Page 1

Cinterion® ELS61-USA

Hardware Interface Description

Version: 01.040a

DocId: els61-usa_hid_v01.040a

M2M.GEMALTO.COM

Page 2

Cinterion® ELS61-USA Hardware Interface Description

2

Page 2 of 113

Document Name:

Version:

Date:

DocId:

Status

Cinterion

®

ELS61-USA Hardware Interface Description

01.040a

2017-08-31

els61-usa_hid_v01.040a

Confidential / Preliminary

GENERAL NOTE

THE USE OF THE PRODUCT INCLUDING THE SOFTWARE AND DOCUMENTATION (THE "PRODUCT") IS SUBJECT TO THE RELEASE NOTE PROVIDED TOGETHER WITH PRODUCT. IN ANY

EVENT THE PROVISIONS OF THE RELEASE NOTE SHALL PREVAIL. THIS DOCUMENT CONTAINS

INFORMATION ON GEMALTO M2M PRODUCTS. THE SPECIFICATIONS IN THIS DOCUMENT ARE

SUBJECT TO CHANGE AT GEMALTO M2M'S DISCRETION. GEMALTO M2M GMBH GRANTS A NONEXCLUSIVE RIGHT TO USE THE PRODUCT. THE RECIPIENT SHALL NOT TRANSFER, COPY,

MODIFY, TRANSLATE, REVERSE ENGINEER, CREATE DERIVATIVE WORKS; DISASSEMBLE OR

DECOMPILE THE PRODUCT OR OTHERWISE USE THE PRODUCT EXCEPT AS SPECIFICALLY

AUTHORIZED. THE PRODUCT AND THIS DOCUMENT ARE PROVIDED ON AN "AS IS" BASIS ONLY

AND MAY CONTAIN DEFICIENCIES OR INADEQUACIES. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, GEMALTO M2M GMBH DISCLAIMS ALL WARRANTIES AND LIABILITIES.

THE RECIPIENT UNDERTAKES FOR AN UNLIMITED PERIOD OF TIME TO OBSERVE SECRECY

REGARDING ANY INFORMATION AND DATA PROVIDED TO HIM IN THE CONTEXT OF THE DELIVERY OF THE PRODUCT. THIS GENERAL NOTE SHALL BE GOVERNED AND CONSTRUED

ACCORDING TO GERMAN LAW.

Copyright

Transmittal, reproduction, dissemination and/or editing of this document as well as utilization of its contents and communication thereof to others without express authorization are prohibited. Offenders will be

held liable for payment of damages. All rights created by patent grant or registration of a utility model or

design patent are reserved.

Copyright © 2017, Gemalto M2M GmbH, a Gemalto Company

Trademark Notice

Gemalto, the Gemalto logo, are trademarks and service marks of Gemalto and are registered in certain

countries. Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries. All other registered trademarks or trademarks mentioned

in this document are property of their respective owners.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 3

Cinterion® ELS61-USA Hardware Interface Description

Contents

113

Page 3 of 113

Contents

1 Introduction.................................................................................................................9

1.1 Key Features at a Glance .................................................................................. 9

1.2 ELS61-USA System Overview......................................................................... 12

1.3 Circuit Concept ................................................................................................ 13

2 Interface Characteristics ..........................................................................................15

2.1 Application Interface ........................................................................................ 15

2.1.1 Pad Assignment.................................................................................. 15

2.1.2 Signal Properties................................................................................. 17

2.1.2.1 Absolute Maximum Ratings ................................................ 23

2.1.3 USB Interface...................................................................................... 24

2.1.3.1 Reducing Power Consumption............................................ 25

2.1.4 Serial Interface ASC0 ......................................................................... 26

2.1.5 Serial Interface ASC1 ......................................................................... 28

2.1.6 UICC/SIM/USIM Interface................................................................... 30

2.1.6.1 Enhanced ESD Protection for SIM Interface....................... 32

2.1.7 Digital Audio Interface (DAI) ............................................................... 33

2.1.7.1 Pulse Code Modulation Interface (PCM)............................. 33

2.1.7.2 Inter IC Sound Interface ...................................................... 35

2.1.7.3 Solutions for the Digital Audio Interface .............................. 36

2.1.7.4 Electrical Characteristics of the Voiceband Part ................. 37

2.1.8 RTC Backup........................................................................................ 39

2.1.9 GPIO Interface .................................................................................... 40

2.1.10 I

2.1.11 SPI Interface ....................................................................................... 44

2.1.12 PWM Interfaces .................................................................................. 45

2.1.13 Pulse Counter ..................................................................................... 45

2.1.14 Control Signals.................................................................................... 45

2.2 RF Antenna Interface....................................................................................... 48

2.2.1 Antenna Interface Specifications ........................................................ 48

2.2.2 Antenna Installation ............................................................................ 50

2.2.3 RF Line Routing Design...................................................................... 51

2.3 Sample Application .......................................................................................... 57

2.3.1 Sample Level Conversion Circuit........................................................ 59

2

C Interface ........................................................................................ 42

2.1.14.1 Status LED .......................................................................... 45

2.1.14.2 Power Indication Circuit ...................................................... 46

2.1.14.3 Host Wakeup....................................................................... 46

2.1.14.4 Fast Shutdown .................................................................... 47

2.2.3.1 Line Arrangement Examples ............................................... 51

2.2.3.2 Routing Example................................................................. 56

3 Operating Characteristics........................................................................................60

3.1 Operating Modes ............................................................................................. 60

3.2 Power Up/Power Down Scenarios................................................................... 61

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 4

Cinterion® ELS61-USA Hardware Interface Description

Contents

113

3.2.1 Turn on ELS61-USA ........................................................................... 61

3.2.1.1 Connecting ELS61-USA BATT+ Lines ................................ 61

3.2.1.2 Switch on ELS61-USA Using ON Signal............................. 63

3.2.1.3 Automatic Power On ........................................................... 64

3.2.2 Restart ELS61-USA ............................................................................ 65

3.2.2.1 Restart ELS61-USA via AT+CFUN Command.................... 65

3.2.2.2 Restart ELS61-USA Using EMERG_RST........................... 66

3.2.3 Signal States after Startup .................................................................. 67

3.2.4 Turn off ELS61-USA ........................................................................... 68

3.2.4.1 Switch off ELS61-USA Using AT Command........................ 68

3.2.5 Automatic Shutdown ........................................................................... 70

3.2.5.1 Thermal Shutdown .............................................................. 70

3.2.5.2 Undervoltage Shutdown...................................................... 71

3.2.5.3 Overvoltage Shutdown........................................................ 71

3.3 Power Saving................................................................................................... 72

3.3.1 Power Saving while Attached to WCDMA Networks .......................... 72

3.3.2 Power Saving while Attached to LTE Networks.................................. 73

3.3.3 Wake-up via RTS0.............................................................................. 74

3.4 Power Supply................................................................................................... 75

3.4.1 Power Supply Ratings......................................................................... 75

3.4.2 Measuring the Supply Voltage (VBATT+)........................................... 78

3.4.3 Monitoring Power Supply by AT Command ........................................ 78

3.5 Operating Temperatures.................................................................................. 79

3.6 Electrostatic Discharge .................................................................................... 80

3.6.1 ESD Protection for Antenna Interfaces ............................................... 80

3.7 Blocking against RF on Interface Lines ........................................................... 81

3.8 Reliability Characteristics................................................................................. 83

Page 4 of 113

4 Mechanical Dimensions, Mounting and Packaging...............................................84

4.1 Mechanical Dimensions of ELS61-USA........................................................... 84

4.2 Mounting ELS61-USA onto the Application Platform....................................... 86

4.2.1 SMT PCB Assembly ........................................................................... 86

4.2.1.1 Land Pattern and Stencil..................................................... 86

4.2.1.2 Board Level Characterization.............................................. 88

4.2.2 Moisture Sensitivity Level ................................................................... 88

4.2.3 Soldering Conditions and Temperature .............................................. 89

4.2.3.1 Reflow Profile ...................................................................... 89

4.2.3.2 Maximum Temperature and Duration.................................. 90

4.2.4 Durability and Mechanical Handling.................................................... 91

4.2.4.1 Storage Conditions.............................................................. 91

4.2.4.2 Processing Life.................................................................... 92

4.2.4.3 Baking ................................................................................. 92

4.2.4.4 Electrostatic Discharge ....................................................... 92

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 5

Cinterion® ELS61-USA Hardware Interface Description

Contents

113

Page 5 of 113

4.3 Packaging ........................................................................................................ 93

4.3.1 Tape and Reel .................................................................................... 93

4.3.1.1 Orientation........................................................................... 93

4.3.1.2 Barcode Label ..................................................................... 94

4.3.2 Shipping Materials .............................................................................. 95

4.3.2.1 Moisture Barrier Bag ........................................................... 95

4.3.2.2 Transportation Box.............................................................. 97

4.3.3 Trays ................................................................................................... 98

5 Regulatory and Type Approval Information...........................................................99

5.1 Directives and Standards................................................................................. 99

5.2 SAR requirements specific to portable mobiles ............................................. 102

5.3 Reference Equipment for Type Approval....................................................... 103

5.4 Compliance with FCC and IC Rules and Regulations ................................... 104

6 Document Information............................................................................................106

6.1 Revision History ............................................................................................. 106

6.2 Related Documents ....................................................................................... 106

6.3 Terms and Abbreviations ............................................................................... 106

6.4 Safety Precaution Notes ................................................................................ 110

7 Appendix..................................................................................................................111

7.1 List of Parts and Accessories......................................................................... 111

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 6

Cinterion® ELS61-USA Hardware Interface Description

Tables

118

Page 6 of 113

Tables

Table 1: Pad assignments............................................................................................ 16

Table 2: Signal properties ............................................................................................ 17

Table 3: Absolute maximum ratings............................................................................. 23

Table 4: Signals of the SIM interface (SMT application interface) ............................... 30

Table 5: Overview of DAI/PCM lines............................................................................ 33

Table 6: Overview of DAI/I

Table 7: Audio parameters adjustable by AT command .............................................. 37

Table 8: GPIO lines and possible alternative assignment............................................ 40

Table 9: Host wakeup lines.......................................................................................... 46

Table 10: Return loss in the active band........................................................................ 48

Table 11: RF Antenna interface UMTS/LTE (at operating temperature range) ............. 48

Table 12: Overview of operating modes ........................................................................ 60

Table 13: Signal states................................................................................................... 67

Table 14: Temperature dependent behavior.................................................................. 70

Table 15: Voltage supply ratings.................................................................................... 75

Table 16: Current consumption ratings.......................................................................... 76

Table 17: Board temperature ......................................................................................... 79

Table 18: Electrostatic values ........................................................................................ 80

Table 19: EMI measures on the application interface.................................................... 82

Table 20: Summary of reliability test conditions............................................................. 83

Table 21: Reflow temperature ratings............................................................................ 90

Table 22: Storage conditions ......................................................................................... 91

Table 23: Directives ....................................................................................................... 99

Table 24: Standards of North American type approval .................................................. 99

Table 25: Standards of European type approval............................................................ 99

Table 26: Requirements of quality ............................................................................... 100

Table 27: Standards of the Ministry of Information Industry of the

People’s Republic of China.......................................................................... 100

Table 28: Toxic or hazardous substances or elements with defined

concentration limits ...................................................................................... 101

Table 29: List of parts and accessories........................................................................ 111

Table 30: Molex sales contacts (subject to change) .................................................... 112

2

S lines ............................................................................... 35

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 7

Cinterion® ELS61-USA Hardware Interface Description

Figures

118

Page 7 of 113

Figures

Figure 1: ELS61-USA system overview ........................................................................ 12

Figure 2: ELS61-USA block diagram ............................................................................ 13

Figure 3: ELS61-USA RF section block diagram .......................................................... 14

Figure 4: Numbering plan for connecting pads (bottom view)....................................... 15

Figure 5: USB circuit ..................................................................................................... 24

Figure 6: Serial interface ASC0..................................................................................... 26

Figure 7: ASC0 startup behavior................................................................................... 27

Figure 8: Serial interface ASC1..................................................................................... 28

Figure 9: ASC1 startup behavior................................................................................... 29

Figure 10: External UICC/SIM/USIM card holder circuit ................................................. 31

Figure 11: SIM interface - enhanced ESD protection...................................................... 32

Figure 12: Long frame PCM timing, 256kHz ................................................................... 34

Figure 13: DAI startup timing........................................................................................... 34

Figure 14: I

Figure 15: Block circuit for DAI to analog converter........................................................ 36

Figure 16: Sample circuit for analog to DAI box.............................................................. 36

Figure 17: Audio programming model............................................................................. 37

Figure 18: RTC supply variants....................................................................................... 39

Figure 19: GPIO startup behavior ................................................................................... 41

Figure 20: I

Figure 21: I

Figure 22: Characteristics of SPI modes......................................................................... 44

Figure 23: Status signaling with LED driver .................................................................... 45

Figure 24: Power indication circuit .................................................................................. 46

Figure 25: Fast shutdown timing ..................................................................................... 47

Figure 26: Antenna pads (bottom view) .......................................................................... 50

Figure 27: Embedded Stripline with 65µm prepreg (1080) and 710µm core .................. 51

Figure 28: Micro-Stripline on 1.0mm standard FR4 2-layer PCB - example 1 ................ 52

Figure 29: Micro-Stripline on 1.0mm Standard FR4 PCB - example 2............................ 53

Figure 30: Micro-Stripline on 1.5mm Standard FR4 PCB - example 1............................ 54

Figure 31: Micro-Stripline on 1.5mm Standard FR4 PCB - example 2............................ 55

Figure 32: Routing to application‘s RF connector - top view........................................... 56

Figure 33: Schematic diagram of ELS61-USA sample application ................................. 58

Figure 34: Sample level conversion circuit...................................................................... 59

Figure 35: Sample circuit for applying power using an external µC ................................ 62

Figure 36: ON circuit options........................................................................................... 63

Figure 37: ON timing ....................................................................................................... 64

Figure 38: Automatic ON circuit based on voltage detector - option 1............................ 64

Figure 39: Automatic ON circuit based on voltage detector - option 2............................ 65

Figure 40: Emergency restart timing ............................................................................... 66

Figure 41: Switch off behavior......................................................................................... 69

Figure 42: Power saving and paging in WCDMA networks............................................. 72

Figure 43: Power saving and paging in LTE networks.................................................... 73

Figure 44: Wake-up via RTS0......................................................................................... 74

Figure 45: Position of reference points BATT+ and GND ............................................... 78

Figure 46: ESD protection for RF antenna interface ....................................................... 80

Figure 47: EMI circuits..................................................................................................... 81

Figure 48: ELS61-USA– top and bottom view................................................................. 84

Figure 49: Dimensions of ELS61-USA (all dimensions in mm) ....................................... 85

Figure 50: Land pattern (top view) .................................................................................. 86

2

S timing, 8kHz sample rate.......................................................................... 35

2

C interface connected to V180 .................................................................... 42

2

C startup behavior ....................................................................................... 43

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 8

Cinterion® ELS61-USA Hardware Interface Description

Figures

118

Page 8 of 113

Figure 51: Recommended design for 110µm thick stencil (top view).............................. 87

Figure 52: Recommended design for 150µm thick stencil (top view).............................. 87

Figure 53: Reflow Profile................................................................................................. 89

Figure 54: Carrier tape .................................................................................................... 93

Figure 55: Reel direction ................................................................................................. 93

Figure 56: Barcode label on tape reel ............................................................................. 94

Figure 57: Moisture barrier bag (MBB) with imprint......................................................... 95

Figure 58: Moisture Sensitivity Label .............................................................................. 96

Figure 59: Humidity Indicator Card - HIC ........................................................................ 97

Figure 60: Tray dimensions............................................................................................. 98

Figure 61: Reference equipment for Type Approval ..................................................... 103

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 9

Cinterion® ELS61-USA Hardware Interface Description

1 Introduction

14

Page 9 of 113

1 Introduction

This document1 describes the hardware of the Cinterion® ELS61-USA module. It helps you

quickly retrieve interface specifications, electrical and mechanical details and information on

the requirements to be considered for integrating further components.

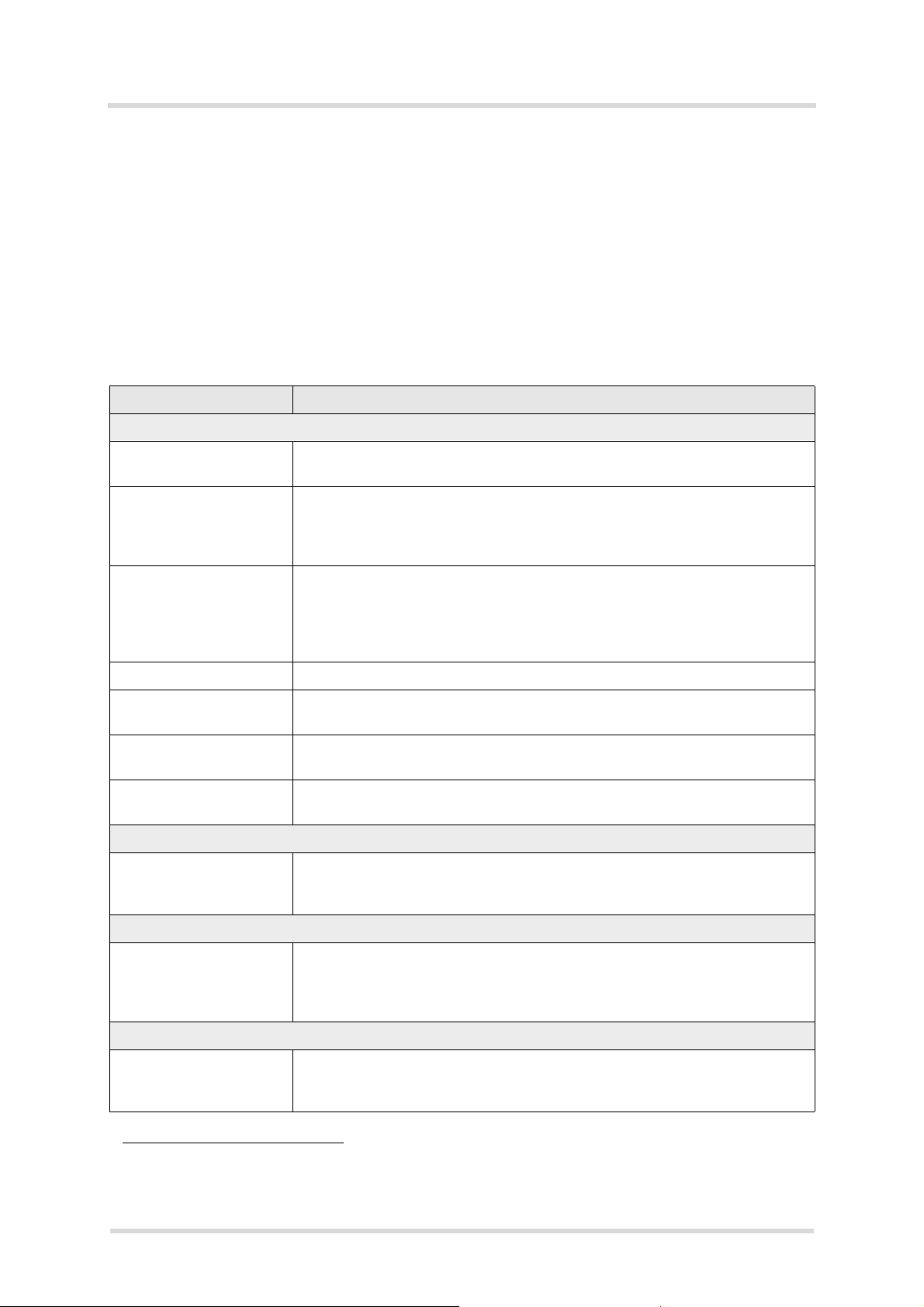

1.1 Key Features at a Glance

Feature Implementation

General

Frequency bands UMTS/HSPA+: Triple band, 850 (BdV) / AWS (BdIV) / 1900MHz (BdII)

LTE: Quad band, 700 (Bd12) / 850 (Bd5) / AWS (Bd4) / 1900MHz (Bd2)

Output power (according

to Release 99)

Output power (according

to Release 8)

Power supply 3.0V to 4.5V

Operating temperature

(board temperature)

Physical Dimensions: 27.6mm x 25.4mm x 2.2mm

RoHS All hardware components fully compliant with EU RoHS Directive

LTE features

3GPP Release 9 UE CAT 1 supported

HSPA features

Class 3 (+24dBm +1/-3dB) for UMTS 1900,WCDMA FDD BdII

Class 3 (+24dBm +1/-3dB) for UMTS AWS, WCDMA FDD BdIV

Class 3 (+24dBm +1/-3dB) for UMTS 850, WCDMA FDD BdV

Class 3 (+23dBm ±2dB) for LTE 1900,LTE FDD Bd2

Class 3 (+23dBm ±2dB) for LTE AWS, LTE FDD Bd4

Class 3 (+23dBm ±2dB) for LTE 850, LTE FDD Bd5

Class 3 (+23dBm ±2dB) for LTE 700, LTE FDD Bd12

Normal operation: -30°C to +85°C

Extended operation: -40°C to +90°C

Weight: approx. 3.5g

DL 10.2Mbps, UL 5.2Mbps

3GPP Release 8 DL 7.2Mbps, UL 5.7Mbps

HSDPA Cat.8 / HSUPA Cat.6 data rates

Compressed mode (CM) supported according to 3GPP TS25.212

UMTS features

3GPP Release 4 PS data rate – 384 kbps DL / 384 kbps UL

CS data rate – 64 kbps DL / 64 kbps UL

1. The document is effective only if listed in the appropriate Release Notes as part of the technical documentation delivered with your Gemalto M2M product.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 10

Cinterion® ELS61-USA Hardware Interface Description

1.1 Key Features at a Glance

14

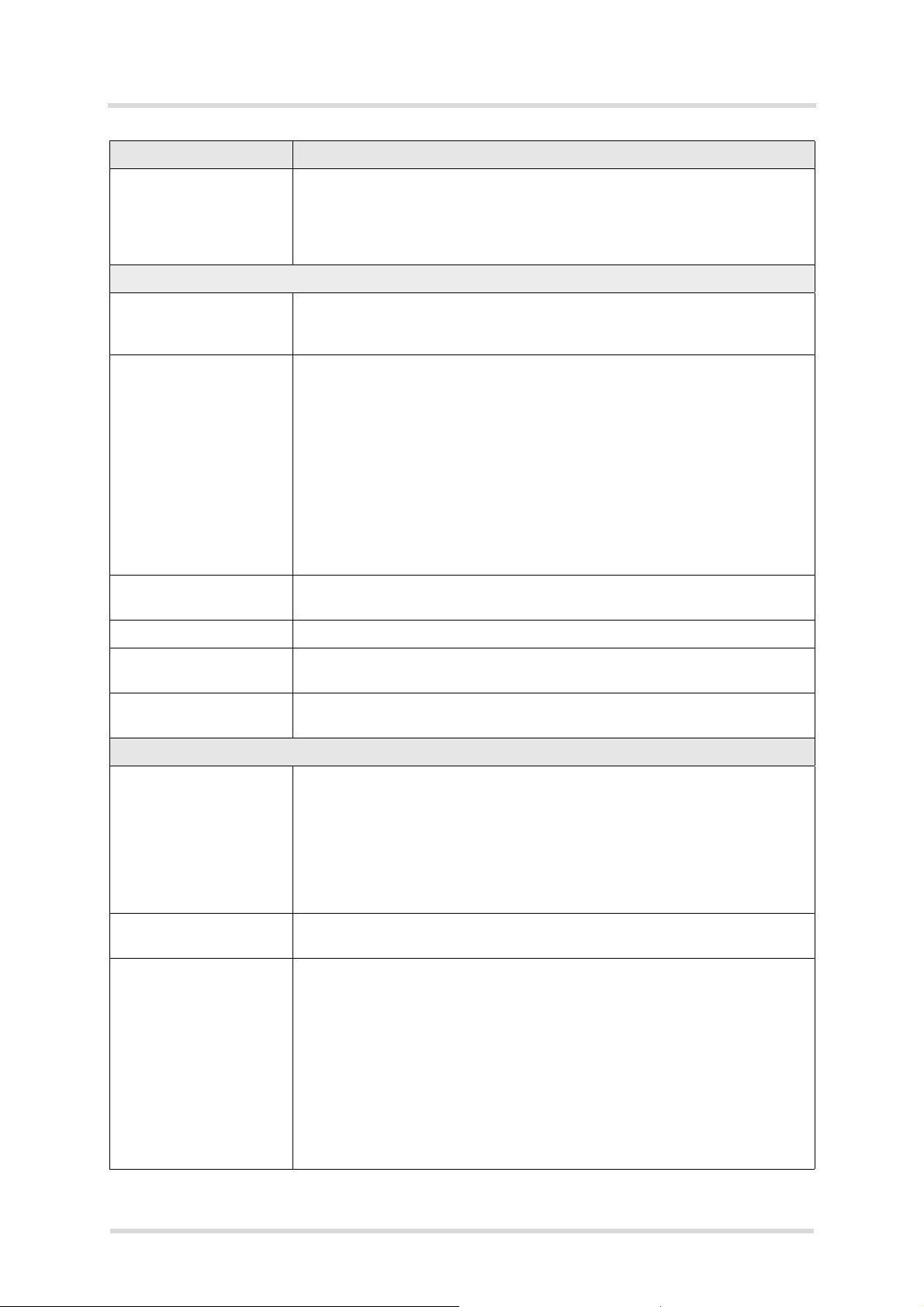

Feature Implementation

SMS Point-to-point MT and MO

Cell broadcast

Text and PDU mode

Storage: SIM card plus SMS locations in mobile equipment

Software

AT commands Hayes 3GPP TS 27.007, TS 27.005, Gemalto M2M

AT commands for RIL compatibility

Java™ Open Platform Java™ Open Platform with

• Java™ profile IMP-NG & CLDC 1.1 HI

• Secure data transmission via HTTPS/SSL

• Multi-threading programming and multi-application execution

Major benefits: seamless integration into Java applications, ease of programming, no need for application microcontroller, extremely cost-efficient

hardware and software design – ideal platform for industrial applications.

1

Page 10 of 113

The memory space available for Java programs is 30MB in the flash file

system and 18MB RAM. Application code and data share the space in the

flash file system and in RAM.

Microsoft™ compatibility RIL for Pocket PC and Smartphone

SIM Application Toolkit SAT letter classes b, c, e; with BIP

Audio Support for Voice over LTE (VoLTE), i.e. Voice Service via IMS (IP-based

Multimedia Subsystem) with CSFB

Firmware update Generic update from host application over ASC0 or USB modem.

Interfaces

Module interface Surface mount device with solderable connection pads (SMT application

interface). Land grid array (LGA) technology ensures high solder joint reliability and allows the use of an optional module mounting socket.

For more information on how to integrate SMT modules see also [3]. This

application note comprises chapters on module mounting and application

layout issues as well as on additional SMT application development equipment.

USB USB 2.0 High Speed (480Mbit/s) device interface, Full Speed (12Mbit/s)

compliant

2 serial interfaces ASC0 (shared with GPIO lines):

• 8-wire modem interface with status and control lines, unbalanced, asynchronous

• Adjustable baud rates: 1,200bps to 921,600bps

• Autobauding: 1,200bps to 230,400bps

• Supports RTS0/CTS0 hardware flow control.

ASC1 (shared with GPIO lines):

• 4-wire, unbalanced asynchronous interface

• Adjustable baud rates: 1,200bps to 921,60bps

• Autobauding: 1,200bps to 230,400bps

• Supports RTS1/CTS1 hardware flow control

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 11

Cinterion® ELS61-USA Hardware Interface Description

Page 11 of 113

1.1 Key Features at a Glance

14

Feature Implementation

Audio 1 digital audio interface (DAI), shared with GPIO lines

UICC interface Supported SIM/USIM cards: 3V, 1.8V

GPIO interface 22 GPIO lines comprising:

13 lines shared with ASC0, ASC1 and SPI lines, with network status indication, PWM functionality, fast shutdown and pulse counter

4 GPIO lines shared with DAI interface

5 GPIO lines not shared

2

I

C interface Supports I2C serial interface

SPI interface Serial peripheral interface, shared with GPIO lines

Antenna interface pads 50. UMTS/LTE main antenna, UMTS/LTE Rx Diversity antenna

Power on/off, Reset

Power on/off Switch-on by hardware signal ON

Switch-off by AT command

Switch off by hardware signal FST_SHDN instead of AT command

Automatic switch-off in case of critical temperature or voltage conditions

Reset Orderly shutdown and reset by AT command

Emergency reset by hardware signal EMERG_RST

Special features

Real time clock Timer functions via AT commands

TTY/CTM support Integrated CTM modem

Evaluation kit

Evaluation module ELS61-USA module soldered onto a dedicated PCB that can be connected

to an adapter in order to be mounted onto the DSB75.

DSB75 DSB75 Development Support Board designed to test and type approve

Gemalto M2M modules and provide a sample configuration for application

engineering. A special adapter is required to connect the ELS61-USA evaluation module to the DSB75.

1. HTTP/SecureConnection over SSL version 3.0 and TLS versions 1.0, 1.1, and 1.2 are supported. For

details please refer to Java User’s Guide for Cinterion

®

ELS61-USUSA.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 12

Cinterion® ELS61-USA Hardware Interface Description

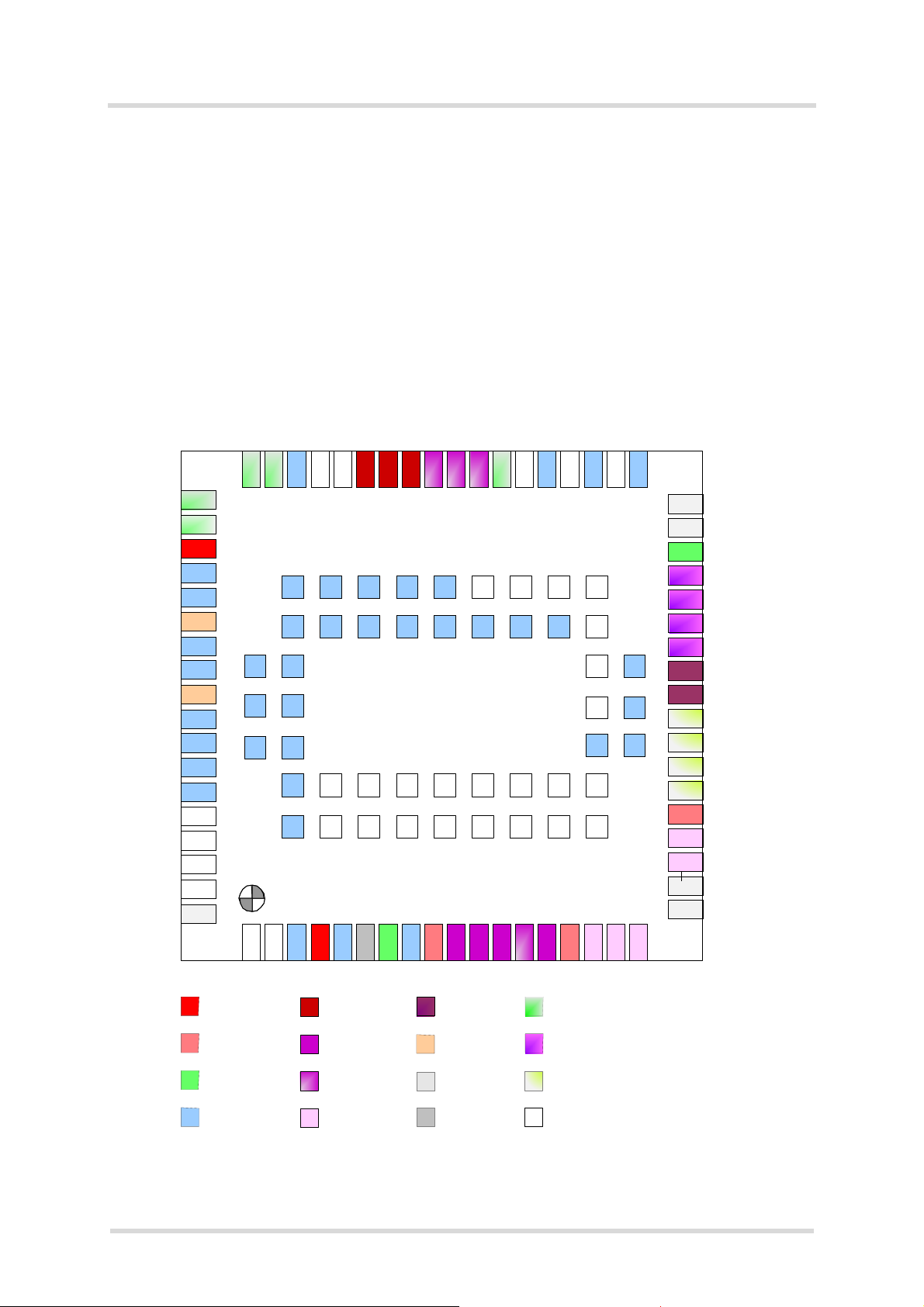

GPIO

interface

I2C

USB

ASC0 lines

ASC1/SPI

CONTROL

RTC

POWER

Rx diversity

antenna

(UMTS/LTE)

Module

SIM interface

(with SIM det ection)

SIM card

Application

Power supply

Backup supply

Emergency reset

ON

Serial in terface/

SPI interface

Serial modem

interface lines

I2C

GPIO

3

4

4

5

2

5

1

1

1

2

USB

Rx diversity

1

Status LED

1

DAC (PWM) PWM

2

Fast

shutdown

Fast shutdown

1

1

COUNTER

Pulse counter

1

ASC0 lines

Serial modem

inte rfac e line s/

SPI interface

4

Main ante nn a

(UMTS/LTE)

Main ante nn a

1

DAI lines

4

PCM/I2 S

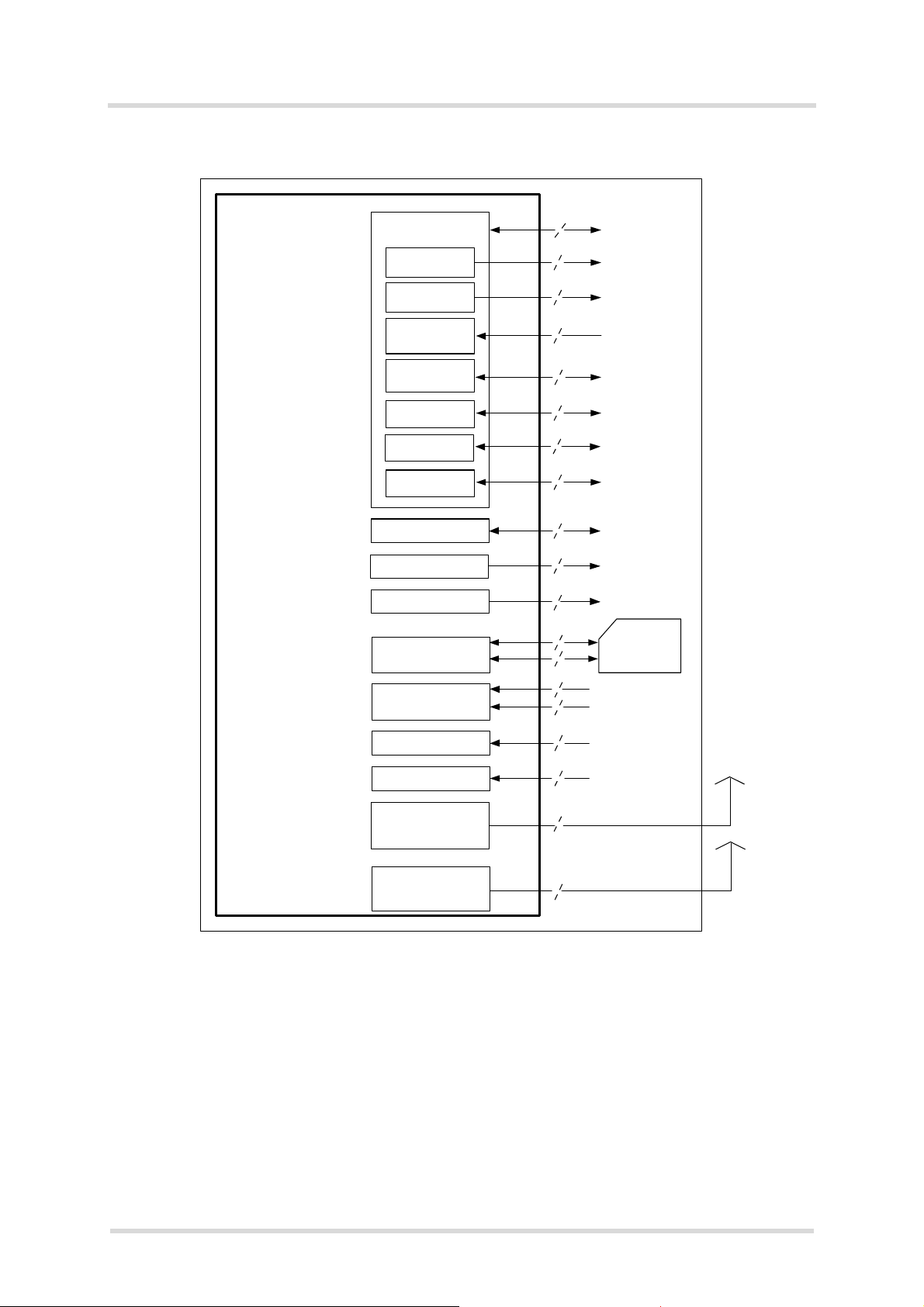

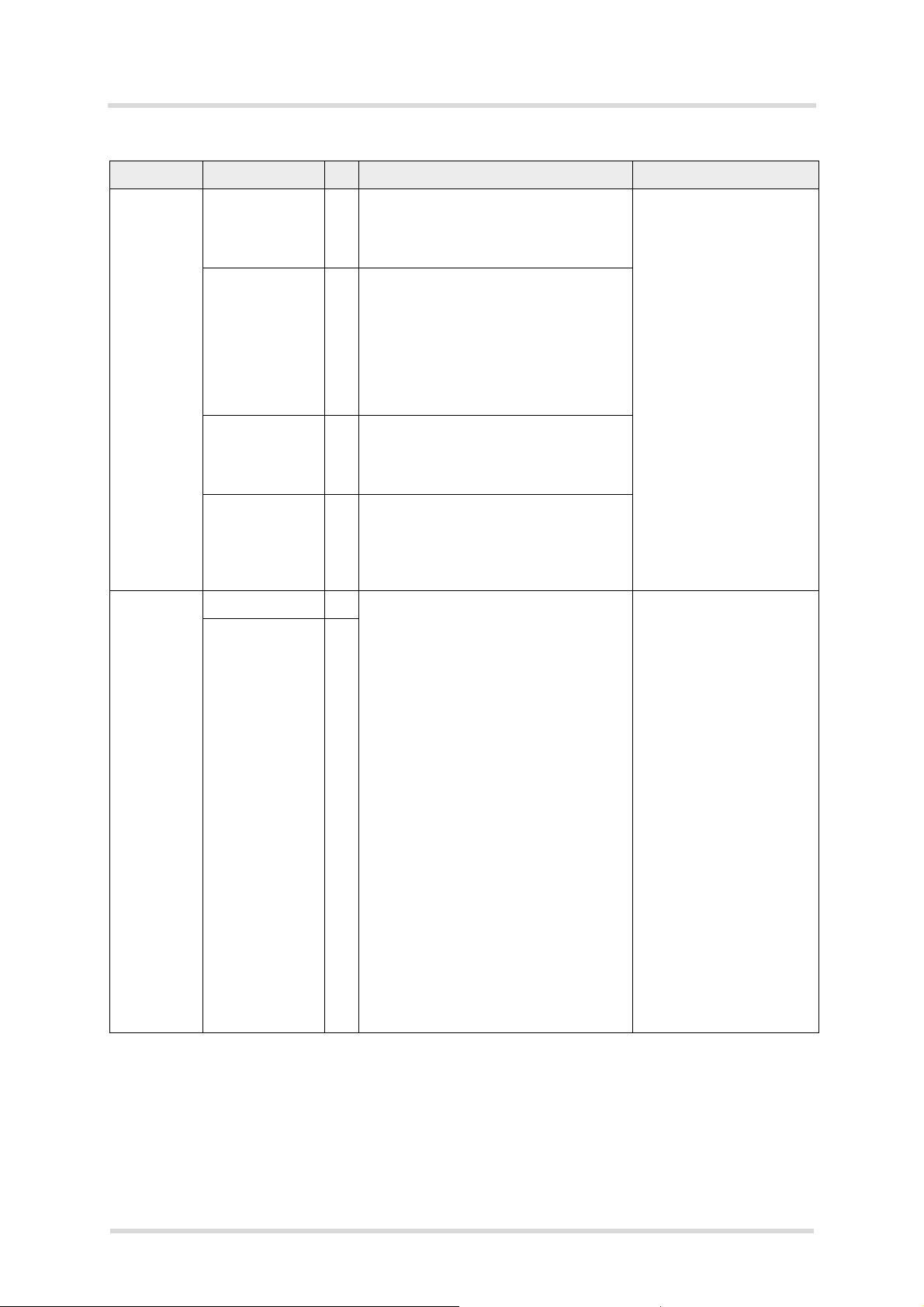

1.2 ELS61-USA System Overview

14

1.2 ELS61-USA System Overview

Page 12 of 113

Figure 1: ELS61-USA system overview

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 13

Cinterion® ELS61-USA Hardware Interface Description

SD1 SD2

SD2

LDOs

PMU

LDOs

ON

Reset_BB

SD3

I2CDAT

I2CCLK

USB

GPIO

SIM

CCIN

LPDDR2

SDRAM

FLASH

VDD

VDD

ADQ0 ~ ADQ15

DDR_ CA_0~DDR _CA_9

DDR _DQ_ 0~DDR _DQ_1 5

Con trol

Con trol

CCIN

SIM

GPIO

ASC0

USB

I2C

ON circuit

ON

EMERG _RST

BATT+

BB

RX/TX

RF control

V180

Baseband

controller

and

Power

management

DAI

PCM/I2S/

GPIO

USIF1/

GPIO

FST_SHDWN

ASC1/G PIO/

SPI

USIF3

Page 13 of 113

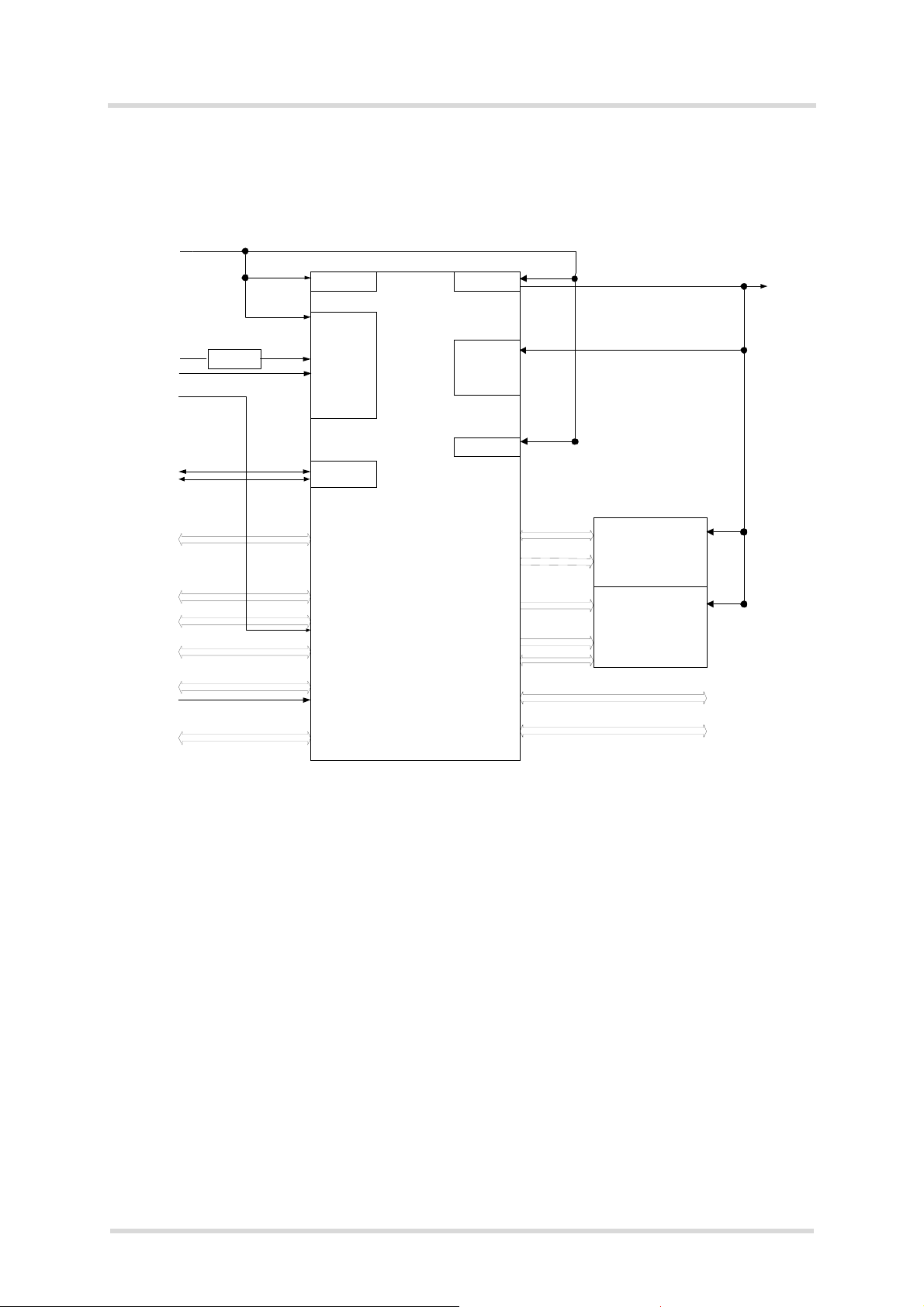

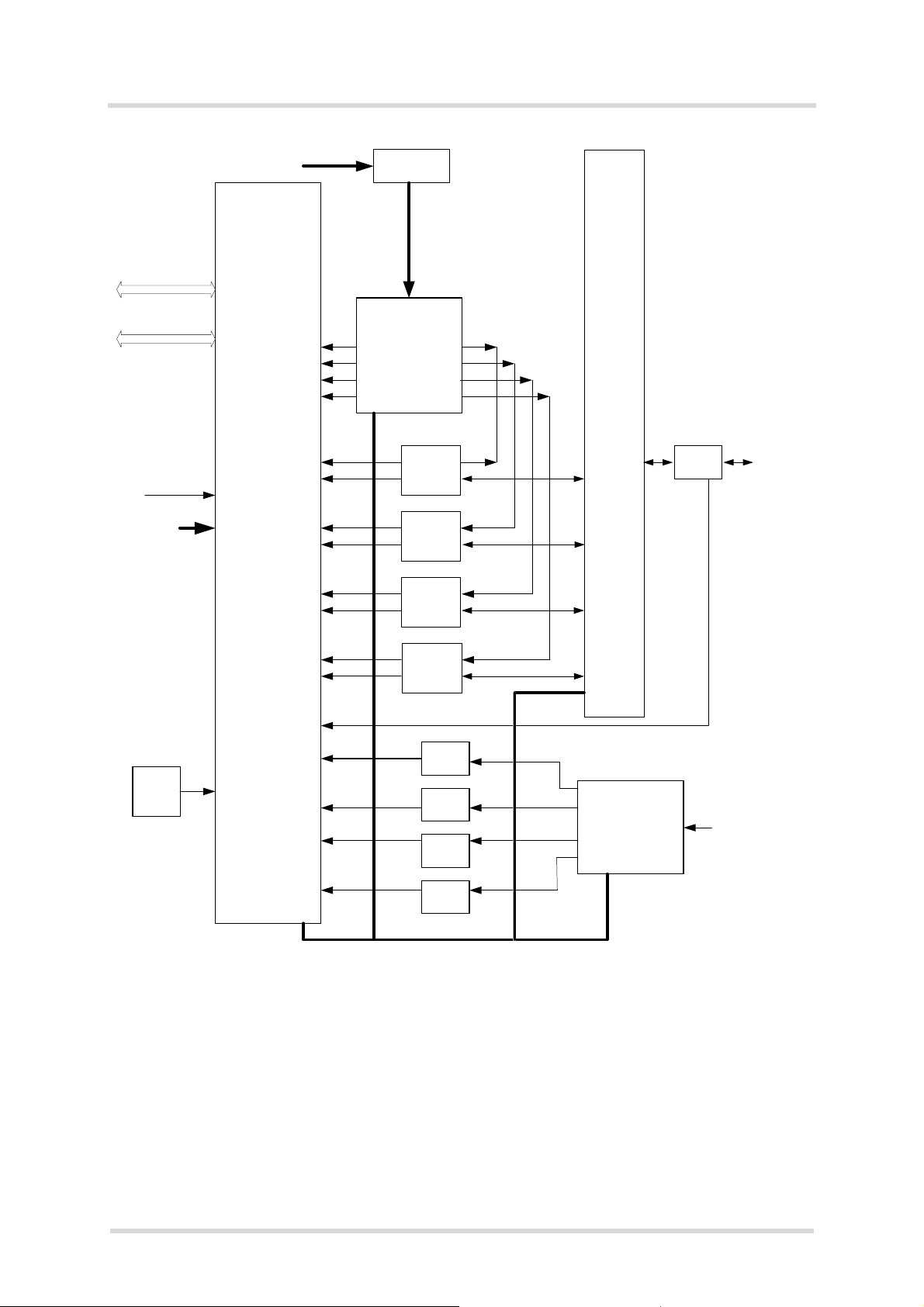

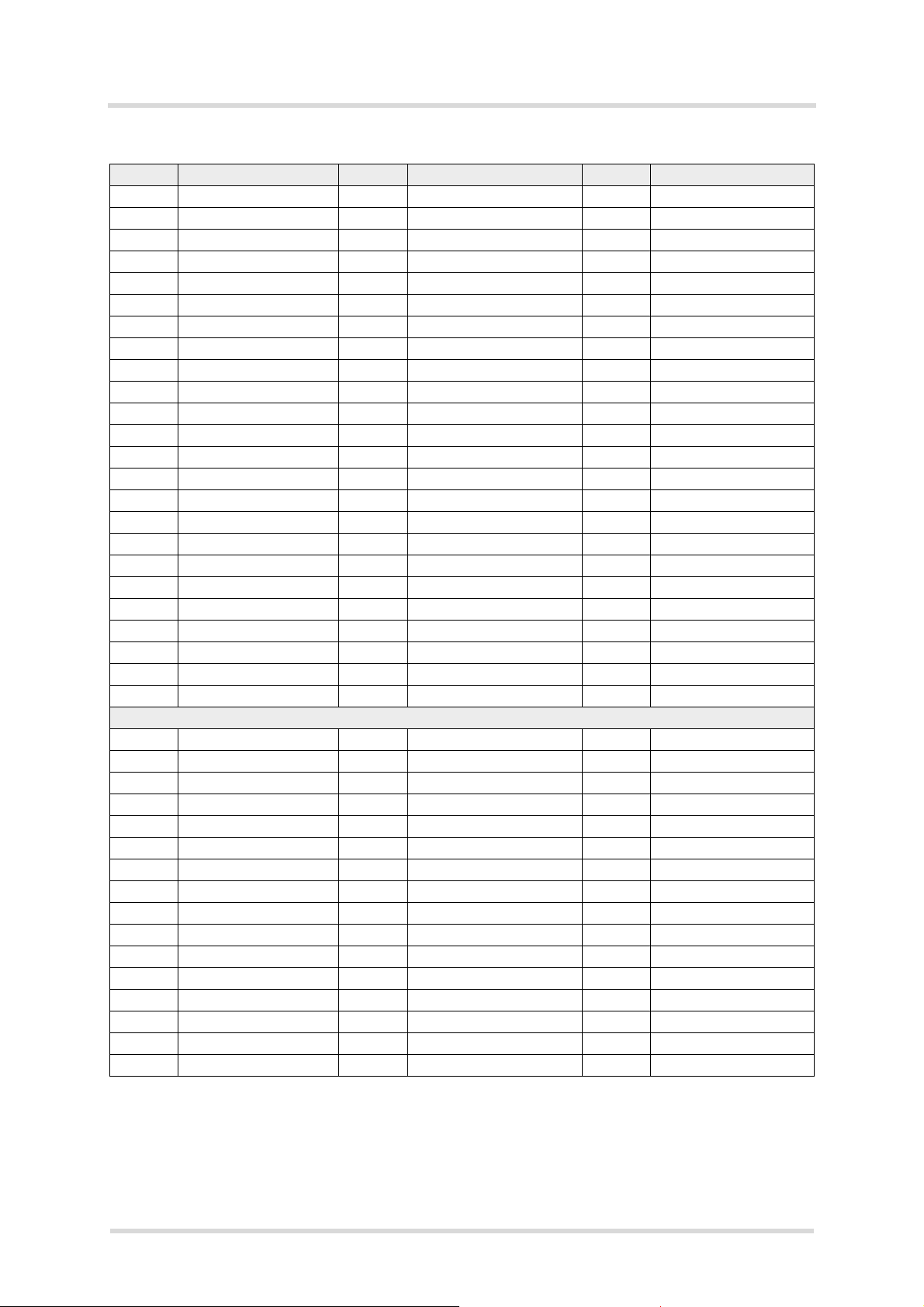

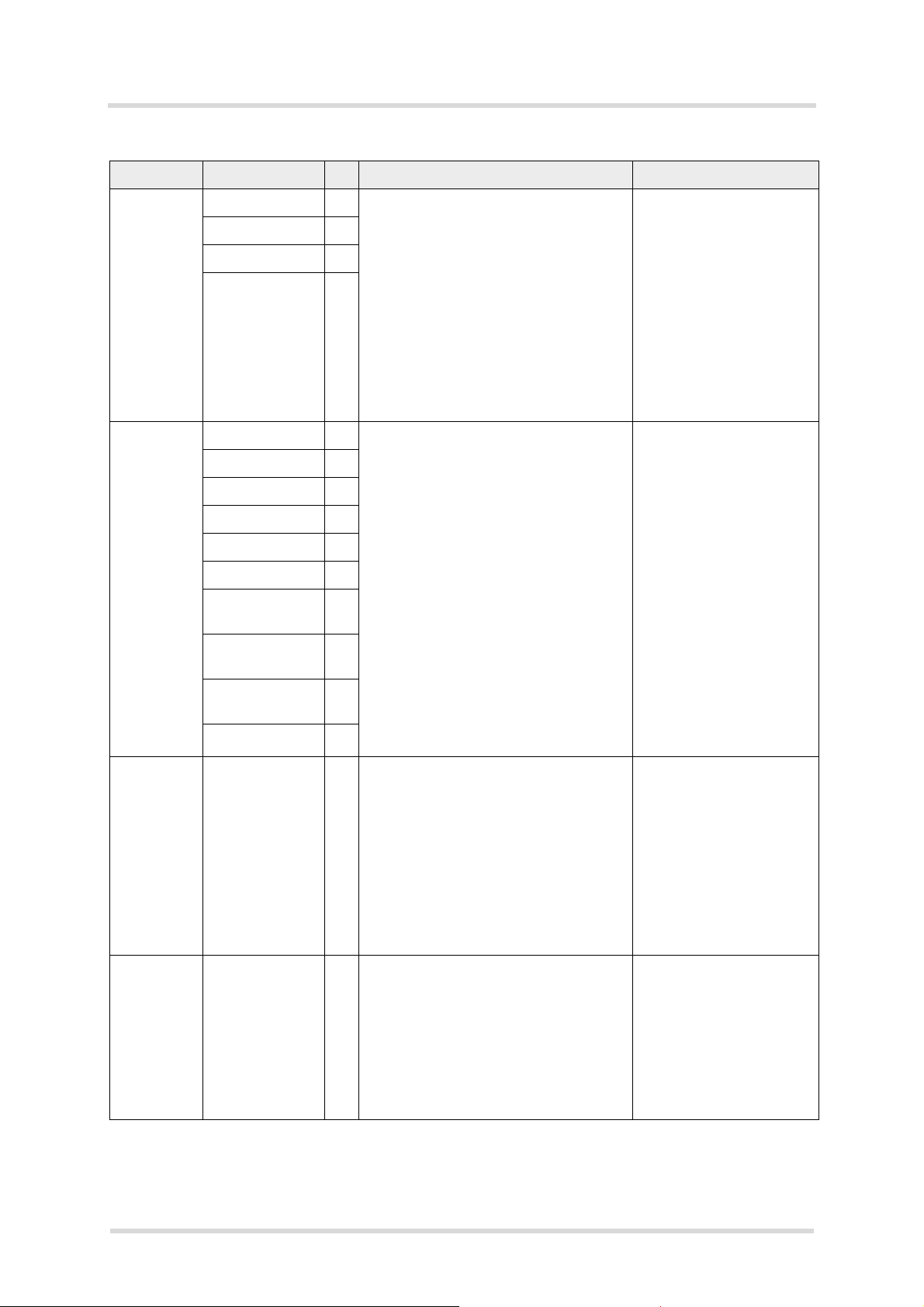

1.3 Circuit Concept

14

1.3 Circuit Concept

Figure 2 and Figure 3 show block diagrams of the ELS61-USA module and illustrate the major

functional components:

Figure 2: ELS61-USA block diagram

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 14

Cinterion® ELS61-USA Hardware Interface Description

LTE / UMTS

RF transceiver

SKY77622

SKY13525

SKY13525

Band2

SAW

Filter

Band4

SAW

Filter

Band5

SAW

Filter

Band12

SAW

Filter

Diversity Antenna

Band2

Duplexer

Band4

Duplexer

Band5

Duplexer

Band12

Duplexer

Antenna

Coupler

B2_OUT

B4_OUT

B5_OUT

B12_OUT

4G_HB_IN

2G/3G_HB_IN

4G_LB_IN

2G/3G_LB_IN

TQ_H

TP_H

TQ_L

TP_L

RX_M1

RX_M1X

RX_H4

RX_H4X

RX_L1

RX_L1X

RX_L3

RX_L3X

4G_HB_IN

4G_HB_IN

4G_HB_IN

4G_HB_IN

TRX4

TRX6

TRX5

TRX2

TRX2

TRX1

TRX3

TRX5

PA DCDC

SKY87000

BATT+

RF

FBR_RF2

MAIN_FWD

MIPI

26MHz

RX/TX

BATT+

BB

V180

RF control

1.3 Circuit Concept

14

Page 14 of 113

Figure 3: ELS61-USA RF section block diagram

Confidential / Preliminary

els61-usa_hid_v01.040a 2017-08-31

Page 15

Cinterion® ELS61-USA Hardware Interface Description

Supply pads: BATT+

Control pads

GND pads

ASC0 pads

Combined GPI O/ASC1 /SPI pads

SIM pads

I2C pads

Supply pads: Ot her

Combined GPIO/Control pads

(LED, PWM, COUNTER, FST_ SHDN)

USB pads

GPIO pads

21821721621521421321221121020 9208207

206

205204203202201

33

32

31

30

29

28

27

26

25

24

23

22

21

20

53

54

55

56

57

58

59

60

61

62

63

64

65

66

223224225226227228229230231232233234235236237238239240

67 68 69 70 71 72 73

74 75 76 77 78 79 80

93 94 95 96 97 98 99

100 101 102 103 104 105 106

85 86

89 90

81 82

87 88

91 92

83 84

243

244

241

242

222

221

220

219

252

245

250

251

249

248

247

246

RF antenna pad s

Do not use

Not connected

Reserved

Combined GPI O/

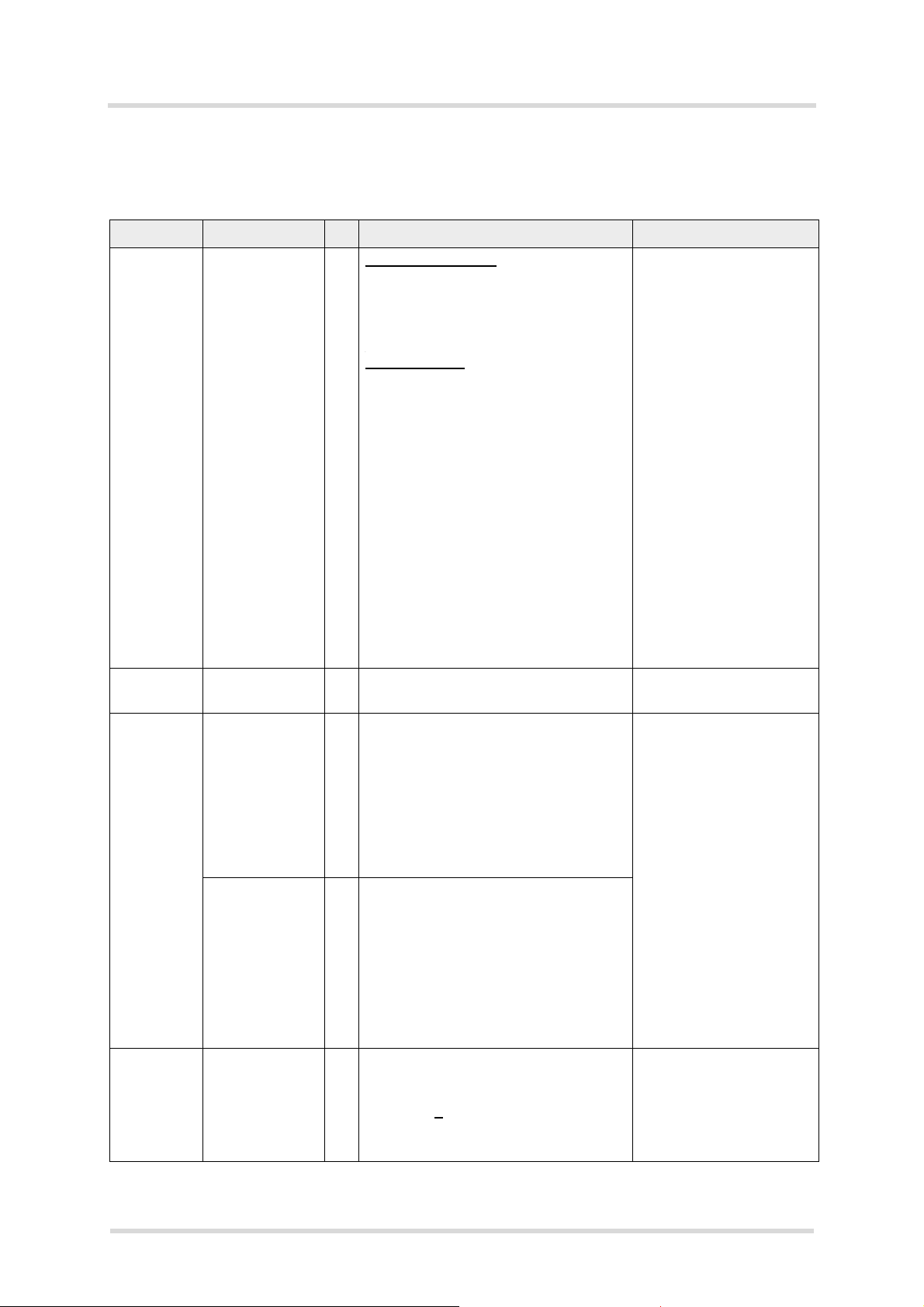

ASC0/SPI pads

ADC pad

Combined GPI O/DAI pads

Page 15 of 113

2 Interface Characteristics

59

2 Interface Characteristics

ELS61-USA is equipped with an SMT application interface that connects to the external application. The SMT application interface incorporates the various application interfaces as well as

the RF antenna interface.

2.1 Application Interface

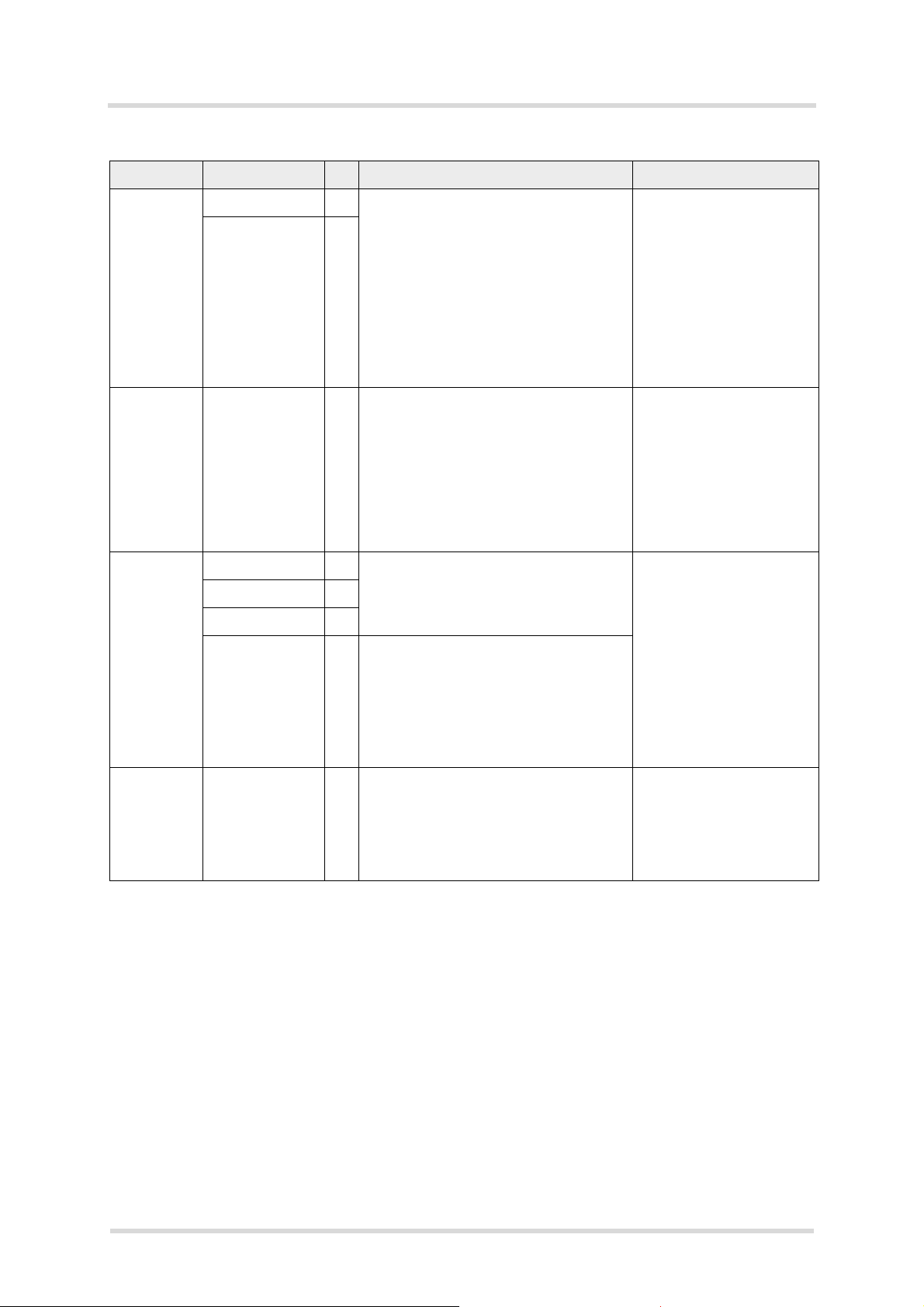

2.1.1 Pad Assignment

The SMT application interface on the ELS61-USA provides connecting pads to integrate the

module into external applications. Figure 4 shows the connecting pads’ numbering plan, the

following Table 1 lists the pads’ assignments.

els61-usa_hid_v01.040a 2017-08-31

Figure 4: Numbering plan for connecting pads (bottom view)

Confidential / Preliminary

Page 16

Cinterion® ELS61-USA Hardware Interface Description

Page 16 of 113

2.1 Application Interface

59

Table 1: Pad assignments

Pad no. Signal name Pad no. Signal name Pad no. Signal name

201 Not connected 24 GPIO22/FSC 235 USB_DN

202 Not connected 25 GPIO21/DIN 236 Not connected

203 GND 26 GPIO23/BCLK 237 Not connected

204 BATT+

BB

27 I2CDAT 238 GND

205 GND 28 I2CCLK 239 GPIO5/LED

206 ADC1 29 GPIO17/TXD1/MISO 240 GPIO6/PWM2

207 ON 30 GPIO16/RXD1/MOSI 241 GPIO7/PWM1

208 GND 31 GPIO18/RTS1 242 GPIO8/COUNTER

209 V180 32 GPIO19/CTS1/SPI_CS 53 BATT+

RF

210 RXD0 33 EMERG_RST 54 GND

211 CTS0 221 GPIO12 55 GND

212 TXD0 222 GPIO11 56 ANT_DRX

213 GPIO24/RING0 223 GND 57 GND

214 RTS0 224 Not connected 58 GND

215 VDDLP 225 GND 59 ANT_MAIN

216 CCRST 226 Not connected 60 GND

217 CCIN 227 GND 61 GND

218 CCIO 228 Not connected 62 GND

219 GPIO14 229 GPIO4/FST_SHDN 63 GND

220 GPIO13 230 GPIO3/DSR0/SPI_CLK 64 Not connected

20 CCVCC 231 GPIO2/DCD0 65 Not connected

21 CCCLK 232 GPIO1/DTR0 66 Not connected

22 VCORE 233 VUSB 243 Not connected

23 GPIO20/DOUT 234 USB_DP 244 GPIO15

Centrally located pads

67 Not connected 83 GND 99 GND

68 Not connected 84 GND 100 GND

69 Not connected 85 GND 101 GND

70 Not connected 86 GND 102 GND

71 Not connected 87 Not connected 103 GND

72 Not connected 88 GND 104 Not connected

73 Not connected 89 GND 105 Not connected

74 Do not use 90 GND 106 Not connected

75 Do not use 91 Not connected 245 GND

76 Not connected 92 GND 246 Not connected

77 Not connected 93 GND 247 Not connected

78 Not connected 94 GND 248 Not connected

79 Not connected 95 GND 249 Not connected

80 Not connected 96 GND 250 GND

81 GND 97 GND 251 GND

82 GND 98 GND 252 GND

Signal pads that are not used should not be connected to an external application.

Please note that the reference voltages listed in Table 2 are the values measured directly on

the ELS61-USA module. They do not apply to the accessories connected.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 17

Cinterion® ELS61-USA Hardware Interface Description

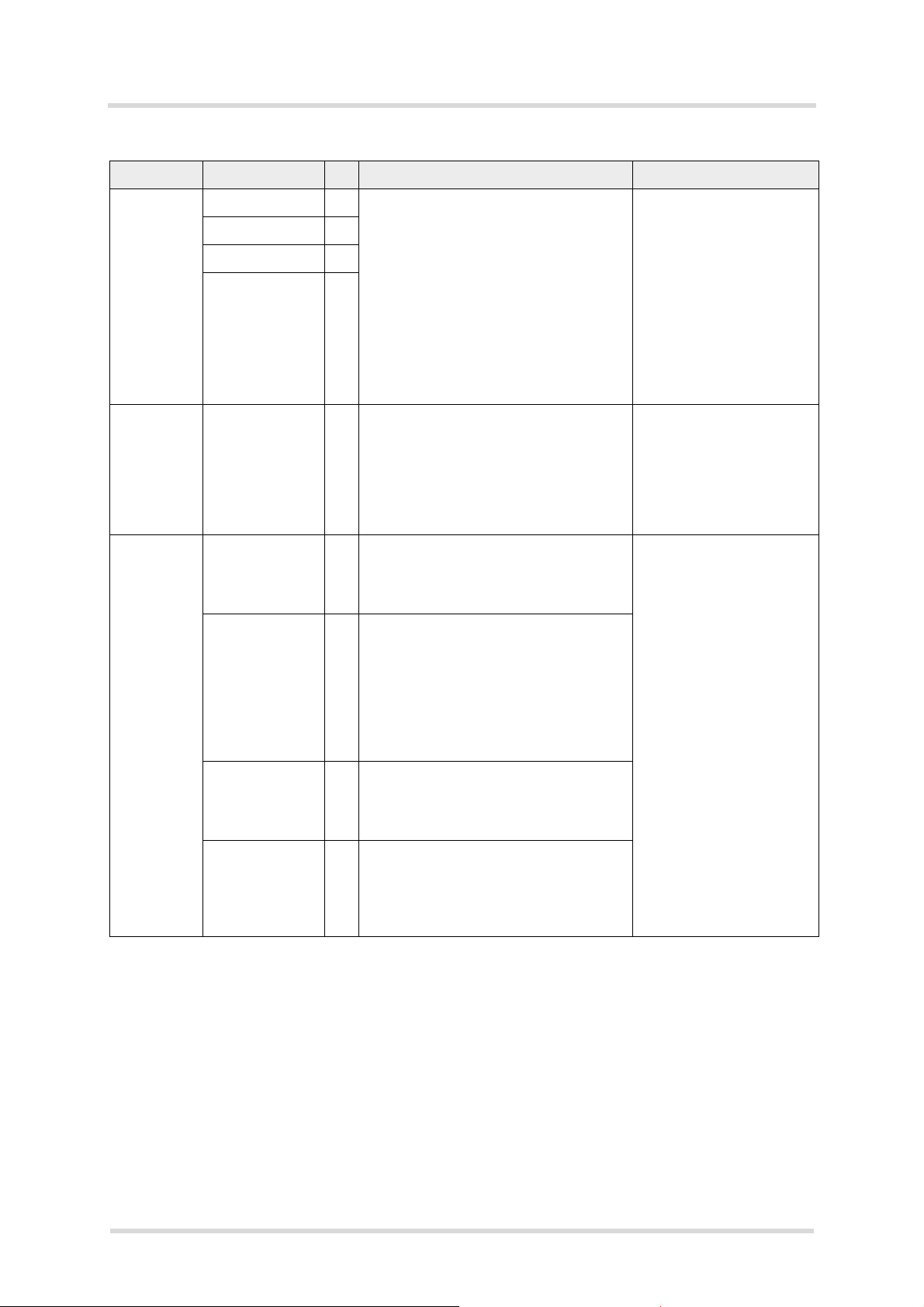

2.1 Application Interface

59

2.1.2 Signal Properties

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 17 of 113

Power

supply

Power

supply

BATT+

BATT+

BB

RF

I WCDMA activated:

VImax = 4.5V

V

norm = 3.8V

I

V

min = 3.0V during Transmit active.

I

Imax = 900mA during Tx

LTE activated:

VImax = 4.5V

V

norm = 3.8V

I

V

min = 3.0V during Transmit active.

I

Lines of BATT+ and GND

must be connected in

parallel for supply purposes because higher

peak currents may occur.

Minimum voltage must

not fall below 3.0V including drop, ripple, spikes

and not rise above 4.5V.

BATT+

and BATT+RF

BB

require an ultra low ESR

capacitor:

BATT+

BATT+

--> 150µF

BB

--> 150µF

RF

If using Multilayer

Ceramic Chip Capacitors

(MLCC) please take DCbias into account.

Note that minimum ESR

value is advised at

<70m.

GND Ground Application Ground

External

V180 O Normal operation:

supply

voltage

VCORE O V

Ignition ON

V180 should be used to

V

norm = 1.80V ±3%

O

max = -10mA

I

O

supply level shifters at

the interfaces or to supply

external application cirSLEEP mode Operation:

V

Sleep = 1.80V ±5%

O

I

max = -10mA

O

cuits.

VCORE and V180 may

be used for the power

CLmax = 100µF

norm = 1.2V ±2.5%

O

I

max = -10mA

O

CLmax = 100nF

SLEEP mode Operation:

V

Sleep = 0.90V...1.2V ±4%

O

I

max = -10mA

O

indication circuit.

Vcore and V180 are

sensitive against back-

powering by other sig-

nals. While switched off

these voltage domains

must have <0.2V.

If unused keep lines

open.

1

IVIHmax = 5V tolerant

V

min = 1.3V

IH

max = 0.5V

V

IL

Slew rate <

1ms

This signal switches the

module on, and is rising

edge sensitive triggered.

Internal pull down value

ON ___|~~~~

for this signal is 100k.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 18

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 18 of 113

Emer-

EMERG_RST I R

gency

restart

RTC

VDDLP I/O V

backup

USB VUSB_IN I V

USB_DN I/O Full and high speed signal characteris-

USB_DP

Serial

Interface

ASC0

RXD0 O V

CTS0 O

DSR0 O

DCD0 O

RING0 O

TXD0 I V

RTS0 I Pull down resistor active

DTR0 I Pull up resistor active

1k, CI 1nF

I

V

max = VDDLP max

OH

V

min = 1.35V

IH

V

max = 0.3V at ~200µA

IL

~~|___|~~ low impulse width > 10ms

norm = 1.8V ±5%

O

I

max = -25mA

O

V

max = 1.9V

I

V

min = 1.0V

I

I

typ < 1µA

I

min = 3V

I

V

max = 5.25V

I

Active and suspend current:

I

< 100µA

max

tics according USB 2.0 Specification.

max = 0.25V at I = 1mA

OL

V

min = 1.55V at I = -1mA

OH

V

max = 1.85V

OH

max = 0.35V

IL

V

min = 1.30V

IH

V

max = 1.85V

IH

V

max = 0.35V at > 50µA

IL

V

min = 1.30V at < 240µA

IH

V

max = 1.85V at < 240µA

IH

V

max = 0.35V at < -200µA

IL

V

min = 1.30V at > -50µA

IH

V

max = 1.85V

IH

This line must be driven

low by an open drain or

open collector driver connected to GND.

If unused keep line open.

It is recommended to use

a serial resistor between

VDDLP and a possible

capacitor (bigger than

1µF).

If unused keep line open.

All electrical characteristics according to USB

Implementers' Forum,

USB 2.0 Specification.

If unused keep lines

open.

If unused keep lines

open.

Note that some ASC0

lines are originally available as GPIO lines. If

configured as ASC0

lines, the GPIO lines are

assigned as follows:

GPIO1 --> DTR0

GPIO2 --> DCD0

GPIO3 --> DSR0

GPIO24 --> RING0

The DSR0 line is also

shared with the SPI interface‘s SPI_CLK signal.

Note that DCD0/GPIO2

must not be driven low

during startup

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 19

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 19 of 113

Serial

Interface

ASC1

SIM card

detection

3V SIM

Card Interface

RXD1 O V

TXD1 I

RTS1 I

CTS1 O

CCIN I R

CCRST O V

CCIO I/O V

max = 0.25V at I = 1mA

OL

V

min = 1.55V at I = -1mA

OH

V

max = 1.85V

OH

V

max = 0.35V

IL

V

min = 1.30V

IH

V

max = 1.85V

IH

110k

I

V

min = 1.45V at I = 15µA,

IH

V

max= 1.9V

IH

V

max = 0.3V

IL

max = 0.30V at I = 1mA

OL

V

min = 2.45V at I = -1mA

OH

V

max = 2.90V

OH

max = 0.50V

IL

V

min = 2.05V

IH

V

max = 2.90V

IH

If unused keep line open.

Note that the ASC1 interface lines are originally

available as GPIO lines.

If configured as ASC1

lines, the GPIO lines are

assigned as follows:

GPIO16 --> RXD1

GPIO17 --> TXD1

GPIO18 --> RTS1

GPIO19 --> CTS1

CCIN = High, SIM card

inserted.

For details please refer to

Section 2.1.6.

If unused keep line open.

Maximum cable length or

copper track to SIM card

holder should not exceed

100mm.

CCCLK O V

CCVCC O V

V

max = 0.25V at I = 1mA

OL

V

min = 2.50V at I = -1mA

OH

V

max = 2.90V

OH

max = 0.25V at I = 1mA

OL

V

min = 2.40V at I = -1mA

OH

V

max = 2.90V

OH

min= 2.70V

O

V

typ = 2.90V

O

V

max = 3.30V

O

I

max = -30mA

O

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 20

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 20 of 113

1.8V SIM

Card Interface

2

C I2CCLK IO Open drain IO

I

CCRST O V

CCIO I/O V

CCCLK O V

CCVCC O V

I2CDAT IO

max = 0.25V at I = 1mA

OL

V

min = 1.45V at I = -1mA

OH

V

max = 1.90V

OH

max = 0.35V

IL

V

min = 1.25V

IH

V

max = 1.85V

IH

V

max = 0.25V at I = 1mA

OL

V

min = 1.50V at I = -1mA

OH

V

max = 1.85V

OH

max = 0.25V at I = 1mA

OL

V

min = 1.50V at I = -1mA

OH

V

max = 1.85V

OH

min = 1.75V

O

V

typ = 1.80V

O

V

max = 1.85V

O

I

max = -30mA

O

V

min = 0.35V at Imax = 4mA (Imax

OL

= Imax external + I pull-up)

V

max = 1.85V

OH

R external pull up min = 560

V

max = 0.35V

IL

V

min = 1.3V

IH

V

max = 1.85V

IH

Maximum cable length or

copper track to SIM card

holder should not exceed

100mm.

2

According to the I

C Bus

Specification Version 2.1

for the fast mode a rise

time of max. 300ns is permitted. There is also a

maximum V

=0.4V at

OL

3mA specified.

The value of the pull-up

depends on the capacitive load of the whole sys-

2

tem (I

C Slave + lines).

The maximum sink current of I2CDAT and

I2CCLK is 4mA.

2

I

C interface of the module already has internal

1KOhm pull up resistor to

V180 inside the module.

Please take this into consideration during application design.

If lines are unused keep

lines open.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 21

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 21 of 113

SPI SPI_CLK O

MOSI O

MISO I

SPI_CS O

GPIO

interface

GPIO1-GPIO3 IO

GPIO4 IO

GPIO5 IO

GPIO6 IO

GPIO7 IO

GPIO8 IO

GPIO11GPIO15

GPIO16GPIO19

GPIO20GPIO23

GPIO24 IO

VOLmax = 0.25V at I = 1mA

VOHmin = 1.55V at I = -1mA

VOHmax = 1.85V

VILmax = 0.35V

V

min = 1.30V

IH

V

max = 1.85V

IH

VOLmax = 0.25V at I = 1mA

VOHmin = 1.55V at I = -1mA

max = 1.85V

V

OH

VILmax = 0.35V

V

min = 1.30V

IH

V

max = 1.85V

IH

Imax = ±5mA

IO

IO

IO

If lines are unused keep

lines open.

Note that the SPI interface lines are originally

available as GPIO lines.

If configured as SPI lines,

the GPIO lines are

assigned as follows:

GPIO3 --> SPI_CLK

GPIO16 --> MOSI

GPIO17 --> MISO

GPIO19 --> SPI_CS

If unused keep line open.

Please note that most

GPIO lines can be configured by AT command for

alternative functions:

GPIO1-GPIO3: ASC0

control lines DTR0,

DCD0 and DSR0

GPIO4: Fast shutdown

GPIO5: Status LED line

GPIO6/GPIO7: PWM

GPIO8: Pulse Counter

GPIO16-GPIO19: ASC1

or SPI

GPIO20-GPIO23: DAI

GPIO24: ASC0 control

line RING0

Fast

FST_SHDN I V

shutdown

Status LED LED O

max = 0.35V

IL

V

min = 1.30V

IH

V

max = 1.85V

IH

~~|___|~~ low impulse width > 1ms

VOLmax = 0.25V at I = 1mA

VOHmin = 1.55V at I = -1mA

VOHmax = 1.85V

This line must be driven

low.

If unused keep line open.

Note that the fast shutdown line is originally

available as GPIO line. If

configured as fast shutdown, the GPIO line is

assigned as follows:

GPIO4 --> FST_SHDN

If unused keep line open.

Note that the LED line is

originally available as

GPIO line. If configured

as LED line, the GPIO

line is assigned as follows:

GPIO5 --> LED

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 22

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 22 of 113

PWM PWM1 O

PWM2 O

Pulse

COUNTER I Internal up resistor active

counter

Digital

audio interface (DAI)

FSC O V

BCLK O

DOUT O

DIN I V

VOLmax = 0.25V at I = 1mA

VOHmin = 1.55V at I = -1mA

VOHmax = 1.85V

V

max = 0.35V at < -200µA

IL

V

min = 1.30V at > -50µA

IH

V

max = 1.85V

IH

max = 0.25V at I = 1mA

OL

V

min = 1.55V at I = -1mA

OH

V

max = 1.85V

OH

max = 0.35V

IL

V

min = 1.30V

IH

V

max = 1.85V

IH

If unused keep lines

open.

Note that the PWM lines

are originally available as

GPIO lines. If configured

as PWM lines, the GPIO

lines are assigned as follows:

GPIO7 --> PWM1

GPIO6 --> PWM2

If unused keep line open.

Note that the COUNTER

line is originally available

as GPIO line. If configured as COUNTER line,

the GPIO line is assigned

as follows:

GPIO8 --> COUNTER

If unused keep line open.

Note that the DAI interface lines are originally

available as GPIO lines.

If configured as DAI lines,

the GPIO lines are

assigned as follows:

GPIO22 --> FSC

GPIO23 --> BCLK

GPIO20 --> DOUT

GPIO21 --> DIN

ADC

(Analog-toDigital Con-

ADC1 I R

= 1M

I

V

= 0V ... 1.2V (valid range)

I

V

max = 1.2V

IH

ADC can be used as

input for external measurements.

verter)

Resolution 1024 steps

If unused keep line open.

Tolerance 0.3%

1. After the operating voltage is applied, it is required to wait at least 1 second to trigger the ON signal.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 23

Cinterion® ELS61-USA Hardware Interface Description

Page 23 of 113

2.1 Application Interface

59

2.1.2.1 Absolute Maximum Ratings

The absolute maximum ratings stated in Table 3 are stress ratings under any conditions.

Stresses beyond any of these limits will cause permanent damage to ELS61-USA.

Table 3: Absolute maximum ratings

1

Parameter Min Max Unit

Supply voltage

BATT+

, BATT+

BB

RF

-0.5 +5.5 V

Voltage at all signal lines in Power Down mode -0.3 +0.3 V

Voltage at digital lines in normal operation -0.2 V180 + 0.2 V

Voltage at SIM/USIM interface, CCVCC in normal operation -0.5 +3.3 V

VDDLP input voltage -0.15 2.0 V

Voltage at ADC line in normal operation 0 1.2 V

V180 in normal operation +1.7 +1.9 V

Current at V180 in normal operation -0 +50 mA

VCORE in normal operation +0.85 +1.25 V

Current at VCORE in normal operation -0 +50 mA

Voltage at ON signal -0.5 +6.5 V

Current at single GPIO -5 +5 mA

Current at all GPIO -50 +50 mA

Voltage at VCORE, V180 in power down mode -0.2 +0.2 V

1. Positive noted current means current sourcing from ELS61-USA. Negative noted current means current

sourcing towards ELS61-USA.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 24

Cinterion® ELS61-USA Hardware Interface Description

VBUS

DP

DN

VREG (3V075)

BATT+

USB_DP

2)

lin. reg.

GND

Module

Detection only

VUSB_IN

USB part

1)

RING0

Host wakeup

1)

All serial (including RS) and pull-up resistors for data lines are implemented.

USB_DN

2)

2)

If the USB interface is operated in High Speed mode (480MHz), it is recommended to take

special care routing the data lines USB_DP and USB_DN. Application layout should in this

case implement a differential impedance of 90 ohms for proper signal integrity.

R

S

R

S

SMT

Page 24 of 113

2.1 Application Interface

59

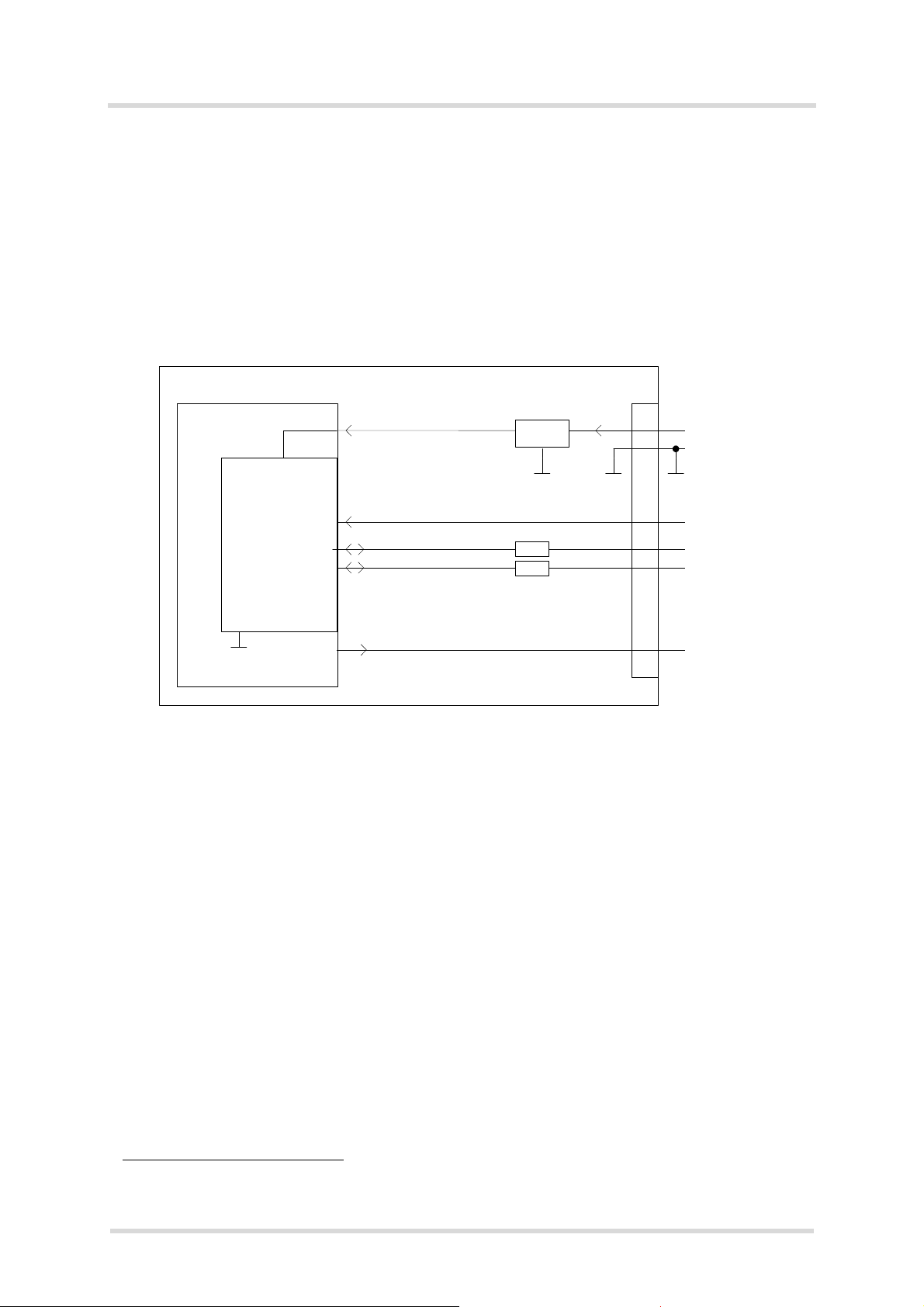

2.1.3 USB Interface

ELS61-USA supports a USB 2.0 High Speed (480Mbit/s) device interface that is Full Speed

(12Mbit/s) compliant. The USB interface is primarily intended for use as command and data interface and for downloading firmware.

The external application is responsible for supplying the VUSB_IN line. This line is used for cable detection only. The USB part (driver and transceiver) is supplied by means of BATT+. This

is because ELS61-USA is designed as a self-powered device compliant with the “Universal Serial Bus Specification Revision 2.0”

1

.

Figure 5: USB circuit

To properly connect the module's USB interface to the external application, a USB 2.0 compatible connector and cable or hardware design is required. For more information on the USB related signals see Table 2. Furthermore, the USB modem driver distributed with ELS61-USA

needs to be installed.

1. The specification is ready for download on http://www.usb.org/developers/docs/

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 25

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Page 25 of 113

2.1.3.1 Reducing Power Consumption

While a USB connection is active, the module will never switch into SLEEP mode. Only if the

USB interface is in Suspended state or Detached (i.e., VUSB_IN = 0) is the module able to

switch into SLEEP mode thereby saving power. There are two possibilities to enable power reduction mechanisms:

• Recommended implementation of USB Suspend/Resume/Remote Wakeup:

The USB host should be able to bring its USB interface into the Suspended state as

described in the “Universal Serial Bus Specification Revision 2.0“

work, the VUSB_IN line should always be kept enabled. On incoming calls and other events

ELS61-USA will then generate a Remote Wakeup request to resume the USB host controller.

See also [5] (USB Specification Revision 2.0, Section 10.2.7, p.282):

"If USB System wishes to place the bus in the Suspended state, it commands the Host Controller to stop all bus traffic, including SOFs. This causes all USB devices to enter the Suspended state. In this state, the USB System may enable the Host Controller to respond to

bus wakeup events. This allows the Host Controller to respond to bus wakeup signaling to

restart the host system."

1

. For this functionality to

• Implementation for legacy USB applications not supporting USB Suspend/Resume:

As an alternative to the regular USB suspend and resume mechanism it is possible to

employ the RING0 line to wake up the host application in case of incoming calls or events

signalized by URCs while the USB interface is in Detached state (i.e., VUSB_IN = 0). Every

wakeup event will force a new USB enumeration. Therefore, the external application has to

carefully consider the enumeration timings to avoid loosing any signalled events. For details

on this host wakeup functionality see Section 2.1.14.3. To prevent existing data call connections from being disconnected while the USB interface is in detached state (i.e., VUSB_IN=0) it is possible to call AT&D0, thus ignoring the status of the DTR line (see also [1]).

1. The specification is ready for download on http://www.usb.org/developers/docs/

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 26

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Page 26 of 113

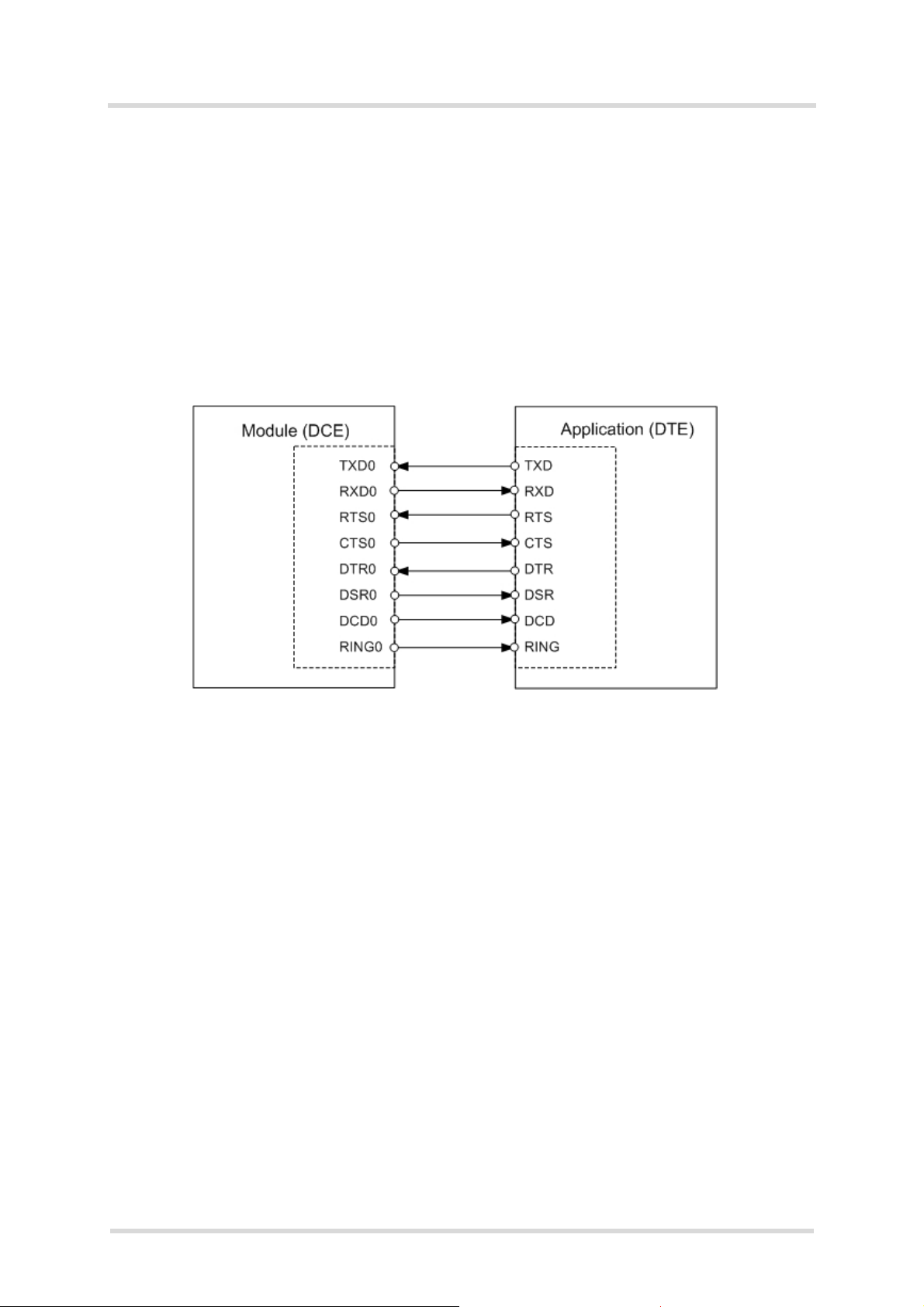

2.1.4 Serial Interface ASC0

ELS61-USA offers an 8-wire unbalanced, asynchronous modem interface ASC0 conforming to

ITU-T V.24 protocol DCE signalling. The electrical characteristics do not comply with ITU-T

V.28. The significant levels are 0V (for low data bit or active state) and 1.8V (for high data bit

or inactive state). For electrical characteristics please refer to Table 2. For an illustration of the

interface line’s startup behavior see Figure 7.

ELS61-USA is designed for use as a DCE. Based on the conventions for DCE-DTE connections it communicates with the customer application (DTE) using the following signals:

• Port TXD @ application sends data to the module’s TXD0 signal line

• Port RXD @ application receives data from the module’s RXD0 signal line

Figure 6: Serial interface ASC0

Features:

• Includes the data lines TXD0 and RXD0, the status lines RTS0 and CTS0 and, in addition,

the modem control lines DTR0, DSR0, DCD0 and RING0.

• The RING0 signal serves to indicate incoming calls and other types of URCs (Unsolicited

Result Code). It can also be used to send pulses to the host application, for example to

wake up the application from power saving state.

• Configured for 8 data bits, no parity and 1 stop bit.

• ASC0 can be operated at fixed bit rates from 1,200bps up to 921,600bps.

• Autobauding supports bit rates from 1,200bps up to 230,400bps.

• Supports RTS0/CTS0 hardware flow control. The hardware hand shake line RTS0 has an

internal pull down resistor causing a low level signal, if the line is not used and open.

Although hardware flow control is recommended, this allows communication by using only

RXD and TXD lines.

• Wake up from SLEEP mode by RTS0 activation (high to low transition; see Section 3.3.2).

Note: The ASC0 modem control lines DTR0, DCD0, DSR0 and RING0 are originally available

as GPIO lines. If configured as ASC0 lines, these GPIO lines are assigned as follows:

GPIO1 --> DTR0, GPIO2 --> DCD0, GPIO3 --> DSR0 and GPIO24 --> RING0. Also, DSR0 is

shared with the SPI_CLK line of the SPI interface and may be configured as such. Configuration is done by AT command (see [1]). The configuration is non-volatile and becomes active

after a module restart.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 27

Cinterion® ELS61-USA Hardware Interface Description

TXD0

RXD0

RTS0

CTS0

DTR0/GPIO1

DSR0/GPIO3

DCD0/GPIO2

RING0/GPIO24

ON

EMERG_RST

PU

PD

PD

PD

PD

PU

PD

PU

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

Reset

state

V180

VCORE

PD

PU

PU

PU

PD

PD

PD

Page 27 of 113

2.1 Application Interface

59

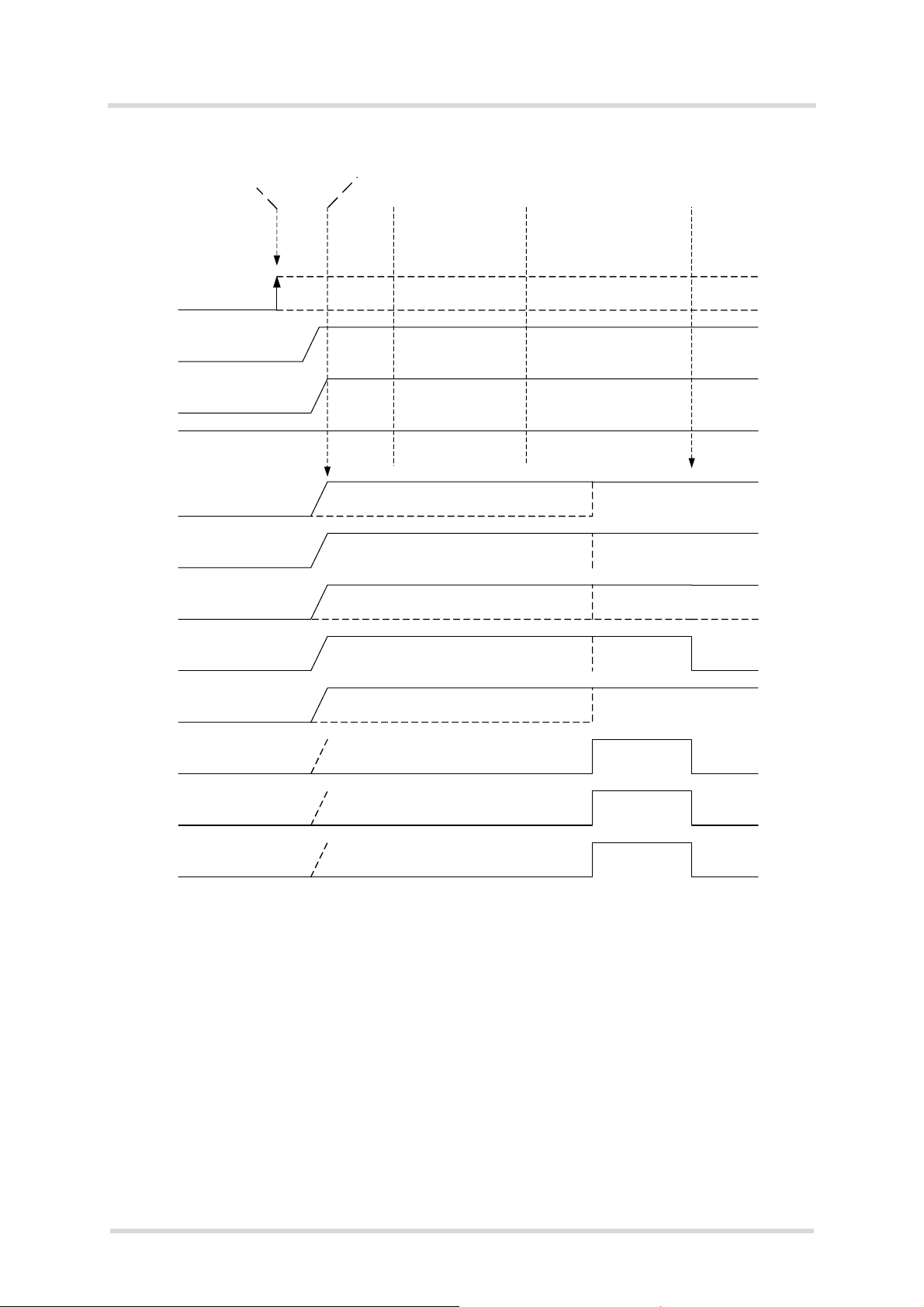

The following figure shows the startup behavior of the asynchronous serial interface ASC0.

For pull-up and pull-down values see Table 13.

Figure 7: ASC0 startup behavior

Notes:

During startup the DTR0 signal is driven active low for 500µs. It is recommended to provide a

470

serial resistor for the DTR0 line to prevent shorts (high current flow).

No data must be sent over the ASC0 interface before the interface is active and ready to receive data (see Section 3.2.1).

An external pull down to ground on the DCD0 line during the startup phase activates a special

mode for ELS61-USA. In this special mode the AT command interface is not available and the

module may therefore no longer behave as expected.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 28

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Page 28 of 113

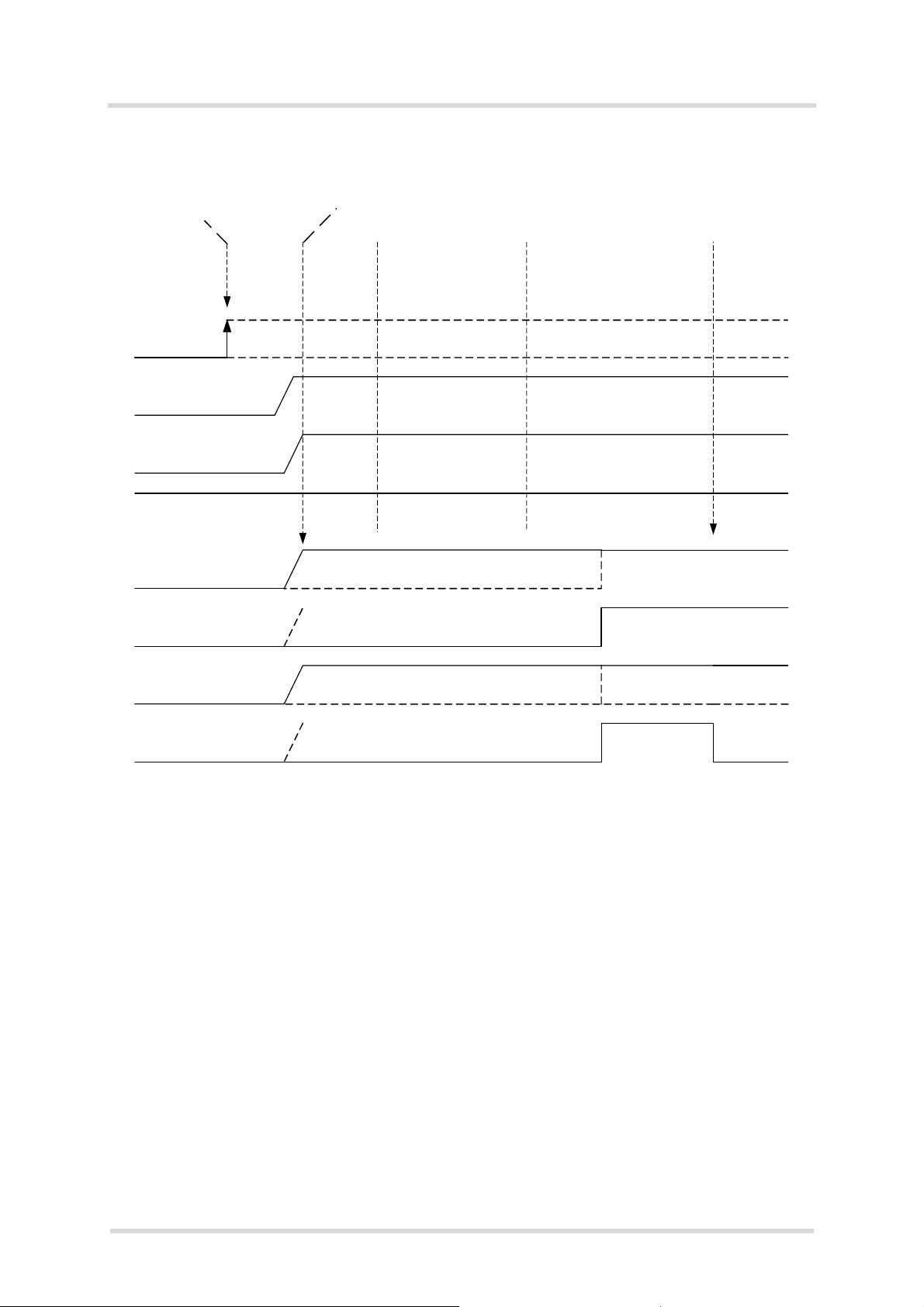

2.1.5 Serial Interface ASC1

Four ELS61-USA GPIO lines can be configured as ASC1 interface signals to provide a 4-wire

unbalanced, asynchronous modem interface ASC1 conforming to ITU-T V.24 protocol DCE

signalling. The electrical characteristics do not comply with ITU-T V.28. The significant levels

are 0V (for low data bit or active state) and 1.8V (for high data bit or inactive state). For electrical

characteristics please refer to Table 2. For an illustration of the interface line’s startup behavior

see Figure 9.

The ASC1 interface lines are originally available as GPIO lines. If configured as ASC1 lines,

the GPIO lines are assigned as follows: GPIO16 --> RXD1, GPIO17 --> TXD1, GPIO18 -->

RTS1 and GPIO19 --> CTS1. Configuration is done by AT command (see [1]: AT^SCFG). The

configuration is non-volatile and becomes active after a module restart.

ELS61-USA is designed for use as a DCE. Based on the conventions for DCE-DTE connections it communicates with the customer application (DTE) using the following signals:

• Port TXD @ application sends data to module’s TXD1 signal line

• Port RXD @ application receives data from the module’s RXD1 signal line

Figure 8: Serial interface ASC1

Features

• Includes only the data lines TXD1 and RXD1 plus RTS1 and CTS1 for hardware handshake.

• On ASC1 no RING line is available.

• Configured for 8 data bits, no parity and 1 or 2 stop bits.

• ASC1 can be operated at fixed bit rates from 1,200 bps to 921,600 bps.

• Autobauding supports bit rates from 1,200bps up to 230,400bps.

• Supports RTS1/CTS1 hardware flow. The hardware hand shake line RTS0 has an internal

pull down resistor causing a low level signal, if the line is not used and open. Although hardware flow control is recommended, this allows communication by using only RXD and TXD

lines.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 29

Cinterion® ELS61-USA Hardware Interface Description

TXD1/GPIO17

RXD1/GPIO16

RTS1/GPIO18

CTS1/GPIO19

ON

EMERG_RST

PD

PD

PD

PD

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

Reset

state

V180

VCORE

PD

2.1 Application Interface

59

Page 29 of 113

The following figure shows the startup behavior of the asynchronous serial interface ASC1.

*) For pull-down values see Table 13.

Figure 9: ASC1 startup behavior

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 30

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Page 30 of 113

2.1.6 UICC/SIM/USIM Interface

ELS61-USA has an integrated UICC/SIM/USIM interface compatible with the 3GPP 31.102

and ETSI 102 221. This is wired to the host interface in order to be connected to an external

SIM card holder. Five pads on the SMT application interface are reserved for the SIM interface.

The UICC/SIM/USIM interface supports 3V and 1.8V SIM cards. Please refer to Table 2 for

electrical specifications of the UICC/SIM/USIM interface lines depending on whether a 3V or

1.8V SIM card is used.

The CCIN signal serves to detect whether a tray (with SIM card) is present in the card holder.

To take advantage of this feature, an appropriate SIM card detect switch is required on the card

holder. For example, this is true for the model supplied by Molex, which has been tested to operate with ELS61-USA and is part of the Gemalto M2M reference equipment submitted for type

approval. See Section 7.1 for Molex ordering numbers.

Table 4: Signals of the SIM interface (SMT application interface)

Signal Description

GND Separate ground connection for SIM card to improve EMC.

CCCLK Chipcard clock

CCVCC SIM supply voltage.

CCIO Serial data line, input and output.

CCRST Chipcard reset

CCIN Input on the baseband processor for detecting a SIM card tray in the holder. If the SIM is

removed during operation the SIM interface is shut down immediately to prevent destruction of the SIM. The CCIN signal is by default low and will change to high level if a SIM card

is inserted.

The CCIN signal is mandatory for applications that allow the user to remove the SIM card

during operation.

The CCIN signal is solely intended for use with a SIM card. It must not be used for any other

purposes. Failure to comply with this requirement may invalidate the type approval of

ELS61-USA.

Note [1]: No guarantee can be given, nor any liability accepted, if loss of data is encountered after removing

the SIM card during operation. Also, no guarantee can be given for properly initializing any SIM card that

the user inserts after having removed the SIM card during operation. In this case, the application must

restart ELS61-USA.

Note [2]: On the evaluation board, the CCIN signal is inverted, thus the CCIN signal is by default high and

will change to a low level if a SIM card is inserted.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 31

Cinterion® ELS61-USA Hardware Interface Description

SIM

CCVCC

CCRST

CCIO

CCCLK

220nF

1nF

CCIN

V180

2.1 Application Interface

59

The figure below shows a circuit to connect an external SIM card holder.

Page 31 of 113

Figure 10: External UICC/SIM/USIM card holder circuit

The total cable length between the SMT application interface pads on ELS61-USA and the

pads of the external SIM card holder must not exceed 100mm in order to meet the specifications of 3GPP TS 51.010-1 and to satisfy the requirements of EMC compliance.

To avoid possible cross-talk from the CCCLK signal to the CCIO signal be careful that both

lines are not placed closely next to each other. A useful approach is using a GND line to shield

the CCIO line from the CCCLK line.

An example for an optimized ESD protection for the SIM interface is shown in Section 2.1.6.1.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 32

Cinterion® ELS61-USA Hardware Interface Description

CCRST

CCCLK

CCIO

CCVCC

CCIN

GND

123

654

SIM_RST

SIM_CLK

SIM_IO

SIM_VCC

SIM_DET

Module

2.1 Application Interface

59

2.1.6.1 Enhanced ESD Protection for SIM Interface

Page 32 of 113

To optimize ESD protection for the SIM interface it is possible to add ESD diodes to the SIM

interface lines as shown in the example given in Figure 11.

1

The example was designed to meet ESD protection according ETSI EN 301 489-1/7: Contact

discharge: ± 4kV, air discharge: ± 8kV.

Figure 11: SIM interface - enhanced ESD protection

1. Note that the protection diode shall have low internal capacitance less than 5pF for IO and CLK.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 33

Cinterion® ELS61-USA Hardware Interface Description

2.1 Application Interface

59

Page 33 of 113

2.1.7 Digital Audio Interface (DAI)

ELS61-USA supports a digital audio interface that can be employed either as pulse code modulation interface (see Section 2.1.7.1) or as inter IC sound interface (see Section 2.1.7.2). Operation of these interface variants is mutually exclusive, and can be configured by AT command

(AT^SAIC; see [1]).

2.1.7.1 Pulse Code Modulation Interface (PCM)

Four ELS61-USA GPIO lines can be configured as pule code modulation interface (PCM). The

PCM functionality allows for the use of an external codec like the W681360 (see Section

2.1.7.3).

The PCM interface supports the following features:

• Master and Slave mode

• Long frame and short frame

• 8kHz sample rate / 125µs frame duration (narrow band), 16kHz sample rate / 62.5µs frame

duration (wide band)

• Bit clock: 256kHz (sample rate of 8kHz), 264kHz (short frame), 520kHz (sample rate of

8kHz), 528kHz (short frame), 1040kHz (sample rate of 16kHz)

• The most significant bit MSB is transferred first

• Data write at rising edge / data read at falling edge

• Common frame sync signal for transmit and receive

The four GPIO lines can be configured as DAI/PCM interface signals as follows: GPIO20 -->

DOUT, GPIO21--> DIN, GPIO22 --> FSC and GPIO23 --> BCLK. The configuration is done by

AT command (see [1]). It is non-volatile and becomes active after a module restart. Table 5 describes the available DAI/PCM lines at the digital audio interface. For electrical details see Sec-

tion 2.1.2.

Table 5: Overview of DAI/PCM lines

Signal name Input/Output Description

DOUT O PCM data from

DIN I PCM data from external codec to

FSC O

BCLK O Bit clock to external codec.

Frame synchronization signal to external codec:

Long frame (8kHz)

ELS61-USA to external codec.

ELS61-USA.

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 34

Cinterion® ELS61-USA Hardware Interface Description

BCLK

DOUT

DIN

FSC

MSB

MSB

LSB

LSB

14 13

14

13

1

1

12

12

2

2

MSB

MSB

125 µs

DIN/GPIO21

FSC/GPIO22

BCLK/GPIO23

DOUT/GPIO20

PD

PD

PD

PD

CTS0

ON

EMERG_RST

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

Reset

state

V180

VCORE

Page 34 of 113

2.1 Application Interface

59

Figure 12 shows the PCM timing for the master mode available with ELS61-USA.

Figure 12: Long frame PCM timing, 256kHz

The following figure shows the start up behavior of the DAI interface. The start up configuration

of functions will be activated after the software initialization of the command interface. With an

active state of CTS0 (low level) the initialization of the DAI interface is finished.

Figure 13: DAI startup timing

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 35

Cinterion® ELS61-USA Hardware Interface Description

BCLK

DOUT

DIN

FSC

MSB

MSB

LSB

LSB

14 13

14 13

1

1

12

12

2

2

MSB

MSB

125 µs

2.1 Application Interface

59

2.1.7.2 Inter IC Sound Interface

Page 35 of 113

The Inter IC Sound interface (I2S) is enabled using the AT command AT^SAIC (see [1]). An

2

activation is possible only out of call and out of tone presentation. The I

2

capabilities comply with the requirements laid out in the Phillips I

S Bus Specifications,

S properties and

revised June 5, 1996.

2

The I

S interface has the following characteristics:

• Clock Modes: Master with permanent clock option

• Sampling Rate: 8kHz (narrow band), 16kHz (wide band)

• Bit clock: 512kHz

The digital audio interface pads available for the PCM interface are also available for the I

interface. In I

2

S mode they have the same electrical characteristics (for more information on the

2

DOUT, DIN, FSC and BCLK pads please refer to Section 2.1.2 and Section 2.1.7.1).

The table below lists the available pads at the module’s digital audio interface.

Table 6: Overview of DAI/I

Signal name Input/Output Description

DOUT O I

DIN I I

FSC O Frame synchronization signal to external codec:

2

S lines

2

S data from module to external codec.

2

S data from external codec to module.

Word alignment (WS)

S

BCLK O Bit clock to external codec: 512kHz

2

The following figure shows the I

S timing for the master mode available with the module.

Figure 14: I

2

S timing, 8kHz sample rate

els61-usa_hid_v01.040a 2017-08-31

Confidential / Preliminary

Page 36

Cinterion® ELS61-USA Hardware Interface Description

W681360

13-Bit-Linear-

CODEC

PCM to Analog Converter

Module

DIN

DOUT

FSC

BCLK

+3.0V

+3.0V

BCLK

DOUT

FSC

DIN

R5

1k

R6

1k

R9

100k

Mic1

MICRO PHONE

1

2

+

C6

100uF

C3

10nF

C2

100nF

R8 100kR7 20 k

C1

100nF

U1

W681360

15

6

5

8

1

4

9

10

2

3

19

18

17

16

14

13

12

11

7

20

VSS

VDD

PO+

DR

VAGREF

PO-

BCLKR

PDI

RO-

PI

TI+

TITG

HB

FST

DT

BCLKT

MCLK

FSR

VAG

R1 75 k

R2 75 k

C7 420pF

C8 420 pF

R4 1k

R3 1k

C4 100nF

C5 100nF

LS1

SPEAKER

Speaker gain

Low lev el input

+3.0V

Module

Output lines:

FSC

BCLK

DOUT

Input line:

DIN

5V tolerant

V180

VCC

VCC

74V HC1GT50

74LV C1G34

Page 36 of 113

2.1 Application Interface

59

2.1.7.3 Solutions for the Digital Audio Interface

Figure 15 and Figure 16 show an example of using the digital audio interface of the module.

The below mentioned sample Nuvoton codec W681360 can be replaced with a DSP. In the example, framesync and clock master is the module (FSC line) and thus the RF network.

Figure 15: Block circuit for DAI to analog converter

This DAI analog converter is well suited for evaluating and testing a telephone handset and can

be used instead of the headset interface of the DSB75.

Figure 16: Sample circuit for analog to DAI box

On the module side, the DAI interface has to be enabled. This can be done by using the following AT command: AT^SCFG="GPIO/mode/DAI","std".

Please note that level converters are required between the module‘s 1.8V digital audio lines