Page 1

GE ZENITH™ SERIES MDU

MONITORED DISTRIBUTION UNIT

50KVA – 750KVA

OWNER’S MANUAL

(01/2013)

Page 2

Table of Contents

Table of Contents

TABLE OF CONTENTS.........................................................................................................................................................2

1.0 INTRODUCTION............................................................................................................................................................4

2.0 RECEIVING YOUR MDU ................................................................................................................................................5

2.1. RECEIVING AND UNPACKING INSTRUCTIONS........................................................................................................................5

2.2. INSPECTION PROCEDURES ................................................................................................................................................6

3.0 INSTALLATION PROCEDURES .....................................................................................................................................7

3.1. EQUIPMENT PLACEMENT...................................................................................................................................................7

3.1.1. Clearances..........................................................................................................................................................7

3.1.2. Raised Floor........................................................................................................................................................8

3.1.3. Cabling ...............................................................................................................................................................8

3.1.4. Cabinet Leveling.................................................................................................................................................8

3.1.5. Raised floor loading...........................................................................................................................................8

3.1.6. Raised floor cable entry .....................................................................................................................................8

3.2. SYSTEM GROUNDING RECOMMENDATIONS .........................................................................................................................9

3.2.1. Power System Grounding..................................................................................................................................9

3.2.2. Grounding Conductors ......................................................................................................................................9

3.3. INTERNAL WIRE SIZING..................................................................................................................................................12

3.4. HIGH FREQUENCY (RF) GROUNDING (COMPUTER ROOMS) ...................................................................................................13

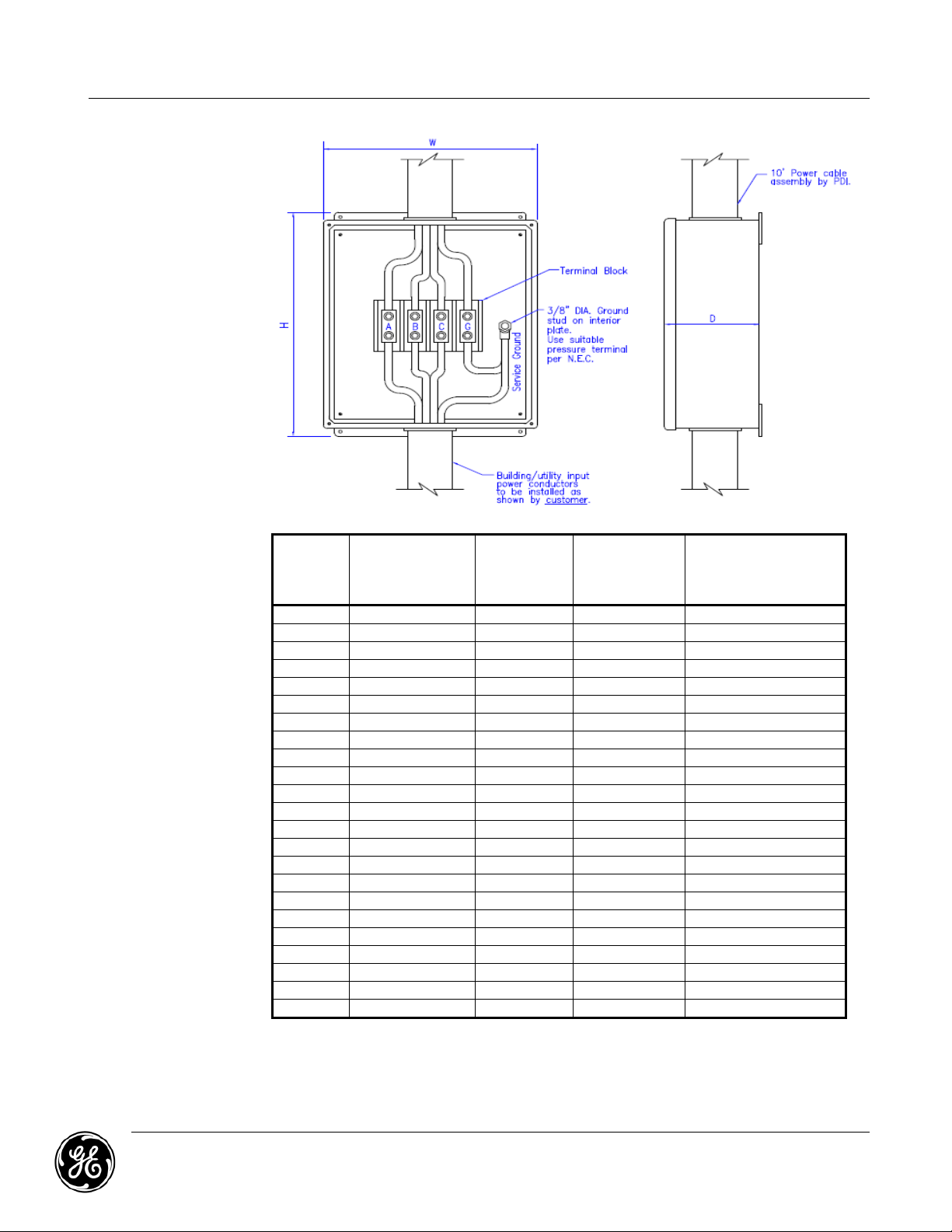

3.5. INPUT POWER JUNCTION BOX AND CABLE ASSEMBLY (OPTIONAL)........................................................................................13

3.6. TORQUE SPECIFICATIONS ...............................................................................................................................................14

3.6.1. Structural Fasteners.........................................................................................................................................14

3.6.2. MCCB’s, MCSW’s, Contactors, and Other Electrical Components ..................................................................14

3.7. TORQUE VALUE QUICK REFERENCE..................................................................................................................................14

3.7.1. Standard Circuit Breakers (Mains & Sub-feeds) ..............................................................................................14

3.7.2. Transformer Lugs.............................................................................................................................................15

3.7.3. Fasteners..........................................................................................................................................................15

3.7.4. Terminal Blocks and Distribution Breakers.....................................................................................................15

3.7.5. Junction Box and Power Cable Sizing Chart ..................................................................................................16

3.7.6. System Power-Up Procedure ..........................................................................................................................17

3.8. CUSTOMER CONNECTIONS: LOW VOLTAGE INTERFACE BOARD.............................................................................................18

3.8.1. GE Zenith Series Monitoring Package .............................................................................................................18

3.8.2. M4 Monitoring Package...................................................................................................................................19

3.8.3. Optional Low Voltage Junction Box................................................................................................................21

3.8.4. Output Distribution Cable(s) Installation .........................................................................................................21

4.0 SYSTEM MONITORING ...............................................................................................................................................23

4.1. GE ZENITH SERIES MDU MONITOR .................................................................................................................................23

4.1.1. LCD Monitor Layout .........................................................................................................................................23

4.1.2. GE Zenith Series Monitor Features ..................................................................................................................24

4.1.3. Control Functions.............................................................................................................................................26

4.1.4. Monitor Screens ...............................................................................................................................................27

4.1.5. Contractor Connections...................................................................................................................................30

4.1.6. Communications..............................................................................................................................................30

5.0 BRANCH CIRCUIT MONITORING SYSTEM (BCMS)....................................................................................................33

5.1. BCMS COMPONENTS....................................................................................................................................................33

5.1.1. Acquisition Module...........................................................................................................................................33

5.1.2. Current Transformers (Panel board CT’s) ........................................................................................................34

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 2

Page 3

Table of Contents

5.1.3. Current Transformers (CT’s) .............................................................................................................................34

5.2. BCMS LOCAL MONITORING VIA GE ZENITH SERIES MDU MONITOR ....................................................................................35

5.2.1. BCMS Device Setup..........................................................................................................................................35

5.2.2. Panel board Information .................................................................................................................................36

6.0 SYSTEM TROUBLESHOOTING ....................................................................................................................................39

6.1. SYSTEM SAFETY PRECAUTIONS........................................................................................................................................39

6.1.1. Troubleshooting guidelines (GE Zenith Series Monitoring Package)..............................................................39

7.0 GE ZENITH SERIES MONITOR ALARM DESCRIPTION ..............................................................................................40

8.0 SPECIAL INSTRUCTIONS ............................................................................................................................................42

8.1. OUTPUT PANEL BOARDS.................................................................................................................................................42

8.1.1. Panel board manufacturers ............................................................................................................................42

8.2. OUTPUT DEDICATED CIRCUIT BREAKERS (SUB-FEEDS) ........................................................................................................43

8.3. LOW VOLTAGE INTERFACE BOARD (CONTRACTOR BOARD)...................................................................................................43

9.0 WARRANTY, MAINTENANCE AND TERMS ................................................................................................................44

9.1. GE SERVICE DEPARTMENT..............................................................................................................................................44

9.1.1. GE’s Standard Warranty..................................................................................................................................44

9.1.2. Start Up ............................................................................................................................................................44

9.1.3. Maintenance Contracts ...................................................................................................................................44

9.1.4. Time and Materials ..........................................................................................................................................44

9.2. GE MAINTENANCE CONTRACTS.......................................................................................................................................45

9.2.1. Features & Benefits..........................................................................................................................................45

10.3 WARRANTY VALIDATION REQUEST...................................................................................................................................46

9.4. WARRANTY AGREEMENT ................................................................................................................................................47

10.0 APPENDICES ...............................................................................................................................................................48

10.1. APPENDIX A – MDU INPUT BREAKER SIZING CHART ......................................................................................................48

10.2. APPENDIX B - CLASS A COMPUTING DEVICE: INFORMATION TO USER ..............................................................................49

11.0 SPARE PARTS ..............................................................................................................................................................50

11.1. SPARE PARTS KITS - GE ZENITH MDU WITH M4 MONITORING PACKAGE..........................................................................51

11.2. SPARE PARTS KITS - GE ZENITH MDU WITH GE ZENITH SERIES MONITORING PACKAGE .....................................................51

11.2.1. GE Zenith Series MDU - “Option A” Kit.............................................................................................................51

11.2.2. GE Zenith Series MDU - “Option B” Kit.............................................................................................................51

11.2.3. GE Zenith Series MDU w/ BCMS - “Option C” Kit.............................................................................................51

12.0 DRAWINGS..................................................................................................................................................................52

12.1. TYPICAL OUTLINE, 30KVA-150KVA MDU ..................................................................................................................53

12.2. TYPICAL OUTLINE, 200KVA-300KVA MDU ................................................................................................................54

12.3. TYPICAL OUTLINE, 400KVA – 750KVA MDU ..............................................................................................................55

12.4. TYPICAL 30KVA–300KVA MDU FLOOR STAND (11”–76” HEIGHTS)...............................................................................56

12.5. TYPICAL 400KVA–750KVA MDU FLOOR STAND (60” HEIGHT SHOWN)..........................................................................57

13.0 NOTES..........................................................................................................................................................................58

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 3

Page 4

1.0 Introduction

GE Zenith Controls, (GE) designs and manufactures the finest power distribution products available on the

market today. GE’s Monitored Distribution Units (MDUs) are completely self-contained, factory-tested units

designed primarily for power conditioning, voltage transformation, isolation, over-current protection,

distribution, static transfer switching and monitoring of AC power for computers and other equipment

sensitive to power quality.

Your MDU is carefully assembled by craftsmen from parts manufactured to exact specifications from the

highest quality materials. Only the optional input power junction box requires field installation.

GE MDU’s are designed to be an integral part of your power quality solution, while allowing for easy expansion

and relocation of your system capacity requirements.

This manual includes user operation and installation information for the GE Zenith - Series Monitored

Distribution Unit with GE’s GE Zenith Series monitoring package or M4 monitoring system

If you require additional information or need technical assistance please contact GE’s field support division at

any time.

Introduction

GE ZENITH CONTROLS, INC.

601 SHILOH ROAD

PLANO, TX 75074

(800) 637-1738

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 4

Page 5

2.0 Receiving Your MDU

2.1. Receiving and Unpacking Instructions

GE carefully packages every MDU to ensure damage-free delivery to your job site. GE recommends

the following unpacking procedures be followed upon delivery.

1. Inspect packaging, exterior panels, and doors for any visible damage (i.e. scratches dents,

cracks, or torn packaging). If any damage exists, please call the GE Service Team at (800) 637-

1738.

2. Remove the outer layer of protective shrink wrap from the unit.

3. Carefully cut the safety bands, making sure that they do not scrape the exterior of the unit or

scratch the paint. Use eye, face, and hand protections to guard against injury when bands are

cut.

4. At this point, your unit is ready to be removed from the pallet using a fork-lift truck. Use extreme

caution to ensure the unit is properly centered on the forks.

5. Once the unit is completely off the pallet and ramp, carefully remove the under layer of

protective shrink wrap.

6. Ensure that the casters both rotate and can roll freely so as not to damage the flooring.

7. The unit is now ready to be rolled into its final position and prepared for installation. Please refer

to the Installation Procedures listed on page 8 before proceeding.

8. If any further assistance is needed, please call the GE Service Team at (800) 637-1738.

Receiving Your MDU

Note: The MDUs should not be loosened from the shipping pallet until all handling by a forklift or

pallet jack is completed. Complete internal inspection should be done only after

equipment positioning and prior to electrical hookup.

Note: Any damages must be noted on the bill of laden with a detailed description of the

damages incurred. A claim will need to be filed with the freight company at the time of

delivery. Failure to properly document all damages may result in the unit’s warranty

being voided.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 5

Page 6

2.2. Inspection Procedures

The following inspection procedures should be performed immediately after your unit has arrived.

Report any damages immediately to your GE Service Team by calling (800) 637-1738. All freight

damage claims should be initiated with the freight carrier immediately.

1. CABINET: Inspect packaging, exterior panels, and doors for any visible damage (i.e. scratches

dents, cracks, or torn packaging). If any damage is noted, please the GE Service Team at (800)

637-1738.

2. TRANSFORMER: Inspect the transformer for any loose connections or displacement during

shipment. Check to make sure all terminal lugs are tight and secure.

3. INTERNAL FEEDERS: Ensure all lug connections are tight and secure.

Check the main input feeder connections at the main breaker to be sure vibration has not

loosened the terminal screws.

Using the same procedure, check the feeders from the load side of the main breaker to

the primary side of the transformer.

Check all other lugs (i.e. neutral bus, ground bus, terminal blocks, etc.).

4. OUTPUT DISTRIBUTION CABLE ASSEMBLIES: cable coils must be inspected for cuts and/or damaged

conduits. Each cable should be uncoiled and inspected individually.

Note: Do not remove the cable shipping pallet until the unit is near its final position

5. INPUT POWER JUNCTION BOX (POWER J-BOX): carefully inspect the entire box for damage.

Receiving Your MDU

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 6

Page 7

3.0 Installation Procedures

Output

208V

Input

480V

600V

Without

w/ (1)

w/ (2)

w/ (1)

w/ (2)

The following section of your owner’s/operator’s manual covers the general requirements for the installation

of your Monitored Distribution Unit and its associated components.

Note: A GE authorized field engineer and/or a licensed electrician must install each unit. Startup by a

GE certified technician is also required to validate the warranty.

3.1. Equipment placement

The preferred location of your MDU is in the center of the room. Although this location is not

mandatory, it will allow accessibility for preventative maintenance (PM) checks and any other

required services. Follow the National Electrical Code (NEC) and local electrical codes for panel board

clearance requirements. The MDU is intended for indoor installation in an area with ambient

temperatures of 32F to 104F (OC to 40C) with a relative humidity of 0% to 95% (non-condensing).

3.1.1. Clearances

Refer to the MDU shop drawings/submittals for recommended minimum service

clearances. The NEC requires the indicated front and rear clearances for service access

(see Drawings section for typical clearances). Clearance above the unit is required for

cooling airflow (exhaust). Units with optional side cars with the distribution section also

require service access clearance on the side. A MDU produces heat under normal

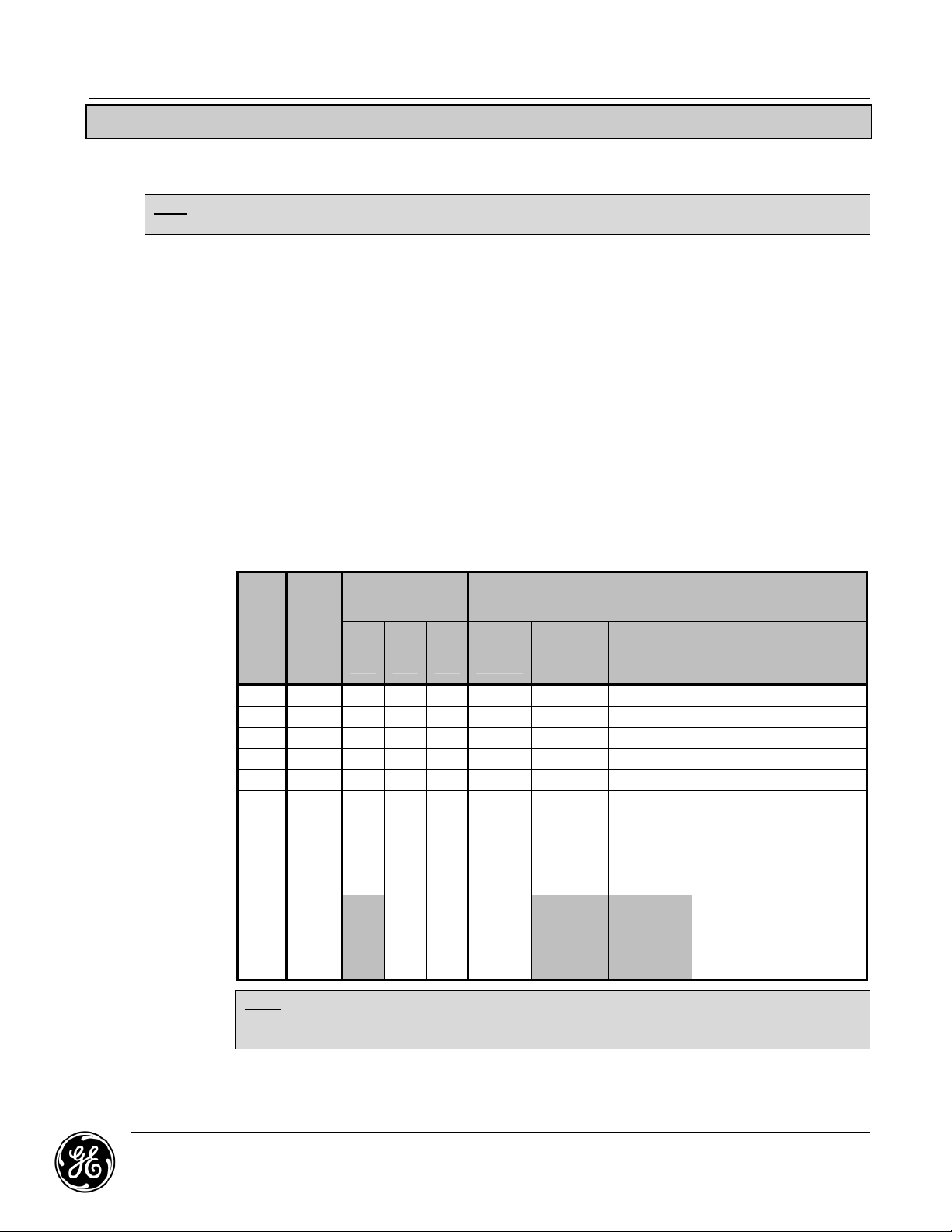

operation. Figure 1 shows typical MDU weights and heat generation.

Installation Procedures

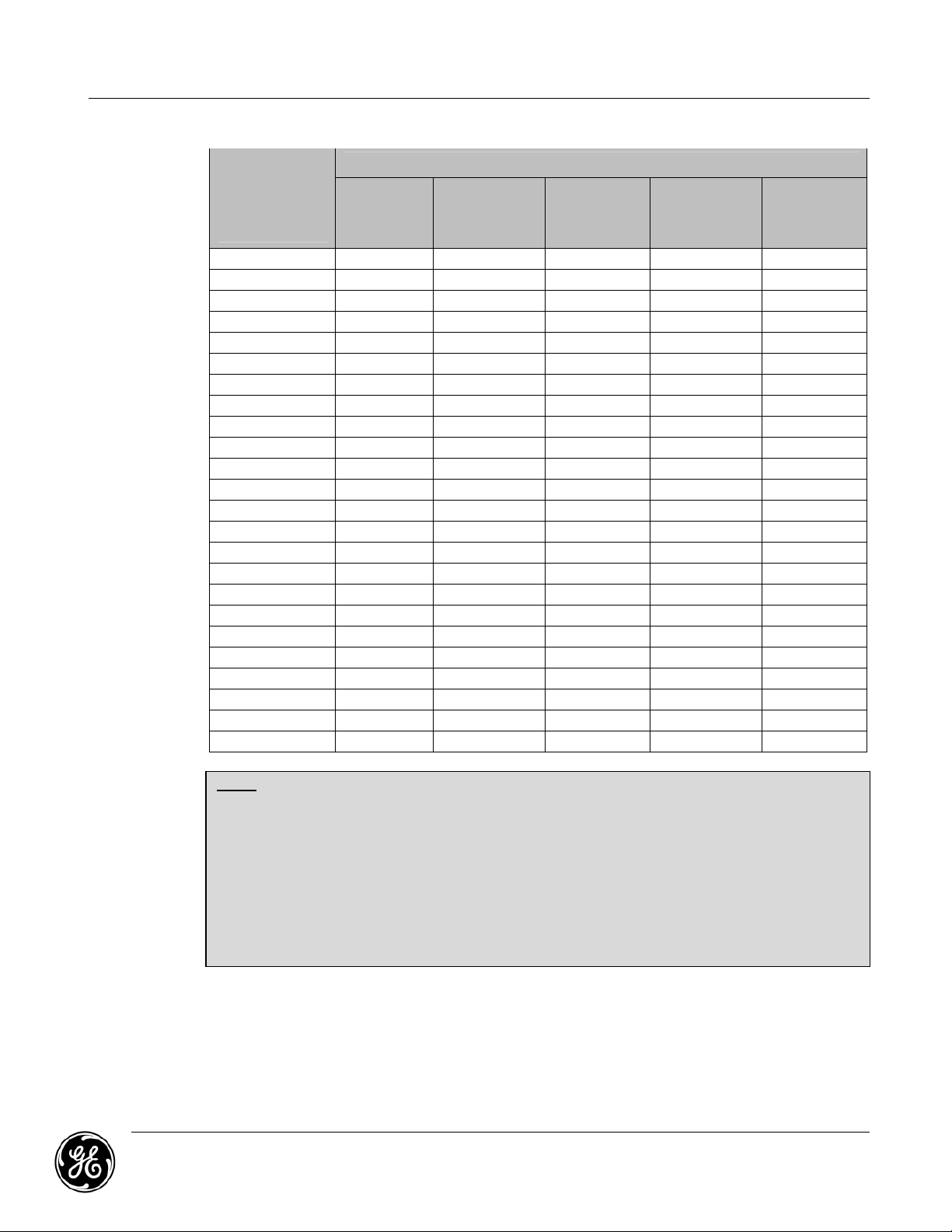

Figure 1: MDU Approximate Weights and Heat Generation

MDU

Ratin

g

(kVA)

Heat

(kBTU)

Full Load

Amperage

Input

Input

Sidecar

Sidecar

MDU Weight (Lbs)

9”-

Sidecars

9”-

21”-

Sidecar

Sidecars

15 2.7 42 18 14 574 724 874 824 1074

30 4.8 83 36 29 945 1095 1245 1195 1445

50 7.1 139 60 48 1302 1452 1602 1552 1802

75 7.6 208 90 72 1470 1620 1770 1720 1970

100 8.4 278 120 96 1785 1935 2085 2035 2285

125 10.4 347 150 120 1855 2005 2155 2105 2355

150 12.2 416 180 144 1967 2117 2267 2217 2467

200 15.6 555 241 192 2149 2299 2449 2399 2649

225 17.6 625 271 217 2457 2607 2757 2707 2957

300 21.0 833 361 289 3297 3447 3597 3547 3797

400 34.6 N/A 481 384 2900 N/A N/A 3150 3400

500 43.3 N/A 601 481 3900 N/A N/A 4150 4400

625 54.1 N/A 752 602 4489 N/A N/A 4739 4989

750 64.9 N/A 903 721 5390 N/A N/A 5640 5890

21”-

Note: Weights listed are for MDU’s with k-20 transformers and no sidecars. For k-1 weight,

multiply 0.72. For k-13 weights, multiply by 1.12. Weights are for estimate purposes

only. Actual shipping weight may vary.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 7

Page 8

3.1.2. Raised Floor

If the MDU is placed on a raised floor, it is recommended that the casters rest as close as

possible to the corners of the floor tiles. This will allow the unit to span (1) one complete

floor tile, permitting cutouts in the tile.

3.1.3. Cabling

The unit location may be specified on a floor plan which shows related equipment as well

as identifying distribution cable runs. These cable runs should be recorded on panel board

legend cards. Each legend card specifies the circuit location on the panel board and the

computer or peripheral description.

3.1.4. Cabinet Leveling

Once the MDU has been positioned in its permanent location, turn down the (2) two front

and the (2) two rear (optional) leveling pads on the base of the MDU until they make firm

contact with the floor or landing surface. Level the unit and assure that the leveling pads

are always in contact with the floor or landing surface. The primary purpose of the leveling

pads is to prevent movement of the cabinet before and during attachment of the output

cables. Casters, if provided with the MDU, will support the weight of the unit.

3.1.5. Raised floor loading

Additional floor bracing is recommended for all units. The weight of larger units should be

considered in the room design. The raised floor system must be able to support both the

MDU as well as any other associated equipment. GE recommends that the end user

properly compute raised floor loading and supply proper floor bracing when needed.

Installation Procedures

Floor stands can also be provided by GE to support the MDU’s weight on the raised floor.

Note: GE does not recommend the removal of Casters for MDU sizes up to 300kVA.

Floor stands are designed to support your MDU with casters in place. Placing

the MDU on the floor or stand without casters may damage the MDU cabinet

which may void your warranty.

For typical floor weights of the MDU, please refer to Figure 1 on the previous page, or your

submittal package.

3.1.6. Raised floor cable entry

When applicable, provisions must be made for cable entry through the raised floor once

the MDU has been properly located. The cable entry configuration should be free of any

sharp edges and designed to allow permanent access for the distribution cables and input

power cables. The tile directly in front of the unit should be easily removable for access to

these cables.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 8

Page 9

3.2. System Grounding Recommendations

Note: Grounding for this equipment must not violate any local building or electrical codes.

System grounding has long been a topic affecting the computer equipment industry. The proper

grounding of your GE Monitored Distribution Unit is critical to the operation of the unit. Improper

grounding of a system may create unsafe conditions as well as electrical noise that may cause data

processing problems. GE has conducted a great deal of research on system grounding, and makes

the following recommendations.

3.2.1. Power System Grounding

The primary concern is to provide a safe system that both complies with the electrical code

(NEC article 250 in the USA, Canadian Electrical Code Section, 10, IEEE wiring regulations

and chapter 54 in the UK) and ensures proper and safe equipment operation. The MDU

should have a parity sized, green grounding conductor connected from the power J box to

the nearest grounding electrode. The MDU contains a factory wired, green grounding

conductor (within the power cable) from the power J box to a single ground point inside

the MDU cabinet. From this single ground point, each piece of equipment should be

separately grounded via a green grounding conductor within the flexible output computer

grade cable.

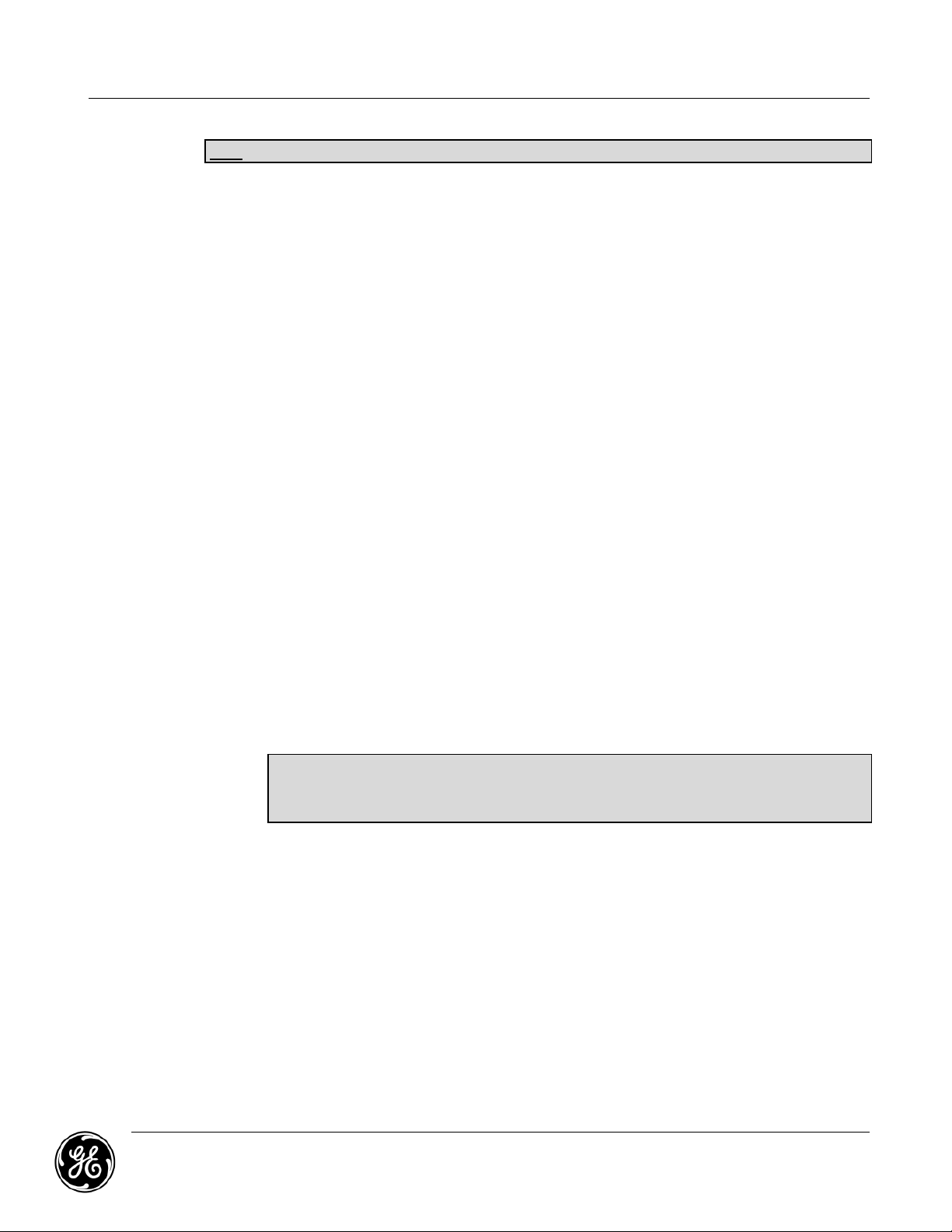

3.2.2. Grounding Conductors

An isolation grounding conductor identical in size, insulation material, and thickness to the

grounded and ungrounded branch circuit supply conductors should be installed as part of

the branch circuit that supplies the system. This grounding conductor should be marked

green (or green with yellow stripe) when using a (4) four wire system. A typical power wiring

diagram is illustrated in Figure 2.

Installation Procedures

This grounding conductor should be grounded at the nearest available grounding

electrode in accordance with all electrical codes. The output cabling receptacles of the

MDU should be the same grounding type. The grounding conductors serving these

receptacles should be terminated at the MDU ground bus.

Figure 2 provides the ground wire ratings.

Grounding for systems with Remote Panel boards:

Careful consideration should be given to the grounding of systems with remote Panel

boards. See FIPS PUB 94 or contact GE’s factory for recommendations.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 9

Page 10

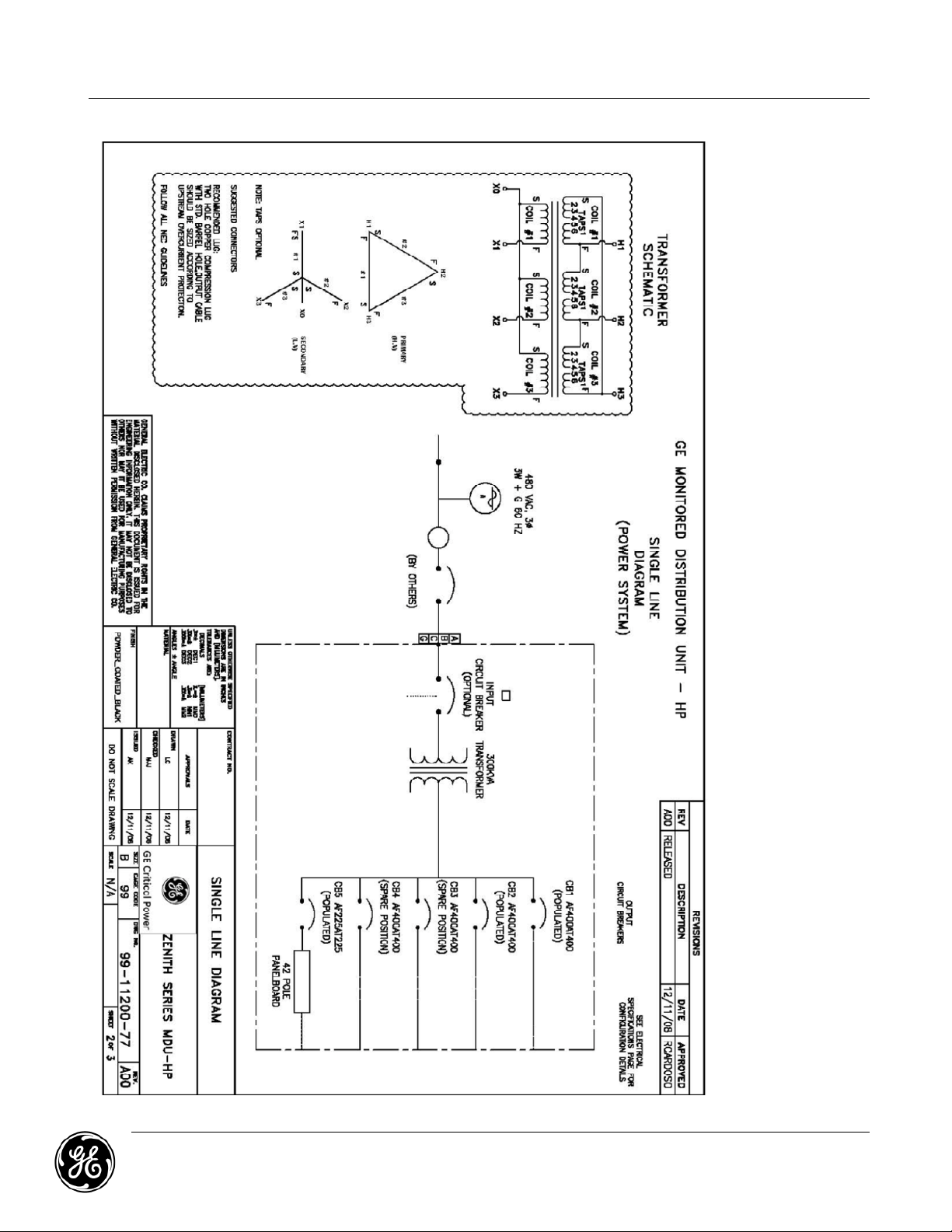

Figure 2: Typical MDU Oneline Diagram (15kVA – 300kVA)

Installation Procedures

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 10

Page 11

Figure 2: Typical MDU Oneline Diagram (400kVA – 750kVA)

Installation Procedures

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 11

Page 12

3.3. Internal Wire Sizing

Circuit Breaker

Installation Procedures

Protective

or Actual

Amperage

25 #10 #14 #10 #12 #10

30 #10 #12 #8 #10 #10

40 #8 #10 #8 #10 #10

50 #8 #10 #6 #10 #10

60 #8 #8 #4 #8 #10

70 #8 #8 #3 #8 #8

80 #6 #8 #3 #8 #8

90 #6 #8 #2 #6 #8

100 #4 #8 #1 #6 #8

110 #4 #8 #1 #4 #6

125 #4 #8 1/0 #4 #6

150 #2 #6 2/0 #3 #6

175 #1 #6 3/0 #2 #6

200 1/0 #4 3/0 #1 #6

225 1/0 #4 4/0 1/0 #4

250 2/0 #3 250MCM 1/0 #4

300 3/0 #2 350MCM 2/0 #4

350 4/0 #1 400MCM 3/0 #3

400 250MCM 1/0 500MCM 4/0 #3

500 350MCM 2/0 750MCM 300MCM #2

600 500MCM 3/0 1000MCM 400MCM #1

700 700MCM 4/0 1500MCM 500MCM 1/0

800 800MCM 250MCM N/A 700MCM 1/0

1000 1000MCM 350MCM N/A 1000MCM 2/0

Phase Wire,

Single

3,4

1,3,4,6

Phase Wire,

Two

Parallel

Internal Conductors

Neutral

Wire,

1,3,4,6

Single

1,3,4,6

Neutral Wire,

Two

Parallel

1,3,4,6

Ground

Wire,

Single

1,3,4,6

Notes:

1. Conductor ratings are based on NEC Table 310.17.

2. Deleted.

3. All wires must be UL listed.

4. Conductors must be separated for air circulation – not bundled

5. Parallel conductor lengths must be equal within 2% (e.g. two parallel conductors 10 feet

long must match in length within 2.4”).

6. For components like circuit breakers, the 75°C column in NEC Table 310.17 must be used.

7. For components like bus bars that allow 90°C connections, the 90°C column in NEC Table

310.17 can be used.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 12

Page 13

Installation Procedures

3.4. High Frequency (RF) Grounding (computer rooms)

In addition to the power grounding system, a reference grounding system for high frequency noise is

desirable (with the two systems being bonded together for the same reference potential). A grid

made up of (2) two foot squares will provide an effective signal reference grounding system. The

raised floor can be utilized if it has firmly connected metal stringers providing good electrical

connections. If this type of floor is not available, a grid can be fabricated by laying a mesh (2 foot

square) of braided copper strap directly on the concrete sub floor (electrically connected at each

intersection point). The frames of all the data processing equipment, including the MDU, should be

connected (by the shortest possible distance) to the reference grid with braided copper. Finally, the

reference grid should be bonded to the MDU for a single point potential ground reference.

For optimum performance all distances for power and high frequency grounding should be kept to

an absolute minimum. To summarize, a radial grounding of this type (utilizing a single ground point)

will ensure that your facility is electrically safe, complies with all code requirements, and will be

essentially free of ground caused computer noise and problems.

3.5. Input Power Junction Box and Cable Assembly (Optional)

Warning: Verify that incoming high voltage circuits are not energized before making any

connections in the input junction box.

If the MDU is equipped with an input junction box, then the input junction box (power J box) and

power cable assembly must be installed in accordance with all applicable electrical codes. The

power J box should be installed only by a qualified electrical contractor.

The location of the power J box in relation to the MDU is a critical relationship. The power J box must

be located within (6) six feet of the MDU. It must be positioned so as to allow accessibility after the

MDU has been installed. Extreme care should be taken so as not to restrict the positioning of any

power cabling. If the MDU is positioned with its rear panel up against a wall, the power J box must

be installed at least 36 inches (3 feet) from the wall and in a position that will allow future

accessibility. Do not obstruct the floor tiles located directly above the power J box.

It is recommended that the power J box location allows the input power cables to enter the unit

through the floor tile cutouts.

If a junction box is not furnished, the input power feeder should be connected to the main input

landings internal to the MDU.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 13

Page 14

3.6. Torque Specifications

3.6.1. Structural Fasteners

Structural fasteners are typically used for fastening the MDU to a supplied floor stand or

concrete slab. If structural fasteners are required per assembly instructions, refer to the

table below for typical torque values. Tighten steel hardware parts (except electrical

connections) to the values given in the following table.

Bolt Diameter Tightening Torque (in-lb)

#8 (5/32”) 15

#10 (3/16”) 20

3.6.2. MCCB’s, MCSW’s, Contactors, and Other Electrical Components

Always tighten electrical component (CBs, contactors, etc.) connections to the

manufacturer’s torque specifications furnished with the component. There are some

guidelines for electrical components if no manufacturer data is available. Tighten

connections using Belleville type (spring) washers until washers are flat.

Installation Procedures

1/4” 120

5/16” 228

3/8” 396

7/16” 648

1/2” 936

3.7. Torque Value Quick Reference

Use the following as a reference only. Always check the breaker or component labeling and/or

instructions for proper torque values. DO NOT OVER TORQUE!

Always use the manufacturer’s hardware on CBs, contactors, etc. Once connections are torqued and

sealed, make sure that removable lug covers are reinstalled,

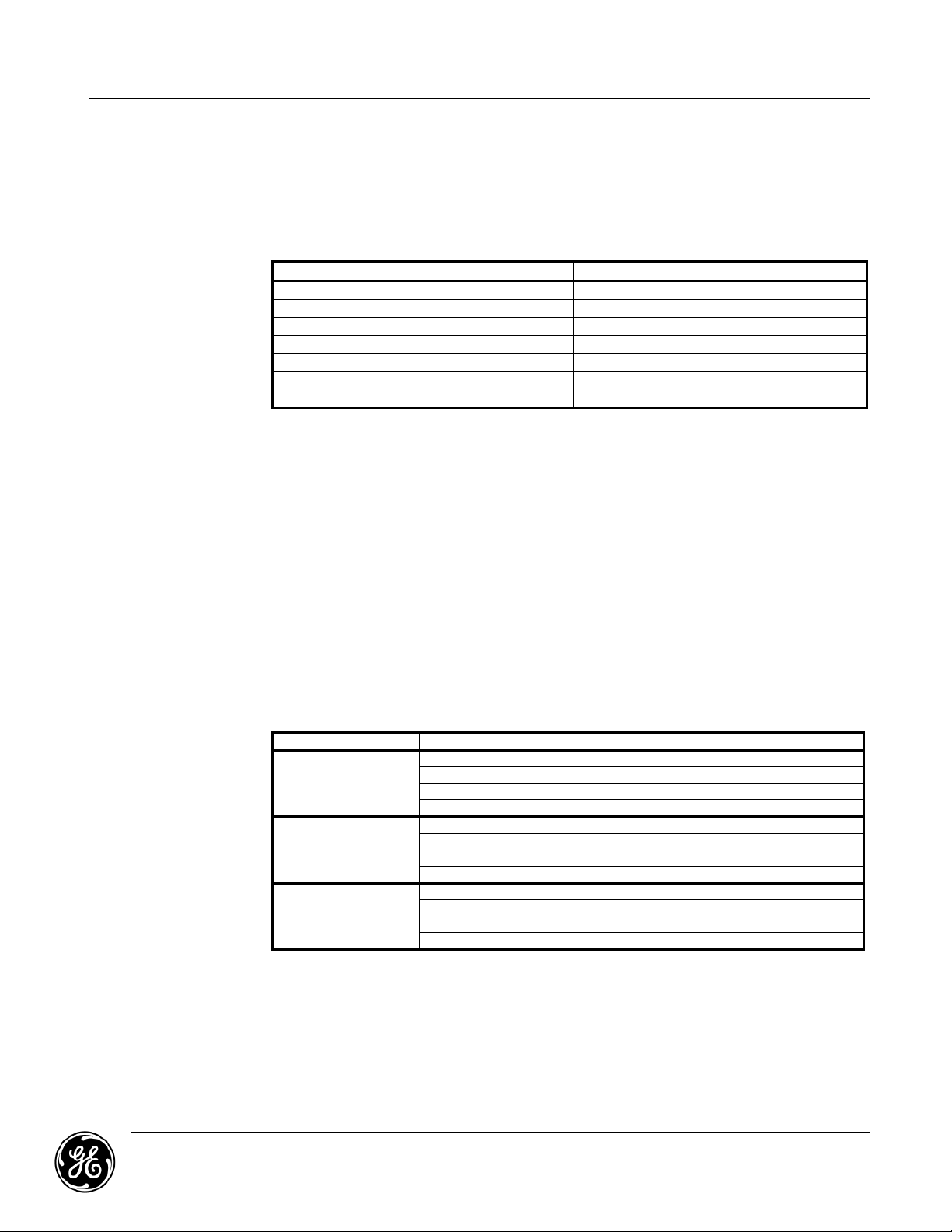

3.7.1. Standard Circuit Breakers (Mains & Sub-feeds)

Manufacturer Breaker Frame / Bolt Required Torque (ft-lb)

Square D

Cutler Hammer

ABB ISOMAX

Rear Lug Mounting Bolt

requires

Rear Lug Mounting Bolt 9.2

F Frame 6.7

K Frame 20.9

L Frame 31.3

M Frame 25.0

F Frame 10.0

J Frame 22.9

K Frame 22.9 (Wire Smaller than 250 MCM)

K Frame 31.3 (Wire 250 MCM or larger)

S3 22.9

S4 22.9

S5 22.9

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 14

Page 15

3.7.2. Transformer Lugs

1/8”4535

5/32”

100

80

3/16”

120

100

7/32”

150

120¼”200

150

5/16”

275

225

3/8”

375

300½”500

400

9/16”

600

500

Wire Size (Awg or MCM) Required Torque (ft-lb)

3.7.3. Fasteners

Installation Procedures

2/0 4.2

250 22.9

350 31.3

500 31.3

Wire Size

installed,

AWG or

MCM

SLOTTED HEAD SCREWDRIVER TORQUE VALUE (in-lb)

Slot width up to 3/64”

Slot length up to ¼”

Slot width over 3/64”

Slot length over ¼”

SCREW CONNECTOR

TORQUE VALUE (in-

#14 15 in-lb 25 in-lb

#12 15 in-lb 25 in-lb

#10 15 in-lb 25 in-lb

#8 20 in-lb 25 in-lb

#6 25 in-lb 35 in-lb

#4 N/A 35 in-lb

#3 N/A 40 in-lb N/A

#2 N/A 40 in-lb

#1 N/A 40 in-lb

1/0 N/A 40 in-lb

2/0 N/A 40 in-lb

3/0 N/A 40 in-lb N/A

4/0 N/A 40 in-lb N/A

Hex Socket Size

SOCKET HEAD SCREW CONNECTOR

TORQUE VALUE (in-lb)

HEX SOCKET ALLEN SCREW

TORQUE VALUE (in-lb)

lb)

35

35

35

40

45

45

50

50

50

50

3.7.4. Terminal Blocks and Distribution Breakers

Torque ratings vary depending on item in use. Please refer to label on the item.

3.0 ft-lb of torque is typically required for Distribution Breakers. There is a wide variation of

torque requirements for terminal blocks with various sizes.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 15

Page 16

3.7.5. Junction Box and Power Cable Sizing Chart

Main Input

Size (Amps)

Input Power Cable

(#-Size)

Input Power

(#-Size)

Installation Procedures

Circuit

Breaker

25 1 - 8 AWG 1 - 1" 12" x 10" x 5" 4 Pole - # 12 - 2/0

30 1 - 6 AWG 1 - 1" 12" x 10" x 5" 4 Pole - # 12 - 2/0

40 1 - 6 AWG 1 - 1" 12" x 10" x 5" 4 Pole - # 12 - 2/0

50 1 - 6 AWG 1 - 1" 12" x 10" x 5" 4 Pole - # 12 - 2/0

60 1 - 6 AWG 1 - 1" 12" x 10" x 5" 4 Pole - # 12 - 2/0

70 1 - 4 AWG 1 - 1 1/4" 12" x 10" x 5" 4 Pole - # 12 - 2/0

80 1 - 4 AWG 1 - 1 1/4" 12" x 10" x 5" 4 Pole - # 12 - 2/0

90 1 - 3 AWG 1 - 1 1/4" 12" x 10" x 5" 4 Pole - # 12 - 2/0

100 1 - 3 AWG 1 - 1 1/4" 12" x 10" x 5" 4 Pole - # 12 - 2/0

110 1 - 2 AWG 1 - 1 1/4" 12" x 10" x 5" 4 Pole - # 12 - 2/0

125 1 - 1 AWG 1 - 1 1/2" 12" x 10" x 5" 4 Pole - # 12 - 2/0

150 1 - 1/0 AWG 1 - 1 1/2" 12" x 10" x 5" 4 Pole - # 12 - 2/0

175 1 - 2/0 AWG 1 - 2" 16" x 14" x 6" 4 Pole - # 6 - 350 MCM

200 1 - 3/0 AWG 1 - 2" 16" x 14" x 6" 4 Pole - # 6 - 350 MCM

225 1 - 4/0 AWG 1 - 2" 16" x 14" x 6" 4 Pole - # 6 - 350 MCM

250 1 - 250 MCM AWG 1 - 2 1/2" 24" x 18" x 6" 4 Pole - # 6 - 350 MCM

300 2 - 3/0 AWG 1 - 3" 24" x 18" x 6" 4 Pole - # 6 - 350 MCM

350 2 - 4/0 AWG 2 - 2" 24" x 18" x 6" 4 Pole - # 4 - 500 MCM

400 2 - 4/0 AWG 2 - 2" 24" x 18" x 6" 4 Pole - #4 - 500 MCM

500 2 - 250 MCM AWG 2 - 2 1/2" 24" x 18" x 6" 4 Pole - #4 - 500 MCM

600 2 - 350 MCM AWG 2 - 3" 24" x 18" x 6" 4 Pole - #4 - 500 MCM

700 2 - 500 MCM AWG 2 - 3" 24" x 18" x 6" 4 Pole - #4 - 500 MCM

800 3 - 300 MCM AWG 3 - 2 1/2" Special Special

Wire Size Per

Phase & Ground

Cable

Conduit Size

Input Junction

Box Size

(H x W x D)

Input Junction Box

Terminal Block Size

(# Poles - Wire Range)

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 16

Page 17

3.7.6. System Power-Up Procedure

Note: Before applying utility power to the unit, the electrician performing the

installation and/or a factory authorized representative should be present to

verify that the following steps have been performed properly.

1. Confirm that the MDU’s main input circuit breaker is in the “off” position.

2. Ensure that all of the MDU’s output circuit breakers or sub-feed breakers are in the “off

“position.

3. The installing contractor should now verify that the input voltage to the unit matches

the input voltage rating of the unit as identified on the system’s legend label found on

the interior of the front door. The input voltage rating also appears on the transformer

label located on the top of the high isolation transformer positioned at the rear of the

unit.

4. Ensure that the power J box has been installed correctly (i.e. proper phase rotation and

safe grounding practices as indicated above).

Warning: Ensure that the above conditions are met before applying incoming power to

the MDU.

5. Apply Power to the unit

6. Measure for the proper MDU input voltage. This should match the units rating (+ 5% to

-10% from nominal rating).

7. Check the phase rotation (clockwise) and voltage at the power J box.

8. Check to ensure the emergency power off (EPO) light is on.

Installation Procedures

9. Energize the MDU main breaker by setting the toggle to the “on” position.

Note: If the main breaker trips to the “off” position when energized, contact GE ’s

service division at (800)637-1738 as this is an indication of a fault in the unit.

10. Perform an EPO check by depressing the EPO button and assuring that the main

breaker shunt trips.

11. Manually reset the main breaker to the “on” position. This may require that you

manually trip the lever all the way to the “off” position.

12. Check the output voltages. If the output voltages are not within acceptable limits, it

may require the taps on the transformer be changed. Each transformer is labeled with

the tap connections. All tap changes must be done with the input power turned off.

13. The MDU is now ready to sequentially energize the branch circuit breakers.

14. Units equipped with monitoring can be activated by depressing the monitor on/off

button located to the left of the LCD display. See System Monitoring on page 23 of this

manual for monitor operation.

Note: Equipment attached to the MDU may require special start up procedures. Please

consult the individual manufacturers for these requirements.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 17

Page 18

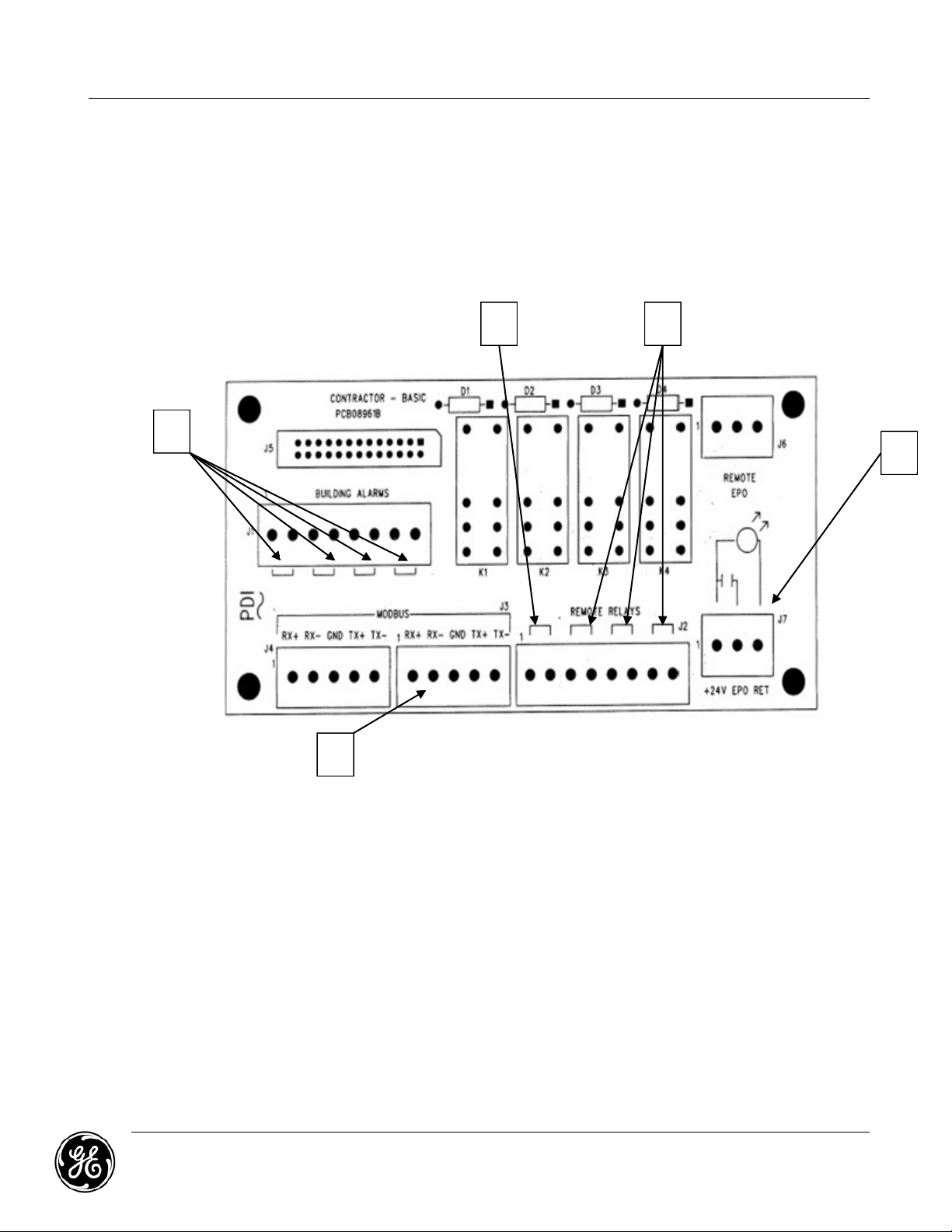

3.8. Customer Connections: Low Voltage Interface Board

2

Customer connections for remote monitoring or controls are found on the MDU’s Low Voltage

Interface Board (contractor board). This board is mounted internally within the MDU and is located

behind the safety cover between the output distribution panels in the lower front of the unit. All

interface wiring should be run within the cabinet for termination on the contractor board. All

interface wiring (building alarms, AC alarms, halon alarms, remote power off systems, etc.) and

contacts are to be provided by others.

3.8.1. GE Zenith Series Monitoring Package

1

4

Installation Procedures

5

3

1. Summary Alarm: Dry Contact point to advise when unit is in alarm.

2. Dry Contact Remote Relays: Programmable dry contacts for external output of

specific internal alarms

3. ModBus Connection: 4-wire configuration connection is located on the Customer

connection terminal block

4. Building Alarm: Input terminal block to provide unit with input on four (4) external

building alarms

5. Remote EPO: Connection point for input of remote EPO signal to system. This is a dry

contact connection point. Connection of voltage to this point can cause damage to the

unit. Connect external dry contacts to terminals marked +24v and EPO for EPO circuit. The

return position is if there is also a light for the remote EPO button.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 18

Page 19

3.8.2. M4 Monitoring Package

Installation Procedures

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 19

Page 20

Installation Procedures

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 20

Page 21

3.8.3. Optional Low Voltage Junction Box

An optional Low Voltage Junction Box may be provided with your MDU, and is an extension

of the Low Voltage Interface Board for Customer connections external to the MDU. This

provides a convenient access to the MDU’s interface terminals without exposing the

internal components of the MDU. The box is wall-mountable, and houses a contractor

board that is connected to the MDU via 10-ft long interface cables.

3.8.4. Output Distribution Cable(s) Installation

Warning: The MDU should be de-energized before attempting to install any output

cables or assemblies. Power distribution cables and assemblies should be

installed by a qualified electrical contractor and/or a factory authorized GE

representative. For assistance call GE at (800) 637-1738.

The MDU should be in its permanent position with all input power cables properly

connected before going any further. If the unit is resting on raised floor tiles, verify the

proper cutouts have been made before continuing. Be careful not to remove an excessive

amount of floor tiles that could cause the flooring to become unstable.

Note: Special care must be taken when assigning circuit breaker positions for proper

load balancing.

Optional output distribution cables may have been shipped already attached to the unit. If

this is the case, they should be removed from the pallet and uncoiled. After they are

uncoiled, they should be inspected before installation. Remove necessary floor tiles and lay

out the cables to their respective equipment. After the cables have been properly laid out,

replace all removed floor tiles.

Installation Procedures

Note: Output cables on k-rated units must have a neutral wire that is twice the size of

the phase wires.

With the output cables unattached and the unit in its permanent position, the following

procedures should be followed:

1. Open and remove the access door to the distribution panel board or sub-feed breaker.

2. Remove dead front cover panel exposing branch circuits or sub-feed breaker(s).

3. Remove cable entry cover panel.

4. Install the appropriate circuit breakers, if not factory-installed

5. Locate an appropriate sized pre-punched conduit knock out.

6. Remove locknut from distribution cable end.

7. Feed cable conductor up through knock out and re-install locknut.

8. Tighten locknut securely.

9. Remove the necessary floor tiles and route the cable to its respective equipment.

Note: Care should be taken when placing the output cables in the units to properly

align and lace these due to the limited area for placing cables. This will be

especially true for 400kVA-750kVA rated MDU’s when the maximum number of

sub-feeds are utilized. Please call the GE factory for any assistance needed to

insure the placement of these cables.

10. Replace floor tiles.

11. Strip insulation approximately 1/2 inch from the end of the cable.

12. Connect phase wires to the output circuit breaker terminals according to the chart

below:

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 21

Page 22

Installation Procedures

Country Color coding (Phase A,B,C)

United States (US) Black, Red Blue

Canada Red, Black, Blue

United Kingdom (UK) Red, Blue, Yellow

13. Connect the ground wire (green or green with yellow tracer) to the distribution panel

ground bus.

14. If the cable requires a neutral wire (white), connect this wire to the distribution panel

neutral bus.

15. Checks to make sure all connections are securely tightened.

16. Remove the blank fillers from the distribution cover panels for the required circuit

breakers.

17. Reinstall and properly align all panels previously removed.

18. Mark (with pencil) installed breakers on the distribution cover panel identification card.

19. Check for proper phase rotation and voltage before attaching the other end of cable

to its associated equipment.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 22

Page 23

4.0 System Monitoring

5

2

If all the previous instructions have been properly completed, it is time to activate the monitor display panel.

The monitor display panel has its own power on/off switch located in the lower left hand corner of the display

panel. Depress the on/off button and the LCD display window will illuminate indicating that power is being

supplied to the monitor. The MDU will either be equipped with a GE Zenith Series or an M4 monitoring

package. Refer to the Bill of Materials to verify your specific model

4.1. GE Zenith Series MDU Monitor

GE’s GE Zenith Series MDU Monitor features a graphic LCD panel accessible from the front of the

MDU. The monitor is part of a microprocessor based Operator Interface Module that monitors

analog power points within the MDU unit.

4.1.1. LCD Monitor Layout

System Monitoring

1. LED Status Indicator

2. Graphics Display

3. Esc/Setup

4. Navigation Controls

5. Enter/Toggle Screen

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 23

Page 24

4.1.2. GE Zenith Series Monitor Features

Feature Std / Optional

Mod Bus; RS485/RS422 Communication ports Std.

SNMP Communication Optional

LCD Graphic Display 40x16 char

Standard Contractor Board:

2A Building Alarm contacts – Qty (4)

5A Relay Contacts (summary alarm) – Qty (4)

Standard Contractor Board:

2A Building Alarm contacts – Qty (8)

5A Relay Contacts (summary alarm) – Qty (8)

Remote EPO Contacts Std.

Customized Application Specific Display Optional

Audible Alarm annunciation Std.

System Monitoring

Std

Optional

Guarded "Emergency Power off" (EPO) Pushbutton (may be disabled

at customer request)

Std.

Monitor On/Off Switch Std.

Monitor mounted on a draw-out mechanism (ease of service) Std.

BCMS for panel board branch circuits and/or sub-feed breakers Std.

Output KVA Std.

Output KW Std.

Output KWH Std.

Power Factor Std.

Synchronous Clock Std.

Date and time of day Std.

Accepts Standard CT inputs Std.

600 Volt Direct Connection on Voltage Inputs (for 600V MDU) Optional

Accuracy: ±2% current and voltage readings Std.

Min/Max Readings of metered data for BCMS Screens Std.

Password Protected Std.

Set-point controlled alarm logging Std.

Operating Range -25C - +70C

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 24

Std.

Page 25

System Monitoring

Feature Std / Optional

1-Vin: 1-V

1-Vin: 2-V

2-Vin: 1-V

out

out

out

, 1-I

, 2-I

, 1-I

out

out

out

Std.

Optional

Optional

Input Voltage THD Std.

Input Ground Current Std.

Neutral Current Std.

Phase Loss Std.

Ground Fault Alarm Std.

Time & Date Stamp for alarms Std.

Alarm Conditions

Input Frequency (Hz) (Frequency Deviation) Std.

Input Phase Rotation (Phase Rotation Error) Std.

Low Transformer Temperature alarm 180 C

High Transformer Temperature alarm 200 C

Std.

Std.

High Temperature Shutdown (may be disabled at customer request) Std.

True RMS Metering Std.

Input Voltage - Line to Line (High/Low alarm) Std.

Output Voltage - Line to Line (High/Low alarm) Std.

Output Voltage - Line to Neutral (High/Low alarm) Std.

THD - Input Voltage Std.

Output Current - A,B & C phases (phase loss and high current alarm) Std.

Current - Output neutral (High Current Alarm) Std.

Ground Current (Ground Fault Alarm) Std.

Over-Voltage / Under-Voltage Shutdown Optional

Ground Fault Shutdown Optional

Phase Rotation / Phase Loss Shutdown Optional

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 25

Page 26

4.1.3. Control Functions

The control and monitoring functions are maintained as separate circuits to prevent a

monitor malfunction from affecting equipment operation. Only excessively high

temperature in the transformer will automatically shut down the MDU system. If your MDU

is equipped with any other internal automatic shutdown system, it will be a separate

device located in the monitor tray area.

Note: GE strongly advises against any other automatic shutdown devises except

remote EPO functions.

Computer room air handling/conditioning equipment may be connected to the control

interface board (contractor board) for automatic shutdown of this equipment during

emergencies.

The emergency power off push-button and/or remote emergency power off switches will

cause the unit to shut down.

1. Emergency Power Off

A guarded and illuminated EPO push-button is interfaced to the shunt trip mechanism

of the main circuit breaker. Activation of this momentary contact push-button causes

the main circuit breaker to trip, thus removing all connected loads from the electrical

service.

System Monitoring

2. LED Indicator

A simple red light/green light display is provided for non-technical personnel. Any

monitored parameter outside of the threshold limits will illuminate a red light above

the display for identification of the fault condition. When all parameters are nominal, a

green light will illuminate.

3. Horn

The display has a horn that will sound if an alarm is present. The horn can be enabled

and disabled in the setup options.

4. LCD Display Panel

The LCD panel displays all analog inputs, digital inputs, calculated points, and alarm

indications. The LCD provides alpha-numeric display capabilities to insure correct

interpretation of the unit’s monitoring functions.

5. Front Panel Buttons

The front panel has (6) six buttons that allow navigation through the different screens

on the display. Pressing any button will turn the backlight on. After the backlight is on,

you can use them to navigate through the screens.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 26

Page 27

4.1.4. Monitor Screens

1. Banner/Alarm Screen

The display will revert to the banner screen after some time. This screen shows the banner

and any alarms on the unit. The up and down arrow buttons will scroll through the alarms

on the screen designated by the “>” on the left side of the screen. Any alarms with “> to

clear” on the right side can be cleared by pressing the right arrow button when the alarm

is selected. There can be several pages of alarms, and scrolling down will take you to the

next page.

System Monitoring

2. MDU Device Screen

Several different devices can be connected to the display. Pressing “Enter” on the banner

screen will take you to the first device. This is the main MDU device page showing analog

parameters. Pressing the “Enter” button will switch you to other devices (if available) and

then back to the Banner Screen. Other devices can include Branch Circuit Monitoring,

Temperature Monitoring, etc. The up and down arrow buttons are used to navigate

through the different pages.

.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 27

Page 28

System Monitoring

3. Setup Screen

The Setup Screen can be reached from the Banner Screen or any Device Screen by

pressing the “Esc” button. Once in the Setup Screen, you will have to enter the password to

continue. The default password is “GE”. The password can be changed in the Setup

Screen. Once the password is entered correctly, the lock symbol located in the top right

corner of the display will appear opened. After the lock appears opened, you can change

parameters. It will automatically lock back after a set period of time with no button

presses. The up and down arrow buttons are used to select the items to be changes. The

selected item is designated by the “>” on the left side of the screen. The left and right arrow

keys are used to change the information. For the options where text is changed (banner,

password, etc.), the “>” will be replaced by a “–“and an underscore will appear under the

letter or number to be changed. The up and down arrow buttons will change the letter or

number. When you are finished, you must scroll back to the beginning. The “–” will return to

a “>” and you can scroll to the next setup option.

Typical Setup Options

1 Banner

2 Devices

Upstream

3

Modbus

Downstream

4

Modbus

5 Password Allows the user to set or change the password (up to six-characters).

6 Time and Date

7 Horn Used to enable or disable the horn.

8 Devices

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 28

User-customizable banner that shows on the main banner/alarm

screen. This can be changed while in setup mode.

Specifies the number of devices connected to the monitor via

ModBus Protocol. Each device connected to the display must have a

different modbus address.

This is used to change the modbus settings of the port that the

customer uses to connect to read modbus information. The address,

baud rate, and parity can all be changed.

This is used to change the modbus settings of the port that connects

to the devices in the unit to read modbus information. The baud rate

and parity can all be changed. GE does not recommend changing the

ModBus settings as communication problems may occur.

This is used to set the time and date. To change AM and PM you

have to roll the hour past 12. When you have the information

entered correctly move to the “SET” and hit enter.

The next screen is used for device setup. A device such as BCMS can

be set up to disable certain alarms that are not desired. You can also

change the panel board size for trending info.

Page 29

System Monitoring

For SNMP or Web enabled MDU’s, the last screen is used to change

all the SNMP information.

a. IP – The IP address of the unit

b. SNM – Subnet Mask

9 SNMP/WEB

c. DGW – The Default Gateway

d. DNS – The Domain Name Server

e. TDS – The Trap Destination Server

f. Trap Enable – Specifies whether or not you want traps sent

out.

More information is available in the SNMP section of this manual.

Note: There can be several pages of options as a result of special project

requirements

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 29

Page 30

4.1.5. Contractor Connections

1. Printed Circuit Boards (PCB)

A low voltage control junction box shall not be included on this equipment. All Remote

Emergency Power Off, building alarms, output relays, communication ports and other

control wiring shall be terminated onto a Contractor Interface Board which is an integral

component within the MDU system itself.

Standard Interface Board

a. Remote Emergency Power Off interconnect positions

b. Four (4) Relay Contacts (NO contacts) rated 5 amps (summary alarm)

c. Four (4) Building alarm contacts rated 5 amps

d. Remote monitoring connection ports (ModBus RTU Protocol, RS-422/485)

Advanced Interface Board (optional)

a. Remote emergency power off interconnect positions

b. Eight (8) Relay Contacts (NO contacts) rated 5 amps (summary alarm)

c. Eight (8) Building alarm contacts rated 2 amps

d. Remote monitoring connection ports (ModBus RTU Protocol, RS-422/485)

e. Local monitoring of GE approved devices (ModBus RTU Protocol, RS-422/485)

Note: The Tx+ and Tx- are transmission points, and should be connected to the

receiver of the monitoring system. The Rx- and Rx+ are receiving points.

System Monitoring

4.1.6. Communications

1. ModBus RTU

a. Hardware

The GE Zenith™ Series MDU monitor has a 4 or 2 wire plus ground, RS-422/RS-485

compatible interface. The communications parameters for the interface are 9600

baud, 8 bit, even parity, and 1 stop bit as standard with options for odd and no parity

and 2400, 4800 and 19200 baud. For (4) four wire all commands are sent to the

monitor on (1) one pair and all replies from the monitor are on the other pair. The pair

on which an M4 sends will be in a high impedance state until an M4 responds to a

command. For (2) two wire all commands are sent to a GE ZENITH™ SERIES and all

replies from a GE ZENITH™ SERIES are sent on the same pair. The pair will be in a high

impedance state until an M4 responds to a command. For (2) two wire

communications the transmit + and receive + must be jumped together as well as the

transmit - and receive -. You must also verify that the packet is complete before

another transmit is initiated. The interface is isolated.

b. Packets

The monitor never initiates communications, rather it responds to command packets

sent to it. Each command packet sent to the monitor has an address byte that

includes the address of the destination of that monitor. It does not respond to packets

addressed to “0”.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 30

Page 31

System Monitoring

c. Registers

Most of the analog values are 2 byte integers representing a parameter such as input

voltage, current, etc. KWH takes 2 of the 2-byte integers. Some parameters require

scaling, and are noted in the points list.

d. Prerequisites

Each connected monitor must have a unique address between 1 and 255. The Setup

screen is used to set up the address of the monitor. It also uses additional sequential

address for each device. The number of devices is also in the setup screen.

Note: improper configuration of a GE Zenith Series Monitor may block other

monitors or devices on the chain.

e. Biasing and Termination

Since there is only one master, the master can and should drive its transmit pair

continuously. But slaves do not drive the master’s receive pair until they send the

master a response. As soon as they are finished, they stop driving the master’s receive

pair. This is necessary since other slaves may need to send responses on the master’s

receive pair. Therefore, most of the time the master’s receive pair is just floating. The

master’s adapter SHOULD drive its transmit pair continuously and, of course, never

drive the receive line, except in an effort to be 2 wire compatible. Most adapters do not

drive the transmit pair until the start of the first character sent, and only continue to

drive the transmit pair a few milliseconds after the last character (meaning the

master’s transmit pair is usually just floating most of the time).

f. Wiring

RS485/RS422 cable length can be up to 4000ft if the proper cable is used. To achieve

this you need to have a shielded cable with 2 twisted pairs and shield/ground. The two

transmit lines need to be in one twisted pair and the two receive lines need to be in the

other twisted pair. The cable resistance should be 27 ohms/1000ft @ 1 kHz or less and

the mutual capacitance should be 14pf/ft @ 1 kHz or less. RS422 is typically (4) four

wire, and RS485 is typically (2) two wire and is slower than RS422.

g. Supported Commands and Replies

Note that these are typical for the product. See the point list for specifics.

a. Report slave ID

Sent Hex: 01 11 C0 2C

Reply Hex: 01 11 0D EA FE 52 50 50 20 44 69 73 70 6C 61 79 A3 A6

b. Read holding registers

Sent Hex: 01 03 00 00 00 01 84 0A

Reply Hex: 01 03 02 00 00 B8 44

c. Write single register

Sent Hex: 01 06 00 00 00 00 89 CA

Reply Hex: 01 06 00 00 00 00 89 CA

The flag and data numbers shown here are in “human” numbers. The first analog

channel is numbered 1 but, in software, it is accessed by an index value of 0. It is

common for a system to be one register off due to this situation, so it is important to

verify that the registers are correct early in the configuration procedure. As similar

readings are in adjacent registers, being one register off is not necessarily apparent.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 31

Page 32

2. SNMP

a. Hardware

The GE Zenith Series Monitor has an expansion board that can be used to provide

SNMP. The expansion board plugs into the main display board. The SNMP parameters

are configured in the setup menu on the third page. See the setup menu for more

information about configuring the SNMP. SNMP version 1 is supported.

b. Prerequisites

Each connected monitor must have a unique address. The Setup screen is used to set

up the address of the monitor.

Note: improper configuration of a GE Zenith Series Monitor may conflict with

other monitors or devices on the network.

c. Wiring

The connection to the SNMP expansion board is made with a standard Ethernet cable.

d. Supported Commands

Note that these are typical for the product. See the mib file associated with your MDU

configuration for specifics.

a. snmpget

b. snmp

c. write single register

System Monitoring

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 32

Page 33

5.0

Branch Circuit Monitoring System (BCMS)

Your

the Plus version as an

An installed BCMS

currents. The total currents a

Plus

calculations.

Parameters are displayed locally on the

5.1.

GE

601

Plano, TX 75074

option

Calibration and Set

Panelboard #2 Even

Panelboard #2 Odd

Panelboard #1 Even

ENITH

S

MDU

option

Ribbon cable connection for

Ribbon cable connection for

Ribbon cable connection for

Ribbon cable connection for

Panelboard #1 Odd

HILOH

may be equipped with

BCMS Components

5.1.1.

ONTROLS

OAD

in addition to current monitoring,

24 VAC Connection

-

Basic

Acquisition Module

The Acquisition module consists of a fuse, small control transformer and a printed circuit

board (Figure 1 in Appendix A) mounted on a plate. There can be up to 4 CT modules

connected to this board, for a to

digital points. There are also eight terminals for Power CT’s to enable the BCMS to monitor

total current. It sends this information out via ModBus RTU to the local display or customer

supplie

-

up Port (J16)

(2,

(J5

(1, 3, 5…)

(J4

(J3

(J2

added feature to the

option renders the capability to

4, 6…)

PB2B)

PB2A)

(2, 4, 6…)

—

(1, 3, 5…)

—

d monitoring system.

PB1B)

PB1A)

re a summation of the branch circuit breakers on each panel board

GE’sBranch

GE Zenith Series

MDU Owner’

MDU

Circuit Monitoring System

system

measures and monitors source voltages

system

tal of 84 CT’s. There are terminals for six voltages and four

s Manual

measure

MDU

Monitor.

and monitor panel board and/or sub

Branch Circuit Monitoring System (BCMS)

(

BCMS

BCMS

) in either the

TB1

Ground Input

Neutral Input

120 VAC Input

Source 1 Voltage (J9)

RetRXRX+ (TX+)

TX

TX+

Source 2 Voltage (J10)

Source Breaker Closed (J1)

Neutral and Grd. CT Currents (J11)

Panel board 2 CT Currents (J13)

Panel board 1 CT Currents (J12)

Factory Programming Port

(TX

and determines

)

Basic

.

RS485

(J14)

January 2013

Page

version or

The BCMS

feed

power

33

.

-

,

-

-

-

—

—

Z

C

R

Page 34

GE

601

Plano, TX 75074

ENITHSHILOH

5.1.2.

5.1.3.

ONTROLS

OAD

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

ea

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

ch have two wires for existing p

new installation applications and individually mounted split core CT’s that

-

core CTs for sub

MDU Owner’

core CTs for sub

Panel

normally placed on both sides of a panel board. The wire to

normally placed on both sides of a panel board. The wire to

board

anel

s Manual

board

board applications are available.

feed monitoring

feed monitoring

CT’s)

Bran

ch Circuit Monitoring System (BCMS)

purposes make sure the label and

January 2013

Page

34

-

Z

C

R

Page 35

Branch Circuit Monitoring System (BCMS)

5.2. BCMS Local Monitoring via GE Zenith Series MDU Monitor

5.2.1. BCMS Device Setup

Prior to this setup, ensure that all devices have been connected to the monitor via ModBus.

Each BCMS device being added the monitor needs to be assigned a unique ModBus

address. The MDU device is typically assigned address “1”, while subsequent devices are

assigned “2…, 3”, etc.

Device List:

To add a BCMS device, navigate to the main monitor setup screen as described on page

28. While on the main monitor setup, position the cursor “>” on “DEVICES” (using the up or

down keys) and press “ENTER”. This will take the user to the Device List illustrated on this

page. Based on detected connections, the GE Zenith Series Monitor automatically

generates this list.

Device Settings:

Position the cursor on the desired device in the list and

Press “ENTER” to modify settings for that particular device on the next screen (illustrated in

bottom-right section of this page). Once settings are configured, return to the Banner

Screen described on page 27 by pressing “ESC”.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 35

Page 36

5.2.2. Panel board Information

While at the main MDU device screen, press “ENTER” each time to navigate the user

through the various connected devices that have been activated. Once in the BCMS device

summary screen, use the up or down arrow keys to navigate through branch circuit

parameters for each panel board.

Panel board Load Summary:

Displays percentage load per branch circuit on the panel.

Branch Circuit Monitoring System (BCMS)

Panel board Branch Circuits:

Displays currents and alarm status for each branch circuit on the panel. The user scrolls

through the 42-circuits using the up or down arrow keys.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 36

Page 37

Branch Circuit Monitoring System (BCMS)

Panel board Main Parameters:

Shows total currents and voltages for the panel board.

Panel board Power Calculations:

Displays true RMS kW, kVA, kVAR, and also shows kWH.

Panel board Current Trending:

Displays current trends for the panel board over a period of time

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 37

Page 38

Branch Circuit Monitoring System (BCMS)

1. ModBus Data Interface

The normal data protocol is ModBus RTU and uses a 4-wire plus shield, multi-point

EIA/TIA-422-B (RS-422) interface. The default communications parameters for the

interface are 9600 baud, 8 bit, even parity, and 1 stop bit. Parity can be changed.

Optionally, the BCMS data interface can be strapped for 2 wire plus shield RS-485, and

2 wire plus ground RS-232. Note that RS-232 is only possible if there is only one BCMS

(there is no multi-point or daisy chain) and the distance to the computer is less than 20

ft. The communications parameters remain the same. Address 1 is the default base

address. It is changed from the service port.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 38

Page 39

6.0 System Troubleshooting

S

P

R

6.1. System Safety Precautions

DANGER: There is high voltage equipment inside the MDU cabinet. Always use extreme

caution and follow all recommended safety precautions.

DO NOT operate the MDU without all exterior panels properly in place.

DO NOT allow unauthorized personnel to perform any services on your MDU. Please contact

GE’s field support division at (800) 637-1738 for your authorized service agent and for

assistance.

DO NOT touch any printed circuit board without consulting GE’s field support division.

Improper handling of circuitry could cause damage to your MDU and void the

warranty.

If following the troubleshooting procedures below does not repair your MDU, contact GE’s

Service Team at (800) 637-1738 for scheduling service.

6.1.1. Troubleshooting guidelines (GE Zenith Series Monitoring Package)

System Troubleshooting

YMPTOM

No power to unit Unit not connected to

Individual output

circuit has no

power.

No output from unit

but indicators are

on

No upstream

communication

No audible

indication

No able to scroll

thru screens

Not able to see

MDU output

readings

Unable to see BCMS

(optional) panels on

front panel

ROBABLECAUSE

power J box. Main

Breaker not enabled

Output circuit breaker

and or cable is not

connected to MDU.

Main breaker is

turned off or has

tripped

Not able to remotely

communicate to the

monitor

No audible when an

alarm occurs

Cannot see panel

information

No output voltages or

currents are

displayed

No BCMS currents are

displayed on monitor

screens.

EMEDY

Connect unit to Power J box.

Turn on or reset main circuit breaker

Connect output circuit to MDU and

energize circuit.

Check LCD Display for active alarms,

then reset main breaker.

Press the ESC key and verify remote

upstream address, baud rate, & parity

are set correctly.

Press the ESC key and verify the horn is

enabled.

Press the enter button firmly to view

MDU information

Once on the input screen, use the Up

or down arrows to access output

screens.

Verify a BCMS is connected to the

downstream port and press the esc

key to setup the number of additional

Panel boards added.

GE ZENITH CONTROLS MDU Owner’s Manual

601 SHILOH ROAD January 2013

Plano, TX 75074 Page 39

Page 40

GE Zenith Series Monitor Alarm Description

7.0 GE Zenith Series Monitor Alarm Description

ALARM NAME ALARM MESSAGE ALARM DESCRIPTION

Input Phase Rotation "PHASE ROTATION" If the phase rotation is incorrect on the unit's input, the

unit will alarm.

High Temperature Transformer "THERM OVERTEMP” If the 180oC thermal switches located in the windings of

the transformer reach their rating or better, the unit

will alarm. First part of a two stage high transformer

temperature alarm system.

High Temperature Transformer

Shutdown

Input Voltage Phase A-B High “INPUT VOLT AB HIGH" If the input voltage on phase A-phase B goes above the

Input Voltage Phase B-C High “INPUT VOLT BC HIGH" If the input voltage on phase B-phase C goes above the

Input Voltage Phase C-A High "INPUT VOLT CA HIGH" If the input voltage on phase C-phase A goes above the

Input Voltage Phase A-B Low “INPUT VOLT AB LOW" If the input voltage on phase A-phase B goes below the

Input Voltage Phase B-C Low “INPUT VOLT BC LOW" If the input voltage on phase B-phase C goes below the

Input Voltage Phase C-A Low "INPUT VOLT CA LOW" If the input voltage on phase C-phase A goes below the

Output Voltage Line A-B High “OUTPUT VOLT AB HIGH" If the output voltage on line A-line B goes above the

Output Voltage Line B-C High " OUTPUT VOLT BC HIGH" If the output voltage on line B-line C goes above the

Output Voltage Line C-A High " OUTPUT VOLT CA HIGH" If the output voltage on line C-line A goes above the

Output Voltage Line A-B Low " OUTPUT VOLT AB LOW" If the output voltage on line A-line B goes below the

Output Voltage Line B-C Low "OUTPUT VOLT BC LOW” If the output voltage on line B-line C goes below the

Output Voltage Line C-A Low "OUTPUT VOLT CA LOW" If the output voltage on line C-line A goes below the

Output Voltage Line

A - Neutral High

Output Voltage Line

B - Neutral High

Output Voltage Line

C - Neutral High

"THERM HIGHTEMP" If the 200

the transformer reach their rating or better, the unit's

main circuit breaker will shunt trip, shutdown the unit.

Second part of a two stage high transformer

temperature alarm system.

preset level line to line, the unit will alarm.

preset level line to line, the unit will alarm.

preset level line to line, the unit will alarm.

preset level line to line, the unit will alarm.

preset level line to line, the unit will alarm.

preset level line to line, the unit will alarm.