Page 1

GE Digital Energy

Power Quality

Zenith

ZBTS/ZBTSD Series

Bypass Isolation Transfer Switches

100-4000 Amps

Operation & Maintenance Manual

Page 2

Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Equipment Inspection and Storage . . . . . . . . . .

11

Final Equipment Inspection . . . . . . . . . . . . . . .

11

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

Power Connections . . . . . . . . . . . . . . . . . . . . . . .

12

Engine Start Control Connections . . . . . . . . .

12-3

Initial Energization . . . . . . . . . . . . . . . . . . . . .

13-4

Control Connections . . . . . . . . . . . . . . . . . . . . . 5

Entelli-Switch 250 Microprocessor Controller . . . . .

16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

LCD & Keypad . . . . . . . . . . . . . . . . . . . . . . . . . .

17

User Setting for Voltage & Frequency . . . . . . .

1 8

Accessory Group Packages. . . . . . . . . . . . . . . . . 9

Accessory Definitions . . . . . . . . . . . . . . . . . . 10-13

How to Set the System Clock . . . . . . . . . . . . . . 13

CDT One Event Timer Exerciser . . . . . . . . . . 14

CDP Clock Exerciser . . . . . . . . . . . . . . . . . . . . 15

User Setup - CFG Menu . . . . . . . . . . . . . . . . . . 16

User Setup - SET Menu . . . . . . . . . . . . . . . . . . 17

User Setup - System Info . . . . . . . . . . . . . . . . . 18

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

119

ATS Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . .

119

Standard Transition . . . . . . . . . . . . . . . . . . . . . 19

Delayed Transition . . . . . . . . . . . . . . . . . . . . . . 19

Page

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . 20

Standard Transition . . . . . . . . . . . . . . . . . . . . .

120

Delayed Transition . . . . . . . . . . . . . . . . . . . . . . 20

Bypass-Isolation Operation . . . . . . . . . . . . . . . 21

100-400 Amps . . . . . . . . . . . . . . . . . . . . . . . . . .

122

600-1200 Amps . . . . . . . . . . . . . . . . . . . . . . . . .

123

1600-4000 Amps . . . . . . . . . . . . . . . . . . . . . . . .

1 24

1600-3000 Amps, Horizontal Bypass . . . . . . . .

1 25

Controls Power Supply (CPS) . . . . . . . . . . . . . . . . . 26

Schematics, Standard & Delay . . . . . . . . . . . . .

127

Troubleshooting & Diagnostics . . . . . . . . . . . . . . . . 28

Maintenance and Testing . . . . . . . . . . . . . . . . . . . . . 29

Inspection and Cleaning . . . . . . . . . . . . . . . . . 29

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

129

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

129

ZBTSH/ZBTSDH . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Standard Control Panel Layout (SSRCP) . . . . 30

Panel Mount Control Relays . . . . . . . . . . . . . .

130

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . 31

Adjustments and Settings . . . . . . . . . . . . . . . . . . . . . 32

Solid State Timers . . . . . . . . . . . . . . . . . . . . . . .

132

Voltage/Frequency Sensor (VSFM) . . . . . . . . .

132

Solid State Phase Relay . . . . . . . . . . . . . . . . . . .

132

Table of Contents

Authorized Service

For GE parts and service, call: 773 299-6600

Introduction

GE Zenith Transfer Switches are used to provide a continuous

source of power for lighting and other critical loads by automatically transferring from Source 1 power to Source 2 power

in the event that Source 1 voltage falls below preset limits.

Voltage sensing and system control is performed via a stateof-the-art microcontroller located on the cabinet door. It

is designed to give highly accurate control of the transfer

switch system.

All GE Zenith transfer switches are designed for use on

emergency or standby systems, and are rated for total

system or motor loads. Transfer switches are UL Listed

under Standard 1008 and CSA Certified under Standard

C22.2 No. 178 and IEC Listed under Standard 947.

NOTES:

A protective device such as a molded case

circuit breaker or fused disconnect switch

MUST be installed on both sources of

incoming power for circuit protection

and as a disconnection device.

All references made within this manual

about the term “S1” or “Source 1” relate

to a Normal Power Source. All references

made about the term “S2” or “Source 2”

relate to an Emergency or Alternative

Power Source.

Page 3

71R-4000

B 1

■

ZBTS / ZBTSD Operation & Maintenance Manual

Safety

Each GE Zenith transfer switch is factory wired and

tested. A complete information package is furnished

with each switch which includes:

a. Sequence of operation.

b. Description and operation of

all accessories supplied.

c. Power panel connection diagram

and schematic.

d. Description and identification of

all customer field connections.

Installation of GE Zenith transfer switches includes:

a. Mounting the transfer switch cabinet.

b. Connection of Source 1, Source 2,

and Load cables or bus bars.

c. Connection of external control

circuits as required.

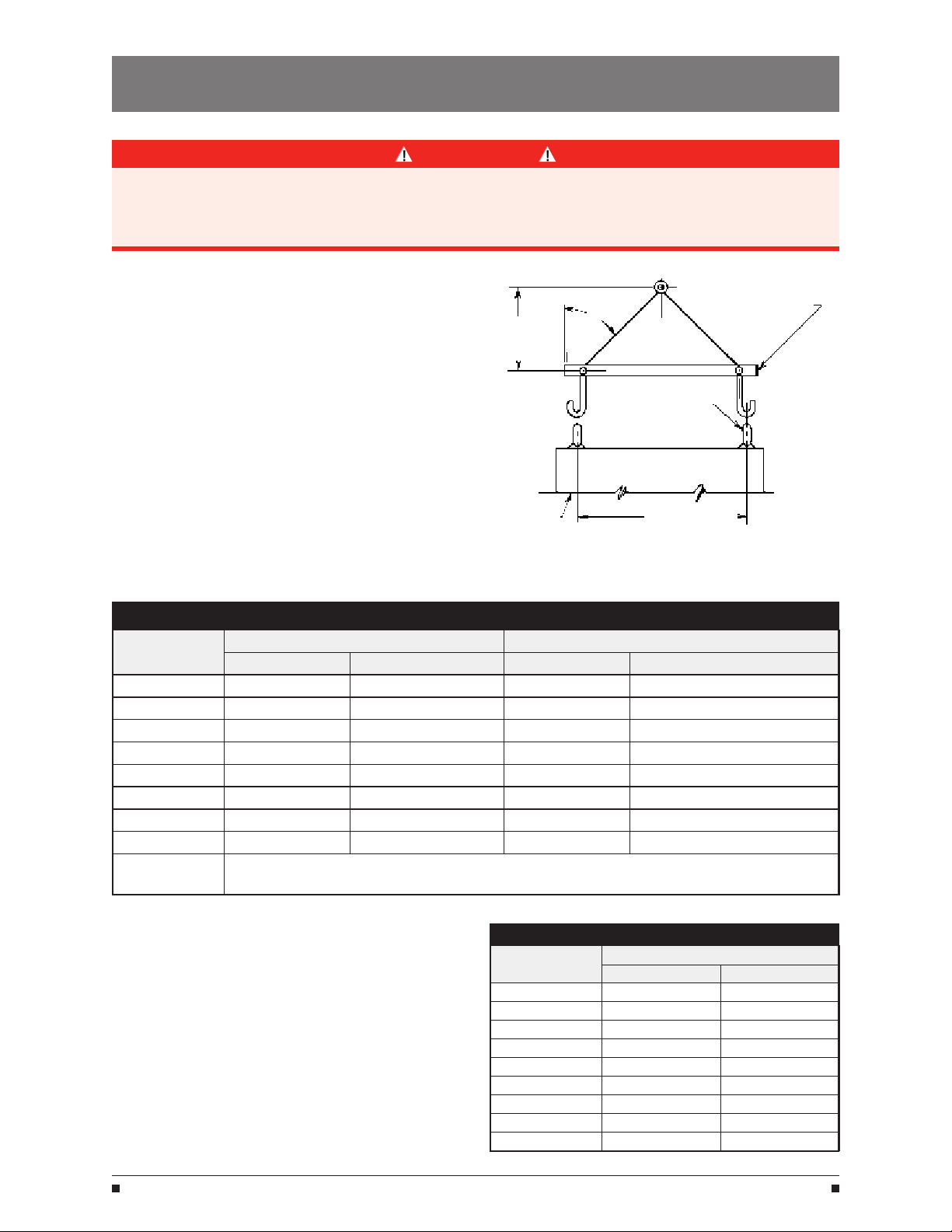

Mounting

Adequate lifting means must be used to mount the transfer

switch into place. The recommended method for moving the

transfer switch using the lifting eyes, where supplied, and

a spreader bar is illustrated in Figure 1. Enough room should

be allowed to open the cabinet doors fully for inspection

and servicing of the switch per NEC and local codes.

The safe operation of your switch is GE Zenith’s focus. The

proper storage, installation, operation and maintenance

will help increase the life of the switch.

Equipment Inspection

and Storage

Once you have received the transfer switch, inspect it for

any damage. This includes damage to the enclosure, power

panel, control panel and wiring harness. If any damage is

found or suspected, file a claim as soon as possible with the

carrier and notify the nearest

GE Zenith representative.

Before installation, if it is necessary, store the transfer

switch in a clean dry place, protected from dirt and water.

Provide ample air circulation and heat, if necessary, to

prevent condensation.

5% to 95%

(non-condensing)

-30°C to

+75°C

(-22°F to

+167°F)

40-400

AMP

(molded shell)

-20°C to +65°C

(-4°F to +149°F)

40-4000

AMP

(all other frame

and panel types)

-20°C to +60°C

(-4°F to +140°F)

Operating

Storage Temperature

Temperature (Ambient): Humidity

Final Equipment Inspection

Prior to energizing the transfer switch:

1. Remove any debris incurred, with a vacuum,

due to shipment or installation.

2. Verify that all cabled connections are correct

and that phase rotation of both sources match.

3. Check engine start connections.

4. Verify the correct connection of all control wires.

5. Check settings of all timers and adjust

as necessary.

6. Adjust any optional accessories as required.

7. Check the lug torque values of the power

connections.

NOTE: Lug torque values are specified

in table 2 on Pg 2.

8. Make sure that all covers and barriers are

installed and properly fastened.

NOTE: Power panels ship from GE Zenith

in Source 1 Position.

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Due to hazardous voltage and current, GE Zenith

recommends that a

GE Zenith Certified technician

or a qualified electrician must perform the

installation and maintenance of the switch.

Do not use a blower since debris may

become lodged in the electrical and

mechanical components and cause damage.

Before drilling conduit entry holes or any

accessory mounting holes, cover and protect

the switch and control panel to prevent dirt

and metal fragments from entering the

mechanical and electrical components.

Failure to do so may result in

damage and malfunction of the switch.

DANGER

CAUTION

WARNING

CAUTION

Page 4

2

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Installation

Table 2

Tightening Torque for Lugs

Socket Size

Across Flats

Torque

Lb. - In.

Lb. - Ft.

45

1/8

4

100

5/32

8

120

3/16

10

150

7/32

12

200

1/4

17

275

5/16

23

375

3/8

31

500

1/2

42

600

9/16

50

Power Connections

GE Zenith transfer switches are supplied with UL listed

solderless screw type terminals as standard for the Source 1,

Source 2 and Load power connections. Table 1 lists the

number and sizes of cable lugs supplied as standard for

each switch amp rating.

Connect the Source 1, Source 2, and Load conductors

to the clearly marked terminals on the transfer switch.

Remove surface oxides from cables by cleaning with a wire

brush. Verify that all connections are correct before

tightening the lugs. All cable lug connections must be

tightened to the proper torque values as shown in Table 2.

NOTE: Do not run cables or wiring behind

front-connected transfer switches.

Table 1

Power Connections: Screw Type Terminals for External Power Connections

Switch Size

(Amps)

40

80

100

150

200, 225, 2500

260, 300*, 400

600

800, 1000, 1200

Source 1, Source 2 & Load Terminals

1 #8 AWG to 1/0

Cable Per Pole Range of Wire Sizes

1 #8 AWG to 1/0

1 #8 AWG to 1/0

1 #8 AWG to 3/0

1 #6 AWG to 250 MCM

1 #4 AWG to 600 MCM

2 #2 AWG to 600 MCM

4 #2 AWG to 600 MCM

Neutral Bar (When Required)

3 #8 AWG to 1/0

No. of Cables Range of Wire Sizes

3 #8 AWG to 1/0

3 #8 AWG to 1/0

3 #8 AWG to 300 MCM

3 #6 AWG to 300 MCM

3 #4 AWG to 300 MCM

8 #2 AWG to 600 MCM

12 #2 AWG to 600 MCM

1600, 2000

2600, 300 0, 4000

Line, Load and Neutral terminals are located in the rear of switch

and arranged for bus bar locations

Engine Start

Control Connections

Engine-start control wires connect to control terminals

beside the Entelli-Switch 250. Engine start terminals are

indicated by a schematic symbol (the symbol indicates

the contact state for a de-energized normal source).

Figure 2 shows the engine-start contacts.

Make all other necessary control connections to the

control panel terminal blocks per the schematics

supplied with the ATS.

NOTE: All control wires (18-12 AWG) must be

torqued to 19 in/lbs.

D

CABINET

LIFTING EYES

SPREADER BAR

H

45°

Figure 1

NOTE: When lifting the switch using a spreader bar,

height H must be equal to half of distance D.

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

DANGER

Page 5

71R-4000

B 3

■

ZBTS / ZBTSD Operation & Maintenance Manual

Installation

(cont’d)

Engine Start

Control Connections

The engine-start terminals are clearly identified by a label

on the microcontroller backplate. In the case of manual

transfer switches, or in other applications not requiring

the microprocessor, clearly marked terminal blocks are

provided in the upper left corner of the control panel

for the engine start control wires.

Figure 2 shows location of engine start connections for

Bypass Isolation Transfer Switch. Figure 6 (pg.5) shows

location of engine start connections for Automatic

Transfer Switch.

Terminals for field connections to the A3 Source 2 auxiliary

contacts and the A4 Source 1 auxiliary contacts are also

provided. These terminals are clearly marked and appear

on the side of the power panel. On 400 amp metal frame

units these terminals appear on the bracket above the

operator handle.

Initial Energization

Before proceeding, refer to the information package

supplied with the ATS and read and understand the

information on all accessories provided.

1. Unlock the enclosure.

2. Open the enclosure.

3. Verify the correct system voltage.

NOTE: The equipment rating nameplate on the

transfer switch lists the voltage. See

Figure 4

.

4. Close Source 1 circuit. breaker.

NOTE: The controller will illuminate Source 1

Available LED if proper voltage is sensed.

5. Verify the phase to phase voltages at Source 1

line terminals.

6. Close Source 2 circuit breaker.

7. Start the generator’s engine.

NOTE: The controller will illuminate Source 2

Available LED when preset voltage

and frequency levels are reached.

8. Verify the phase to phase voltages at Source 1

line terminals.

9. Verify that the phase rotation of Source 1

is the same as the phase rotation of

Source 2.

10. Shut down the generator’s engine.

11. Place the starting control in the

Automatic position.

12. Complete the visual inspection of the transfer switch.

13. Close the enclosure.

14. Lock the enclosure.14. Lock the enclosure.

Figure 2

E

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

DANGER

Figure 3A –

Horizontal

Bypass/Isolation

Transfer Switch

Customer

Connections

Figure 3 (Typical)

XBN

XBE

4

1

Interconnect plug plate

RNH

5

6

P Relay

2

(Engine Start)

3

Contact rating is

10 Ampere at 120VAC

or 28VDC Gold plated

Interlock Logic

Assembly

ATR

A4-1

A4-1

A4-2

A4-2

A3-1

A3-1

A3-2

A3-2

A4B-1

A4B-1

A3B-1

A3B-1

Input/Output

option relays.

Control Power Supply

Auxiliary contact

connections.

E11

E12

E12A

E13

Engine Start

Connections

Page 6

4

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Installation

(cont’d)

NOTE: When the voltage and frequency

reach preset values, the Source 2

Available LED will illuminate.

7. Verify the phase to phase voltages at Source 2

line terminals.

8. Verify that the phase rotation of

Source 2 is the same as the phase

rotation of Source 1.

9. Shut down the generator's engine.

(Place in Automatic Mode.)

NOTE: Source 2 Available LED will turn off.

NOTE: The engine generator will continue

to run for the duration of Source 2

Stop Delay Timer.

10. Place the disconnect switch to ENABLE.

11. Complete the visual inspection of the

transfer switch.

12. Close the enclosure.

13. Lock the enclosure.

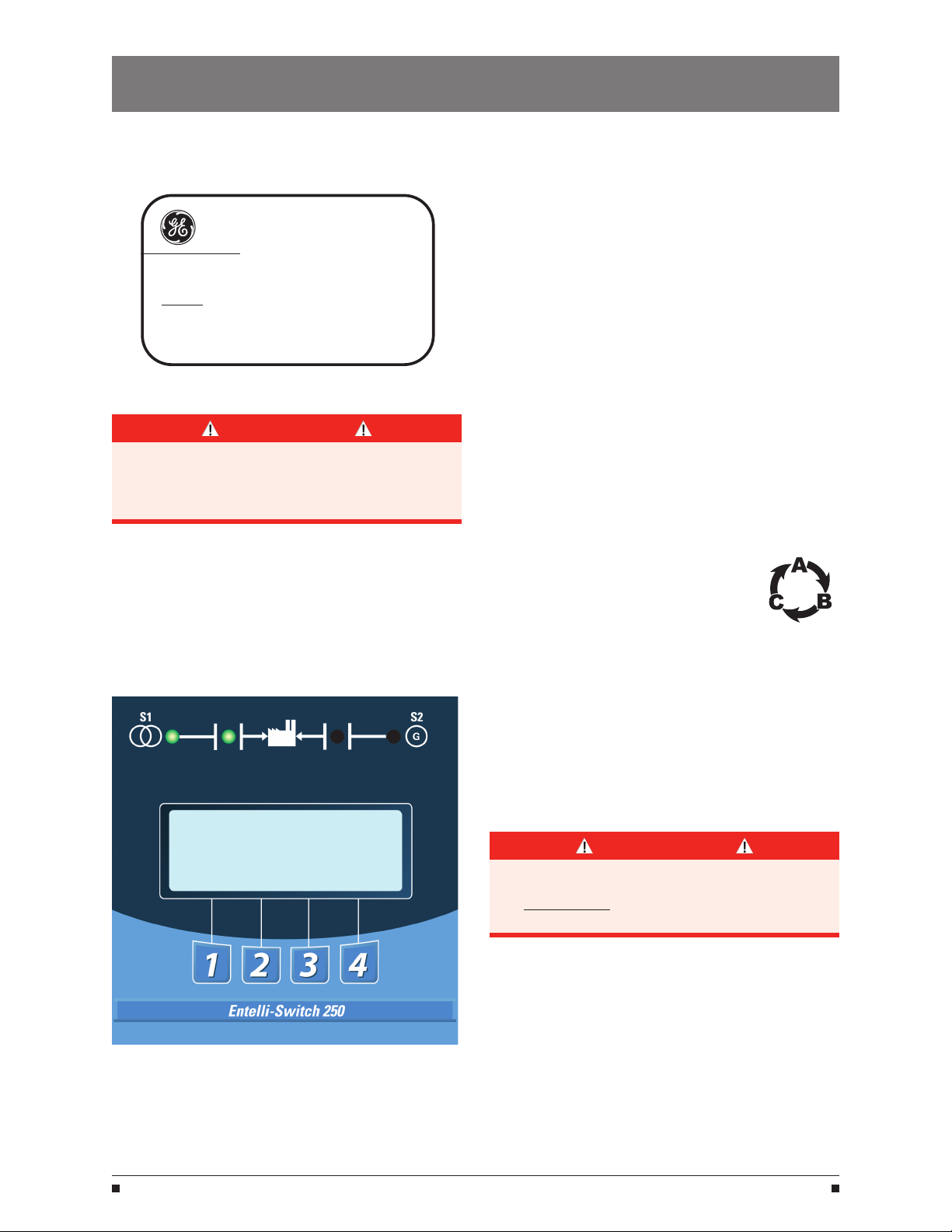

Figure 5 – LCD and keypad

After all options and accessories are checked and verified,

follow these steps to set up the ATS. Refer to Entelli-Switch

250 display Figure 5. The annunciation LEDs illuminate to

indicate (1) source availability, (2) ATS position, and (3)

Entelli-Switch 250 control function (timing).

1. Unlock the enclosure.

2. Open the enclosure.

3. Place the Disconnect Switch in the Inhibit.

NOTE: This step is only performed if the

“DS” Option was purchased.

4. Close the external (up-stream) Source 1

circuit breaker.

NOTES: Source 1 Available and Source 1

Position LED’s will illuminate.

If Source 1 Available LED does not

illuminate, verify that Source 1 Voltage

is above the preset restore value.

The Gen-Set will start and run while

Source 2 stop Delay Timer is timing.

5. Close the External (up-stream) Source 2 line

circuit breaker.

6. Start the engine generator in

MANUAL mode.

When performing a hi-pot or

dielectric test on the power section,

DISCONNECT the control panel plugs from

the microprocessor to avoid potential damage.

S1 OK

21:56

MON 23 APR 2008

MORE TEST

WARNING

Figure 4

SERIAL NUMBER:

RATING

: VOLTS -

AMPS -

SYSTEM VOLTS:

MODEL NUMBER:

HZ -

PHASE -

GE Zenith Controls

Certain accessories, per specific

schematics, can inhibit automatic transfer.

Engine Gen-Set could start when

engine control wires are attached.

Initial Energization

(cont’d)

CAUTION

Page 7

71R-4000

B 5

■

ZBTS / ZBTSD Operation & Maintenance Manual

Installation

(cont’d)

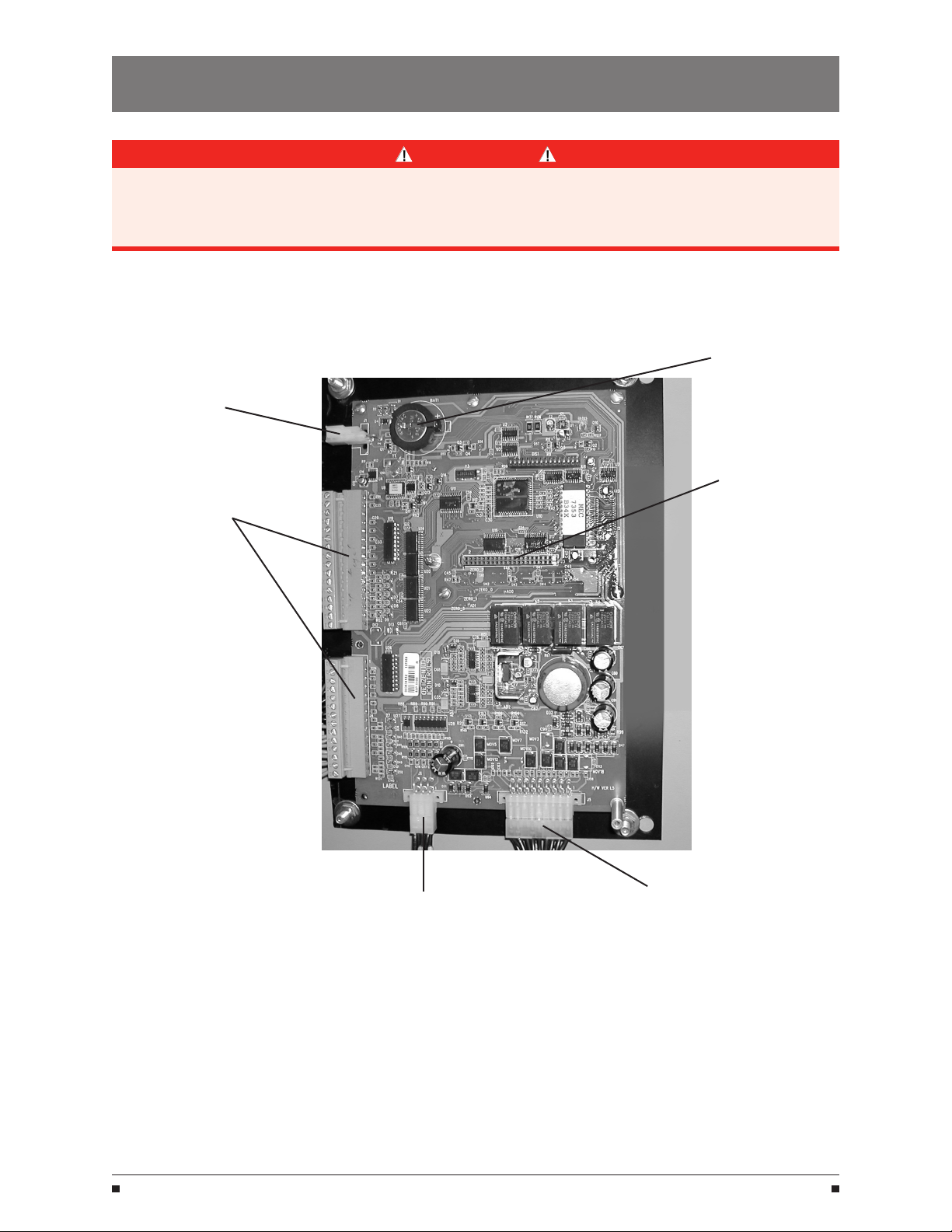

A complete information package is furnished with each

transfer switch including a complete connection diagram

and schematic which details all necessary control circuit

field connections.

The engine start control wires connect to the engine start

relay terminals located to the left of the microprocessor.

Figure 6 shows the location of these terminals.

To R/T Box

To Power Panel

Input/Output

Connectors

to I/O Modules

Engine Start

Connections

Clock Program

Backup Battery

Remove protective strip to

enable clock functions

Network Connector

Control Connections

The terminals are clearly identified by a label on the

microcontroller backplate. In the case of manual transfer

switches, or in other applications not requiring the

microprocessor, clearly marked terminal blocks are

provided in the upper left corner of the control panel

for the engine start control wires.

Figure 6

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

DANGER

Page 8

6

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Entelli-Switch 250 Controller

Entelli-Switch 250 Controller

Consists of two major assemblies:

I. The Microprocessor contains the following:

A. Entelli-Switch 250 Board - Customer Input and

Output (I/O) for system interface. Located on the

left hand side of the back of the unit (see figure 7)

1. I/O accessories that can be found here are:

a. Engine start relay P output

b. Pre-Signal to transfer T3, W3 and

UMD output (optional)

c. Transfer Inhibit Q3 and Q7 input

(optional)

d. Remote test Q2 input (optional)

e. Network interface ZNET

input/output (optional)

B. LCD and Keypad located on the exterior of the

door (see figure 8)

1. User accessibility to the following:

a. LED indication of source availability

b. LED indication of transfer switch position

c. LCD screen indicates:

(1) timer count down (numeric)

(2) event reporting (text)

d. Keypad provides user interface to:

[in conjunction with LCD screen]

(1) Setting sensors and timers

(2) Configuring logic accessories

II. The Controls Power Supply (CPS)

Contains transformers which drop line voltage

to control level for controller input and SCR

inputs (see figure 7).

Figure 7

Figure 8

I/O Interface

CPS

Engine Start Relay P

Battery Strip

and

Access

Code Label

Entelli-Switch 250

Board

S1 OK

21:56

MON 23 APR 2008

MORE TEST

Page 9

71R-4000

B 7

■

ZBTS / ZBTSD Operation & Maintenance Manual

Entelli-Switch 250 Controller

(cont’d)

LCD & Keypad

These options are accessible through the LCD and keypad

(see figure below). To become familiar with the options

loaded into a particular unit, scrolling through the SET

and CFG menu will show the descriptions of the options

(see pages 16-17). These menus are the very same menus

that are used to access the setting and/or configuration

of these options. The SET (setting) menu is primarily

used to show or change, time and voltage settings. The

CFG menu is primarily used to turn an option on or off.

When scrolling through these menus, no changes can be

made without entry of the access code. The factory set sixdigit access code is located on a white label on the back

of the unit (see figure 11 pgs. 16-18).

The Entelli-Switch 250 has many logic options. Each controller

is downloaded with options at the time of manufacture.

The collection of options that any one controller has is

specified at the time of order placement. The following

pages include all the options that can reside in the controller. Not all units include all options.

Entelli-Switch 250Entelli-Switch 250

S1 OK

01: 50

WED 31 MAY 2008

Source 2 (Red)

indicates Source 2

is acceptable for use

Source 1 LED (Green)

indicates Source 1 is

acceptable for use

Exercise Event

“Impending”

SET Menu

MORE CFG TEST SET

#1 or the word on the LCD

above the key. The word above

the key changes depending on

which screen is being displayed.

#2 or the word on the LCD

above the key. The word above

the key changes depending on

which screen is being displayed.

#3 or the word on the LCD

above the key. The word above

the key changes depending on

which screen is being displayed.

#4 or the word on the LCD

above the key. The word above

the key changes depending on

which screen is being displayed.

Current Time,

Day and

Date of Display

Source 1 Position LED (Green)

indicates Power Panel (ATS)

is closed to Source 1 position

Source 2 Position LED (Red)

indicates Power Panel (ATS)

is closed to Source 2 position

Menus (more, cfg, test)

Keypad

* E *

LCD Screen

Figure 9

Page 10

8

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

User Setting for Voltage & Frequency

Standard 3-Phase Sensing

on 3 and 4 Pole Units

Source 1

Under Voltage “Restore”

Factory Default: 90%

This adjustment determines the minimum acceptable

voltage required to transfer to Source 1. Adjust via the SET

menu. Range is 85% to 100% in 1% increments (see page 17).

Once satisfied, the T timer will begin timing to transfer

to Source 1.

Under Voltage “Fail”

Factory Default: 80%

This adjustment determines the low voltage threshold.

Adjust via the SET menu. Range is 75% to 98% in 1%

increments (see page 17). “Fail” must be a minimum of 2%

below “Restore” setting. Once voltage falls below threshold,

P timer begins timing to signal Source 2 Generator to start.

Under Frequency “Restore”

Factory Default: 95%

This adjustment determines the minimum acceptable

frequency required to transfer to Source 1. Adjust via the

SET menu. Range is 90% to 100% in 1% increments (see

page 17). Once satisfied, the T timer will begin timing

to transfer to Source 1.

Under Frequency “Fail”

Factory Default: 90%, (5 seconds minimum)

This adjustment determines the low frequency threshold.

Adjust via the SET menu. Range is 88% to 98% in 1%

increments (see page 17). “Fail” must be a minimum of

2% below “Restore” setting. Once satisfied, the T timer

will begin timing to transfer to Source 1.

Over Frequency “Restore”

Factory Default: 102%

This adjustment determines the minimum acceptable

Over Frequency threshold at which the transfer switch

is allowed to re-transfer to Source 1. Adjust via the SET

menu. Range is 102% to 104% in 1% increments (see

page 17). “Restore” must be a minimum of 1% below

“Fail” setting.

Over Frequency “Fail”

Factory Default: 105%

This adjustment determines the maximum acceptable

Over Frequency. Adjust via the SET menu. Range is 103%

to 105% in 1% increments (see page 17).Once exceeded,

the P timer begins timing to signal the generator to start.

Source 2

Under Voltage “Restore”

Factory Default: 90%

This adjustment determines the minimum acceptable

voltage required to transfer to Source 2. Adjust via the

SET menu. Range is 85% to 100% in 1% increments

(see page 17). Once satisfied, the W timer will begin

timing to transfer to Source 2.

Under Voltage “Fail”

Factory Default: 80%

This adjustment determines the low voltage threshold.

Adjust via the SET menu. Range is 75% to 98% in 1%

increments (see page 17). “Fail” must be a minimum of

2% below “Restore” setting. Once voltage falls below

threshold, T timer will be bypassed to expedite the

transfer to Source 1.

Over Voltage “Fail”

Factory Default: 110%

This adjustment determines the maximum acceptable

Over Voltage. Adjust via the SET menu. Range is 105%

to 110% in 1% increments (see page 17). Once exceeded,

the T timer will be bypassed to expedite the transfer to

Source 1.

Over Voltage “Restore”

Factory Default: 105%

This adjustment determines the minimum acceptable

Over Voltage threshold at which the transfer switch is

allowed to transfer to Source 2. Adjust via the SET menu.

Range is 103% to 105% in 1% increments (see page 17).

“Restore” must be a minimum of 2% below “Fail” setting.

Under Frequency “Restore”

Factory Default: 95%

This adjustment determines the minimum acceptable

frequency required to transfer to Source 2. Adjust via the

SET menu. Range is 90% to 100% in 1% increments (see

page 17). Once satisfied, the W timer will begin timing

to transfer to Source 2.

Under Frequency “Fail”

Factory Default: 90%, (5 seconds minimum)

This adjustment determines the low frequency threshold.

Adjust via the SET menu. Range is 88% to 98% in 1%

increments (see page 17). “Fail” must be a minimum of

2% below “Restore” setting. Once satisfied, the W timer

will begin timing to transfer to Source 2.

Over Frequency “Fail”

Factory Default: 105%

This adjustment determines the maximum acceptable

Over Frequency. Adjust via the SET menu. Range is 103%

to 105% in 1% increments (see page 17). Once exceeded,

the T timer will be bypassed to expedite the transfer to

Source 1.

Over Frequency “Restore”

Factory Default: 102%

This adjustment determines the minimum acceptable

Over Frequency threshold at which the transfer switch is

allowed to re-transfer to Source 2. Adjust via the SET menu.

Range is 102% to 104% in 1% increments (see page 17).

“Restore” must be a minimum of 1% below “Fail” setting.

Page 11

71R-4000

B 9

■

ZBTS / ZBTSD Operation & Maintenance Manual

Accessory Group Packages

Standard Accessory included in the group package.

Optional Accessory not included but can be added to group package.

Optional Accessory. Can not be used with accessory having the same symbol.

N/A

Denotes an Accessory with 2 circuits as a standard.

Denotes an Accessory with 3 circuits as a standard.

Table 3

*

Delayed Transition Units Only.

**

Optional for 40-400 Amp

2

2

3

Page 12

10

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Accessory Definitions

6P

Test Switch, Momentary

6A

Test Switch, Maintained Auto/Momentary Test

6AP

Test Switch, Maintained/Momentary utilizing keypad

6B

Test Switch, Maintained - Auto / Momentary - Test,

Key Operated

6C

Test Switch, Maintained - Auto / Maintained - Test,

Key Operated

A1

Auxiliary Contact, operates on Source 1 line failure.

A1E

Auxiliary Contact, operates on Source 2 line failure.

A3

Auxiliary Contact: Closed in emergency (Source 2)

Additional Available (10 max.) and need to be specified.

A4

Auxiliary Contact: Closed in normal (Source 1)

Additional Available (10 max.) and need to be specified.

A62

Sequential Universal Motor Load Disconnect Circuit.

Normally closed auxiliary contacts for motor loads.

Open 0-60 seconds prior to transfer, after transfer,

or both in either direction then re-close in timed

sequence after transfer.

AB3

Auxiliary Contact: Closed in bypass emergency (Source 2)

(S.P.D.T.) (Standard up to 400 Amp) Additional Available

(10 max.) and need to be specified.

AB4

Auxiliary Contact: Closed in bypass normal (Source 1)

(S.P.D.T.) (Standard up to 400 Amp) Additional Available

(10 max.) and need to be specified.

B9

Battery charger connections.

Calibrate

While monitoring the actual Phase to Phase voltage levels

and Frequency with a calibrated test equipment, the

Phase to Phase voltage sensing and Frequency can be

adjusted accordingly. Calibration capabilities are available

for Frequency and AB, BC, CA Phase to Phase voltage for

both Sources. Adjust via SET menu (see page 18)

CDP

Clock Exerciser Load/ No Load: Allows the Generator

to start and run unloaded or to simulate a power failure,

start Generator and run under load. Can be configured

by end user for 1, 7, 14, 28, 365 day cycle. (See page 16)

CDT

Load or NO-Load. One event exerciser with adjustable

Engine exercise timer. Exercise duration can be set

between 5 and 60 minutes in 1 minute increments. Can

be configured to run every 1, 7, 14, or 28 days. Factory

Default is 20minutes. When exerciser is impending,

(*E*) appears in the upper right hand corner of LCD

screen. See page 15 for instructions. Configured via

CFG (see page 17). Set via SET menu (see page 18).

CTAP

Alarm Panel on transfer to Source 2 with Silence button.

DS

Disconnect Switch, Auto/Inhibit. Inhibits transfer in either

direction when in inhibit. Allows automatic operation

when in Auto. (40-400 Amps optional, 600-4000 Amps

standard)

DT

(Delayed Transition Only)

Time Delay from Neutral Switch position to Source 1

position. Adjustable 0-10 minutes in 1 second increments.

Standard setting is 5 seconds Adjust via SET menu

(see page 18)

DW

(Delayed Transition Only)

Time Delay from Neutral Switch position to Source 2

position. Adjustable 0-10 minutes in 1 second increments.

Standard setting is 5 seconds.Adjust via SET menu

(see page 18)

E

Engine Start Contact

EL/P

Event Log: Sequentially Numbered Log of 16 events

that track date, time, reason and action taken

System Data: Total Life Transfers (N2P)

Days Powered Up

Total Transfers to S2

Total S1 Failures

Time S1 available in Hrs

Time S2 available in Hrs. (N1P)

F

Fan contact, operates when generator is running.

HT

Heater and Thermostat

K

Frequency Meter, Door mount.

K/P

Frequency Indication for S1 and S2

L

LNP Center-off position LCD-Indicator

Indicating LED lights:

L1 Indicates Switch in Source 2 position.

L2 Indicates Switch in Source 1 position.

L3 Indicates Source 1 available.

L4 Indicates Source 2 available.

Page 13

71R-4000

B 11

■

ZBTS / ZBTSD Operation & Maintenance Manual

Accessory Definitions

(cont’d)

M1

Single Phase Amp Meter

M2

Three Phase Amp Meter

M80

3000 Digital Power Monitor

M82

5200 Digital Power Meter

M83A

EPM 5300 Digital Power Meter with Modbus Port

M83B

EPM 5350 Digital Power Meter with Ethernet Port

M84

7430 Digital Power Meter , Wye or Delta

M85A

EPM 9450 Digital Power Meter, Ethernet

M85B

EPM 9450 Digital Power Meter with Internal 56K Mod.

M86A

EPM 9650 Digital Power Meter, Wye or Delta,

RS232 or RS485

M86B

EPM 9650 Digital Power Meter, Wye or Delta,

RS232 or RS485

N1

Running Time Meter, Door mount

N2

Operation Counter, Door Mount

P1

Time Delay Source 2 Start. Adjustable 0-10 seconds. Standard

setting is 3 seconds. Adjust via SET menu (see page 18)

P2

Time Delay S2 Start. Adjustable 1/6 to 300 seconds.

Q2

Remote Peak Shave or Area Protection Circuit.

Energize Q2 to simulate Source 1 Line failure causing

the Generator to start and transfer the load to Source 2.

Should Emergency fail during this operation, Transfer

Switch will retransfer back to Source 1.

Q3

Remote inhibit transfer to Source 2 circuit. Energize

Q3 input to allow transfer to Source 2. To enable Q3

option, engage Q3 jumper.

Q7

Inhibit transfer to Source 1 circuit. Energize Q7 input

to prevent transfer to Source 1.

R1-1/R1-3

Source 1 Over Voltage sensing for single and three

phase systems.

Source 1 Over Voltage “Fail”

Factory Default: 110%

This adjustment determines the maximum acceptable

over voltage. Adjust via the SET menu. Range is 105% to

110% in 1% increments (see page 18). Once exceeded,

the P timer begins timing to signal the Generator to start.

Source 1 Over Voltage “Restore”

Factory Default: 105%

This adjustment determines the minimum acceptable

over Voltage threshold at which the Transfer Switch is

allowed to automatically transfer to Source 1. Adjust via

SET menu. Range is 103% to 108% in 1% increments.

“Restore” must be a minimum of 2% below “Fail” setting

(see page 18).

R15/R15D

Load Shed

Should Source 2 become overloaded, a signal can be

given to switch to the dead or Mid position.

R16

Phase Rotation Sensing

Can be turned on or off via CFG menu (see page 17).

Factory Default is on. This feature prevents Line Source

to Line Source transfers from occurring between dissimilar

phase sequences. This condition is primarily caused by

an installation error. Connections from Source 1 and

Source 2 need be verified, compared, and corrected to

remedy the inconsistent phase rotation between the

sources. WARNING: Turning off this feature can cause

severe damage to loads.

R26

Interruptable Power Rate Provisions

Allow transfer out of Source 1 position to Source 2 or

dead Source 2. Alarm and Pre-Signal circuit included.

Page 14

12

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Accessory Definitions

(cont’d)

R50

In Phase Monitor this feature restricts Live to Live Source

Transfers to occur unless both Sources are within 7 electri-

cal degrees or less of each other. (live Source to live Source

transfers usually occur during transfer back to Source 1

or during Testing). R50 does not change the operation

of the Automatic Transfer Switch in a power failure mode.

After all timer functions have elapsed, the CHECKING

FOR SOURCE SYNCHRONISM will be displayed as well

as the direction of transfer (S1-S2 for example denotes

transfer from Source 1 to Source2). When synchronism is

accomplished, transfer will take place.

Notes: - If S2 Frequency is less than S1 Frequency,

display will show a series of (- - - - -…..) symbols.

- If S2 Frequency is greater than S1 Frequency,

display will show a series of (+++++…..) symbols.

- Each (-) or (+) symbol represents 10 electrical

degrees out of phase. A maximum of 18 symbols

(180 electrical degrees) can be monitored.

- The number of (-) or (+) symbols decrease

as the two sources approach synchronism

and increase as the two sources drift out

of synchronism.

- If S1 and S2 Frequencies are identical, the

display will show a series of alternating

- - - -

symbols (++++…) which also indicate the

approximate out of phase degrees

In the event that the Sources do not come within 7

electrical degrees of each other within 60 seconds, the

unit will display the message: SYNCH CHECKING and

will allow the user to BYPASS. If the BYPASS button is

pressed, the unit will display the message: WARNING

MAY CAUSE DAMAGE TO THE LOAD. Pressing XFR

will actually bypass the R50. Since R50 is a passive device,

the length of time it takes to reach Synchronism is dependent on the frequency difference between the two

Sources. Source 1 is usually a Utility and the frequency

is not within the control of the consumer. Source 2

needs to be adjusted to create an adequate difference

in order for the transfer to happen a timely fashion.

Note: For optimum performance, Source 2

Generator should be adjusted a Maximum of

2 Hertz above or below the Utility frequency,

minimum of 0.1 Hertz. (58 to 59.9) or

(60.1 to 62) Hertz. Adjustment of Generator

to 60Hertz could cause lengthy transfer delay

.

R50 Feature can be turned ON or OFF via CFG Menu

(see page 17). Factory Default if OFF.

S5P

Auto / Semi Manual selector

In “Auto” position, retransfer to Source 1 is automatic

after the T timer has timed out. The T time delay is

bypassed if Source 2 fails. In “Manual”, retransfer to

Source 1 is upon depression of BYPASS DELAY button

YEN or if Source 2 fails.

S12P

Auto / Manual Selector

In “Auto” position, the Automatic Transfer Switch

functions automatically as specified with the Switch

drawings. In “Manual” the Automatic Transfer Switch will

transfer to either direction upon depression of Source 1

or Source 2 transfer buttons. Should Source 1 fail, the

Generator (Source 2), will automatically start. Once

transferred in Manual, the Switch maintains position

selected even if selected power fails.

S13P

Transfer Commit. Configured via CFG menu. (see page 17)

When this Feature is set to OFF: The transfer Switch is

not committed to transfer unless the outage duration is

longer than the timers that precede the transfer to

Source 2 position. This assumes that the outage will be

an isolated event. When this Feature is set to ON: The

transfer Switch is committed to transfer to Source 2

position once the W timer has begun timing, even if

Source 1 power returns before the transfer to Source 2.

This is to ensure that the transfer takes place, because

one outage may be followed by another.

S14

Test / Auto / Source 1 Selector, Door mount

SW1

Auto/Off/Start Engine control selector, Door mount

(Keyed or non-keyed operation available)

SW2

Auto / Off Engine control selector, Door mount

(Keyed or non-keyed operation available)

SW3

Source Priority Selector Switch, Door mount

Allows selection of Source 1 or Source 2 to be the Prime

Source. Transfer Switch will transfer to selected Prime

Source if that Source is available. (Keyed or non-keyed

operation available)

T

Time Delay (S1) Source 1 Stable Timer. To delay transfer

to Source 1 (immediate retransfer on Source 2 failure).

Adjustable 0-60 minutes in 1 second increments.

Standard setting is 30 minutes. Adjust via SET menu

(see page 18)

T3/W3

Elevator Pre-Signal Auxiliary Contacts: Open 0-60

seconds prior to transfer to either direction, re-closes

after transfer.

U

(S2) Source 2 Stop Delay Timer. Allows Engine to run

unloaded after switch retransfer to Source 1. Adjustable

0-60 minutes in 1 second increments. Standard setting is

5 minutes. Adjust via SET menu (see page 18)

Page 15

71R-4000

B 13

■

ZBTS / ZBTSD Operation & Maintenance Manual

Accessory Definitions

(cont’d)

UMD

Universal Motor Load Disconnect Circuit: Auxiliary

Contact opens 0-60 seconds prior to transfer in either

direction, re-closes after transfer. Can be configured by

end user for Pre-transfer, Post-transfer, or both.

VI

Voltage Imbalance (Three Phase)

For a three phase source, this feature monitors phase

voltage ratios based on a selected range within a selected

time window. Should any phase fall below the selected

lower window limit or exceed the selected higher window

limit within the selected time frame, the controller initiates

transfer to the other source.

Range: 5% to 20% of Nominal voltage,

10 to 30 seconds window, user adjustable.

Resolution: 1% Increments

Minimum Differential: 2% between “Fail”

and “Restore” settings.

Factory default: 10% “Fail”, 8% “Restore”, 30 Seconds.

See CFG Menu page 17 to configure ON or OFF.

See SET Menu page 18 to set Percentage and time windows

W

Time Delay (S2) Source 2 Stable Timer. To delay transfer

to Source 2. Adjustable 0-5 minutes in 1 second increments.

Standard setting is 1 second. Adjust via SET menu (see

page 18)

YEN

Bypass Timers Key utilizing Keypad. When applicable,

the system prompts the user to press a button to bypass

(T) or (W) Timers should the user so desires.

ZNET

Network Communications Interface Card

How to Set the System Clock

How to Set the System Clock

Set System Clock, time and date

· If the clock is not set, the display will show SET SYSTEM

CLOCK on the second line of the S1 OK screen.

· The S1 OK screen will show time (hours and minutes)

on the second line if the system clock has been set.

(Date on third line)

Setting the System Clock

(Start from S1 OK screen)

1. Remove battery protective white plastic strip

near P relay. *

2. Press MORE then press SET.

3. Press MORE and scroll to SET SYSTEM CLOCK

using the MORE key.

4. Press SEL.

5. ENTER ACCESS CODE located on the white label

on the back of the controller.

6. Press SEL.

7. Use the up and down keys to change the hour value.

8. Press SAVE (this will enter this value and move

cursor to minutes).

9. Use the up and down keys to change the minutes.

10. Press SAVE (this will enter this value and move

cursor to month).

11. Use the up and down key up to change the month.

12. Press SAVE (This will enter this value and complete

the clock setting).

13. Use the up and down keys to change the date.

14. Press SAVE (this will enter this value and move

cursor to year).

15. Use the up and down keys to change year.

16. Press SAVE (this will enter this value and

compete the clock setting).

17. To edit settings, press SEL and repeat steps 6-16.

18. If the setting is satisfactory, press MORE (unit then

returns to the SET menu then press BACK, then ESC.)

* Replacement battery part #K-4100

Battery will last 5 years and provides power to retain clock

function only (Controller functions without battery).

Page 16

14

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Load / No-Load

One event Exerciser with adjustable Timer. Exercise

duration can be set between 5 and 60 minutes in

1 minute increments. Can be configured to run every

1,7,14, or 28 days. Factory default is 20 minutes.

How to CONFIGURE (CFG) and Set (SET)

the Timer Exerciser

1. Beginning from the S1 OK screen,

press MORE then CFG.

2. Press MORE to scroll to CONFIG TIMER

EXERCISER screen.

3. The third line of the CONFG TIMER EXERCISER

will show either DAILY, WEEKLY, 14 DAY, 28 DAY,

or OFF.

4. If the third line of the CONFG TIMER EXERCISER

shows DAILY, WEEKLY, 14 DAY, or 28 DAY as

desired, then proceed to step 10.

5. If the third line of the CONFG TIMER EXERCISER

shows OFF or if another timer selection is desired,

continue.

6. Press SEL.

7. Enter ACCESS code located on white label

on the back of the controller.

8. Press UP or DOWN to select DAILY, WEEKLY,

14 DAY, or 28 DAY as desired.

9. Press SAVE.

10. Press MORE to scroll to CONFG TIMER

EXERCISER (XFR) or (NO XFR).

11. Press Up or Down to select XFR (Load Transfer)

or NO XFR (No Load Transfer).

12. Press SAVE.

13. Press MORE repeatedly to BACK then S1 OK screen.

Set (SET) the Exerciser:

14. Beginning from the S1 OK screen,

press MORE then SET.

15. Press MORE repeatedly until

EXER S2 RUN TIME screen.

16. Press SEL

17. Enter ACCESS code located on white label

on the back of the controller.

18. Press SEL

19. Cursor is indicated as a line under character to

be changed. Change values with up and down keys.

20. Press SAVE when complete.

21. Press MORE repeatedly until SET USER SETUP

then press BACK then ESC to the S1 OK screen.

How to Initiate CDT Exerciser and to start an

exercise cycle every 1, 7, 14, or 28 days

From S1 screen

1) Press TEST

2) Press MORE

3) Press START TEST TIMER (to initiate Test).

• If the CDT Exerciser is Factory configured for a

Load Exerciser, the Controller will immediately start

a load exercise. The controller will start the

generator, transfer the load to Source 2 and remain

in Source 2 for the duration set for EXER S2 RUN

TIME in the SET menu. The controller will

retransfer the load back to Source 1 after the S1

stable timer has timed out and run the generator

unloaded for the duration of the S2 stop delay timer

(Engine Cool Down Timer).

• If the CDT Exerciser is Factory configured for a

No-Load Exerciser, the Controller will immediately

start a No-load exercise. The controller will start the

generator and run it unloaded for the duration of

the S2 stop delay timer (Engine Cool Down Timer).

Exercise will be repeated at the same time as initiated

on every 1, 7, 14, or 28 days according to the selection

made in the Configure CFG menu.

How to Bypass (Cancel) an exercise during

an exercise cycle

1) Press BPASS

2) Allow the controller to complete the Engine

cool down cycle

If the CDT Exerciser is Factory configured for a

No-Load Exerciser Or allow the controller to complete

retransfer to Source 1 If the CDT Exerciser is Factory

configured for a Load Exerciser

How to Bypass the next exercise event and Keep

the rest of scheduled events unchanged

1) Press Test

2) Press MORE

3) Press BYPASS EXER

To re-institute the next exercise event back,

press CANCL BPASS

How to initiate a new exercise start time

1) Press TEST

2) Press MORE

3) Press EXER CANCL

4) Press START TIMER TEST

How to check the next exercise event

1) From S1 OK screen, press MORE three times.

2) The unit will display the PLANT EXERCISER NEXT

event in DAYS, HOURS, and MINUTES

3) Press ESC to S1 OK Screen.

Notes:

- *E* appears in the upper right hand corner

of LCD screen when exercise is impending.

- For Load Exerciser, actual exercise period

(ATS in S2 position)= CDT (Exerciser)

timing period +T (S1 stable Timer) timing period.

CDT One Event Timer Exerciser

Page 17

SET

EXERCISER

00:00

To save value and to

move cursor to next

field to be changed.

Indicates # of

Exercise Periods

BACK ^ v SAVE

Indicates type of Exerciser

DAILY, WEEKLY, 14-DAY,

28-DAY or 365-DAY

Indicates Exerciser start:

Time for DAILY Exerciser

Time & Day for WEEKLY Exerciser

Time, Date & Month for 14-DAY,

28-DAY and 365-DAY Exerciser

(24 Hour System)

To previous field

or to exit screen.

Up and Down

Use to change values.

Cursor

NL#1

Load No-Load (CDP)

Exercise Indicator

Exercise duration for this

event in hours and minutes

up to 10 hours per event

71R-4000

B 15

■

ZBTS / ZBTSD Operation & Maintenance Manual

CDP Clock Exerciser

Load / No-Load Clock Exerciser

Allows the Generator to start and run unloaded or to

simulate a power failure, start Generator and run under

load. Can be configured by the end user for 1, 7, 14, 28,

or 365 day cycles.

• A total of 7 independent No Load exercise periods

(up to 10 hours each) can be programmed for each

of the daily, weekly, 14-day, and 28-day exercisers.

• A total of 12 independent No Load exercise periods

(up to 10 hours) can be programmed for the

365-day Exerciser.

How to Configure (CFG) the Exerciser

1. Beginning from the S1 OK screen, press MORE

then CFG.

2. Press MORE to scroll to CONFIG CLOCK

EXERCISER screen.

3. The third line of the CONFG CLOCK EXERCISER

will show either DAILY, WEEKLY, 14 DAY, 28 DAY,

365 DAY or OFF.

4. If the third line of the CONFG CLOCK EXERCISER

shows DAILY, WEEKLY, 14 DAY, 28 DAY, or 365 DAY

as desired, press MORE repeatedly to BACK.

Press ESC then proceed to the SET menu to

set the EXERCISER.

5. If the third line of the CONFG CLOCK EXERCISER

shows OFF, continue.

6. Press SEL.

7. Enter ACCESS code located on white label on

the back of the controller.

8. Press UP or DOWN to select DAILY, WEEKLY,

14 DAY, 28 DAY, or 365 DAY as desired.

9. Press SAVE.

10. Press MORE repeatedly to BACK then ESC

to S1 OK screen.

How to set (SET) the DAILY Exerciser

1. Beginning from the S1 OK screen, press MORE

then SET.

2. Press MORE repeatedly until SET EXERCISER

screen.

3. Press SEL.

4. Enter ACCESS code located on white label

on the back of the controller.

5. Press SEL

6. Cursor is indicated as a line under character to

be changed. Change values with up and down keys.

Press SAVE after each entry to save value and to

move to the next value to be changed.

7. Press BACK when complete.

8. Press MORE repeatedly until SET USER SETUP.

Press BACK then ESC to the S1 OK screen.

How to Bypass (Cancel) an exercise during

an exercise cycle

1) Press BPASS

2) Allow the controller to complete the Engine

cool down cycle.

If the CD Exerciser is configured or Set for a No-Load

Exercise. Or allow the controller to complete retransfer

to Source 1. If the CD Exerciser is configured for a

Load Exerciser

How to Bypass the next exercise event and Keep

the rest of scheduled events unchanged

1) Press TEST

2) Press MORE

3) Press BYPASS EXER

To re-institute the next exercise event back,

press CANCL BPASS

How to check the next exercise event

1) From S1 OK screen, press MORE three times.

2) The unit will display the PLANT EXERCISER NEXT

event in DAYS, HOURS, and MINUTES

3) Press ESC to S1 OK Screen.

Notes:

• In the S1 OK screen, an (*E*) appears in the upper

right hand corner of LCD screen when exercise

is impending.

• For Load Exerciser, actual exercise period

(ATS in S2 position)= CDT (Exerciser)

timing period +T (S1 Stable Timer) timing period.

• A value greater than zero must be entered in the

Exerciser duration field to be accepted as a valid

exercise period.

• The Exercise cycle will be repeated on a regular

basis as programmed and initiated in the SET menu

depending on what Exerciser was configured

(selected) in the CFG menu.

Figure 10

Page 18

16

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Entelli-Switch 250 User Setup - CFG Menu

Turn options ON or OFF via

keypad through the CFG menu

Enter six digit access code

(The factory assigned six-digit access code

is located on the back of the controller)

Figure 11

1

Engine Start Relay (De-Energized)

Network Communications

(Option)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J2

*

PROG 1

PROG 2

GRD (Input Sink)

NIA OUT

ELEV. PRE. OUT

ALARM OUT

MOTOR DISC. OUT

INHIB.>S1

INHIB.>S2

Input and output availability

subject to factory configuration.

*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J4

*

+12v (Output Source)

LN OUT

L4 OUT

L3 OUT

L2 OUT

L1 OUT

YN IN

YE IN

TSNL IN

Q2/TSL IN

S12 IN

Lithium Battery

Exerciser Battery

Replacement-K-4100 (BR2032)

Service Life-10 Years

† During normal operation

User Access Code

Default-121212

PRODUCT INFORMATION

www.geindustrial.com

24-Hour Service

(773)299-6600

Entelli-Switch MX250

A2

(-)

A1

(+)

RELAY

14 11 12

Customer

Input

Voltage

COM

J2-3

N.O N.C

To

J2/J4

Inputs

WARNING

1

Controller Inputs must be relay Isolated.

2

Controller Outputs have Limited Source Capacity.

Use only GE Zenith-specified Output Modules.

11 14

R1

A1

(+)

12

21 24 22

A2

(-)

Output

Contacts

22

R1 Output

R1 Output

Contact Rating: 10A @ 250 VAC or 30 VDC

2

3

4

5

6

2421121411

LS OUT

STE OUT

TMS IN

LS IN

S5 IN

TM

2008

Page 19

71R-4000

B 17

■

ZBTS / ZBTSD Operation & Maintenance Manual

Entelli-Switch 250 User Setup - SET Menu

Change adjustable values

through the SET menu.

Enter six digit access code

(The factory assigned six-digit access code

is located on the back of the controller)

Figure 11

1

Engine Start Relay (De-Energized)

Network Communications

(Option)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J2

*

PROG 1

PROG 2

GRD (Input Sink)

NIA OUT

ELEV. PRE. OUT

ALARM OUT

MOTOR DISC. OUT

INHIB.>S1

INHIB.>S2

Input and output availability

subject to factory configuration.

*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J4

*

+12v (Output Source)

LN OUT

L4 OUT

L3 OUT

L2 OUT

L1 OUT

YN IN

YE IN

TSNL IN

Q2/TSL IN

S12 IN

Lithium Battery

Exerciser Battery

Replacement-K-4100 (BR2032)

Service Life-10 Years

† During normal operation

User Access Code

Default-121212

PRODUCT INFORMATION

www.geindustrial.com

24-Hour Service

(773)299-6600

Entelli-Switch MX250

A2

(-)

A1

(+)

RELAY

14 11 12

Customer

Input

Voltage

COM

J2-3

N.O N.C

To

J2/J4

Inputs

WARNING

1

Controller Inputs must be relay Isolated.

2

Controller Outputs have Limited Source Capacity.

Use only GE Zenith-specified Output Modules.

11 14

R1

A1

(+)

12

21 24 22

A2

(-)

Output

Contacts

22

R1 Output

R1 Output

Contact Rating: 10A @ 250 VAC or 30 VDC

2

3

4

5

6

2421121411

LS OUT

STE OUT

TMS IN

LS IN

S5 IN

TM

2008

Page 20

18

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Entelli-Switch 250 User Setup - System Info

View System Data

Enter six digit access code

(The factory assigned six-digit access code

is located on the back of the controller)

Figure 11

1

Engine Start Relay (De-Energized)

Network Communications

(Option)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J2

*

PROG 1

PROG 2

GRD (Input Sink)

NIA OUT

ELEV. PRE. OUT

ALARM OUT

MOTOR DISC. OUT

INHIB.>S1

INHIB.>S2

Input and output availability

subject to factory configuration.

*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J4

*

+12v (Output Source)

LN OUT

L4 OUT

L3 OUT

L2 OUT

L1 OUT

YN IN

YE IN

TSNL IN

Q2/TSL IN

S12 IN

Lithium Battery

Exerciser Battery

Replacement-K-4100 (BR2032)

Service Life-10 Years

† During normal operation

User Access Code

Default-121212

PRODUCT INFORMATION

www.geindustrial.com

24-Hour Service

(773)299-6600

Entelli-Switch MX250

A2

(-)

A1

(+)

RELAY

14 11 12

Customer

Input

Voltage

COM

J2-3

N.O N.C

To

J2/J4

Inputs

WARNING

1

Controller Inputs must be relay Isolated.

2

Controller Outputs have Limited Source Capacity.

Use only GE Zenith-specified Output Modules.

11 14

R1

A1

(+)

12

21 24 22

A2

(-)

Output

Contacts

22

R1 Output

R1 Output

Contact Rating: 10A @ 250 VAC or 30 VDC

2

3

4

5

6

2421121411

LS OUT

STE OUT

TMS IN

LS IN

S5 IN

TM

2008

Page 21

71R-4000

B 19

■

ZBTS / ZBTSD Operation & Maintenance Manual

Testing

ATS Testing

Start generator and verify proper voltage, frequency and

phase sequence (match to Source 1). Shut down gen set

and place in Auto. Complete the visual inspection of the

transfer switch, and close the cabinet door.

Initiate the test by pressing the TEST button on the LCD

keypad. The controller will then prompt for your access

code. After entering the code, three test options will appear—

XFR LOAD, FAST TEST and NO XFR (See Figure 12).

• XFR LOAD test starts the generator and using the

current timer settings, transfers the load to Source 2.

• FAST TEST test presets timer values to a maximum

30 seconds during the test. After completion of

the test, all timers are reset to their original

values. (T3, W3, DT and DW remain)

• NO XFR test starts the generator but does not

transfer the load to the Source 2.

Press and hold the desired test option button until

the switch transfers to Source 2 (load test) or until the

generator has been run for the desired amount of time

(no load test). Releasing the test button before W timer

timeout will abort the test (Exception: when the transfer

commit option, is configured “ON”).

To test lamps, press TEST then scroll through MORE, then

press LAMP TEST. To cancel LAMP TEST press MORE.

Standard Transition

When the test is initiated, the controller initiates the Time

Delay Source 2 Start Timer (Engine Start Timer “P”) cycle.

A manual CANCEL button is provided to cancel the test

if desired. Upon completion of the (P) time delay, an Engine

start Signal is sent to Source 2. When Source 2 voltage and

frequency reach the preset “Restore” Values, the time delay

to Source 2 Timer (W) begins its timing cycle to ensure

voltage and frequency stabilization before transfer. A manual

pushbutton BYPASS is provided to bypass the “W” time

delay if desired. After the (W) time delay, the MX controller

initiates a transfer signal through the SCR-E to operate the

main transfer operator. The load is now transferred to

Source 2 line. The transfer switch is mechanically locked.

SN limit switch awaits the next operation to Source 1.

Restoration of Source 1 Power:

Deactivating the test switch initiates re-transfer to Source 1

sequence. The delay to Source 1 Timer (T) begins its

timing cycle to ensure voltage and frequency stabilization

before retransfer. A manual pushbutton BYPASS is provided

to bypass the “T” time delay if desired. After the (T) time

delay, the MX controller initiates a transfer signal through

the SCR-N to operate the main transfer operator. The load

is now transferred to Source 1 line. The transfer switch is

mechanically locked. SE limit switch awaits the next

operation to Source 2.

Immediately after re-transfer,

the S2 Stop Delay Timer (Delay

to Engine Stop “U”) begins

its cycle to allow Source 2

Engine to run unloaded. A

manual pushbutton BYPASS

is provided to bypass the “U”

time delay if desired. Upon

completion of the (U) timing

cycle, the controller sends

an Engine stop signal.

Delayed Transition

Source 1 Power Failure:

When the test is initiated, the controller initiates the Time

Delay Source 2 Start (Engine Start Timer “P”) cycle. A

manual CANCEL button is provided to cancel the test if

desired Upon completion of the (P) time delay, an Engine

start Signal is sent to Source 2. When Source 2 voltage

and frequency reach the preset “Restore” values, the time

delay to open Source 1 timer (W) begins its timing cycle

to ensure voltage and frequency stabilization before retransfer. A manual pushbutton BYPASS is provided to

bypass the “W” time delay if desired. After the (W) time

delay, the MX controller initiates a transfer signal through

the SCR-NO to operate the main transfer operator. The

load is now transferred to the Open position. The time

delay to Source 2 timer (DW) begins its timing cycle.

After the (DW) time delay, the MX controller initiates a

transfer signal through the SCR-E to operate the main

transfer operator. The load is now transferred to Source 2

line. The transfer switch is mechanically locked. SN

limit switch awaits the next operation to Source 1.

Restoration of Source 1 Power:

Deactivating the test switch initiates re-transfer to Source 1

sequence. The delay to open Source 2 Timer (T) begins

its timing cycle to ensure voltage and frequency stabilization

before retransfer. A manual pushbutton BYPASS is provided

to bypass the “T” time delay if desired. After the (T) time

delay, the MX controller initiates a transfer signal through

the SCR-EO to operate the main transfer operator. The

load is now transferred to the Open position. The time

delay to Source 1 timer (DT) begins its timing cycle. After

the (DT) time delay, the MX controller initiates a transfer

signal through the SCR-N to operate the main transfer

operator. The load is now transferred to Source 1 line.

The transfer switch is mechanically locked. SE limit switch

awaits the next operation to Source 2.

Immediately after re-transfer, the S2 Stop Delay Timer

(Delay to Engine Stop “U”) begins its cycle to allow

Source 2 Engine to run unloaded. A manual pushbutton

BYPASS is provided to bypass the “U” time delay if

desired. Upon completion of the (U) timing cycle,

the controller sends an Engine stop signal.

SYSTEM TEST

FAST XFR NO

MORE TEST LOAD XFR

A periodic test of the transfer switch under load conditions is recommended to insure proper operation.

(See National Electric Code articles 700 and 701)

NOTICE

Figure 12

Page 22

20

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Sequence of Operation

Standard Transition

Source 1 Power Failure:

When Source 1 voltage or frequency has fallen below the

preset “Fail” values, the controller initiates the Time Delay

Source 2 Start Timer (Engine Start Timer “P”) cycle. Upon

completion of the (P) time delay, an Engine start Signal

is sent to Source 2. When Source 2 voltage and frequency

reach the preset “Restore” Values, the time delay to Source 2

Timer (W) begins its timing cycle to ensure voltage and

frequency stabilization before transfer. A manual pushbutton BYPASS is provided to bypass the “W” time delay

if desired. After the (W) time delay, the MX controller

initiates a transfer signal through the SCR-E to operate the

main transfer operator. The load is now transferred to

Source 2 line. The transfer switch is mechanically locked.

SN limit switch awaits the next operation to Source 1.

Restoration of Source 1 Power:

When Source 1 power reach the preset “Restore” values,

the controller initiates re-transfer to Source 1 sequence.

The delay to Source 1 Timer (T) begins its timing cycle

to ensure voltage and frequency stabilization before

retransfer. A manual pushbutton BYPASS is provided to

bypass the “T” time delay if desired. After the (T) time

delay, the MX controller initiates a transfer signal through

the SCR-N to operate the main transfer operator. The

load is now transferred to Source 1 line. The transfer

switch is mechanically locked. SE limit switch awaits the

next operation to Source 2.

Immediately after re-transfer, the S2 Stop Delay Timer

(Delay to Engine Stop “U”) begins its cycle to allow

Source 2 Engine to run unloaded. A manual pushbutton

BYPASS is provided to bypass the “U” time delay if desired.

Upon completion of the (U) timing cycle, the controller

sends an Engine stop signal.

Delayed Transition

Source 1 Power Failure:

When Source 1 voltage or frequency has fallen below the

preset “Fail” values, the controller initiates the Time Delay

Source 2 Start (Engine Start Timer “P”) cycle. Upon

completion of the (P) time delay, an Engine start Signal

is sent to Source 2. When Source 2 voltage and frequency

reach the preset “Restore” values, the time delay to open

Source 1 timer (W) begins its timing cycle to ensure

voltage and frequency stabilization before re-transfer.

A manual pushbutton BYPASS is provided to bypass the

“W” time delay if desired. After the (W) time delay, the

MX controller initiates a transfer signal through the

SCR-NO to operate the main transfer operator. The load

is now transferred to the Open position. The time delay to

Source 2 timer (DW) begins its timing cycle. After the (DW)

time delay, the MX controller initiates a transfer signal

through the SCR-E to operate the main transfer operator.

The load is now transferred to Source 2 line. The transfer

switch is mechanically locked. SN limit switch awaits the

next operation to Source 1.

Restoration of Source 1 Power:

When Source 1 power reach the preset “Restore” values,

the controller initiates re-transfer to Source 1 sequence.

The delay to open Source 2 Timer (T) begins its timing

cycle to ensure voltage and frequency stabilization before

retransfer. A manual pushbutton BYPASS is provided to

bypass the “T” time delay if desired. After the (T) time

delay, the MX controller initiates a transfer signal through

the SCR-EO to operate the main transfer operator. The

load is now transferred to the Open position. The time delay

to Source 1 timer (DT) begins its timing cycle. After the

(DT) time delay, the MX controller initiates a transfer

signal through the SCR-N to operate the main transfer

operator. The load is now transferred to Source 1 line.

The transfer switch is mechanically locked. SE limit

switch awaits the next operation to Source 2.

Immediately after re-transfer, the S2 Stop Delay Timer

(Delay to Engine Stop “U”) begins its cycle to allow

Source 2 Engine to run unloaded. A manual pushbutton

BYPASS is provided to bypass the “U” time delay if desired.

Upon completion of the (U) timing cycle, the controller

sends an Engine stop signal.

Timer Designations as they appear in the SET menu

ATS Type P W DW T DT U

Standard Time Delay Time Delay Time Delay S2 Stop

Transition S2 Start S2 Stable S1 Stable Delay

Delayed Time Delay Time Delay ATS Open Time Delay ATS Open S2 Stop

Transition S2 Start S2 Stable Time to S2 S1 Stable Time to S1 Delay

Source 1 Transfer to Source 2

Source 1

Transfer to Source 1 Engine

Fails

Returns

Cooldown

Table 4

Page 23

71R-4000

B 21

■

ZBTS / ZBTSD Operation & Maintenance Manual

Sequence of Operation

(cont’d)

Bypass-Isolation Operation

An automatic transfer switch equipped with a bypassisolation switch provides the ability to withdraw the

ATS for testing and/or maintenance purposes without

interrupting the served load.

Operation of the unit is quick and convenient requiring

only one operator and less than one minute to complete.

Instructions are mounted on the front of each isolation

switch door along with a mimic panel providing indication

of power source availability and ATS/bypass switch positions.

The bypass switch is normally open on both sources with

the ATS feeding the system load. During operation, the

bypass is closed paralleling the ATS contacts which then

allows withdrawal of the ATS to the “TEST” or “ISOLATE”

positions. Mechanical and electrical interlocks are included

to prevent cross-servicing or bypassing to a dead source.

In the “TEST” position, the ATS is disconnected from the

load (now fed through the bypass) but control power is

present to allow complete operational testing through

the control panel of the transfer switch

In the “ISOLATE” position, the ATS is completely withdrawn

and may be removed from the enclosure for maintenance

if desired.

After the isolation operation, if the bypass is closed on

Source 1 and if this source fails, an auxiliary contact on

the bypass control will automatically start the enginegenerator set. When the second source is available, the

manual handle of the bypass may be operated to transfer

the load to the available source. Interlocks prevent both

this transfer, if the ATS is in the circuit and connected to

the opposite source or reconnection of the ATS unless

the positions match.

Figure 13 Figure 14

While the bypass switch is out of the AUTO

position/mode, the ATS is INHIBITED from

automatic operation. Make certain the ATS is left

in automatic after completion of any service.

WARNING

BYPASS

SOURCE 1

SOURCE 1

AVAILABLE

BYPASS

SOURCE 1

BYPASS

SOURCE 2

SOURCE 1

AVAILABLE

SOURCE 2

AVAILABLE

Page 24

22

71R-4000

B

■

ZBTS / ZBTSD Operation & Maintenance Manual

Sequence of Operation

(cont’d)

100-400 AMP

1) Automatic

a) Manually operated Bypass Switch contacts

(BN/BE) are open and ATS is supplying load.

b) Disconnect Switch (DS) is in Auto.

2) To Bypass ATS

a) Open bottom cabinet door and turn DS to Inhibit.

b) Position manual bypass handle (MBH) to same

power source as ATS.

3) To Test ATS

a) Bypass per above instructions.

b) Move ATS location handle (ALH) to Test location.

c) Turn DS to Auto.

d) Test Switch (TS) on bottom cabinet door

will allow electrical operation of ATS.

4) To Isolate ATS

a) Bypass per above instructions.

b) Move ALH to Isolate location.

5) To Remove ATS

a) Bypass and isolate per above instructions.

b) Move ALH to Release location.

c) Disconnect multipin plugs.

d) Lift ATS out of drawer.

6) To Reconnect ATS

a) Place ATS into drawer slots (front rollers first).

b) Turn DS to Inhibit.

c) Manually position ATS into same source

as Bypass Switch.

d) Reconnect multipin plugs and external

connections to ATS.

e) Push ATS inward to engage carriage.

f) Move ALH to Test location (as indicated by light).

g) Turn DS to Auto and use TS to electrically

operate ATS.

h) Turn DS to Inhibit.

i) Move ALH to Auto location.

j) Turn DS to Auto and open Bypass with MBH.

k) ATS is now fully automatic.

Notes:

1. DS in Inhibit will prevent ATS electrical operation.

2. Do not use excessive force on mechanical handles.

3. Figures depict Bypass Source 1. Sequence is the same for Bypass Source 2.

4. When ATS is in Test or Isolate, Bypass Switch is manual transfer switch to either available source (indicated on light panel).

5. To operate Bypass Switch when ATS is in Test or Isolate, position MBH to available power source.

Legend

:

1. BP - Bypass switch (indicated by contacts BN/BE) is a three position switch.

2. ATS - Automatic Transfer Switch.

Figure 15

Page 25

71R-4000

B 23

■

ZBTS / ZBTSD Operation & Maintenance Manual

600-1200 AMP

1) Automatic

a) Manually operated Bypass Switch contacts

(BN/BE) are open and ATS is supplying load.

b) Disconnect Switch (DS) is in Auto.

2) To Bypass ATS

a) Open bottom cabinet door and turn DS to Inhibit.

b) Turn Bypass Selector Switch (BSS) to same power

source as ATS

c) Position manual bypass handle (MBH) upward.

3) To Test ATS

a) Bypass per above instructions.

b) Rotate crank mechanism counter-clockwise until

ATS test light is illuminated.

c) Turn DS to Auto.

d) Test Switch (TS) on bottom cabinet door will allow

electrical operation of ATS.

4) To Isolate ATS

a) Bypass per above instructions.

b) Rotate cank mechanism counter-clockwise

until ATS Isolated light is illuminated.

5) To Remove ATS

a) Bypass and isolate per above instructions.

b) Disconnect multipin plugs and external

connections to ATS.

c) Rotate four power panel latches to vertical

position, slide ATS forward and lock mechanism

in place.

d) ATS can now be removed from cabinet.

6) To Reconnect ATS

a) Place ATS in slide mechanism.

b) Unlock slide mechanism. Slide ATS over power

panel latches and rotate latches to horizontal

position.

c) Turn DS to Inhibit.

d) Manually position ATS into same source

as Bypass Switch.

e) Reconnect multipin plugs and external

connections to ATS.

f) Rotate crank mechanism clockwise until

ATS Test light is illuminated.

g) Turn DS to Auto and use TS to electrically

operate ATS.