GE Lighting Tetra Contour, GERDXNLE1, GERCXNLE1, GEYAXNLE1, GEGLXNLE1 Installation Manual

...

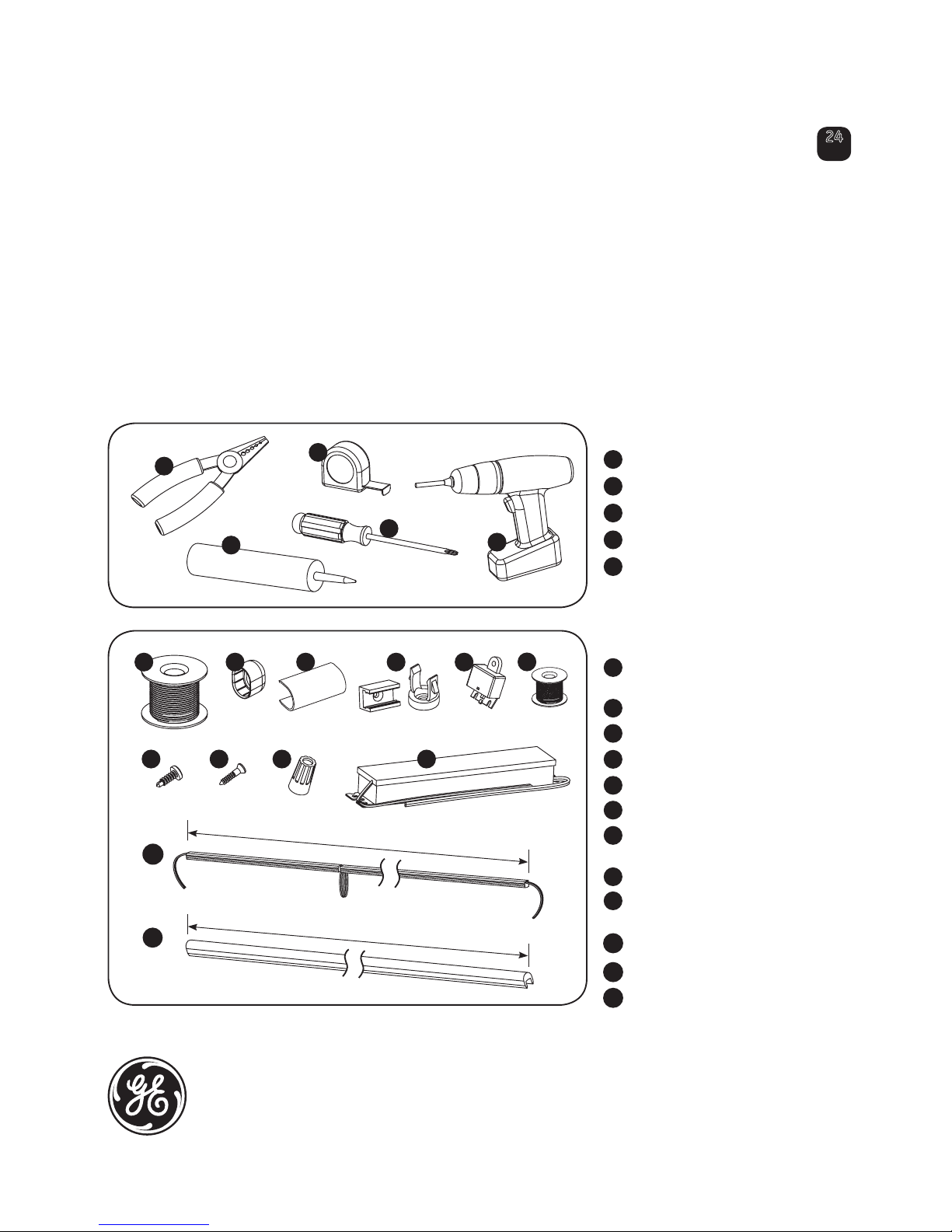

Tools required:

Components required:

UL approved 18 AWG (0.82mm 2 ) supply

wire

End caps

Light guide connectors

Mounting clips

Weather box

22 AWG (0.33mm

2

) tie-wire

#8 & #10 (M3 or M4) self drilling pan

head screws

#6 (M2) screws

UL approved 22-14 AWG (0.33-2.08mm

2

)

twist-on wire connectors

Tetra 24 Volt Power Supply

Tetra Contour light engine

Tetra Contour light guide

Tools and Components

1

2

3

4

5

6

7

8

* NOTE: xx = color code

9

10

11

12

(GERDXNLE1, GERCXNLE1, GEYAXNLE1, GEGLXNLE1, GEBLXNLE1, GEWHXNLE1, GEWWXNLE1)

Installation Guide

Tetra®Contour

LED Lighting System

GE

Lighting Solutions

24

Volt

imagination at work

) m

4

4

.

2

(

t

e

e

f

8

1 2 4

7

9

5

) m

4

4

.

2

(

t

e

e

f

8

3

10

11

12

8

1

2

4

3

5

Wire stripper/cutter

Tape measure

Screwdriver

Electrical grade silicone

Cordless drill

1

2

3

4

5

®

6

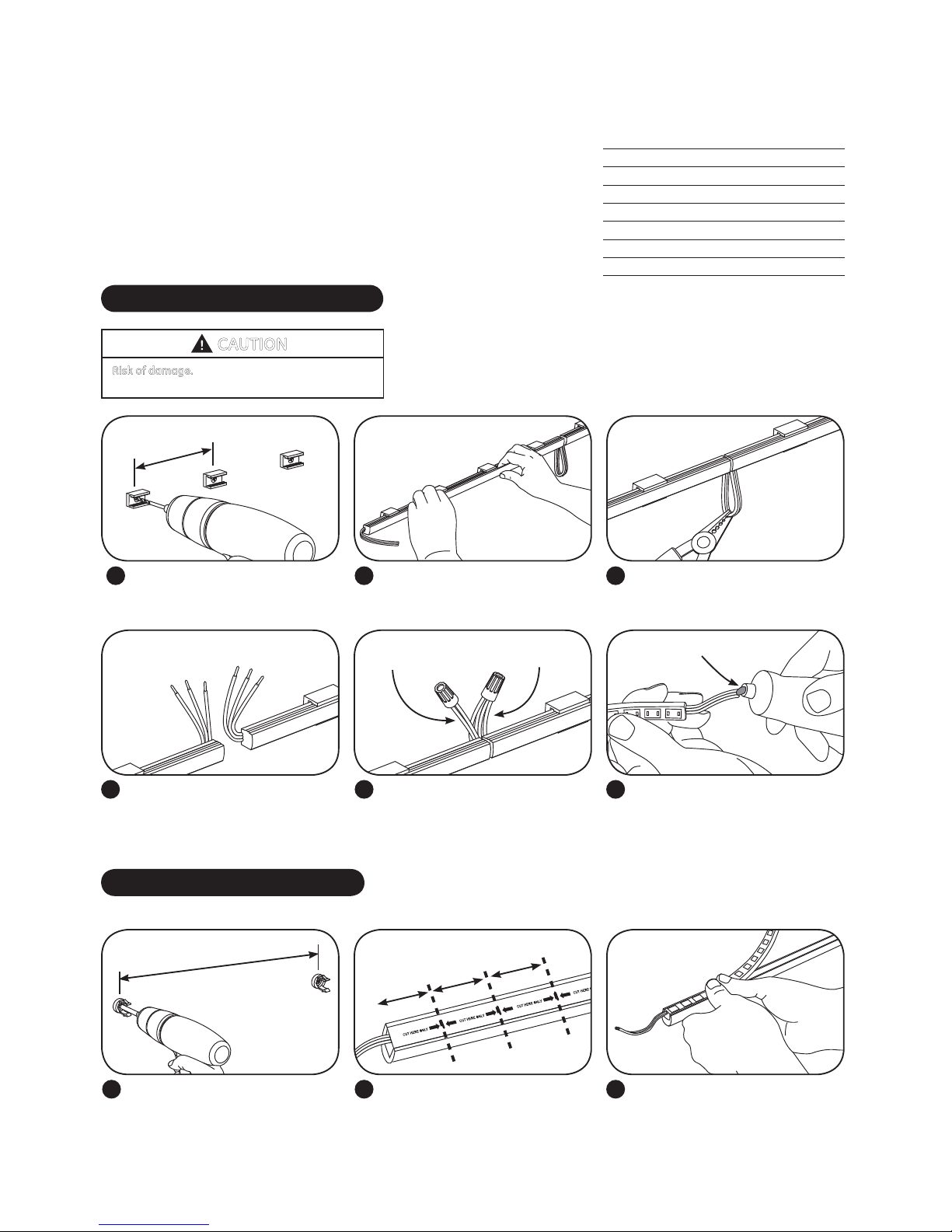

Attaching Light Engines

1

Push each 16 in. (406mm) light engine

segment into the clips. Fold loose

wires behind light engines.

2

Install a mounting clip, using #6 (M2)

counter sink screws, every 5–8 inches

(127–203mm) on center until the end

of the run is reached.

5-8 in. (127-203mm)

Electrical grade silicone

3 1

Push the light engine segments down

into the light guide.

Install a minimum of one clip per 18 in.

(457mm) using #10 (M4) screws.

NOTE: Standard neon hardware can

also be used.

Plan the layout by measuring the design layout and dividing by 8 ft. (2.44m) to

determine the required quantity of Tetra Contour. Refer to the Cutting Resolution Chart

at right when cutting any Tetra Contour section.

NOTE: Do not use more than one suffix code for each respective application, as mixing

suffix codes may result in appearance variation. Suffix code can be found on the

packaging label.

METHOD A - without light guides

If required, cut wire loops between

sections or through light engine in the

appropriate area (refer to the Cutting

Resolution table above).

3

Use twist-on wire connectors to join

cut wires together. Fold wires behind

light engines.

6 5

CAUTION: Anytime light engine or

supply wire is cut and wire is exposed,

electrical grade silicone must be

applied (see list on the next page for

recommendations).

METHOD B - with light guides

2

Push into clips

If required, cut wire loops between

sections or through light engine (refer

to the Cutting Resolution table above).

NOTE: Installation methods shown are for straight runs. For custom shapes, refer to the Light Guide Forming Instructions.

18 in. (457mm)

Connect two

negatives (–)

Connect four

positives (+)

NOTE: Installation methods shown are for straight runs. For custom shapes, install

mounting clips at regular intervals throughout the shape to provide adequate

support for the light engine.

NOTE: DO NOT bend the light engine to an inside radius that is tighter than 5/8 in.

(16mm). The light engine is not intended for excessive or repetitive bending.

Cutting Resolution Table

4

Separate wires and identify outer

conductors as positive (+) and

middle conductors as negative (–).

Strip ends back 0.5 in. (13mm).

+

+

+

+

–

–

Separate wires

CAUTION

Risk of damage. Light engine by itself is intended

for use in dry indoor application only.

Light Engine Color Cutting Resolution

Red 2.67 in. (68mm)

Red-Orange 2.67 in. (68mm)

Amber 2.67 in. (68mm)

Green 2.00 in. (51mm)

Blue 2.00 in. (51mm)

White 2.00 in. (51mm)

Warm White 2.00 in. (51mm)

Loading...

Loading...