Page 1

Cinterion® ELS31-VA/ELS51-VA

Hardware Interface Description

Version: 01.000

DocId: ELS31-VA_ELS51-VA_HID_v01.000

M2M.GEMALTO.COM

Page 2

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2

Page 2 of 106

Document Name:

Version:

Date:

DocId:

Status:

Cinterion® ELS31-V A/ELS51-V A Hardware Interface Description

01.000

2017-01-04

ELS31-VA_ELS51-VA_HID_v01.000

Confidential / Preliminary

GENERAL NOTE

THE USE OF THE PRODUCT INCLUDING THE SOFTWARE AND DOCUMENTATION (THE "PRODUCT") IS SUBJECT TO THE RELEASE NOTE PROVIDED TOGETHER WITH PRODUCT. IN ANY

EVENT THE PROVISIONS OF THE RELEASE NOTE SHALL PREVAIL. THIS DOCUMENT CONTAINS

INFORMATION ON GEMALTO M2M PRODUCTS. THE SPECIFICATIONS IN THIS DOCUMENT ARE

SUBJECT TO CHANGE AT GEMALTO M2M'S DISCRETION. GEMALTO M2M GMBH GRANTS A NONEXCLUSIVE RIGHT TO USE THE PRODUCT. THE RECIPIENT SHALL NOT TRANSFER, COPY,

MODIFY, TRANSLATE, REVERSE ENGINEER, CREATE DERIVATIVE WORKS; DISASSEMBLE OR

DECOMPILE THE PRODUCT OR OTHERWISE USE THE PRODUCT EXCEPT AS SPECIFICALLY

AUTHORIZED. THE PRODUCT AND THIS DOCUMENT ARE PROVIDED ON AN "AS IS" BASIS ONLY

AND MAY CONTAIN DEFICIENCIES OR INADEQUACIES. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, GEMALTO M2M GMBH DISCLAIMS ALL WARRANTIES AND LIABILITIES.

THE RECIPIENT UNDERTAKES FOR AN UNLIMITED PERIOD OF TIME TO OBSERVE SECRECY

REGARDING ANY INFORMATION AND DATA PROVIDED TO HIM IN THE CONTEXT OF THE DELIVERY OF THE PRODUCT. THIS GENERAL NOTE SHALL BE GOVERNED AND CONSTRUED

ACCORDING TO GERMAN LAW.

Copyright

Transmittal, reproduction, dissemination and/or editing of this document as well as utilization of its contents and communication thereof to others without express authorization are prohibited. Offenders will be

held liable for payment of damages. All rights created by patent grant or registration of a utility model or

design patent are reserved.

Copyright © 2017, Gemalto M2M GmbH, a Gemalto Company

Trademark Notice

Gemalto, the Gemalto logo, are trademarks and service marks of Gemalto and are registered in certain

countries. Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries. All other registered trademarks or trademarks mentioned

in this document are property of their respective owners.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 3

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Contents

106

Page 3 of 106

Contents

1 Introduction.................................................................................................................9

1.1 Key Features at a Glance .................................................................................. 9

1.2 ELS31-VA/ELS51-VA System Overview ......................................................... 12

1.3 Circuit Concept ................................................................................................ 13

2 Interface Characteristics ..........................................................................................14

2.1 Application Interface ........................................................................................ 14

2.1.1 Pad Assignment.................................................................................. 14

2.1.2 Signal Properties................................................................................. 16

2.1.2.1 Absolute Maximum Ratings ................................................ 21

2.1.3 USB Interface...................................................................................... 22

2.1.3.1 Interface implementation..................................................... 23

2.1.3.2 Reducing Power Consumption............................................ 24

2.1.4 Serial Interface ASC0 ......................................................................... 25

2.1.4.1 Serial Interface Start-up Behavior ....................................... 26

2.1.5 Serial Interface ASC1 ......................................................................... 27

2.1.6 UICC/SIM/USIM Interface................................................................... 29

2.1.7 Digital Audio Interface......................................................................... 31

2.1.8 Pulse Code Modulation Interface (PCM) ............................................ 31

2.1.9 Inter IC Sound Interface (I

2.1.10 GPIO Interface .................................................................................... 34

2.1.11 I

2

C Interface ........................................................................................ 36

2.1.12 SPI Interface ....................................................................................... 38

2.1.13 Pulse Counter ..................................................................................... 39

2.1.14 HSIC Interface (ELS51-VA Only)........................................................ 39

2.1.15 SDIO Interface (ELS51-VA Only)........................................................ 39

2.1.16 Control Signals.................................................................................... 42

2.1.16.1 Status LED .......................................................................... 42

2.1.16.2 Power Indication Circuit ...................................................... 43

2.1.16.3 Host Wakeup....................................................................... 43

2.1.16.4 Fast Shutdown .................................................................... 45

2.2 RF Antenna Interface....................................................................................... 46

2.2.1 Antenna Interface Specifications ........................................................ 46

2.2.2 Antenna Installation ............................................................................ 47

2.2.3 RF Line Routing Design...................................................................... 48

2.2.3.1 RF Interface Signals Circuit Diagram Example................... 48

2.2.3.2 Line Arrangement Examples ............................................... 49

2.3 Sample Application .......................................................................................... 54

2.3.1 Prevent Back Powering....................................................................... 56

2.3.2 Sample Level Conversion Circuit........................................................ 56

2

S).............................................................. 33

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 4

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Contents

106

Page 4 of 106

3 Operating Characteristics........................................................................................57

3.1 Operating Modes ............................................................................................. 57

3.2 Power Up/Power Down Scenarios................................................................... 58

3.2.1 Turn on ELS31-VA/ELS51-VA ............................................................ 58

3.2.1.1 Connecting ELS31-VA/ELS51-VA BATT Lines.................... 58

3.2.1.2 Switch on ELS31-VA/ELS51-VA Using ON Signal .............. 59

3.2.2 Restart ELS31-VA/ELS51-VA............................................................. 60

3.2.2.1 Restart ELS31-VA/ELS51-VA via AT+CFUN Command ..... 60

3.2.2.2 Restart ELS31-VA/ELS51-VA Using EMERG_RST ............ 60

3.2.3 Signal States after First Startup .......................................................... 62

3.2.4 Turn off ELS31-VA/ELS51-VA ............................................................ 63

3.2.4.1 Switch off ELS31-VA/ELS51-VA Using AT Command ......... 63

3.2.5 Automatic Shutdown ........................................................................... 64

3.2.5.1 Thermal Shutdown .............................................................. 64

3.2.5.2 Undervoltage Shutdown...................................................... 65

3.2.5.3 Overvoltage Shutdown........................................................ 65

3.3 Power Saving................................................................................................... 66

3.3.1 Power Saving while Attached to LTE Networks.................................. 66

3.3.2 Wake-up via RTS0/RTS1.................................................................... 67

3.4 Power Supply................................................................................................... 68

3.4.1 Power Supply Ratings......................................................................... 69

3.4.2 Minimizing Power Losses ................................................................... 70

3.4.3 Measuring the Supply Voltage (BATT_BB)......................................... 70

3.4.4 Monitoring Power Supply by AT Command ........................................ 70

3.5 Operating Temperatures.................................................................................. 71

3.6 Electrostatic Discharge .................................................................................... 72

3.6.1 ESD Protection for Antenna Interface................................................. 72

3.7 Blocking against RF on Interface Lines ........................................................... 73

3.8 Reliability Characteristics................................................................................. 76

4 Mechanical Dimensions, Mounting and Packaging...............................................77

4.1 Mechanical Dimensions of ELS31-VA/ELS51-VA ........................................... 77

4.2 Mounting ELS31-VA/ELS51-VA onto the Application Platform........................ 79

4.2.1 SMT PCB Assembly ........................................................................... 79

4.2.1.1 Land Pattern and Stencil..................................................... 79

4.2.1.2 Board Level Characterization.............................................. 81

4.2.2 Moisture Sensitivity Level ................................................................... 81

4.2.3 Soldering Conditions and Temperature .............................................. 82

4.2.3.1 Reflow Profile ...................................................................... 82

4.2.3.2 Maximum Temperature and Duration .................................. 83

4.2.4 Durability and Mechanical Handling.................................................... 84

4.2.4.1 Storage Conditions.............................................................. 84

4.2.4.2 Processing Life.................................................................... 85

4.2.4.3 Baking ................................................................................. 85

4.2.4.4 Electrostatic Discharge ....................................................... 85

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 5

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Contents

106

Page 5 of 106

4.3 Packaging ........................................................................................................ 86

4.3.1 Tape and Reel .................................................................................... 86

4.3.1.1 Orientation........................................................................... 86

4.3.1.2 Barcode Label ..................................................................... 87

4.3.2 Shipping Materials .............................................................................. 88

4.3.2.1 Moisture Barrier Bag ........................................................... 88

4.3.2.2 Transportation Box.............................................................. 90

4.3.3 Trays ................................................................................................... 91

5 Regulatory and Type Approval Information...........................................................93

5.1 Directives and Standards................................................................................. 93

5.2 SAR requirements specific to portable mobiles ............................................... 95

5.3 Reference Equipment for Type Approval......................................................... 96

5.4 Compliance with FCC and IC Rules and Regulations ..................................... 97

6 Document Information..............................................................................................99

6.1 Revision History ............................................................................................... 99

6.2 Related Documents ....................................................................................... 100

6.3 Terms and Abbreviations ............................................................................... 100

6.4 Safety Precaution Notes ................................................................................ 103

7 Appendix..................................................................................................................104

7.1 List of Parts and Accessories......................................................................... 104

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 6

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Tables

106

Page 6 of 106

Tables

Table 1: Pad assignments............................................................................................ 15

Table 2: Signal properties ............................................................................................ 16

Table 3: Absolute maximum ratings............................................................................. 21

Table 4: Signals of the SIM interface (SMT application interface) ............................... 29

Table 5: Overview of PCM pin functions...................................................................... 32

Table 6: Overview of I

Table 7: GPIO lines and possible alternative assignment............................................ 34

Table 8: SDIO interface features.................................................................................. 39

Table 9: SDIO interface lines ....................................................................................... 40

Table 10: SDIO timings.................................................................................................. 40

Table 11: Host wakeup line............................................................................................ 43

Table 12: Return loss in the active band........................................................................ 46

Table 13: RF Antenna interface LTE.............................................................................. 46

Table 14: Overview of operating modes ........................................................................ 57

Table 15: Signal states................................................................................................... 62

Table 16: Temperature dependent behavior.................................................................. 64

Table 17: Voltage supply ratings.................................................................................... 69

Table 18: Current consumption ratings.......................................................................... 69

Table 19: Board temperature ......................................................................................... 71

Table 20: Electrostatic values ........................................................................................ 72

Table 21: EMI measures on the application interface.................................................... 74

Table 22: Summary of reliability test conditions............................................................. 76

Table 23: Reflow temperature ratings............................................................................ 82

Table 24: Storage conditions ......................................................................................... 84

Table 25: Directives ....................................................................................................... 93

Table 26: Standards of North American type approval .................................................. 93

Table 27: Standards of Verizon type approval............................................................... 93

Table 28: Standards of GCF type approval.................................................................... 93

Table 29: Requirements of quality ................................................................................. 93

Table 30: Standards of the Ministry of Information Industry of the

People’s Republic of China............................................................................ 94

Table 31: Toxic or hazardous substances or elements with defined concentration

limits............................................................................................................... 94

Table 32: Antenna gain limits for FCC and IC................................................................ 97

Table 33: List of parts and accessories........................................................................ 104

Table 34: Molex sales contacts (subject to change) .................................................... 105

2

S pin functions ......................................................................... 33

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 7

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Figures

106

Page 7 of 106

Figures

Figure 1: ELS31-VA/ELS51-VA system overview......................................................... 12

Figure 2: ELS31-VA/ELS51-VA baseband block diagram ............................................ 13

Figure 3: Numbering plan for connecting pads (bottom view)....................................... 14

Figure 4: USB circuit ..................................................................................................... 22

Figure 5: USB Additional ESD Protection Implementation............................................ 23

Figure 6: Serial interface ASC0..................................................................................... 25

Figure 7: ASC0 startup behavior................................................................................... 26

Figure 8: Serial interface ASC1..................................................................................... 27

Figure 9: ASC1 startup behavior................................................................................... 28

Figure 10: External UICC/SIM/USIM card holder circuit ................................................. 30

Figure 11: PCM timing short frame (4096KHz, 16kHz sample rate) ............................... 32

Figure 12: I

Figure 13: GPIO startup behavior ................................................................................... 35

Figure 14: I

Figure 15: I

Figure 16: Characteristics of SPI modes......................................................................... 38

Figure 17: SDIO interface timing diagrams (Input/Output).............................................. 40

Figure 18: Status signaling with LED driver .................................................................... 42

Figure 19: Power indication circuit .................................................................................. 43

Figure 20: Wake-up via RING0 ....................................................................................... 44

Figure 21: Fast shutdown timing ..................................................................................... 45

Figure 22: Antenna pads (bottom view) .......................................................................... 47

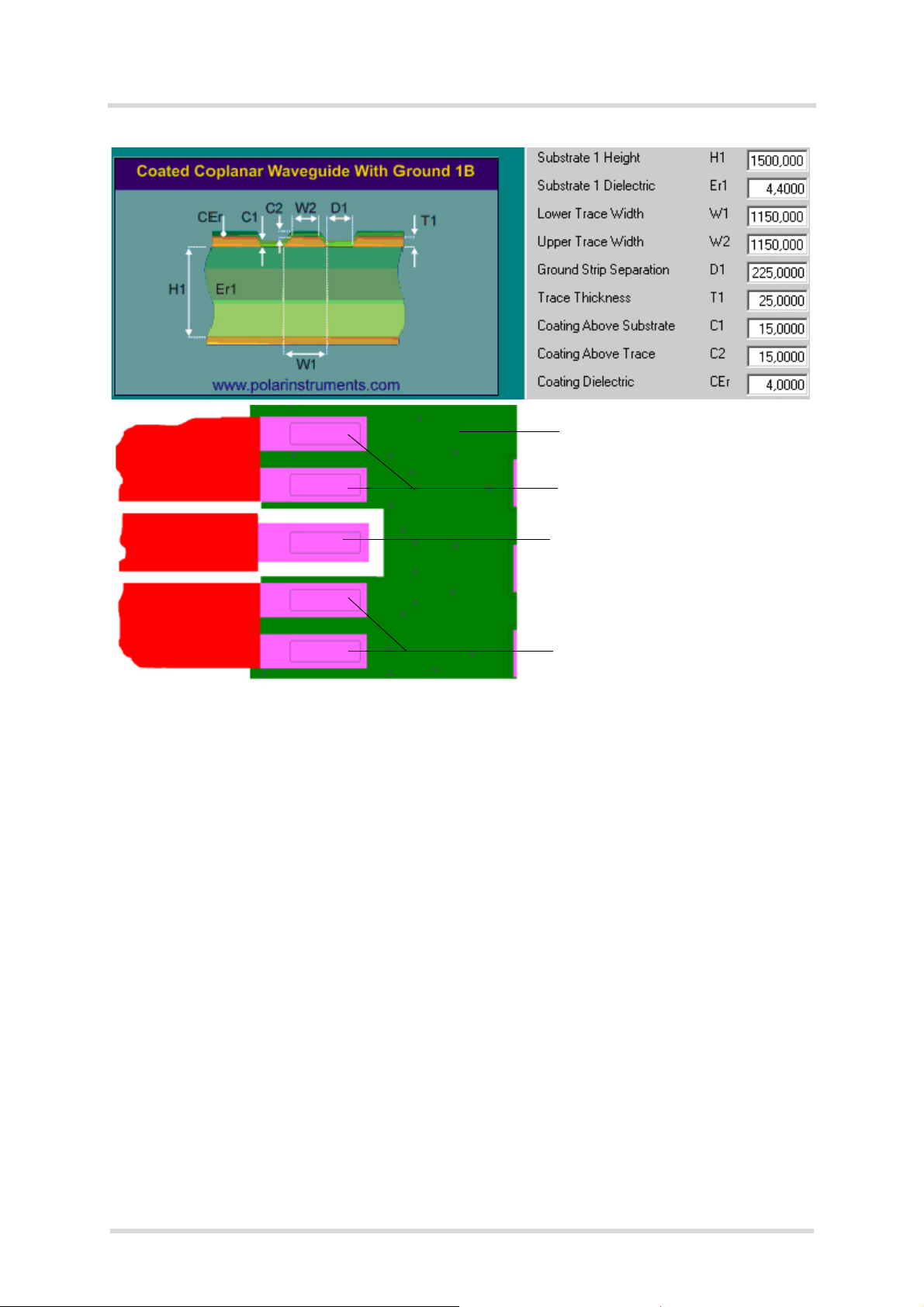

Figure 23: RF interface signals example......................................................................... 48

Figure 24: Embedded Stripline with 65µm prepreg (1080) and 710µm core .................. 49

Figure 25: Micro-Stripline on 1.0mm standard FR4 2-layer PCB - example 1 ................ 50

Figure 26: Micro-Stripline on 1.0mm Standard FR4 PCB - example 2............................ 51

Figure 27: Micro-Stripline on 1.5mm Standard FR4 PCB - example 1............................ 52

Figure 28: Micro-Stripline on 1.5mm Standard FR4 PCB - example 2............................ 53

Figure 29: Schematic diagram of ELS31-VA/ELS51-VA sample application.................. 55

Figure 30: Sample level conversion circuit...................................................................... 56

Figure 31: Sample circuit for applying power using an external µC ................................ 58

Figure 32: ON timing ....................................................................................................... 59

Figure 33: Emergency restart timing ............................................................................... 60

Figure 34: Switch off behavior......................................................................................... 63

Figure 35: Power saving and paging in LTE networks.................................................... 66

Figure 36: Wake-up via RTS0/RTS1............................................................................... 67

Figure 37: Position of reference points BATT_BB/BATT_RF and GND.......................... 70

Figure 38: ESD protection for RF antenna interface ....................................................... 72

Figure 39: EMI circuits..................................................................................................... 73

Figure 40: ELS31-VA/ELS51-VA– top and bottom view ................................................. 77

Figure 41: Dimensions of ELS31-VA/ELS51-VA (all dimensions in mm)........................ 78

Figure 42: Dimensions of ELS31-VA/ELS51-VA (all dimensions in mm) - bottom view . 78

Figure 43: Land pattern (top view) .................................................................................. 79

Figure 44: Recommended design for 120 micron thick stencil (top view, dual design)... 80

Figure 45: Reflow Profile................................................................................................. 82

Figure 46: Carrier tape .................................................................................................... 86

Figure 47: Reel direction ................................................................................................. 86

Figure 48: Barcode label on tape reel ............................................................................. 87

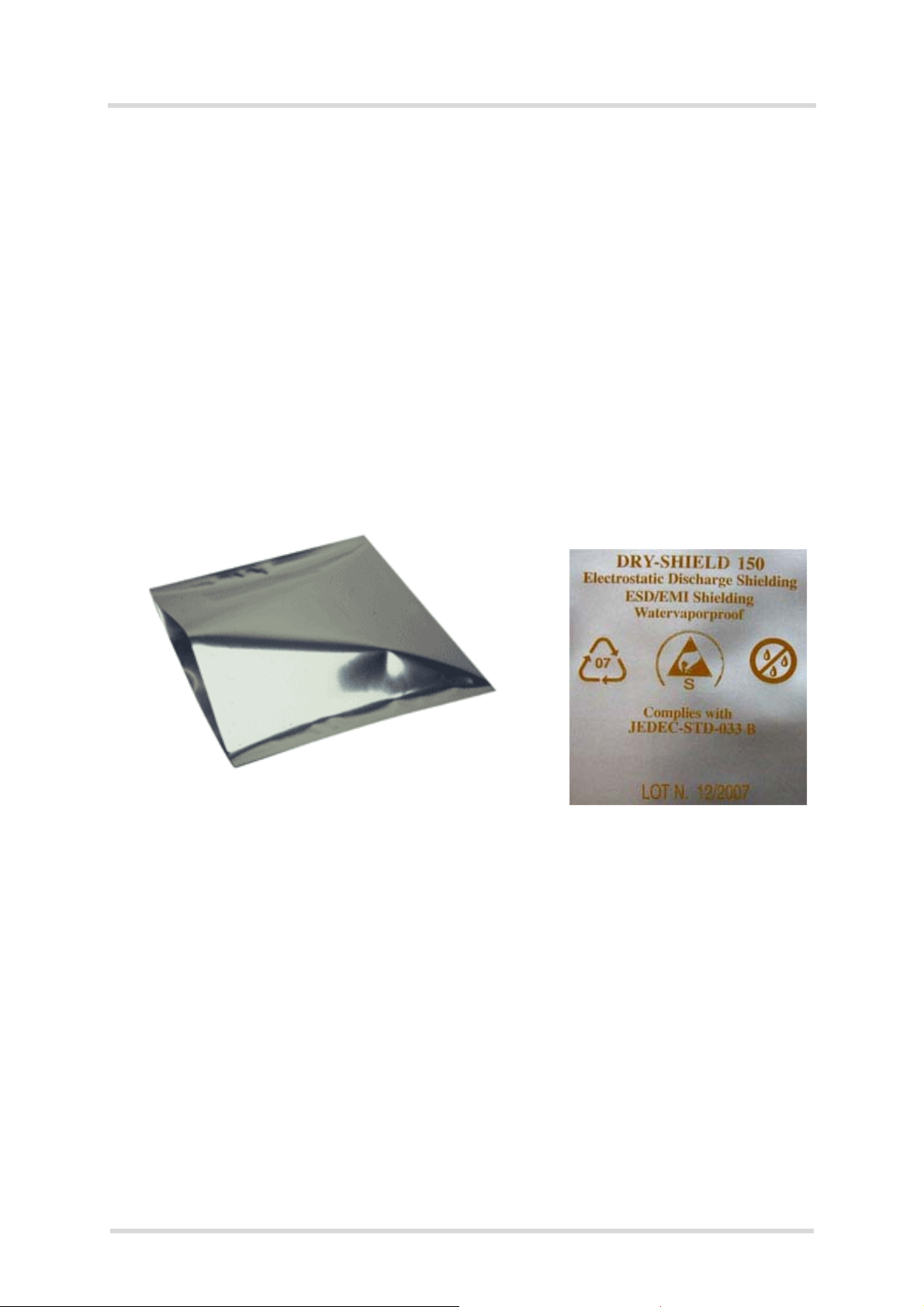

Figure 49: Moisture barrier bag (MBB) with imprint......................................................... 88

2

S timing (slave mode) .................................................................................. 33

2

C interface connected to V180 .................................................................... 36

2

C startup behavior ....................................................................................... 37

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 8

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Figures

106

Page 8 of 106

Figure 50: Moisture Sensitivity Label .............................................................................. 89

Figure 51: Humidity Indicator Card - HIC ........................................................................ 90

Figure 52: Small quantity tray.......................................................................................... 91

Figure 53: Tray to ship odd module amounts.................................................................. 91

Figure 54: Trays with packaging materials...................................................................... 91

Figure 55: Tray dimensions............................................................................................. 92

Figure 56: Reference equipment for Type Approval ....................................................... 96

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 9

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

1 Introduction

13

Page 9 of 106

1 Introduction

This document1 describes the hardware of the Cinterion® ELS31-VA and ELS51-VA modules

for Verizon Networks. It helps you quickly retrieve interface specifications, electrical and mechanical details and information on the requirements to be considered for integrating further

components.

The ELS31-VA and ELS51-VA modules include a baseband, a complete dual band RF frontend, memory and required circuitry to meet 3GPP E-UTRA (Long Term Evolution - LTE, Release 10 set of specifications) and Verizon Wireless LTE UE specifications.

The module variants differentiate a follows:

- ELS31-VA provides LTE connectivity with IP Services

- ELS51-VA adds a Linux execution environment available for customer applications

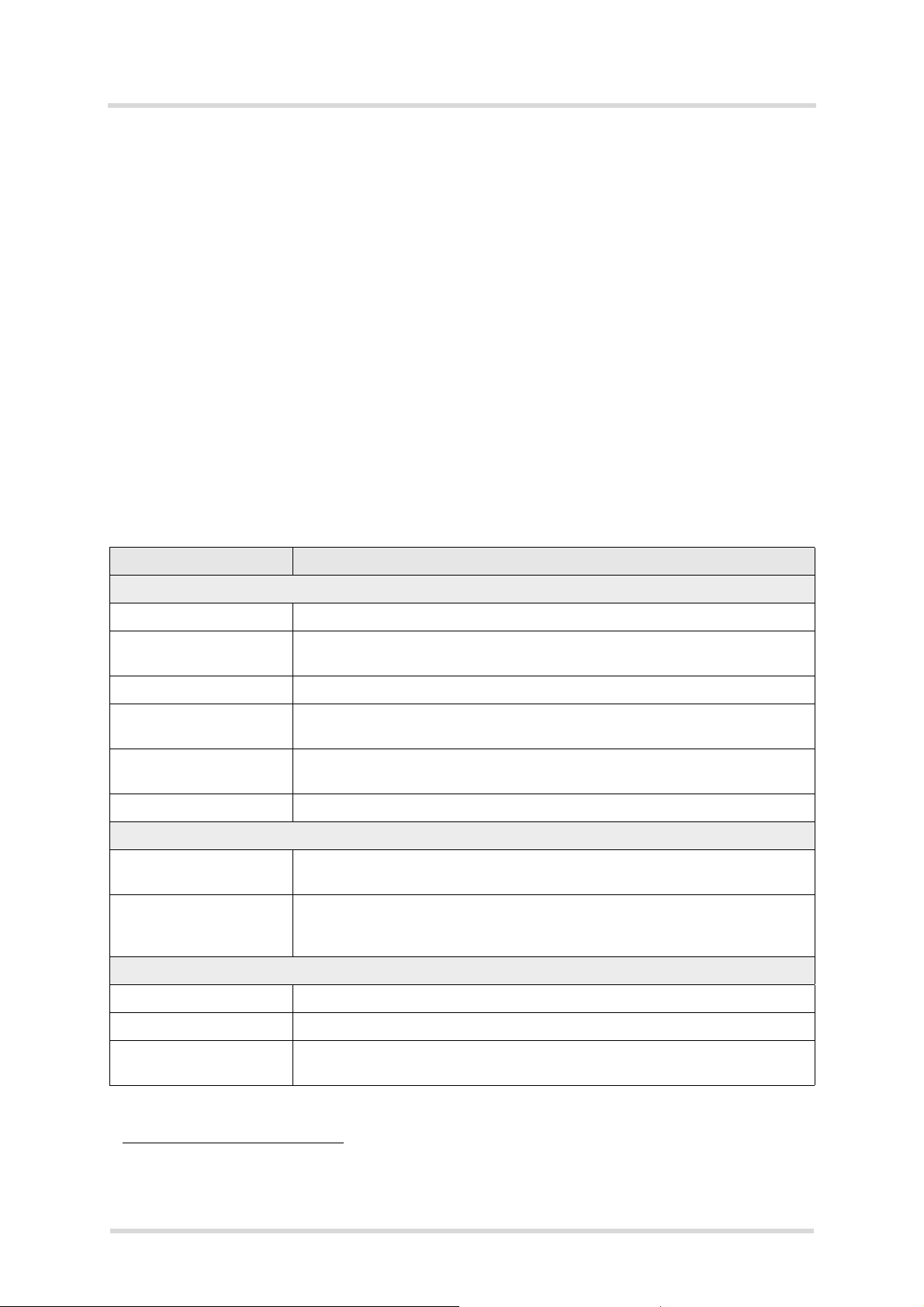

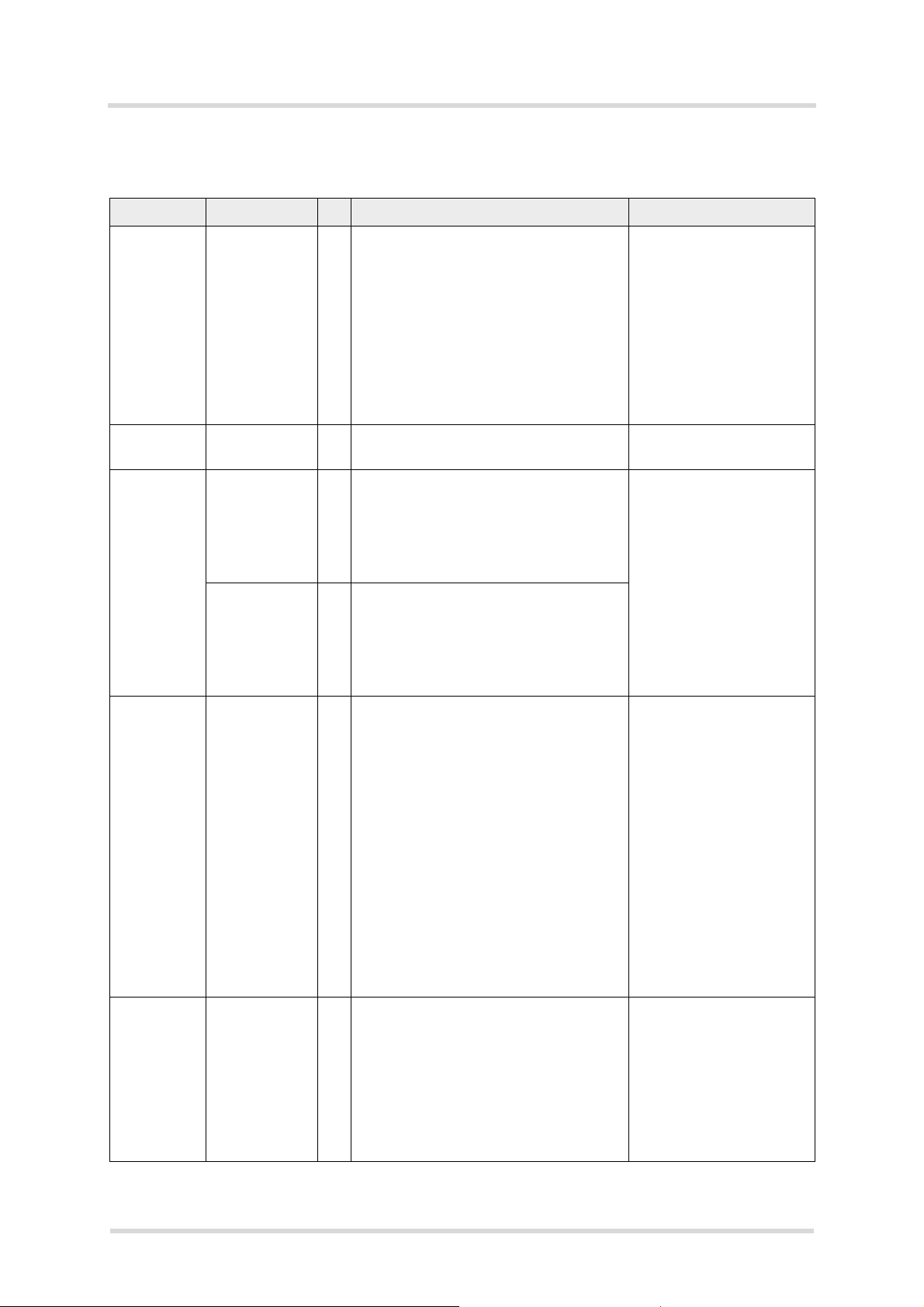

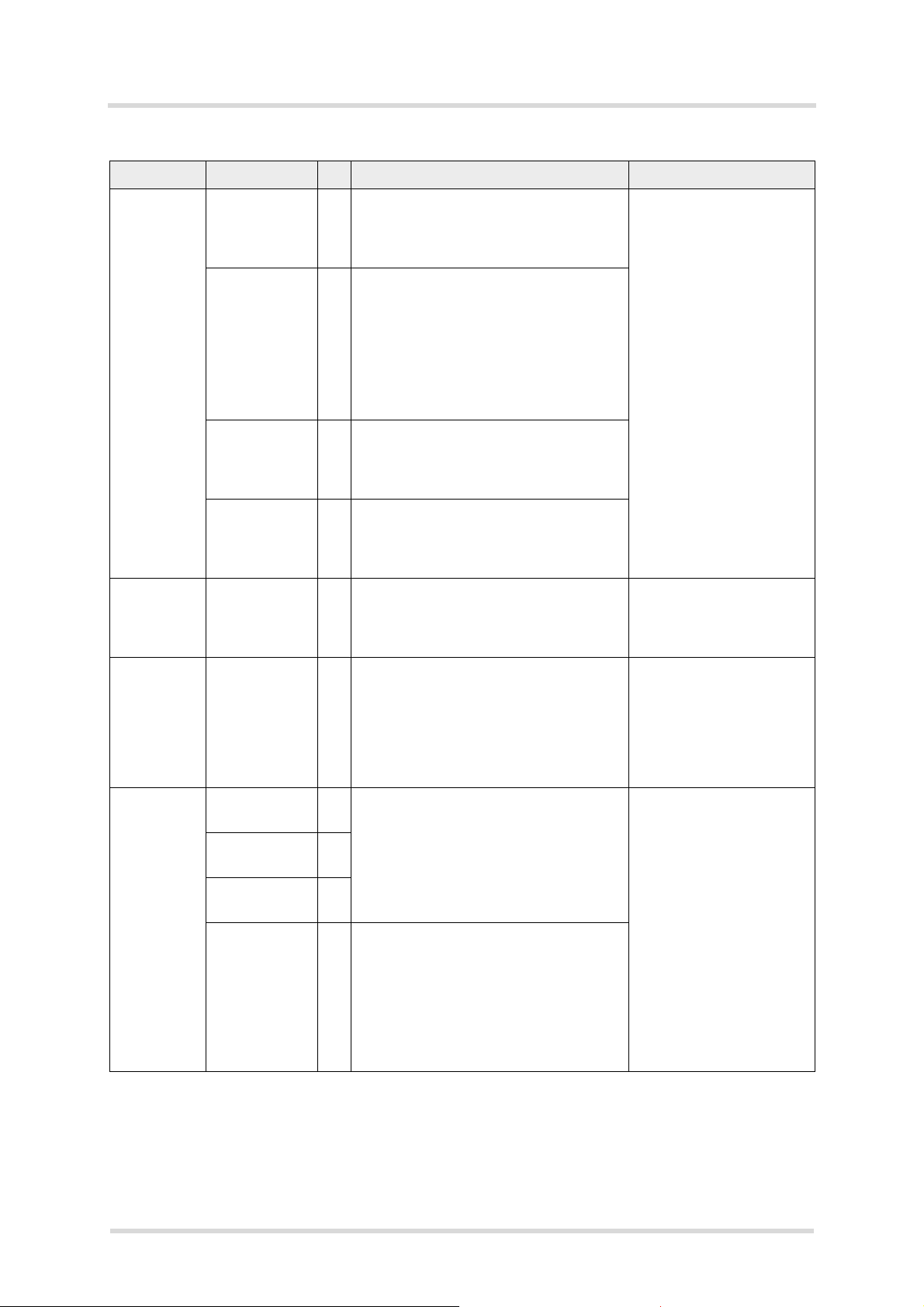

1.1 Key Features at a Glance

Feature Implementation

General

Frequency bands LTE dualband: B4, B13

Output power Class 3 (+23dBm +-2dB) for LTE AWS, LTE B4

Class 3 (+23dBm +-2dB) for LTE 700, LTE FDD B13

Power supply 3.3V to 4.5V

Operating temperature

(board temperature)

Physical Dimensions: 27.60mm x 18.80mm x 2.05mm

RoHS All hardware components fully compliant with EU RoHS Directive

LTE features

3GPP Release 9 DL 10Mbps, UL 5Mbps

SMS Point-to-point MT and MO

Software

AT commands Hayes, 3GPP TS 27.007, TS 27.005, product specific

Normal operation: -30°C to +80°C

Extended operation: -40°C to +90°C

Weight: approx. 3g

LTE Cat. 1 data rates

Text mode

Storage in mobile equipment

SIM Application Toolkit SAT Release 99

Firmware update Generic update from host application over ASC0 or USB modem

OTA over ASC0 and over USB

1. The document is effective only if listed in the appropriate Release Notes as part of the technical documentation delivered with your Gemalto M2M product.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 10

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Page 10 of 106

1.1 Key Features at a Glance

13

Feature Implementation

Interfaces

Module interface Surface mount device with solderable connection pads (SMT application

interface). Land grid array (LGA) technology ensures high solder joint reliability and allows the use of an optional module mounting socket.

For more information on how to integrate SMT modules see also [4]. This

application note comprises chapters on module mounting and application

layout issues as well as on SMT application development equipment.

USB USB 2.0 High Speed (480Mbit/s) device interface, Full Speed (12Mbit/s)

compliant

2 serial interfaces ASC0:

• 8-wire modem interface with status and control lines, unbalanced, asynchronous

• Default baud rate: 115,200 baud

• Adjustable baud rates: 4,800 to 921,600, no autobauding support

• Supports RTS0/CTS0 hardware flow control.

• Indication of incoming data/SMS on RING0 (can be used to wake up

host from power down modes)

ASC1 (shared with GPIO lines):

• 4-wire, unbalanced asynchronous interface

• Default baud rate: 115,200 baud

• Adjustable baud rates: 4,800bps to 921,600bps

• Supports RTS1/CTS1 hardware flow control

UICC interface Supported SIM/USIM cards: 3V, 1.8V

Embedded UICC Module is prepared for an embedded UICC

GPIO interface 20 pads of the application interface programmable as GPIO pads (17) or

GPO pads (3):

GP(I)Os can be configured as COUNTER, FST_SHDN, ASC0, ASC1, SPI,

and DAI signal lines

Programming is done via AT commands

2

I

C interface Supports I2C serial interface

SPI interface Supports SPI interface

SDIO ELS51-VA only:

4 wire interface.

HSIC ELS51-VA only:

High Speed Interchip Communication interface.

ADC

Digitial audio interface 4 GPIO lines can be configured as PCM/I

Analog-to-Digital Converter with one unbalanced analog input.

2

S lines for VoLTE communica-

tion.

Antenna interface pads 50Ω LTE main antenna, 50LTE diversity antenna

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 11

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

1.1 Key Features at a Glance

13

Feature Implementation

Power on/off, Reset

Power on/off Switch-on by hardware signal ON

Switch-off by AT command

Switch off by hardware signal GPIO4/FST_SHDN instead of AT command

Automatic switch-off in case of critical temperature and voltage conditions

Reset Orderly shutdown and reset by AT command

Emergency reset by hardware signal EMERG_RST

Evaluation kit

Evaluation module ELS31-VA/ELS51-VA module soldered onto a dedicated PCB that can be

connected to an adapter in order to be mounted onto the DSB75.

DSB75 DSB75 Development Support Board designed to test and type approve

Gemalto M2M modules and provide a sample configuration for application

engineering. A special adapter is required to connect the ELS31-VA/ELS51VA evaluation module to the DSB75.

Page 11 of 106

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 12

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

GPIO

interface

I2C

USB

ASC0

ASC0

CONTROL

POWER

ANTENNA

(LTE dual band)

Module

SIM interface

(with SIM detection)

SIM card

Application

Power supply

Emergency reset

ON

Serial modem

interface

Serial modem

interface

I2C

USB

Antenna /

div. Antenna

GPIOs

Status

LED

FST_SHDN

Fast shutdown

ADC

ADC

COUNTER

Pulse counter

GP(I)Os

HSIC

SDIO

HSIC

SDIO

SPI

SPI

SPI

SPI

ASC1

Serial interface

PCM/DAI

PCM/DAI

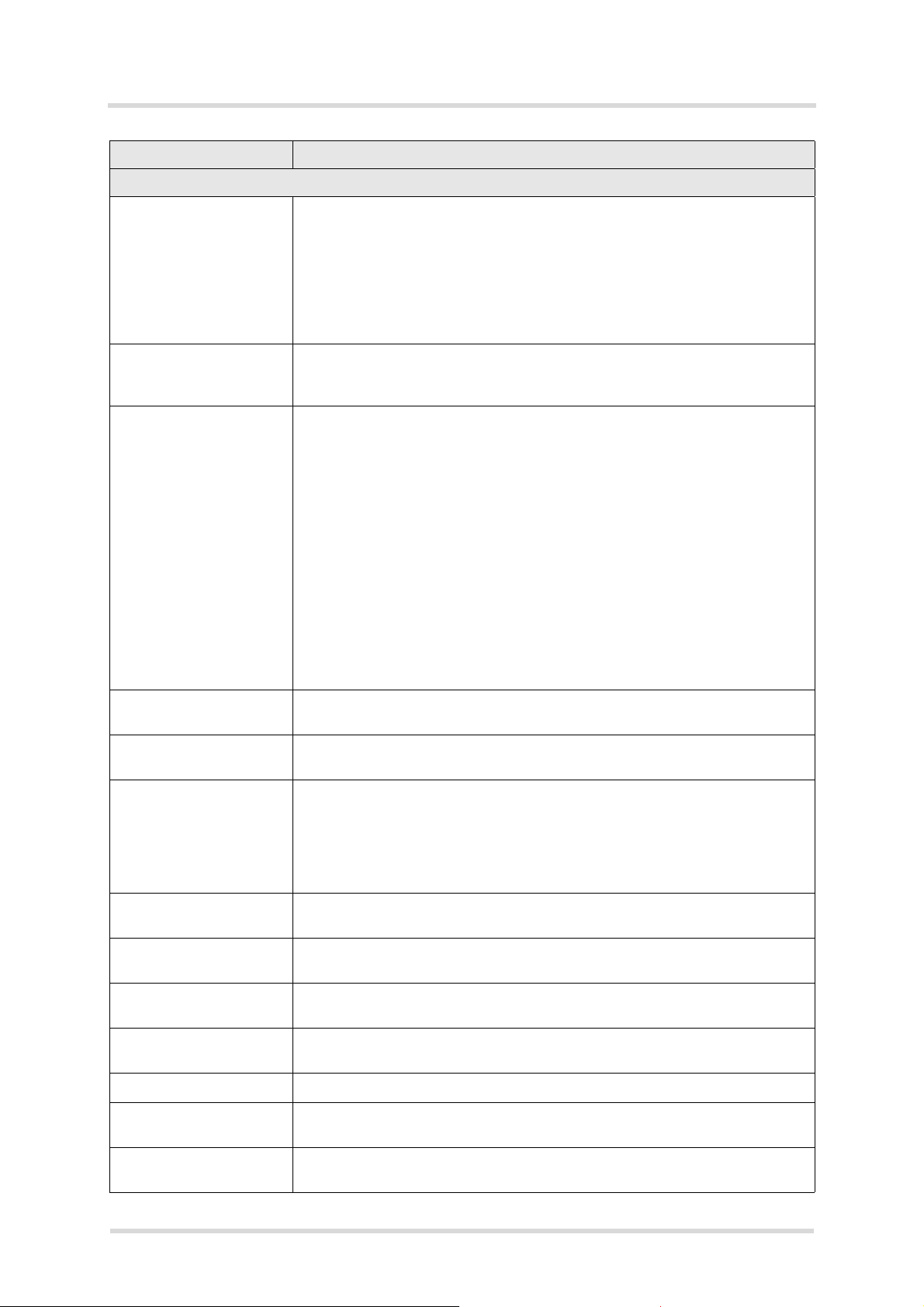

1.2 ELS31-VA/ELS51-VA System Overview

13

1.2 ELS31-VA/ELS51-VA System Overview

Page 12 of 106

Figure 1: ELS31-VA/ELS51-VA system overview

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 13

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

SPDT

RF Swi tch

B13 Duplexer

B4 Duplexer

SPDT

RF Swi tch

PA DC/DC PMIC

B13 SAW

B4 SAW

SQN3241

B13 PA

B4 PA

Pri mary

Antenna

Div ers ity

Antenna

TCXO

Cont rol

RXIF1

RXIF2

TXIF

CLKREF

512Mbit LPDDR

SPI Fl ash

ELS31-V 256Mbit

ELS51-V 512Mbit

SIM

Level

Shifter

32.768kHz

Xtal

SQN3223

GPIO

SPI

UARTS

USB

HSIC

SDIO

SIM

Page 13 of 106

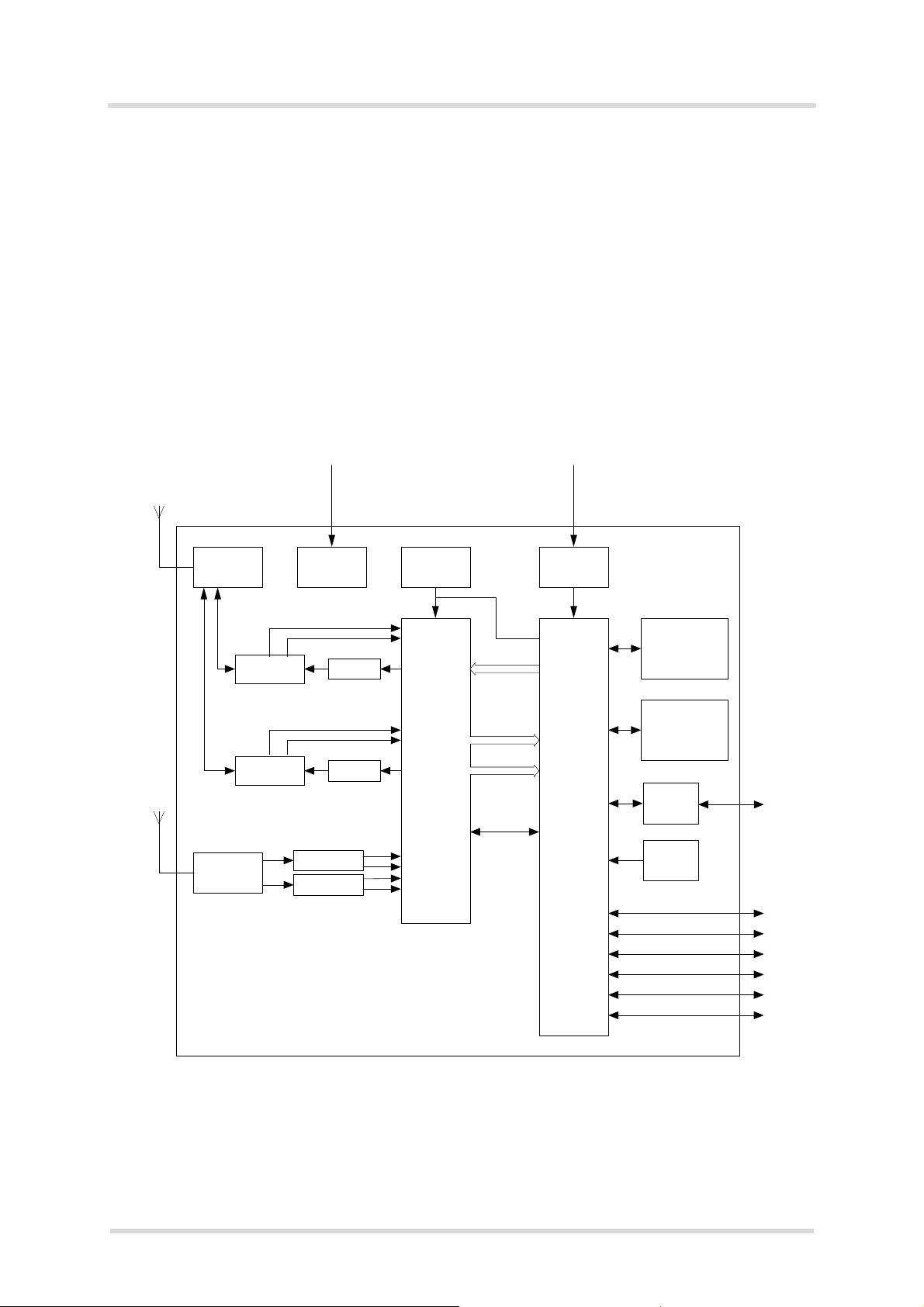

1.3 Circuit Concept

13

1.3 Circuit Concept

The following figure shows block diagram of the ELS31-VA/ELS51-VA module and illustrate

the major functional components (see Figure 2):

Baseband block:

• baseband processor and power management

• serial NOR flash and LPDDR RAM memory

• Application interface (SMT with connecting pads)

LTE RF section:

• RF transceiver

• RF power amplifier/front-end module and duplexers

• Receive SAW filters

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Figure 2: ELS31-VA/ELS51-VA baseband block diagram

Confidential / Preliminary

Page 14

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

53

65

64

63

62

61

60

59

58

57

56

55

54

66

33

21

22

23

24

25

26

27

28

29

30

31

32

20

106

9291

9897969594

9089

85 86

93

74

99

87 88

8483

7978777675

8281

80

727170696867

105104103102101100

73

44

19181716151413121110987654321

3435363839404142434546474849505152

Supply pads : BATT+

Control pads

GND pads

ASC0 pads

SPI pads

SIM pads RF antenna pad

I2C pads

ADC pad

Supply pads : Other

Combined GPIO /DAI pads

Com bined GPIO / Control pads

(LED, COUNTER, FST_SHDN)

Do not use

Not connected

Reserved

USB pads

Combined GPIO/ASC1/HSIC pads

Combined GPIO /

ASC0 pads

250

251

252

245

249

248

247

246

Test points , do not

use

HSIC pads

37

SDIO pads

35

GPIO pads

Page 14 of 106

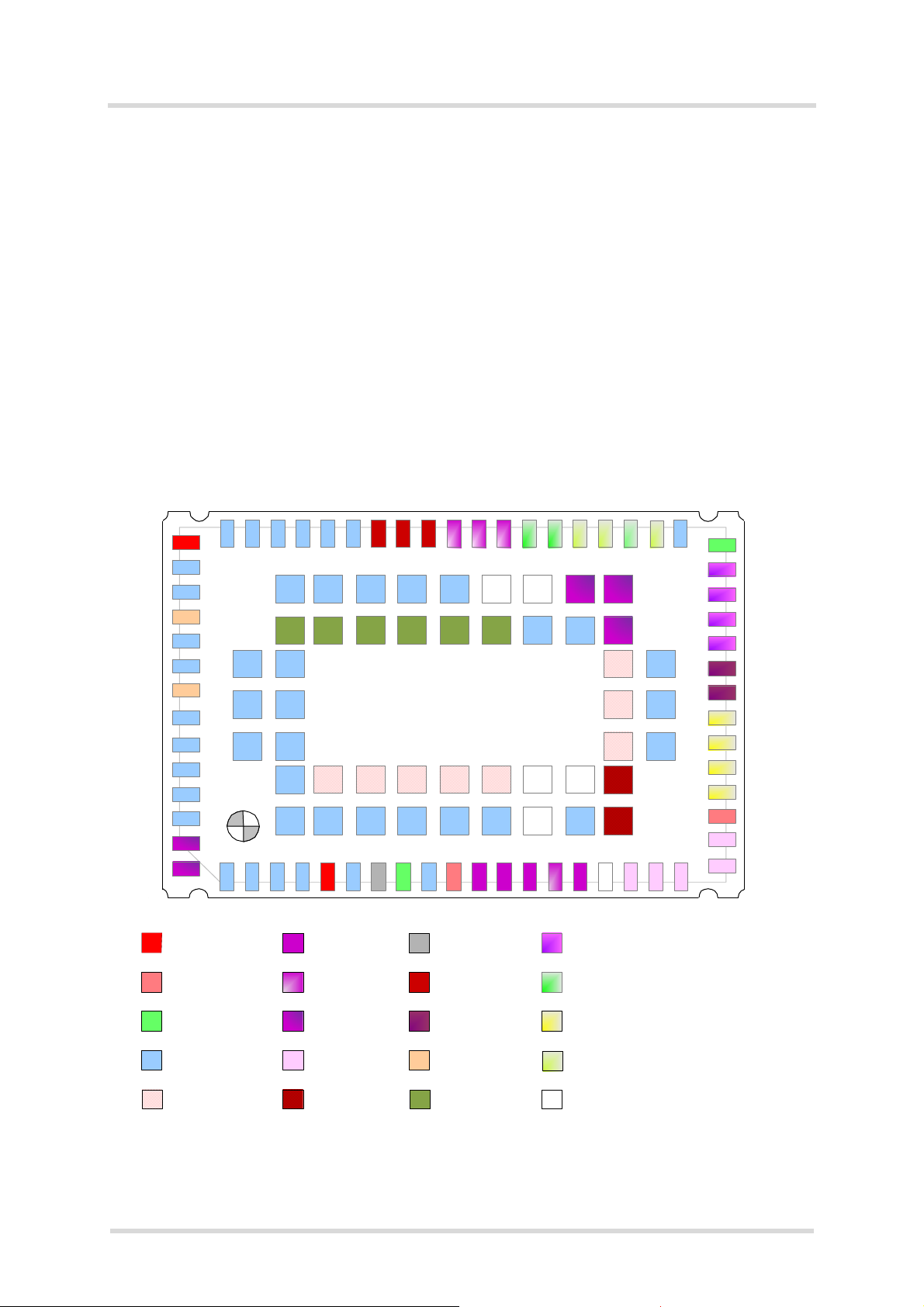

2 Interface Characteristics

56

2 Interface Characteristics

ELS31-VA/ELS51-VA is equipped with an SMT application interface that connects to the external application. The SMT application interface incorporates the various application interfaces

as well as the RF antenna interfaces.

2.1 Application Interface

2.1.1 Pad Assignment

The SMT application interface on the ELS31-VA/ELS51-VA provides connecting pads to integrate the module into external applications. Figure 3 shows the connecting pads’ numbering

plan, the following Table 1 lists the pads’ assignments.

Figure 3: Numbering plan for connecting pads (bottom view)

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 15

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

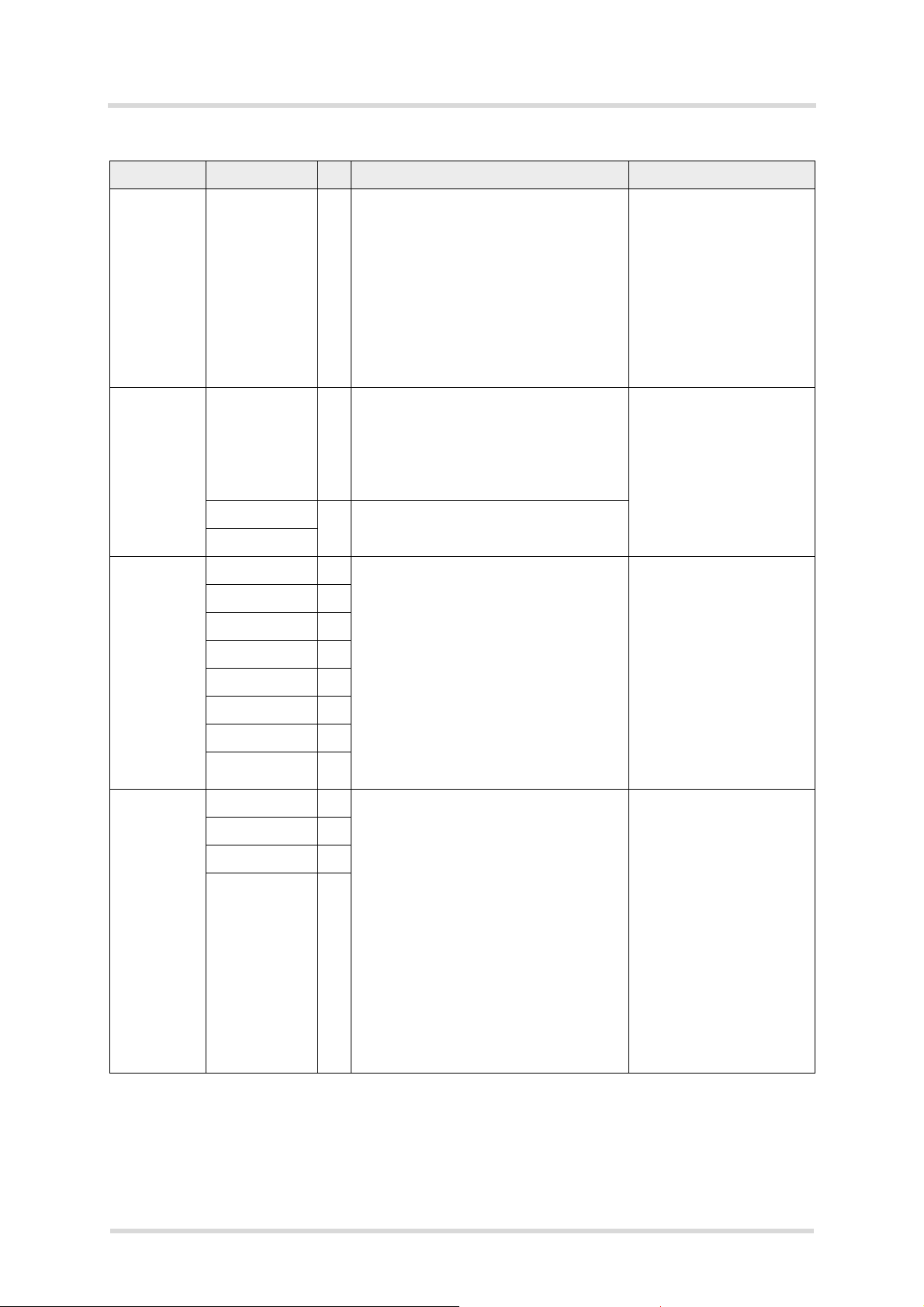

Table 1: Pad assignments

Pad no. Signal name Pad no. Signal name Pad no. Signal name

1 GND 23 GPIO20/PCM_I2S_OUT 45 USB_DP

2 GND 24 GPIO22/PCM_I2S_FSC 46 USB_DN

3 GND 25 GPIO21/PCM_I2S_IN 47 GND

4 GND 26 GPO23/PCM_I2S_CLK 48 GND

5 BATT_RF 27 I2CDAT 49 GND

6 GND 28 I2CCLK 50 GND

7 ADC1 29 GPIO17/TXD1/HOST_ACTIVE 51 GND

8 ON 30 GPIO16/RXD1/AP_WAKEUP 52 GND

9 GND 31 GPIO18/RTS1/CP_WAKEUP 53 BATT_BB

10 V180 32 GPIO19/CTS1/SUSPEND 54 GND

11 RXD0 33 EMERG_RST 55 GND

12 CTS0 34 GND 56 DIV_ANT

13 TXD0 35 GPIO25 57 GND

14 RING0/GPIO24 36 GPIO8/COUNTER 58 GND

15 RTS0 37 GPIO7 59 RF_OUT

16 Not connected 38 GPIO6 60 GND

17 CCRST 39 LED/GPO5 61 GND

18 CCIN 40 GPIO4/FST_SHDN 62 GND

19 CCIO 41 DSR0/GPIO3 63 GND

20 CCVCC 42 DCD0/GPIO2 64 GND

21 CCCLK 43 DTR0/GPIO1 65 GPIO27/SPI_CS2

22 VCORE 44 VUSB 66 GPO26/SPI_CS1

Centrally located pads

67 GND 83 Do not use (test) 99 GND

68 GND 84 GND 100 GND

69 GND 85 GND 101 GND

70 GND 86 GND 102 GND

71 GND 87 Do not use (test) 103 GND

72 Not connected 88 GND 104 Not connected

73 GND 89 GND 105 Not connected

74 Do not use (test) 90 GND 106 SPI_MOSI

75 Do not use (test) 91 Do not use (test) 245 GND

76 Do not use (test) 92 GND 246 HSIC_DATA

77 Do not use (test) 93 SDIO0 247 HSIC_STRB

78 Do not use (test) 94 SDIOCLK 248 SPI_CLK

79 Not connected 95 SDIO1 249 SPI_MISO

80 Do not use 96 SDIO2 250 GND

81 GND 97 SDIO3 251 SDIOCMD

82 GND 98 GND 252 GND

Page 15 of 106

Signal pads that are not used should not be connected to an external application.

Please note that the reference voltages listed in Table 2 are the values measured directly on

the ELS31-VA/ELS51-VA module. They do not apply to the accessories connected.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 16

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

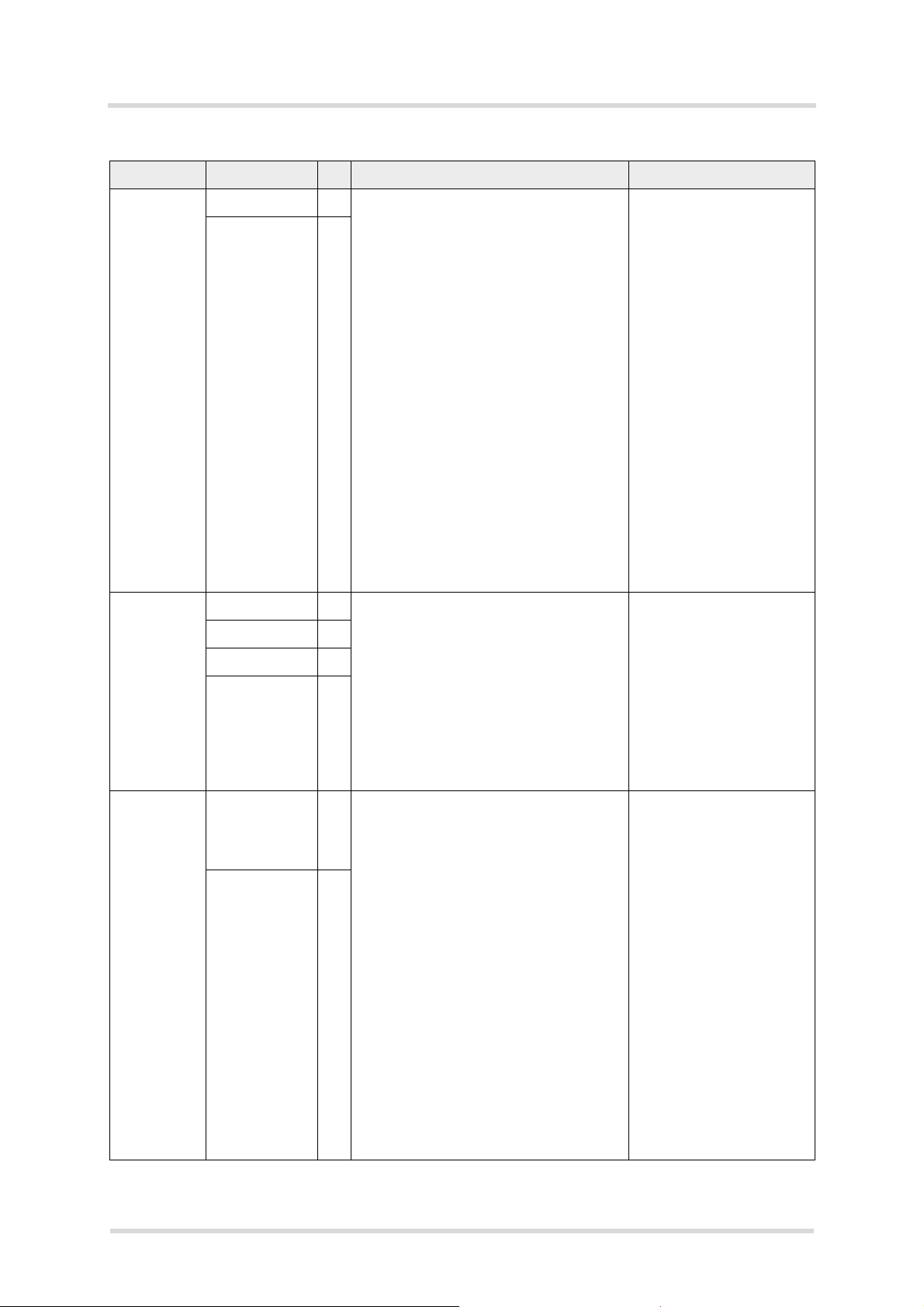

2.1.2 Signal Properties

Table 2: Signal properties

Function Signal name IO Signal form and level Comment

Page 16 of 106

Power

supply

Power

supply

External

supply

voltage

BATT_BB

BATT_RF

IV

max = 4.5V

I

V

norm = 3.8V

I

V

min = 3.3V

I

Imax=720mA nominal voltage 3.8V

- 300 mA for BATT_RF

Lines of BATT+ and GND

must be connected in

parallel for supply purposes because higher

peak currents may occur.

- 420 mA for BATT_BB

Minimum voltage must

not fall below 3.3V including drop, ripple, spikes

and not rise above 4.5V.

GND Ground Application Ground

V180 O V

VCORE O V

norm = 1.80V

O

V

min = 1.71 V

O

V

max = 1.89V

O

I

max = 50mA

O

CLmax = 2µF

norm = 1.1V

O

V

min= 1.09

O

V

max= 1.12

O

I

max = 50mA

O

V180 may be used to

supply level shifters at

the interfaces or to supply

external application circuits.

If unused keep line open.

CLmax = 100nF

Ignition ON I BATT_BB= 4.5V

V

max = 5.5V

IH

V

min = 2.16V

IH

max = 1.79V

V

IL

V

min=0V

IL

BATT_BB= 3.3V

V

max = 5.5V

IH

V

min = 1.7V

IH

V

max = 1.3V

IL

V

min = 0V

IL

Min low time before rising edge

<=100µs

Rin = 380k

--

|____ high level min. 100µs

max = 5.5V

min = 0.85V

max =0.65V

min= 0V

Emergency

restart

EMERG_RST I V

ON ___|

IH

V

IH

V

IL

V

IL

Internal pull-up resistor

Low impulse width > 10ms

Edge triggered signal to

switch the module on.

Set this signal low before

and after the startup

impulse. Input is Schmitt

Trigger.

The ON signal can be

connected to BATT_BB.

In this case, the module

cannot be switched off by

a fast shutdown, but can

only be switched off by

disconnecting BATT_BB.

Pulse triggered signal to

reset the module. This

line must be driven low by

an open drain or open

collector driver connected to GND. See also

Section 3.2.2.2.

If unused keep line open.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 17

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

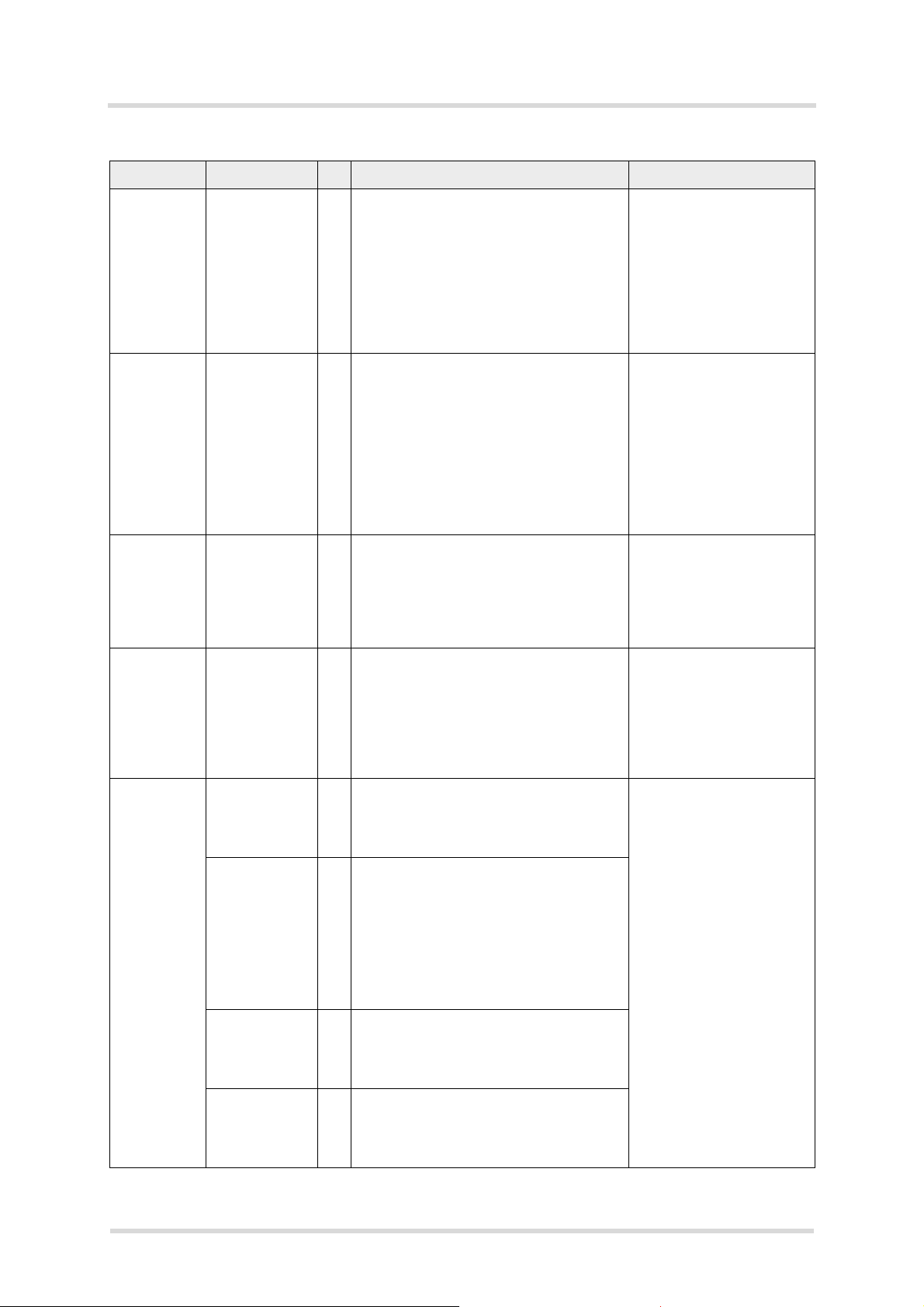

Table 2: Signal properties (Continued)

Function Signal name IO Signal form and level Comment

Page 17 of 106

Fast

FST_SHDN I V

shutdown

USB VUSB_IN I V

USB_DN I/O Full and high speed signal characteris-

USB_DP

Serial

Interface

ASC0

RXD0 O V

CTS0 O

RING0 O

TXD0 I

RTS0 I

DTR0 I

DCD0 O

DSR0 O

max = 0.63V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

~~|___|~~ low impulse width > 10ms

min = 3V

I

V

max = 5.25V

I

Active and suspend current:

I

< 100µA

max

tics according USB 2.0 Specification.

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

This line must be driven

low.

If unused keep line open.

Note that the fast shutdown line is originally

available as GPIO line. If

configured as fast shutdown, the GPIO line is

assigned as follows:

GPIO4 --> FST_SHDN

All electrical characteristics according to USB

Implementers' Forum,

USB 2.0 Specification.

If unused keep lines

open.

If unused keep lines

open.

By delivery default, lines

are available as ASC0

interface lines.

If configured for use as

GPIOs the assignment is

as follows:

DTR0 --> GPIO1

DCD0 --> GPIO2

DSR0 --> GPIO3

RING0 --> GPIO24

Serial

Interface

ASC1

RXD1 O V

CTS1 O

TXD1 I

RTS1 I

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

If unused keep lines

open.

By delivery default, ASC1

interface lines are available as GPIO lines.

If configured as ASC1

lines, the GPIO lines are

assigned as follows:

GPIO16 --> RXD1

GPIO17 --> TXD1

GPIO18 --> RTS1

GPIO19 --> CTS1

ASC1 is available as data

interface.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 18

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Table 2: Signal properties (Continued)

Function Signal name IO Signal form and level Comment

2

I

C I2CCLK IO VOLmax = 0.45V

V

min = 1.35V

I2CDAT IO

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

According to the I

Specification Version 2.1

for the fast mode a rise

time of max. 300ns is permitted. There is also a

maximum V

3mA specified.

Minimum R external pullup (connected to V180

power supply) is 391

Ohms. The value of the

pull-up depends on the

capacitive load of the

whole system (I

+ lines).

The maximum sink current of I2CDAT and

I2CCLK is 4.6mA.

Page 18 of 106

2

C Bus

=0.4V at

OL

2

C Slave

SPI SPI_CLK O V

SPI_MOSI O

SPI_MISO I

SPI_CS1

O

SPI_CS2

GPIO interface

GPIO1-4

GPIO6-22

IO V

GPIO24,25,

27

GPO5,23,26 O

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

If lines are unused keep

lines open.

If lines are unused keep

lines open.

By delivery default, the

SPI CS interface lines are

available as GPIO lines.

If configured as SPI lines,

the GPIO lines are

assigned as follows:

GPO26 --> SPI_CS1

GPIO27 --> SPI_CS2

If unused keep line open.

Please note that some

GPIO lines are or can be

can be configured by AT

command for alternative

functions:

GPIO1-GPIO3: ASC0

control lines DTR0,

DCD0, and DSR0

GPIO4: FST_SHDN

GPO5: LED

GPIO8: Pulse Counter

GPIO16-GPIO19: ASC1,

HSIC control lines

GPIO20-GPO23: PCM/

2

I

S lines

GPIO24: ASC0 control

line RING0

GPO26-GPIO27: SPI CS

signals

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 19

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Table 2: Signal properties (Continued)

Function Signal name IO Signal form and level Comment

Page 19 of 106

Status LED LED O V

Pulse

COUNTER I V

counter

ADC

ADC1 I R

(Analog-toDigital converter)

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = -0.3V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

= 10kOhm

I

V

= 0V ... 2.0V

I

Resolution 1024 steps

Tolerance +/-2%

If unused keep line open.

By delivery default, the

line is available as LED

line.

If configured for use as

GPIO line, the LED line is

assigned as follows:

LED --> GPO5

If unused keep line open.

By delivery default, the

COUNTER line is originally available as GPIO

line. If configured for use

as COUNTER line, the

GPIO line is assigned as

follows:

GPIO8 --> COUNTER

ADC1 can be used as

input for external measurements.

If unused keep line open.

SIM card

detection

3V SIM

Card Interface

CCIN I R

CCRST O V

CCIO I/O V

CCCLK O V

CCVCC O V

90kOhm

I

V

max = 0.63V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

typical = 2.065V

OH

V

max = 2.95V

OH

V

typical = 0.1V @1mA

OL

V

max = 0.3V

OL

max = 0.44V

IL

V

min = -0.15V

IL

V

min = 2.065V

IH

V

max = 3.15V

IH

V

typical = 0.1V @1mA

OL

VOLmax = 0.3V

V

min = 2.065V at I = -10µA

OH

V

max = 2.95V

OH

typical = 2.065V

OH

V

max = 2.95V

OH

V

typical = 0.1V @1mA

OL

V

max = 0.3V

OL

min = 2.85V

O

typ = 2.95V

V

O

V

max = 3.10V

O

I

max = -50mA

O

CCIN = High, SIM card

inserted.

For details please refer to

Section 2.1.6.

If unused keep line open.

Maximum cable length or

copper track to SIM card

holder should not exceed

100mm.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 20

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Table 2: Signal properties (Continued)

Function Signal name IO Signal form and level Comment

Page 20 of 106

1.8V SIM

CCRST O V

Card Interface

CCIO I/O V

CCCLK O V

CCVCC O V

HSIC HSIC_DATA

HSIC_STRB

typical = 1.26V

OH

V

max = 1.8V

OH

V

typical = 0.1V @1mA

OL

V

max = 0.3V

OL

max = 0.27V

IL

V

min=-0.15V

IL

VIHmin = 1.26V

V

max = 2V

IH

V

typical = 0.1V @1mA

OL

V

max = 0.3V

OL

V

min = 1.26V at I = -10µA

OH

VOHmax = 1.85V

typical = 1.26V

OH

V

max = 1.8V

OH

V

typical = 0.1V @1mA

OL

V

max = 0.3V

OL

min = 1.7V

O

V

typ = 1.80V

O

V

max = 1.9V

O

I

max = -50mA

O

IO Signal characteristics according to

“High-Speed Inter-Chip USB Electrical

Specification”, Version 1, September

23, 2007

HSIC available with

ELS51-VA only.

See also Section 2.1.14.

SDIO SDIOCMD

SDIOCLK

SDIO0

SDIO1

SDIO2

SDIO3

S)

PCM_I2S_-

CLK

PCM_I2S_

FSC

Digital

audio

interface

(PCM/I

2

PCM_I2S_

IN

PCM_I2S_

OUT

IO V

IV

I

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

V

max = 0.63V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

max = 0.63V

IL

V

min = 1.17V

IH

V

max = 1.85V

IH

I

OV

max = 0.45V

OL

V

min = 1.35V

OH

V

max = 1.85V

OH

SDIO available with

ELS51-VA only.

See also Section 2.1.15.

If unused keep line open.

Note that the PCM interface lines are originally

available as GPIO lines.

If configured as PCM

lines, the GPIO lines are

assigned as follows:

GPIO23 --> PCM_I2S_CLK

GPIO22 --> PCM_I2S_

FSC

GPIO20 --> PCM_I2S_

OUT

GPIO21 --> PCM_I2S_

IN

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 21

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 21 of 106

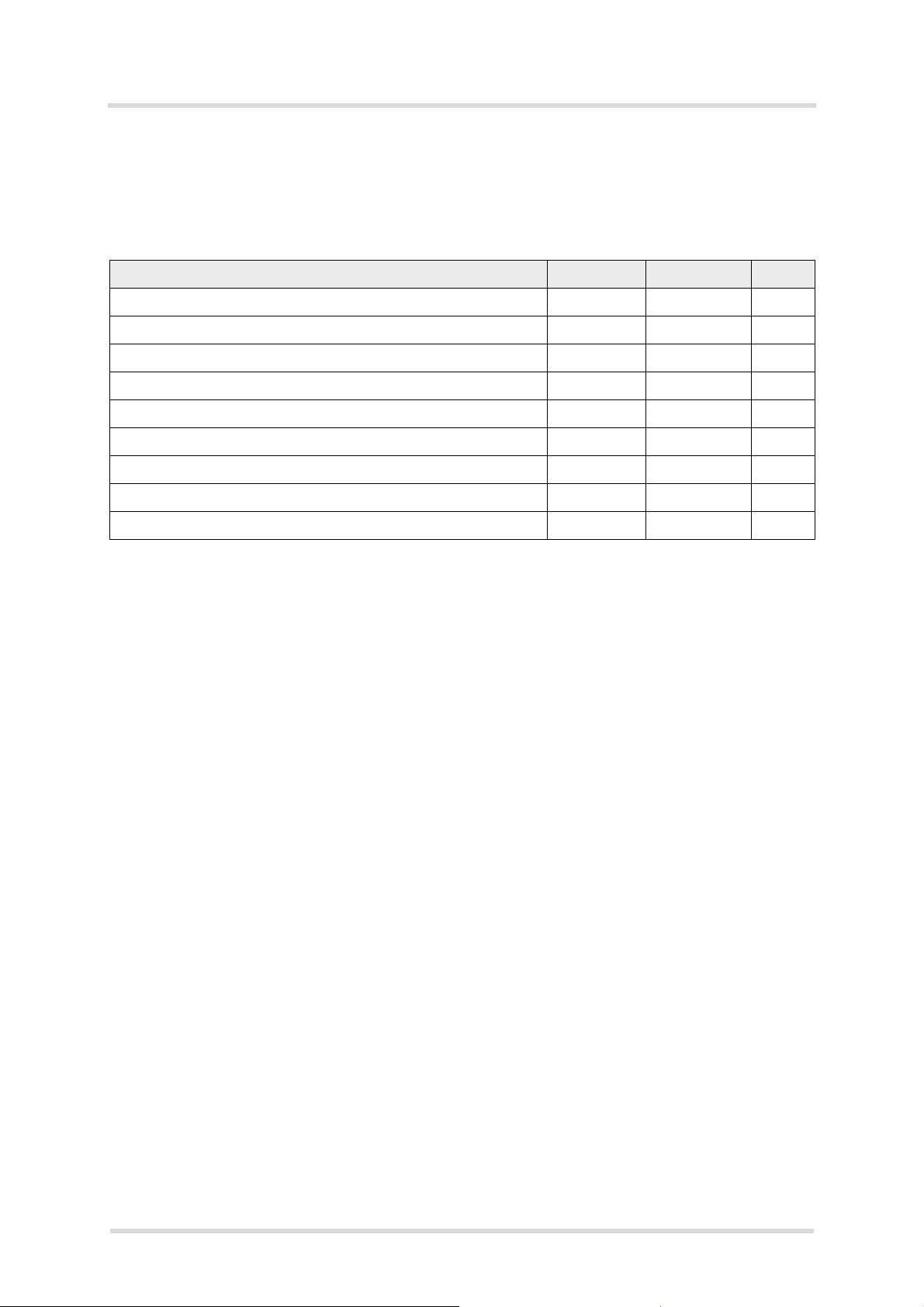

2.1.2.1 Absolute Maximum Ratings

The absolute maximum ratings stated in Table 3 are stress ratings under any conditions.

Stresses beyond any of these limits will cause permanent damage to ELS31-VA/ELS51-VA.

Table 3: Absolute maximum ratings

Parameter Min Max Unit

Supply voltage BATT+

Voltage at all digital lines in Power Down mode -0.3 +0.3 V

Voltage at digital lines in normal operation -0.2 2.0 V

Voltage at SIM/USIM interface, CCVCC in normal operation -0.5 +3.6 V

Voltage at ADC line in normal operation 0 2 V

Voltage at analog lines in Power Down mode -0.3 +0.3 V

V180 in normal operation +1.7 +1.9 V

Current at V180 in normal operation 50 mA

Current at VCORE in normal operation 50 mA

, BATT+

BB

RF

-0.3 +4.5 V

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 22

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

VBUS

DP

DN

VREG (3V075)

BATT+

USB_DP

2)

lin. reg.

GND

Module

Detection only

VUSB_IN

USB part

1)

RING0

Host wakeup

1)

It is recommended to add EMI suppression filter (see section 2.1.3.1)

USB_DN

2)

2)

If the USB interface is operated in High Speed mode (480MHz), it is recommended to take

special care routing the data lines USB_DP and USB_DN. Application layout should in this

case implement a differential impedance of 90Ohm for proper signal integrity.

SMT

Page 22 of 106

2.1 Application Interface

56

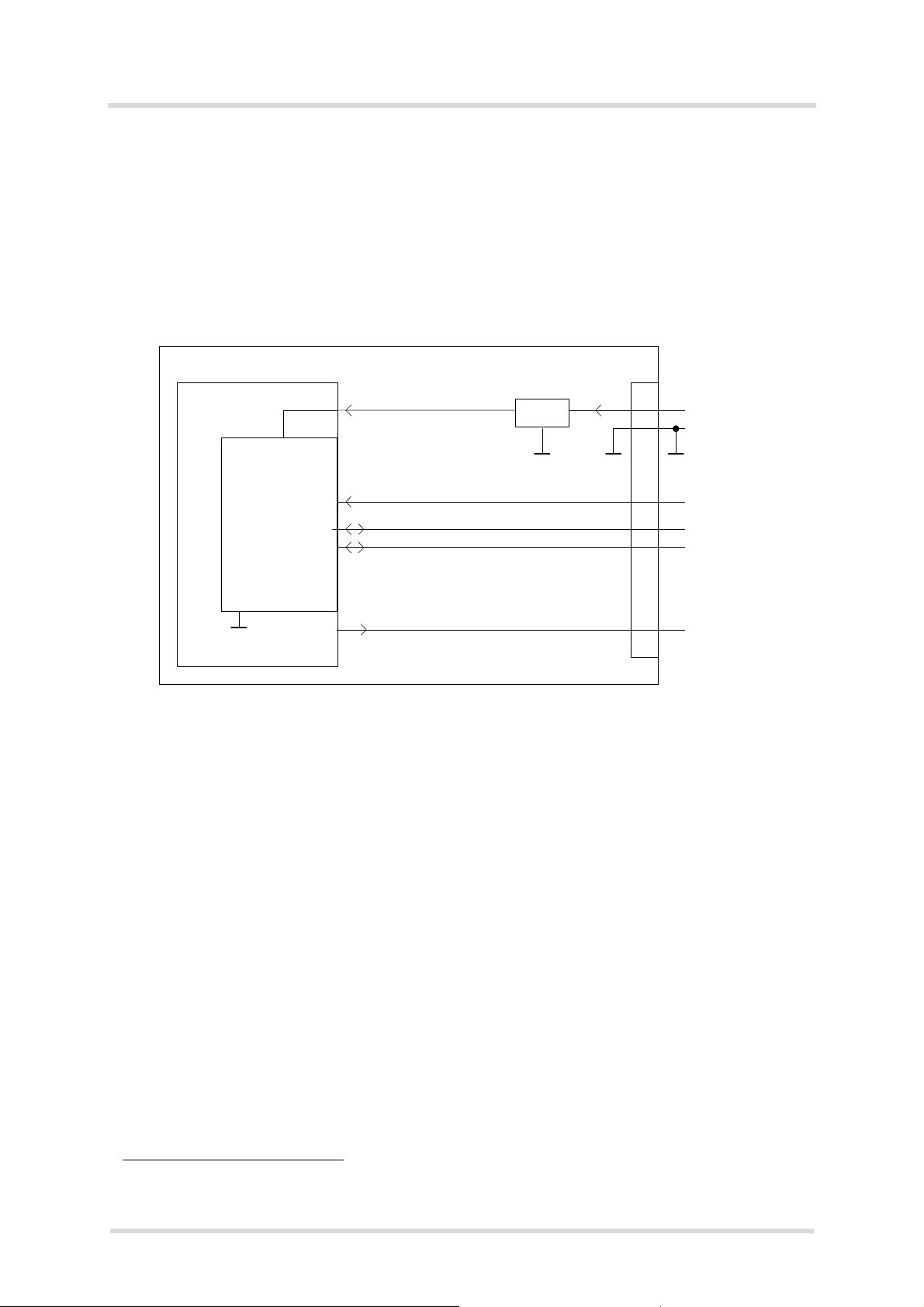

2.1.3 USB Interface

ELS31-VA/ELS51-VA supports a USB 2.0 High Speed (480Mbit/s) device interface that is Full

Speed (12Mbit/s) compliant. The USB interface is primarily intended for use as command and

data interface and for downloading firmware.

The V

line is used for cable detection only, this is to be supplied by the external device. The

USB

USB circuitry in the ELS31-VA/ELS51-VA is designed to meet the USB 2.0 specification for

1

self-power.2.0”

.

Figure 4: USB circuit

To properly connect the module's USB interface to the external application, a USB 2.0 compatible connector and cable or hardware design is required. For more information on the USB related signals see Table 2. Furthermore, the USB modem driver distributed with ELS31-VA/

ELS51-VA needs to be installed.

1. The specification is ready for download on http://www.usb.org/developers/docs/

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 23

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

USB_DP

USB_DN

GND

VUSB

GND

1

12

3

12

342

3

4

65

45

46

ELS31

ELS51

J1

USB-Type B

F1

U1

Page 23 of 106

2.1 Application Interface

56

2.1.3.1 Interface implementation

Figure 5 shows a standard USB interfacing circuit for "off board" interfacing (connection directly

to a USB connector).

If the USB interface is directly wired to a Host interface, the additional ESD protection (U1 on

Figure 5) is not necessary, as the final product will not be a "hot swappable" item. The filter is

used to offer high impedance to higher frequency components of the USB signals. This helps

reduce any potential RF noise coming from these USB wires.

Figure 5: USB Additional ESD Protection Implementation

The digital signals USB_DP and USB_DN are sensitive to track design. Make sure these signals are routed with 90 Ohms differential resistance. If the host product is containing other USB

interfaces, then ensure that the rules used to design those are replicated here too. An overvoltage protection device U1 is recommended, such as ESD5V3U2U-03F.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 24

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 24 of 106

2.1.3.2 Reducing Power Consumption

While a USB connection is active, the module will never switch into SLEEP mode. Only if the

USB interface is in Suspended state or Detached (i.e., VUSB_IN = 0) is the module able to

switch into SLEEP mode thereby saving power. There are two possibilities to enable power reduction mechanisms:

• Recommended implementation of USB Suspend/Resume/Remote Wakeup:

The USB host should be able to bring its USB interface into the Suspended state as

described in the “Universal Serial Bus Specification Revision 2.0“

work, the VUSB_IN line should always be kept enabled. On incoming calls and other events

ELS31-VA/ELS51-VA will then generate a Remote Wakeup request to resume the USB

host controller.

See also [5] (USB Specification Revision 2.0, Section 10.2.7, p.282):

"If USB System wishes to place the bus in the Suspended state, it commands the Host Controller to stop all bus traffic, including SOFs. This causes all USB devices to enter the Suspended state. In this state, the USB System may enable the Host Controller to respond to

bus wakeup events. This allows the Host Controller to respond to bus wakeup signaling to

restart the host system."

1

. For this functionality to

• Implementation for legacy USB applications not supporting USB Suspend/Resume:

As an alternative to the regular USB suspend and resume mechanism it is possible to

employ the RING0 line to wake up the host application in case of incoming calls or events

signalized by URCs while the USB interface is in Detached state (i.e., VUSB_IN = 0). Every

wakeup event will force a new USB enumeration. Therefore, the external application has to

carefully consider the enumeration timings to avoid loosing any signalled events. For details

on this host wakeup functionality see Section 2.1.16.3.

Note: Existing data connections will not be disconnected even if the USB interface is in de-

tached state. URCs will be queued during detached state, but may be signaled to the host via

host wakeup line RING0.

1. The specification is ready for download on http://www.usb.org/developers/docs/

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 25

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 25 of 106

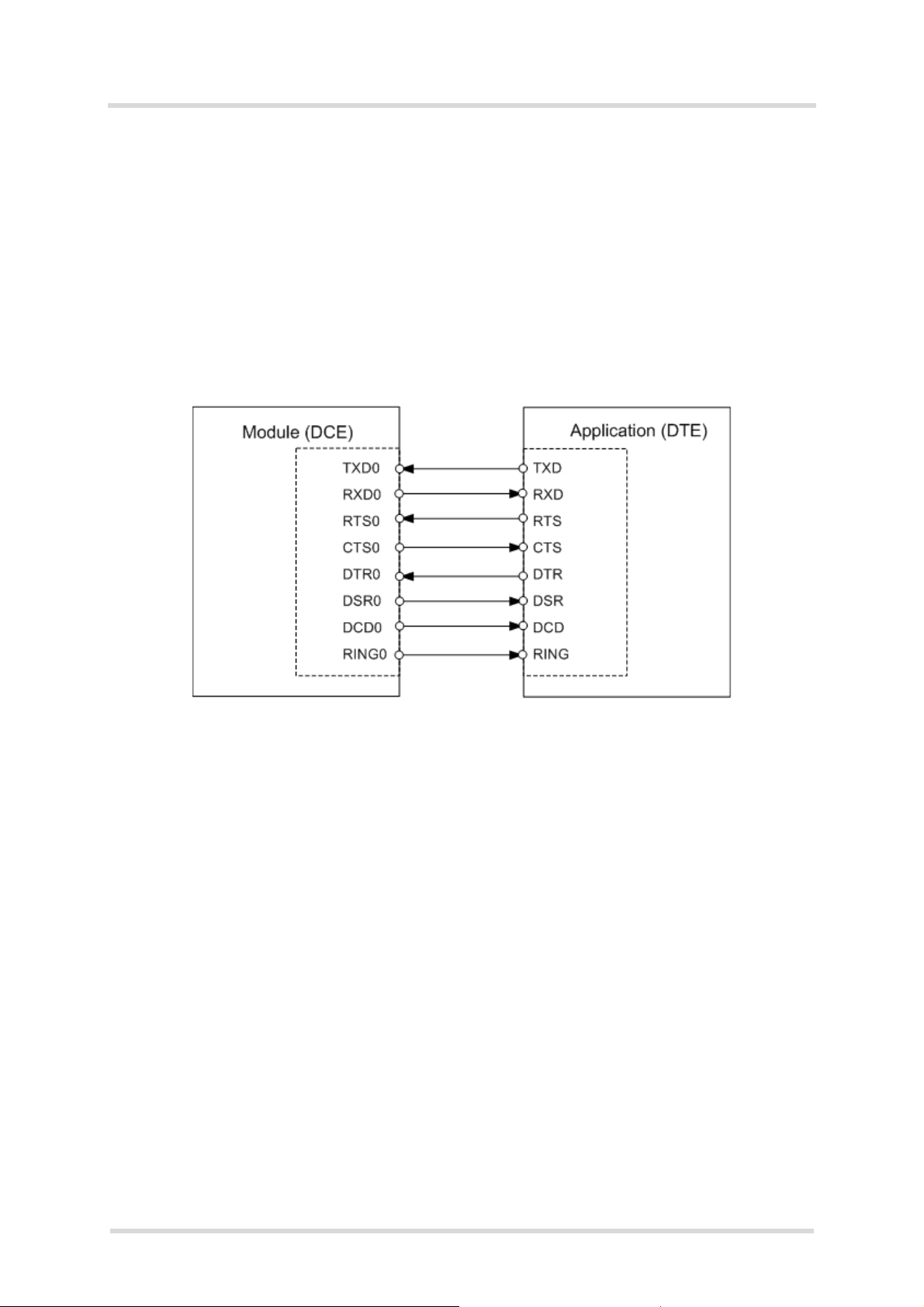

2.1.4 Serial Interface ASC0

ELS31-VA/ELS51-VA offers an 8-wire unbalanced, asynchronous modem interface ASC0 conforming to ITU-T V.24 protocol DCE signalling. The electrical characteristics do not comply with

ITU-T V.28. The significant levels are 0V (for low data bit or active state) and 1.8V (for high data

bit or inactive state). For electrical characteristics please refer to Table 2. For an illustration of

the interface line’s startup behavior see Figure 7.

ELS31-VA/ELS51-VA is designed for use as a DCE. Based on the conventions for DCE-DTE

connections it communicates with the customer application (DTE) using the following signals:

• Port TXD @ application sends data to the module’s TXD0 signal line

• Port RXD @ application receives data from the module’s RXD0 signal line

Figure 6: Serial interface ASC0

Features:

• Includes the data lines TXD0 and RXD0, the status lines RTS0 and CTS0 and, in addition,

the modem control lines DTR0, DSR0, DCD0 and RING0.

• Configured for 8 data bits, no parity and 1 stop bit.

• ASC0 can be operated at fixed bit rates from 4800bps up to 921600bps.

• Supports RTS0/CTS0 hardware flow control. Communication is possible by using only RXD

and TXD lines, if RTS0 is pulled low.

• Wake up from SLEEP mode by RTS0 activation (high to low transition; see Section 3.3.2).

The ASC0 interface is dedicated to signaling via AT commands (3GPP standard 27.007 + module specific AT commands).

Note: The ASC0 modem control lines DTR0, DCD0, DSR0 and RING0 can also be configured

as GPIO lines. If configured as GPIO lines, these GPIO lines are assigned as follows:

DTR0 --> GPIO1, DCD0 --> GPIO2, DSR0 --> GPIO3 and RING0 --> GPIO24.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 26

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

TXD0

RXD0

RTS0

CTS0

DTR0

DSR0

DCD0

RING0

ON

EMERG_RST

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

V180

VCORE

Reset

state

Page 26 of 106

2.1 Application Interface

56

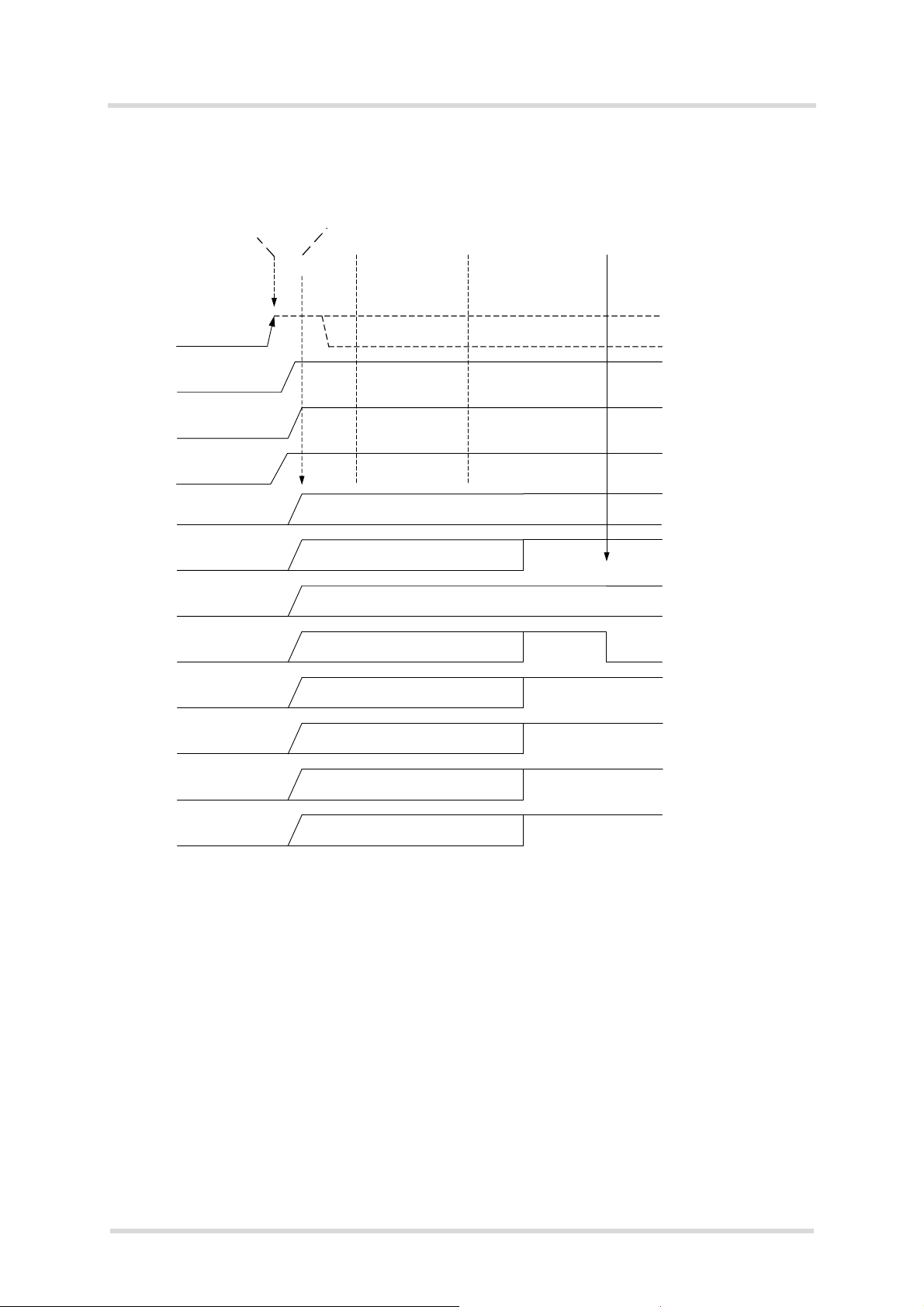

2.1.4.1 Serial Interface Start-up Behavior

The following figure shows the startup behavior of the asynchronous serial interface ASC0.

For pull-up and pull-down values see Table 15.

Figure 7: ASC0 startup behavior

No data must be sent over the ASC0 interface before the interface is active and ready to receive data (see Section 3.2.1).

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 27

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 27 of 106

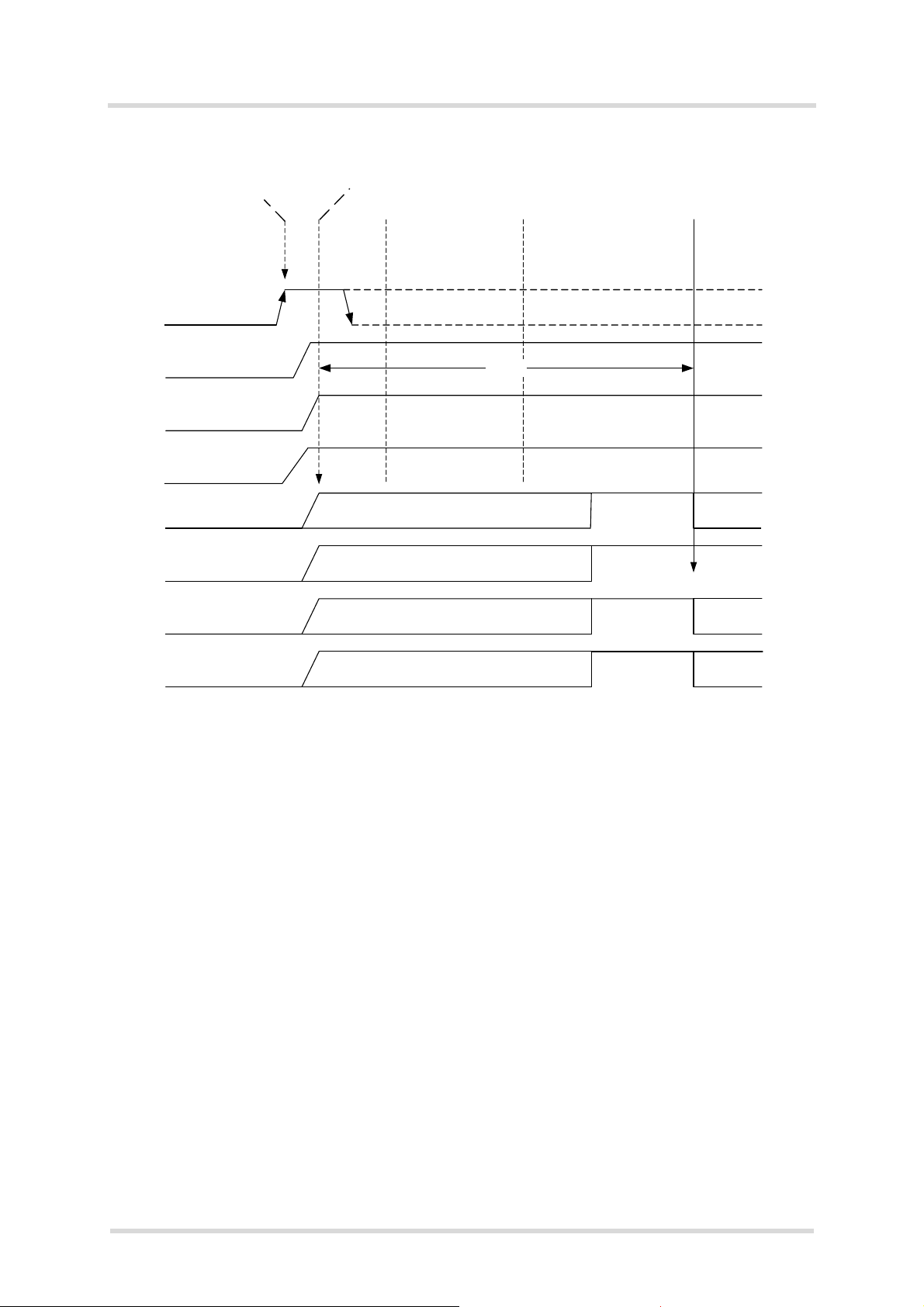

2.1.5 Serial Interface ASC1

ELS31-VA/ELS51-VA provides a 4-wire unbalanced, asynchronous modem interface ASC1

conforming to ITU-T V.24 protocol DCE signaling. The electrical characteristics do not comply

with ITU-T V.28. The significant levels are 0V (for low data bit or active state) and 1.8V (for high

data bit or inactive state). For electrical characteristics please refer to Table 2. For an illustration of the interface line’s startup behavior see Figure 9. ASC1 can only be used as data interface.

The ASC1 interface lines are originally available as GPIO lines. If configured as ASC1 lines,

the GPIO lines are assigned as follows: GPIO16 --> RXD1, GPIO17 --> TXD1, GPIO18 -->

RTS1 and GPIO19 --> CTS1. Configuration is done by AT command (see [1]: AT^SCFG). The

configuration is non-volatile and becomes active after a module restart.

ELS51-VA is designed for use as a DCE. Based on the conventions for DCE-DTE connections

it communicates with the customer application (DTE) using the following signals:

• Port TXD @ application sends data to module’s TXD1 signal line

• Port RXD @ application receives data from the module’s RXD1 signal line

Figure 8: Serial interface ASC1

Features

• Includes only the data lines TXD1 and RXD1 plus RTS1 and CTS1 for hardware handshake.

• On ASC1 no RING line is available.

• Configured for 8 data bits, no parity and 1 or 2 stop bits.

• ASC1 can be operated at fixed bit rates from 4800 bps to 921600 bps.

• Supports RTS1/CTS1 hardware flow control. Communication is possible by using only RXD

and TXD lines, if RTS1 is pulled low.

• Wake up from SLEEP mode by RTS0 activation (high to low transition; see Section 3.3.2).

AT commands for signaling are not supported on ASC1 interface. ASC1 is intended only for

data transfer in a Linux environment.

The following figure shows the startup behavior of the asynchronous serial interface ASC1.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 28

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

TXD1

RXD1

RTS1

CTS1

ON

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

V180

VCORE

EMERG_RST

Reset

state

~ 15sec

2.1 Application Interface

56

Page 28 of 106

*) For pull-down values see Table 15.

Figure 9: ASC1 startup behavior

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 29

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 29 of 106

2.1.6 UICC/SIM/USIM Interface

ELS31-VA/ELS51-VA has an integrated UICC/SIM/USIM interface compatible with the 3GPP

31.102 and ETSI 102 221. This is wired to the host interface in order to be connected to an

external SIM card holder. Five pads on the SMT application interface are reserved for the SIM

interface.

The UICC/SIM/USIM interface supports 3V and 1.8V SIM cards. Please refer to Table 2 for

electrical specifications of the UICC/SIM/USIM interface lines depending on whether a 3V or

1.8V SIM card is used.

The CCIN signal serves to detect whether a tray (with SIM card) is present in the card holder.

The CCIN signal must be connected to V180 for the detection to work on the module. Otherwise the SIM card can never be detected by the module.

Using the CCIN signal is mandatory for compliance with the GSM 11.11 recommendation if the

mechanical design of the host application allows the user to remove the SIM card during operation. To take advantage of this feature, an appropriate SIM card detect switch is required on

the card holder. For example, this is true for the model supplied by Molex, which has been tested to operate with ELS31-VA/ELS51-VA and is part of the Gemalto M2M reference equipment

submitted for type approval. See Section 7.1 for Molex ordering numbers.

Table 4: Signals of the SIM interface (SMT application interface)

Signal Description

GND Separate ground connection for SIM card to improve EMC.

CCCLK Chipcard clock

CCVCC SIM supply voltage.

CCIO Serial data line, input and output.

CCRST Chipcard reset

CCIN Input on the baseband processor for detecting a SIM card tray in the holder. If the SIM is

removed during operation the SIM interface is shut down immediately to prevent destruction of the SIM. The CCIN signal is by default low and will change to high level if a SIM card

is inserted.

The CCIN signal is mandatory for applications that allow the user to remove the SIM card

during operation.

The CCIN signal is solely intended for use with a SIM card. It must not be used for any other

purposes. Failure to comply with this requirement may invalidate the type approval of

ELS31-VA/ELS51-VA.

Note: No guarantee can be given, nor any liability accepted, if loss of data is encountered after

removing the SIM card during operation. Also, no guarantee can be given for properly initializing any SIM card that the user inserts after having removed the SIM card during operation. In

this case, the application must restart ELS31-VA/ELS51-VA.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 30

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

SIM

CCVCC

CCRST

CCIO

CCCLK

220nF

1nF

CCIN

V180

2.1 Application Interface

56

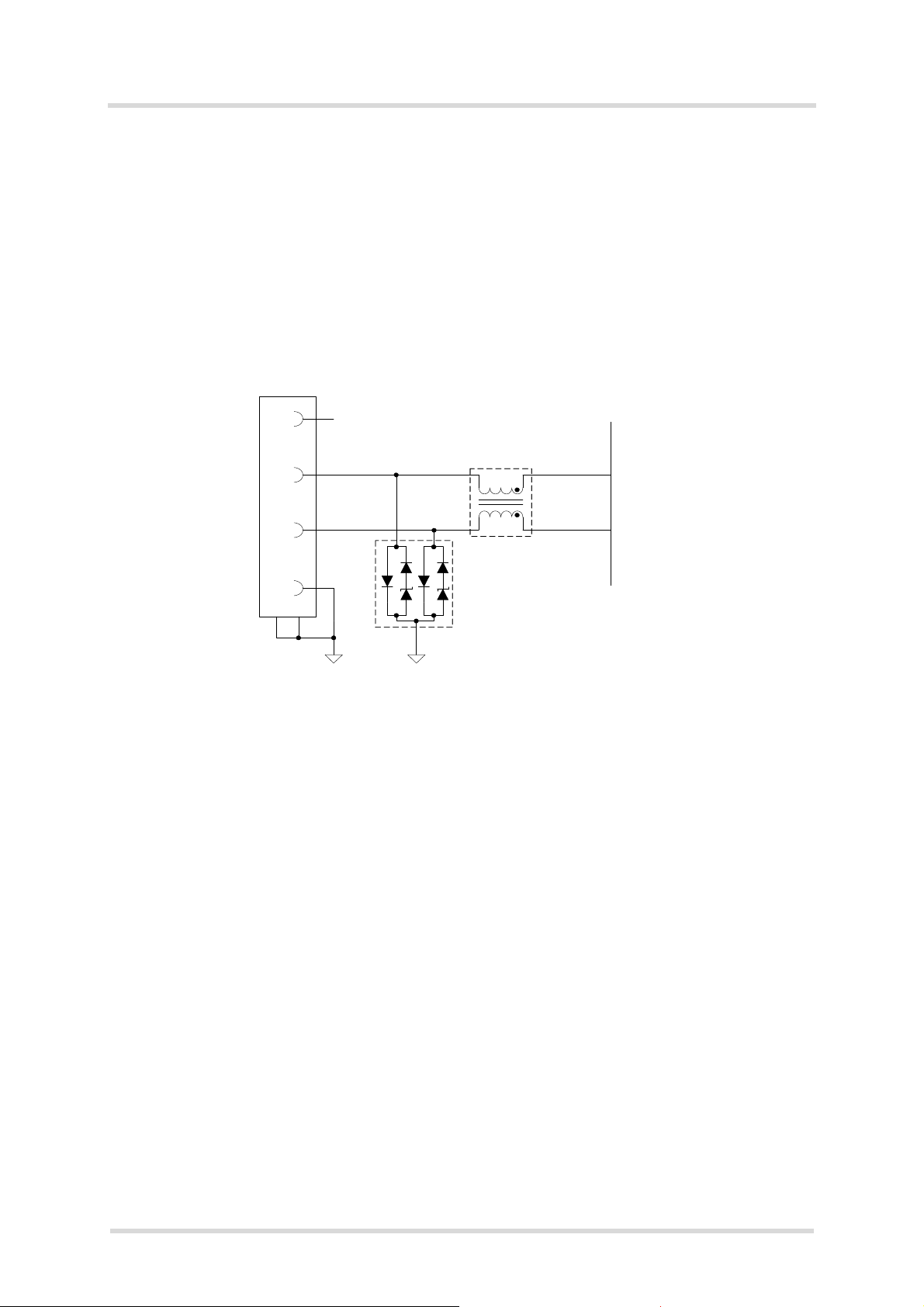

The figure below shows a circuit to connect an external SIM card holder.

Page 30 of 106

Figure 10: External UICC/SIM/USIM card holder circuit

The total cable length between the SMT application interface pads on ELS31-VA/ELS51-VA

and the pads of the external SIM card holder must not exceed 100mm in order to meet the

specifications of 3GPP TS 51.010-1 and to satisfy the requirements of EMC compliance.

To avoid possible cross-talk from the CCCLK signal to the CCIO signal be careful that both

lines are not placed closely next to each other. A useful approach is using a GND line to shield

the CCIO line from the CCCLK line.

The ELS31-VA/ELS51-VA includes embedded ESD protection for the SIM interface that complies to ETSI EN 301 489-1/7: Contact discharge: ± 4kV, air discharge: ± 8kV.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 31

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

2.1 Application Interface

56

Page 31 of 106

2.1.7 Digital Audio Interface

ELS31-VA/ELS51-VA supports a digital audio interface that can be employed either as pulse

code modulation interface (see Section 2.1.8) or as inter IC sound interface (see Section 2.1.9).

Operation of these interface variants is mutually exclusive, and can be configured by AT command (see [1])). Default setting is pulse code modulation.

2.1.8 Pulse Code Modulation Interface (PCM)

Note: ELS31-VA/ELS51-VA's PCM interface is reserved for future use. Usage as digital audio

interface is currently not supported.

ELS31-VA/ELS51-VA's PCM interface can be used to connect audio devices capable of pulse

code modulation. The PCM functionality is limited to the use of covers the use of narrowband

codecs with 8kHz sample rate and wideband codecs with 16kHz sample rate onlyas well. Configured for wideband the The PCM interface runs at 16 kHz sample rate (62.5µs frame length),

while the signal processing maintains this rate in a wideband AMR call or samples automatically down to 8kHz in a narrowband call. Therefore, the PCM sample rate is independent of the

audio bandwidth of the call.

The PCM interface has the following implementation:

•Slave mode

• Short frame synchronization, long frame synchronization

• 8kHz and 16kHz sample rate

• 256kHz, 512kHz, 2048kHz bit clock at 8kHz sample rate

• 256kHz, 512kHz, 1024kHz, 4096kHz bit clock at 16kHz sample rate

For the PCM configuration the AT^SAIC command parameters <clock>, <mode>, <frame_mode>, <ext_clk_mode> and <sample_rate> (see [1]) cannot be configured in any combina-

tion. The following notes, must be considered while configuring the PCM interface:

ELS31-VA/ELS51-VA’s digital audio interface can only be operated in slave mode. Therefore,

the <mode> parameter must be set to <1>, and the <ext_clk_mode> be set to not permanent

resp. off. Further, while in slave mode the <clock>, <frame_mode> and <sample_rate> must

be set according to the characteristics of the external master. There is no automatic detection

of the received clock frequency, frame length and sample rate.

Four GPIOs can be configured by AT command as PCM signals: GPIO20 --> PCM_I2S_OUT,

GPIO21--> PCM_I2S_IN, GPIO22 --> PCM_I2S_FSC and GPIO23 --> PCM_I2S_CLK. The

setting is non-volatile and becomes active after a module restart (see also [1]).

Table 5 describes the available DAI/PCM lines at the digital audio interface. For electrical de-

tails see Section 2.1.2.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 32

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

MSB

MSB

LSB

LSB

14 13

14 13

1

1

12

12

2

2

MSB

MSB

62.5 µs

PCM_I2S_CLK

PCM_I2S_FSC

PCM_I2S_OUT

PCM_I2S_IN

2.1 Application Interface

56

Table 5: Overview of PCM pin functions

Page 32 of 106

Signal name on

B2B connector

SMT application

Signal

configuration

inactive

Signal

direction:

Slave

Description

interface

PCM_I2S_OUT PD O PCM data from ELS31-VA/ELS51-VA to external

codec

PCM_I2S_IN PD I PCM data from external codec to ELS31-VA/

ELS51-VA

PCM_I2S_FSC PD I Frame synchronization signal from external codec

PCM_I2S_CLK PD I Bit clock from external codec

Note: PCM data is always formatted as 16-bit uncompressed two’s complement. Also, all PCM

data and frame synchronization signals are written to the PCM bus on the rising clock edge and

read on the falling edge.

The timing of a PCM short frame is shown in Figure 11.

Figure 11: PCM timing short frame (4096KHz, 16kHz sample rate)

Configured to short frame synchronization, the pulse on PCM_I2S_FSC should be one clock

period wide and occur one clock before the data, using long frame the pulse should have a duty

cycle of 50% starting with the first data bit.

Characteristics of Audio Modes

ELS31-VA/ELS51-VA has various audio modes selectable with AT^SNFS (for details on

AT^SNFS see [1]).

Audio mode 1 with its default settings is used for type approval with the Votronic handset via

the DSB75 codec adapter. The handset is adjusted for the type 3.2 low-leakage ear simulator

for narrowband and wideband calls.

The other modes are customer specific modes, and can as such be prepared for specific requirements.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 33

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

PCM_I2S_CLK

PCM_I2S_OUT

PCM_I2S_IN

PCM_I2S_FSC

MSB

MSB

LSB

LSB

14 13

14 13

1

1

12

12

2

2

MSB

MSB

125 µs

Page 33 of 106

2.1 Application Interface

56

2.1.9 Inter IC Sound Interface (I2S)

The I2S Interface is a standardized bidirectional I2S ("Inter-IC Sound Interface") based digital

audio interface for transmission of mono voice signals for telephony services.

2

The I

S interface can be enabled and configured using the AT command AT^SAIC (see [1]).

An activation is possible only out of call and out of tone presentation. The I

capabilities comply with the requirements laid out in the Phillips I2S Bus Specifications, revised

June 5, 1996.

2

The I

S interface has the following characteristics:

• Bit clock mode: Slave, requires external master clock input

• Sampling rate: 8KHz (narrowband), 16KHz (wideband)

• 256kHz bit clock at 8kHz sample rate

• 512kHz bit clock at 16kHz sample rate

• Frame length: 32 bit stereo voice signal (16 bit word length)

2

S properties and

The digital audio interface lines available for the PCM interface are also available for the I

interface. In I

Table 6 lists the available I

Table 6: Overview of I

Signal name on

SMT application

interface

PCM_I2S_OUT PD O I

PCM_I2S_IN PD I I

PCM_I2S_FSC PD I Frame synchronization signal from external codec

PCM_I2S_CLK PD I Bit clock from external codec

2

S mode they have the same electrical characteristics.

2

S interface signals, Figure 12 shows the I2S timing.

2

S pin functions

Signal

configuration

inactive

Signal

direction:

Slave

Description

2

S data from ELS31-VA/ELS51-VA to external

codec

2

S data from external codec to ELS31-VA/ELS51-

VA

Word alignment (WS)

2

S

Figure 12: I

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

2

S timing (slave mode)

Confidential / Preliminary

Page 34

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

Page 34 of 106

2.1 Application Interface

56

2.1.10 GPIO Interface

ELS31-VA/ELS51-VA offers a GPIO interface with 17 GPIO and 3 GPO lines. The lines are

shared with other interfaces or functions: Fast shutdown (see Section 2.1.16.4), status LED

(see Section 2.1.16.1), a pulse counter (see Section 2.1.13), ASC0 (see Section 2.1.4), ASC1

(see Section 2.1.5), SPI (see Section 2.1.12), HSIC (see Section 2.1.14), and digital audio interface (DAI; see Section 2.1.7).

The following table shows the configuration variants for the GPIO pads. All variants are mutually exclusive, i.e. a pad configured for instance as Status LED is locked for alternative usage.

Table 7: GPIO lines and possible alternative assignment

GPIO Fast

Shutdown

GPIO1 DTR0

GPIO2 DCD0

GPIO3 DSR0

GPIO4 FST_SHDN

GPO5 LED

GPIO6

GPIO7

GPIO8 COUNTER

GPIO16 RXD1 AP_WAKEUP

GPIO17 TXD1 HOST_ACTIVE

GPIO18 RTS1 CP_WAKEUP

GPIO19 CTS1 SUSPEND

GPIO20 PCM_I2S_OUT

GPIO21 PCM_I2S_IN

GPIO22 PCM_I2S_FSC

GPO23 PCM_I2S_CLK

GPIO24 RING0

Status

LED

Pulse

Counter

ASC0 ASC1 SPI HSIC PCM

GPIO25

GPO26 SPI_CS1

GPIO27 SPI_CS2

After startup, the above mentioned alternative GPIO line assignments can be configured using

AT commands (see [1]). The configuration is non-volatile and available after module restart.

Notes:

• GPO5, GPO23 and GPO26 are GPOs only.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 35

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

GPIO1 - 8 Hi-Z

CTS0

ON

EMERG_RST

Power supply active

Start up

Firmware

initialization

Command interface

initialization

Interface

active

V180

VCORE

GPIO16 - 27

Hi-Z

Reset

state

2.1 Application Interface

56

Page 35 of 106

The following figure shows the startup behavior of the GPIO interface. With an active state of

the ASC0 interface line CTS0, the initialization of the GPIO interface lines is also finished.

*) For pull down values see Table 15.

Figure 13: GPIO startup behavior

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 36

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

I2CCLK

I2CDAT

GND

I2CCLK

I2CDAT

GND

Module Application

V180

R pull up

R pull up

R pull up

R pull up

Page 36 of 106

2.1 Application Interface

56

2.1.11 I2C Interface

I2C is a serial, 8-bit oriented data transfer bus for bit rates up to 100kbps. It consists of two lines,

the serial data line I2CDAT and the serial clock line I2CCLK. The module acts as a single master device, e.g. the clock I2CCLK is driven by the module. I2CDAT is a bi-directional line. Each

device connected to the bus is software addressable by a unique 7-bit address, and simple

master/slave relationships exist at all times. The module operates as master-transmitter or as

master-receiver. The customer application transmits or receives data only on request of the

module.

To configure and activate the I2C bus use the AT^SSPI command. Detailed information on the

AT^SSPI command as well explanations on the protocol and syntax required for data transmission can be found in [1].

2

The I

C interface can be powered via the V180 line of ELS31-VA/ELS51-VA. If connected to

the V180 line, the I

Down mode.

2

C interface will properly shut down when the module enters the Power

In the application I2CDAT and I2CCLK lines need to be connected to a positive supply voltage

via a pull-up resistor. For electrical characteristics please refer to Table 2.

Figure 14: I

2

C interface connected to V180

Note: Good care should be taken when creating the PCB layout of the host application: The

traces of I2CCLK and I2CDAT should be equal in length and as short as possible.

ELS31-VA_ELS51-VA_HID_v01.000 2017-01-04

Confidential / Preliminary

Page 37

Cinterion® ELS31-VA/ELS51-VA Hardware Interface Description

I2CCLK

I2CDAT

Open drain

Open drain

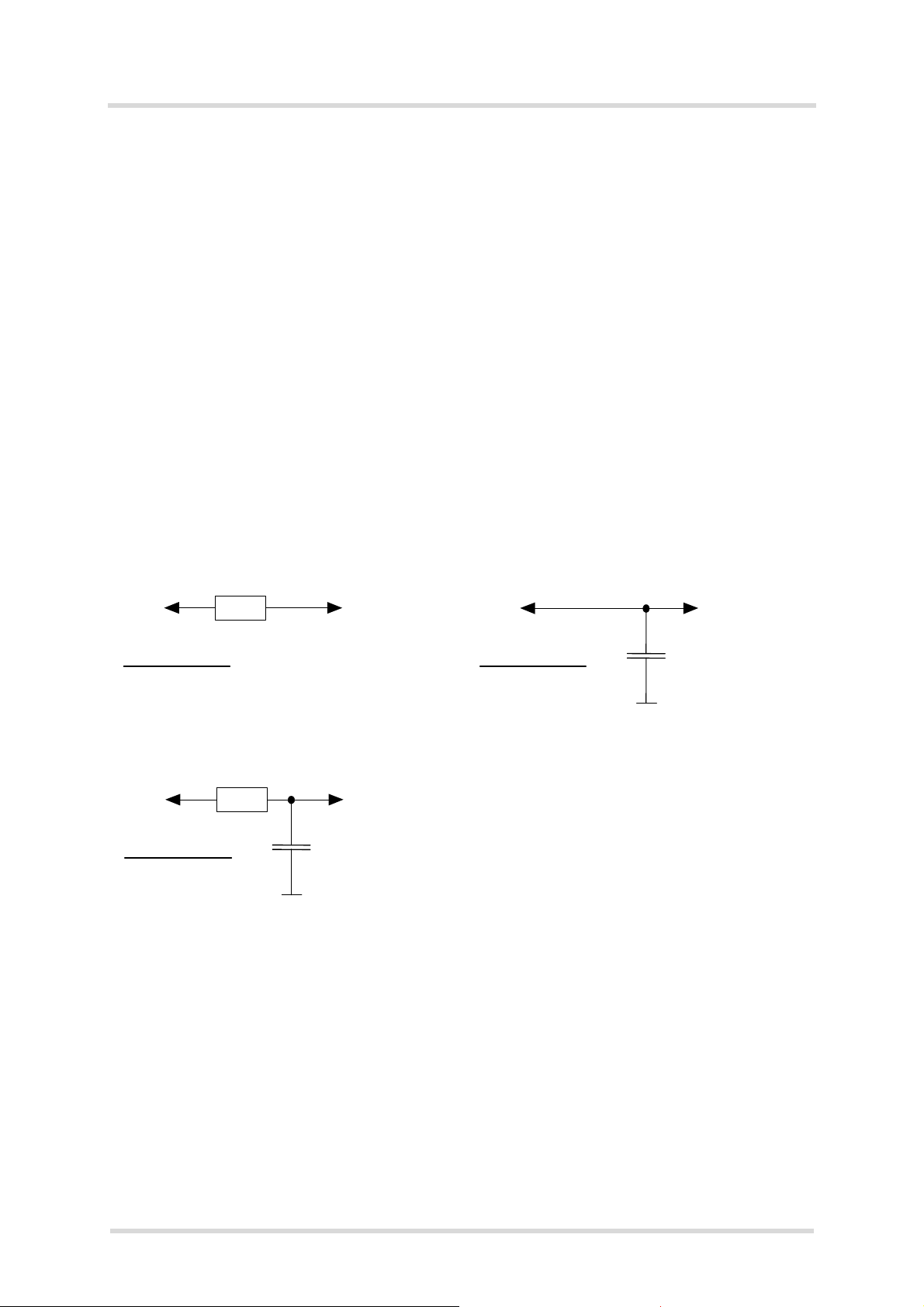

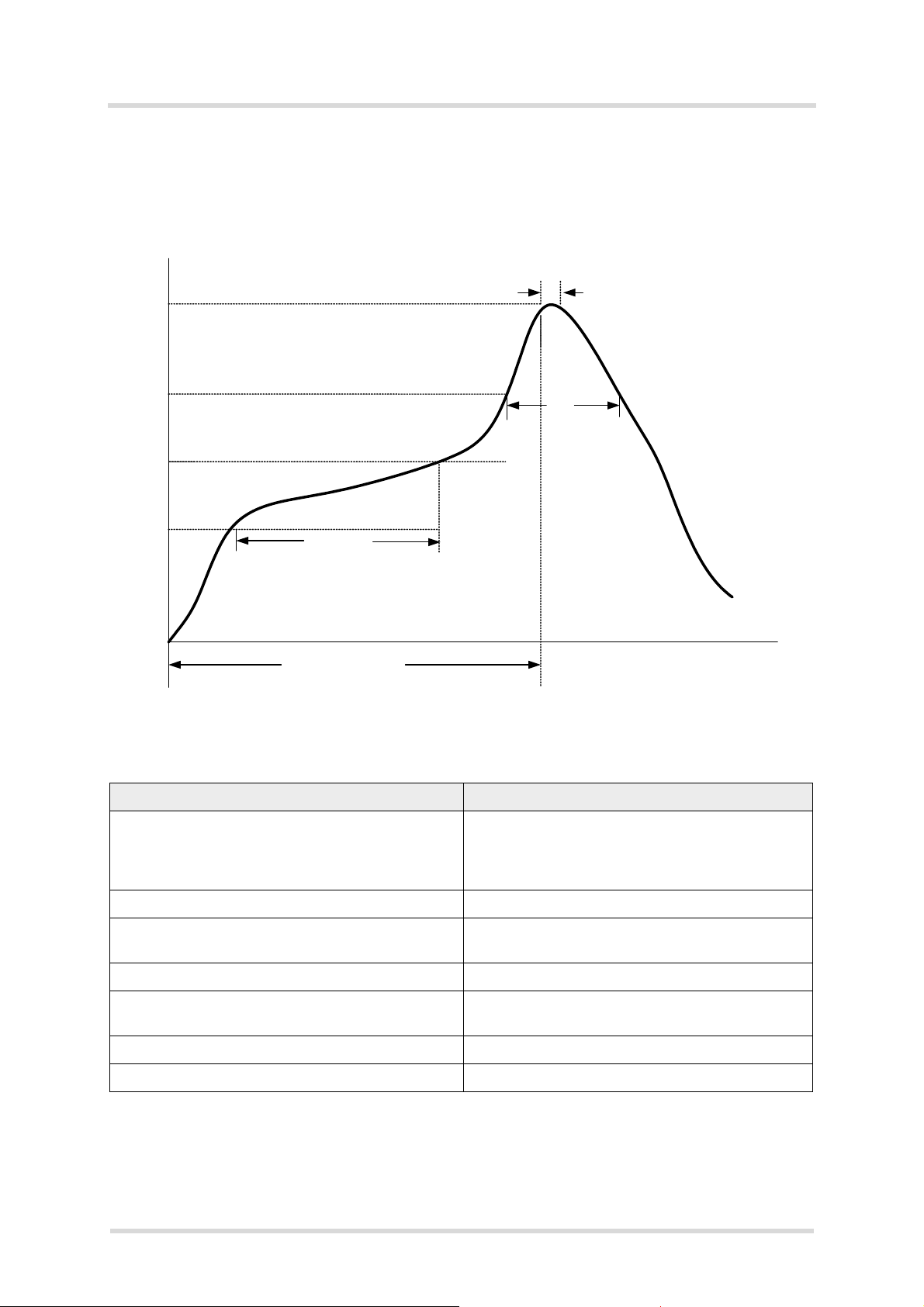

(external pull up)