Page 1

GE Zenith™ Series DPB

Distributed Power Busway

INSTALLATION & OPERATION

MANUAL

Page 2

Series DPB Busway Installation & Operation Manual

©2013 General Electric Company. All rights reserved. This product or document is protected by copyright and distributed

under licenses restricting its use, copying, distribution and recompilation. No part of this product or document may be

reproduced in any form, by any means, without the prior written authorization of General Electric Company and its

licensors, if any.

TRADEMARKS

GE Zenith™ Series DBP Distrubuted Power Busway and other marks in this document may be trademarks or registered

trademarks of General Electric Company.

All other products, services, or company names mentioned herein are claimed as trademarks and trade names by their

respective companies.

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-

INFRINGEMENT. THIS PUBLICATION COULD INCLUDE TECHNICAL INACCURACIES OR TYPOGRAPHICAL ERRORS. CHANGES ARE

PERIODICALLY ADDED TO THE INFORMATION HEREIN, THESE CHANGES WILL BE INCORPORATED IN NEW EDITIONS OF THE

PUBLICATION. GENERAL ELECTRIC COMPANY MAY MAKE IMPROVEMENTS AND/OR CHANGES IN THE PRODUCT(S) AND/OR

THE PROGRAM(S) DESCRIBED IN THIS PUBLICATION AT ANY TIME.

Contact information:

GE Critical Power

2501 Pecan Street

Bonham, TX 75418

www.geindustrial.com/criticalpower

Series DPB Bus System Installation & Operation Manual

March 2013

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 3

TABLE OF CONTENTS

Installation Guide ................................................................................................................................1

Introduction ................................................................................................................................................................ 2

Safety Warning ......................................................................................................................................................... 3

Receiving, Handling, & Storage ......................................................................................................................... 4

RECEIVING ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

HANDLING ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

STORAGE ............................................................................................................................................................................................... ...........................4

Installation ..................................................................................................................................................................5

PRE-INSTALLATION REVIEW �������������������������������������������������������������������������������������������������������������������������������������������������������������� 5

INSTALLATION HAZARD ���������������������������������������������������������������������������������������������������������������������������������������������������������������������� 6

VERTICAL BUSWAY INSTALLATION ........................................................................................................................................... ...........................6

HORIZONTAL BUSWAY INSTALLATION �������������������������������������������������������������������������������������������������������������������������������������������� 7

BUSWAY SYSTEM MOUNTING ������������������������������������������������������������������������������������������������������������������������������������������������������������ 8

MOUNTING THE END FEED ���������������������������������������������������������������������������������������������������������������������������������������������������������������� 9

VERTICAL END FEED SUPPORT������������������������������������������������������������������������������������������������������������������������������������������������� 9

HORIZONTAL END FEED SUPPORT ������������������������������������������������������������������������������������������������������������������������������������������ 9

MOUNTING THE BUSRAIL ����������������������������������������������������������������������������������������������������������������������������������������������������������������� 10

SUPPORT �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 10

NEUTRALS ALIGNMENT ������������������������������������������������������������������������������������������������������������������������������������������������������������ 10

INSTALLATION OF THE SPLICE CONNECTOR – 160 - 250 AMP �����������������������������������������������������������������������������������������������11

INSTALLATION OF OPTIONAL "C-CLIPS" FOR 35kAIC RATED 400A BUSWAY ����������������������������������������������������������������������15

END FEED C-CLIP INSTALLATION �������������������������������������������������������������������������������������������������������������������������������������������15

BUSRAIL AND SPLICE JOINT C-CLIP INSTALLATION ���������������������������������������������������������������������������������������������������������15

INSTALLATION OF THE SPLICE CONNECTOR – 400 AMP ����������������������������������������������������������������������������������������������������������17

INSTALLATION OF THE END CAP CLOSURE PLATE ���������������������������������������������������������������������������������������������������������������������20

CABLE TERMINATIONS TO THE END FEED BOX ���������������������������������������������������������������������������������������������������������������������������21

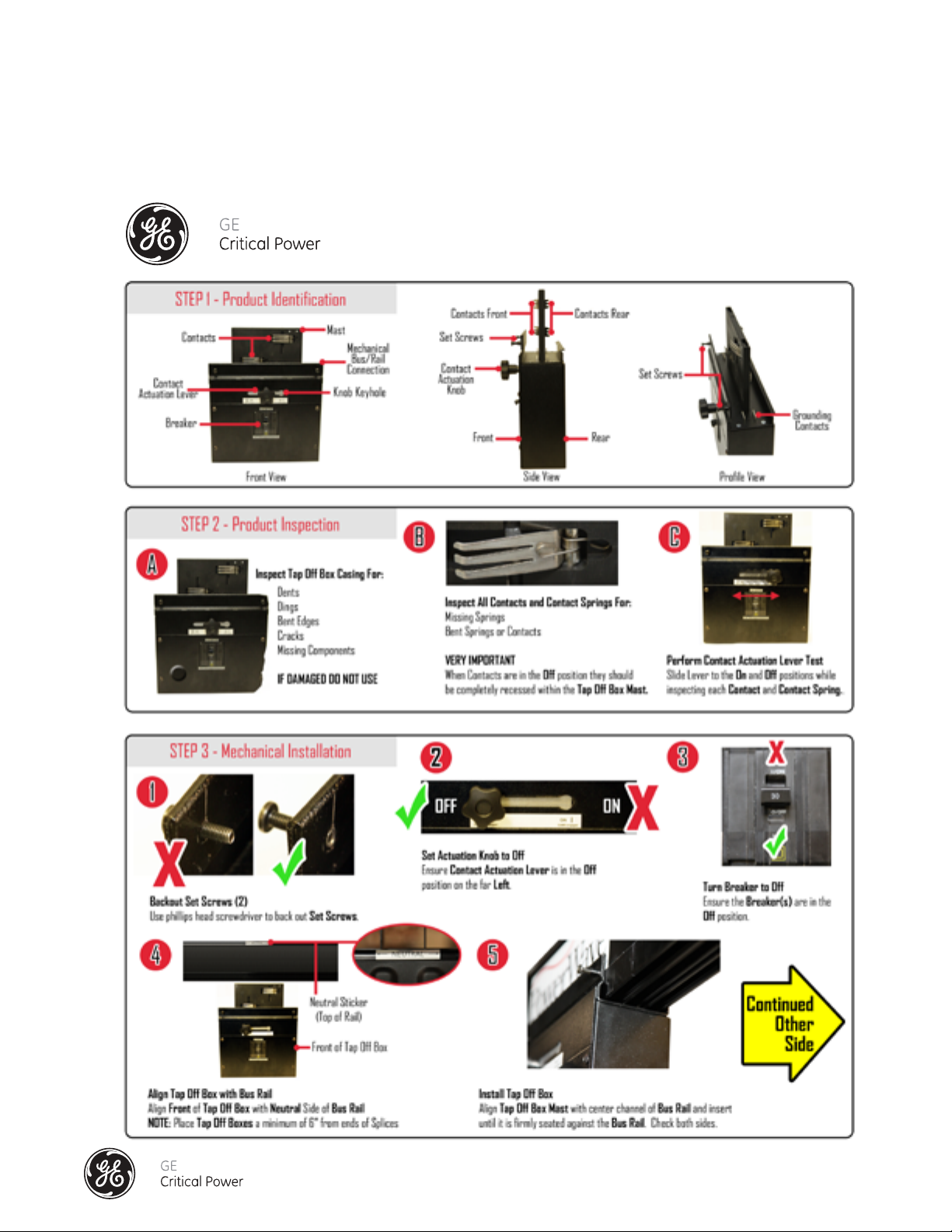

TAP OFF BOX INSTALLATION ������������������������������������������������������������������������������������������������������������������������������������������������������������23

INSTALLATION WARNING �������������������������������������������������������������������������������������������������������������������������������������������������������23

TAP OFF BOX MOUNTING ��������������������������������������������������������������������������������������������������������������������������������������������������������24

Before Energizing The Busway Checklist ....................................................................................................25

Energizing The Busway System ......................................................................................................................26

Maintenance ............................................................................................................................................................27

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 4

TABLE OF CONTENTS, CONTINUED

Branch Circuit Monitoring System (BCMS) ............................................................................ 29

Safety Warning .......................................................................................................................................................30

Scope ...........................................................................................................................................................................31

System Description ...............................................................................................................................................32

Power Monitoring System Overview .............................................................................................................32

Option 1 - TAP OFF BOX MONITORING ONLY ������������������������������������������������������������������������������������������������������������������������������ 33

SAFETY WARNING ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 33

END FEED BOX COMPONENTS ���������������������������������������������������������������������������������������������������������������������������������������������� 33

ACCUMULATOR PCB������������������������������������������������������������������������������������������������������������������������������������������������������������������34

POWER INSERTER PCB ������������������������������������������������������������������������������������������������������������������������������������������������������������� 34

SAFETY WARNING ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

TAP OFF BOX MONITORING COMPONENTS ������������������������������������������������������������������������������������������������������������������������ 35

COMMUNICATIONS CABLE CONNECTION ��������������������������������������������������������������������������������������������������������������������������� 35

Option 2 - END FEED MONITORING ONLY ������������������������������������������������������������������������������������������������������������������������������������ 36

SAFETY WARNING ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 36

END FEED BOX COMPONENTS ���������������������������������������������������������������������������������������������������������������������������������������������� 36

ACCUMULATOR PCB������������������������������������������������������������������������������������������������������������������������������������������������������������������37

POWER INSERTER PCB ������������������������������������������������������������������������������������������������������������������������������������������������������������� 37

INPUT PM PCB ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 38

Option 3 - TAP OFF BOX AND END FEED MONITORING CONCURRENTLY ����������������������������������������������������������������������������39

SAFETY WARNING ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 39

END FEED BOX COMPONENTS ���������������������������������������������������������������������������������������������������������������������������������������������� 39

ACCUMULATOR PCB������������������������������������������������������������������������������������������������������������������������������������������������������������������40

POWER INSERTER PCB ������������������������������������������������������������������������������������������������������������������������������������������������������������� 40

INPUT PM PCB ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 41

SAFETY WARNING ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 41

TAP OFF BOX MONITORING COMPONENTS ������������������������������������������������������������������������������������������������������������������������ 41

COMMUNICATIONS CABLE CONNECTION ��������������������������������������������������������������������������������������������������������������������������� 42

Communications ....................................................................................................................................................43

CONNECTING THE END FEED BOX TO LOCAL DISPLAYS OR BMS / DCIM SOLUTIONS ���������������������������������������������������� 44

RS 485 FOUR-WIRE CONNECTION ���������������������������������������������������������������������������������������������������������������������������������������� 44

RS 485 TWO-WIRE CONNECTION ����������������������������������������������������������������������������������������������������������������������������������������� 45

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 5

TABLE OF CONTENTS, CONTINUED

ACCUMULATOR BOARD CONNECTIONS ��������������������������������������������������������������������������������������������������������������������������������������� 46

BCMS SETUP DOCUMENTATION ����������������������������������������������������������������������������������������������������������������������������������������������������� 47

REQUIRED MATERIAL ����������������������������������������������������������������������������������������������������������������������������������������������������������������47

STARTUP ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 47

USING THE ACCUMULATOR SETUP PROGRAM ������������������������������������������������������������������������������������������������������������������48

COMMON PROCEDURES ���������������������������������������������������������������������������������������������������������������������������������������������������������� 50

DATA TAB �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 51

WINDOW TAB �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������52

CUSTOMER CONNECTIONS TO 7" LOCAL DISPLAY �������������������������������������������������������������������������������������������������������������������� 53

PRODUCT INTRODUCTION ������������������������������������������������������������������������������������������������������������������������������������������������������ 53

COMPONENT IDENTIFICATION �����������������������������������������������������������������������������������������������������������������������������������������������55

POWER CONNECTIONS ������������������������������������������������������������������������������������������������������������������������������������������������������������ 56

MODBUS CONNECTION �����������������������������������������������������������������������������������������������������������������������������������������������������������57

MODBUS CONNECTIONS ON IX DISPLAY INTERFACE BOARD ���������������������������������������������������������������������������������������� 58

MODBUS TO 7" LOCAL DISPLAY WIRING SCHEMATIC ������������������������������������������������������������������������������������������������������ 59

CHANGE MODBUS RTU FROM RS422 TO VIA ETHERNET ������������������������������������������������������������������������������������������������ 60

Appendix A: Tap Off Box Monitoring Specifications ...............................................................................62

MONITORED PARAMETERS ���������������������������������������������������������������������������������������������������������������������������������������������������������������62

ALARM PARAMETERS ������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 63

PERSONALIZATION �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������64

Appendix B: End Feed (Input PM PCB) Monitoring Specifications ....................................................65

MONITORED PARAMETERS ���������������������������������������������������������������������������������������������������������������������������������������������������������������65

ALARM PARAMETERS ������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 66

PERSONALIZATION �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������67

Appendix C: Bus Monitoring System Schematic Diagrams ................................................................68

BRANCH CIRCUIT MONITORING SYSTEM BOARD INTERCONNECTION �������������������������������������������������������������������������������� 68

INPUT POWER MONITOR BOARD TO END FEED CURRENT TRANSFORMERS CONNECTIONS ����������������������������������������69

Appendix D: Points List for the End Feed Input PM PCB.......................................................................71

Appendix E: Points List for the Tap Of Box IntelliBUS Board ..............................................................78

Appendix F: Specifications .................................................................................................................................86

GENERAL ����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 86

INPUT PM BOARD SPECIFICATIONS ����������������������������������������������������������������������������������������������������������������������������������������������� 86

INTELLIBUS BOARD SPECIFATIONS ������������������������������������������������������������������������������������������������������������������������������������������������ 86

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 6

TABLE OF CONTENTS, CONTINUED

NETWORK COMMUNICATIONS �������������������������������������������������������������������������������������������������������������������������������������������������������87

LISTINGS �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������87

Appendix G: Service ..............................................................................................................................................88

STANDARD WARRANTY ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 88

START UP ����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 88

TRAINING ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 88

EXTENDED WARRANTY ��������������������������������������������������������������������������������������������������������������������������������������������������������������������� 88

TIME AND MATERIALS ������������������������������������������������������������������������������������������������������������������������������������������������������������������������88

SPARE PARTS ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 89

Appendix H: Quick Install Sheets ....................................................................................................................90

160A - 400A SPLICE QUICK INSTALL SHEET ���������������������������������������������������������������������������������������������������������������������������������90

TAP OFF BOX QUICK INSTALL SHEET ��������������������������������������������������������������������������������������������������������������������������������������������� 92

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 7

LIST OF FIGURES

Figure 1 - Vertical Busway Installation ����������������������������������������������������������������������������������������������������6

Figure 2 - Horizontal Busway Installation �����������������������������������������������������������������������������������������������7

Figure 3 - Vertical End Feed Support ��������������������������������������������������������������������������������������������������������9

Figure 4 - Horizontal End Feed Support ���������������������������������������������������������������������������������������������������9

Figure 5 - Busrail Mounting Support around Splice Point ����������������������������������������������������������������10

Figure 6 - Busrail Neutrals Alignment ����������������������������������������������������������������������������������������������������10

Figure 7 - Splice Installation Overview 160 - 250 Amp ����������������������������������������������������������������������11

Figure 8 - Splice Installation Detail 160 - 250 Amp�����������������������������������������������������������������������������12

Figure 8�1 - Cam Spacers in Locked Position����������������������������������������������������������������������������������������13

Figure 8�2 - Dowel Pin ���������������������������������������������������������������������������������������������������������������������������������13

Figure 8�5 - Dowel Pin O-Ring Inside "E" Clip ����������������������������������������������������������������������������������������14

Figure 8�3 - Positioning of Dowel Pins ����������������������������������������������������������������������������������������������������14

Figure 8�4 - Insertion of Dowel Pin ����������������������������������������������������������������������������������������������������������14

Figure 9 - End Feed C-Clip Installation - 400 Amp ������������������������������������������������������������������������������15

Figure 10 - Busrail C-Clip Installation - 400 Amp ��������������������������������������������������������������������������������15

Figure 11 - Busrail C-Clip Profile View - 400 Amp �������������������������������������������������������������������������������16

Figure 12 - Busrail Cam Spacers ��������������������������������������������������������������������������������������������������������������16

Figure 13 - Busrail C-Clip Splice and E-Clip Location - 400 Amp ����������������������������������������������������16

Figure 14 - Splice Installation Overview - 400 Amp����������������������������������������������������������������������������17

Figure 15 - Splice Installation Detail 400 Amp �������������������������������������������������������������������������������������18

Figure 15�1 - Cam Spacers in Locked Position �������������������������������������������������������������������������������������18

Figure 15�2 - Dowel Pin �������������������������������������������������������������������������������������������������������������������������������19

Figure 15�3 - Positioning of Dowel Pins ��������������������������������������������������������������������������������������������������19

Figure 15�4 - Insertion of Dowel Pin ��������������������������������������������������������������������������������������������������������19

Figure 15�5 - Dowel Pin O-Ring Inside "E" Clip �������������������������������������������������������������������������������������20

Figure 16 - Busrail End Cap Installation ������������������������������������������������������������������������������������������������20

Figure 17 - Standard End Feed Cable Terminations ���������������������������������������������������������������������������21

Figure 18 - Branch Circuit Monitoring (BCMS) End Feed Cable Terminations �����������������������������21

Figure 19 - End Feed Current Transformer (CT) Orientation ������������������������������������������������������������22

Figure 20 - Tap Off Box Connections ������������������������������������������������������������������������������������������������������24

Figure 21 - Tap Off Box Mounting and Energizing ������������������������������������������������������������������������������24

Figure 22 - Branch Circuit Monitoring System Overview ������������������������������������������������������������������32

Figure 23 - Option 1 - Branch Circuits via BCMS-Equipped Tap Off Boxes ����������������������������������33

Figure 24 - Option 1 - End Feed Box Monitoring Components ��������������������������������������������������������33

Figure 25 - Accumulator PCB ��������������������������������������������������������������������������������������������������������������������34

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 8

LIST OF FIGURES, CONTINUED

Figure 26 - Power Inserter PCB ����������������������������������������������������������������������������������������������������������������34

Figure 28 - Tap Off Box Communication Interface Into Busrail ������������������������������������������������������35

Figure 27 - Tap Off Box with Branch Circuit Monitoring Installed ��������������������������������������������������35

Figure 29 - Option 2 - Busway Input Feeder Monitoring �������������������������������������������������������������������36

Figure 30 - Option 2 - End Feed Box Bus Monitoring Components ������������������������������������������������36

Figure 31 - Accumulator PCB ��������������������������������������������������������������������������������������������������������������������37

Figure 32 - Power Inserter PCB ����������������������������������������������������������������������������������������������������������������37

Figure 33 - Input PM Board ������������������������������������������������������������������������������������������������������������������������38

Figure 34 - Option 3 - End Feed Power and Tap Off Branch Circuits Monitoring �����������������������39

Figure 35 - Option 3 - End Feed Box Monitoring Components ��������������������������������������������������������39

Figure 36 - Accumulator PCB ��������������������������������������������������������������������������������������������������������������������40

Figure 37 - Power Inserter PCB ����������������������������������������������������������������������������������������������������������������40

Figure 38 - Input PM PCB ���������������������������������������������������������������������������������������������������������������������������41

Figure 39 - Tap Off Box with Branch Circuit Monitoring Installed ��������������������������������������������������41

Figure 40 - Tap Off Box Communication Interface Into Series DPB Busrail���������������������������������42

Figure 41 - RS485 Four-Wire Connection Scheme ������������������������������������������������������������������������������44

Figure 42 - RS485 Two-Wire Connection Scheme �������������������������������������������������������������������������������45

Figure 43 - End Feed Accumulator Board ���������������������������������������������������������������������������������������������46

Figure 44 - BCMS Setup Startup Screen �������������������������������������������������������������������������������������������������47

Figure 45 - BCMS Setup Tab ����������������������������������������������������������������������������������������������������������������������48

Figure 46 - BCMS Setup Tab Detail ����������������������������������������������������������������������������������������������������������49

Figure 47 - BCMS Setup Data Tab Window �������������������������������������������������������������������������������������������51

Figure 48 - 7" Series DPB Bus Systems Local Display ������������������������������������������������������������������������53

Figure 49 - 7" Local Display End Feed Screenshot ������������������������������������������������������������������������������54

Figure 50 - 7" Local Display Tap Off Box Screenshot �������������������������������������������������������������������������54

Figure 51 - 7" Series DPB Local Display Primary Components �������������������������������������������������������55

Figure 52 - IX Display Interface Board ��������������������������������������������������������������������������������������������������56

Figure 53 - Modbus Wiring Diagram ������������������������������������������������������������������������������������������������������57

Figure 54 - Connections on IX Display Interface Board ��������������������������������������������������������������������58

Figure 55 - Modbus to 7" Local Display Wiring Schematic ���������������������������������������������������������������59

Figure 56 - Branch Circuit Monitoring System Board Interconnection �����������������������������������������68

Figure 57 - Input Power Monitor Board to End Feed Current Transformers Schematic ����������69

Figure 59 - End Feed Current Transformer (CT) Orientation ������������������������������������������������������������70

Figure 58 - End Feed Input Power Monitor Board �������������������������������������������������������������������������������70

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

Page 9

INSTALLATION GUIDE

160, 225, 250, 400 AMP

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

1

Page 10

Series DPB Busway Installation & Operation Manual

INTRODUCTION

This manual details the fundamental instructions required for the proper handling, storage, installation and maintenance of

the Series DPB Busway manufactured by GE Critical Power.

Installers shall familiarize themselves with this document and become familiar with the design and specific characteristics of

each Series DPB Busway component and run. Proper planning and coordination between trades is important for an efficient

installation.

Every component shall be tested, inspected and packaged at the assembly plant. Manufacturing details are checked and

tested regarding the mechanical and electrical specification of the system. After factory inspection, the busway is boxed and

crated for shipment to the job site. The catalogue number and job number will be clearly marked on each shipping package

and individual item.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

2

Page 11

Series DPB Busway Installation & Operation Manual

SAFETY WARNING

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

Only qualied electrical maintenance personnel should install, operate, service and maintain

this busway system and associated equipment. This document should not be viewed as

sufcient for those who are not otherwise qualied to operate, service, or maintain the

equipment discussed.

Turn off power to the busway before installing, removing, or working on this equipment.

CONFIRM THAT ALL POWER IS OFF

Always use a properly rated voltage sensing device to conrm that all power is off. Always

wear proper protection.

The accurate operation of this equipment depends upon proper handling, installation,

operation, and maintenance.

Failure to follow these instructions may result in serious injury or death

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

3

Page 12

Series DPB Busway Installation & Operation Manual

RECEIVING, HANDLING, & STORAGE

WARNING

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

Protect this equipment from containments such as water, salt, concrete dust and other corrosive

environments before and during installation.

Equipment and packing are not weather resistant and shall not be stored outside or exposed to

the environment

Do not sit, walk or stand on this equipment.

RECEIVING

HANDLING

Failure to follow these instructions may result in equipment damage, serious

injury or death.

Upon receipt, check the packing list against the equipment received to ensure the order and shipment are

complete. Claims for shortages or other errors must be made in writing to GE Corp within 30 days after the

receipt of your shipment.

Upon receipt, inspect the busway packaging components and sections for any damage that may have

occurred during shipping. If damage is found, immediately make a claim with the carrier and notify

GE Critical Power.

Cut the banding that secures the package with band cutters.

Exercise care when unpacking.

Handle these products with care, avoid damage to the components, do not drop, bend, pierce or mishandle in

any manner the system as this may lead to a faulty installation

Avoid denting or mishandling that may cause damage. Ensure the handling personnel and equipment at the

job site is adequate for handling the busway.

Use the correct tools to remove the packing at each busway end. Take care not to damage the housing,

which could result in a failure of the busway. Avoid using objects with sharp edges to lift the busway.

STORAGE

Most packaging is recyclable dispose of all packing appropriately.

If the busway is not installed and energized immediately, store the busway in its original packaging in a clean,

dry space.

Busway should not be stored outdoors.

Busway should not be stored in a moist environment.

Protect against moisture.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

4

Page 13

Series DPB Busway Installation & Operation Manual

INSTALLATION

PRE-INSTALLATION REVIEW

PROPER INSTALLATION OF THE SERIES DPB BUSWAY IS

ESSENTIAL TO THE BUSWAY OPERATION.

Before installing the busway:

1) Conduct an insulation resistance test on each busway device to check for possible

damage during shipment or storage. Ensure the phase-to-phase, phase-to-neutral,

and phase-to-ground isolation.

2) Confirm that the ambient temperature range is within acceptable limits –10°C through +40°C.

If not, please consult the factory for possible de-rating.

3) Ensure that there is sufficient clearance from the walls, ceilings, and load devices.

4) Ensure that the factory-manufactured mounting supports will conform to the recommended

spacing guidelines as detailed in the section titled "Mounting the Busrail".

5) Ensure that all splice connections, end feed units, and tap off boxes will be accessible after

installation.

6) After determining the clearances and the mounting method (vertical or horizontal) for the busway

system, level and align the end feeds and busrails before the final tightening and alignment of all

supporting members.

7) Align the busbar ends of adjoining sections, verifying proper busbar alignment, phasing,

and spacing.

8) Verify that the incoming system phasing, and voltage match the busway system phasing and

rated voltage.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

5

Page 14

Series DPB Busway Installation & Operation Manual

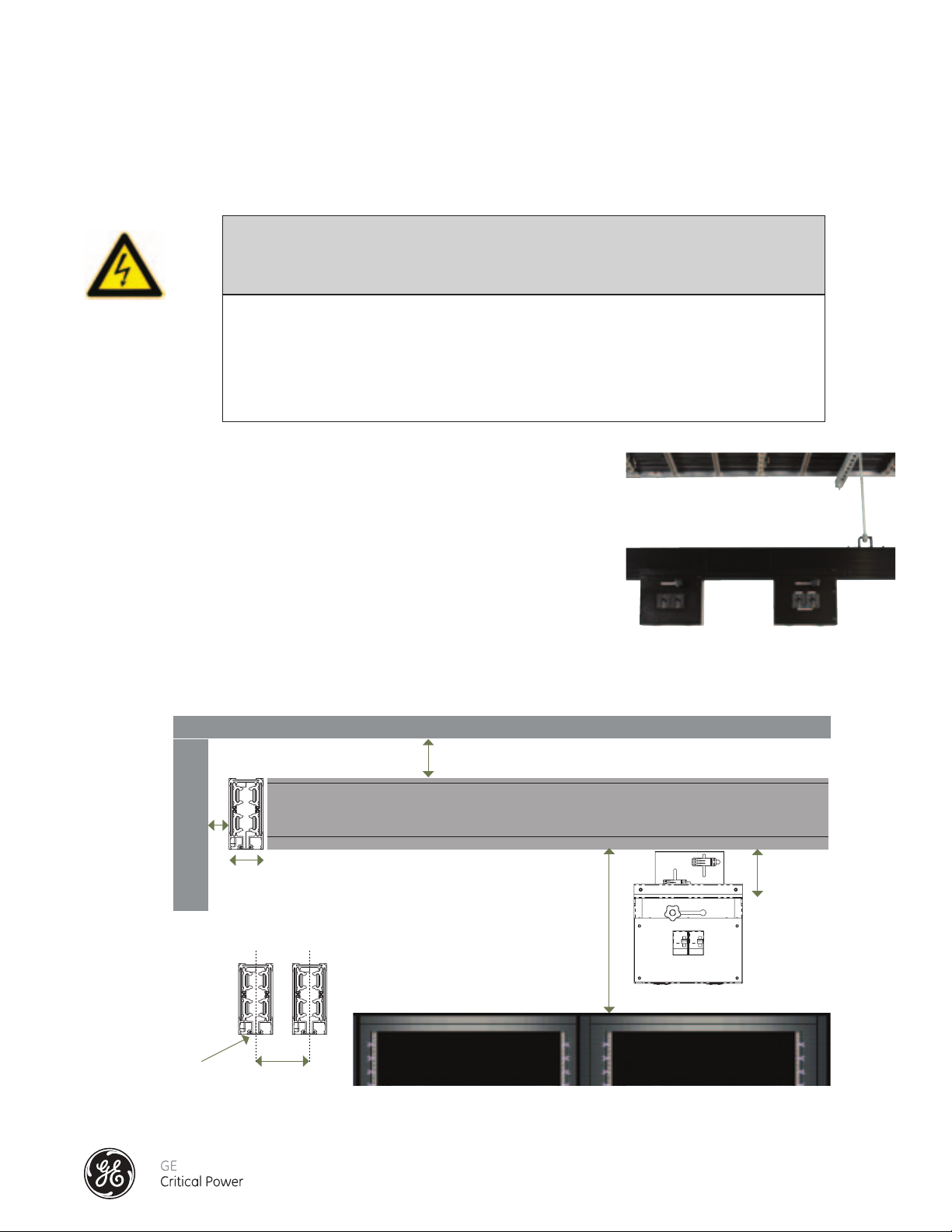

INSTALLATION HAZARD

Depending on the installation orientation of the busways, the following WARNING should always be considered.

CAUTION

HAZARD OF EQUIPMENT DAMAGE

Always maintain the minimum required clearance distance as shown below.

Failure to follow these instructions may result in equipment damage or personal

injury.

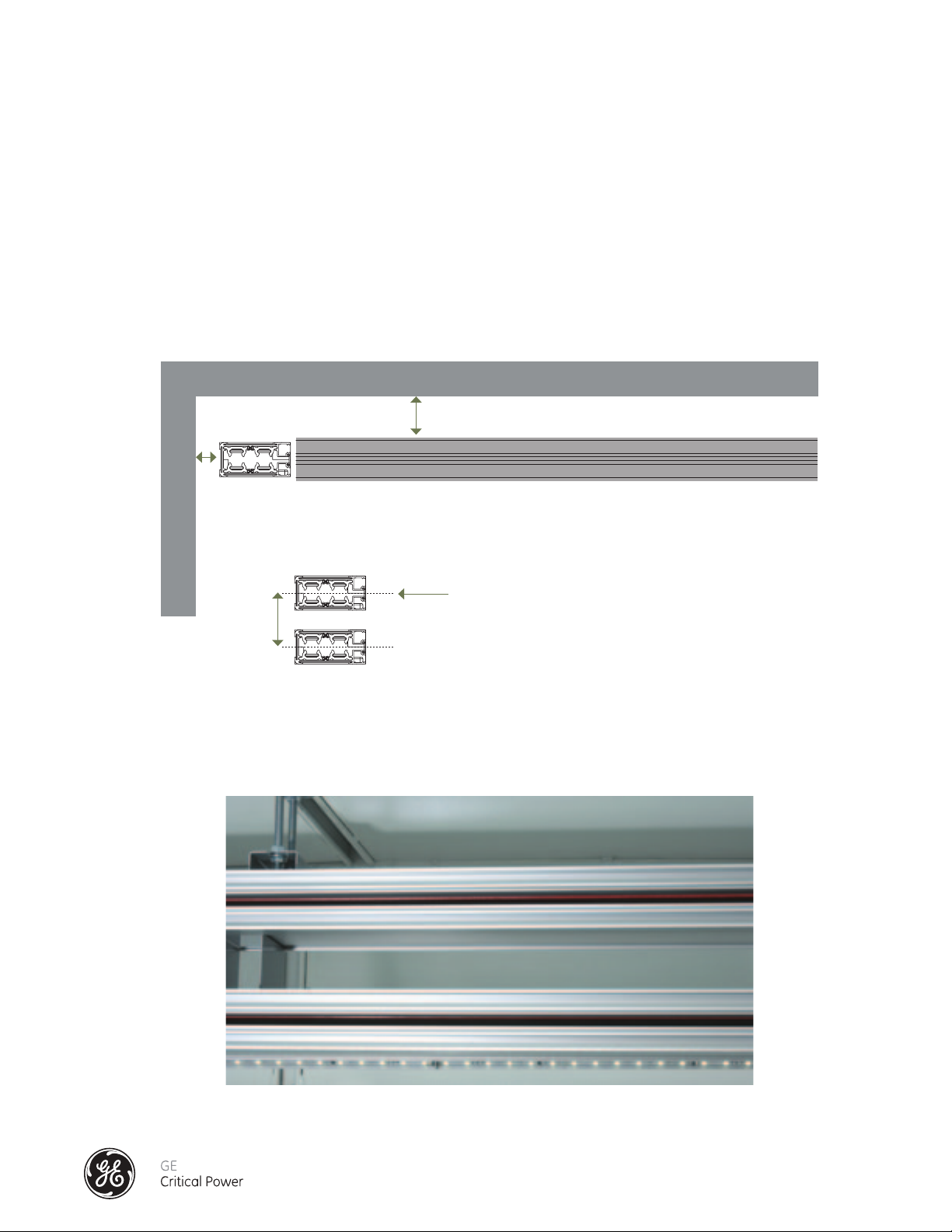

VERTICAL BUSWAY INSTALLATION

See Figure 1. For busways installed vertically with channel opening down,

always maintain:

A minimum clearance distance of 6 inches (153 mm) from the top of the

busways to the ceiling and 1 inch (26mm) from the wall.

Parallel runs for two systems mounted in the same area shall have the following

clearances between the systems.

A minimum clearance distance of 6 inches (153 mm) from the center-point of

busway run A to the next run B.

ceiling

6"

wall

1"

2.5"

bus rail A

underside of busway

bus rail B

18" minimum

Top of Server Cabinet

or Equipment

5"

underside of busway

6"

Figure 1 - Vertical Busway Installation

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

6

Page 15

Series DPB Busway Installation & Operation Manual

HORIZONTAL BUSWAY INSTALLATION

See Figure 2. For busways installed flat wise or horizontally, maintain the following clearances.

A minimum clearance of 6 inches (153mm) from top of bus to ceiling.

A minimum clearance distance of 1 inch (26 mm) from the back of the busways to the edge of the wall.

A minimum clearance distance of 6 inches (153 mm) from the center-point of one busway run to

the next when mounted in a stacked configuration, one above the other.

ceiling

6"

1.0"

underside of busway

wall

bus rail A

Tap Off box insertion

6"

bus rail B

Figure 2 - Horizontal Busway Installation

Example A/B Horizontal Busway Installation

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

7

Page 16

Series DPB Busway Installation & Operation Manual

BUSWAY SYSTEM MOUNTING

SPECIFIED AND SAFE OPERATION OF THE SERIES DPB BUSWAY IS DEPENDENT ON ITS

PROPER INSTALLATION. MISALIGNMENT OF THE BUSWAY COMPONENTS, (END FEEDS,

BUS RAILS, AND SPLICES) WILL COMPROMISE ITS PERFORMANCE.

1) End Feed enclosures must be securely mounted so that they are completely level (side-to-side and front-to-back).

2) Bus Rails must be securely installed so that they are level and completely aligned to the End Feed enclosures and with

adjoining Bus Rail sections.

3) When each Busway run is properly supported / mounted, leveled , and aligned, all Splices must be verified to be

"un-cammed" (not actuated with Cam Actuator Tool).

4) The Splice units must be able to move freely and fully into both sections of adjoining sections of bus before the Splices can

be "cammed" (actuated).

5) Once the free movement of the Splice units is verified, the Splice can be actuated. The installation of Dowel Pins completes

the correct installation of the Splices.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

8

Page 17

Series DPB Busway Installation & Operation Manual

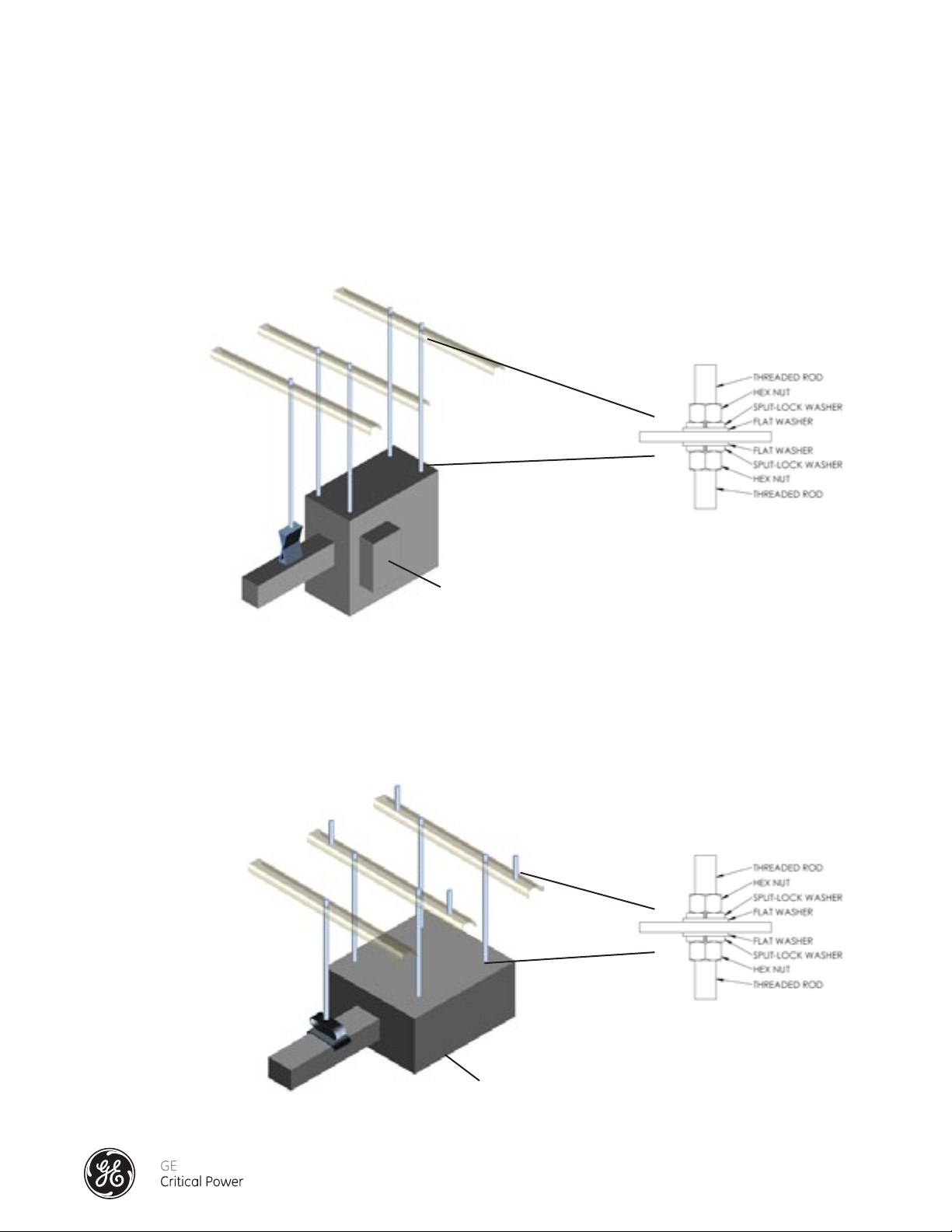

MOUNTING THE END FEED

VERTICAL END FEED SUPPORT

Series DPB End Feed enclosures can be mounted in a number of ways. The recommended method for mounting Series DPB

End Feed enclosures is as shown in Figure 3. Four 3/8" threaded rods (see Figure 3A) secure the enclosure to the ceiling or to

UnistrutTM, and a standard busway hanger supports the Splice Extension. These need to be aligned and leveled to each other

so that the End Feed is completely level after installation.

UNISTRUT

TM

Figure 3A

THREADED ROD

END FEED

VERTICAL BUSRAIL HANGER

END FEED OR

CEILING / UNISTRUT

TM

OPTIONAL BCMS

MONITORING MODULE

Figure 3 - Vertical End Feed Support

HORIZONTAL END FEED SUPPORT

Series DPB End Feed enclosures can be horizontally mounted. The recommended method is similar to the vertical mounting

method and is shown in Figure 4 below. The enclosure is supported by four 3/8" threaded rods (see Figure 4A) secure the

enclosure to the ceiling or to UnistrutTM, and a standard busway hanger supports the Splice Extension. These need to be

aligned and leveled to each other so that the End Feed is completely level after installation.

UNISTRUT

TM

HORIZONTAL BUSRAIL HANGER

THREADED ROD

END FEED

OPTIONAL BCMS

MONITORING MODULE

ON BOTTOM OF END FEED

Figure 4 - Horizontal End Feed Support

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

Figure 4A

END FEED OR

CEILING / UNISTRUT

GE Confidential

TM

9

Page 18

Series DPB Busway Installation & Operation Manual

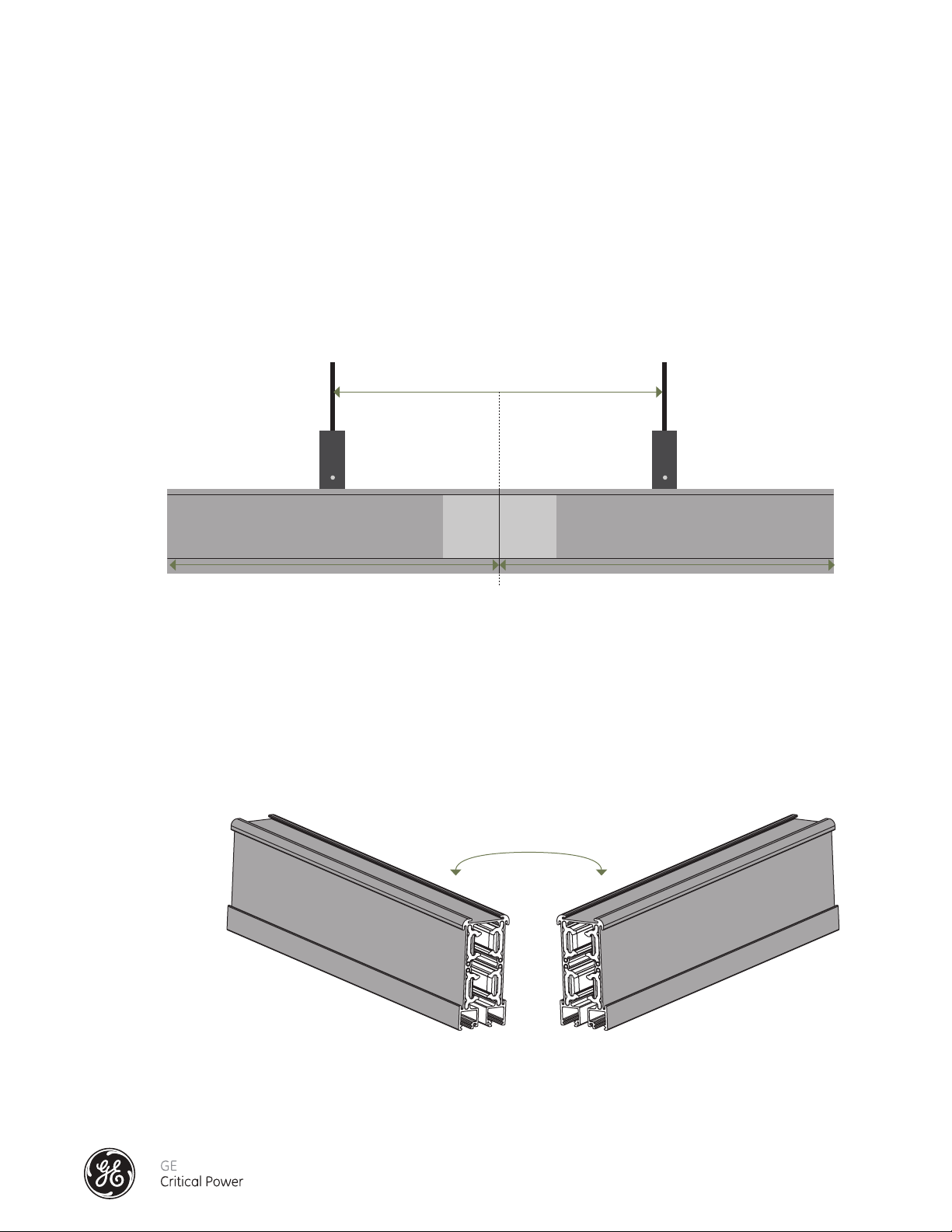

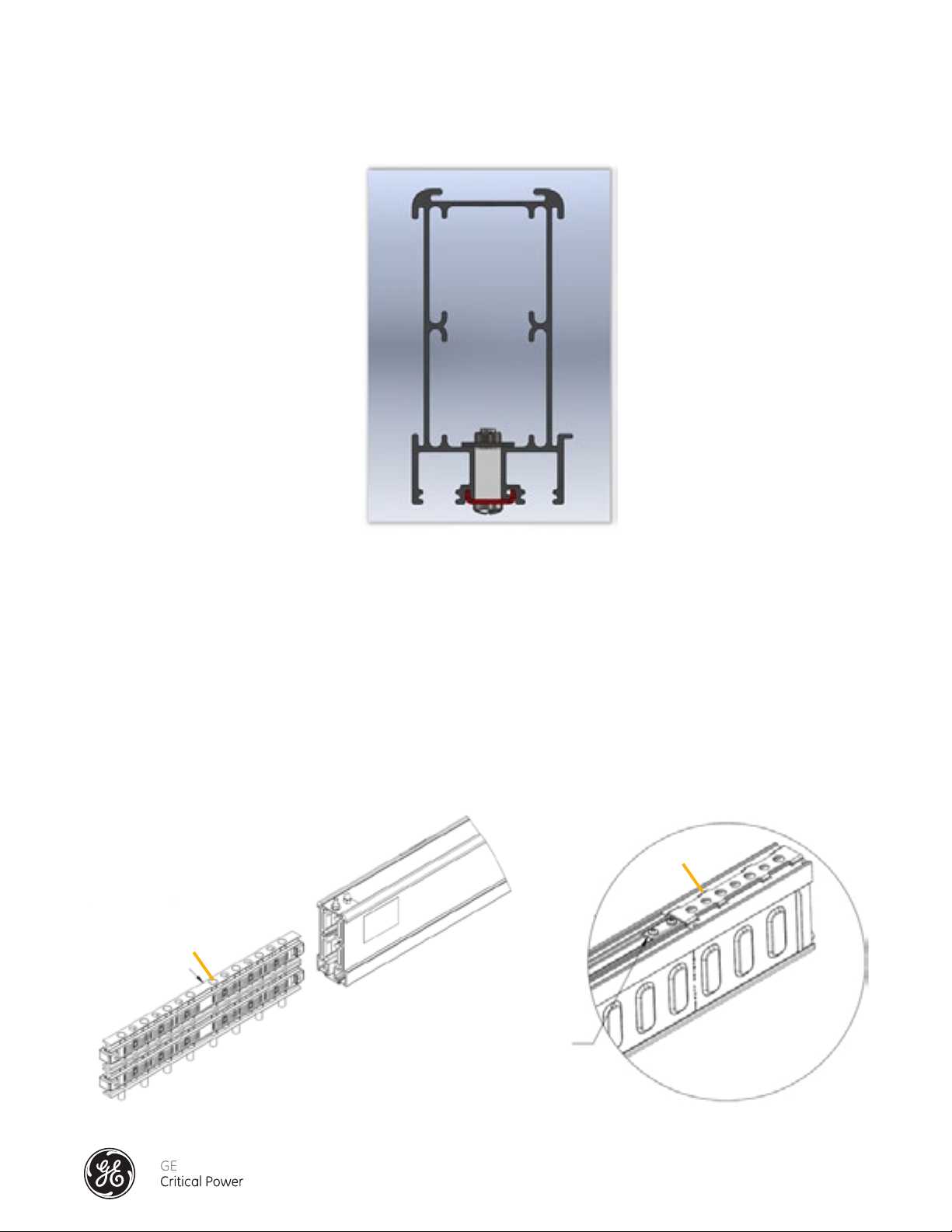

MOUNTING THE BUSRAIL

SUPPORT

When mounting the bus rail please use the supplied hangers that are designed to fit into the top and or side channels found

on each section of bus rail. Each section of bus rail should have at least one hanger and threaded rod assembly with the

maximum span being 5' on centers. 10' and 12' bus rail sections should have a minimum of two hanger and threaded rod

assemblies. Bus Rail lengths longer than 12' should have a minimum of three hangers and threaded rod assemblies. The

span of the hanger and threaded support at a Splice point should be a maximum of 6' on center. Each section of bus rail

needs to be aligned and level. See Figure 5.

Threaded Rod and

Hanger Assembly

6'

X

Figure 5 - Busrail Mounting Support around Splice Point

NEUTRALS ALIGNMENT

Our busway system is designed so that it is NOT possible to mount the busways if the neutral conductor is not in phase with

one another from section to section. The neutral conductor of each element MUST be aligned on the same side of the system. Clear markings are also made on the busway system to ensure proper phasing. See Figure 6.

Threaded Rod and

Hanger Assembly

X

X = 10' to 12'

neutral to neutral

neutral

NA

Figure 6 - Busrail Neutrals Alignment

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

A

C

CB

neutral

N

B

GE Confidential

10

Page 19

Series DPB Busway Installation & Operation Manual

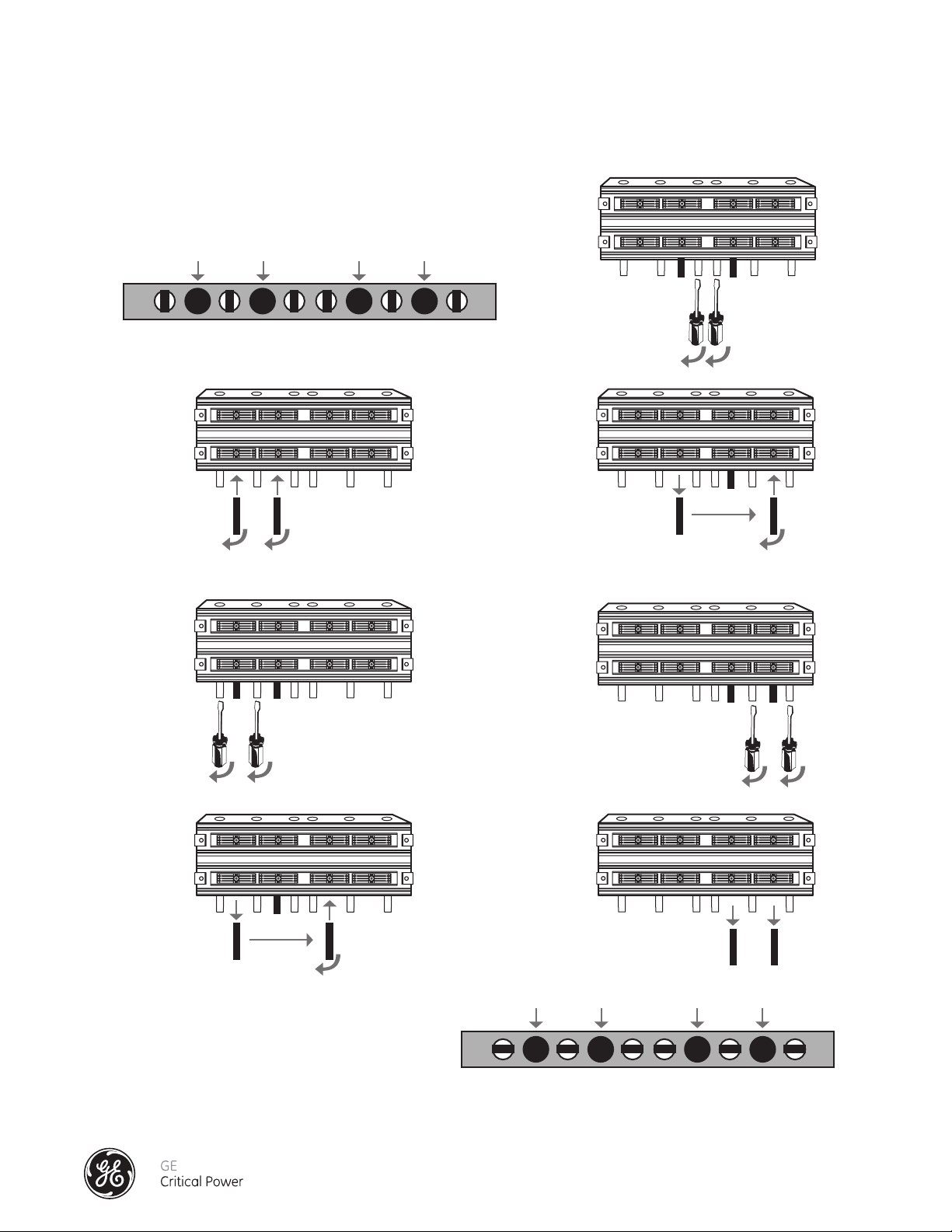

INSTALLATION OF THE SPLICE CONNECTOR – 160 - 250 AMP

All busway sections are shipped from the factory with one splice pack assembly. As each busway section is

mounted on its hanger supports, the abutting end of the splice section can be installed to

the adjoining busway section.

Connection of Busway Sections and Fittings: (See Figure 7)

1) Each section of busway will come with one Splice Pack assembly (D) and two "E" Clips (E) one at each

end of the bus section. Make sure the “E” Clips are always installed on each end of each rail.

2) Bus sections are phase-keyed to maintain proper circuit phasing of the run.

3) Section 2 (with the splice) and Section 1 (without splice) will be aligned on their respective supports. Slide

Section 1 forward on the splice pack.

4) Slide Splice Joint Covers (B & C) and "E" Clip (E) into place positioning them equally across the bus.

5) Slide Grounding Plate (A) into place and secure the four grounding screws to the busway.

Torque values for the set screws is 60 in-lbs minimum and a maximum of 85 in-lbs.

6) Slide the Splice Pack Assembly so that it is positioned equally on either side of the bus section joint.

Allen-head screws

1 2

A Top Grounding Plate with set screws

E E

7) Starting from one end of the Splice Pack (Figure 8), only use the steel cam-actuator tools supplied to

expand the splice joint contact assemblies into contact with bus sections bus bars.

i) Insert one tool into the first cam port #1; the second cam-actuator tool into the adjacent cam port

#2. Rotate each tool ¼ turn to expand the contact plates.

ii) Rotate the adjacent, non-metallic cam spacers (a & b), ¼ turn to hold the expanded contact plate

in place. DO NOT ATTEMPT TO USE THE NON-METALLIC CAMSPACERS TO EXPAND THE CONTACT

PLATE ASSEMBLIES.

iii) Rotate and remove the cam actuator tool in cam port #1, and insert it into cam port #3. Rotate the

steel tool in cam port #3, 1/4 turn clockwise to expand the contact plates.

iv) Rotate the adjacent, non-metallic cam spacers (c & d), 1/4 turn clockwise.

v) Rotate and remove the cam actuator tool in cam port #2, and insert it into cam port #4. Rotate the

steel tool in cam port #4 to expand the contact plates.

vi) Rotate the adjacent, non-metallic cam spacers (e & f), 1/4 turn clockwise.

vii) Rotate and remove the cam actuator tools.

B Side Cover Support Plate

C Side Cover Support Plate

D Splice Pack Assembly

E “E” clip

Figure 7 - Splice Installation Overview 160 - 250 Amp

B

A

D

C

1 Bus Section

2 Bus Section

Splice Pack

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

11

Page 20

Series DPB Busway Installation & Operation Manual

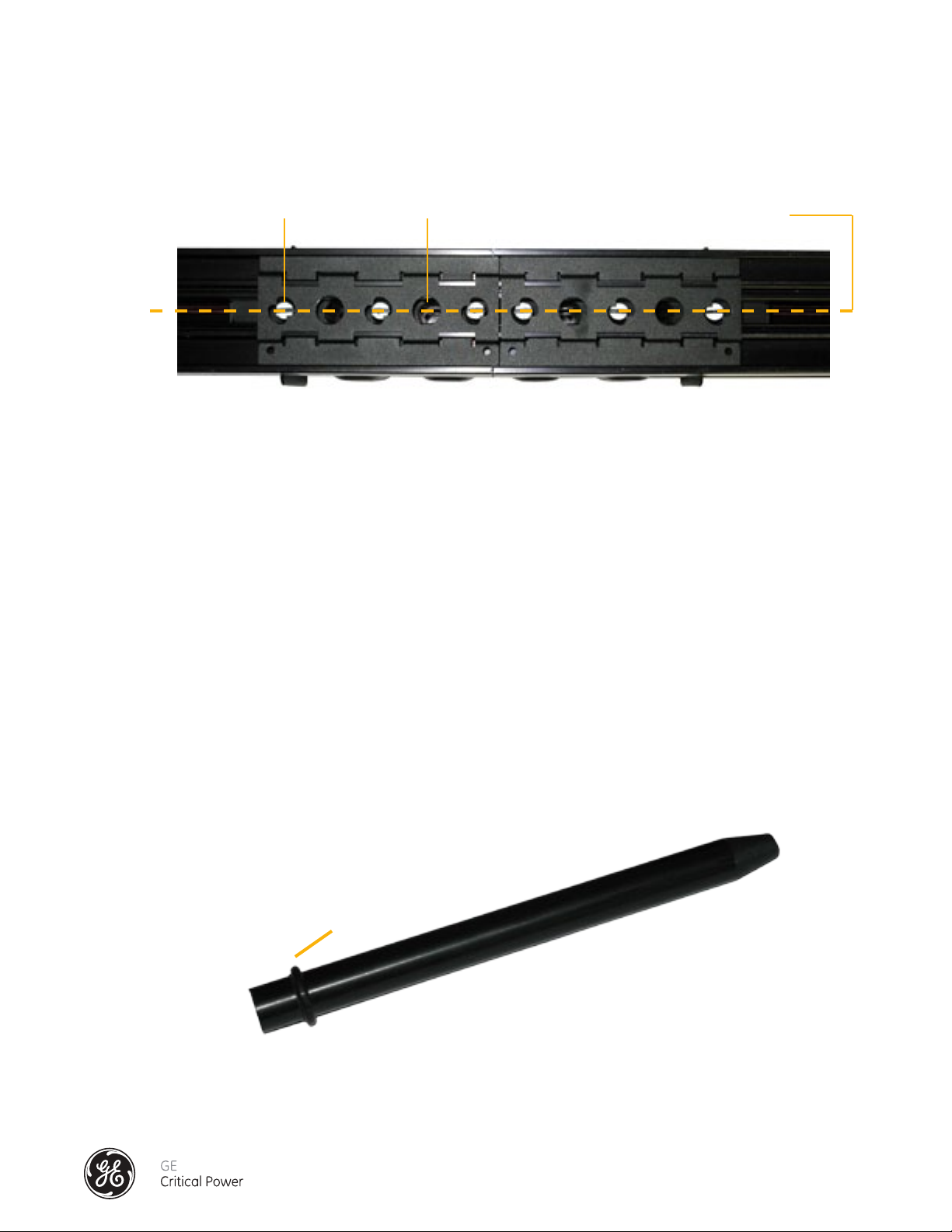

a

b

cd

ef

a

Cam

Port #1

Cam Spacers

Cam

Port #2

b

cd

ef

Cam

Port #3

Cam

Port #4

12 34

rotate Spacers

c & d

rotate Spacers e & f

move from

Cam 2 to Cam 4

a

Cam

Port #1

Cam Spacers

Cam

Port #2

b

cd

cd

ef

ef

Cam

Port #3

Cam

Port #4

a

Cam

Port #1

Cam Spacers

Cam

Port #2

bcde f

Cam

Port #3

Cam

Port #4

1/4 turn

clockwise

1/4 turn

clockwise

1/4 turn

clockwise

12 34

12 34

Figure 8 - Splice Installation Detail 160 - 250 Amp

cd

Step 4

Cam

bottom view

Port #1

12 34

Cam

Port #2

Step 1

1/4 turn

clockwise

1/4 turn

clockwise

ab

Step 2

Cam

Port #3

Cam

Port #4

cam spacer alignment before installation

insert tool into

Cam 1 & 2

Step 5

Step 6

1/4 turn

clockwise

move from

Cam 2 to Cam 4

rotate Spacers

c & d

1/4 turn

clockwise

1/4 turn

clockwise

ef

1/4 turn

clockwise

1/4 turn

clockwise

Step 3

1/4 turn clockwise

rotate Spacers a & b

move from

Cam 1 to Cam 3

rotate Spacers e & f

1/4 turn clockwise 1/4 turn clockwise

Step 7

remove Cam tools

Cam

Port #1

Cam

Port #2

Cam

Port #3

Cam

Port #4

12 34

a

cam spacer position - splice installation complete as seen from bottom

bcde f

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

12

Page 21

Series DPB Busway Installation & Operation Manual

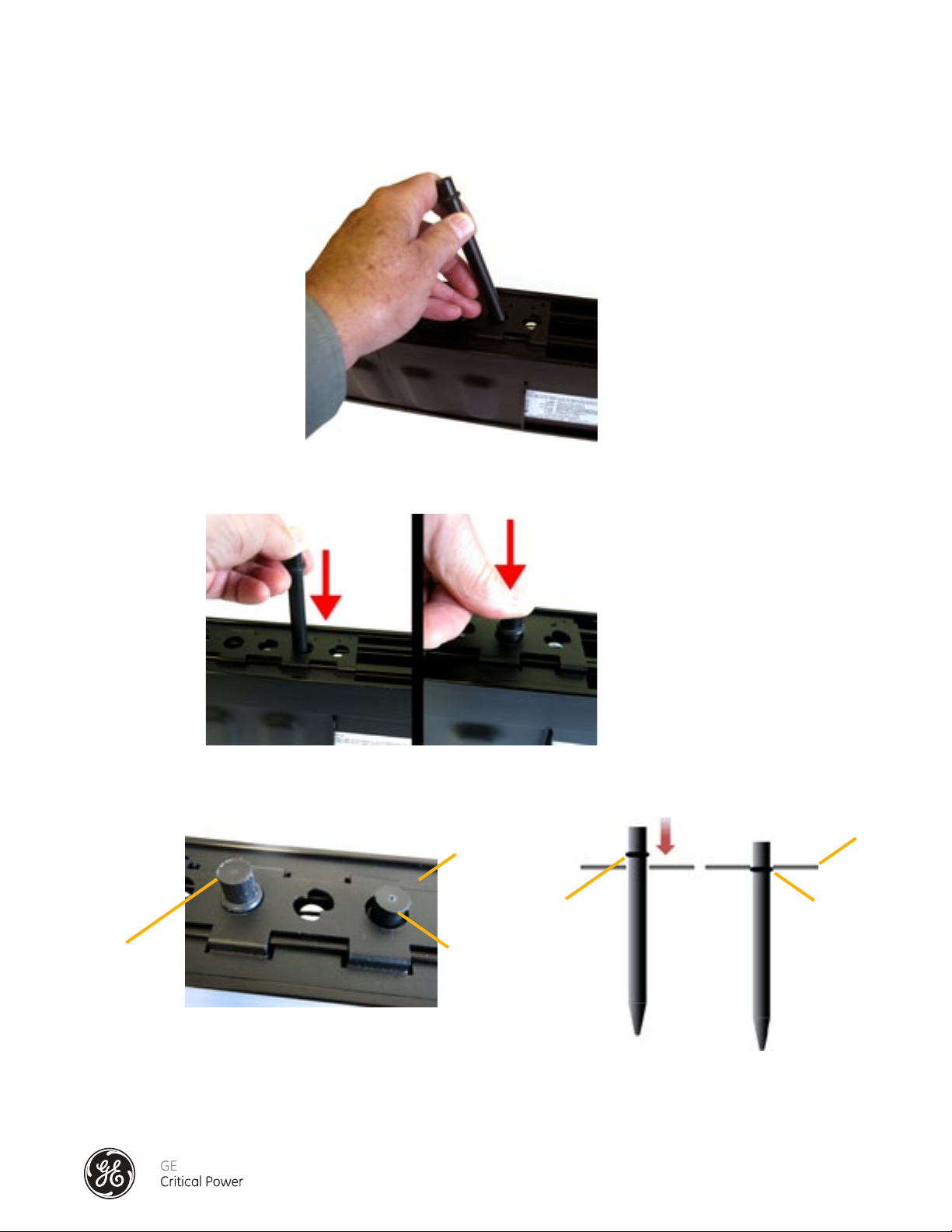

8.) CAUTION: DO NOT proceed to 9) Installation of the Dowel Pin Devices until the Cam Spacers are

verified to be in the locked position. A properly installed Splice, when viewed from the bottom (open

channel) of the joined bus sections will show the Cam Spacers in the Locked Position as show in

Figure 8.1 below.

Cam Spacer Cam Actuator Tool Port

Cams in Locked Position

Figure 8.1 - Cam Spacers in Locked Position

9.) Installation Of The Dowel Pin Devices

The Dowel Pins are used to secure open Cam Actuator Tool ports and add Cam Spacer functionality.

Material Required for Initial Installation (before busway is energized*):

Four Dowel Pin Devices

10) Inspect the busway, and verify that the splice connections of the busway have been installed correctly

per INSTALLATION OF THE SPLICE CONNECTOR – 160 to 250 AMP.

1. Verify no gaps between the bus connections

2. Verify the E-clips are positioned properly.

3. Verify the Cam Spacers (white-tipped, slotted lock pins) are positioned properly.

*please contact factory service for dowel pin installation procedure when working on an energized

busway (800-225-4838)

11.) Each Dowel Pin has an O-ring set into a small groove on the insertion end of the dowel pin.

(See Figure 8.2).

O-Ring

Figure 8.2 - Dowel Pin

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

13

Page 22

Series DPB Busway Installation & Operation Manual

12.) Position the Dowel Pin into the round port between the first pair (viewed left-to-right, or right-to-left) of

installed white-tipped, slotted Cam Spacers. The conical pointed end is inserted first, and the end with

the O-ring inserted last. (See Figure 8.3)

Figure 8.3 - Positioning of Dowel Pins

13.) Using pressure push the Dowel Pin so that it is inserted completely into the Cam Actuator Tool Hole.

(See Figure 8.4)

Figure 8.4 - Insertion of Dowel Pin

14.) Make sure that the O-ring on the dowel is inside the E-clip. (See Figure 8.5)

E Clip

Before

Before

After

Figure 8.5 - Dowel Pin O-Ring Inside "E" Clip

15.) Repeat Step 13 until all four (4) vacant Cam-Actuator Tool Ports have Dowel Pins in them.

16.) Repeat the process for each splice in the bus run until complete.

E Clip

After

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

14

Page 23

Series DPB Busway Installation & Operation Manual

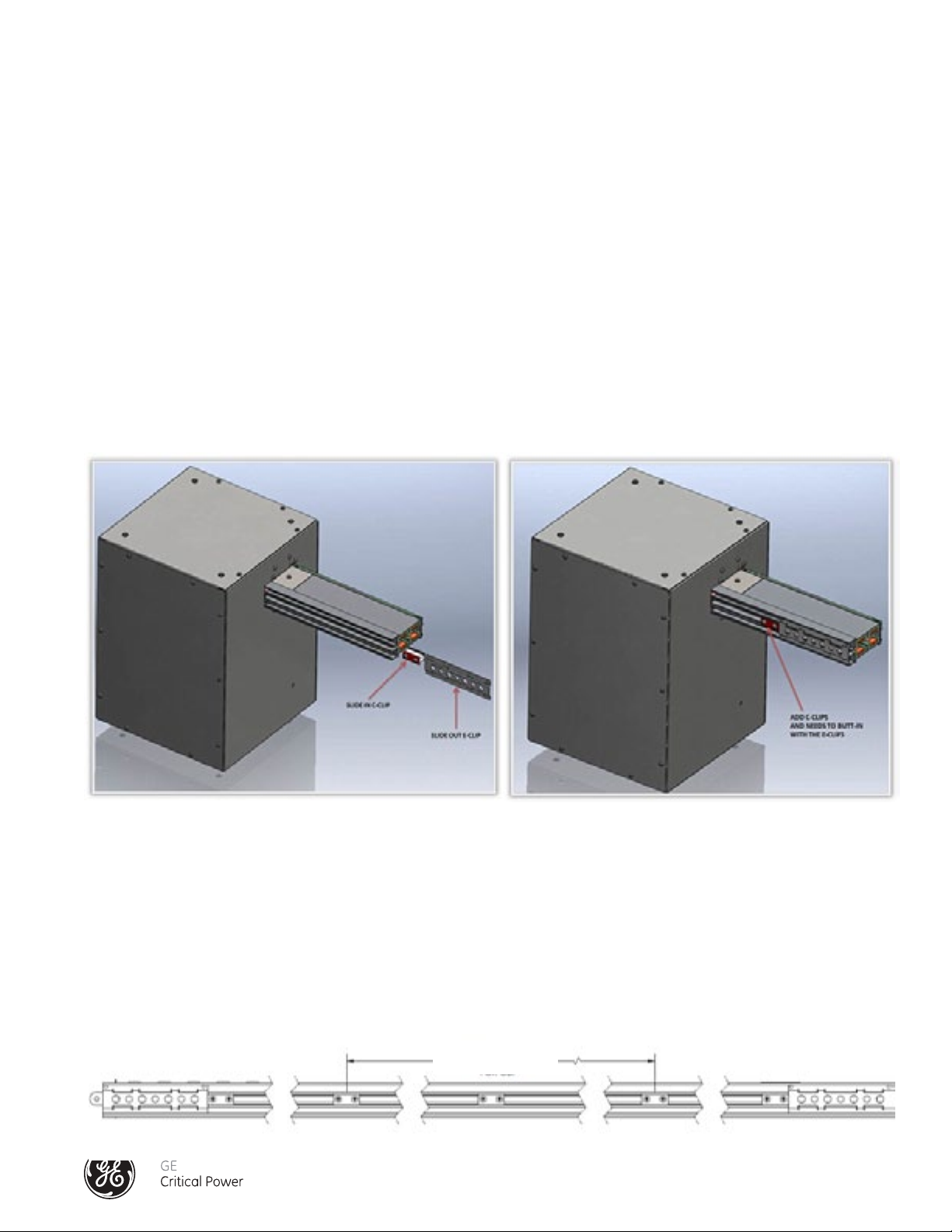

INSTALLATION OF OPTIONAL "C-CLIPS" FOR 35kAIC RATED 400A BUSWAY

The 35 kAIC rated 400A Busway utilizes a C-Clip to control tolerances in the busrail channel opening. Detailed below are the

modified installation instructions to install these C-Clips on End Feeds and Busrails.

END FEED C-CLIP INSTALLATION

See Figure 9 - End Feed C-Clip Installation - 400 Amp

1.) Locate the C-clip

2.) Remove E-clip by sliding it off the bus rail of the End Feed

3.) Install the C-clip by sliding into place between the walls of the open channel.

4.) Reinstall the E-clip.

5.) Position C-clip so that that it butts up against the E-clip.

6.) Tighten screws on C-clip.

NOTE: Loosen, do not remove, the two screws of the C-clip assembly.

Figure 9 - End Feed C-clip Installation - 400 Amp

BUSRAIL AND SPLICE JOINT C-CLIP INSTALLATION

Install C-clips at the prescribed locations on the bus rail. (See Figure 10 - Busrail C-Clip Installation - 400 Amp).

1.) A C-clip should be placed approximately every 31.5" along the busrail or 2 x 31.5" (63") Pitch Location For Clip. If Tap Off

Boxes are installed in the busrail and meet the 31.5" requirement then a C-clip is not required. If a 31.5" opening exists along

the busrail then a C-clip will need to be installed.

NOTE: Loosen, do not remove, the two screws of the C-clip assembly.

2x31.5" (63")

Pitch Location For Clip

Figure 10 - Busrail C-Clip Installation - 400 Amp

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

15

Page 24

Series DPB Busway Installation & Operation Manual

2.) Slide the C-clip into bus rail positioning the C-clip as shown in (Figure 11 - Busrail C-Clip Profile View - 400 Amp). NOTE: Do

not tighten the screws yet.

Figure 11 - Busrail C-Clip Profile View - 400 Amp

3.) Position a Splice Connector into the bus rail that has been properly mounted and supported (leveled, aligned).

NOTE: When the busway is mounted horizontally, make sure the Cam Spacers are flush with the top of the Splice Connector

before positioning the assembly. (See Figure 12 - Cam Spacers)

4.) Bring the ends of busrails to be spliced together, position the Splice Pack equally across the joint, position the E-clips, Side

Support Plates, and Grounding plate ready for Splice cam actuation. (See Figure 13 - Busrail C-Clip Splice and E-Clip Location - 400 Amp).

5.) Install the Splice per section "INSTALLATION OF THE SPLICE CONNECTOR - 400 AMP".

6.) Position and tighten the two screws of each C-clip.

E-clip

Cam Spacer

Figure 12 - Busrail Cam Spacers

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

C-clip

Figure 13 - Busrail C-Clip Splice and E-Clip Location - 400 Amp

GE Confidential

16

Page 25

Series DPB Busway Installation & Operation Manual

INSTALLATION OF THE SPLICE CONNECTOR – 400 AMP

All busway sections will come from the factory with one splice connection.

As the busways section is mounted on its hanger supports, the abutting end of the splice section can be

installed to the adjoin busway section.

Connection of Busway Sections and Fittings: (See Figure 14)

1) Each section of busway will come with one Splice Pack assembly (D) and two "E" Clips (E) one at each

end of the bus section. Make sure the “E” Clips are always installed on each end of each rail.

2) Bus sections are phase-keyed to maintain proper circuit phasing of the run.

3) Section 2 (with the splice) and Section 1 (without splice) will be aligned on their respective supports.

Slide Section 1 forward on the splice pack.

4) Slide Splice Joint Covers (B & C) and "E" Clip (E) into place positioning them equally across the bus.

5) Slide Grounding Plate (A) into place and secure the four grounding screws to the busway. Tighten each

nut to a torque value of 85 in-lbs.

6) Slide the Splice Pack Assembly so that it is positioned equally on either side of the bus section joint.

Grounding Stud Nut

diagram 7

A

B

D

Splice Pack

C

A Top Grounding Plate

E E

7) See Figure 8 for Splice Installation reference. Starting from one end of the Splice Pack (Figure 15),

only use the steel cam-actuator tools supplied to expand the splice joint contact assemblies into

contact with bus sections bus bars.

i) Insert one tool into the first cam port #1; the second cam-actuator tool into the adjacent cam port

#2. Rotate each tool ¼ turn to expand the contact plates.

ii) Rotate the adjacent, non-metallic cam spacers (a & b), ¼ turn to hold the expanded contact plate

in place. DO NOT ATTEMPT TO USE THE NON-METALLIC CAMSPACERS TO EXPAND THE CONTACT

PLATE ASSEMBLIES.

iii) Rotate and remove the cam actuator tool in cam port #1, and insert it into cam port #3. Rotate the

steel tool in cam port #3, ¼ turn to expand the contact plates.

iv) Rotate the adjacent, non-metallic cam spacers (c & d), ¼ turn.

v) Rotate and remove the cam actuator tool in cam port #2, and insert it into cam port #4. Rotate

and remove the cam actuator tool in cam port #3, and insert it into cam port #5. Rotate the steel

tools in cam ports #4 and #5 to expand the contact plates.

vi) Rotate the adjacent, non-metallic cam spacers (e & f), ¼ turn.

B Side Cover Support Plate

C Side Cover Support Plate

D Splice Pack Assembly

E “E” clip

Figure 14 - Splice Installation Overview - 400 Amp

1 Bus Section

2 Bus Section

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

17

Page 26

Series DPB Busway Installation & Operation Manual

Cam

Cam

Cam

Cam

Cam

Cam

a

Cam

Port #1

Cam Spacers

bottom view

Cam

Port #2

bcdefgh

Cam

Port #3

Cam

Port #4

Cam

Port #5

Cam

Port #6

123 456

vii) Rotate and remove the cam actuator tool in cam port #4, and insert it into cam port #6. Rotate the

steel tool in cam port #6 to expand the contact plates.

viii) Rotate the adjacent, non-metallic cam spacers (g & h), ¼ turn.

ix) Rotate and remove the cam actuator tools.

Port #1

123 456

a

bottom view

Cam

Port #1

123 456

a

Port #2

Port #3

Port #4

Port #5

Port #6

bcdefgh

cam spacer alignment before installation

Cam

Port #2

Cam

Port #3

Cam

Port #4

Cam

Port #5

Cam

Port #6

bcdefgh

cam spacer position - splice installation complete as seen from bottom

Figure 15 - Splice Installation Detail 400 Amp

8.) CAUTION: DO NOT proceed to 9) Installation of the Dowel Pin Devices until the Cam Spacers are

verified to be in the locked position. A properly installed Splice, when viewed from the bottom (open

channel) of the joined bus sections will show the Cam Spacers in the Locked Position as show in Figure

15.1 below.

Cam Spacer Cam Actuator Tool Hole

Cams in Locked Position

Figure 15.1 - Cam Spacers in Locked Position

9.) Installation Of The Dowel Pin Devices

The Dowel Pins are used to secure open Cam Actuator Tool ports and add Cam Spacer functionality.

Material Required for Initial Installation (before busway is energized*):

10) Inspect the busway, and verify that the splice connections of the busway have been installed correctly

Six Dowel Pin Devices

per INSTALLATION OF THE SPLICE CONNECTOR – 400 AMP.

1. Verify no gaps between the bus connections

2. Verify the E-clips are positioned properly.

3. Verify the Cam Spacers (white-tipped, slotted lock pins) are positioned properly.

* please contact factory service for dowel pin installation procedure when working on an energized

busway (800-225-4838)

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

18

Page 27

Series DPB Busway Installation & Operation Manual

11.) Each Dowel Pin has an O-ring set into a small groove on the insertion end of the dowel pin.

(See Figure 15.2).

O-Ring

Figure 15.2 - Dowel Pin

12.) Position the Dowel Pin into the round port between the first pair (viewed left-to-right, or right-to-left) of

installed white-tipped, slotted Cam Spacers. The conical pointed end is inserted first, and the end with

the O-ring inserted last. (See Figure 15.3)

Figure 15.3 - Positioning of Dowel Pins

13.) Using pressure push the Dowel Pin so that it is inserted completely into the Cam Actuator Tool Hole.

(See Figure 15.4)

Figure 15.4 - Insertion of Dowel Pin

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

19

Page 28

Series DPB Busway Installation & Operation Manual

14.) Insert another Dowel into the next empty port on the splice. (Six empty tool ports per 400A splice

connection). Make sure that the O-ring on the dowel is inside the black bracket (E-clip) (See Figure 15.5)

E Clip

Before

Before

After

Figure 15.5 - Dowel Pin O-Ring Inside "E" Clip

15.) Repeat Step 13 until all the vacant Cam-Actuator Tool ports have Dowel Pins in them.

16.) Repeat the process for each splice in the bus run until complete.

16) Repeat the process for each splice in the bus run until complete.

INSTALLATION OF THE END CAP CLOSURE PLATE

Always terminate each busway run with an end cap in order to prevent any contact with live

conductors or internal components inside the extruded aluminum busrail housing. See Figure 16.

E Clip

After

To install, align side and top tabs with channels on busrail and tap in using a rubber mallet until flush.

The method of installation of the end caps is common for all mounting positions.

Figure 16 - Busrail End Cap Installation

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

20

Page 29

Series DPB Busway Installation & Operation Manual

CABLE TERMINATIONS TO THE END FEED BOX

STANDARD END FEED

Run all conduit fittings and supports;

attach cable to the listed lugs on the

termination pad.

Ensure that phasing is correct

(see Figure 17).

Once complete, torque all connections

with a torque wrench to the values

specified on the label located inside the

End Feed Box.

ØC

N

ØA

ØB

GROUND

Figure 17 - Standard End Feed Cable Terminations

BRANCH CIRCUIT MONITORING (BCMS)

END FEED

Run all conduit fittings and supports;

attach cable to the listed lugs on the

termination pad.

Ensure that phasing is correct (see Figure

18) and that Current Transformers (CT)

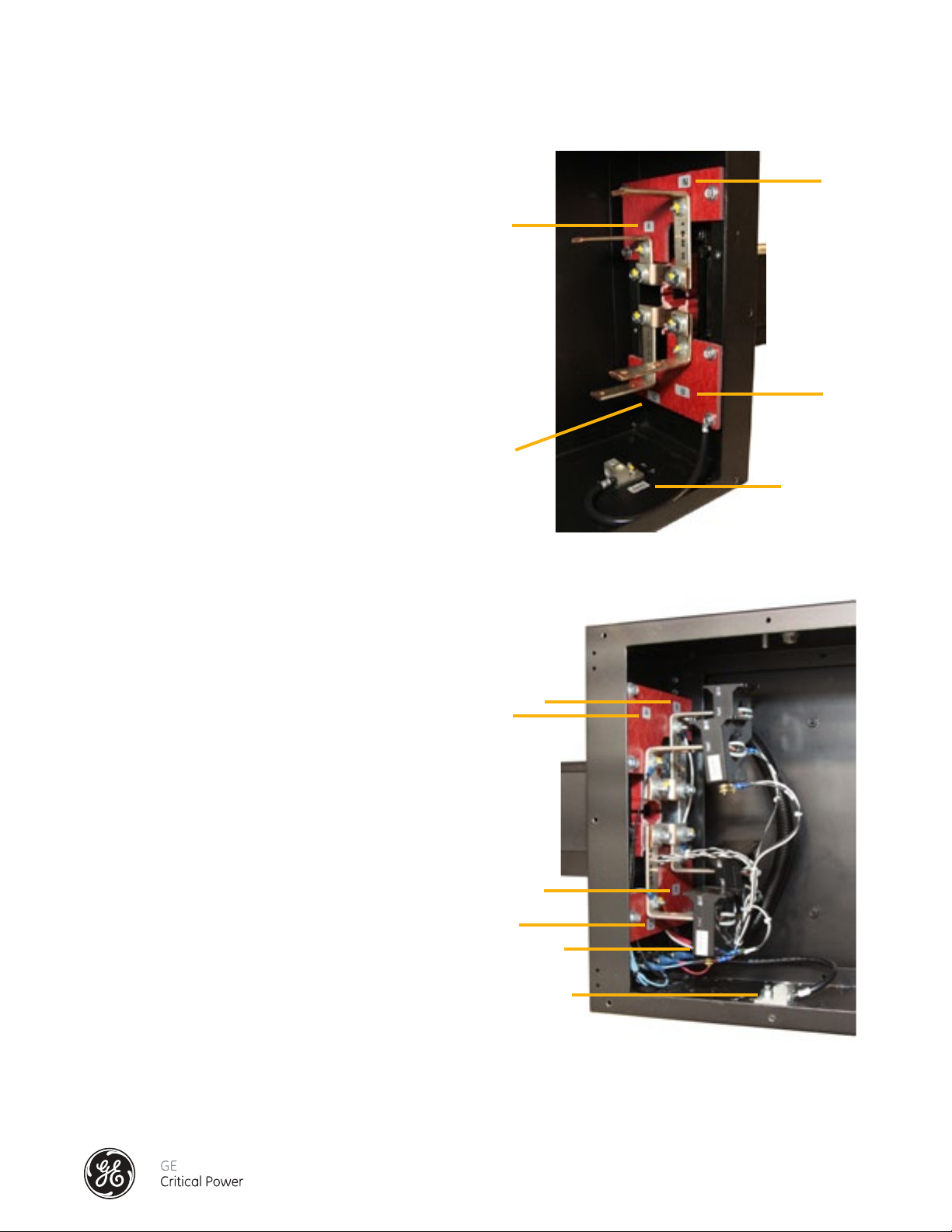

are facing in the correct direction (see

Figure 19). The H1 notation on the CT

should be facing the input power source.

Once complete, torque all connections

with a torque wrench to the values

specified on the label on the End Feed Box.

N

ØA

ØB

ØC

CT

GROUND

Figure 18 - Branch Circuit Monitoring (BCMS) End Feed Cable Terminations

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

21

Page 30

Series DPB Busway Installation & Operation Manual

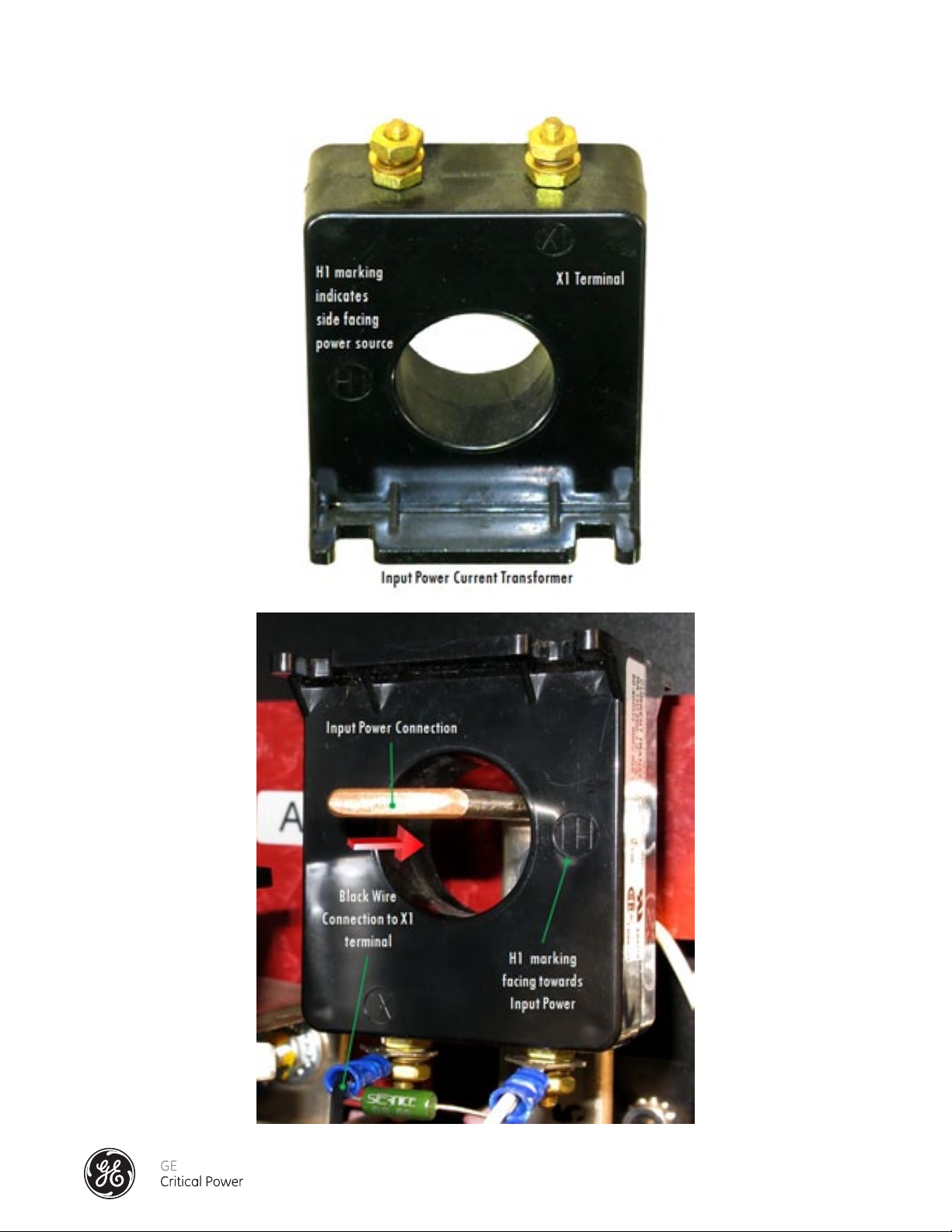

Figure 19 - End Feed Current Transformer (CT) Orientation

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

22

Page 31

Series DPB Busway Installation & Operation Manual

TAP OFF BOX INSTALLATION

INSTALLATION WARNING

Depending on the installation orientation of the busways, the following WARNING should always be exercised when

mounting and energizing the Tap Off Boxes:

CAUTION

HAZARD OF EQUIPMENT DAMAGE

Always maintain the minimum required clearance distance as shown below.

Ensure sufcient clearance for the doors of the Tap Off Units to open or close without obstruction

Ensure sufcient access to the switch or circuit breaker of the tap off units

Failure to follow these instructions may result in equipment damage or personal injury.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

23

Page 32

Series DPB Busway Installation & Operation Manual

TAP OFF BOX MOUNTING

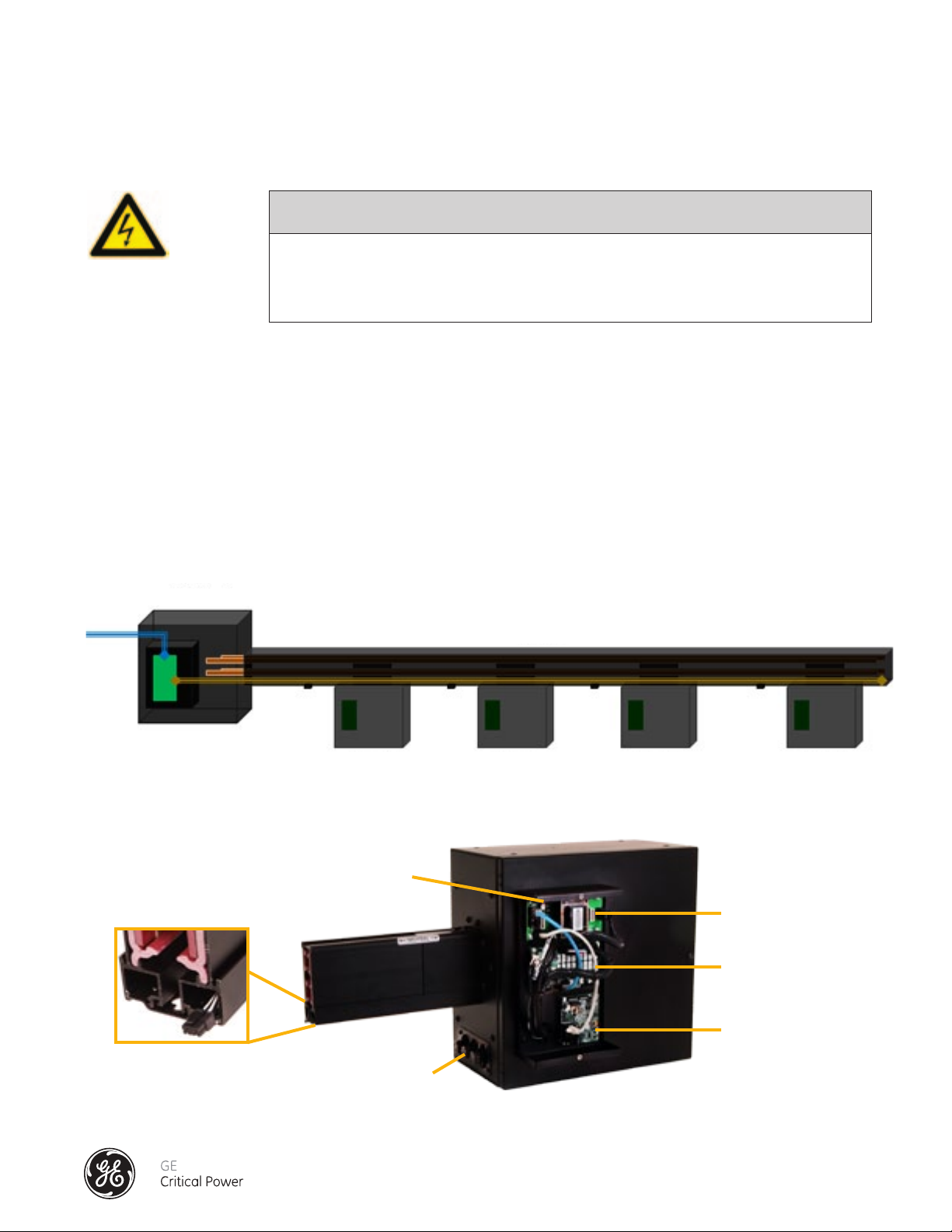

Busway Tap Off Boxes have cam-actuated connections to the busway system as shown in Figure 20. As a safety feature

the insertion of the Tap Off Box cannot be made into the busway system if the cam knob is in the ON position and the tap off

contacts are extended. In the same way a Tap Off Box cannot be removed from the busway system while it is in the ON

position. The contacts will not pass through the opening until fully retracted and the bus insulation will keep the contacts

from passing through the bus until they are fully disengaged and closed. As a further safety feature the contacts are spring

activated to the OFF position to ensure that they fully retract.

Contacts

Cam Knob

Tap Off

Box

CAM OFF

Tap Off

Box

CAM ON

isolated ground connection (optional)

Cam Knob

Contacts

Retracted

Contacts

Contacts

Extended

TOP VIEW

OFF

Figure 20 - Tap Off Box Connections

Insertion and phase control are part of the safety built into every Tap Off Box. A lip is designed into the busrail that will

not allow the Tap Off Box to be inserted backwards. The Tap Off Box is inserted to the busway as shown in Figure 21. The

ground connection will be made and the phasing will be aligned in step 3 when the Tap Off Box is fully seated against the

busrail, and hold-down screws are screwed in over top of the side channel lip. NOTE: Do not tighten the hold down screws

so that they penetrate the busrail. To enegize the Tap Off Box, slide the cam knob to the ON position engaging the Contacts

to the bus Phasing and Neutral bus bars. As a safety feature the ground connection is always made first.

TOP VIEW

ON

STEP 1 STEP 2 STEP 3

neutral neutral neutral neutral

OFF

OFF

OFF

Figure 21 - Tap Off Box Mounting and Energizing

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

HOLD DOWN SCREWS

GE Confidential

STEP 4

ON

CAM KNOB

24

Page 33

Series DPB Busway Installation & Operation Manual

BEFORE ENERGIZING THE BUSWAY CHECKLIST

Before energizing the busway, some precautionary inspections and reviews are necessary.

1. Perform a complete visual inspection of all end feed connections (See Figure 12 (Standard) and

13 (BCMS)), splice couplings (See Figure 8 (160-250A) and Figure 10 (400A)) and tap off boxes

(See Figure 16).

2. Ensure that all protective devices are correctly rated with respect to the loads supplied,

or in accordance with project specifications, and that they are in the OFF position.

3. Check that all the Tap Off Boxes protective devices are in the OFF position.

4. Conduct a Resistance Test between A: busrail-to-busrail assembly, and B: busrail-to-tap off box.

A: Value shall be < 0.005 ohms

B: Value shall be < 0.006 ohms

5. Check the grounding connections of all devices are secure and tightened. Note: A Torque

Specification label can be found inside each End Feed.

Lug Torque (End Feed) Record: ______________________

6. 6. Verify the phase of the busway matches the system phasing before re-connecting.

a) Verify that all Tap Off Units are facing forward to the front (neutral) of the busway

b) Verify that all connection phasing is correct

c) Verify that all incoming power feeds are phased correctly to the bus system

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

25

Page 34

Series DPB Busway Installation & Operation Manual

ENERGIZING THE BUSWAY SYSTEM

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

Only qualied electrical technicians or personnel should install, operate, service or maintain the

structured busway system and connected devices. This document is not sufcient for those who

are not qualied to operate, service, or maintain the electrical equipment.

The successful operation of this equipment depends upon proper handling, installation, operation, and maintenance.

Failure to follow these instructions may result in serious injury or death

When the equipment is energized for the first time, qualified personnel should be present. Care should be taken

because if there are any short-circuits and/or ground faults caused by damage or poor installation practices

that are not detected during the "BEFORE ENERGIZING" checklist procedures, serious damage can result when

the power is applied.

The busway should have no electrical load connected or in the ON position when initially energized. Prior to

energization ensure that all devices connected to the busway system are in their OFF position.

Energize the equipment in sequence by starting at the source end and working towards the load.

Energize the main devices, and then the branch-circuit devices. Turn the devices to the ON position.

After all protective devices have been turned on, loads may be turned on.

Occurrence of sparking at any point along the busway is not normal condition. De-energize the

busway immediately. Correct the cause of the sparking condition. Then, conduct an insulation

resistance test before attempting to energize again.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

26

Page 35

Series DPB Busway Installation & Operation Manual

MAINTENANCE

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

Only qualied electrical maintenance personnel should install, operate, service or maintain this

equipment. This document should not be viewed as sufcient for those who are not otherwise

qualied to operate, service, or maintain the equipment discussed.

Turn off power to the busway before installing, removing, or working on this equipment.

Always use a properly rated voltage sensing device to conrm power is off.

The successful operation of this equipment depends upon proper handling, installation, operation, and maintenance.

Failure to follow these instructions may result in serious injury or death

CAUTION

CLEANING - HAZARD OF EQUIPMENT DAMAGE

Wipe down busway with a dry cloth.

Spray propellants and cleaning or compounds may cause degradation of certain components of

the busway system. Ensure that all cleaning liquids are rated for use on electrical equipment.

Before using products to clean, dry or lubricate components during installation or maintenance,

consult GE.

Failure to follow these instructions may result in equipment damage or personal

injury.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

27

Page 36

Series DPB Busway Installation & Operation Manual

MAINTENANCE

Series DPB Bus Systems™ require only nominal maintenance. Inspect the busway annually or after any short circuit or

ground fault. Perform the following maintenance procedures:

Carefully inspect all the system. Verify that all Splice Cams (See Figure 8 (160-250A) and Figure 15 (400A)) and are properly

installed and in the locked position. Using a thermal scanning device to record the thermal rise of each termination in each end

feed (See Figure 17 (Standard) and 18 (BCMS)). Record this information for comparison for year over year reviews. Changes in

excess of 5°C should be inspected more carefully; however the monitoring of more than 5 degrees could be due to change on

the loads and not the performance of the busway components.

Check the torque on all power connections using a torque wrench. The tightening torque is specified on the label found in

the End Feed Box (See Figures 17 & 18).

If any busrails, splices, end feed terminations or tap off box contacts are badly discolored, corroded or pitted the devices

must be replaced with new devices.

Ensure that all mechanisms and mechanical interlocks are in satisfactory operational condition.

Check the insulation resistance before re-energizing the busway. Keep a permanent record of resistance readings. Conduct

the insulation resistance test according to the section "Before Enegizing the Busway Checklist".

Energize the equipment again following the instructions in the section "Energizing the Busway System".

After performing all the above inspections and necessary repairs, it may be desirable to perform an infrared temperature

test on all the electrical connections. Conduct this test after the busway is re-energized and reaches a stabilized operating

temperature.

For additional maintenance services please see Appendix H: Service.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

28

Page 37

BRANCH CIRCUIT MONITORING SYSTEM

(BCMS)

INSTALLATION GUIDE

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

29

Page 38

Series DPB Busway Installation & Operation Manual

SAFETY WARNING

DANGER

SEVERE INJURY OR DEATH CAN RESULT FROM ELECTRICAL SHOCK DURING

CONTACT WITH HIGH VOLTAGE CONDUCTORS, MONITORING PCBS, OR RELATED

EQUIPMENT.

DISCONNECT AND LOCK OUT ALL POWER SOURCES DURING INSTALLATION AND

SERVICE.

APPLICATIONS SHOWN AND DESCRIBED ARE SUGGESTED MEANS OR INSTALLATION.

IT IS THE RESPONSIBILITY OF THE INSTALLER TO ENSURE THAT THE INSTALLATION

IS IN COMPLIANCE WITH ALL NATIONAL AND LOCAL CODES.

INSTALLATION SHOULD BE ATTEMPTED ONLY BY INDIVIDUALS FAMILIAR WITH

CODES, STANDARDS, AND PROPER SAFETY PROCEDURES FOR HIGH-VOLTAGE

INSTALLATIONS.

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, INSTALL IN A TEMPERATURE

AND HUMIDITY CONTROLLED INDOOR AREA FREE OF CONDUCTIVE CONTAMINANTS.

THE PRODUCT IS NOT INTENDED FOR INSTALLATION IN HAZARDOUS LOCATIONS.

READ INSTRUCTIONS THOROUGHLY PRIOR TO INSTALL.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

30

Page 39

Series DPB Busway Installation & Operation Manual

SCOPE

This manual includes user operation and installation information for the GE Series DPB Busway Branch Circuit Monitoring

System. It is intended to aid the user in the safe handling and use of the system. It is recommended that a copy of this

document be kept in a safe place for easy review. Each section of this manual may contain bold type notes in a rectangle

box, warnings and cautions that pertain to your Series DPB Busway Branch Circuit Monitoring system.

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

31

Page 40

Series DPB BuswayInstallation & Operation Manual

SYSTEM DESCRIPTION

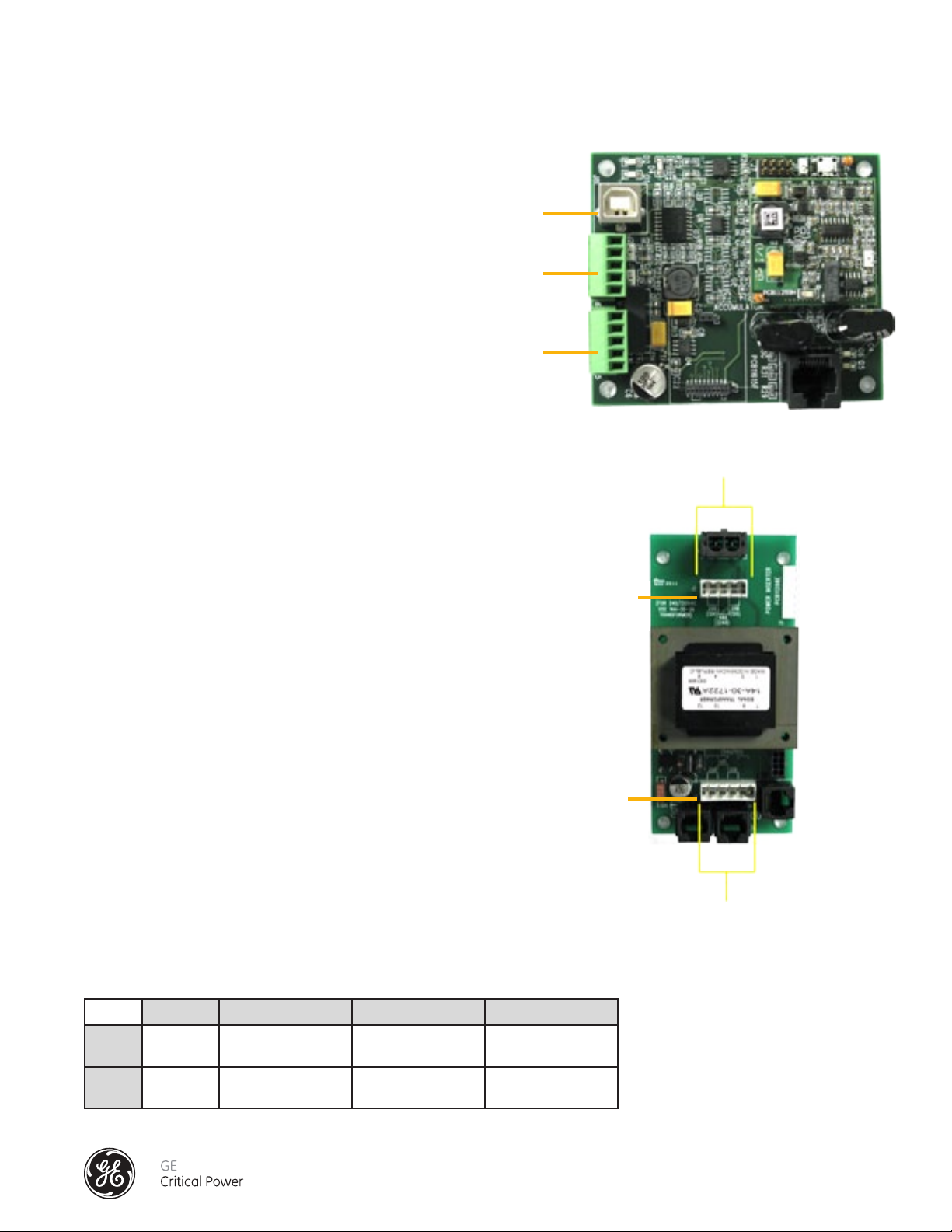

This monitoring system is designed for use with the GE Series DPB Busway to provide detailed power parameter information

for the busway input feeders (End Feed Boxes) and branch circuits of the power distribution boxes (Tap Off Boxes). The system

consists of a Communications Hub module located on the End Feed Box which can acquire power information from the

busway input feeders and the branch circuits of Tap Off Boxes equipped with the Branch Circuit Monitoring System (BCMS). The

system is capable of monitoring the power infrastructures of Mission Critical, Industrial and Commercial facilities.

The Series DPB Busway busrail is equipped with an integrated communication cable inside a channel along the bottom of

the rail section. Communication connectors (see Figure 22) are distributed equally along the span of a bus rail to enable

interconnection to each Tap Off Box.. This allows a BCMS-equipped Tap Off Box to communicate with the Input PM /

Accumulator PCBs of the communication hub via a communication receptacle and the interface cable. (see Figure 22 Series DPB Branch Circuit Monitoring System Overview)

Information collected by the Input PM / Accumulator is outputted via Modbus™ RTU through a serial port which can be

routed to a local display as well as via an Ethernet gateway and/or to a customer-supplied monitoring system.

There are two different levels of firmware available – BCMS Basic -Current only, and BCMS Plus – Current Plus Voltage.

See Appendix A, TAP OFF BOX MONITORING SPECIFICATIONS, and Appendix B, END FEED (INPUT PM BOARD) MONITORING

SPECIFICATIONS.

Figure 22 - Branch Circuit Monitoring System Overview

POWER MONITORING SYSTEM OVERVIEW

The power monitoring capabilities of the system may be configured as follows,

Option 1 - Tap Off Box Monitoring Only (see pages 30-32)

Option 2 - End Feed Monitoring Only (see pages 33-35)

Option 3 - Tap Off Box and End Feed Monitoring Concurrently (see pages 36-39)

Installation & Operation Manual, GE Series DPB Busway

March 25, 2013, Rev 0

GE Confidential

32

Page 41

Series DPB Busway Installation & Operation Manual

Option 1 - TAP OFF BOX MONITORING ONLY

SAFETY WARNING

CAUTION

SEVERE INJURY OR DEATH CAN RESULT FROM ELECTRICAL SHOCK DURING CONTACT WITH

HIGH VOLTAGE CONDUCTORS, MONITORING PCBS, OR RELATED EQUIPMENT. DISCONNECT

AND LOCK OUT ALL POWER SOURCES DURING INSTALLATION AND SERVICE.

END FEED BOX COMPONENTS

The OPTION 1 configuration (Figure 23) enables power monitoring of the branch circuit loads connected to each BCMSEquipped Tap Off Box. Busway source power input monitoring is not available since the Input Power Monitor board is not

installed in the End Feed.

The Option 1 configured End Feed Box contains the data acquisition system consisting of an Accumulator PCB, and a Power

Inserter PCB (Figure 24). The power disconnects for the circuit boards are the readily accessible fuses mounted on the