R-Series PDU v4

Instruction Manual

geistglobal.com

R-Series PDU v4 Instruction Manual

Table of Contents

Part I

Part II

Specifications

................................................................................................................................... 41 Overview

................................................................................................................................... 42 Environmental

.......................................................................................................................................................... 4Temperature

.......................................................................................................................................................... 4Humidity

.......................................................................................................................................................... 4Elevation

................................................................................................................................... 43 Electrical

................................................................................................................................... 54 Receptacle Ratings

................................................................................................................................... 55 Networking

.......................................................................................................................................................... 5Ethernet Link Speed

.......................................................................................................................................................... 5Protocols

.......................................................................................................................................................... 5User Interfaces

................................................................................................................................... 56 EMC Verification

Installation

................................................................................................................................... 61 Guidelines

................................................................................................................................... 72 Mounting

.......................................................................................................................................................... 7Full Length Brackets

.......................................................................................................................................................... 7Mini "L" Brackets (SLB-4)

.......................................................................................................................................................... 8Vertical Extension Brackets (VCB-1)

.......................................................................................................................................................... 8Toolless Mounting Hardware (11621)

.......................................................................................................................................................... 9Toolless Full Length Brackets (TLFL)

.......................................................................................................................................................... 9Single Side Mount 2 Unit Brackets (TSMX2)

.......................................................................................................................................................... 10Offset/Side Mount Brackets (EZB-1)

.......................................................................................................................................................... 107" Extension Brackets (XB-7)

.......................................................................................................................................................... 11Flush Mount Brackets (FM)

.......................................................................................................................................................... 11Adjustable Mount Brackets (AM)

.......................................................................................................................................................... 12Panel Mount Brackets (PM)

.......................................................................................................................................................... 1223" Conversion Mounting Brackets (23-RM)

.......................................................................................................................................................... 13Cable Mount Brackets (CMB-1)

.......................................................................................................................................................... 1319" Horizontal/Panel Mount Brackets (7938)

4

6

Part III

Part IV

Hardware

................................................................................................................................... 141 Control Device

................................................................................................................................... 152 Network Setup

.......................................................................................................................................................... 15Windows

.......................................................................................................................................................... 18Mac

Web Interface

................................................................................................................................... 201 Sensors

.......................................................................................................................................................... 20Overview

......................................................................................................................................................... 21Configuration and Operation

.......................................................................................................................................................... 25Alarms & Warnings

14

20

geistglobal.com/support

......................................................................................................................................................... 26Alarms & Warnings Configuration

.......................................................................................................................................................... 29Cameras

......................................................................................................................................................... 29Camera Configuration

.......................................................................................................................................................... 30Logging

......................................................................................................................................................... 32Logging Configuration

................................................................................................................................... 332 System

.......................................................................................................................................................... 33User Accounts

.......................................................................................................................................................... 35Network

.......................................................................................................................................................... 36Email

.......................................................................................................................................................... 38SNMP

.......................................................................................................................................................... 40LDAP

.......................................................................................................................................................... 41Syslog

.......................................................................................................................................................... 41Time

.......................................................................................................................................................... 41Admin

.......................................................................................................................................................... 42Locale

.......................................................................................................................................................... 42Restore Defaults

.......................................................................................................................................................... 42Firmware Update

................................................................................................................................... 443 Help

.......................................................................................................................................................... 44Info

.......................................................................................................................................................... 44Support Site

Part V

Technical Support

................................................................................................................................... 451 Resetting PDU

................................................................................................................................... 452 Service and Maintance

................................................................................................................................... 453 More Technical Support

................................................................................................................................... 454 Using Microsoft Exchange as an SMTP server

45

GM1174 - R-Series PDU Instruction Manual

3

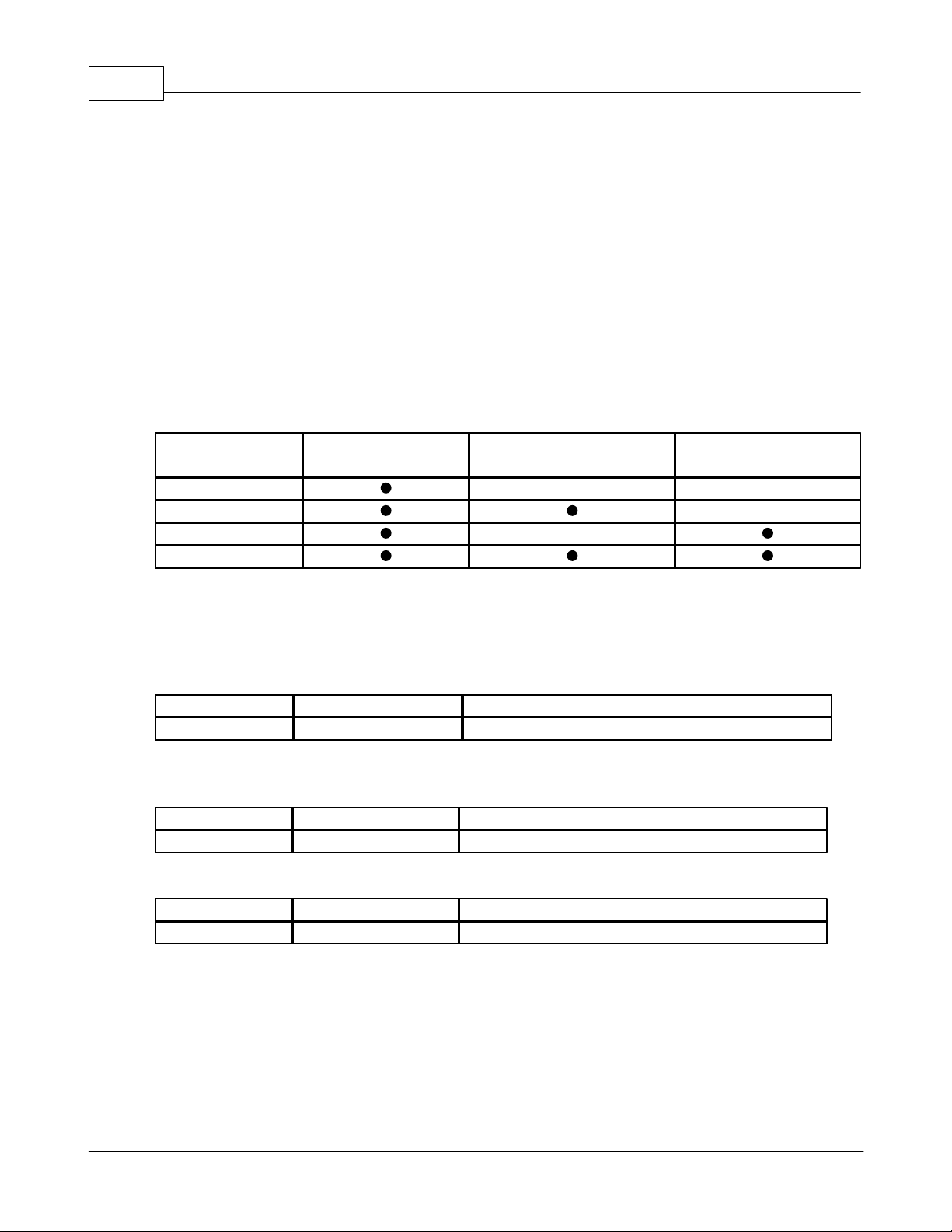

R-Series PDU v4 Instruction Manual4

Input Power

Monitoring

Outlet Level Power

Monitoring

Outlet Level

Switching

RCX

RCO

RCM-O

RCU-O

Operating

10°C (50°F) min

45°C (113°F) max

Storage

-25°C (-13°F) min

65°C (149°F) max

Operating

5% min

95% max (non-condensing)

Storage

5% min

95% max (non-condensing)

Operating

0 m (0 ft) min

2000 m (6561 ft) max

Storage

0 m (0 ft) min

15240 m (50000 ft) max

1 Specifications

1.1 Overview

The R-Series are rack level power distribution units (PDUs) with monitoring via a

built-in web server. Web pages, including logging and graphs, are generated by the

unit to monitor power and environmental conditions within the cabinet, several data

formats are available. R-Series PDUs support optional external sensors and network

cameras. These units can be built for installation in single-phase, three-phase Delta

or Wye building wiring configurations. There are four families within the R-Series;

RCX, RCO, RCM-O and RCU-O.

1.2 Environmental

1.2.1 Temperature

1.2.2 Humidity

1.2.3 Elevation

1.3 Electrical

See nameplate for unit ratings.

© 2014 Geist

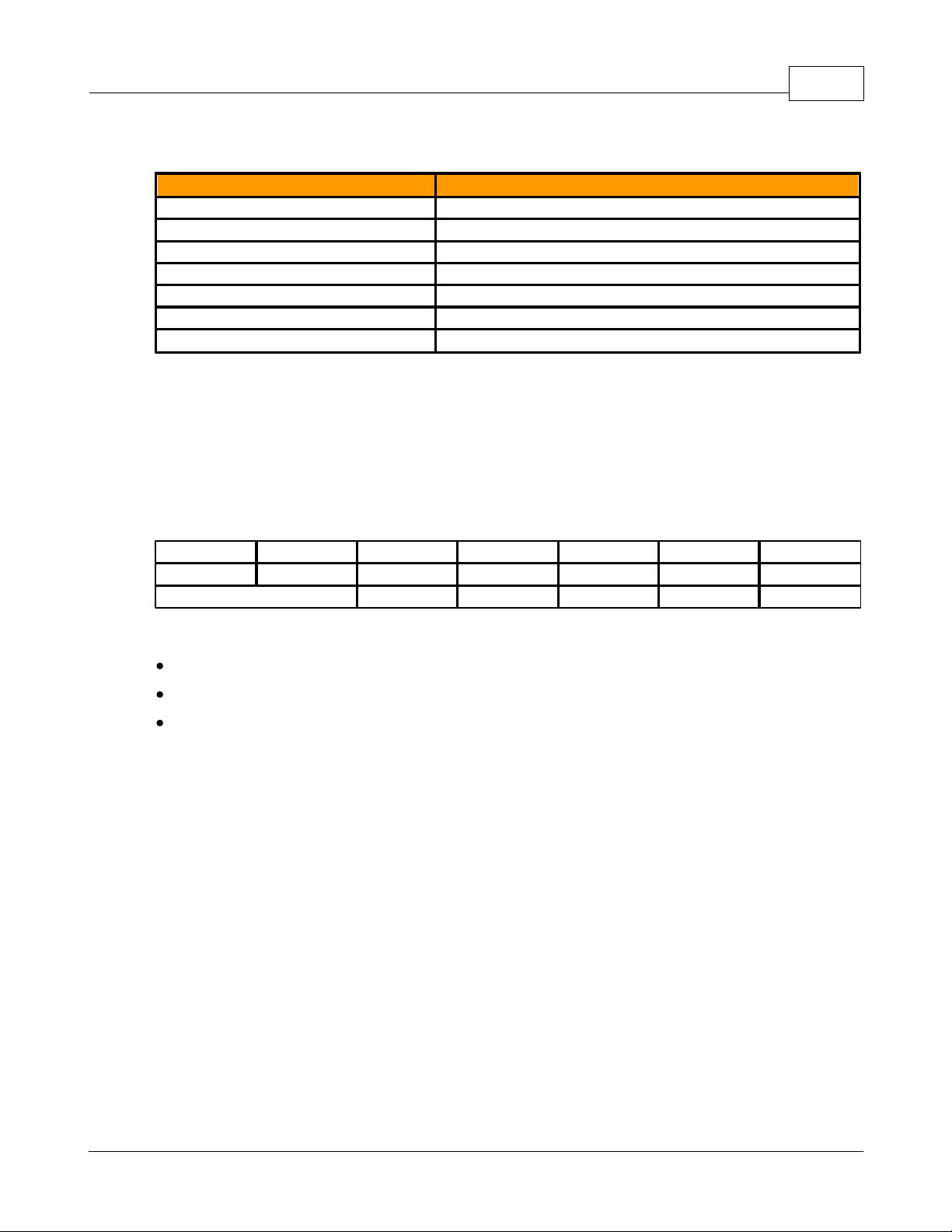

1.4 Receptacle Ratings

Type

Ratings

NEMA 5-15R or L5-15R

125Vac, 15A

NEMA 5-20R or L5-20R

125Vac, 20A

NEMA 6-20R or L6-20R

250Vac, 20A

NEMA L5-30R

125Vac, 30A

NEMA L6-30R

250Vac, 30A

IEC-60320 C13

250Vac, 10A (UL & CSA 15A, 250Vac)

IEC-60320 C19

250Vac, 16A (UL & CSA 20A, 250Vac)

ARP

IPv4

IPv6

ICMP

ICMPv6

NDP

TCP

UDP

DNS

HTTP

HTTPS

SMTP

SMTPS

DHCP

SNMP (v1/v2c/v3)

LDAP

NTP

SSH

Telnet

Syslog

1.5 Networking

1.5.1 Ethernet Link Speed

10/100 Mbit; full-duplex

1.5.2 Protocols

Specifications 5

1.5.3 User Interfaces

JSON-based web GUI

Command-line interface using SSH/Telnet

SNMP

1.6 EMC Verification

This Class A device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

Warning: Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate this equipment.

© 2014 Geist

R-Series PDU v4 Instruction Manual6

2 Installation

2.1 Guidelines

The ambient temperature of the rack should be no greater than 45°C.

Install the PDU such that the amount of airflow required for safe operation of

equipment is not compromised.

Mount the PDU so that a hazardous condition is not achieved due to uneven

mechanical loading.

Follow nameplate ratings when connecting equipment to the branch circuit. Take

into consideration the effect that overloading of the circuits might have on

overcurrent protection and supplied wiring.

The PDU relies on the building installation for protection from overcurrent. A

certified overcurrent protection device is required in the building installation. The

overcurrent protection device should be sized according to the PDU’s nameplate

ratings and local/national electrical code.

Reliable earthing of rack-mount equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to

the branch circuit. The PDU must be connected to an earthed socket outlet.

PDU is intended for restricted-access locations. Only qualified service personnel

should install and access the PDU.

For pluggable equipment, install the PDU so the input plug or appliance coupler

may be disconnected for service.

The PDU is intended for indoor use only. Do not install the unit in wet or outdoor

environments, and do not install it next to water tanks or plumbing.

The PDU is intended for use with TN, TT, or IT power supply systems.

Installation

1. Using appropriate hardware, mount unit to rack. (See next section for examples.)

2. Plug PDU into an appropriately-rated and protected branch-circuit receptacle.

3. Plug in the devices to be powered by the PDU.

4. Turn on each device connected to the PDU. Sequential power-up is

recommended to avoid high inrush current.

© 2014 Geist

2.2 Mounting

Full Length Bracket

Mini "L" Brackets (SLB-4)

Optional brackets sold separately.

2.2.1 Full Length Brackets

Installation 7

2.2.2 Mini "L" Brackets (SLB-4)

© 2014 Geist

R-Series PDU v4 Instruction Manual8

Vertical Extension Brackets (VCB-1)

Toolless Mounting Hardware

2.2.3 Vertical Extension Brackets (VCB-1)

2.2.4 Toolless Mounting Hardware (11621)

© 2014 Geist

2.2.5 Toolless Full Length Brackets (TLFL)

Toolless Full Length Brackets (TLFL)

Single Side Mount 2 Unit Brackets (TSMX2)

Installation 9

2.2.6 Single Side Mount 2 Unit Brackets (TSMX2)

© 2014 Geist

R-Series PDU v4 Instruction Manual10

Offset/Side Mount Brackets

7" Extension Brackets

2.2.7 Offset/Side Mount Brackets (EZB-1)

2.2.8 7" Extension Brackets (XB-7)

© 2014 Geist

2.2.9 Flush Mount Brackets (FM)

Flush Mount Brackets (FM)

Adjustable Mount Brackets

Installation 11

2.2.10 Adjustable Mount Brackets (AM)

© 2014 Geist

R-Series PDU v4 Instruction Manual12

Panel Mount Brackets

23" Conversion Mounting Brackets (23-RM)

2.2.11 Panel Mount Brackets (PM)

2.2.12 23" Conversion Mounting Brackets (23-RM)

© 2014 Geist

2.2.13 Cable Mount Brackets (CMB-1)

Cable Mount Brackets (CMB-1)

19" Horizontal/Panel Mount Brackets (7938)

Installation 13

2.2.14 19" Horizontal/Panel Mount Brackets (7938)

© 2014 Geist

R-Series PDU v4 Instruction Manual14

3 Hardware

3.1 Control Device

The R-Series PDUs have an advanced feature set for data centers that need full

remote monitoring, logging and alarms with options for outlet level monitoring and

switching control. The PDU supports multiple I/O options.

1. Remote Sensor Port ( ): Two RJ12 ports for connecting Geist plug-and-play

remote sensors (sold separately). Splitters may be used to add additional sensors.

Each sensor has a unique serial number and is automatically discovered. RSeries PDUs support up to sixteen sensors.

2. Serial Communication Port ( ): The R-Series PDUs provide an out-of-band,

serial monitoring interface. The unit provides a RJ-45 port for RS-232 serial

communication, providing support for Telnet and SSH via command line.

3. Remote Display Port ( ): An optional remote display (RSD2X8) can be

connected to the R-Series PDU.

4. Ethernet Port ( ): RJ45 port for connecting the PDU to a TCP/IP network.

5. Network-Reset Button ( ):

Holding the network-reset button for 15 seconds during normal operation will

restore the default IP address and reset the user accounts.

Holding the network-reset button during power-up will reset all of the unit's

settings back to factory-default values.

6. Hard-Reboot Button ( ): Pressing the hard-reboot button reboots the monitoring

device. This acts as a power-cycle for the device, and does not change or remove

any user information. Note: This will NOT affect power to the connected devices.

7. Activity/Idle LEDs ( )

8. Power Status LED ( )

9. Local LCD Display: The local display scrolls through the values of the

measurements selected on the LCD Display page.

For R-Series Switched PDUs, there is an LED next to each outlet providing feedback

for the current state.

© 2014 Geist

Loading...

Loading...