Page 1

1

Item

Qty

Description

1 1 Slide Assembly

2 5 Tamper-resistant Screws (1/4-20 x .625)

3 5 Flat Washer

4 1 Mounting Plate

5 7 Lock Washer

6 2 Tamper-resistant Screws (1/4-20 x .500)

7 1 Taptite

8 1 Shim

9 1 Pivot Bar Assembly

CAUTION: To avoid electrical hazard, make sure

primary and secondary circuits are not energized

while working in the compartment.

Key Lock Mounting Accessory Kit for 3200-4000A Substructure

Cat. No’s WPS32SUBSH1, WPS32SUBSH2, WPH32SUBSH1,

WPH32SUBSH2, WPS40SUBSH1, and WPS40SUBSH2

WPSKLMTG2:

Table 1. List of parts included in the key lock mounting kit

WPSKLMTG2.

KIT CONTENTS (Cat. No. WPSKLMTG2)

This kit shown above contains the retaining angle

with slide assembly, pivot bar assembly, mounting

plate, and mounting hardware. This unit installs on

the left side of the substructure. Key lock is

furnished by the customer. See back of this sheet

for lock required. Installation requires 5/32” tamperresistant hex wrench.

DEH-158 Installation Instructions R04

WavePro ™ Power Circuit Breakers

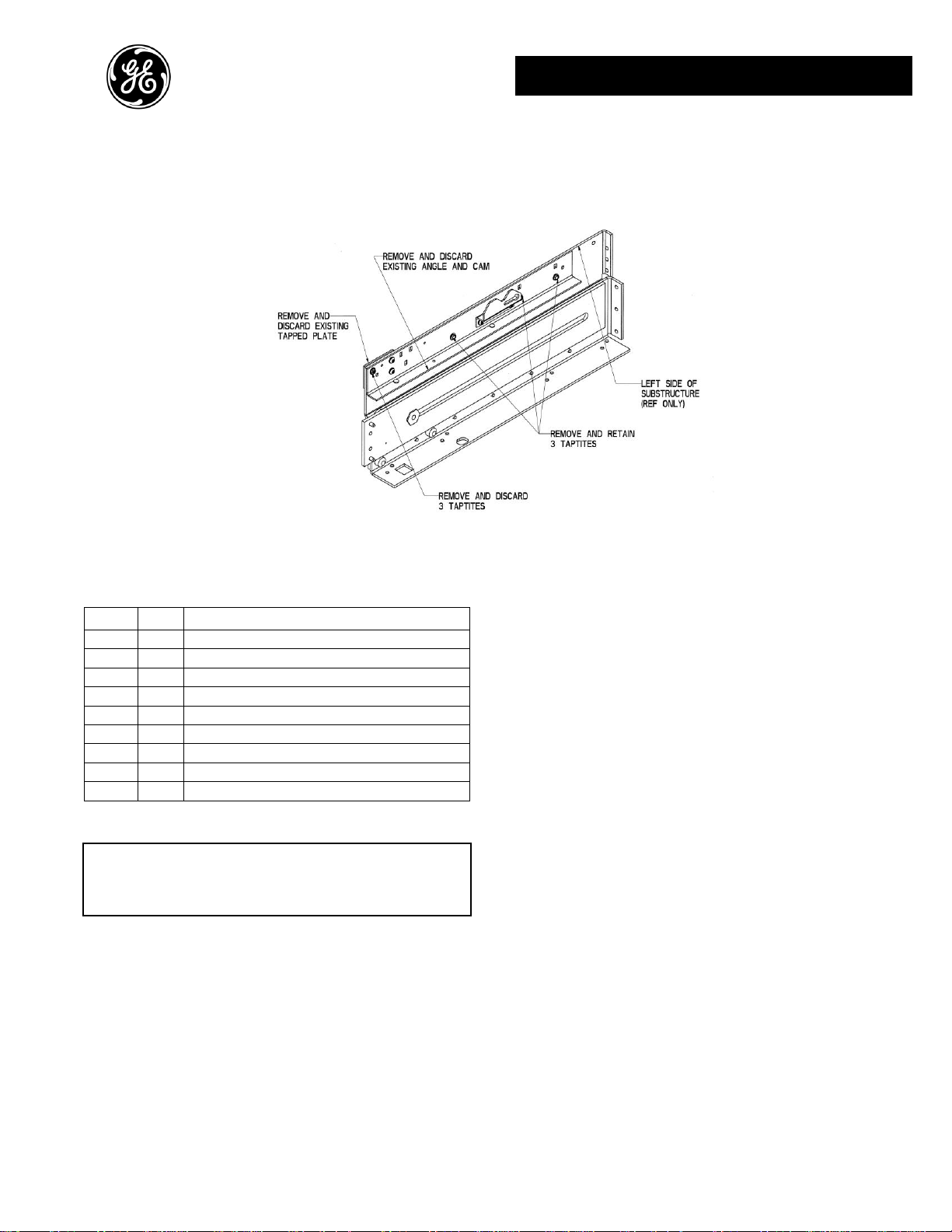

Fig. 1

INSTRUCTIONS

1. Remove parts as shown in Fig. 1.

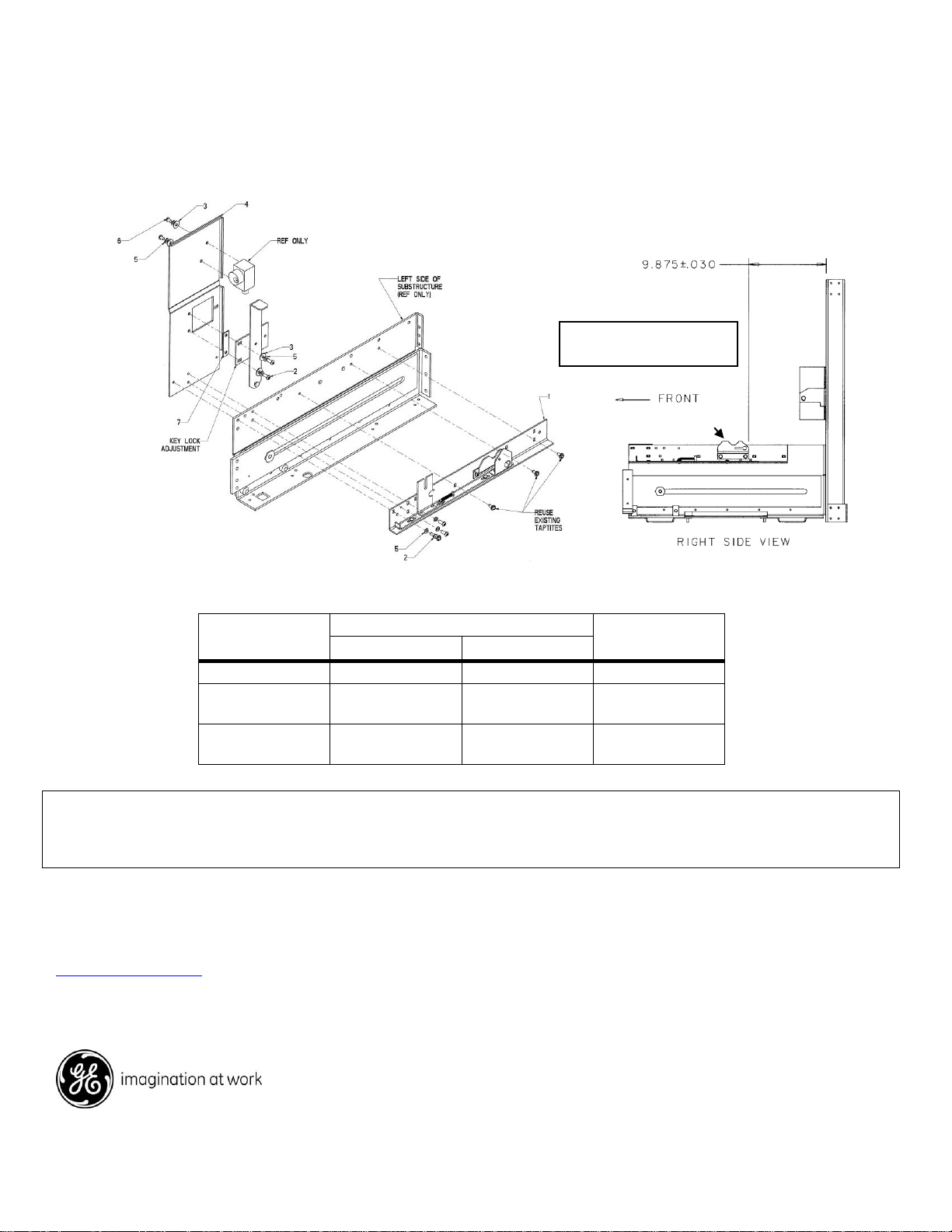

2. Assemble the customer supplied key lock to the

mounting plate (item #4) using 2 tamperresistant screws (item #6), lock washers (item

#5), and flat washers (item #3) as shown in Fig.

2.

3. Mount the retaining angle with slide assembly

(item #1) to left side of substructure reusing 3

taptites as shown in Fig. 2. (Leave hardware

loose.)

4. Attach key lock and mounting plate assembly to

the left side of the substructure using 3 tamperresistant screws (item #2) and lock washers

(item #5) as shown in Fig. 2. (Leave hardware

loose.)

5. If needed, adjust fixed cam as shown in Fig. 3.

Screws may need to be loosened and roll pin

removed in order to make adjustment. Torque

hardware to 7-9 Ft-Lbs. Drill 0.1875 diameter

hole through the fixed cam and side frame.

Reuse and install roll pin.

6. Insert pivot bar rivet into slide assembly slot and

mount to left side of substructure using shim

(item #8), 2 tamper resistant screws (Item #2),

Page 2

2

Number of

locks & keys

Key removable when:

Kirk key

interlock

Key Location

Bolt Location

1

Extended

KR1007510

2 Lower

Upper

Extended

Withdrawn

KR1007521

2 Lower

Upper

Extended

Extended

KR1007520

Fixed Cam

If fixed cam is adjusted, drill

hole and re-install roll pin.

lock washers (item #5), flat washers (item #3),

and 1 taptite (item #7) with flat washer (item #3)

as shown in Fig. 2. (Leave hardware loose.)

7. Move and hold slide assembly back.

8. Extend key lock bolt.

9. Release slide assembly and allow it to return.

10. Torque hardware to 7-9 Ft-Lbs.

11. Retract key lock bolt.

12. After assembly, assure slide assembly moves

freely.

Fig. 2 Fig. 3

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible

contingency to be met in connection with installation, operation or maintenance. Should further information be desired or

should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be

referred to the General Electric Company.

GE Industrial Solutions

41 Woodford Ave.

Plainville, CT 06062

www.geindustrial.com

© 2012 General Electric Company

All Rights Reserved

DEH – 158 R04 06/12

Loading...

Loading...