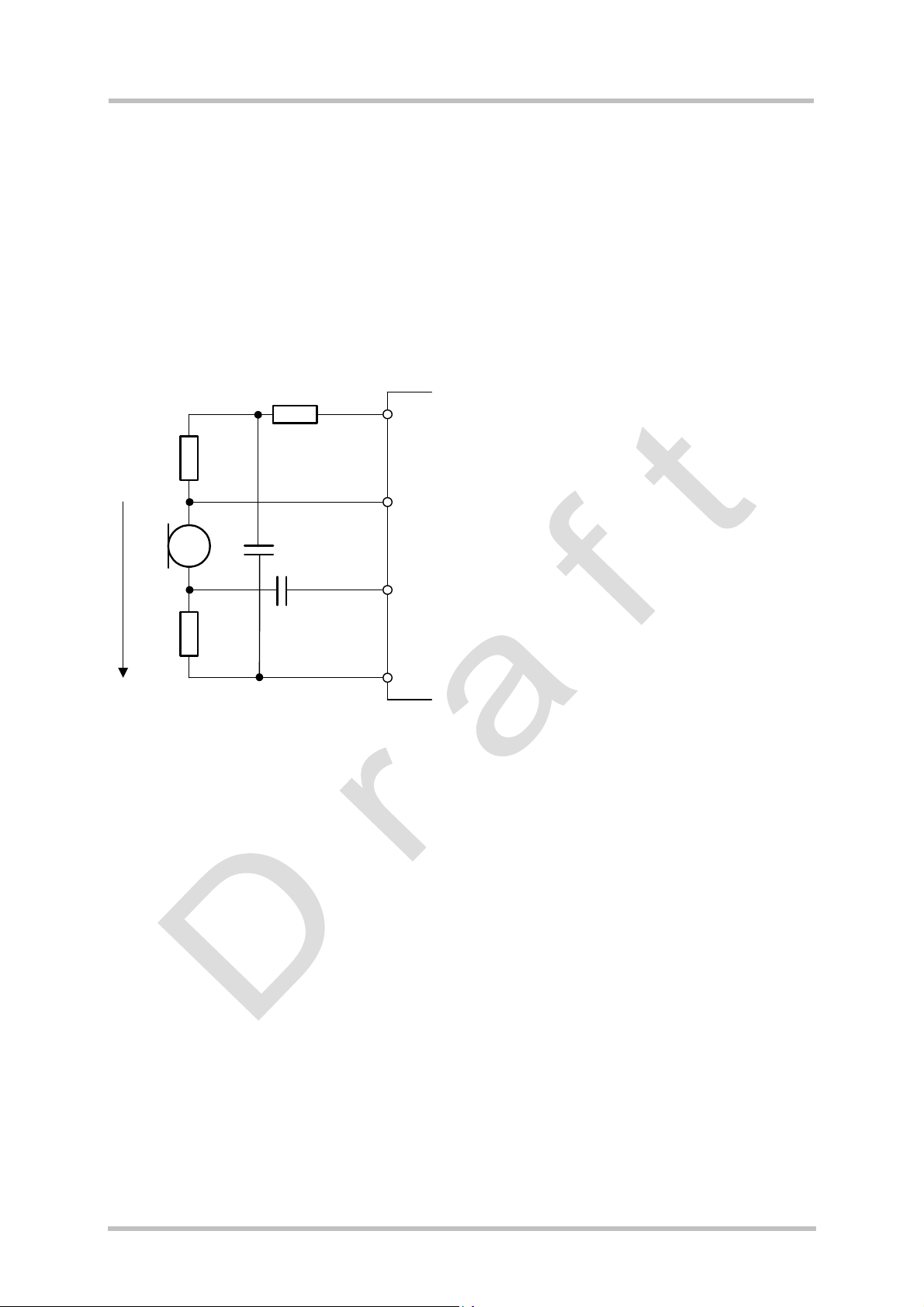

3.12 I2C Interface

I2C is a serial, 8-bit oriented data transfer bus for bit rates up to 400kbps in Fast mode. It

consists of two lines, the serial data line I2CDAT and the serial clock line I2CCLK.

The TC65 module acts as a single master device, e.g. the clock I2CCLK is driven by module.

I2CDAT is a bi-directional line.

Each device connected to the bus is software addressable by a unique 7-bit address, and

simple master/slave relationships exist at all times. The module operates as mastertransmitter or as master-receiver. The customer application transmits or receives data only

on request of the module.

To configure and activate the I

two lines I2CCLK and I2DAT are locked for use as SPI lines. Vice versa, the activation of the

SPI locks both lines for I

explanations on the protocol and syntax required for data transmission can be found in [1].

2

The I

C interface can be powered from an external supply or via the VEXT line of TC65. If

connected to the VEXT line the I

enters the Power-down mode. If you prefer to connect the I

supply, take care that VCC of the application is in the range of V

shut down when the PWR_IND signal goes high. See figures below as well as Section 7 and

Figure 38.

In the application I2CDAT and I2CCLK lines need to be connected to a positive supply

voltage via a pull-up resistor.

For electrical characteristics please refer to Table 17.

2

C bus use the AT^SSPI command. If the I2C bus is active the

2

C. Detailed information on the AT^SSPI command as well

2

C interface will be properly shut down when the module

2

C interface to an external power

and that the interface is

VEXT

GSM module

I2CDAT

I2CCLK

GND

Application

VCC

R

p

Figure 15: I2C interface connected to VCC of application

R

p

I2CDAT

I2CCLK

GND

w

VEXT

TC65_HD_V00.450 Page 51 of 96 20.04.2005

Page 4

TC65 Hardware Interface Description

Strictly confidential / Draft

s

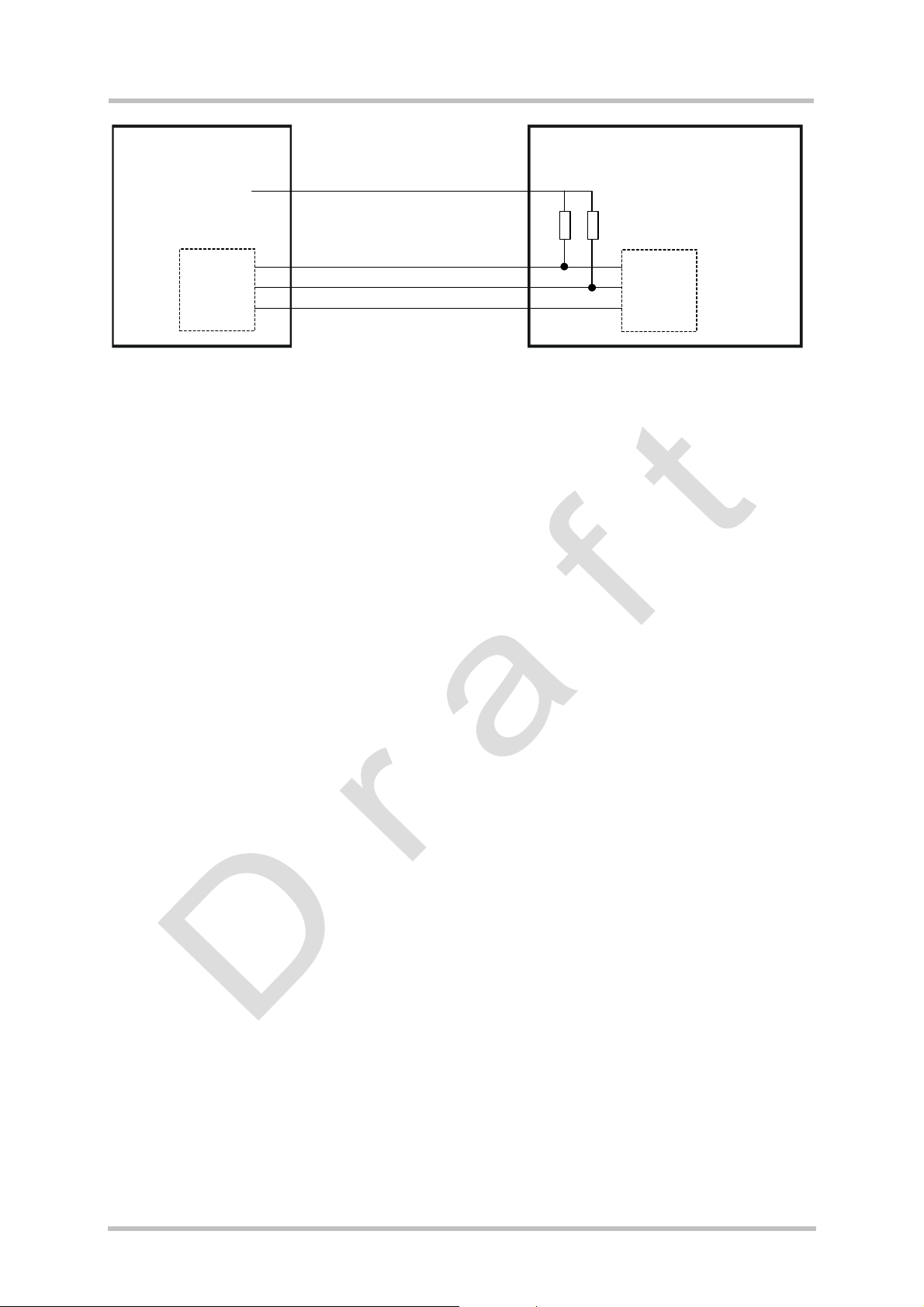

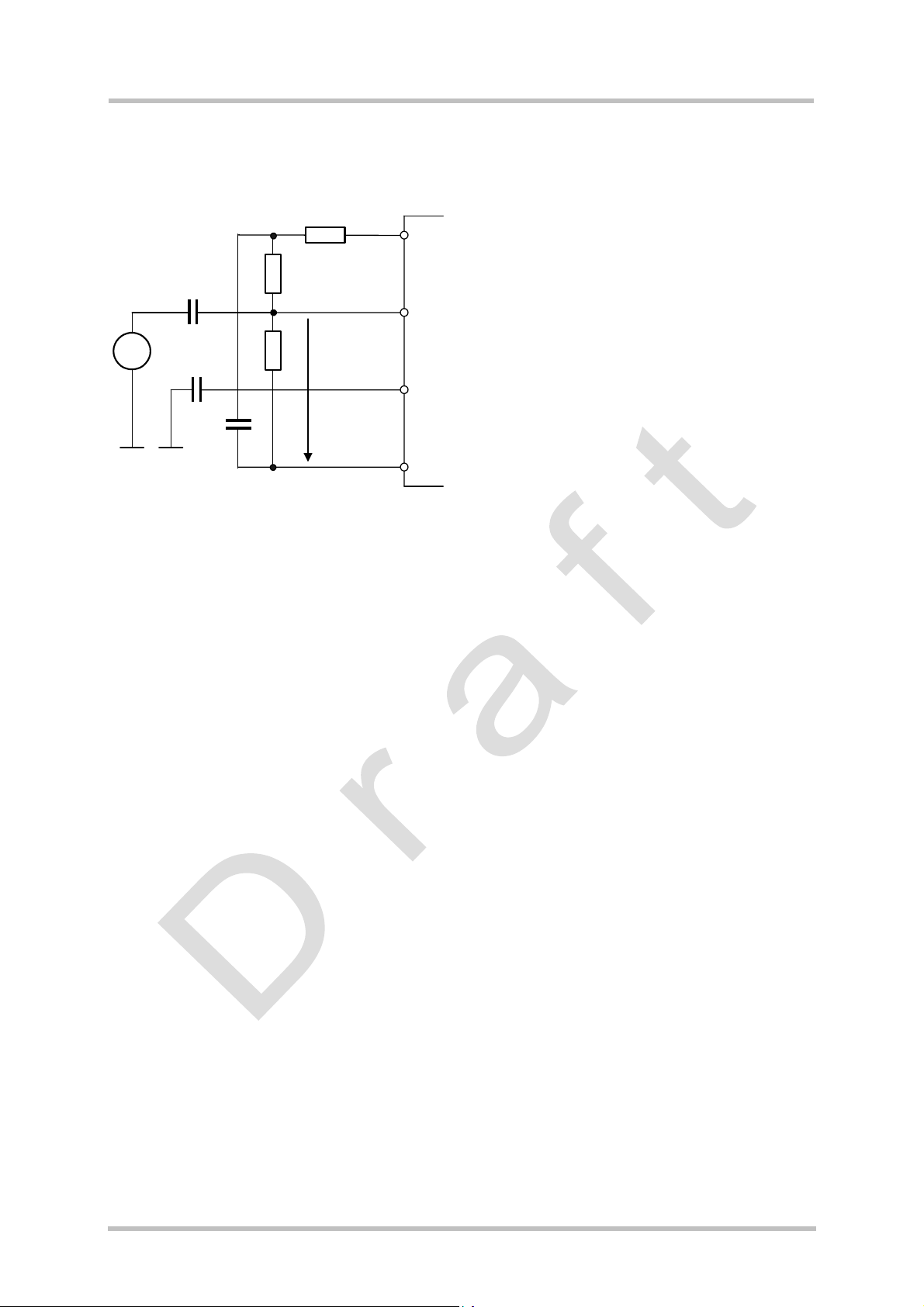

GSM module

VEXT

I2CDAT

I2CCLK

GND

R

p

Application

R

p

I2CDAT

I2CCLK

GND

Figure 16: I2C interface connected to VEXT line of TC65

Note: Good care should be taken when creating the PCB layout of the host application: The

traces of I2CCLK and I2CDAT should be equal in length and as short as possible.

TC65_HD_V00.450 Page 52 of 96 20.04.2005

Page 5

TC65 Hardware Interface Description

r

A

A

Strictly confidential / Draft

s

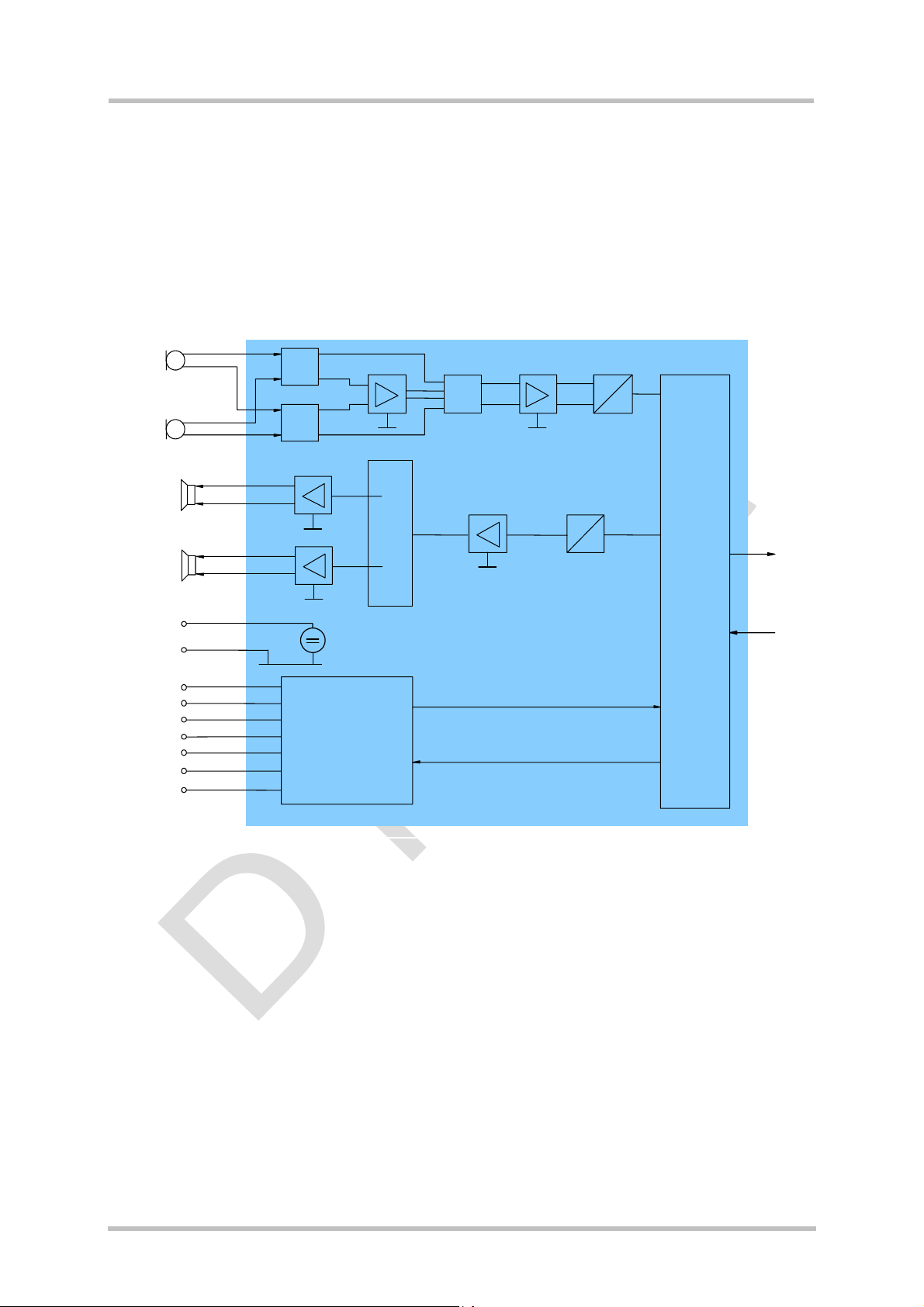

3.13 Audio Interfaces

TC65 comprises three audio interfaces available on the board-to-board connector:

• Two analog audio interfaces, both with balanced or single-ended inputs/outputs.

• Serial digital audio interface (DAI) designed for PCM (Pulse Code Modulation).

This means you can connect up to three different audio devices, although only one interface

can be operated at a time. Using the AT^SAIC command you can easily switch back and

forth.

MICP1

MICN1

MUX

VMIC

AGND

USC0

USC1

USC2

USC3

USC4

USC5

USC6

MICP2

MICN2

EPP1

EPN1

EPP2

EPN2

MUX

Digital

Audio

Interface

Analog switch

Figure 17: Audio block diagram

D

D

DSP

Ai

Interface

To suit different types of accessories the audio interfaces can be configured for different

audio modes via the AT^SNFS command. The electrical characteristics of the voiceband part

vary with the audio mode. For example, sending and receiving amplification, sidetone paths,

noise suppression etc. depend on the selected mode and can be altered with AT commands

(except for mode 1).

Both analog audio interfaces can be used to connect headsets with microphones or

speakerphones. Headsets can be operated in audio mode 3, speakerphones in audio

mode 2. Audio mode 5 can be used for a speech coder without signal pre or post processing.

When shipped from factory, all audio parameters of TC65 are set to interface 1 and audio

mode 1. This is the default configuration optimized for the Votronic HH-SI-30.3/V1.1/0

handset and used for type approving the Siemens reference configuration. Audio mode 1 has

fix parameters which cannot be modified. To adjust the settings of the Votronic handset

simply change to another audio mode.

TC65_HD_V00.450 Page 53 of 96 20.04.2005

Page 6

TC65 Hardware Interface Description

Strictly confidential / Draft

s

3.13.1 Speech Processing

The speech samples from the ADC or DAI are handled by the DSP of the baseband

controller to calculate e.g. amplifications, sidetone, echo cancellation or noise suppression

depending on the configuration of the active audio mode. These processed samples are

passed to the speech encoder. Received samples from the speech decoder are passed to

the DAC or DAI after post processing (frequency response correction, adding sidetone etc.).

Full rate, half rate, enhanced full rate, adaptive multi rate (AMR), speech and channel

encoding including voice activity detection (VAD) and discontinuous transmission (DTX) and

digital GMSK modulation are also performed on the GSM baseband processor.

3.13.2 Microphone Circuit

TC65 has two identical analog microphone inputs. There is no on-board microphone supply

circuit, except for the internal voltage supply VMIC and the dedicated audio ground line

AGND. Both lines are well suited to feed a balanced audio application or a single-ended

audio application.

The AGND line on the TC65 board is especially provided to achieve best grounding

conditions for your audio application. As there is less current flowing than through other GND

lines of the module or the application, this solution will avoid hum and buzz problems.

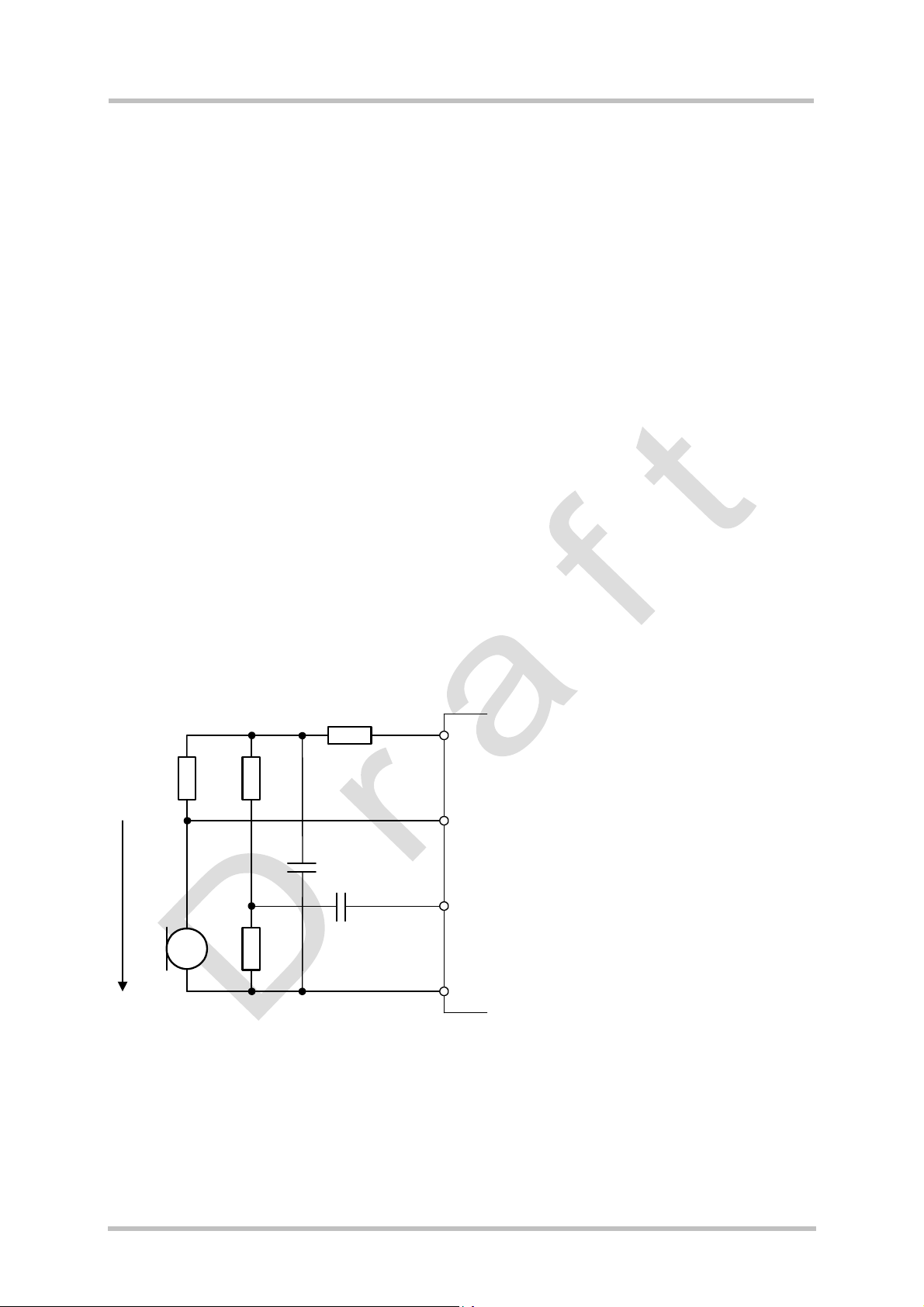

3.13.2.1 Single-ended Microphone Input

Figure 18 as well as Figure 38 show an example of how to integrate a single-ended

microphone input.

VMIC

R

R

A

V

Bias

R

A

C

F

R

B

VMIC

MICPx

GSM module

MICNx

C

K

AGND

Figure 18: Single ended microphone input

R

has to be chosen so that the DC voltage across the microphone falls into the bias voltage

A

range of 1.0V to 1.6V and the microphone feeding current meets its specification.

The MICNx input is automatically self biased to the MICPx DC level. It is AC coupled via C

to a resistive divider which is used to optimize supply noise cancellation by the differential

microphone amplifier in the module.

RA = typ. 2k

R

= typ. 5k

B

R

= typ. 470Ohm

VMIC

C

= typ. 100nF

k

= typ. 22µF

C

F

V

= typ. 2.5V

MIC

V

= 1.0V … 1.6V, typ. 1.5V

bias

K

TC65_HD_V00.450 Page 54 of 96 20.04.2005

Page 7

TC65 Hardware Interface Description

Strictly confidential / Draft

s

The VMIC voltage should be filtered if gains larger than 20dB are used. The filter can be

attached as a simple first order RC-network (R

and CF).

VMIC

This circuit is well suited if the distance between microphone and module is kept short. Due

to good grounding the microphone can be easily ESD protected as its housing usually

connects to the negative terminal.

3.13.2.2 Differential Microphone Input

Figure 19 shows a differential solution for connecting an electret microphone.

VMIC

R

VMIC

R

A

MICPx

C

F

GSM module

RA = typ. 1k

R

= 470Ohm

VMIC

C

= typ. 100nF

K

C

= typ. 22µF

F

V

= typ. 2.5V

MIC

V

= 1.0V … 1.6V, typ. 1.5V

bias

MICNx

V

Bias

R

A

C

K

AGND

Figure 19: Differential microphone input

The resulting DC voltage between MICPx and AGND should be in the range of 1.0V to 1.6V

to bias the input amplifier. MICNx is automatically self biased to the MICPx DC level. The

resulting AC differential voltage is then amplified in the GSM module.

The VMIC voltage should be filtered if gains larger than 20dB are used. The filter can be

attached as a simple first order RC-network (R

and CF).

VMIC

The advantage of this circuit is that it can be used if the application involves longer lines

between microphone and module.

TC65_HD_V00.450 Page 55 of 96 20.04.2005

Page 8

TC65 Hardware Interface Description

Strictly confidential / Draft

s

3.13.2.3 Line Input Configuration with OpAmp

Figure 20 shows an example of how to connect an opamp into the microphone circuit.

VMIC

R

C

K

R

VMIC

A

MICPx

~

R

C

K

C

F

A

MICNx

V

Bias

GSM module

AGND

Figure 20: Line input configuration with OpAmp

RA = typ. 47k

R

= 470Ohm

VMIC

C

= typ. 100nF

k

= typ. 22µF

C

F

V

= typ. 2.5V

MIC

V

= typ. ½ V

bias

= 1.25V

MIC

The AC source (e.g. an opamp) and its reference potential have to be AC coupled to the

MICPx resp. MICNx input terminals. The voltage divider between VMIC and AGND is

necessary to bias the input amplifier. MICNx is automatically self biased to the MICPx DC

level.

The VMIC voltage should be filtered if gains larger than 20dB are used. The filter can be

attached as a simple first order RC-network (R

and CF). If a high input level and a lower

VMIC

gain are applied the filter is not necessary.

If desired, MICNx via C

can also be connected to the inverse output of the AC source

K

instead of connecting it to the reference potential for differential line input.

TC65_HD_V00.450 Page 56 of 96 20.04.2005

Page 9

TC65 Hardware Interface Description

Strictly confidential / Draft

s

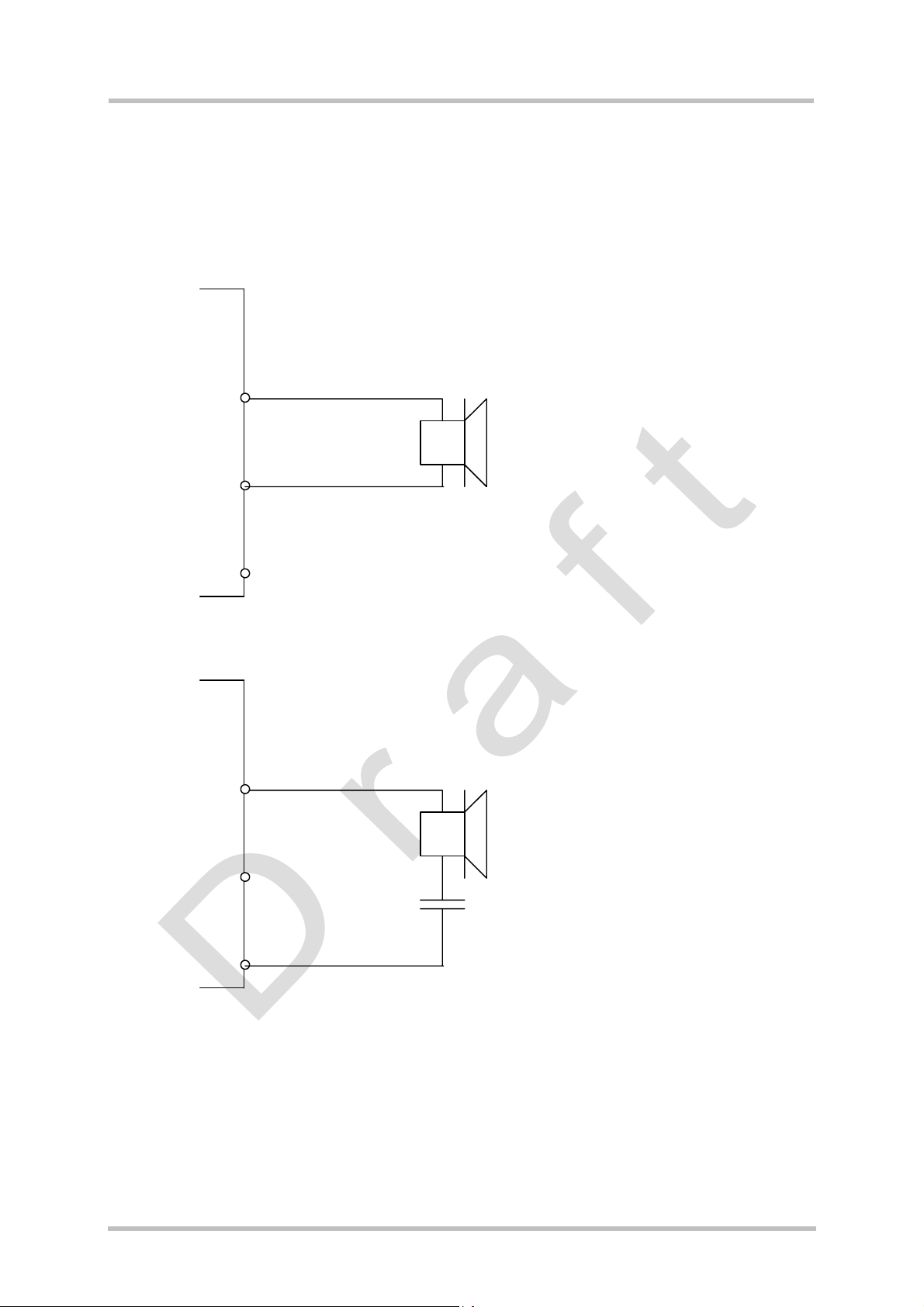

3.13.3 Loudspeaker Circuit

The GSM module comprises two analog speaker outputs: EP1 and EP2. Output EP1 is able

to drive a load of 8Ohms while the output EP2 can drive a load of 32Ohms. Each interface

can be connected in differential and in single ended configuration. See examples in Figure

21 and Figure 22.

Loudspeaker impedance

EPP1/EPN1

= typ. 8Ohm

Z

L

EPPx

GSM module

EPNx

EPP2/EPN2

Z

= typ. 32Ohm

L

AGND

Figure 21: Differential loudspeaker configuration

EPPx

GSM module

EPNx

AGND

Loudspeaker impedance

EPP1/EPN1

Z

= typ. 8Ohm

L

C

= 220µF

k

EPP2/EPN2

= typ. 32Ohm

Z

L

C

= 47µF

k

+

C

k

Figure 22: Single ended loudspeaker configuration

TC65_HD_V00.450 Page 57 of 96 20.04.2005

Page 10

TC65 Hardware Interface Description

Strictly confidential / Draft

3.13.4 Digital Audio Interface DAI

TBD

s

TC65_HD_V00.450 Page 58 of 96 20.04.2005

Page 11

TC65 Hardware Interface Description

Strictly confidential / Draft

s

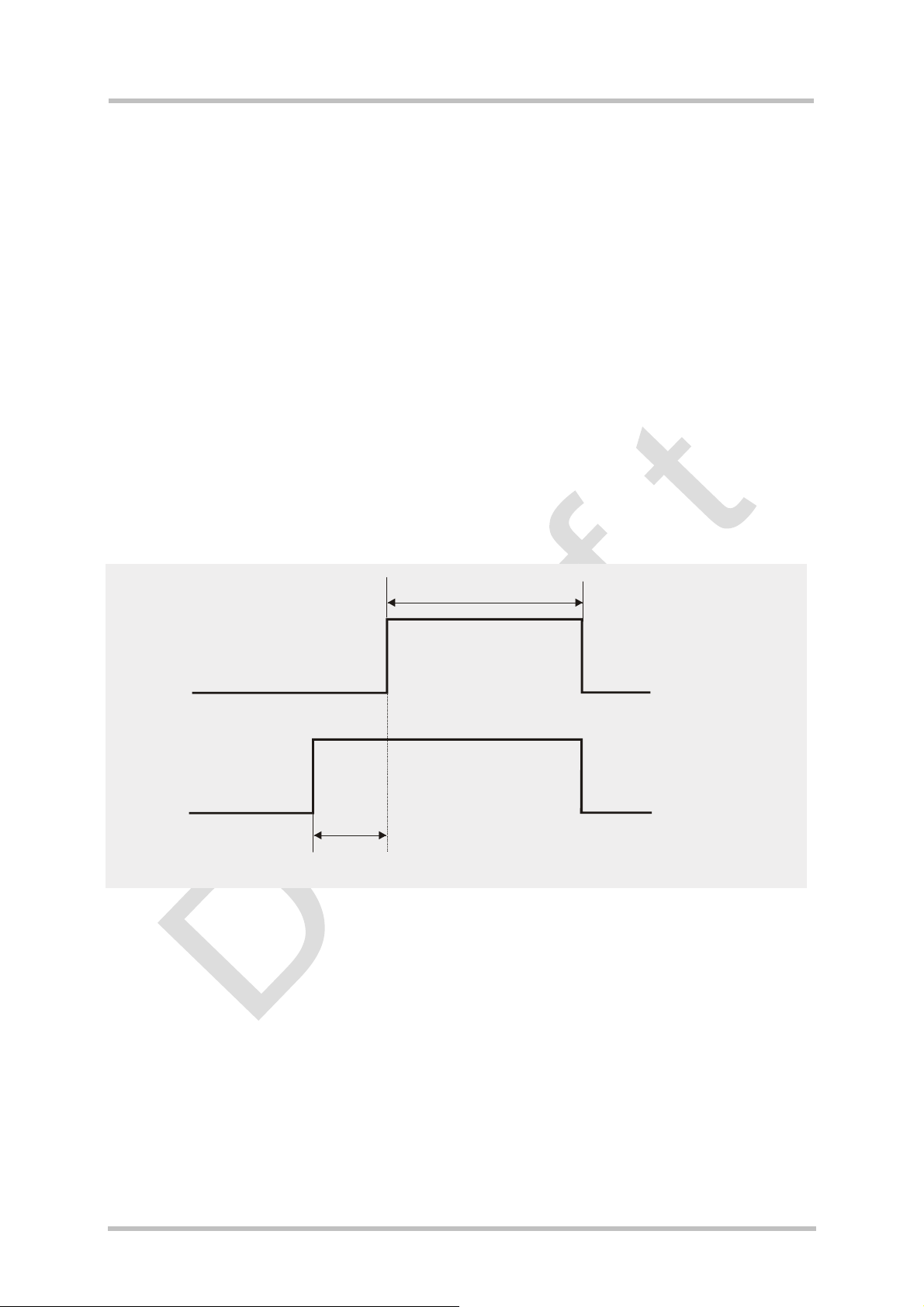

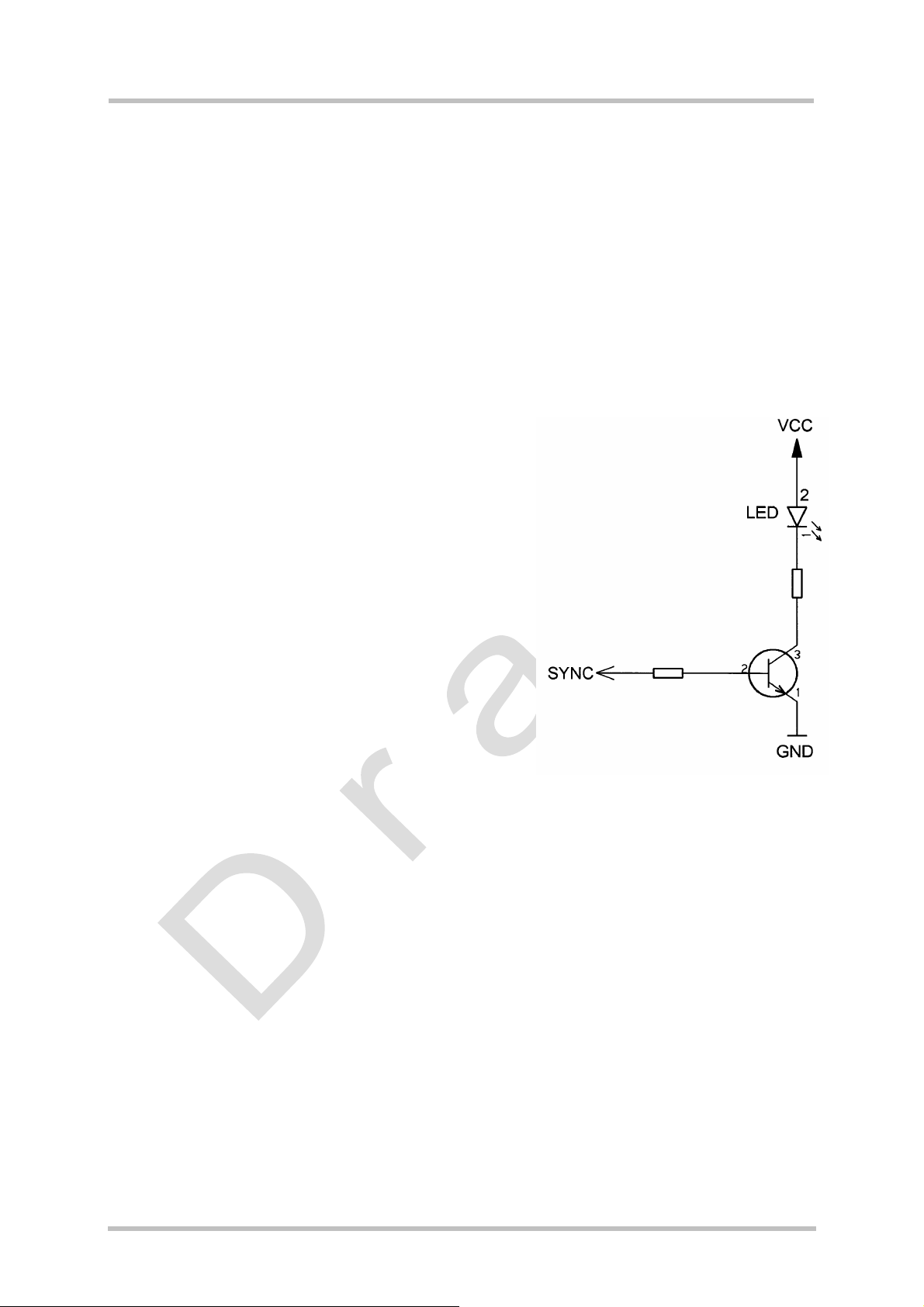

3.14 Control Signals

3.14.1 Synchronization Signal

The synchronization signal serves to indicate growing power consumption during the transmit

burst. The signal is generated by the SYNC pin (pin number 32). Please note that this pin

can adopt three different operating modes which you can select by using the AT^SSYNC

command: the mode AT^SSYNC=0 described below, and the two LED modes AT^SSYNC=1

or AT^SSYNC=2 described in [1] and Section 3.14.2.

The first function (factory default AT^SSYNC=0) is recommended if you want your

application to use the synchronization signal for better power supply control. Your platform

design must be such that the incoming signal accommodates sufficient power supply to the

TC65 module if required. This can be achieved by lowering the current drawn from other

components installed in your application.

The timing of the synchronization signal is shown below. High level of the SYNC pin

indicates increased power consumption during transmission.

1 Tx 577 µs every 4.616 ms

2 Tx 1154 µs every 4.616 ms

Transmit burst

SYNC signal

*)

The duration of the SYNC signal is always equal, no matter whether the traffic or the

*)

t = 180 sµ

Figure 25: SYNC signal during transmit burst

access burst are active.

TC65_HD_V00.450 Page 59 of 96 20.04.2005

Page 12

TC65 Hardware Interface Description

Strictly confidential / Draft

s

3.14.2 Using the SYNC Pin to Control a Status LED

As an alternative to generating the synchronization signal, the SYNC pin can be configured

to drive a status LED that indicates different operating modes of the TC65 module. To take

advantage of this function the LED mode must be activated with the AT^SSYNC command

and the LED must be connected to the host application. The connected LED can be operated

in two different display modes (AT^SSYNC=1 or AT^SSYNC=2). For details please refer to

[1].

Especially in the development and test phase of an application, system integrators are

advised to use the LED mode of the SYNC pin in order to evaluate their product design and

identify the source of errors.

To operate the LED a buffer, e.g. a transistor or gate,

must be included in your application. A sample circuit

is shown in Figure 26. Power consumption in the LED

mode is the same as for the synchronization signal

mode. For details see Table 17, SYNC pin.

Figure 26: LED Circuit (Example)

TC65_HD_V00.450 Page 60 of 96 20.04.2005

Page 13

TC65 Hardware Interface Description

Strictly confidential / Draft

s

4 Antenna Interface

The RF interface has an impedance of 50Ω. TC65 is capable of sustaining a total mismatch

at the antenna connector or pad without any damage, even when transmitting at maximum

RF power.

The external antenna must be matched properly to achieve best performance regarding

radiated power, DC-power consumption, modulation accuracy and harmonic suppression.

Antenna matching networks are not included on the TC65 PCB and should be placed in the

host application.

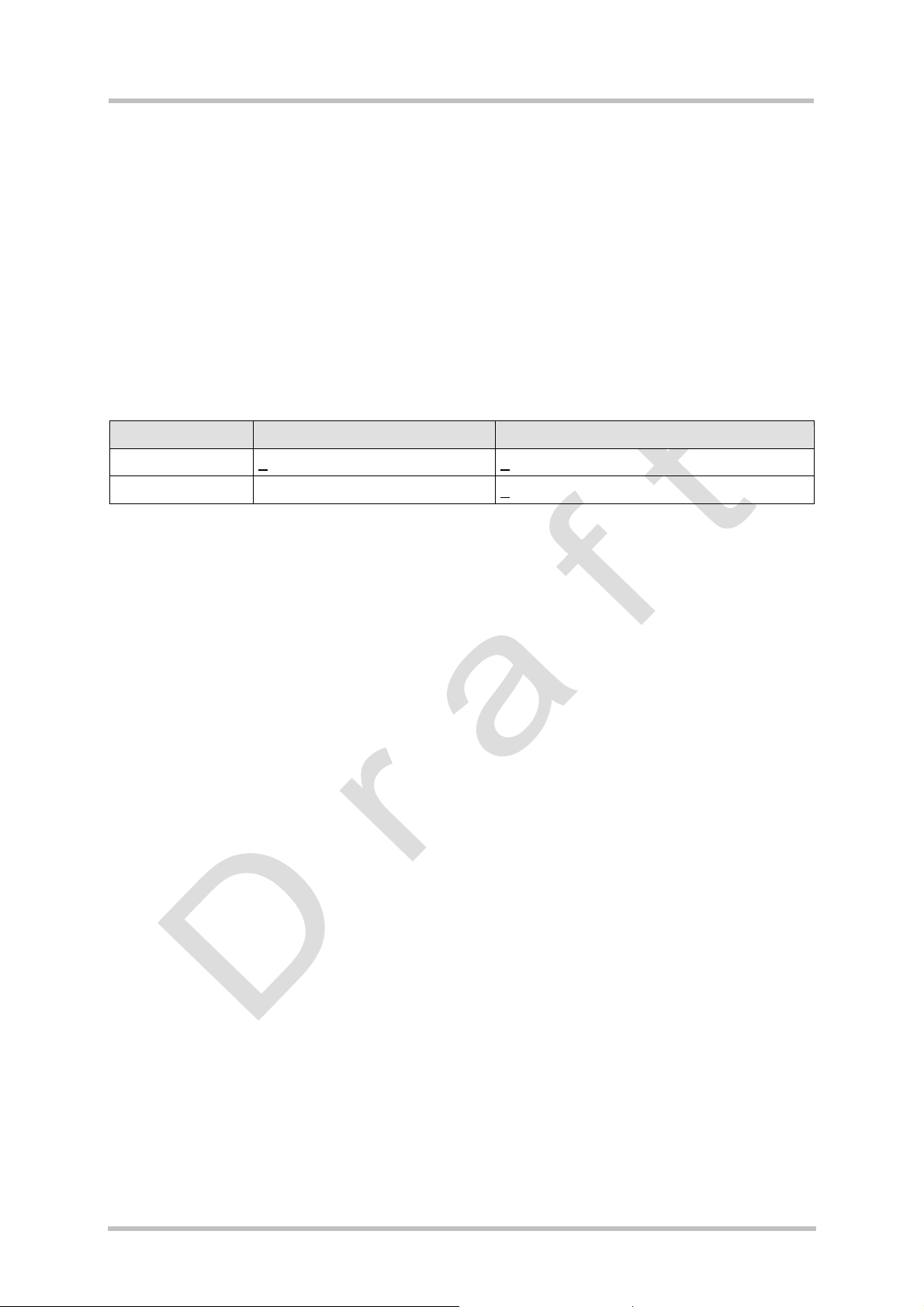

Regarding the return loss TC65 provides the following values in the active band:

Table 11: Return loss in the active band

State of module Return loss of module Recommended return loss of application

Receive > 8dB > 12dB

Transmit not applicable > 12dB

The connection of the antenna or other equipment must be decoupled from DC voltage. This

is necessary because the antenna connector is DC coupled to ground via an inductor for

ESD protection.

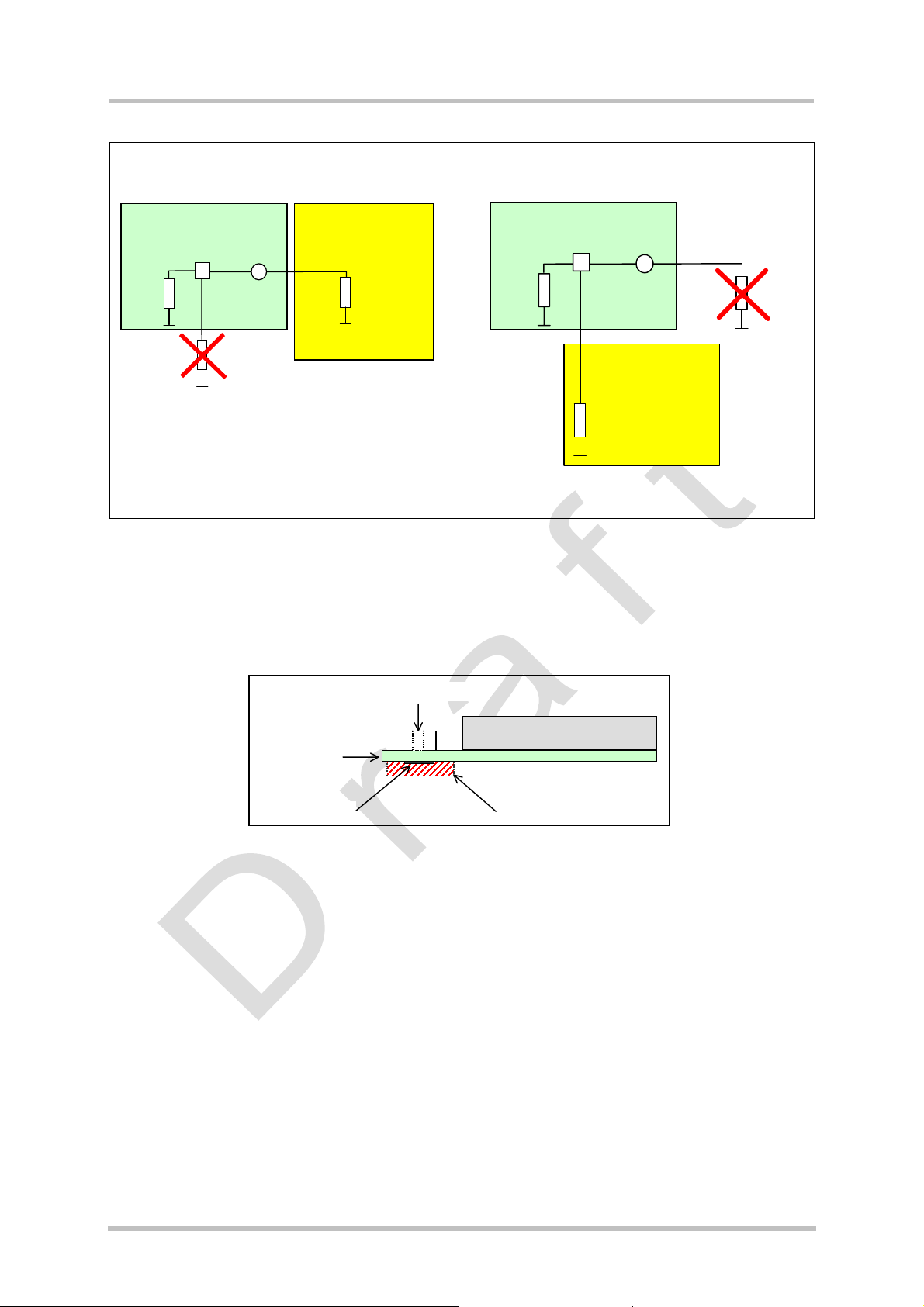

4.1 Antenna Installation

To suit the physical design of individual applications TC65 offers two alternative approaches

to connecting the antenna:

• Recommended approach: U.FL-R-SMT antenna connector from Hirose assembled on

the component side of the PCB (top view on TC65). See Section 4.3 for details.

• Antenna pad and grounding plane placed on the bottom side. See Section 4.2.

The U.FL-R-SMT connector has been chosen as antenna reference point (ARP) for the

Siemens reference equipment submitted to type approve TC65. All RF data specified

throughout this manual are related to the ARP. For compliance with the test results of the

Siemens type approval you are advised to give priority to the connector, rather than using the

antenna pad.

IMPORTANT: Both solutions can only be applied alternatively. This means, whenever an

antenna is plugged to the Hirose connector, the pad must not be used. Vice versa, if the

antenna is connected to the pad, then the Hirose connector must be left empty.

TC65_HD_V00.450 Page 61 of 96 20.04.2005

Page 14

TC65 Hardware Interface Description

A

A

Strictly confidential / Draft

Antenna connected to Hirose connector:

Module

Antenna or

measurement

PAD

50Ohm

U.FL

equipment

50Ohm

Antenna connected to pad:

Module

PAD

50Ohm

s

U.FL

Z

Z

50Ohm

Figure 27: Never use antenna connector and antenna pad at the same time

ntenna

No matter which option you choose, ensure that the antenna pad does not come into contact

with the holding device or any other components of the host application. It needs to be

surrounded by a restricted area filled with air, which must also be reserved 0.8mm in height.

U.FL antenna connector

RF section

PCB

ntenna pad

Restricted area

Figure 28: Restricted area around antenna pad

TC65_HD_V00.450 Page 62 of 96 20.04.2005

Page 15

TC65 Hardware Interface Description

Strictly confidential / Draft

s

4.2 Antenna Pad

The antenna can be soldered to the pad, or attached via contact springs. For proper

grounding connect the antenna to the ground plane on the bottom of TC65 which must be

connected to the ground plane of the application.

When you decide to use the antenna pad take into account that the pad has not been

intended as antenna reference point (ARP) for the Siemens TC65 type approval. The

antenna pad is provided only as an alternative option which can be used, for example, if the

recommended Hirose connection does not fit into your antenna design.

Also, consider that according to the GSM recommendations TS 45.005 and TS 51.010-01 a

50Ω connector is mandatory for type approval measurements. This requires GSM devices

with an integral antenna to be temporarily equipped with a suitable connector or a low loss

RF cable with adapter.

Notes on soldering:

• To prevent damage to the module and to obtain long-term solder joint properties you are

advised to maintain the standards of good engineering practice for soldering.

• Be sure to solder the antenna core to the pad and the shielding of the coax cable to the

ground plane of the module next to the antenna pad. The direction of the cable is not

relevant from the electrical point of view.

TC65 material properties:

TC65 PCB: FR4

Antenna pad: Gold plated pad

4.2.1 Suitable Cable Types

For direct solder attachment, we suggest to use the following cable types:

• RG316/U 50Ohm coaxial cable

• 1671A 50Ohm coaxial cable

Suitable cables are offered, for example, by IMS Connector Systems. For further details and

other cable types please contact http://www.imscs.com

.

TC65_HD_V00.450 Page 63 of 96 20.04.2005

Page 16

TC65 Hardware Interface Description

Strictly confidential / Draft

4.3 Antenna Connector

TC65 uses an ultra-miniature SMT antenna connector supplied

from Hirose Ltd. The product name is:

U.FL-R-SMT

The position of the antenna connector on the TC65 board can be

seen in Figure 35.

Figure 29: Mechanical dimensions of U.FL-R-SMT connector

Table 12: Product specifications of U.FL-R-SMT connector

Item Specification Conditions

s

Ratings

Nominal impedance

Rated frequency DC to 3GHz

Mechanical characteristics

Female contact holding

force

Repetitive operation Contact resistance:

Vibration No momentary disconnections of

Shock No momentary disconnections of

Environmental characteristics

Humidity resistance No damage, cracks and looseness

50Ω

0.15N min

Center 25mΩ

Outside 15mΩ

1µs;

No damage, cracks and looseness

of parts

1µs.

No damage, cracks and looseness

of parts.

of parts.

Insulation resistance:

100MΩ min. at high humidity

500MΩ min. when dry

Operating temp:-40°C to + 90°C

Operating humidity: max. 90%

Measured with a ∅ 0.475 pin

gauge

30 cycles of insertion and

disengagement

Frequency of 10 to 100Hz, single

amplitude of 1.5mm, acceleration

of 59m/s

direction of each of the 3 axes

Acceleration of 735m/s2, 11ms

duration for 6 cycles in the

direction of each of the 3 axes

Exposure to 40°C, humidity of

95% for a total of 96 hours

2

, for 5 cycles in the

Temperature cycle No damage, cracks and looseness

of parts.

Contact resistance:

Center 25mΩ

Outside 15mΩ

Salt spray test No excessive corrosion 48 hours continuous exposure to

Temperature: +40°C → 5 to 35°C

→ +90°C → 5 to 35°C

Time: 30min → within 5min →

30min within 5min

5% salt water

TC65_HD_V00.450 Page 64 of 96 20.04.2005

Page 17

TC65 Hardware Interface Description

Strictly confidential / Draft

Table 13: Material and finish of U.FL-R-SMT connector and recommended plugs

Part Material Finish

Shell Phosphor bronze Silver plating

Male center contact Brass Gold plating

Female center contact Phosphor bronze Gold plating

s

Insulator Plug: PBT

Receptacle: LCP

Black

Beige

Mating plugs and cables can be chosen from the Hirose U.FL Series. Examples are shown

below and listed in Table 14. For latest product information please contact your Hirose dealer

or visit the Hirose home page, for example http://www.hirose.com

.

Figure 30: U.FL-R-SMT connector with U.FL-LP-040 plug

Figure 31: U.FL-R-SMT connector with U.FL-LP-066 plug

TC65_HD_V00.450 Page 65 of 96 20.04.2005

Page 18

TC65 Hardware Interface Description

Strictly confidential / Draft

s

In addition to the connectors illustrated above, the U.FL-LP-(V)-040(01) version is offered as

an extremely space saving solution. This plug is intended for use with extra fine cable (up to

∅ 0.81mm) and minimizes the mating height to 2mm. See Figure 32 which shows the Hirose

datasheet.

Figure 32: Specifications of U.FL-LP-(V)-040(01) plug

TC65_HD_V00.450 Page 66 of 96 20.04.2005

Page 19

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Table 14: Ordering information for Hirose U.FL Series

Item Part number HRS number

Connector on TC65 U.FL-R-SMT CL331-0471-0-10

Right-angle plug shell for

∅ 0.81mm cable

Right-angle plug for

∅ 0.81mm cable

Right-angle plug for

∅ 1.13mm cable

Right-angle plug for

∅ 1.32mm cable

Extraction jig E.FL-LP-N CL331-04441-9

U.FL-LP-040 CL331-0451-2

U.FL-LP(V)-040 (01) CL331-053-8-01

U.FL-LP-068 CL331-0452-5

U.FL-LP-066 CL331-0452-5

TC65_HD_V00.450 Page 67 of 96 20.04.2005

Page 20

TC65 Hardware Interface Description

Strictly confidential / Draft

s

5 Electrical, Reliability and Radio Characteristics

5.1 Absolute Maximum Ratings

The absolute maximum ratings stated in Table 15 are stress ratings under non-operating

conditions. Stresses beyond any of these limits will cause permanent damage to TC65.

Table 15: Absolute maximum ratings under non-operating conditions

Parameter Min Max Unit

Supply voltage BATT+ -0.3 5.5 V

Voltage at digital pins -0.3 3.05 V

Voltage at analog pins -0.3 3.0 V

Voltage at VCHARGE pin -0.3 5.5 V

Voltage at CHARGEGATE pin -0.3 5.5 V

VUSB_IN -0.3 5.5

VSENSE 5.5

ISENSE 5.5

V

V

V

5.2 Operating Temperatures

Test conditions were specified in accordance with IEC 60068-2 (still air). The values stated

below are in compliance with GSM recommendation TS 51.010-01.

Table 16: Operating temperatures

Parameter Min Typ Max Unit

Ambient temperature (according to GSM 11.10) -30 +25 +65*) °C

Automatic shutdown

TC65 board temperature

Battery temperature

Ambient temperature for charging (software controlled fast

charging)

-30

-20

0 --- +45 °C

---

---

+90

+60

*)

°C

Due to temperature measurement uncertainty, a tolerance on these switching off thresholds

may occur. The possible deviation is in a range of:

• ± 3°C at the overtemperature limit

• ± 5°C at the undertemperature limit

*)

On TC65 the automatic overtemperature shutdown threshold is set to 90°C board

temperature. This prevents permanent damage to components on the board. Consider

the ratio of output power, supply voltage and operating temperature: to achieve T

amb max

= 65°C in GPRS Class 8 (GSM900/ GSM850) with 2W RF power the supply voltage

must not be higher than 4.2V.

TC65_HD_V00.450 Page 68 of 96 20.04.2005

Page 21

TC65 Hardware Interface Description

Strictly confidential / Draft

s

5.3 Pin Assignment and Signal Description

The Molex board-to-board connector on TC65 is an 80-pin double-row receptacle. The

names and the positions of the pins can be seen from Figure 1 which shows the top view of

TC65.

1 GND GND 80

2 ADC1_IN DAC_OUT 79

3 ADC2_IN PWR_IND 78

4 GND

5 GPIO10 GPIO9 76

6 GPIO8 SPICS 75

7 SPIDI GPIO4 74

8 GPIO7 GPIO3 73

9 GPIO6 GPIO2 72

10 GPIO5 GPIO1 71

11 I2CCLK_SPICLK I2CDAT_SPIDO 70

12 VUSB_IN USB_DP 69

13 DAI5 USB_DN 68

14 ISENSE VSENSE 67

15 DAI6 VMIC 66

16 CCCLK EPN2 65

17 CCVCC EPP2 64

18 CCIO EPP1 63

19 CCRST EPN1 62

20 CCIN MICN2 61

21 CCGND MICP2 60

22 DAI4 MICP1 59

23 DAI3 MICN1 58

24 DAI2 AGND 57

25 DAI1 IGT 56

26 DAI0 EMERG_RST 55

27 BATT_TEMP DCD0 54

28 SYNC CTS1 53

29 RXD1 CTS0 52

30 RXD0 RTS1 51

31 TXD1 DTR0 50

32 TXD0 RTS0 49

33 VDDLP DSR0 48

34 VCHARGE RING0 47

35 CHARGEGATE VEXT 46

36 GND BATT+ 45

37 GND BATT+ 44

38 GND BATT+ 43

39 GND BATT+ 42

40 GND BATT+ 41

Do not use

77

Figure 33: Pin assignment (component side of TC65)

TC65_HD_V00.450 Page 69 of 96 20.04.2005

Page 22

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Please note that the reference voltages listed in Table 17 are the values measured directly

on the TC65 module. They do not apply to the accessories connected.

Table 17: Signal description

Function Signal name IO Signal form and level Comment

Power

supply

Power

supply

Charge

Interface

External

supply

voltage

BATT+ I

GND Ground Application Ground

VCHARGE I

BATT_TEMP I

ISENSE I

VSENSE I

CHARGEGATE O

VEXT O

VImax = 4.5V

typ = 3.8V

V

I

V

min = 3.2V during Tx burst on board

I

I ≈ 2A, during Tx burst

n Tx = n x 577µs peak current every

4.616ms

min = 1.015 * V

V

I

V

max = 5.45V

I

Connect NTC with R

BATT+

≈ 10kΩ @ 25°C to

NTC

ground. See Section 3.5.3 for B value of

NTC.

max = 4.65V

V

I

∆VImax to V

= +0.3V at normal

BATT+

condition

max = 4.5V

V

I

max = 5.5V

V

O

I

max = 1mA

O

Normal mode:

V

min = 2.75V

O

V

typ = 2.93V

O

V

max = 3.05V

O

I

max = -50mA

O

Five pins of BATT+ and GND

must be connected in parallel

for supply purposes because

higher peak currents may

occur.

Minimum voltage must not fall

below 3.2V including drop,

ripple, spikes.

This line signalizes to the

processor that the charger is

connected.

If unused keep pin open.

Battery temperature

measurement via NTC

resistance.

NTC should be installed

inside or near battery pack to

enable proper charging and

deliver temperature values.

If unused keep pin open.

ISENSE is required for

measuring the charge current.

For this purpose, a shunt

resistor for current

measurement needs to be

connected between ISENSE

and VSENSE.

If unused connect pin to

VSENSE.

VSENSE must be directly

connected to BATT+ at

battery connector or external

power supply.

Control line to the gate of

charge FET

If unused keep pin open.

VEXT may be used for

application circuits, for

example to supply power for

an I2C

If unused keep pin open.

Not available in Power-down

mode. The external digital

logic must not cause any

spikes or glitches on voltage

VEXT.

TC65_HD_V00.450 Page 70 of 96 20.04.2005

Page 23

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Function Signal name IO Signal form and level Comment

Power

indicator

Ignition IGT I

Emergency

reset

PWR_IND O VIHmax = 10V

max = 0.4V at Imax = 2mA

V

OL

R

≈ 30kΩ, CI ≈ 10nF

I

V

max = 0.8V at Imax = -150µA

IL

V

max = 4.5V (V

OH

~~~

ON

EMERG_RST I

R

≈ 5kΩ

I

V

max = 0.2V at Imax = -0.5mA

IL

V

min = 1.75V

OH

max = 3.05V

V

OH

Signal

Falling edge resets module.

Synchronization

SYNC O

VOLmax = 0.3V at I = 0.1mA

min = 2.3V at I = -0.1mA

V

OH

max = 0.05V

V

OH

n Tx = n x 577µs impulse each 4.616ms,

with ___µs forward time.

RTC backup VDDLP I/O RI ≈ 1kΩ

V

max = 4.5V

O

= 4.3V:

V

BATT+

V

= 3.2V at IO = -500µA

O

= 0V:

V

BATT+

V

= 2.7V…4.5V at I

I

|____|

~~~

|______|

)

BATT+

~~~

Active Low ≥ 400ms

~~~

Pull down ≥ 10ms

= 15µA

max

PWR_IND (Power Indicator)

notifies the module’s on/off

state.

PWR_IND is an open

collector that needs to be

connected to an external pullup resistor. Low state of the

open collector indicates that

the module is on. Vice versa,

high level notifies the Powerdown mode.

Therefore, the pin may be

used to enable external

voltage regulators which

supply an external logic for

communication with the

module, e.g. level converters.

This signal switches the

mobile on.

This line must be driven low

by an open drain or open

collector driver.

Reset function in case of

emergency: Pull down and

release EMERG_RST. Falling

edge will reset the module.

Data stored in the volatile

memory will be lost. For

orderly software controlled

reset rather use the

AT+CFUN command (e.g.

AT+CFUN=,1).

This line must be driven by

open drain or open collector.

If unused keep pin open.

There are two alternative

options for using the SYNC

pin:

a) Indicating increased

current consumption during

uplink transmission burst.

Note that the timing of the

signal is different during

handover.

b) Driving a status LED to

indicate different operating

modes of TC65. The LED

must be installed in the host

application.

If unused keep pin open.

If unused keep pin open.

TC65_HD_V00.450 Page 71 of 96 20.04.2005

Page 24

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Function Signal name IO Signal form and level Comment

SIM interface

specified for

use with 3V

SIM card

SIM interface

specified for

use with

1.8V SIM

card

ASC0

Serial

interface

CCIN I

CCRST O

CCIO I/O

R

≈ 100kΩ

I

V

max = 0.6V at I = -25µA

IL

V

min = 2.1V at I = -10µA

IH

V

max = 3.05V

O

R

≈ 47Ω

O

V

max = 0.25V at I = +1mA

OL

V

min = 2.5V at I = -0.5mA

OH

V

max = 2.95V

OH

R

≈ 4.7kΩ

I

V

max = 0.75V

IL

V

min = -0.3V

IL

V

min = 2.1V

IH

V

max = CCVCCmin + 0.3V = 3.05V

IH

RO ≈ 100Ω

V

max = 0.3V at I = +1mA

OL

V

min = 2.5V at I = -0.5mA

OH

V

max = 2.95V

OH

CCCLK O

R

≈ 100Ω

O

V

max = 0.3V at I = +1mA

OL

V

min = 2.5V at I = -0.5mA

OH

V

max = 2.95V

OH

CCVCC O VOmin = 2.75V

V

typ = 2.85V

O

V

max = 2.95V

O

I

max = -20mA

O

CCGND Ground

CCIN I

CCRST O

CCIO I/O

CCCLK O

R

≈ 100kΩ

I

V

max = 0.6V at I = -25µA

IL

V

min = 2.1V at I = -10µA

IH

V

max = 3.05V

O

R

≈ 47Ω

O

V

max = 0.25V at I = +1mA

OL

V

min = 1.45V at I = -0.5mA

OH

V

max = 1.90V

OH

R

≈ 4.7kΩ

I

V

max = 0.45V

IL

V

min = 1.35V

IH

V

max = CCVCCmin + 0.3V = 2.00V

IH

≈ 100Ω

R

O

V

max = 0.3V at I = +1mA

OL

V

min = 1.45V at I = -0.5mA

OH

V

max = 1.90V

OH

R

≈ 100Ω

O

V

max = 0.3V at I = +1mA

OL

V

min = 1.45V at I = -0.5mA

OH

V

max = 1.90V

OH

CCVCC O VOmin = 1.70V,

V

typ = 1.80V

O

V

max = 1.90V

O

I

max = -20mA

O

CCGND Ground

RXD0

TXD0

CTS0

RTS0

DTR0

DCD0

DSR0

RING0

O

O

O

O

O

max = 0.2V at I = 2mA

V

OL

V

min = 2.55V at I = -0.5mA

OH

I

V

max = 3.05V

OH

I

V

max = 0.8V

IL

I

V

min = 2.0V

IH

max = VEXTmin + 0.3V = 3.05V

V

IH

CCIN = Low, SIM card holder

closed

Maximum cable length or

copper track 100mm to SIM

card holder.

All signals of SIM interface

are protected against ESD

with a special diode array.

Usage of CCGND is

mandatory.

CCIN = Low, SIM card holder

closed

Maximum cable length or

copper track 100mm to SIM

card holder.

All signals of SIM interface

are protected against ESD

with a special diode array.

Usage of CCGND is

mandatory.

Serial interface for AT

commands or data stream.

If lines are unused keep pins

open.

TC65_HD_V00.450 Page 72 of 96 20.04.2005

Page 25

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Function Signal name IO Signal form and level Comment

ASC1

Serial

interface

RXD1

TXD1

CTS1

RTS1

O

O

max = 0.2V at I = 2mA

V

OL

V

OH

I

V

OH

I

VILmax = 0.8V

V

min = 2.0V

IH

max = VEXTmin + 0.3V = 3.05V

V

IH

min = 2.55V at I = -0.5mA

max = 3.05V

Serial interface for AT

commands or data stream.

If lines are unused keep pins

open.

2

I2C interface

SPI

Serial

Peripheral

Interface

USB

General

Purpose

Input/Output

I2CCLK _SPICLK O VOLmax = 0.2V at I = 2mA

V

min = 2.55V at I = -0.5mA

OH

V

max = 3.05V

OH

I2CDAT_SPIDO I/O V

max = 0.2V at I = 2mA

OL

V

max = 0.8V

IL

V

min = 2.0V

IH

VIHmax = VEXTmin + 0.3V = 3.05V

SPIDI

I2CDAT_SPIDO

I2CCLK_SPICLK

SPICS

O

O

O

VUSB_IN I VINmin = 4.0V

USB_DN I/O

USB_DP I/O

GPIO1 I/O

GPIO2 I/O

GPIO3 I/O

GPIO4 I/O

GPIO5 I/O

GPIO6 I/O

GPIO7 I/O

GPIO8 I/O

GPIO9 I/O

GPIO10 I/O

max = 0.2V at I = 2mA

I

V

OL

V

min = 2.55V at I = -0.5mA

OH

V

max = 3.05V

OH

VILmax = 0.8V

V

min = 2.0V,

IH

V

max = VEXTmin + 0.3V = 3.05V

IH

V

max = 5.25V

IN

Differential Output Crossover voltage

Range

V

min = 1.5V, V

CRS

max = 2.0V

CRS

Driver Output Resistance

Z

typ = 32Ohm

DRV

V

max = 0.2V at I = 2mA

OL

V

min = 2.55V at I = -0.5mA

OH

V

max = 3.05V

OH

VILmax = 0.8V

V

min = 2.0V,

IH

V

max = VEXTmin + 0.3V = 3.05V

IH

I

C interface is only available

if the two pins are not used as

SPI interface.

I2CDAT is configured as

Open Drain and needs a pullup resistor in the host

application.

According to the I2C Bus

Specification Version 2.1 for

the fast mode a rise time of

max. 300ns is permitted.

There is also a maximum

V

=0.4V at 3mA specified.

OL

The value of the pull-up

depends on the capacitive

load of the whole system (I2C

Slave + lines). The maximum

sink current of I2CDAT and

I2CCLK is 4mA.

If lines are unused keep pins

open.

If the Serial Peripheral

Interface is active the I2C

interface is not available.

If lines are unused keep pins

open.

If lines are unused keep pins

open.

If unused keep pins with a pull

up or pull down resistor while

the GPIO is set to input.

TC65_HD_V00.450 Page 73 of 96 20.04.2005

Page 26

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Function Signal name IO Signal form and level Comment

Digital

Converter

Digital

Analog

Converter

Digital Audio

interface

Analog

Audio

interface

ADC_IN1 I Analog

ADC_IN2 I

Input voltage: V

Ri ≈ 450kOhm

min = 0V, VImax = 2.4V

I

fCmax < 3kHz

Sensitivity, accuracy: 12 Bit

1 Bit = 0.585mV

DAC_OUT O V

DAI0

O

DAI1

DAI2

O

DAI3

DAI4

DAI5 I

DAI6 O

max = 0.2V at I = 2mA

OL

V

min = 2.55V at I = -0.5mA

OH

V

max = 3.05V

OH

VOLmax = 0.2V at I = 2mA

V

min = 2.55V at I = -0.5mA

OH

I

V

max = 3.05V

OH

I

VILmax = 0.8V

V

min = 2.0V

I

IH

max = VEXTmin + 0.3V = 3.05V

V

IH

VMIC O VOmin = 2.4V

typ = 2.5V

V

O

max = 2.6V

V

O

= 2mA

I

max

EPP2 O

EPN2 O

1.0954Vpp (differential) typical

3.4Vpp differential maximal

Audio mode TBD

Measurement conditions TBD

Minimum differential resp. single ended

load 27Ohms

EPP1 O

EPN1 O

1.0954Vpp (differential) typical

6.0Vp-p differential maximal

Audio mode TBD

Measurement conditions TBD

Minimum differential resp. single ended

load 7.5Ohms

MICP1 I

MICN1 I

MICP2 I

MICN2 I

Full Scale Input Voltage 1.578Vpp

0dBm0 Input Voltage 1.0954Vpp

At MICNx, apply external bias from 1.0V to

1.6V.

Audio mode TBD

Measurement conditions TBD

AGND Analog Ground GND level for external audio

Inputs used for measuring

external voltages.

ADC_IN1 and ADC_IN2 are

internally multiplexed through

analog switch.

PWM signal which can be

smoothed by an external filter.

See Table 10 for details.

If unused keep pins open.

Microphone supply for

customer feeding circuits

The audio output can directly

operate a 32-Ohmloudspeaker.

If unused keep pins open.

The audio output can directly

operate an 8-Ohmloudspeaker.

If unused keep pins open.

Balanced or single ended

microphone or line inputs with

external feeding circuit (using

VMIC and AGND).

If unused keep pins open.

circuits

TC65_HD_V00.450 Page 74 of 96 20.04.2005

Page 27

TC65 Hardware Interface Description

Strictly confidential / Draft

s

5.4 Power Supply Ratings

Table 18: Power supply ratings

Parameter Description Conditions Min Typ Max Unit

BATT+

I

RTC Backup @ BATT+ = 0V 25 µA OFF State

VDDLP

I

BATT+

1)

Measured after module INIT (switch ON the module and following switch OFF);

applied voltage on BATT+ (w/o INIT) show increased POWER DOWN supply current.

2)

Additional conditions:

SLEEP measurements started 3 minutes after switch ON the module

Averaging times: SLEEP mode - 3 minutes; IDLE mode - 1.5 minutes

Communication tester settings: no neighbor cells, no cell reselection

USB interface disabled

Supply voltage Directly measured at reference point

Voltage drop during

transmit burst

Voltage ripple Normal condition, power control level

supply current

Average standby

supply current2)

TP BATT+ and TP GND, see chapter

3.2.2

Voltage must stay within the min/max

values, including voltage drop, ripple,

spikes.

Normal condition, power control level

for P

for P

@ f<200kHz

@ f>200kHz

POWER DOWN mode

SLEEP mode @ DRX = 9 TBD mA

SLEEP mode @ DRX = 5 TBD mA

SLEEP mode @ DRX = 2 TBD mA

IDLE mode @ DRX = 2 TBD mA

out max

out max

1)

50 100 µA

3.2 3.8 4.5 V

400 mV

50

2

mV

mV

TC65_HD_V00.450 Page 75 of 96 20.04.2005

Page 28

TC65 Hardware Interface Description

Strictly confidential / Draft

Table 19: Current consumption during transmit burst

Mode GSM call GPRS Class 8 GPRS Class10 GPRS Class 12

Timeslot configuration 1Tx / 1Rx 1Tx / 4Rx 2Tx / 3Rx 4Tx / 1Rx

Frequency*) 850/900MHz

s

Maximum possible power

(RF power nominal)

Radio/output power reduction

with command AT^SCFG,

parameter <ropr>

Current characteristics

Burst current @ 50Ω antenna

(typ.)

Burst current @ total mismatch 3.2A 3.2A 3.2A 2.3A 2.3A 1.9A

Average current @ 50Ω antenna

(typ.)

2W

(33dBm)

<ropr> = 1 .. 3

2.0A 2.0A 2.0A 1.5A 1.5A 1.3A

335mA 385mA 610mA 485mA 810mA 710mA

2W

(33dBm)

<ropr> = 1 .. 3

2W

(33dBm)

<ropr> = 1

1W

(30dBm)

<ropr> = 2 or 3

1W

(30dBm)

<ropr> = 1

0.5W

(27dBm)

<ropr> = 2 or 3

Average current @ total

mismatch

*)

Currents in the frequency bands GSM 1800MHz and GSM 1900MHz are lower due to lower RF output levels.

AT parameters are given in brackets <...> and marked italic.

TC65_HD_V00.450 Page 76 of 96 20.04.2005

485mA 535mA 910mA 685mA 1210mA 1010mA

Page 29

TC65 Hardware Interface Description

Strictly confidential / Draft

s

5.5 Electrostatic Discharge

The GSM engine is not protected against Electrostatic Discharge (ESD) in general.

Consequently, it is subject to ESD handling precautions that typically apply to ESD sensitive

components. Proper ESD handling and packaging procedures must be applied throughout

the processing, handling and operation of any application that incorporates a TC65 module.

Special ESD protection provided on TC65:

Antenna interface: one spark discharge line (spark gap)

SIM interface: clamp diodes for protection against overvoltage.

The remaining ports of TC65 are not accessible to the user of the final product (since they

are installed within the device) and therefore, are only protected according to the “Human

Body Model” requirements.

TC65 has been tested according to the EN 61000-4-2 standard. The measured values can

be gathered from the following table.

Table 20: Measured electrostatic values

Specification / Requirements Contact discharge Air discharge

ETSI EN 301 489-7

ESD at SIM port

ESD at antenna port

Human Body Model (Test conditions: 1.5kΩ, 100pF)

ESD at USB interface

ESD at all other interfaces

± 4kV ± 8kV

± 4kV ± 8kV

± 1kV ± 1kV

± 1kV ± 1kV

Note: Please note that the values may vary with the individual application design. For

example, it matters whether or not the application platform is grounded over external

devices like a computer or other equipment, such as the Siemens reference

application described in Chapter 8.

TC65_HD_V00.450 Page 77 of 96 20.04.2005

Page 30

TC65 Hardware Interface Description

Strictly confidential / Draft

s

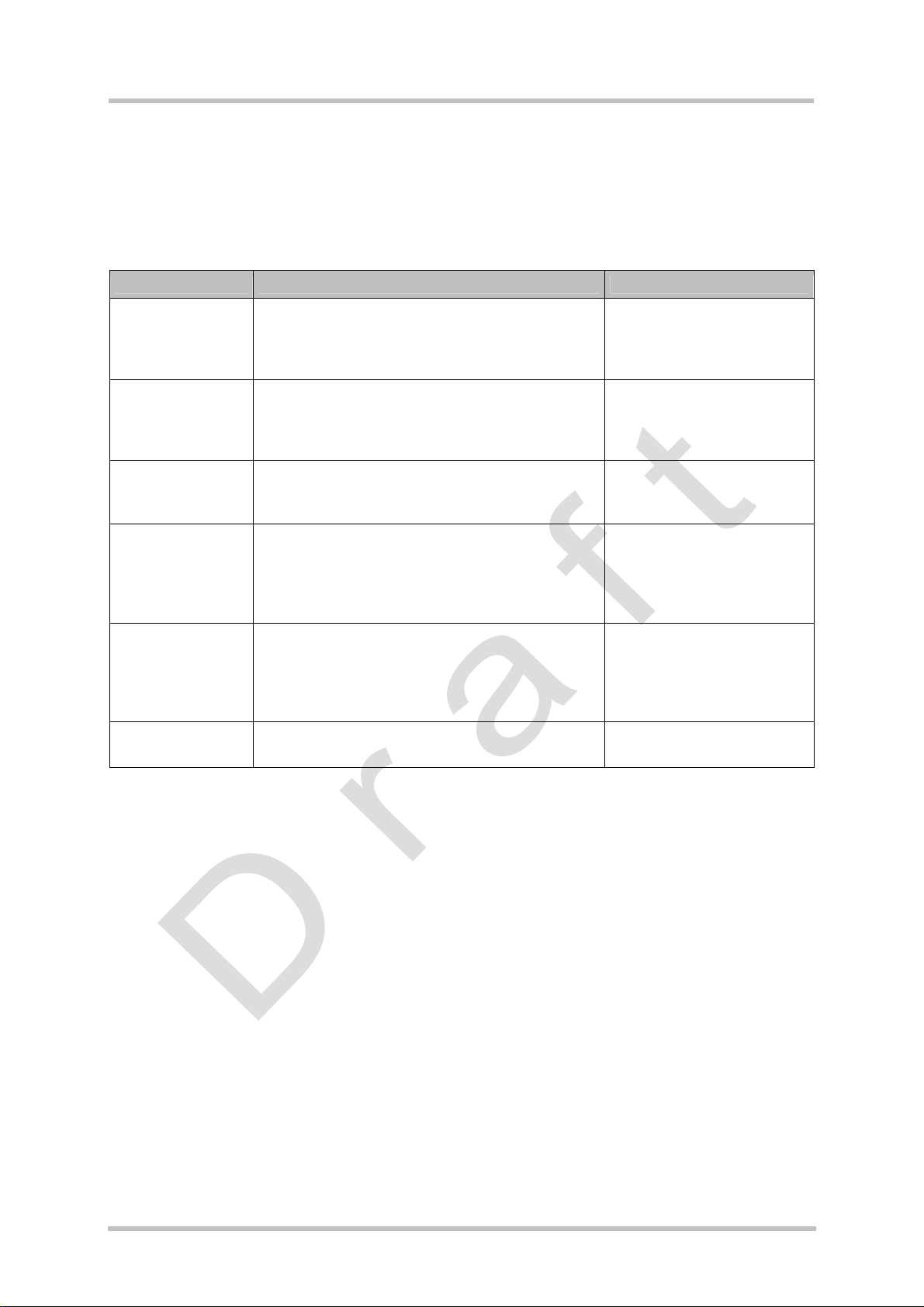

5.6 Reliability Characteristics

The test conditions stated below are an extract of the complete test specifications.

Table 21: Summary of reliability test conditions

Type of test Conditions Standard

Vibration Frequency range: 10-20Hz; acceleration: 3.1mm

amplitude

Frequency range: 20-500Hz; acceleration: 5g

Duration: 2h per axis = 10 cycles; 3 axes

Shock half-sinus Acceleration: 500g

Shock duration: 1msec

1 shock per axis

6 positions (± x, y and z)

Dry heat Temperature: +70 ±2°C

Test duration: 16h

Humidity in the test chamber: < 50%

Temperature

change (shock)

Damp heat cyclic High temperature: +55°C ±2°C

Cold (constant

exposure)

Low temperature: -40°C ±2°C

High temperature: +85°C ±2°C

Changeover time: < 30s (dual chamber system)

Test duration: 1h

Number of repetitions: 100

Low temperature: +25°C ±2°C

Humidity: 93% ±3%

Number of repetitions: 6

Test duration: 12h + 12h

Temperature: -40 ±2°C

Test duration: 16h

DIN IEC 68-2-6

DIN IEC 68-2-27

EN 60068-2-2 Bb ETS

300019-2-7

DIN IEC 68-2-14 Na

ETS 300019-2-7

DIN IEC 68-2-30 Db

ETS 300019-2-5

DIN IEC 68-2-1

TC65_HD_V00.450 Page 78 of 96 20.04.2005

Page 31

TC65 Hardware Interface Description

Strictly confidential / Draft

s

6 Mechanics

6.1 Mechanical Dimensions of TC65

Figure 34 shows the top view of TC65 and provides an overview of the board's mechanical

dimensions. For further details see Figure 35.

Pin 1

Pin 80

Figure 34: TC65 – top view

TC65_HD_V00.450 Page 79 of 96 20.04.2005

Page 32

TC65 Hardware Interface Description

Strictly confidential / Draft

s

All dimensions in mm

Figure 35: Dimensions of TC65

TC65_HD_V00.450 Page 80 of 96 20.04.2005

Page 33

TC65 Hardware Interface Description

Strictly confidential / Draft

s

6.2 Mounting TC65 to the Application Platform

There are many ways to properly install TC65 in the host device. An efficient approach is to

mount the TC65 PCB to a frame, plate, rack or chassis.

Fasteners can be M2 screws plus suitable washers, circuit board spacers, or customized

screws, clamps, or brackets. In addition, the board-to-board connection can also be utilized

to achieve better support. To help you find appropriate spacers a list of selected screws and

distance sleeves for 3mm stacking height can be found in Section 9.2.

When using the two small holes take care that the screws are inserted with the screw head

on the bottom of the TC65 PCB. Screws for the large holes can be inserted from top or

bottom.

For proper grounding it is strongly recommended to use large ground plane on the bottom of

board in addition to the five GND pins of the board-to-board connector. The ground plane

may also be used to attach cooling elements, e.g. a heat sink or thermally conductive tape.

To prevent mechanical damage, be careful not to force, bend or twist the module. Be sure it

is positioned flat against the host device.

All the information you need to install an antenna is summarized in Chapter 4. Note that the

antenna pad on the bottom of the TC65 PCB must not be influenced by any other PCBs,

components or by the housing of the host device. It needs to be surrounded by a restricted

space as described in Section 4.1.

TC65_HD_V00.450 Page 81 of 96 20.04.2005

Page 34

TC65 Hardware Interface Description

Strictly confidential / Draft

s

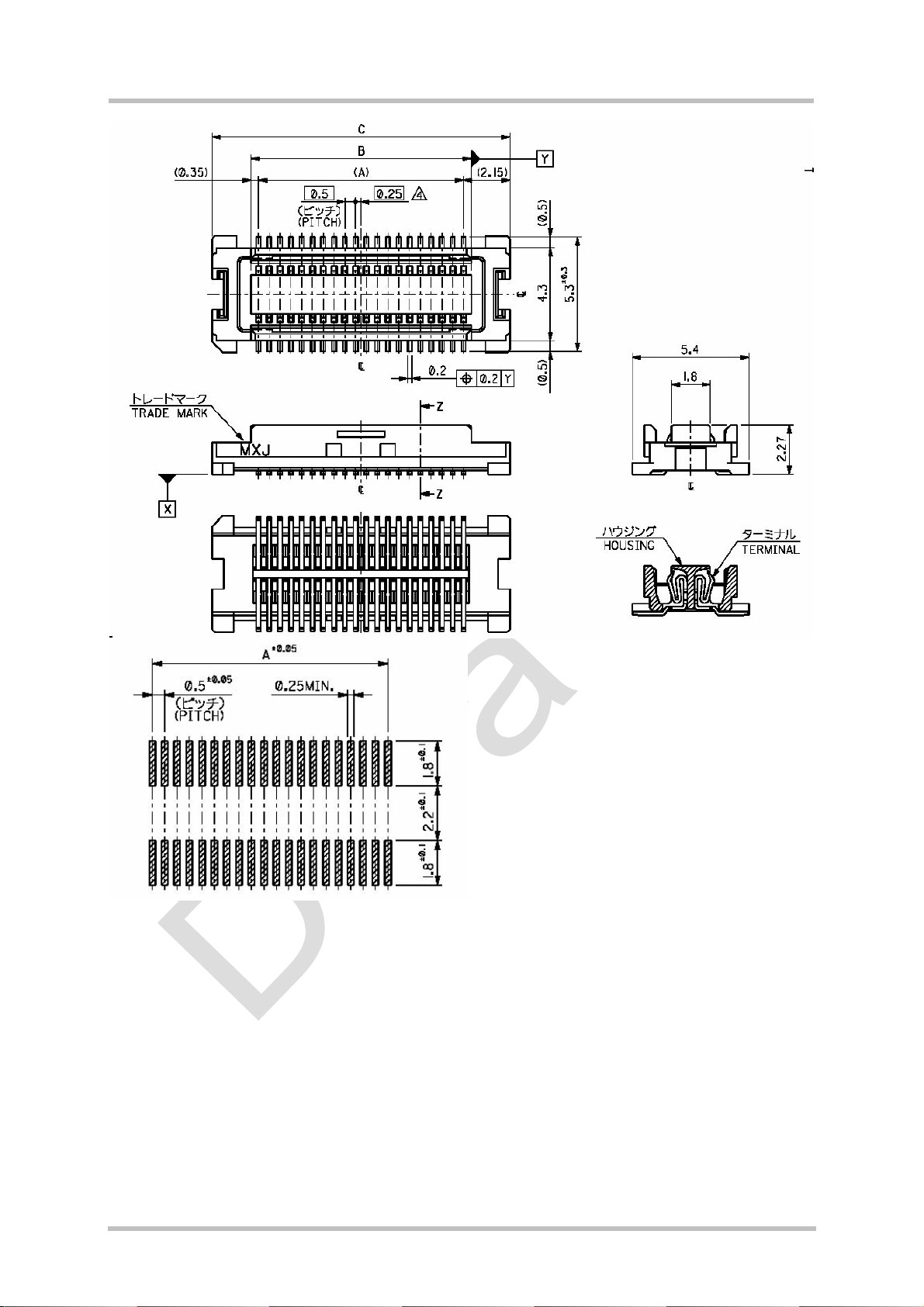

6.3 Board-to-Board Application Connector

This section provides the specifications of the 80-pin board-to-board connector used to

connect TC65 to the external application.

Connector mounted on the TC65 module:

Type: 52991-0808 SlimStack Receptacle

80 pins, 0.50mm pitch,

for stacking heights from 3.0 to 4.0mm,

see Figure 36 for details.

Supplier: Molex

www.molex.com

Table 22: Technical specifications of Molex board-to-board connector

Parameter Specification (80-pin B2B connector)

Electrical

Number of Contacts 80

Contact spacing 0.5mm (.020")

Voltage 50V

Rated current 0.5A max per contact

Contact resistance 50mΩ max per contact

Insulation resistance > 100MΩ

Dielectric Withstanding Voltage 500V AC (for 1 minute)

Physical

Insulator material (housing) White glass-filled LCP plastic, flammability UL 94V 0

Contact material Plating: Gold over nickel

Insertion force 1st < 74.4N

Insertion force 30th < 65.6N

Withdrawal force 1st > 10.8N

Maximum connection cycles 30 (@ 70mΩ max per contact)

Mating connector types for the customer's application

offered by Molex:

• 53748-0808 SlimStack Plug, 3mm stacking height,

see Figure 37 for details.

• 53916-0808 SlimStack Plug, 4mm stacking height

TC65_HD_V00.450 Page 82 of 96 20.04.2005

Page 35

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Figure 36: Molex board-to-board connector 52991-0808 on TC65

TC65_HD_V00.450 Page 83 of 96 20.04.2005

Page 36

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Figure 37: Mating board-to-board connector 53748-0808 on application

TC65_HD_V00.450 Page 84 of 96 20.04.2005

Page 37

TC65 Hardware Interface Description

Strictly confidential / Draft

s

7 Sample Application

Figure 38 shows a typical example of how to integrate a TC65 module into the GSM part of a

mobile application. Usage of the various host interfaces depends on the desired features of

the application.

Audio interface 1 demonstrates the balanced connection of microphone and earpiece. This

solution is particularly well suited for internal transducers. Audio interface 2 uses an

unbalanced microphone and earpiece connection typically found in headset applications.

The charging circuit is optimized for the charging stages (trickle charging and software

controlled charging) as well as the battery and charger specifications described in Section

3.5.

The PWR_IND line is an open collector that needs an external pull-up resistor which

connects to the voltage supply of the microcontroller VCC µC. Low state of the open collector

pulls the PWR_IND signal low and indicates that the TC65 module is active, high level

notifies the Power-down mode.

If the module is in Power-down mode avoid current flowing from any other source into the

module circuit, for example reverse current from high state external control lines. Therefore,

the controlling application must be designed to prevent reverse or return flow. This is not

necessary for the USB interface.

The I2C interface can be powered from an external supply or via the VEXT line of TC65. The

advantage of this solution is that when the module enters the Power-down mode, the I2C

interface is shut down as well. If you prefer to connect an I2C interface to an external power

supply, take care that the interface is shut down when the PWR_IND signal goes high in

Power-down mode.

The EMC measures are best practice recommendations. In fact, an adequate EMC strategy

for an individual application is very much determined by the overall layout and, especially,

the position of components. For example, mounting the internal acoustic transducers directly

on the PCB eliminates the need to use the ferrite beads shown in the sample schematic.

However, when connecting cables to the module’s interfaces it is strongly recommended to

add appropriate ferrite beads for reducing RF radiation.

Disclaimer

No warranty, either stated or implied, is provided on the sample schematic diagram shown in

Figure 38 and the information detailed in this section. As functionality and compliance with

national regulations depend to a great amount on the used electronic components and the

individual application layout manufacturers are required to ensure adequate design and

operating safeguards for their products using TC65 modules.

TC65_HD_V00.450 Page 85 of 96 20.04.2005

Page 38

TC65 Hardware Interface Description

Strictly confidential / Draft

s

TC65 Application

*)

(Draft)

47k

47k

VCC µC

100k

Serial Interface

ASC0

Serial Interface

ASC1

*)

I2C

2 x R

P

BC847

BC847

8

4

2

VCHARGE

IGT

EMERG_RST

PWR_IND

TC65

VEXT (2.9V)

BATT+

BATTEMP

VSENSE

ISENSE

CHARGEGATE

VMIC (2.5V)

MICP1

MICN1

MICP2

Rechargeable

Lithium battery

NTC

470R

100nF

1k

1k

0.3R

SI3441DV

2.7k

22µF

2.2k2.2k

7

CRS04

Digital Audio

ESD

protection

V 5.2V 0.2V

ch arge

+

Charger

USB

(Slave)

SIM

200nF

All SIM components shall be close to card holder.

*)

1nF

3

27pF

SYNC

CCIN

CCVCC

CCRST

CCIO

CCCLK

CCGND

0R (not mounted)

GND

MICN2

EPN1

EPP1

100µF

EPP2

EPN2

AGND

100nF

>8R

>32R

5.6k

*)

depends on final specification

Figure 38: TC65 sample application (draft)

TC65_HD_V00.450 Page 86 of 96 20.04.2005

Page 39

TC65 Hardware Interface Description

Strictly confidential / Draft

s

8 Reference Approval

8.1 Reference Equipment for Type Approval

The Siemens reference setup submitted to type approve TC65 consists of the following

components:

• Siemens TC65 cellular engine

• Development Support Box DSB75

• SIM card reader integrated on DSB75

• U.FL-R-SMT antenna connector and U.FL-LP antenna cable

• Handset type Votronic HH-SI-30.3/V1.1/0

• Li-Ion battery

• PC as MMI

Antenna or 50 Ω

cable to system

simulator

Antenna

GSM module

Flex cable

100mm

SIM

Handset

PC

Power supply

RS-232

Figure 39: Reference equipment for Type Approval

Li-Ion

battery

DSB75

TC65_HD_V00.450 Page 87 of 96 20.04.2005

Page 40

TC65 Hardware Interface Description

Strictly confidential / Draft

s

8.2 Compliance with FCC Rules and Regulations

The FCC Equipment Authorization Certification for the TC65 reference application described

in Section 8.1 is listed under the

FCC identifier QIPTC65

IC: 267W-TC65

granted to Siemens AG.

The TC65 reference application registered under the above identifier is certified to be in

accordance with the following Rules and Regulations of the Federal Communications

Commission (FCC).

Power listed is ERP for Part 22 and EIRP for Part 24

“This device contains GSM and GPRS Class12 functions in the 900 and 1800MHz

Band which are not operational in U.S. Territories.

This device is to be used only for mobile and fixed applications. The antenna(s) used

for this transmitter must be installed to provide a separation distance of at least 20cm

from all persons and must not be co-located or operating in conjunction with any other

antenna or transmitter. Users and installers must be provided with antenna installation

instructions and transmitter operating conditions for satisfying RF exposure com-

pliance. Antennas used for this OEM module must not exceed 8.4dBi gain (GSM 1900)

and 2.9dBi (GSM 850) for mobile and fixed operating configurations. This device is

approved as a module to be installed in other devices.”

The FCC label of the module must be visible from the outside. If not, the host device is

required to bear a second label stating, “Contains FCC ID QIPTC65”.

IMPORTANT: Manufacturers of mobile or fixed devices incorporating TC65 modules are

advised to

• clarify any regulatory questions,

• have their completed product tested,

• have product approved for FCC compliance, and

• include instructions according to above mentioned RF exposure statements in end

product user manual.

Please note that changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

TC65_HD_V00.450 Page 88 of 96 20.04.2005

Page 41

TC65 Hardware Interface Description

Strictly confidential / Draft

s

9 Appendix

9.1 List of Parts and Accessories

Table 23: List of parts and accessories

Description Supplier Ordering information

TC65 Siemens Siemens ordering number: L36880-N8355-A100

Siemens Car Kit Portable Siemens Siemens ordering number: L36880-N3015-A117

DSB75 Support Box Siemens Siemens ordering number: L36880-N8811-A100

Votronic Handset VOTRONIC Votronic HH-SI-30.3/V1.1/0

VOTRONIC

Entwicklungs- und Produktionsgesellschaft für

elektronische Geräte mbH

Saarbrücker Str. 8

66386 St. Ingbert

Germany

Phone: +49-(0)6 89 4 / 92 55-0

Fax: +49-(0)6 89 4 / 92 55-88

e-mail: contact@votronic.com

SIM card holder incl. push

button ejector and slide-in

tray

Board-to-board connector Molex Sales contacts are listed in Table 24.

U.FL-R-SMT antenna

connector

Molex Ordering numbers: 91228

91236

Sales contacts are listed in Table 24.

Hirose See Section 4.3 for details on U.FL-R-SMT

connector, mating plugs and cables.

Sales contacts are listed in Table 25.

TC65_HD_V00.450 Page 89 of 96 20.04.2005

Page 42

TC65 Hardware Interface Description

Strictly confidential / Draft

Table 24: Molex sales contacts (subject to change)

s

Molex

For further information

please click:

http://www.molex.com/

Molex China Distributors

Beijing,

Room 1319, Tower B,

COFCO Plaza

No. 8, Jian Guo Men Nei

Street, 100005

Beijing

P.R. China

Phone: +86-10-6526-9628

Phone: +86-10-6526-9728

Phone: +86-10-6526-9731

Fax: +86-10-6526-9730

Molex Deutschland GmbH

Felix-Wankel-Str. 11

4078 Heilbronn-Biberach

Germany

Phone: +49-7066-9555 0

Fax: +49-7066-9555 29

Email: mxgermany@molex.com

Molex Singapore Pte. Ltd.

Jurong, Singapore

Phone: +65-268-6868

Fax: +65-265-6044

Table 25: Hirose sales contacts (subject to change)

American Headquarters

Lisle, Illinois 60532

U.S.A.

Phone: +1-800-78MOLEX

Fax: +1-630-969-1352

Molex Japan Co. Ltd.

Yamato, Kanagawa, Japan

Phone: +81-462-65-2324

Fax: +81-462-65-2366

Hirose Ltd.

For further information

please click:

http://www.hirose.com

Hirose Electric UK, Ltd

Crownhill Business Centre

22 Vincent Avenue,

Crownhill

Milton Keynes, MK8 OAB

Great Britain

Phone: +44-1908-305400

Fax: +44-1908-305401

Hirose Electric (U.S.A.) Inc

2688 Westhills Court

Simi Valley, CA 93065

U.S.A.

Phone: +1-805-522-7958

Fax: +1-805-522-3217

Hirose Electric Co., Ltd.

5-23, Osaki 5 Chome,

Shinagawa-Ku

Tokyo 141

Japan

Phone: +81-03-3491-9741

Fax: +81-03-3493-2933

Hirose Electric GmbH

Zeppelinstrasse 42

73760 Ostfildern

Kemnat 4

Germany

Phone: +49-711-4560-021

Fax +49-711-4560-729

E-mail info@hirose.de

Hirose Electric Co., Ltd.

European Branche

First class Building 4F

Beechavenue 46

1119PV Schiphol-Rijk

Netherlands

Phone: +31-20-6557-460

Fax: +31-20-6557-469

TC65_HD_V00.450 Page 90 of 96 20.04.2005

Page 43

TC65 Hardware Interface Description

Strictly confidential / Draft

s

9.2 Fasteners and Fixings for Electronic Equipment

This section provides a list of suppliers and manufacturers offering fasteners and fixings for

electronic equipment and PCB mounting. The content of this section is designed to offer

basic guidance to various mounting solutions with no warranty on the accuracy and

sufficiency of the information supplied. Please note that the list remains preliminary although

it is going to be updated in later versions of this document.

9.2.1 Fasteners from German Supplier ETTINGER GmbH

Sales contact: ETTINGER GmbH

http://www.ettinger.de/main.cfm

Phone: +4981 04 66 23 – 0

Fax: +4981 04 66 23 – 0

The following tables contain only article numbers and basic parameters of the listed

components. For further detail and ordering information please contact Ettinger GmbH.

Please note that some of the listed screws, spacers and nuts are delivered with the DSB75

Support Board. See comments below.

Article number: 05.71.038

Length 3.0mm

Material AlMgSi-0,5

For internal diameter M2=2.0-2.3

Internal diameter d = 2.4mm

External diameter 4.0mm

Vogt AG No. x40030080.10

Spacer - Aluminum /

Wall thickness = 0.8mm

TC65_HD_V00.450 Page 91 of 96 20.04.2005

Page 44

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Article number: 07.51.403

Insulating Spacer for M2

Self-gripping

*)

Length 3.0mm

Material Polyamide 6.6

Surface Black

Internal diameter 2.2mm

External diameter 4.0mm

Flammability rating UL94-HB

*)

2 spacers are delivered with DSB75 Support Board

Article number: 05.11.209

Threaded Stud M2.5 - M2 Type E /

External thread at both ends

Length 3.0mm

Material Stainless steel X12CrMoS17

Thread 1 / Length M2.5 / 6.0mm

Thread 2 / Length M2 / 8.0mm

Width across flats 5

Recess yes

Type External / External

TC65_HD_V00.450 Page 92 of 96 20.04.2005

Page 45

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Article number: 01.14.131

Length 8.0mm

Material Steel 4.8

Surface Zinced A2K

Thread M2

Head diameter D = 3.8mm

Head height 1.30mm

Type Slotted cheese head screw

Screw M2 *)

DIN 84 - ISO 1207

Article number: 01.14.141

Length 10.0mm

Material Steel 4.8

Surface Zinced A2K

Thread M2

Head diameter D = 3.8mm

Head height 1.30mm

Type Slotted cheese head screw

*)

2 screws are delivered with DSB75 Support Board

Screw M2

DIN 84 - ISO 1207

TC65_HD_V00.450 Page 93 of 96 20.04.2005

Page 46

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Article number: 02.10.011

Material Steel 4.8

Surface Zinced A2K

Thread M2

Wrench size / Ø 4

Thickness / L 1.6mm

Type Nut DIN/UNC, DIN934

Hexagon Nut *)

DIN 934 - ISO 4032

*)

2 nuts are delivered with DSB75 Support Board

9.3 Data Sheets of Recommended Batteries

The following two data sheets have been provided by VARTA Microbattery GmbH.

Click here for sales contacts and further information: http://www.varta-microbattery.com

TC65_HD_V00.450 Page 94 of 96 20.04.2005

Page 47

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Figure 40: Lithium

Ion battery from

VARTA

TC65_HD_V00.450 Page 95 of 96 20.04.2005

Page 48

TC65 Hardware Interface Description

Strictly confidential / Draft

s

Figure 41: Lithium

Polymer battery

from VARTA

TC65_HD_V00.450 Page 96 of 96 20.04.2005

Loading...

Loading...