Page 1

Data Sheet

March 31, 2010

Document No: DS03-076 ver 1.4

PDF name: zephyr.pdf

Titania™ Power Modules

Zephyr™ Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output; 5V to 12V Input

RoHS Compliant

The Zephyr Power Module provides precise

voltage and very fast transient response in the

industry’s smallest footprint while offering very

high reliability and high efficiency.

Applications

Workstations

Servers

Desktop c omputers

Data processing applications

Distributed power architecture s

Telecommunications equipment

LAN/WAN applications

Description

The Zephyr Power Module is designed to meet the

precise voltage and fast transient requirements of

today’s and tomorrow’s high performance

microprocessor, DSP, memory boards and system level

applications in a distributed power architecture.

Advanced circuit techniques, high-frequency switching,

custom passive and active components, and very highdensity, surface-mount packaging technology deliver

high-quality, ultra compact, non-isolated DC-DC

conversion.

Features

Compliant to RoHS EU Directive 2002/95/EC (-Z

version)

Complian t to ROHS EU Directive 2002/95/EC with

lead solder exemption (non-Z versions)

Transient response met from 0A to rated full load

(up to 600 A/μS)

Exceeds VRM 8.x load transient requirements

No external bulk output capacitors required for

transient response

Wide input range 4.5 V to 12.6V

Wide output range 0.8V to 3.5V

Operation down to zero airflow

Small size and very low profile

Small size: ideal for minimizing motherboard area

in multiprocessor/multi-chip applications

High reliability: 200 FITs/5 million hour MTBF

Surface mount design shipped in JEDEC tray

Single control pin for margining

Single pin for output voltage setting

High efficiency

89% typical @ 16A, V

88% typical @ 18A, V

83% typical @ 20A, V

75% typical @ 20A, V

Remote sense

Programmable output voltage via resistor or

voltage source

Voltage trim capa bility using resistor

Output enable and module OK signals

Output overvoltage, overcurrent, short circuit, and

thermal protection

No heat sink require d

Low inductance surface-mount connections

UL* 1950 Recognized, CSA† C22.2 No. 950-95

Certified, and VDE 0805 (EN60950, IEC950)

Licensed. CE mark meets 73/23/EEC and

93/68/EEC directives

Dimensions: 52.32 mm x 37.08 mm x 5.66 mm

(2.06 in. x 1.460 in. x 0.223 in.)

Total weight: 15.5g (0.55 oz.)

IN = 5V, VOUT = 3.3V

IN = 5V, VOUT = 2.5V

IN = 5V, VOUT = 1.5V

IN = 5V, VOUT = 0.8V

‡

* UL is a registered trademark of Underwriters Laboratories,

Inc.

†

CSA is a registered trademark of Canadian Standards

Association.

‡

This product is intended for integration into end-use

equipment. All the required procedures for CE marking of

end-use equipment should be followed.

LINEAGE POWER 1

Page 2

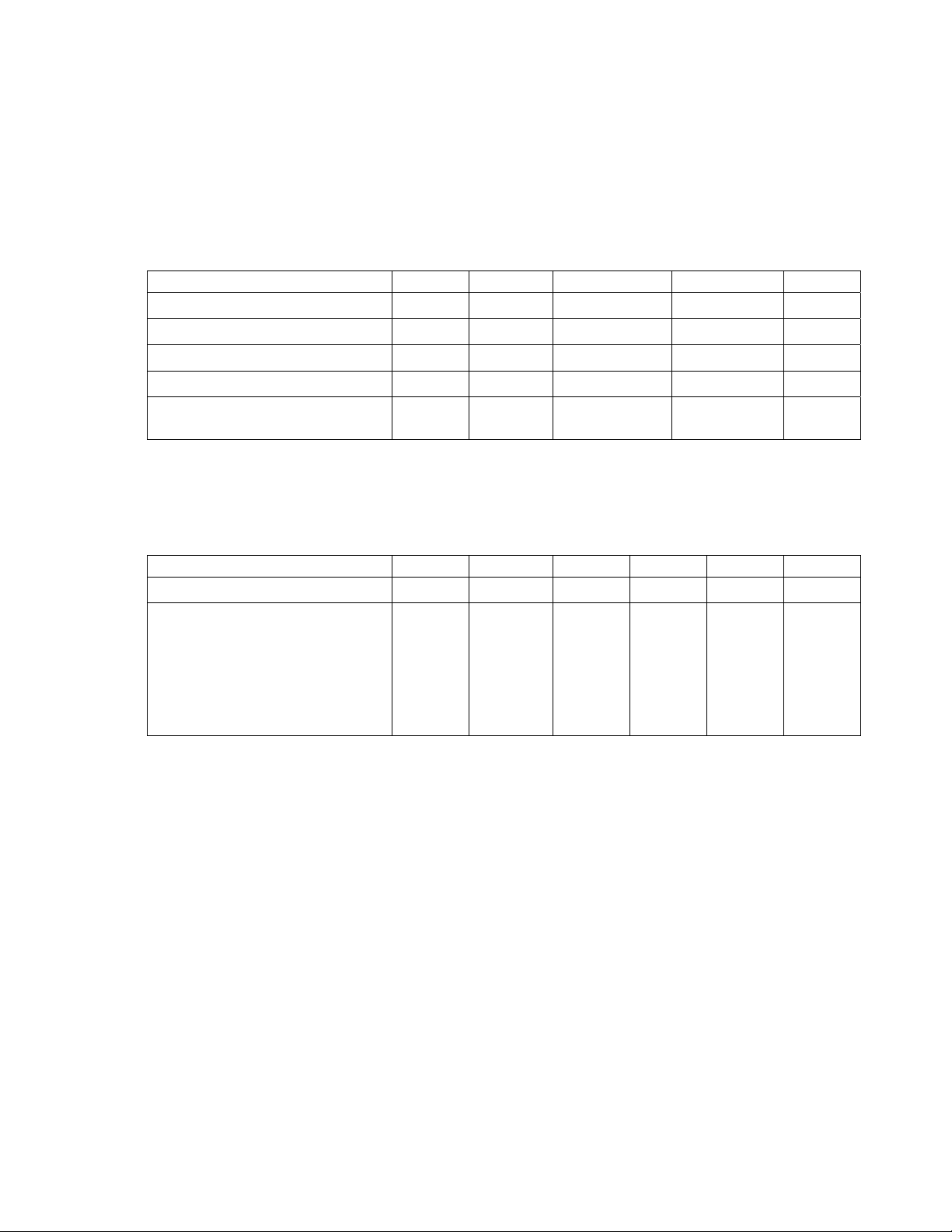

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are

absolute stress ratings only. Functional operation of the device is not implied at these or any other

conditions in excess of those given in the operations sections of the data sheet. Exposure to absolute

maximum ratings for extended periods can adversely affect device reliability.

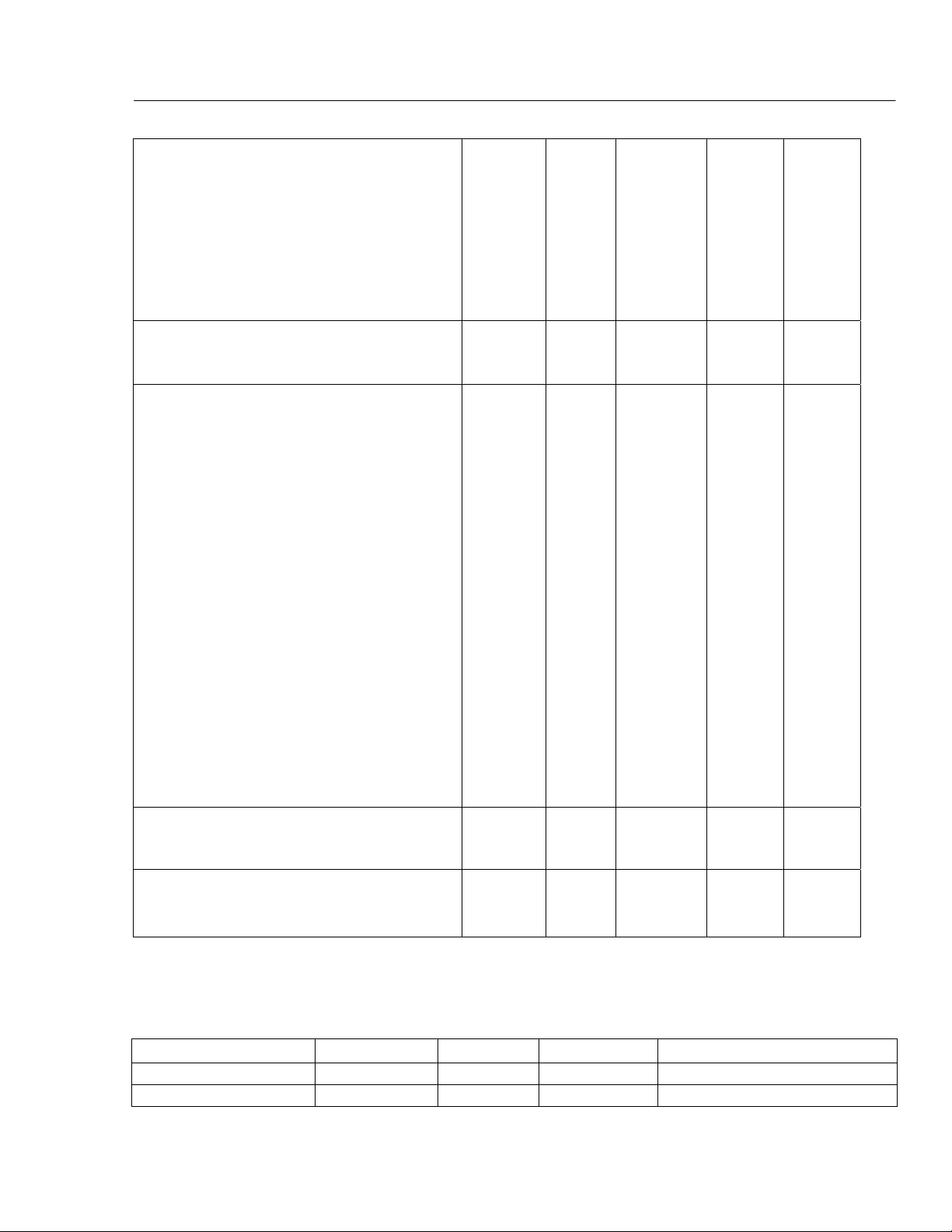

Table 1. Absolute Maximum Ratings

Parameter Device Symbol Min Max Unit

Input Voltage (continuous)

OUTEN Terminal Voltage

Maximum Ambient

Storage Temperature

External Voltage applied

between V

ADJUST+ and VADJUST-

⎯

⎯

⎯

⎯

⎯

VIN – 0.5 13 V

VOUTEN – 0.5 6 V

TMAX

⎯

85 °C

VSTG – 40 150 °C

VEXT

0

3.5

V

Electrical Specifications

Table 2. Input Specifications

Parameter Device Symbol Min Typical Max Unit

Operating Input Voltage

Operating Input Current

• V

IN = 12V, VOUT = 3.3V,

I

OUT = 16A

• V

IN = 5V, VOUT = 3.3V,

I

OUT = 16A

∗

Depends on output voltage

⎯

⎯

⎯

VIN 4.5 12.6 V

I

IN

IIN

⎯

⎯

⎯

⎯

5.5

13.5

∗

∗

A

A

LINEAGE POWER 2

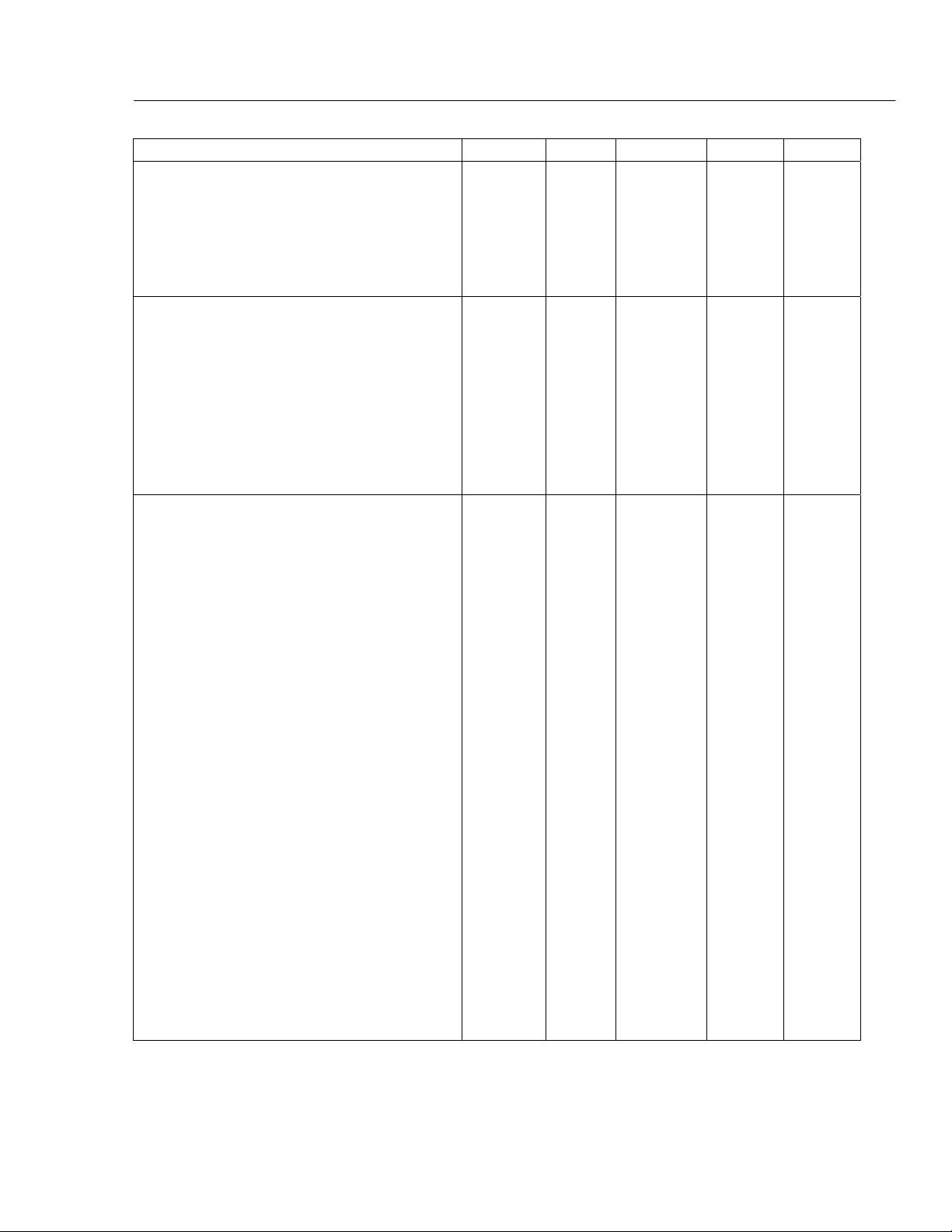

Page 3

Data Sheet

March 31, 2010

Table 3. Output Specifications (TA = 0 °C to 70 °C, VIN = 5V to 12V)

Output Voltage Set Point∗

Zephyr

% error = 1.4 + (0.75/V

V

∗

Static Regulation

Static output voltage variation measured at

output pins on system board with sense

pins connected to measured pins

1. Line Regulation

Output voltage variation as input voltage

changes from 5V to 12V with 50% load

2. Load Regulation

Output voltage variation as load changes

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Parameter Symbol Min Typical Max Unit

+ 2.7/(13.44 + R

OUT = 3.3V

OUT [V])

ADJ[kΩ]) [%]

V

OUT

– 1.6

TRIM pin not connected

V

OUT

VOUT

⎯

⎯

from 0% to 100%

Transient Response, see Figures 5 – 16.

Measured as load changes from IOUT = 0A to

OUT = 16A at slew rate of ΔIOUT/Δt = 600 A/μs

I

1. Peak Deviation

• V

IN = 12V, 0.8V < VOUT < 1.3V

• V

IN = 12V, 1.5V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 1.3V

• V

IN = 5V, 1.5V < VOUT < 3.3V

2. Setting Time (time until V

OUT returns to

10% of peak deviation)

• V

IN = 12V, 0.8V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 3.3V

Measured as load changes from IOUT = 16A to

OUT = 0A at slew rate of ΔIOUT/Δt = 600 A/μs

I

1. Peak Deviation

• V

IN = 12V, 0.8V < VOUT < 1.3V

• V

IN =12V, 1.5V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 1.3V

• V

IN = 5V, 1.5V < VOUT < 3.3V

2. Setting Time (time until V

OUT returns to

10% of peak deviation)

• V

IN = 12V, 0.8V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 3.3V

VOUT

V

OUT

V

OUT

V

OUT

T

SET1

T

SET1

VOUT

V

OUT

V

OUT

V

OUT

T

SET2

TSET2

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

1

1

– 50

– 60

– 70

– 80

30

40

60

70

80

90

30

40

1.6

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

%

mV

mV

mV

mV

mV

mV

μs

μs

mV

mV

mV

mV

μs

μs

LINEAGE POWER 3

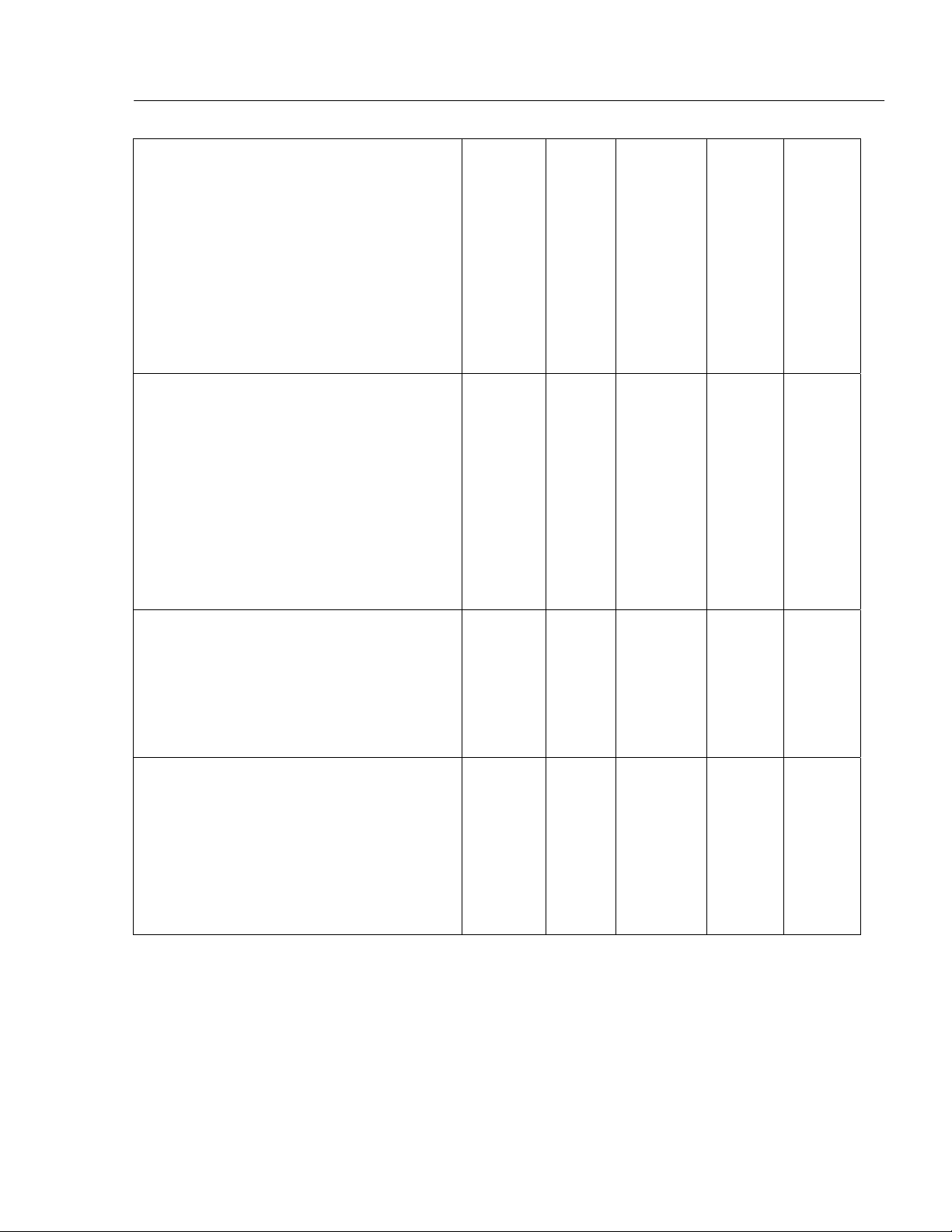

Page 4

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Table 3. Output Specifications (TA = 0 °C to 70 °C, VIN = 5V to 12V), continued

Output Voltage Ripple and Noise, see

Figures 17 – 20. Measured with I

1. RMS Value

• V

IN = 12V, 0.8V < VOUT < 1.8V

• V

IN = 12V, 2.0V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 3.3V

2. Peak-to-peak (DC to 100 MHz)

• V

IN = 12V, 0.8V < VOUT < 2.0V

• V

IN = 12V, 2.5V < VOUT < 3.3V

• V

IN = 5V, 0.8V < VOUT < 3.3V

Total Regulation

Maximum output voltage error in static or

transient condition including ripple and

noise

OUT = 0.8V

• V

• V

OUT = 1.3V

• V

OUT = 1.5V

• V

OUT = 1.8V

• V

OUT = 2.0V

• V

OUT = 2.5V

• V

OUT = 3.3V

Maximum Output Current, depends on

output voltage. See thermal derating curves

for details, Figures 26 – 37.

Airflow: 0 LFM – 400 LFM

Ambient: 25 °C – 70 °C

• V

IN = 5V

• V

IN = 12V

Efficiency, see Figures 38 – 39

T

A = 25 °C, 0 LFM, IOUT = 16A

• V

OUT = 2.5V

V

V

• V

V

V

IN = 12V

IN = 5V

OUT = 0.8V

IN = 12V

IN = 5V

OUT = 16A.

VOUT/RMS

VOUT/RMS

VOUT/RMS

V

OUT/p-p

VOUT/p-p

VOUT/p-p

VOUT

VOUT

VOUT

VOUT

VOUT

VOUT

VOUT

IOUT

IOUT

η

η

η

η

⎯

⎯

⎯

⎯

⎯

⎯

– 104

– 113

– 126

– 131

– 133

– 144

– 152

14

13

⎯

⎯

⎯

⎯

4

5

3

16

20

10

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

86

89

73

78

Data Sheet

March 31, 2010

⎯

⎯

⎯

⎯

⎯

⎯

mVrms

mVrms

mVrms

114

123

136

141

143

154

162

26

24

⎯

⎯

⎯

⎯

mV

mV

mV

mV

mV

mV

mV

mV

mV

mV

A

A

%

%

%

%

LINEAGE POWER 4

Page 5

Data Sheet

March 31, 2010

Table 3. Output Specifications (TA = 0 °C to 70 °C, VIN = 5V to 12V), continued

Efficiency, see Figures 40 – 41

T

V

V

V

V

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

A = 60 °C, 300 LFM, IOUT = 16A

• V

OUT = 2.5V

IN = 12V

IN = 5V

• V

OUT = 0.8V

IN = 12V

IN = 5V

η

η

η

η

⎯

⎯

⎯

⎯

86

88

71

77

⎯

⎯

⎯

⎯

%

%

%

%

Output Current Slew Rate

Step function current from I

16A with no external load capacitors

OUT = 0A to

External Load Capacitance∗

(NOT REQUIRED FOR TRANSIENT RESPONSE)

• VIN = 12V

V

V

V

V

V

V

V

• V

V

V

V

V

V

V

V

∗

Maximum capacitance on output into which

OUT = 0.8V

OUT = 1.3V

OUT = 1.5V

OUT = 1.8V

OUT = 2.0V

OUT = 2.5V

OUT = 3.3V

IN = 5V

OUT = 0.8V

OUT = 1.3V

OUT = 1.5V

OUT = 1.8V

OUT = 2.0V

OUT = 2.5V

OUT = 3.3V

module can start with maximum current

Output Current-limit Inception, for IOUTMAX at

25 °C, 400 LFM. See thermal derating

curves, Figures 26 – 37

Turn-on Response Time, see Figures 1 – 2

Measured at I

OUT = 16A and with maximum

external load capacitor as specified above

ΔI

OUT/Δt

CL

CL

C

L

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

IOUTLIM

ON — 5.0 10.0

T

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

105

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

⎯

600

10,000

6,800

3,300

1,000

1,000

1,000

1,000

10,000

10,000

6,800

3,300

3,300

3,300

1,000

160

A/µs

μF

μF

μF

μF

μF

μF

μF

μF

μF

μF

μF

μF

μF

μF

% IOUTMAX

ms

General Specifications

Table 4. Calculated FIT Rate and Weight

Parameter Min Typ Max Unit

Calculated FIT Rate — — 200 Per 109 device hours

Weight — — 15.5 (0.55) grams (oz.)

LINEAGE POWER 5

Page 6

Zephyr Non-Isolated SMT DC-DC Power Module:

v

v

v

V

,

V

,

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

Safety Considerations

Module’s printed circuit board meets the standards of UL flammability specificatio ns per UL94V-0.

Feature Descriptions

Static Voltage Regulation

The output voltage measured at the converter output pins on the system board will be within the range

shown in Table 3, except during turn-on and turn-off periods. The static limits apply to ambient temperatures

between 0 °C and 70 °C. Static voltage regulation includes:

• DC output initial voltage and set point adjust

• Output load ranges specified in tables above

• Temperature and warm-up input voltage tolerances specified in input voltage and current

Turn-on Response Time

The output voltage will be within the specified range within 10 ms of the input voltage reaching 90% of its

nominal value with O

be inside its specified range within 10 ms. Figure 1 and Figure 2 represent typical start-up waveforms with

the maximum load current and load capacitor on the output indicated in Table 3. A pull-up resi stor of 10 kΩ

is used between Module OK pin and 5V.

UTEN present. When OUTEN is applied with input voltage present, the output voltage will

OUTEN, 5 V/div OUTEN, 5 V/di

MODULE OK, 5 V/di

OUT

0.5 V/div

2 ms/div 2 ms/div

MODULE OK, 5 V/di

OUT

1.0 V/div

Figure 1. Turn-on Waveform: V

OUT = 0.8V, 16A resistive load + 10,000 μF VOUT = 3.3V, 16A resistive load + 1,000 μF

V

IN = 12V, Figure 2. Turn-on Waveform: VIN = 5V,

LINEAGE POWER 6

Page 7

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Overshoot at Turn-on or Turn-off

Overshoot in application or removal of the input voltage, or application or removal of the O

UTEN signal is 5%

above the initially set output voltage. No negative voltage will be present on the output during turn-on or

turn-off.

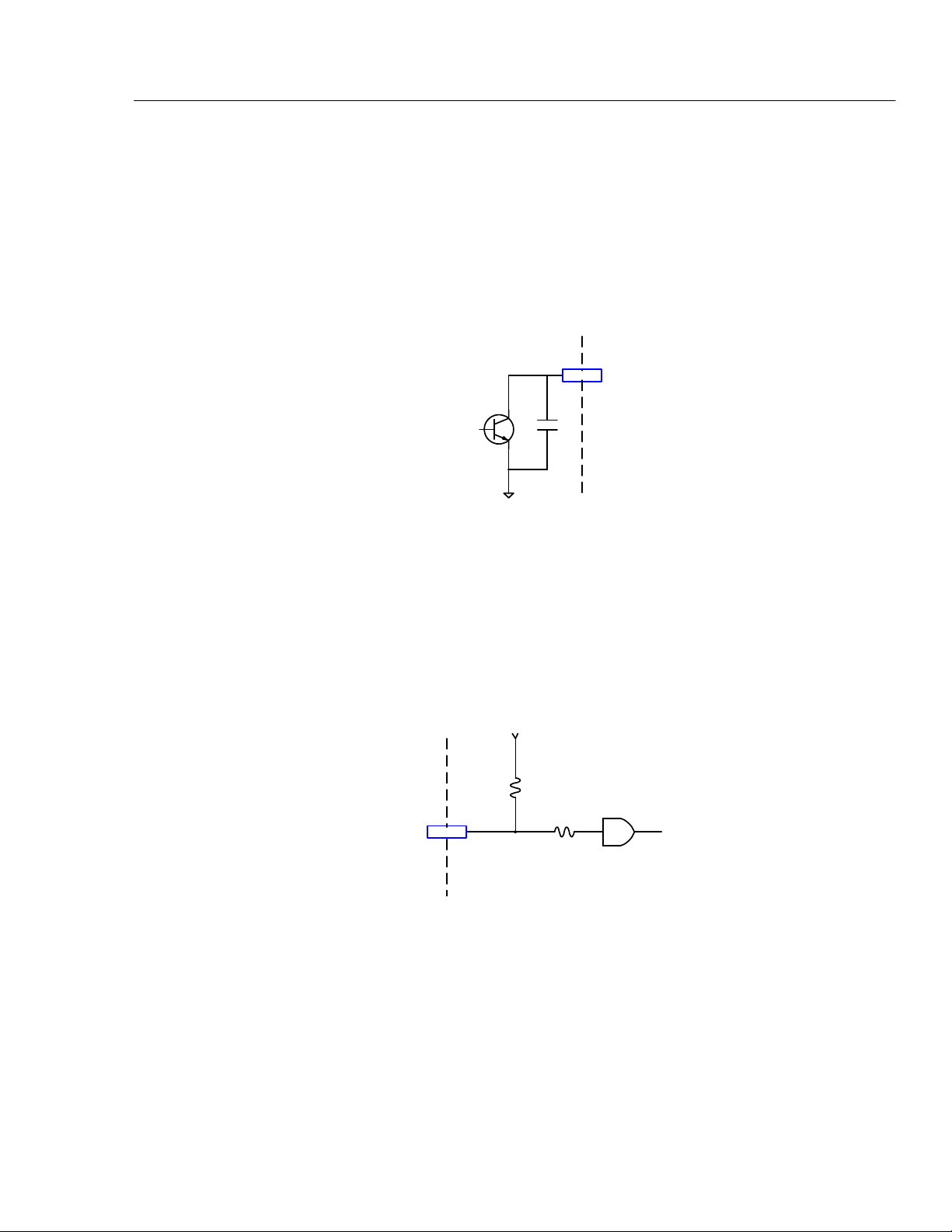

Module OK

An open collector signal with 2.0 mA current sinking capability is provided. The signal is in the low

impedance (less than 250Ω) state whenever V

is no input voltage, and in the open (more than 100 kΩ) state whenever V

The Module OK pin has an internal 0.1

μF capacitor connected to the output voltage return (GND).

OUT is off by more than ± 11% from its nominal value or there

OUT is within its specified range.

P-1 MOD_OK

Isink < 2mA

0.1u

Figure 3. Module OK Circuitry

Output Enable — OUTEN

The module will accept an open collector signal consistent with TTL DC specifications for controlling the

output voltage. The module is enabled when this signal is above 2.0V and disabled when this signal is less

than 0.8V. The module does not source this signal with more than 0.6 mA. It is referenced to output voltage

return (G

ND).

+5V

10k

P-2OUTEN

820

Figure 4. Output Enable Circuitry

LINEAGE POWER 7

Page 8

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

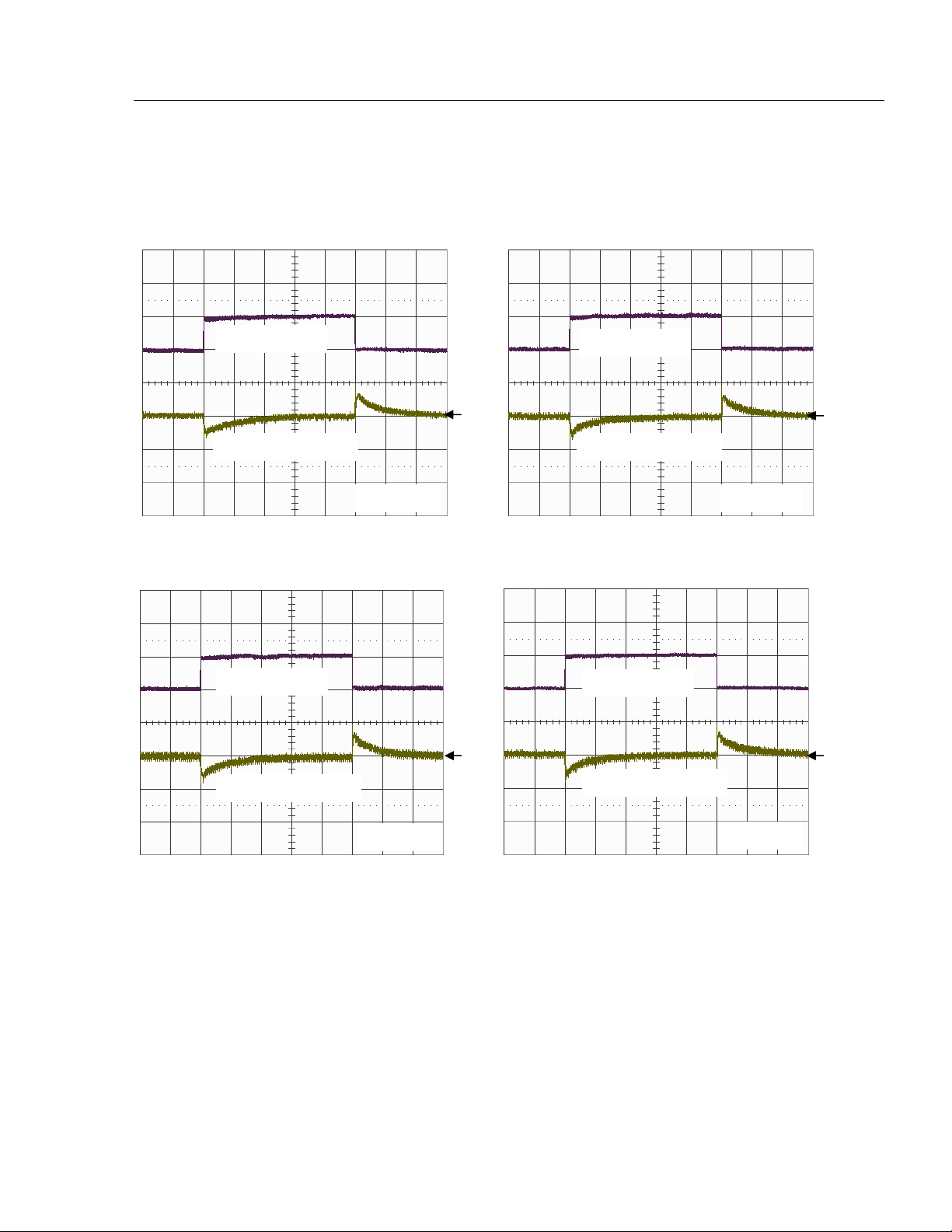

Transient Response

The output voltage measured at the converter output pins on the system board is within the transient range

shown in Table 3. The transient response is measured with DC – 200 MHz frequency band width, and at

ambient temperatures between 0 °C and 70 °C.

Typical transient response and noise waveforms are shown in Figures 5 – 16.

IOUT, 16 A/div

0.8 V

VOUT, 100 mV/div

20 μs/div 20 μs/div

IOUT, 16 A/div

VOUT, 100 mV/div

Figure 5. Transient Response: VIN = 12V, Figure 6. Transient Response: VIN = 12V,

OUT = 0.8V, ΔI = 16A, dI/dt = 600 A/μs VOUT = 1.3V, ΔI = 16A, dI/dt = 600 A/μs

V

IOUT, 16 A/div

1.8 V

VOUT, 100 mV/div

IOUT, 16 A/div

VOUT, 100 mV/div

1.3 V

2.0 V

20 μs/div

20 μs/div

Figure 7. Transient Response: VIN = 12V, Figure 8. Transient Response: VIN = 12V,

OUT = 1.8V, ΔI = 16A, dI/dt = 600 A/μs VOUT = 2.0V, ΔI = 16A, dI/dt = 600 A/μs

V

LINEAGE POWER 8

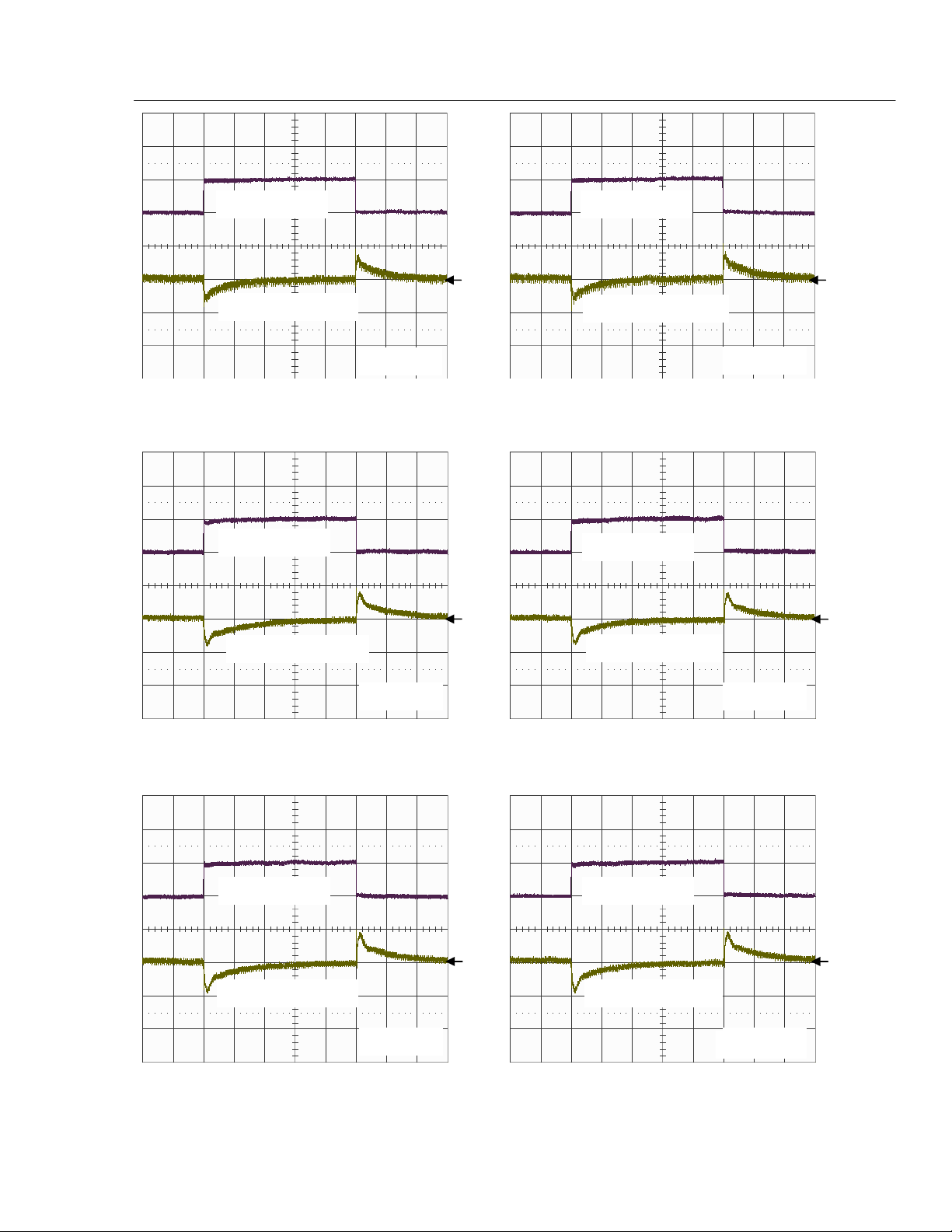

Page 9

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

IOUT, 16 A/div IOUT, 16 A/div

2.5 V

VOUT, 100 mV/div

20 μs/div

VOUT, 100 mV/div

20 μs/div

Figure 9. Transient Response: V

OUT = 2.5V, ΔI =16A, dI/dt = 600 A/μs VOUT = 3.3V, ΔI = 16A, dI/dt = 600 A/μs

V

IN = 12V, Figure 10. Transient Response: VIN = 12V,

IOUT, 16 A/div

0.8 V

VOUT, 100 mV/div

20 μs/div 20 μs/div

IOUT, 16 A/div

VOUT, 100 mV/div

Figure 11. Transient Response: V

OUT = 0.8V, ΔI = 16A, dI/dt = 600 A/μs VOUT = 1.3V, ΔI = 16A, dI/dt = 600 A/μs

V

IN = 5V, Figure 12. Transient Response: VIN = 5V,

3.3 V

1.3 V

IOUT, 16 A/div IOUT, 16 A/div

1.8 V 2.0 V

VOUT, 100 mV/div VOUT, 100 mV/div

20 μs/div 20 μs/div

20 μs/div

Figure 13. Transient Response: V

OUT = 1.8V, ΔI = 16A, dI/dt = 600 A/μs VOUT = 2.0V, ΔI = 16A, dI/dt = 600 A/μs

V

LINEAGE POWER 9

IN = 5V, Figure 14. Transient Response: VIN = 5V,

Page 10

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

IOUT, 16 A/div IOUT, 16 A/div

2.5 V 3.3 V

VOUT, 100 mV/div VOUT, 100 mV/div

Data Sheet

March 31, 2010

20 μs/div 20 μs/div

Figure 15. Transient Response: V

OUT = 2.5V, ΔI = 16A, dI/dt = 600 A/μs VOUT = 3.3V, ΔI = 16A, dI/dt = 600 A/μs

V

IN = 5V, Figure 16. Transient Response: VIN =5V,

Output Voltage Ripple and Noise

Output voltage ripple and noise are defined as periodic or random signals measured at the output pins on

the system board with DC – 200 MHz frequency bandwidth and constant load. Figures 17 – 20 represent

output voltage ripple and noise at characteristic input and output voltages, measured with 200 MHz

bandwidth and 16A constant current load.

VOUT, 10 mV/div VOUT, 10 mV/div

0.5 μs/div 0.5 μs/div

Figure 17. Output Voltage Ripple and Noise: Figure 18. Output Voltage Ripple and Noise:

IN = 12V, VOUT = 0.8V, 16A static load VIN = 12V, VOUT = 3.3V, 16A static load

V

LINEAGE POWER 10

Page 11

Data Sheet

March 31, 2010

VOUT, 10 mV/div VOUT, 10 mV/div

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

0.5 μs/div 0.5 μs/div

Figure 19. Output Voltage Ripple and Noise: Figure 20. Output Voltage Ripple and Noise:

IN = 5V, VOUT = 0.8V, 16A static load VIN = 5V, VOUT = 3.3V, 16A static load

V

Input Voltage Ripple and Noise

Power

Source

1000 μF Electrolytic Cap.

Trace Inductance

1 μF Ceramic Cap.

Zephyr M odule

Load

Figure 21. Test Circuit for Input Voltage Ripple and Noise Measurement

Figures 22 – 25 represent input voltage ripple and noise, measured at the input pins of the system board at

characteristic input and output voltages with 200 MHz bandwidth, under 16A constant current load. The

measurement was made using 50Ω coax cable terminated with 50Ω at the oscilloscope. The input

capacitance consists of two Nichicon PL electrolytic capacitors, 1000 μF/16V each. The printed wiring board

(PWB) trace inductance is 2.1 nH. A ceramic capacitor of 1 μF is attached to the measurement point (input

pins on the system board, see Figure 21).

LINEAGE POWER 11

Page 12

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

VIN, 100 mV/div VIN, 100 mV/div

Data Sheet

March 31, 2010

0.5 μs/div

0.5 μs/div

Figure 22. Input Voltage Ripple and Noise: Figure 23. Input Voltage Ripple and Noise:

IN = 12V, VOUT = 0.8V, 16A static load VIN = 12V, VOUT = 3.3V, 16A static load

V

VIN, 100 mV/div VIN, 100 mV/div

0.5 μs/div 0.5 μs/div

Figure 24. Input Voltage Ripple and Noise: Figure 25. Input Voltage Ripple and Noise:

IN = 5V, VOUT = 0.8V, 16A static load VIN = 5V, VOUT = 3.3V, 16A static load

V

LINEAGE POWER 12

Page 13

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Thermal Ratings

Figures 26 – 37 show thermal derating curves for 12V and 5V input voltages, at different output voltages,

and with different ambient temperatures and airflow.

THERMAL DERATING 12 VIN / 0.8 VOUT

25

24

23

22

21

20

Output Current [A]

0 LFM

19

100 LFM

18

200 LFM

17

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 26. Thermal Derating: VIN = 12V, VOUT = 0.8V Figure 27. Thermal Derating: VIN = 12V, VOUT = 1.3V Figure 26. Thermal Derating: VIN = 12V, VOUT = 0.8V Figure 27. Thermal Derating: VIN = 12V, VOUT = 1.3V

THERMAL DERATING 12 VIN / 1.8 VOUT

22

21

20

19

18

Output Current [A]

0 LFM

17

100 LFM

16

200 LFM

15

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 28. Thermal Derating: VIN = 12V, VOUT = 1.8V Figure 29. Thermal Derating: VIN = 12V, VOUT = 2.0V Figure 28. Thermal Derating: VIN = 12V, VOUT = 1.8V Figure 29. Thermal Derating: VIN = 12V, VOUT = 2.0V

THERMAL DERATING 12 VIN / 2.5 VOUT

20

19

18

17

16

15

Output Current [A]

14

0 LFM

100 LFM

200 LFM

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 30. Thermal Derating: VIN = 12V, VOUT = 2.5V Figure 31. Thermal Derating: VIN = 12V, VOUT = 3.3V Figure 30. Thermal Derating: VIN = 12V, VOUT = 2.5V Figure 31. Thermal Derating: VIN = 12V, VOUT = 3.3V

THERMAL DERATING 12 VIN / 1.3 VOUT

23

22

21

20

19

18

Output Current [A]

17

16

0 LFM

100 LFM

200 LFM

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

THERMAL DERATING 12 VIN / 2.0 VOUT

22

21

20

19

18

0 LFM

17

Output Current [A]

100 LFM

16

200 LFM

15

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

THERMAL DERATING 12 VIN / 3.3 VOUT

18.5

17.5

16.5

15.5

14.5

Output Current [A]

13.5

12.5

0 LFM

100 LFM

200 LFM

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

LINEAGE POWER 13

Page 14

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

THERMAL DERATING 5 VIN / 0.8 VOUT

THERMAL DERATING 5 VIN / 1.3 VOUT

27

26

25

24

23

Output Current [A]

0 LFM

22

100 LFM

21

200 LFM

20

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

25

24

23

22

21

0 LFM

20

100 LFM

Output Current [A]

19

200 LFM

300 LFM

18

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 32. Thermal Derating: VIN = 5V, VOUT = 0.8V Figure 33. Thermal Derating: VIN = 5V, VOUT = 1.3V

THERMAL DERATING 5 VIN / 1.8 VOUT

THERMAL DERATING 5 VIN / 2.0 VOUT

22

21

20

19

18

17

Output Current [A]

16

0 LFM

100 LFM

200 LFM

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

22

21

20

19

0 LFM

18

100 LFM

17

Output Current [A]

200 LFM

16

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 34. Thermal Derating: VIN = 5V, VOUT = 1.8V Figure 35. Thermal Derating: VIN = 5V, VOUT = 2.0V

THERMAL DERATING 5 VIN / 2.5 VOUT

THERMAL DERATING 5 VIN / 3.3 VOUT

20

19.5

19

18.5

18

17.5

17

16.5

16

Output Current [A]

15.5

15

0 LFM

100 LFM

200 LFM

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

18.5

18

17.5

17

16.5

16

15.5

0 LFM

15

100 LFM

14.5

Output Current [A]

13.5

200 LFM

14

300 LFM

400 LFM

25 30 40 50 60 70

Ambient Temperature [°C]

Figure 36. Thermal Derating: VIN = 5V, VOUT = 2.5V Figure 37. Thermal Derating: VIN = 5V, VOUT = 3.3V

LINEAGE POWER 14

Page 15

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Efficiency

Figures 38 – 41 show typical efficiency charts for 12V and 5V input voltages, at different output voltages, and

with different ambient temperatures and airflow.

90

85

80

75

70

65

60

Total Efficiency [%]

55

50

2 4 6 8 10 12 14 16 18 20

0.8 Vout

1.3 Vout

1.5 Vout

1.8 Vout

2 Vout

2.5 Vout

3.3 Vout

Output Current [A]

90

85

80

75

70

65

60

Total Efficiency [%]

55

50

2 4 6 8 10 12 14 16 18

0.8 Vout

1.3 Vout

1.5 Vout

1.8 Vout

2 Vout

2.5 Vout

3.3 Vout

Output Current [A]

Figure 38. Efficiency: VIN = 12V, 25 °C, no airflow Figure 39. Efficiency: VIN = 12V, 60 °C, 300 LFM

95

90

85

80

75

70

Total Efficiency [%]

65

60

2468101214161820

0.8 Vout

1.3 Vout

1.5 Vout

1.8 Vout

2 Vout

2.5 Vout

3.3 Vout

Output Current [A]

95

90

85

80

75

70

Total Efficiency [%]

65

60

2 4 6 8 101214161820

0.8 Vout

1.3 Vout

1.5 Vout

1.8 Vout

2 Vout

2.5 Vout

3.3 Vout

Output Current [A]

Figure 40. Efficiency: V

IN = 5V, 25 °C, no airflow Figure 41. Efficiency: VIN = 5V, 60 °C, 300 LFM

LINEAGE POWER 15

Page 16

Zephyr Non-Isolated SMT DC-DC Power Module:

−

⋅

(

+

⋅

⋅

+

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

Output control

There are two ways to set the output voltage of the Zephyr:

1. A resistor calculated from the following equation can be inserted between V

pin.

OUT

V

V

−

3.3

or

R

=

ADJ

44.33.3

=

For example, to get the output voltage of 2.5V, R

should be attached between these two pins.

Shorting and opening of these pins will give the output voltage of 0.844V and 3.30V, respectively. For the

output voltage beyond this range (up to ± %5), the use of T

The additional output voltage error due to the tolerance R

%

This error should be added to the error given in the “Output Voltage Set Point” section of Table 3 to get

the total DC output voltage error.

2. An external voltage V

voltage. The relation between V

V [%] (3)

V

OUT

⎛

⎜

⎜

=±

_

RADJOUT

EXT [V] can be applied between VADJUST + pin and VADJUST − pin to control output

V

OUT

44.13

⎜

44.3

⎜

⎜

⎝

+

OUT and VEXT is described as follows.

=

R

44.13

+

+

R

ADJ

R

ADJ

1035.11

35.1144.13

OUT

⋅

V

R

ADJ

EXT

[kΩ] (1)

)

ADJ

[V] (2)

ADJ = 27.8 kΩ, the closest standard resistor of 27.7 kΩ

RIM pin is recommended.

ADJ_TOL [%] of RADJ [kΩ] is described as follows.

R

⎛

⎜

144.3

R

ADJ

R

ADJ

[V] (4)

±⋅+

⎜

⎝

⎛

⎜

⎜

⎝

100

R

144.13

±⋅+

100

ADJUST + pin and VADJUST −

⎞

⎞

_

TOLADJ

_

TOLADJ

⎟

⎟

⎟

⎟

⎠

⎞

⎟

⎟

⎠

1001

⋅

−

⎟

⎟

⎟

⎠

44.13

Therefore, in order to set the output voltage to 2.5V, V

specified external voltage (such as DAC) is applied between V

voltage identification code with each corresponding voltage V

resulting output voltages of the module V

ADJUST- pins are open circuit, VOUT = 3.3V (default value).

and V

OUT calculated from the equation (4). Note that if the VADJUST+

EXT = 2.23V. The equation (4) is valid even when

ADJUST+ and VADJUST −. Table 5 shows

EXT supplied from standard DAC, as well as

LINEAGE POWER 16

Page 17

Data Sheet

March 31, 2010

Table 5. Voltage Identification Code with Output Voltage of Module

The additional output voltage error due to the tolerance V

This error should be added to the error given in the “Output Voltage Set Point” section of Table 3, using

ADJ = 0 kΩ, to get the total DC output voltage error.

R

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

VID Pins

EXT [ V ]

VID4 VID3 VID2 VID1 VID0

0 1 1 1 1 1.30 1.811

0 1 1 1 0 1.35 1.849

0 1 1 0 1 1.40 1.886

0 1 1 0 0 1.45 1.923

0 1 0 1 1 1.50 1.961

0 1 0 1 0 1.55 1.998

0 1 0 0 1 1.60 2.035

0 1 0 0 0 1.65 2.072

0 0 1 1 1 1.70 2.110

0 0 1 1 0 1.75 2.147

0 0 1 0 1 1.80 2.184

0 0 1 0 0 1.85 2.221

0 0 0 1 1 1.90 2.258

0 0 0 1 0 1.95 2.295

0 0 0 0 1 2.00 2.333

0 0 0 0 0 2.05 2.370

1 1 1 1 1 No Output 3.300

1 1 1 1 0 2.1 2.407

1 1 1 0 1 2.2 2.481

1 1 1 0 0 2.3 2.556

1 1 0 1 1 2.4 2.630

1 1 0 1 0 2.5 2.705

1 1 0 0 1 2.6 2.779

1 1 0 0 0 2.7 2.853

1 0 1 1 1 2.8 2.928

1 0 1 1 0 2.9 3.002

1 0 1 0 1 3.0 3.077

1 0 1 0 0 3.1 3.151

1 0 0 1 1 3.2 3.225

1 0 0 1 0 3.3 3.300

1 0 0 0 1 3.4 3.374

1 0 0 0 0 3.5 3.449

⎛

⎛

⎜

⎜

⎜

⎜

⎝

%

V

=±

_

VEXTOUT

⎜

⎜

V

V

⎛

⎜

V

EXT

()

±⋅⋅+

11035.11

⎜

⎝

⋅+

1035.11

V

EXT

⎜

⎝

VOUT [ V ]

EXT_TOL [%] of VEXT is described as follows:

⎞

_

TOLEXT

⎟

100

⎟

⎠

0 = Closed

(Connected to Ground)

1 = Open

⎞

⎞

⎟

⎟

⎟

⎟

⎠

−

⎟

[%] (5)

1001

⋅

⎟

⎟

⎠

LINEAGE POWER 17

Page 18

Zephyr Non-Isolated SMT DC-DC Power Module:

⋅−⋅

⋅−⋅

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

Trim

RIM pin is provided to margin high/low the output voltage by certain percentages independent of the output

T

voltage. The equation to margin low by connecting a resistor, R

NOMOUT

VV

R

LOW

=

621654

OUTNOM

VV

⋅−⋅

22

To margin low by 2.5%, R

LOW = 332.0 kΩ. Shorting TRIM pin to OUTSENSE + pin provides the maximum

negative adjustment of 5.0%.

The equation to margin high by connecting a resistor, R

HIGH, from TRIM pin to OUTSENSE – pin is:

R

HIGH

=

588621

NOMOUT

VV

⋅−⋅

22

OUTNOM

VV

To margin high by 2.5%, R

HIGH = 365.0 kΩ. Shorting TRIM pin to OUTSENSE – pin provides the maximum

positive adjustment of 5.0%.

RIM is not connected to OUTSENSE + or OUTSENSE −, VOUT = VNOM.

If T

LOW, from TRIM pin to OUTSENSE + pin is:

[kΩ] (6)

[kΩ] (7)

LINEAGE POWER 18

Page 19

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Output Overvoltage Protection

Protection level: The converter provides overvoltage protection by latching off when the output

voltage rises beyond V

voltage. Care must be taken because the voltage increase due to T

contribute to V

Overvoltage protection circuit protects against shorted feedback/sense connections.

Voltage sequencing: No allowed variation of input voltages or output current or control signals will falsely

trigger an OVP event or damage the module.

TRIP.

TRIP. VTRIP is between 112% and 120% of the nominal output

RIM can also

Reset After Shutdown

If the module goes into an overvoltage shutdown state, the module cannot return to normal operation mode

even after the fault has been removed. Input voltage of the module must be reset to restart the module.

Output Overcurrent Protection

Overcurrent protection is provided to protect the module from damage caused by excessive output current.

Current overload is from 5% to 60% over the maximum output current values given in the thermal derating

curves (at 25 °C, 400 LFM, see thermal derating curves Figure 26 – 37). The module will shut down until the

overload is removed, and then will automatically restart.

Overtemperature Protection

The module is protected against failure from overtemperature conditions created by high ambient

temperature or by low or no airflow condition. It will either operate properly within the requirements or shut

down (nonlatching). The module will function as specified under overtemperature conditions until disabled

(nonlatching) by the protection circuit.

LINEAGE POWER 19

Page 20

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

Remote Sense

The remote sense inputs (OUTSENSE + and OUTSENSE -) should be connected to the load, using separate

sense traces on the system board as shown in Figure 42. Remote sense can compensate for the total output

voltage drop by up to the amount indicated in Table 6. These values are calculated to prevent unwanted

overvoltage protection by the module under the worst possible voltage error listed in Table 3 (including

transient error). In the event of an open remote sense lines, the module will maintain local sense regulation

through 100Ω internal resistors connected to the V

OUT pins, with an additional + 0.3% DC error in VOUT.

Table 6. Maximum Remote Sense Compensation

V

OUT [V] VMAXCOMP [V]

0.8 0.02

1.3 0.10

1.5 0.12

1.8 0.16

2.0 0.19

2.5 0.26

3.3 0.38

VIN +

OUTSENSE +

OUT+

V

RTRACE +

Zephyr Module

Load

TRACE -

IN -

V

UTSENSE -

O

V

OUT-

R

Figure 42. Remote Sense Connection to Load

LINEAGE POWER 20

Page 21

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Environmental

Design including materials is consistent with environmental stan dards in Table 7.

Table 7. Environmental and Reliability Specifications

Temperature

Humidity

Ambient 0 °C to 70 °C at zero to

400 LFM, full load (see Thermal Ratings)

with a maximum rate of change of

5 °C/10 minutes minimum but no more

than 10 °C/hour

To 85% relative humidity To 95% relative humidity

Operating Nonoperating

Ambient – 40 °C to 70 °C with a maximum rate

of change of 20 °C/hour (Thermal shock of

– 40 °C to 70 °C, 10 cycles; transfer time shall

not exceed 5 minutes; duration of exposure to

temperature extremes shall be 20 minutes)

(noncondensing)

Altitude 0 to 10,000 feet 0 to 50,000 feet

Reliability

Calculated MTBF of 5 million hours assuming continuous operation at 55 °C, at 200 LFM

airflow nominal input voltage and 80% maximum load

EMI Complies with the limits of FCC Class B and VDE 243 Level B for radiated emissions

Electrostatic

discharge

15 KV initialization level per specification

number EN61000-3-2. The direct ESD

event shall cause no out-of-regulation

conditions.

(Includes overshoot,

25 KV initialization level

undershoot, and nuisance trips of the

overvoltage protection, overcurrent

protection, or remote shutdown circuitry)

LINEAGE POWER 21

Page 22

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Module Pin-out

The pin-out of Zephyr modules is indicated in

Figure 43 and Table 8.

Figure 43. Top View of Board

(Pins are located on the bottom side)

Table 8. Pin-out of Zephyr Module

1 MODULE OK

2 OUTEN

3 OUTSENSE 4 OUTSENSE+

5 VOUT +

6 VOUT -

7 VOUT +

8 VOUT -

9 VOUT +

10 VOUT 11 VOUT +

12 VOUT 13 VADJUST +

14 VADJUST 15 TRIM

16 RESERVED

17 VIN +

18 VIN +

19 VIN +

20 VIN 21 VIN 22 VIN -

Data Sheet

March 31, 2010

LINEAGE POWER 22

Page 23

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Mechanical Specifications

Mechanical specifications (Table 9) and module outline (Figure 44) are illustrated below. The pin layout and

the recommended pad size are shown in Figure 45 and Figure 46.

Table 9. Mechanical Specifications

Parameter Symbol Min Typical Max Unit

Physical Size L

W

H

—

—

—

37.08 (1.460)

52.32 (2.060)

5.66 (0.223)

37.21 (1.465)

52.45 (2.065)

6.12 (0.241)

Weight — — — 15.5 (0.55) grams (oz.)

0.223 [5.66] NOM.

0.241 [6.12] MAX.

mm (in.)

mm (in.)

mm (in.)

DATE CODE

ZEPHYR

LOT NUM.

SERIAL NUM.

L

T

u

e

c

c

e

h

n

n

t

o

lo

g

ie

s

Z

E

P

H

Y

R

Z

P

H

A

M

2

P22

P21

P20

P19

P18

P17

P1

P16 P15

P2

P5

P3

P4

P6

P7

P8

P9

P10

P11

P13P1 4

P12

Figure 44. Outline of Zephyr Module

LINEAGE POWER 23

Page 24

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

P1 P2

P22

P21

P20

P19

P18

P17

P16 P15

Data Sheet

March 31, 2010

P5

P4P3

P6

P7

P8

P9

P10

P11

P13P1 4

P12

Figure 45. Pin Layout of Zephyr Module

Recom mended PAD Size and Layout

P5

P6

P7

P8

P9

P10

P11

P12

P4 P3

P13 P14

P1P2

P22

P21

P20

P19

P18

P17

P16P1 5

Figure 46. Recommended Pad Size and Layout

LINEAGE POWER 24

Page 25

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Fusing Considerations

A 10A fuse is required for input voltages of 10.6V and higher. It is not required for input voltages below

10.6V. The following fuse or equivalent is recommended:

2

Characteristic Fuse Parameter Littlefuse R451010 Nano

SMF

Fuse Current Rating 10A 10A

Voltage Rating 32 minimum 125

I2t 100 a2sec maximum 26.4 a2sec

DC Interruption Rating

(must be DC rated, not just

35A minimum 35A

AC rated)

UL Recognized Mandatory Yes

The fuse should be located in the input voltage bus side of the input capacitor to minimize inductance

between the input capacitor and the Zephyr Power Module. The fuse shoul d not be located in proximity to

any object which might abnormally ‘preheat’ the fuse, causing undesired melting.

The Zephyr Power Module begins regulating with an input voltage above approximately 4V and will draw

more input current at lower voltages. If the input voltage rise times and fall times are too slow, shorter fuse

life and nuisance opening may occur. To minimize such fuse input current stresses, the module should be

enabled after input voltage is applied and disabled before input voltage is removed, by using the OUTEN pi n.

Fuse, 10A

Minimize this

distance and

inductance

V

IN+

Zephyr Module

DC

Input

Bus

To other

modules

or circuits

Input

Capacitor

V

IN -

OUTEN

Figure 47. Fuse Placement

LINEAGE POWER 25

Page 26

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

Surface Mount Information

Pick and Place

The Zephyr SMT modules use an open frame construction and are designed for a fully automated assembly

process. The modules are fitted with a label designed to provide a large surface area for pick and place

operations. The label meets all the requirements for surface mount processing, as well as safety standards,

and is able to withstand reflow temperatures of up to 300

as product code, serial number and the location of manufacture.

Nozzle Recommendations

The module weight has been kept to a minimum by using open frame construction. Even so, these modules

have a relatively large mass when compared to conventional SMT components. Variables such as nozzle

size, tip style, vacuum pressure and placement speed should be considered to optimize this process. The

minimum recommended nozzle diameter for reliable operation is 6mm. The maximum nozzle outer diameter,

which will safely fit within the allowable component spacing, is 9 mm. Oblong or oval nozzles up to 11 x 9

mm may also be used within the space available.

Tin Lead Soldering

The Zephyr SMT power modules are lead free modules and can be soldered either in a lead-free solder

process or in a conventional Tin/Lead (Sn/Pb) process. It is recommended that the customer review data

sheets in order to customize the solder reflow profile for each application board assembly. The following

instructions must be observed when soldering these units. Failure to observe these instructions may result

in the failure of or cause damage to the modules, and can adversely affect long-term reliability.

In a conventional Tin/Lead (Sn/Pb) solder process peak reflow temperatures are limited to less than 235

Typically, the eutectic solder melts at 183

o

C, wets the land, and subsequently wicks the device connection.

Sufficient time must be allowed to fuse the plating on the connection to ensure a reliable solder joint. There

are several types of SMT reflow technologies currently used in the industry. These surface mount power

modules can be reliably soldered using natural forced convection, IR (radiant infrared), or a combination of

convection/IR. For reliable soldering the solder reflow profile should be established by accurately measuring

the modules CP connector temperatures.

Lead Free Soldering

The –Z version Austin SuperLynx II SMT modules are lead-free (Pb-free) and RoHS compliant and are both

forward and backward compatible in a Pb-free and a SnPb soldering process. Failure to observe the

instructions below may result in the failure of or cause damage to the modules and can adversely affect longterm reliability.

o

C. The label also carries product information such

o

C.

LINEAGE POWER 26

Page 27

Data Sheet

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

300

250

200

150

10 0

REFLOW TEMP (°C)

50

0

Peak Temp 235oC

Hea t zone

oCs-1

max 4

Soak zone

30-240s

Preheat zone

oCs-1

max 4

REFLOW TIME (S)

T

lim

205

Cooling

zone

1- 4

above

o

C

oCs-1

Figure 48. Reflow Profile for Tin/Lead (Sn/Pb) process

240

235

230

225

220

215

210

MAX TEMP SOLDER (°C)

205

200

0 102030405060

Figure 49. Time Limit Curve Above 205

o

C for Tin/Lead (Sn/Pb) process

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. C (Moisture/Reflow Sensitivity Classification for

Nonhermetic Solid State Surface Mount Devices) for both Pb-free solder profiles and MSL classification

procedures. This standard provides a recommended forced-air-convection reflow profile based on the

volume and thickness of the package. The suggested Pb-free solder paste is Sn/Ag/Cu (SAC). The

recommended linear reflow profile using Sn/Ag/Cu solder is shown in Fig. 50.

300

Per J-STD-020 Rev. C

250

200

150

100

Reflow Temp (°C)

50

0

Heating Zone

1°C/Se c o nd

Peak Temp 260°C

* Min. Time Above 235°C

15 Seco nds

*Time Above 217°C

60 Seco nds

Reflow Time (Seconds)

Cooling

Zone

Figure 50. Recommended linear reflow profile using Sn/Ag/Cu solder.

LINEAGE POWER 27

Page 28

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Data Sheet

March 31, 2010

MSL Rating

The Zephyr SMT modules have a MSL rating of 1.

Storage and Handling

The recommended storage environment and handling procedures for moisture-sensitive surface mount

packages is detailed in J-STD-033 Rev. A (Handling, Packing, Shipping and Use of Moisture/Reflo w

Sensitive Surface Mount Devices). Moisture barrier bags (MBB) with desiccant are required for MSL ratings

of 2 or greater. These sealed packages should not be broken until time of use. Once the original package is

broken, the floor life of the product at conditions of ≤ 30°C and 60% relative humidity varies according to the

MSL rating (see J-STD-033A). The shelf life for dry packed SMT packages will be a minimum of 12 months

from the bag seal date, when stored at the following conditions: < 40° C, < 90% relative humidity.

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit-board assembly process prior to electrical board testing. The

result of inadequate cleaning and drying can affect both the reliability of a power module and the testability of

the finished circuit-board assembly. For guidance on appropri ate soldering, cleaning and drying procedures,

refer to Board Mounted Power Modules: Soldering and Cleaning Application Not e (AN0 4-001).

LINEAGE POWER 28

Page 29

Data Sheet

a

©

March 31, 2010

Zephyr Non-Isolated SMT DC-DC Power Module:

0.8V to 3.5V @ 20A Output, 5V to 12V Input

Ordering Information

Please contact your Lineage Power Account Manager or Field Application engineer for pricing and

availability.

Table 10. Coding Scheme for Ordering

Product Description Comcode Expanded Product Description

5 V

IN to12 VIN; 0.8 VOUT to 3.3 VOUT; 20 A IOUT;

Zephyr 5/12 V 0.8/3.5 V 20A J 108601220

ZRA020A0F-VZ 108995148

-Z version refers to RoHS-compliant code.

Zephyr Power Modules are shipped in packages of four JEDEC tra y s with fifteen modules per tray.

World Wide Headquarters

Lineage Power Corporation

601 Shiloh Road, Plano, TX 75074, USA

+1-800-526-7819

(Outside U.S.A.: +1-972-244-9428)

www.lineagepower.com

e-mail: techsupport1@lineagepower.com

Lineage Power reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or

pplication. No rights under any patent accompany the sale of any such product(s) or information.

Lineage Power DC-DC products are protected under various patents. Information on these patents is available at www.lineagepower.com/patents.

2009 Lineage Power Corporation, (Plano, Texas) All International Rights Reserved.

LINEAGE POWER 29

600 A/μsec transient rate; surface mount LISMC

connector; JEDEC tray package

IN to12 VIN; 0.8 VOUT to 3.3 VOUT; 20 A IOUT;

5 V

600 A/μsec transient rate; surface mount LISMC

connector; JEDEC tray package

RoHS Compliant

Asia-Pacific Headquarters

Tel: +65 6593 7211

Europe, Middle-East and Africa Headquarters

Tel: +49 898 780 672 80

India Headquarters

Tel: +91 80 28411633

Document No: DS03-076 ver 1.4

PDF name: zephyr.pdf

Loading...

Loading...