Page 1

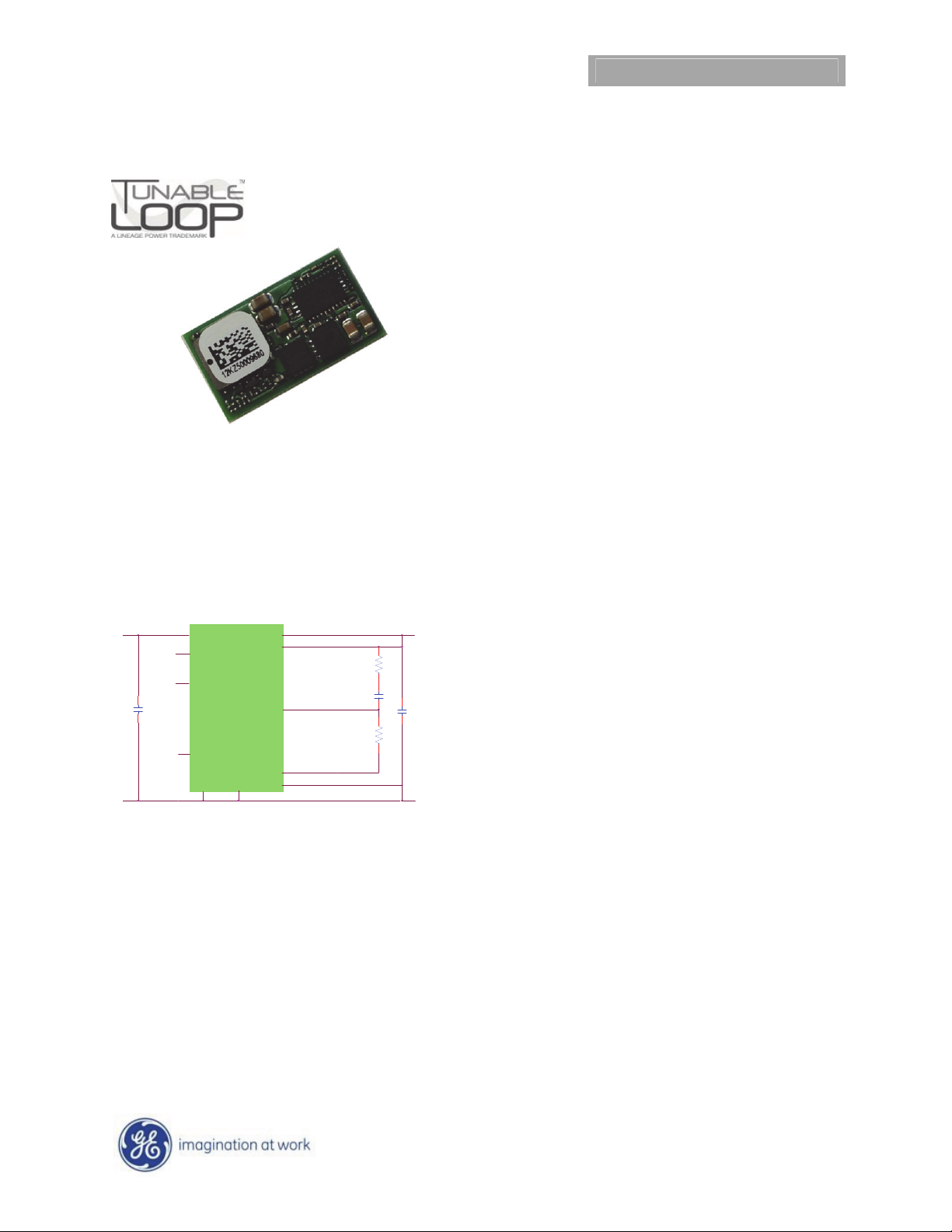

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

RoHS Compliant

Applications

Distributed power architectures

Intermediate bus voltage applications

Telecommunications equipment

Servers and storage applications

Networking equipment

Industrial equipment

GND

VIN

PGOOD

MODULE

SEQ

Cin

ON/OFF

SYNC

SIG_GND

GND

VOUT

VS+

TRIM

VS-

RTUNE

CTUNE

RTrim

Vout+Vin+

Co

Features

Ultra low height design for very dense power

applications.

Small size: 20.32 mm x 11.43 mm x 3 mm (Max)

(0.8 in x 0.45 in x 0.118 in)

Output voltage programmable from 0.6Vdc to 5.5Vdc

via external resistor.

Wide Input voltage range (3Vdc-14.4Vdc)

Wide operating temperature range [-40°C to 105°C]. See

derating curves

DOSA approved footprint

TM

Tunable Loop

to optimize dynamic output voltage

response

Flexible output voltage sequencing EZ-SEQUENCE

Power Good signal

Remote On/Off

Fixed switching frequency with capability of external

synchronization

Output overcurrent protection (non-latching)

Overtemperature protection

Ability to sink and source current

Compatible in a Pb-free or SnPb reflow environment

UL* 60950-1Recognized, CSA

Certified, and VDE

‡

0805:2001-12 (EN60950-1) Licensed

†

C22.2 No. 60950-1-03

Compliant to RoHS II EU “Directive 2011/65/EU”

Compliant to REACH Directive (EC) No 1907/2006

Compliant to IPC-9592 (September 2008), Category 2,

Class II

ISO** 9001 and ISO 14001 certified manufacturing

facilities

Description

The 12A Analog SlimLynxTM Open Frame power modules are non-isolated dc-dc converters that can deliver up to 12A of output

current. These modules operate over a wide range of input voltage (V

voltage from 0.6Vdc to 5.5Vdc, programmable via an external resistor. Features include remote On/Off, adjustable output voltage,

over current and over temperature protection. The module also includes the Tunable Loop

optimize the dynamic response of the converter to match the load with reduced amount of output capacitance leading to savings

on cost and PWB area.

*

UL is a registered trademark of Underwriters Laboratories, Inc.

†

CSA is a registered trademark of Canadian Standards Association.

‡

VDE is a trademark of Verband Deutscher Elektrotechniker e.V.

** ISO is a registered trademark of the International Organization of Standards

February 19, 2014 ©2014 General Electric Corporation. All rights reserved.

= 3Vdc-14.4Vdc) and provide a precisely regulated output

IN

TM

feature that allows the user to

Page 2

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings

only, functional operation of the device is not implied at these or any other conditions in excess of those given in the operations

sections of the data sheet. Exposure to absolute maximum ratings for extended periods can adversely affect the device reliability.

Parameter Device Symbol Min Max Unit

Input Voltage All V

Continuous

IN

SEQ, SYNC, VS+ All 7 V

Operating Ambient Temperature All T

(see Thermal Considerations section)

Storage Temperature All T

A

stg

Electrical Specifications

Unless otherwise indicated, specifications apply over all operating input voltage, resistive load, and temperature conditions.

Parameter Device Symbol Min Typ Max Unit

Operating Input Voltage All VIN 3

Maximum Input Current All I

(VIN=3V to 14V, IO=I

Input No Load Current

= 12Vdc, IO = 0, module enabled)

(V

IN

Input Stand-by Current

(V

= 12Vdc, module disabled)

IN

)

O, max

= 0.6 Vdc I

V

O,set

V

= 5Vdc I

O,set

All I

Inrush Transient All I2t 1 A2s

Input Reflected Ripple Current, peak-to-peak

(5Hz to 20MHz, 1μH source impedance; V

= I

14V

; See Test Configurations)

, IO

Omax

=0 to

IN

All 50 mAp-p

Input Ripple Rejection (120Hz) All -55 dB

IN,max

IN,No load

220 mA

IN,No load

20 mA

IN,stand-by

-0.3 15 V

-40 105 °C

-55 125 °C

⎯

14.4 Vdc

10A Adc

50 mA

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 2

Page 3

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Electrical Specifications (continued)

Parameter Device Symbol Min Typ Max Unit

Output Voltage Set-point (with 0.1% tolerance for external

resistor used to set output voltage)

Output Voltage (Over all operating input voltage, resistive

load, and temperature conditions until end of life)

All V

All V

O, set

O, set

Adjustment Range (selected by an external resistor)

(Some output voltages may not be possible depending on the

All V

O

input voltage – see Feature Descriptions Section)

Remote Sense Range All 0.5 Vdc

Output Regulation (for VO ≥ 2.5Vdc)

Line (VIN=V

Load (IO=I

IN, min

O, min

to V

) All

IN, max

to I

) All

O, max

Output Regulation (for VO < 2.5Vdc)

Line (VIN=V

Load (IO=I

Temperature (T

IN, min

O, min

to V

) All

IN, max

to I

) All

O, max

to T

ref=TA, min

) All

A, max

Output Ripple and Noise on nominal output

(VIN=V

ceramic capacitors)

IN, nom

and IO=I

O, min

to I

Co = 3x47nF // 2x47 μF

O, max

Peak-to-Peak (5Hz to 20MHz bandwidth) All

RMS (5Hz to 20MHz bandwidth) All 20 38 mV

External Capacitance1

Without the Tunable Loop

TM

ESR ≥ 1 mΩ All C

With the Tunable Loop

TM

ESR ≥ 0.15 mΩ All C

ESR ≥ 10 mΩ All C

Output Current (in either sink or source mode) All I

Output Current Limit Inception (Hiccup Mode)

(current limit does not operate in sink mode)

All I

Output Short-Circuit Current All I

(VO≤250mV) ( Hiccup Mode )

Efficiency V

VIN= 12Vdc, TA=25°C V

IO=I

O, max , VO

= V

V

O,set

= 0.6Vdc η 72 %

O,set

= 1.2Vdc η 81 %

O, set

= 1.8Vdc η 85 %

O,set

O, max

O, max

O, max

o

O, lim

O, s/c

-1.0 +1.0 % V

-3.0

⎯

+3.0 % V

0.6 5.5 Vdc

+0.4 % V

⎯

⎯

⎯

⎯

⎯

50 100 mV

⎯

10 mV

5 mV

10 mV

0.4 % V

O, set

O, set

O, set

O, set

pk-pk

rms

2x47

2x47

2x47

2x47 μF

⎯

1000 μF

⎯

10000 μF

⎯

0 12 Adc

130 % I

o,max

1.5 Arms

V

V

V

Switching Frequency All f

1

External capacitors may require using the new Tunable LoopTM feature to ensure that the module is stable as well as getting the best

transient response. See the Tunable Loop

TM

section for details.

= 2.5Vdc η 87.5 %

O,set

= 3.3Vdc η 89 %

O,set

= 5.0Vdc η 92 %

O,set

800

sw

⎯

⎯

kHz

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 3

Page 4

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Electrical Specifications (continued)

Parameter Device Symbol Min Typ Max Unit

Frequency Synchronization All

Synchronization Frequency Range All 760 800 840 kHz

High-Level Input Voltage All V

Low-Level Input Voltage All V

Input Current, SYNC All I

Minimum Pulse Width, SYNC All t

Maximum SYNC rise time All t

IH

IL

SYNC

SYNC

SYNC_SH

General Specifications

Parameter Device Min Typ Max Unit

Calculated MTBF (IO=0.8I

Case 3

, TA=40°C) Telecordia Issue 2 Method 1

O, max

All 15,233,204 Hours

Weight

Feature Specifications

Unless otherwise indicated, specifications apply over all operating input voltage, resistive load, and temperature conditions. See

Feature Descriptions for additional information.

Parameter Device Symbol Min Typ Max Unit

On/Off Signal Interface

(VIN=V

Signal referenced to GND)

Device code with suffix “4” – Positive Logic (See Ordering

Information)

Logic High (Module ON)

Input High Current All IIH

Input High Voltage All VIH

Logic Low (Module OFF)

Input Low Current All IIL

Input Low Voltage All VIL

Device Code with no suffix – Negative Logic (See Ordering

Information)

(On/OFF pin is open collector/drain logic input with

external pull-up resistor; signal referenced to GND)

Logic High (Module OFF)

Input High Current All IIH — — 1 mA

Input High Voltage All VIH 2 — V

Logic Low (Module ON)

Input low Current All IIL — — 50 μA

Input Low Voltage All VIL -0.2 — 0.6 Vdc

IN, min

to V

; open collector or equivalent,

IN, max

2 V

0.4 V

100 nA

100 ns

100 ns

⎯

1.1(0.04)

⎯

⎯

2

⎯

1 mA

V

V

IN,max

⎯ ⎯

-0.2

⎯

1 mA

0.6 V

g (oz.)

Vdc

IN, max

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 4

Page 5

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Feature Specifications (cont.)

Parameter Device Symbol Min Typ Max Units

Turn-On Delay and Rise Times

(VIN=V

Case 1: On/Off input is enabled and then input power is

applied (delay from instant at which V

10% of V

Case 2: Input power is applied for at least one second and

then the On/Off input is enabled (delay from instant at

which Von/Off is enabled until V

Output voltage Rise time (time for Vo to rise from

10% of Vo, set to 90% of Vo, set)

Output voltage overshoot (TA = 25oC

V

With or without maximum external capacitance

Over Temperature Protection

(See Thermal Considerations section)

Tracking Accuracy (Power-Up: 2V/ms) All VSEQ –Vo 100 mV

(Power-Down: 2V/ms) All VSEQ –Vo 100 mV

, IO=I

IN, nom

o, set)

= V

to V

IN

IN, min

to within ±1% of steady state)

O, max , VO

= V

IN, max,IO

until Vo =

IN

IN, min

o = 10% of Vo, set)

= I

to I

O, max

)

O, min

All Tdelay — 0.9 — msec

All Tdelay — 0.8 — msec

All Trise

— 2 — msec

3

All T

ref

130 °C

% V

O,

set

(V

to V

; I

to I

IN, min

IN, max

O, min

Input Undervoltage Lockout

Turn-on Threshold All

Turn-off Threshold All

Hysteresis All

PGOOD (Power Good)

Signal Interface Open Drain, V

Overvoltage threshold for PGOOD ON All

Overvoltage threshold for PGOOD OFF All

Undervoltage threshold for PGOOD ON All

Undervoltage threshold for PGOOD OFF All

Pulldown resistance of PGOOD pin All

Sink current capability into PGOOD pin All

VSEQ < Vo)

O, max

2.475 3.025 Vdc

2.25 2.75 Vdc

0.25 Vdc

108

110

92

90

50

5 mA

supply

≤ 5VDC

%V

set

%V

set

%V

set

%V

set

Ω

O,

O,

O,

O,

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 5

Page 6

OUTPUT

VOLTAGE

ON/OFF

VOLTAGE

t

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Characteristic Curves

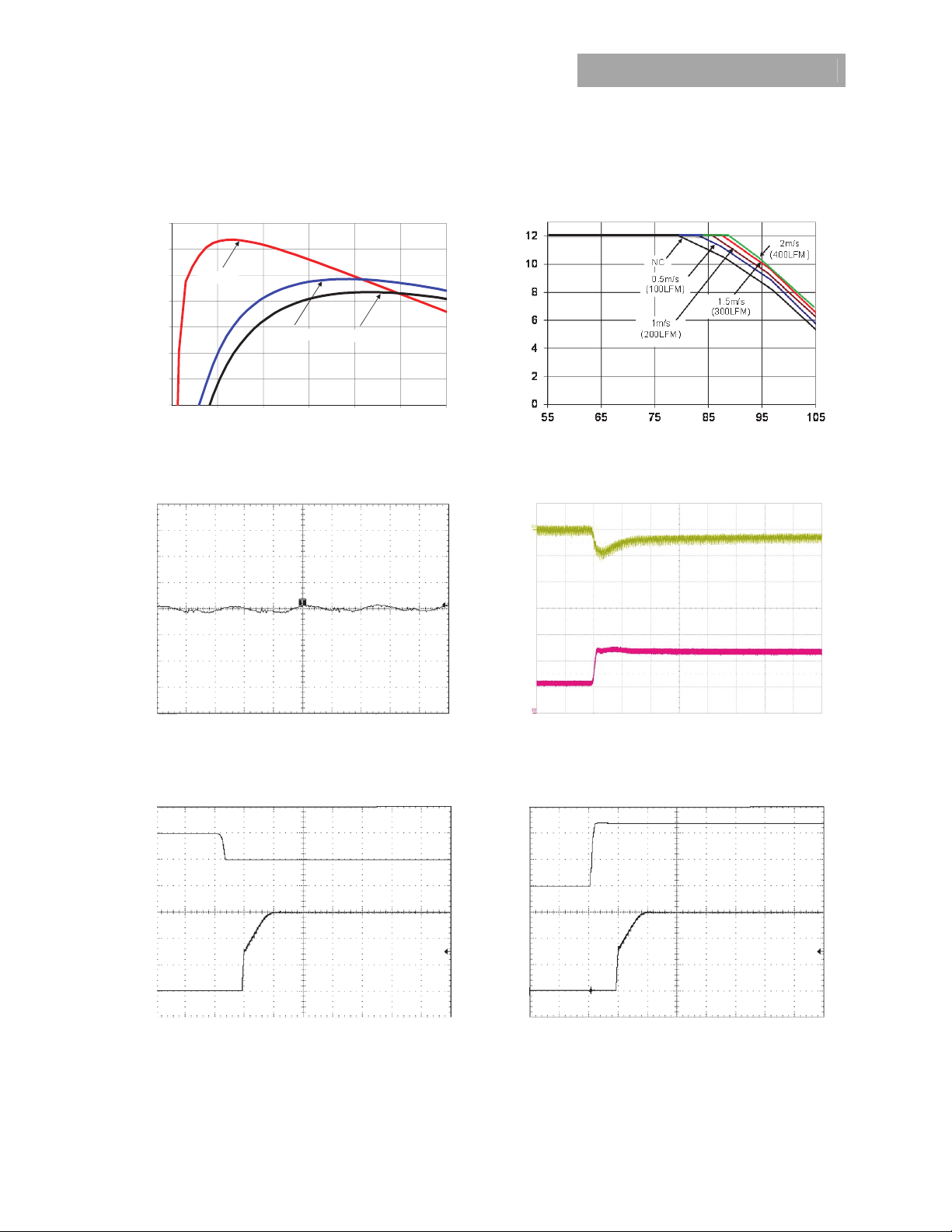

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 0.6Vo and 25oC.

85

80

75

70

65

60

EFFICIENCY, η (%)

55

50

Figure 1. Converter Efficiency versus Output Current.

Vin=3.3V

Vin=12V

024681012

OUTPUT CURRENT, I

Vin=14.4V

(A) AMBIENT TEMPERATURE, TA OC

O

Figure 2. Derating Output Current versus Ambient

Temperature and Airflow.

OUTPUT CURRENT, Io (A)

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 3. Typical output ripple and noise (CO=2x47F

IN

ceramic, V

(V) (5V/div)

ON/OFF

(V) (200mV/div) V

O

= 12V, Io = I

o,max,

).

(V) (10mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT, OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 4. Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout=1x47uF+11x330uF, CTune=47nF,

RTune=180

(V) (5V/div)

IN

(V) (200mV/div) V

O

V

Figure 5. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

).

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 6. Typical Star

o,max

).

I

-up Using Input Voltage (VIN= 12V, Io=

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 6

Page 7

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

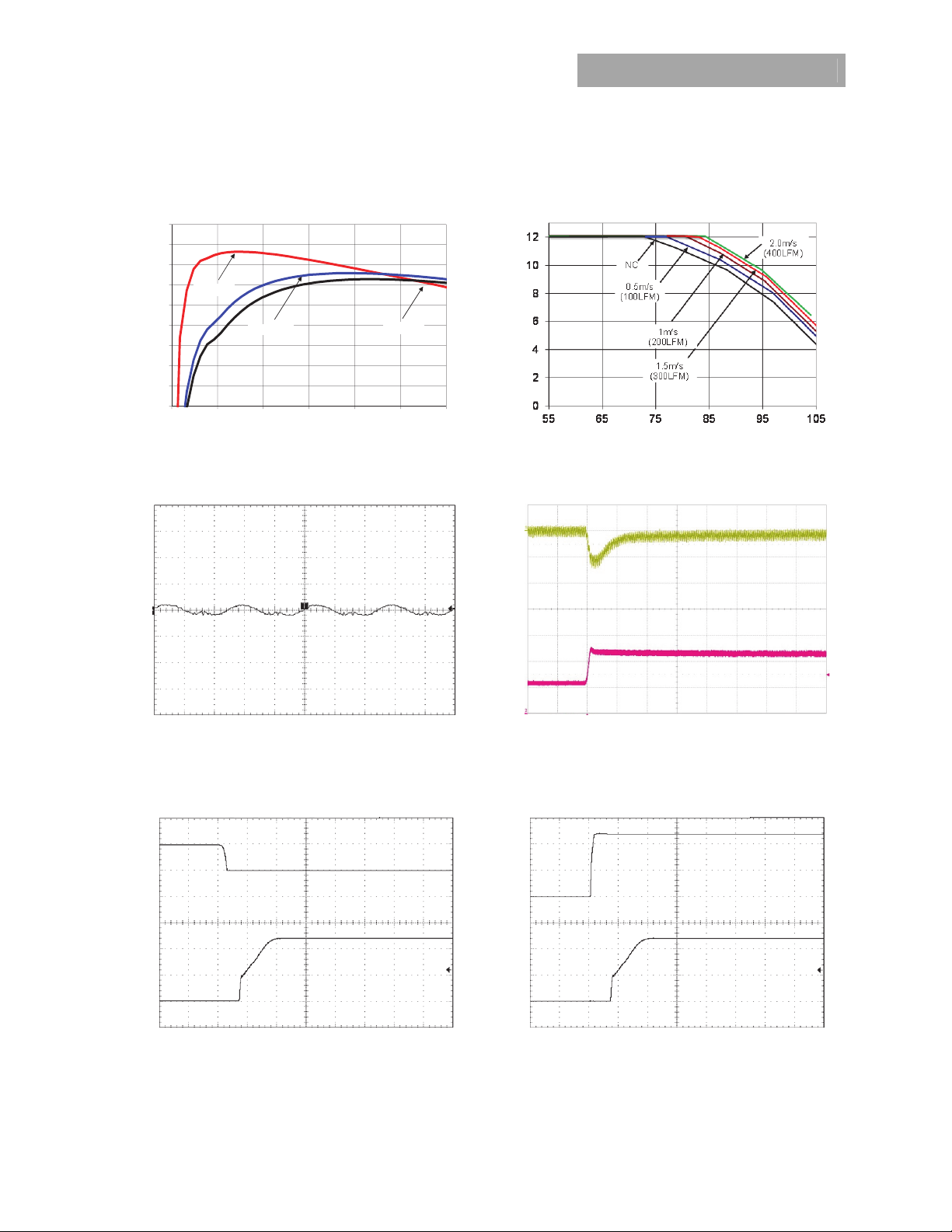

Characteristic Curves

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 1.2Vo and 25oC.

95

90

85

80

Vin=3.3V

75

70

65

60

EFFICIENCY, η (%)

55

50

024681012

Vin=12V

OUTPUT CURRENT, I

Figure 7. Converter Efficiency versus Output Current.

Vin=14.4V

OUTPUT CURRENT, Io (A)

(A) AMBIENT TEMPERATURE, TA OC

O

Figure 8. Derating Output Current versus Ambient

Temperature and Airflow.

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 9. Typical output ripple and noise (CO=2x47F

ceramic, V

IN

= 12V, Io = I

(V) (5V/div)

ON/OFF

(V) (500mV/div) V

O

o,max,

).

(V) (20mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 10. Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout = 3x47uF+3x330uF, CTune = 12nF

& RTune = 220 ohms

(V) (5V/div)

IN

(V) (500mV/div) V

O

OUTPUT VOLTAGE ON/OFF VOLTAGE

V

Figure 11. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 12. Typical Start-up Using Input Voltage (V

).

I

o,max

).

IN

= 12V, Io=

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 7

Page 8

/

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Characteristic Curves

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 1.8Vo and 25oC.

95

90

85

80

75

70

EFFICIENCY, η (%)

65

60

Figure 13. Converter Efficiency versus Output Current.

Vin=3.3V

Vin=12V

024681012

OUTPUT CURRENT, IO (A) AMBIENT TEMPERATURE, TA OC

Vin=14.4V

Figure 14. Derating Output Current versus Ambient

Temperature and Airflow.

OUTPUT CURRENT, Io (A)

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 15. Typical output ripple and noise (CO=2x47F

IN

ceramic, V

(V) (5V/div)

OFF VOLTAGE

ON/OFF

(V) (500mV/div) V

O

= 12V, Io = I

o,max,

).

(V) (20mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT, OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 16. Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout = 2x47uF+2x330uF,

CTune=5600pF & RTune=220

(V) (5V/div)

IN

(V) (500mV/div) V

O

OUTPUT VOLTAGE ON

V

Figure 17. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 18. Typical Start-up Using Input Voltage (V

).

I

o,max

).

IN

= 12V, Io=

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 8

Page 9

OUTPUT

VOLTAGE

ON/OFF

VOLTAGE

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Characteristic Curves

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 2.5Vo and 25oC.

95

90

85

80

75

70

EFFICIENCY, η (%)

65

60

Figure 19. Converter Efficiency versus Output Current.

Vin=4.5V

Vin=14V

Vin=12V

024681012

OUTPUT CURRENT, I

(A) AMBIENT TEMPERATURE, TA OC

O

Figure 20. Derating Output Current versus Ambient

Temperature and Airflow.

OUTPUT CURRENT, Io (A)

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 21. Typical output ripple and noise (CO=2x47F

ceramic, V

IN

= 12V, Io = I

(V) (5V/div)

ON/OFF

(V) (1V/div) V

O

o,max,

).

(V) (50mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT, OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 22. Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout = 2x47uF+1x330uF,

CTune=3300pF & RTune=240

(V) (5V/div)

IN

(V) (1V/div) V

O

V

Figure 23. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 24. Typical Start-up Using Input Voltage (V

).

I

o,max

).

IN

= 12V, Io=

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 9

Page 10

/

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Characteristic Curves

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 3.3Vo and 25oC.

100

95

90

Vin=4.5V

85

80

75

70

EFFICIENCY, η (%)

65

60

024681012

Vin=12V

OUTPUT CURRENT, I

Figure 25. Converter Efficiency versus Output Current.

Vin=14V

OUTPUT CURRENT, Io (A)

(A) AMBIENT TEMPERATURE, TA OC

O

Figure 26. Derating Output Current versus Ambient

Temperature and Airflow.

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 27. Typical output ripple and noise (CO=2x47F

IN

ceramic, V

(V) (5V/div)

OFF VOLTAGE

ON/OFF

(V) (1V/div) V

O

= 12V, Io = I

o,max,

).

(V) (50mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT, OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 28 Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout = 2x47uF+1x330uF,

CTune=2700pF & RTune=300

(V) (5V/div)

IN

(V) (1V/div) V

O

OUTPUT VOLTAGE ON

V

Figure 29. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 30. Typical Start-up Using Input Voltage (V

).

I

o,max

).

IN

= 12V, Io=

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 10

Page 11

/

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Characteristic Curves

The following figures provide typical characteristics for the 12A Analog SlimLynxTM at 5Vo and 25oC.

100

95

90

85

80

75

70

EFFICIENCY, η (%)

65

60

Figure 31. Converter Efficiency versus Output Current.

Vin=7V

Vin=12V

024681012

OUTPUT CURRENT, I

Vin=14V

(A) AMBIENT TEMPERATURE, TA OC

O

Figure 32. Derating Output Current versus Ambient

Temperature and Airflow.

OUTPUT CURRENT, Io (A)

(V) (50mV/div)

O

V

OUTPUT VOLTAGE

TIME, t (500ns/div)

Figure 33. Typical output ripple and noise (CO=2x47F

ceramic, V

OFF VOLTAGE

IN

= 12V, Io = I

(V) (5V/div)

ON/OFF

(V) (2V/div) V

O

o,max,

).

(V) (50mV/div)

O

(A) (5Adiv) V

O

I

OUTPUT CURRENT, OUTPUT VOLTAGE

TIME, t (20μs /div)

Figure 34. Transient Response to Dynamic Load Change from

50% to 100% at 12Vin, Cout = 1x47uF+1x330uF,

CTune=2200pF & RTune=300

(V) (5V/div)

IN

(V) (2V/div) V

O

OUTPUT VOLTAGE ON

V

Figure 35. Typical Start-up Using On/Off Voltage (Io = I

TIME, t (2ms/div) TIME, t (2ms/div)

o,max

OUTPUT VOLTAGE INPUT VOLTAGE

V

Figure 36. Typical Start-up Using Input Voltage (V

).

o,max

).

I

IN

= 12V, Io =

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 11

Page 12

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Design Considerations

Input Filtering

The 12A Analog SlimLynxTM Open Frame module should be

connected to a low ac-impedance source. A highly

inductive source can affect the stability of the module. An

input capacitance must be placed directly adjacent to the

input pin of the module, to minimize input ripple voltage

and ensure module stability.

To minimize input voltage ripple, ceramic capacitors are

recommended at the input of the module. Figure 37 shows

the input ripple voltage for various output voltages at 12A

of load current with 1x22 µF or 2x22 µF ceramic

capacitors and an input of 12V.

450

400

350

300

250

200

150

100

50

0

Figure 37. Input ripple voltage for various output

voltages with 2x22 µF or 3x22 µF ceramic capacitors at

the input (12A load). Input voltage is 12V.

Output Filtering

These modules are designed for low output ripple voltage

and will meet the maximum output ripple specification with

3x0.047 µF ceramic and 2x47 µF ceramic capacitors at the

output of the module. However, additional output filtering

may be required by the system designer for a number of

reasons. First, there may be a need to further reduce the

output ripple and noise of the module. Second, the dynamic

response characteristics may need to be customized to a

particular load step change.

To reduce the output ripple and improve the dynamic

response to a step load change, additional capacitance at

the output can be used. Low ESR polymer and ceramic

capacitors are recommended to improve the dynamic

response of the module. Figure 38 provides output ripple

information, measured with a scope with its Bandwidth

limited to 20MHz for different external capacitance values at

various Vo and a full load current of 12A. For stable

operation of the module, limit the capacitance to less than

the maximum output capacitance as specified in the

electrical specification table. Optimal performance of the

module can be achieved by using the Tunable Loop

described later in this data sheet.

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 12

1x22uF

2x22 uF

0.511.522.533.544.55

TM

feature

40

30

20

2x47uF Ext Cap

4x47uF Ext Cap

6x47uF Ext Cap

8x47uF Ext Cap

Ripple (mVp-p)

10

0

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Output Voltage(Volts)

Figure 38. Output ripple voltage for various output

voltages with external 2x47 µF, 4x47 µF, 6x47 µF or 8x47

µF ceramic capacitors at the output (12A load). Input

voltage is 12V.

Safety Considerations

For safety agency approval the power module must be

installed in compliance with the spacing and separation

requirements of the end-use safety agency standards, i.e.,

UL 60950-1 2nd, CSA C22.2 No. 60950-1-07, DIN EN 609501:2006 + A11 (VDE0805 Teil 1 + A11):2009-11; EN 609501:2006 + A11:2009-03.

For the converter output to be considered meeting the

requirements of safety extra-low voltage (SELV), the input

must meet SELV requirements. The power module has

extra-low voltage (ELV) outputs when all inputs are ELV.

The input to these units is to be provided with a fast acting

fuse (e.g. ABC Bussmann) with a maximum rating of 20 A in

the positive input lead

.

Page 13

─

K

_

_

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Analog Feature Descriptions

Remote On/Off

The 12A Analog SlimLynxTM Open Frame power modules

feature an On/Off pin for remote On/Off operation. Two

On/Off logic options are available. In the Positive Logic

On/Off option, (device code suffix “4” – see Ordering

Information), the module turns ON during a logic High on the

On/Off pin and turns OFF during a logic Low. With the

Negative Logic On/Off option, (no device code suffix, see

Ordering Information), the module turns OFF during logic

High and ON during logic Low. The On/Off signal should be

always referenced to ground. For either On/Off logic option,

leaving the On/Off pin disconnected will turn the module ON

when input voltage is present.

For positive logic modules, the circuit configuration for using

the On/Off pin is shown in Figure 39. When the external

transistor Q2 is in the OFF state, the internal transistor Q7 is

turned ON, which turn Q3 OFF which keeps Q6 OFF and Q5

OFF. This allows the internal PWM #Enable signal to be

pulled up by the internal 3.3V, thus turning the module ON.

When transistor Q2 is turned ON, the On/Off pin is pulled

low, which turns Q7 OFF which turns Q3, Q6 and Q5 ON and

the internal PWM #Enable signal is pulled low and the

module is OFF. A suggested value for R

For negative logic On/Off modules, the circuit configuration

is shown in Fig. 40. The On/Off pin should be pulled high with

an external pull-up resistor (suggested value for the 3V to

14V input range is 20Kohms). When transistor Q2 is in the

OFF state, the On/Off pin is pulled high, transistor Q3 is

turned ON. This turns Q6 ON, followed by Q5 turning ON

which pulls the internal ENABLE low and the module is OFF.

To turn the module ON, Q2 is turned ON pulling the On/Off

pin low, turning transistor Q3 OFF, which keeps Q6 and Q5

OFF resulting in the PWM Enable pin going high.

Q2

+VIN

Rpullup

I

ON/OFF

V

ON/OFF

+

SlimLynx Module

VIN

20K

20K

GND

20K

Q7

20K

100pF

Q3

20K

20K

Figure 39. Circuit configuration for using positive On/Off

logic.

+VIN

SlimLynx Module

Rpullup

I

ON/OFF

20K

+

Q2

V

ON/OFF

GND

20K

470

100pF

Q3

100K

470

100K

4.7K

4.7K

pullup

3.3V

3.3V

is 20kΩ.

Q6

2

Q6

2K

ENABLE

47K

Q5

20K

20K

ENABLE

47K

Q5

20K

20K

Figure 40. Circuit configuration for using negative On/Off

logic.

Monotonic Start-up and Shutdown

The module has monotonic start-up and shutdown behavior

for any combination of rated input voltage, output current

and operating temperature range.

Startup into Pre-biased Output

The module can start into a prebiased output as long as the

prebias voltage is 0.5V less than the set output voltage.

Analog Output Voltage Programming

The output voltage of the module is programmable to any

voltage from 0.6dc to 5.5Vdc by connecting a resistor

between the Trim and SIG_GND pins of the module. Certain

restrictions apply on the output voltage set point depending

on the input voltage. These are shown in the Output Voltage

vs. Input Voltage Set Point Area plot in Fig. 41. The Upper

Limit curve shows that for output voltages lower than 1V, the

input voltage must be lower than the maximum of 14.4V. The

Lower Limit curve shows that for output voltages higher than

0.6V, the input voltage needs to be larger than the minimum

of 3V.

16

14

12

10

8

6

4

Input Voltage (v)

2

0

0.511.522.533.544.555.56

Figure 41. Output Voltage vs. Input Voltage Set Point Area

plot showing limits where the output voltage can be set for

different input voltages.

VIN(+)

ON/OFF

SIG_GND

Upper

Output Voltage (V)

VO(+)

VS+

TRIM

VS

Lower

R

trim

LOAD

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 13

Page 14

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Caution – Do not connect SIG_GND to GND elsewhere in the

layout

Figure 42. Circuit configuration for programming output

voltage using an external resistor.

Without an external resistor between Trim and SIG_GND pins,

the output of the module will be 0.6Vdc.To calculate the

value of the trim resistor, Rtrim for a desired output voltage,

should be as per the following equation:

12

−

Ω

6.0

Figure 43. Circuit Configuration for margining Output

voltage.

Output Voltage Sequencing

The power module includes a sequencing feature, EZSEQUENCE that enables users to implement various types of

output voltage sequencing in their applications. This is

accomplished via an additional sequencing pin. When not

using the sequencing feature, leave it unconnected.

The voltage applied to the SEQ pin should be scaled down by

the same ratio as used to scale the output voltage down to

the reference voltage of the module. This is accomplished by

an external resistive divider connected across the

sequencing voltage before it is fed to the SEQ pin as shown

in Fig. 44. In addition, a small capacitor (suggested value

100pF) should be connected across the lower resistor R1.

For all SlimLynx modules, the minimum recommended delay

between the ON/OFF signal and the sequencing signal is

10ms to ensure that the module output is ramped up

according to the sequencing signal. This ensures that the

module soft-start routine is completed before the

sequencing signal is allowed to ramp up.

V

Rtrim

Rtrim is the external resistor in kΩ

Vo is the desired output voltage.

Table 1 provides Rtrim values required for some common

output voltages.

()

Vo

= k

Table 1

V

(V) Rtrim (K)

O, set

0.6 Open

0.9 40

1.0 30

1.2 20

1.5 13.33

1.8 10

2.5 6.316

3.3 4.444

5.0 2.727

Remote Sense

The power module has a Remote Sense feature to minimize

the effects of distribution losses by regulating the voltage

between the sense pins (VS+ and VS-). The voltage drop

between the sense pins and the VOUT and GND pins of the

module should not exceed 0.5V.

Analog Voltage Margining

Output voltage margining can be implemented in the

module by connecting a resistor, R

to the ground pin for margining-up the output voltage and

by connecting a resistor, R

output pin for margining-down. Figure 43 shows the circuit

configuration for output voltage margining. The POL

Programming Tool, available at www.lineagepower.com

under the Downloads section, also calculates the values of

and R

R

margin-up

margin. Please consult your local GE Critical Power

technical representative for additional details.

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 14

margin-down

margin-down

for a specific output voltage and %

, from the Trim pin

margin-up

, from the Trim pin to

R1=Rtrim

100 pF

Figure 44. Circuit showing connection of the sequencing

signal to the SEQ pin.

When the scaled down sequencing voltage is applied to the

SEQ pin, the output voltage tracks this voltage until the

MODULE

SEQ

20K

Vo

Rmargin-down

Q2

Trim

Rmargin-up

Rtrim

Q1

SIG_GND

SlimLynx Module

SEQ

SIG_GND

Page 15

─

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

output reaches the set-point voltage. The final value of the

sequencing voltage must be set higher than the set-point

voltage of the module. The output voltage follows the

sequencing voltage on a one-to-one basis. By connecting

multiple modules together, multiple modules can track their

output voltages to the voltage applied on the SEQ pin.

The module’s output can track the SEQ pin signal with slopes

of up to 0.5V/msec during power-up or power-down.

To initiate simultaneous shutdown of the modules, the SEQ

pin voltage is lowered in a controlled manner. The output

voltage of the modules tracks the voltages below their setpoint voltages on a one-to-one basis. A valid input voltage

must be maintained until the tracking and output voltages

reach ground potential.

Overcurrent Protection

To provide protection in a fault (output overload) condition,

the unit is equipped with internal current-limiting circuitry

and can endure current limiting continuously. At the point of

current-limit inception, the unit enters hiccup mode. The unit

operates normally once the output current is brought back

into its specified range.

Overtemperature Protection

To provide protection in a fault condition, the unit is

equipped with a thermal shutdown circuit. The unit will shut

down if the overtemperature threshold of 150

exceeded at the thermal reference point T

goes into thermal shutdown it will then wait to cool before

attempting to restart.

o

C(typ) is

.Once the unit

ref

Input Undervoltage Lockout

At input voltages below the input undervoltage lockout limit,

the module operation is disabled. The module will begin to

operate at an input voltage above the undervoltage lockout

turn-on threshold.

Synchronization

The module switching frequency can be synchronized to a

signal with an external frequency within a specified range.

Synchronization can be done by using the external signal

applied to the SYNC pin of the module as shown in Fig. 45,

with the converter being synchronized by the rising edge of

the external signal. The Electrical Specifications table

specifies the requirements of the external SYNC signal. If the

SYNC pin is not used, the module should free run at the

default switching frequency. If synchronization is not being

used, connect the SYNC pin to GND.

Dual Layout

Identical dimensions and pin layout of Analog and Digital

SlimLynx

to the other without needing to change the layout. In both

cases the trim resistor is connected between trim and signal

ground. The output of the analog module cannot be

trimmed down to 0.45V

TM

Open Frame modules permit migration from one

Power Good

The module provides a Power Good (PGOOD) signal that is

implemented with an open-drain output to indicate that the

output voltage is within the regulation limits of the power

module. The PGOOD signal will be de-asserted to a low state

if any condition such as overtemperature, overcurrent or

loss of regulation occurs that would result in the output

voltage going ±10% outside the setpoint value. The PGOOD

terminal can be connected through a pullup resistor

(suggested value 100KΩ) to a source of 5VDC or lower.

MODULE

SYNC

+

GND

Figure 45. External source connections to synchronize

switching frequency of the module.

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 15

Page 16

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Tunable Loop

The module has a feature that optimizes transient response

of the module called Tunable Loop

TM

TM

.

External capacitors are usually added to the output of the

module for two reasons: to reduce output ripple and noise

(see Figure 38) and to reduce output voltage deviations from

the steady-state value in the presence of dynamic load

current changes. Adding external capacitance however

affects the voltage control loop of the module, typically

causing the loop to slow down with sluggish response.

Larger values of external capacitance could also cause the

module to become unstable.

TM

The Tunable Loop

voltage control loop to match the filter network connected

to the output of the module. The Tunable Loop

allows the user to externally adjust the

TM

is

implemented by connecting a series R-C between the VS+

and TRIM pins of the module, as shown in Fig. 47. This R-C

allows the user to externally adjust the voltage loop

feedback compensation of the module.

VOUT

VS+

RTune

MODULE

CO

CTune

TRIM

R-C to tune the module for best transient performance and

stable operation for other output capacitance values.

Table 2. General recommended values of of R

TUNE

and C

TUNE

for Vin=12V and various external ceramic capacitor

combinations.

Co

2x47μF 4x47μF 6x47μF 10x47μF 10x47μF

R

TUNE

C

TUNE

430 390 300 240 180

390pF 1500pF 2700pF 3300pF 8200pF

Table 3. Recommended values of R

TUNE

and C

TUNE

to obtain

transient deviation of 2% of Vout for a 6A step load with

Vin=12V.

Vo 5V 3.3V 2.5V 1.8V 1.2V 0.6V

1x47uF

+330μF

2x47μF

+

330μF

Polymer

1x47μF +

2x330μF

Polymer

3x47μF +

3x330μF

Polymer

1x47μF +

11x330μF

Polymer

1x47uF

Co

+ 330μF

Polymer

Polymer

R

TUNE

300 300 240 220 220 180

C

TUNE

2200pF 2200pF 3300pF 5600pF 12nF 47nF

ΔV

55mV 54mV 47mV 31mV 21mV 8mV

Note: The capacitors used in the Tunable Loop tables are

47 F/4 m ESR ceramic and 330 F/12 m ESR polymer

capacitors.

RTrim

SIG_GND

GND

Figure. 47. Circuit diagram showing connection of R

and C

to tune the control loop of the module.

TUNE

TUME

Recommended values of R

TUNE

and C

for different output

TUNE

capacitor combinations are given in Table 2. Table 2 shows

the recommended values of R

TUNE

and C

for different

TUNE

values of ceramic output capacitors up to 1000uF that

might be needed for an application to meet output ripple

and noise requirements. Selecting R

TUNE

and C

according

TUNE

to Table 2 will ensure stable operation of the module.

In applications with tight output voltage limits in the

presence of dynamic current loading, additional output

capacitance will be required. Table 3 lists recommended

values of R

TUNE

and C

in order to meet 2% output

TUNE

voltage deviation limits for some common output voltages

in the presence of a 6A to 12A step change (50% of full load),

with an input voltage of 12V.

Please contact your GE Critical Power technical

representative to obtain more details of this feature as well

as for guidelines on how to select the right value of external

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 16

Page 17

A

W

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

o

Thermal Considerations

Power modules operate in a variety of thermal environments;

however, sufficient cooling should always be provided to help

ensure reliable operation.

Considerations include ambient temperature, airflow, module

power dissipation, and the need for increased reliability. A

reduction in the operating temperature of the module will

result in an increase in reliability. The thermal data

presented here is based on physical measurements taken in

a wind tunnel. The test set-up is shown in Figure 48. The

preferred airflow direction for the module is in Figure 49.

ind Tunnel

PWBs

25.4_

(1.0)

Power Module

temperatures at these points should not exceed 120

output power of the module should not exceed the rated

power of the module (Vo,set x Io,max).

Please refer to the Application Note “Thermal

Characterization Process For Open-Frame Board-Mounted

Power Modules” for a detailed discussion of thermal

aspects including maximum device temperatures.

C. The

76.2_

(3.0)

x

Figure 49. Preferred airflow direction and location of hotspot of the module (Tref).

12.7_

(0.50)

Probe Location

for measuring

airflow and

ambient

temperature

ir

flow

Figure 48. Thermal Test Setup.

The thermal reference points, T

are also shown in Figure 49. For reliable operation the

used in the specifications

ref

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 17

Page 18

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Example Application Circuit

Requirements:

Vin: 12V

Vout: 1.8V

Iout: 9A max., worst case load transient is from 6A to 9A

ΔVout: 1.5% of Vout (27mV) for worst case load transient

Vin, ripple 1.5% of Vin (180mV, p-p)

Vin+

CI3

CI2

CI1

VIN

PGOOD

MODULE

SEQ

VOUT

VS+

RTUNE

CTUNE

TRIM

RTrim

Vout+

CO1

CO2

CO3

ON/OFF

SIG_GND

GND

SYNC

GND

VS-

CI1 Decoupling cap - 1x0.047μF/16V ceramic capacitor (e.g. Murata LLL185R71C473MA01)

CI2 2x22μF/16V ceramic capacitor (e.g. Murata GRM32ER61C226KE20)

CI3 470μF/16V bulk electrolytic

CO1 Decoupling cap - 1x0.047μF/16V ceramic capacitor (e.g. Murata LLL185R71C473MA01) + 0.1uF/16V 0402size

CO2 1 x 47μF/6.3V ceramic capacitor (e.g. Murata GRM31CR60J476ME19)

CO3 1 x 330μF/6.3V Polymer (e.g. Sanyo Poscap)

CTune 2700pF ceramic capacitor (can be 1206, 0805 or 0603 size)

RTune 221 ohms SMT resistor (can be 1206, 0805 or 0603 size)

RTrim 10kΩ SMT resistor (can be 1206, 0805 or 0603 size, recommended tolerance of 0.1%)

ceramic capacitor

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 18

Page 19

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Mechanical Outline

Dimensions are in millimeters and (inches).

Tolerances: x.x mm ± 0.5 mm (x.xx in. ± 0.02 in.) [unless otherwise indicated]

x.xx mm ± 0.25 mm (x.xxx in ± 0.010 in.)

NC

NC

NC

NC

NC

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 19

Page 20

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Recommended Pad Layout

Dimensions are in millimeters and (inches).

Tolerances: x.x mm ± 0.5 mm (x.xx in. ± 0.02 in.) [unless otherwise indicated]

x.xx mm ± 0.25 mm (x.xxx in ± 0.010 in.)

2

NC

PIN FUNCTION PIN FUNCTION

1 ON/OFF 10 SYNC2

2 VIN 11 NC

3 SEQ 12 NC

4 GND 13 NC

5 TRIM 14 SIG_GND

6 VOUT 15 NC

7 VS+ 16 NC

8 VS-

9 PG

If unused, connect to Ground

NC

NC

NC

NC NC

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 20

Page 21

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Packaging Details

The 12V Analog SlimLynxTM 12A Open Frame modules are supplied in tape & reel as standard. Modules are shipped in quantities of

600 modules per reel.

All Dimensions are in millimeters and (in inches).

Reel Dimensions:

Outside Dimensions: 330.2 mm (13.00)

Inside Dimensions: 177.8 mm (7.00”)

Tape Width: 44.00 mm (1.732”)

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 21

Page 22

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Surface Mount Information

Pick and Place

The 12A Analog SlimLynxTM Open Frame modules use an

open frame construction and are designed for a fully

automated assembly process. The modules are fitted with a

label designed to provide a large surface area for pick and

place operations. The label meets all the requirements for

surface mount processing, as well as safety standards, and is

able to withstand reflow temperatures of up to 300

label also carries product information such as product code,

serial number and the location of manufacture.

Nozzle Recommendations

The module weight has been kept to a minimum by using

open frame construction. Variables such as nozzle size, tip

style, vacuum pressure and placement speed should be

considered to optimize this process. The minimum

recommended inside nozzle diameter for reliable operation is

3mm. The maximum nozzle outer diameter, which will safely

fit within the allowable component spacing, is 7 mm.

Bottom Side / First Side Assembly

This module is not recommended for assembly on the

bottom side of a customer board. If such an assembly is

attempted, components may fall off the module during the

second reflow process

Lead Free Soldering

The modules are lead-free (Pb-free) and RoHS compliant and

fully compatible in a Pb-free soldering process. Failure to

observe the instructions below may result in the failure of or

cause damage to the modules and can adversely affect

long-term reliability.

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. D

(Moisture/Reflow Sensitivity Classification for Nonhermetic

Solid State Surface Mount Devices) for both Pb-free solder

profiles and MSL classification procedures. This standard

provides a recommended forced-air-convection reflow

profile based on the volume and thickness of the package

(table 4-2). The suggested Pb-free solder paste is Sn/Ag/Cu

(SAC). The recommended linear reflow profile using Sn/Ag/Cu

solder is shown in Fig. 50. Soldering outside of the

recommended profile requires testing to verify results and

performance.

MSL Rating

The 12A Analog SlimLynxTM Open Frame modules have a MSL

rating of 2a.

o

C. The

not be broken until time of use. Once the original package is

broken, the floor life of the product at conditions of ≤ 30°C

and 60% relative humidity varies according to the MSL rating

(see J-STD-033A). The shelf life for dry packed SMT packages

will be a minimum of 12 months from the bag seal date,

when stored at the following conditions: < 40° C, < 90%

relative humidity.

300

Per J-STD-020 Rev. D

250

Reflow Temp (°C)

200

150

Heating Zone

1°C/Second

100

50

0

Peak Temp 260° C

Reflow Time (Seconds)

* Min. Time Above 235°C

15 Seconds

*Time Above 21 7°C

60 Seconds

Cooling

Zone

Figure 50. Recommended linear reflow profile using

Sn/Ag/Cu solder.

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing. The result

of inadequate cleaning and drying can affect both the

reliability of a power module and the testability of the

finished circuit-board assembly. For guidance on

appropriate soldering, cleaning and drying procedures, refer

to Board Mounted Power Modules: Soldering and Cleaning

Application Note (AN04-001).

Storage and Handling

The recommended storage environment and handling

procedures for moisture-sensitive surface mount packages is

detailed in J-STD-033 Rev. A (Handling, Packing, Shipping and

Use of Moisture/Reflow Sensitive Surface Mount Devices).

Moisture barrier bags (MBB) with desiccant are required for

MSL ratings of 2 or greater. These sealed packages should

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Page 22

Page 23

GE

Data Sheet

12A Analog SlimLynxTM Open Frame: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.6Vdc to 5.5Vdc output; 12A Output Current

Ordering Information

Please contact your GE Sales Representative for pricing, availability and optional features.

Table 9. Device Codes

Device Code

UNVT012A0X3-SRZ 3 – 14.4Vdc 0.6 – 5.5 Vdc 12A Negative Yes 150029054

UNVT012A0X43-SRZ 3 – 14.4Vdc 0.6 – 5.5 Vdc 12A Positive Yes 150036974

-Z refers to RoHS compliant parts

Table 10. Coding Scheme

Package

Identifier

U NV T 012A0 X 3 -SR Z

P=Pico

U=Micro

M=Mega

G=Giga

Family Sequencing

ND=SlimLynx

Digital Open

Frame

NV=SlimLynx

Analog Open

Frame

Input

Voltage Range

Option

T=with EZ

Sequence

X=without

sequencing

Output

current

Output

Voltage

Output

voltage

12A X =

programm

able output

4 =

positive

No entry =

negative

Output

Current

On/Off

logic

On/Off

Logic

Remote

Sense Options

3 = Remote

Sense

Sequencing Comcodes

S = Surface

R = Tape &

ROHS Compliance

Z = ROHS6

Mount

Reel

Contact Us

For more information, call us at

USA/Canada:

+1 888 546 3243, or +1 972 244 9288

Asia-Pacific:

+86.021.54279977*808

Europe, Middle-East and Africa:

+49.89.74423-206

India:

+91.80.28411633

February 19, 2014 ©2014 General Electric Corporation. All rights reserved. Version 1.0

www.gecriticalpower.com

Loading...

Loading...