Page 1

Data Sheet

January 2008

WP91412® Connectors

The WP91412 Connectors are one-hole or

two-hole, tubular compression-type

terminators. They are available in straight, 45°

bend, or 90° bend configurations and are

intended for use with copper power wire sizes

ranging from 14 AWG to 750 kCMil.

They can be used with flexible power wires

classified as Class I stranding and standard

Class B stranding.

High Conductivity

The connectors are fabricated using seamless,

electrolytic wrought copper for excellent

conductivity and reliability; electro-tin plating

helps preserve connector integrity and also

prevents corrosion.

In addition, the connectors are specified for

extra margins of safety to minimize the risk of

overheating.

Easy, Accurate Installation

Intended for use in power equipment and

central office power system installations,

WP91412 Connectors are designed to be

installed using UL*- or CSA†-approved

compression tools and dies (as necessary).

The economical, standard length barrel is ideal

for space-restrictive applications.

To help reduce the incidence of errors and

ensure proper installation, a color-coding

scheme matches terminal and die sets to

provide the correct number and location of

crimps. Color-coded barrels are matched with

Class I and Class B stranding, which are

UL-listed with tooling, as indicated by the

specification.

The reliable, high-strength WP91412 Connectors

are designed for use with standard and flexible

stranded power wire used in power equipment or

central office applications.

Benefits

■ Provides highly reliable electromechanical

connections for high-energy applications

■ Minimizes the risk of overheating

■ Designed for fast, simplified, error-free

installation

■ Ensures high quality through strict testing and

qualification procedures

■ Meets applicable Telcordia requirements

■ UL-listed with Lineage Power KS power wires for

Class I stranding and standard Class B

stranding

■ Suited for limited-space applications

■ Compatible with UL- or CSA-approved crimp

compression tools

■ UL-listed with tooling identified in the power data

sheets of the WP91412 specification

* UL is a registered trademark of Underwriters Laboratories, Inc.

† CSA is a registered trademark of the Canadian Standards

Association.

Page 2

Data Sheet WP91412

®

Connectors

January 2008

Features

■ High conductivity

■ Seamless, electrolytic

wrought copper construction

■ Corrosion-resistant,

electro-tin plating

■ High-compression

termination design

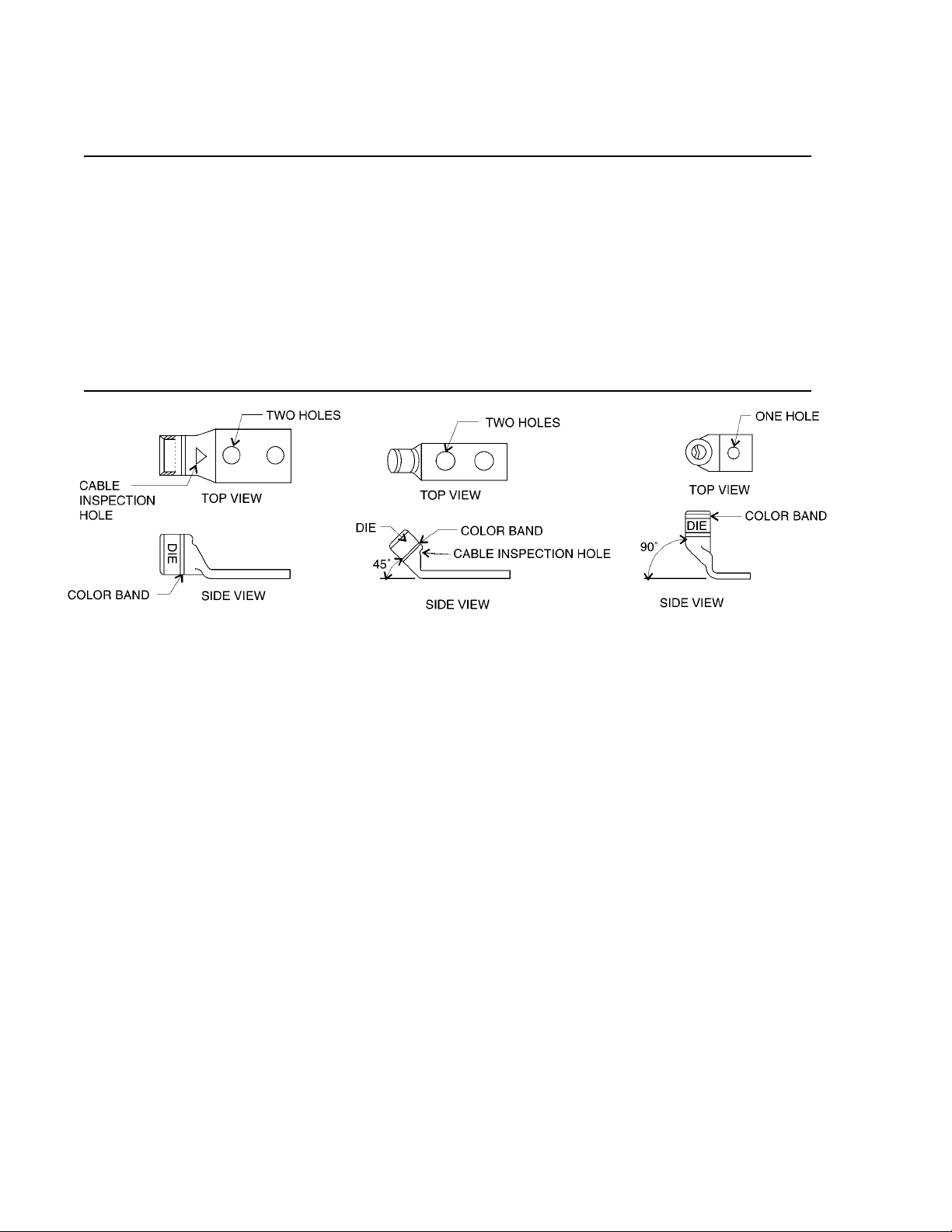

Outline Drawings

■ Accurate color-coding

scheme

■ Economical, standard-length

barrel

■ Single or dual mounting holes

■ Wire-seat inspection window

■ Exceeds commercial and UL

requirements

■ Narrow tongue feature

available in some sizes

Straight Connector 45° Connector 90° Connector

2 Lineage Power

Page 3

Data Sheet WP91412® Connectors

January 2008

Ordering Information

Stranded

Class B

List No. Comcode

L-93 406338145 14-10 14-10 8-10 Straight 1 — 0.36

L-73 405356171 14-10 14-10 8-10 Straight 2 0.625 0.36

L-96 406338178 14-10 14-10 8-10 90 1 — 0.36

L-94 406338152 14-10 14-10 1/4 Straight 1 — 0.41

L-199 CC408611082 14-10 14-10 1/4 Straight 2 0.625 0.36

L-97 406338186 14-10 14-10 1/4 90 1 — 0.41

L-187 407890771 14-10 14-10 3/8 Straight 2 1.000 0.56

L-98 406338194 8 8 8 Straight 1 — 0.45

L-100 406332825 8 8 8 Straight 2 0.625 0.41

L-1 405347402 8 8 10 Straight 1 — 0.39

L-52 405348178 8 8 10 Straight 2 0.625 0.41

L-14 405347766 8 8 10 45 1 — 0.39

L-105 406338368 8 8 3/8 Straight 1 — 0.59

L-102 406338269 8 8 3/8 Straight 2 1.000 0.59

L-74 405356189 8 8 1/4 Straight 1 — 0.41

L-75 406021626 8 8 1/4 Straight 2 0.625 0.41

L-103 406338343 8 8 1/4 Straight 2 0.750 0.41

L-101 406338244 8 8 1/4 Straight 2 1.000 0.41

L-76 406021642 8 8 1/4 45 1 — 0.41

L-195 408562986 8 8 1/4 45 2 0.625 0.41

L-104 406338350 8 8 1/4 90 1 — 0.41

L-99 406338210 8 8 5/16 Straight 1 — 0.45

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Tab

Width

(in.)

L-171 407334671 6 6 10 Straight 1 — 0.43

L-108 406338400 6 6 10 Straight 2 0.625 0.43

L-2 405347436 6 6 1/4 Straight 1 — 0.43

L-3 405347519 6 6 1/4 Straight 2 0.625 0.42

L-110 406338442 6 6 1/4 Straight 2 0.750 0.43

L-109 406338426 6 6 1/4 Straight 2 1.000 0.43

L-15 405347774 6 6 1/4 45 1 — 0.43

L-113 406338467 6 6 1/4 45 2 1.000 0.43

L-196 408562994 6 6 1/4 45 2 0.625 0.44

L-112 406338459 6 6 1/4 90 1 — 0.43

L-137 406434480 6 6 1/4 90 2 0.750 0.43

L-106 406338376 6 6 5/16 Straight 1 — 0.59

L-136 406434472 6 6 5/16 45 1 — 0.59

L-107 406338392 6 6 3/8 Straight 1 — 0.59

L-111 406332841 6 6 3/8 Straight 2 1.000 0.59

Lineage Power 3

Page 4

Data Sheet WP91412

®

Connectors

January 2008

Ordering Information (continued)

Stranded

Class B

List No. Comcode

L-178 407813047 4 4 10 Straight 1 — 0.45

L-4 405347543 4 4 1/4 Straight 1 — 0.55

L-5 405347576 4 4 1/4 Straight 2 0.625 0.55

L-117 406338574 4 4 1/4 Straight 2 0.750 0.55

L-6 405347618 4 4 1/4 45 1 — 0.55

L-197 408563002 4 4 1/4 45 2 0.625 0.55

L-115 406338483 4 4 5/16 Straight 1 — 0.55

L-118 406338582 4 4 5/16 45 1 — 0.55

L-114 406338475 4 4 3/8 Straight 1 — 0.55

L-116 406332940 4 4 3/8 Straight 2 1.000 0.55

L-53 405348186 2 — 1/4 Straight 1 — 0.59

L-54 405348202 2 — 1/4 Straight 2 0.625 0.59

L-122 406338673 2 — 1/4 Straight 2 0.750 0.59

L-16 405347782 2 — 1/4 45 1 — 0.59

L-198 408563010 2 — 1/4 45 2 0.625 0.59

L-119 406338616 2 — 5/16 Straight 1 — 0.59

L-123 406338681 2 — 5/16 45 1 — 0.59

L-120 406338640 2 — 3/8 Straight 1 — 0.59

L-121 406338665 2 — 3/8 Straight 2 1.000 0.59

L-124 406338699 2 — 3/8 45 2 1.000 0.59

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Tab

Width

(in.)

L-7 405347659 — 2 1/4 Straight 1 — 0.68

L-8 405347683 — 2 1/4 Straight 2 0.625 0.68

L-9 405347709 — 2 1/4 45 1 — 0.68

L-172 407334697 — 2 5/16 Straight 1 — 0.68

L-176 407726041 — 2 3/8 Straight 2 1.000 0.68

L-193 408210524 — 2 1/4 45 2 0.625 0.68

L-194 408385524 — 2 1/4 Straight 1 — 0.68

L-125 406338707 1/0 — 1/4 Straight 1 — 0.74

L-179 407817568 1/0 — 1/4 Straight 2 0.625 0.74

L-126 406338715 1/0 — 1/4 Straight 2 0.750 0.74

L-127 406338723 1/0 — 1/4 45 1 — 0.74

L-139 406434506 1/0 — 1/4 45 2 0.750 0.74

L-140 406434514 1/0 — 5/16 Straight 1 — 0.74

L-128 406338731 1/0 — 5/16 45 1 — 0.74

L-55 405348210 1/0 — 3/8 Straight 1 — 0.74

L-56 405348228 1/0 — 3/8 Straight 2 1.000 0.74

L-21 405347899 1/0 — 3/8 45 1 — 0.74

L-22 405347865 1/0 — 3/8 90 1 — 0.74

L-138 406434498 1/0 — 1/2 Straight 1 — 0.74

4 Lineage Power

Page 5

Data Sheet WP91412® Connectors

January 2008

Ordering Information (continued)

Stranded

Class B

List No. Comcode

L-188 408018190 2/0 1/0 1/4 Straight 1 — 0.83

L-180 407817550 2/0 1/0 1/4 Straight 2 0.625 0.83

L-130 406338764 2/0 1/0 1/4 Straight 2 0.750 0.81

L-129 406338822 2/0 1/0 5/16 Straight 1 — 0.81

L-173 407334705 2/0 1/0 5/16 Straight 2 0.875 0.81

L-13 405347758 2/0 1/0 5/16 Straight 2 1.000 0.81

L-10 405347717 2/0 1/0 3/8 Straight 1 — 0.81

L-57 405348236 2/0 1/0 3/8 Straight 2 1.000 0.81

L-11 405347725 2/0 1/0 3/8 45 1 — 0.81

L-12 405347733 2/0 1/0 3/8 90 1 — 0.81

L-144 406434035 2/0 1/0 1/2 Straight 1 — 0.81

L-143 406434027 2/0 1/0 1/2 Straight 2 1.750 0.81

L-142 406434019 2/0 1/0 1/2 Straight 2 1.000 0.81

L-146 406434050 2/0 1/0 1/2 90 1 — 0.81

L-145 406434043 2/0 1/0 5/8 Straight 1 — 0.89

L-181 407817576 — 2/0 1/4 Straight 2 0.625 0.94

L-148 406434076 — 2/0 5/16 Straight 1 — 0.91

L-20 405347857 — 2/0 5/16 Straight 2 1.000 0.91

L-17 405347790 — 2/0 3/8 Straight 1 — 0.91

L-77 406021725 — 2/0 3/8 Straight 2 1.000 0.91

L-18 405347808 — 2/0 3/8 45 1 — 0.91

L-19 405347816 — 2/0 3/8 90 1 — 0.91

L-147 406434068 — 2/0 1/2 Straight 1 — 0.91

L-150 406434092 — 2/0 1/2 Straight 2 1.750 0.91

L-149 406434084 — 2/0 1/2 Straight 2 1.000 0.91

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Tab

Width

(in.)

L-155 406434142 4/0 — 1/4 Straight 1 — 1.00

L-153 406434126 4/0 — 1/4 Straight 2 0.750 1.00

L-156 406434159 4/0 — 1/4 45 1 — 1.00

L-131 406338772 4/0 — 5/16 Straight 1 — 1.00

L-132 406338780 4/0 — 5/16 45 1 — 1.00

L-58 405348244 4/0 — 3/8 Straight 1 — 1.00

L-59 405348251 4/0 — 3/8 Straight 2 1.000 1.00

L-29 405347949 4/0 — 3/8 45 1 — 1.00

L-30 405347956 4/0 — 3/8 90 1 — 1.00

L-151 406434100 4/0 — 1/2 Straight 1 — 1.00

L-152 406434118 4/0 — 1/2 45 1 — 1.00

L-154 406434134 4/0 — 3/4 Straight 1 — 1.00

Lineage Power 5

Page 6

Data Sheet WP91412

®

Connectors

January 2008

Ordering Information (continued)

Stranded

Class B

List No. Comcode

L-157 406434167 — 4/0 5/16 Straight 1 — 1.20

L-158 406434175 — 4/0 5/16 Straight 2 1.000 1.20

L-78 406021741 — 4/0 3/8 Straight 1 — 1.20

L-27 405347923 — 4/0 3/8 Straight 2 1.000 1.09

L-79 406021766 — 4/0 3/8 45 1 — 1.20

L-174 407334713 — 4/0 3/8 90 1 — 1.09

L-80 406021857 — 4/0 3/8 90 1 — 1.20

L-177 407761378 — 4/0 3/8 90 2 1.000 1.09

L-24 405347881 — 4/0 1/2 Straight 1 — 1.20

L-160 406434191 — 4/0 1/2 Straight 2 1.750 1.20

L-159 406434183 — 4/0 1/2 Straight 2 1.000 1.20

L-25 405347907 — 4/0 1/2 45 1 — 1.20

L-26 405347915 — 4/0 1/2 90 1 — 1.20

L-133 406338798 350 — 1/4 Straight 2 0.750 1.31

L-84 406021899 350 — 3/8 Straight 1 — 1.31

L-186 407890763 350 — 3/8 Straight 2 1.000 0.96

L-61 405348277 350 — 3/8 Straight 2 1.000 1.31

L-44 405348095 350 — 3/8 45 2 1.000 1.31

L-66 405356106 350 — 3/8 90 2 1.000 1.31

L-60 405348269 350 — 1/2 Straight 1 — 1.31

L-81 406021865 350 — 1/2 Straight 2 1.250 1.31

L-37 405348020 350 — 1/2 45 1 — 1.31

L-82 406021873 350 — 1/2 45 2 1.750 1.31

L-51 405348160 350 — 1/2 90 1 — 1.31

L-83 406021881 350 — 1/2 90 2 1.750 1.31

L-161 406434209 350 — — Butt Splice — — —

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Tab

Width

(in.)

L-85 406021907 — 350 3/8 Straight 1 — 1.57

L-183 407890748 — 350 3/8 Straight 2 1.000 0.96

L-86 406021915 — 350 3/8 Straight 2 1.000 1.57

L-31 405347964 — 350 1/2 Straight 1 — 1.57

L-163 406434225 — 350 1/2 Straight 2 1.250 1.57

L-34 405347998 — 350 1/2 Straight 2 1.750 1.57

L-32 405347972 — 350 1/2 45 1 — 1.57

L-35 405348004 — 350 1/2 45 2 1.750 1.57

L-33 405347980 — 350 1/2 90 1 — 1.57

L-36 405348012 — 350 1/2 90 2 1.750 1.57

L-162 406434217 — 350 5/8 Straight 1 — 1.57

6 Lineage Power

Page 7

Data Sheet WP91412® Connectors

January 2008

Ordering Information (continued)

Stranded

Class B

List No. Comcode

L-182 407850833 500 — 3/8 Straight 2 1.000 0.96

L-63 405348293 500 — 3/8 Straight 2 1.000 1.57

L-68 405356122 500 — 3/8 45 2 1.000 1.57

L-70 405356148 500 — 3/8 90 2 1.000 1.57

L-62 405348285 500 — 1/2 Straight 1 — 1.57

L-189 408049591 500 — 1/2 Straight 2 1.750 0.96

L-88 406021931 500 — 1/2 Straight 2 1.750 1.57

L-134 406338806 500 — 1/2 Straight 2 1.250 1.57

L-67 405356114 500 — 1/2 45 1 — 1.57

L-90 406021956 500 — 1/2 45 2 1.750 1.57

L-69 405356130 500 — 1/2 90 1 — 1.57

L-92 406021972 500 — 1/2 90 2 1.750 1.57

L-185 407890755 — 500 3/8 Straight 2 1.000 1.63

L-165 406434241 — 500 3/8 Straight 2 1.000 1.78

L-87 406021923 — 500 1/2 Straight 1 — 1.78

L-164 406434233 — 500 1/2 Straight 2 1.250 1.78

L-190 408049583 — 500 1/2 Straight 2 1.750 1.63

L-41 405348061 — 500 1/2 Straight 2 1.750 1.78

L-89 406021949 — 500 1/2 45 1 — 1.78

L-42 405348079 — 500 1/2 45 2 1.750 1.78

L-91 406021964 — 500 1/2 90 1 — 1.78

L-43 405348087 — 500 1/2 90 2 1.750 1.78

L-38 405348038 — 500 5/8 Straight 1 — 1.78

L-39 405348046 — 500 5/8 45 1 — 1.78

L-40 405348053 — 500 5/8 90 1 — 1.78

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Tab

Width

(in.)

L-135 406335141 750 — 3/8 Straight 2 1.000 1.63

L-175 407670603 750 — 3/8 45 2 1.000 1.63

L-191 408049575 750 — 1/2 Straight 2 1.750 1.63

L-65 405348319 750 — 1/2 Straight 2 1.750 1.90

L-72 405356163 750 — 1/2 45 2 1.750 1.90

L-28 405347931 750 — 1/2 90 2 1.750 1.90

L-64 405348301 750 — 5/8 Straight 1 — 1.90

L-71 405356155 750 — 5/8 45 1 — 1.90

L-23 405347873 750 — 5/8 90 1 —

L-166 406434258 750 — — Butt Splice — — —

Lineage Power 7

Page 8

Data Sheet WP91412

©

®

Connectors

January 2008

Ordering Information (continued)

List No. Comcode

Stranded

Class B

Wire Size

Stranded

Class I Wire

Size Bolt Size

Degree of

Bend

Number

of Holes

Center-to-Center

Mounting Hole

Dimensions (in.)

Width

L-184 407890730 — 750 3/8 Straight 2 1.000 1.63

L-170 406434290 — 750 3/8 Straight 2 1.000 2.18

L-167 406434266 — 750 1/2 Straight 1 — 2.18

L-169 406434282 — 750 1/2 Straight 2 1.500 2.18

L-192 408049567 — 750 1/2 Straight 2 1.750 1.63

L-48 405348137 — 750 1/2 Straight 2 1.750 2.18

L-49 405348145 — 750 1/2 45 2 1.750 2.18

L-50 405348152 — 750 1/2 90 2 1.750 2.18

L-45 405348103 — 750 5/8 Straight 1 — 2.18

L-168 406434274 — 750 5/8 Straight 2 1.500 2.18

L-46 405348111 — 750 5/8 45 1 — 2.18

L-47 405348129 — 750 5/8 90 1 — 2.18

Tab

(in.)

LINEAGE POWER

World Wide Headquarters

3000 Skyline Drive, Mesquite, TX 75149, USA

2008 Lineage Power. Lineage Power reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of

their use or application. No rights under any patent accompany the sale of any such product(s) or infor mation.

8 Lineage Power

January 2008

DS03-032 Rev 5

+1-800-843-1797

Outside U.S.A.: +1-972-284-2626

http://www.lineagepower.com

e-mail: techsupport1@lineagepower.com

Loading...

Loading...