Gehl SL7600, SL7800 Operator's Manual

SL7600

SL7800

SKID STEER

LOADER

Form No.

908274

English

OPERATOR’S MANUAL

®

Gehl Company, in cooperation

with the American Society of

Agricultural Engineers and the

Society of Automotive Engineers, has

adopted this Safety Alert Symbol to

pinpoint precautions which, if not

properly followed, can create a safety

hazard. When you see this symbol in

this manual or on the machine itself,

you are reminded to BE ALERT! Your

personal safety is involved!

Operators must have instructions

before running the machine.

Untrained operators can cause

injury or death.

CORRECT

WRONG

Never use loader

without ROPS/FOPS.

Never modify the

ROPS/FOPS structure.

WRONG

Read Operator's Manual

before using machine.

CORRECT

Always fasten seatbelt

snugly. Always keep feet

on the floor/pedals when

operating loader.

Never use the loader to

lift personnel.

WRONG

Do not use loader around

explosive dust or gas, or

where exhaust can contact

flammable material.

SL7600 and SL7800 Skid Steer Loader

Operator’s Manual

TABLE OF CONTENTS

Introduction .........................1

Safety ...........................5

Controls And Safety Equipment..............15

Operation .........................34

Service ..........................45

Troubleshooting ......................63

Maintenance Schedule ..................71

Specifications .......................75

Index ...........................81

Torque Specifications ...................83

Warranty .........................84

Loader Model Number

Loader Serial Number

Engine Serial Number

All-Tach, Hydraloc and Hydraglide are trademarks of Gehl Company.

Gehl and Powerview are registered trademarks of Gehl Company.

INTRODUCTION

This Operator’s Manual gives the owner/operator information about

maintaining and servicing SL7600 and SL7800 skid steer loader models.

More importantly, this manual provides anoperating plan for safe and proper

use of the machine. Major points of safe operation are detailed in the Safety

chapter of this manual.

We ask that you read and understand the contents of this manual completely

and become familiar with your new machine before operating it. See your

authorized Gehl dealer if you have any questions concerning information in

the manual, require extra manuals or for information concerning the

availability of manuals in other languages.

Throughout this manual, information is provided set in italic type and

introduced by the word Note or Important. Read carefully and comply with

the message — it will improve your operating and maintenance efficiency,

help avoid breakdowns and damage, and extend your machine’s life.

A manual storage box in the operator’s compartment holds the Operator’s

Manual and AEM Safety Manual. Please return the manuals to this box and

keep them with the unit at all times. If this machine is resold, we recommend

that these manuals be given to the new owner.

The attachments and equipment available for use with this machine have a

wide variety of potential applications. Read the manual provided with the

attachment to learn how to safely maintain and operate the equipment. Be

sure the machineis suitably equipped for thetype of workto be performed.

Do not use this machine for any applications or purposes other than those

described in this manual or applicable for approved attachments. If the

machine is to be used with special attachments or equipment other thanthose

approved by Gehl Company, consult your Gehl dealer. Any person using

non-approved attachments or making unauthorized modifications is

responsible for the consequences.

The Gehl dealership network stands ready to provide you with any assistance

you may require, including providing genuine Gehl service parts. All service

parts should be obtained from your Gehl dealer. Give complete information

about the part and include the model and serial numbers of your machine.

Record these numbersin the spaceprovided on theTable of Contentspage, as

a handy reference.

Please be aware that Gehl strives to continuously improve its products and

reserves the right to make changes and improvements in the design and

construction of any part without incurring the obligation to install such

changes on any unit previously delivered.

1 908274/BP1202

If this machine was purchased "used," or if the owner's address has changed,

please provide your Gehl dealer or Gehl Company Service Department with

the owner's name and current address, along with the machine model and

serial number. This will allow the registered owner information to be

updated, so that the owner can be notified directly in case of an important

product issue, such as a safety update program.

908274/BP1202 2

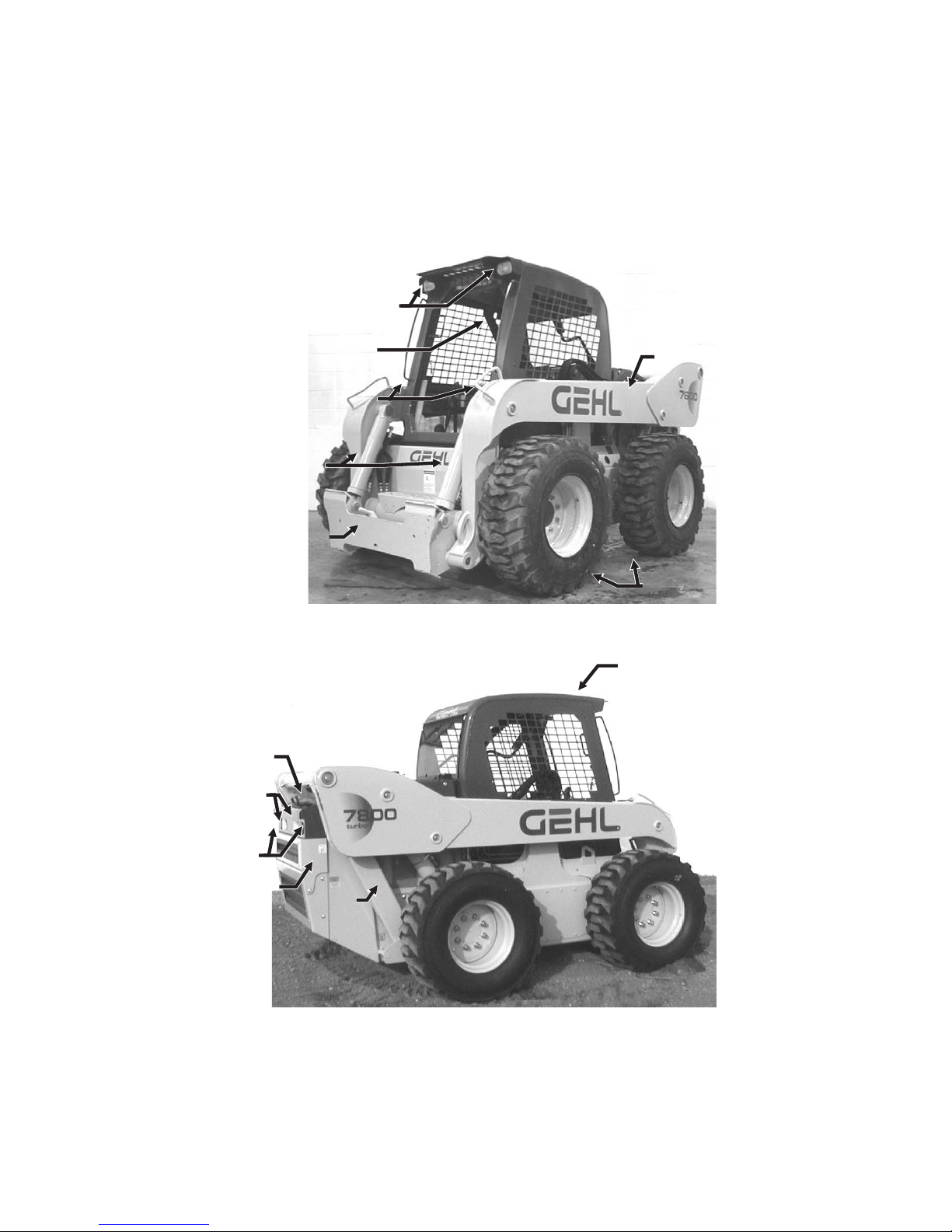

Model Identification

Front Work Lights

Engine

Cover

Rear Work

Lights

Restraint Bar

Hand Holds

Tilt

Cylinders

Hitch

Lift Arm

Tires

Roll Over/

Falling Object

Protective

Structure

(ROPS/FOPS)

Tail Lights

Rear Door

3 908274/BP1202

Rear Link

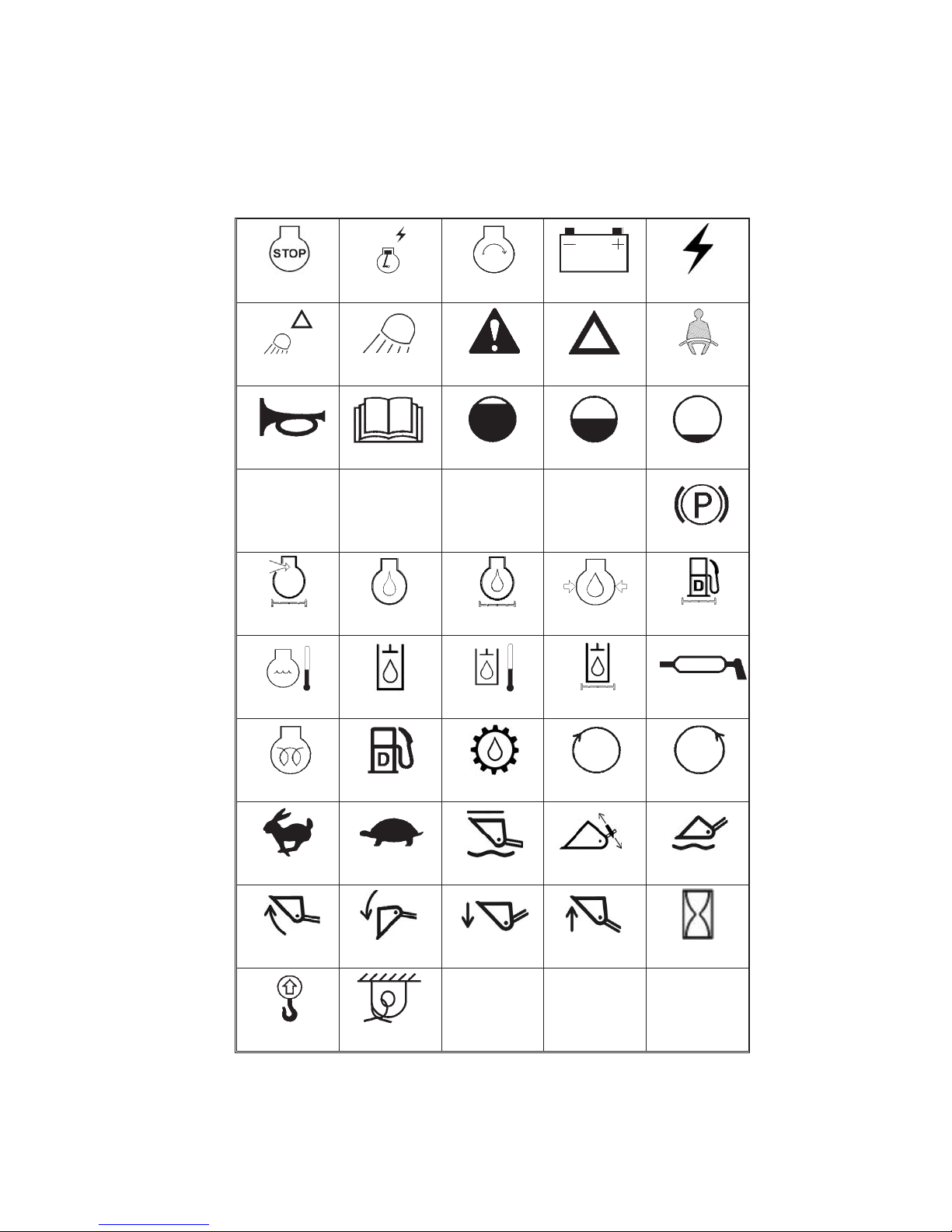

Control/Indicator Symbols

Worklight

w/Flasher

Horn

H-L

High - Low

Engine Air Filter

Engine Coolant

Temperature

Worklight

Read Operator’s

Manual

N

Neutral

Engine Oil

Hydraulic System

Engine StartPower Off Power On

Safety Alert

Volume - Full

F

Forward

Engine Oil Filter Fuel Filter

Hydraulic Oil

Temperature

Battery Charge

Hazard Flasher

Volume- Half Full Volume - Empty

Electrical Power

Seatbelt - Lap

Only

R

Reverse

Engine Oil

Pressure

Hydraulic Oil

Filter

Parking Brake

Grease

Lubrication Point

Pre-Heat

Fast

Bucket - Rollback Bucket - Dump

Lift Point

908274/BP1202 4

Diesel Fuel

Slow

Tie-Down

Chaincase Oil

Bucket - Lower

Clockwise

Rotation

Power HitchRide Control

Bucket - Raise

Counterclockwise

Rotation

Bucket - Float

Service Hours

SAFETY

This safety alertsymbol means Attention! Become alert!Your safety

is involved! It stresses an attitude of “Heads Up for Safety” and can

be found throughout this Operator’s Manual and on the decals on the

machine.

Before operating this machine, read and study the following safety

information. In addition, be sure that everyone who operates or works with

this machine, whether family member or employee, is familiar with these

safety precautions. It is essential to have competent and careful operators,

who are not physically or mentally impaired, and who are thoroughly trained

in the safe operation of the machine and the handling of loads. It is

recommended that the operator be capable of obtaining a valid motor vehicle

operator’s license.

The use of skid steer loaders is subject to certain hazards that cannot be

eliminated by mechanical means, but only by exercising intelligence, care

and common sense. Such hazards include, but are not limited to, hillside

operation, overloading, instability of the load, poor maintenance and using

the equipment for a purpose for which it is not intended or designed.

Gehl

ALWAYS considers the operator’s safety when designing its machinery

and guards exposed moving parts for the operator’s protection. However,

some areas cannot beguarded or shielded in order to assure proper operation.

Furthermore, this Operator’s Manual and the decals on the machine warn of

additional hazards and they should be read and observed closely.

Some photographs in this manual may show doors, guards and shields open

or removed for illustrative purposes only. Be sure that all doors, guards and

shields are in their proper operating positions before starting the engine to

operate the unit.

Different applications may require optional safety equipment, such as a

back-up alarm, horn, mirror, strobe light or an impact-resistantfront door. Be

sure you know the job site hazards and equip your machine as needed.

DANGER

situation which, ifnot avoided, willresult indeath orserious injury.

WARNING

situation which, if not avoided, could result in death or serious

injury.

CAUTION

situation which, if not avoided may result in minor or moderate

injury. May also alert against unsafe practices.

5 908274/BP1202

“DANGER” indicates an imminently hazardous

“WARNING” indicates a potentially hazardous

“CAUTION” indicates a potentially hazardous

Mandatory Safety Shutdown Procedure

Before cleaning, adjusting, lubricating, servicing the unit or leaving it

unattended:

1. Move the drive control handle(s) to the neutral position.

2. Lower the lift arm and attachment completely. If the lift arm must be left

in the raised position,

BE SURE to properly engage the lift arm support

device (page 17).

3. Move the throttle to the low idle position, shut off the engine and remove

the key.

4. Before exiting, move the lift/tilt control(s) to verify that the controls do

not cause movement of the lift arm and hitch.

Safety Reminders

Before Starting

Ü Do not modify the ROPS/FOPS unless instructed to do so in installation

instructions. Modifications such as welding, drillingor cutting can weaken

the structure and reduce the protection it provides. A damaged

ROPS/FOPS cannot be repaired — it must be replaced.

Ü To ensure safe operation, replace damaged or worn-out parts with genuine

Gehl service parts.

Ü Gehl skid steer loaders are designed and intended to be used onlywith Gehl

attachments or approved referral attachments. Gehl cannot be responsible

for operator safety if the loader is used with a non-approved attachment.

Ü Remove all trash and debris from the machine each day, especially in the

engine compartment, to minimize the risk of fire.

Ü

Always face the loader and use the hand holds and steps when getting on

and off the loader. Do not jump off the loader.

Ü

Never use starting fluid (ether).

Ü

Walk around the machine and warn allnearby personnel before starting the

machine.

Ü

Always perform a daily inspection of the machine before using it. Look for

damage, loose or missing parts, leaks, etc.

During Operation

Ü

Machine stability is affected by: the load being carried, the height of the

load, machine speed, abrupt control movements and driving over uneven

terrain.

LOADER TO TIP, THROWING THE OPERATOR OUT OF THE SEAT OR

LOADER, RESULTING IN DEATH OR SERIOUS INJURY.

ALWAYS operate with the seatbelt fastened and the restraint bar lowered.

DISREGARDING ANY OF THESE FACTORS CAN CAUSE THE

Therefore,

Do not exceed the machine’s Rated Operating Load. Carry the load low.

Move the controls smoothly and gradually, and operate at speeds

appropriate for the conditions.

908274/BP1202 6

Always travel with the heavier end of the loader toward the top of the

Ü

incline for additional stability when operating on inclines or ramps.

Do not raise or drop a loaded bucket or fork suddenly. Abrupt movements

Ü

under load can cause serious instability.

Never push the lift control into the “float” position with the bucket or

Ü

attachment loaded or raised, because this will cause the lift arm to lower

rapidly.

Do not drive too close to an excavation or ditch; be sure that the

Ü

surrounding ground has adequate strength to support the weight of the

loader and the load.

Never carry riders. Do not allow others to ride on the machine or

Ü

attachments, because they could fall or cause an accident.

Always look to the rear before backing up the skid steer loader.

Ü

Operate the controls only from the operator’s seat.

Ü

Always keep hands and feet inside the operator’s compartment while

Ü

operating the machine.

Ü New operators must operate the loader in an open area away from

bystanders. Practice with the controls until the loader can be operated

safely and efficiently.

Ü Exhaust fumes can kill. Do not operate this machine in an enclosed area

unless there is adequate ventilation.

Ü When you park the machine and before you leave the seat, check the

restraint bar for proper operation. The restraint bar, when raised,

deactivates the lift/tilt controls and auxiliary hydraulics, and applies the

parking brake.

Maintenance

Ü

Never attempt to by-pass the keyswitch to start the engine. Use only the

jump starting proceduredetailed in theOperation chapter ofthis manual.

Ü

Never use your hands to search for hydraulic fluid leaks. Instead, use a

piece of paper or cardboard. Escaping fluid under pressure can be invisible

and can penetrate the skin and cause serious injury. If any fluid is injected

into your skin, see a doctor at once. Injected fluid must be surgically

removed by a doctor or gangrene may result.

Ü

Always wear safety glasses with side shields when striking metal against

metal. In addition, it is recommended that a softer (chip resistant) material

be used to cushion the blow. Failure to heed could lead to serious injury to

the eyes or other parts of the body.

Ü

Do not smoke or have any spark producing equipment in the area while

filling the fuel tank or while working on the fuel or hydraulic systems.

7 908274/BP1202

Potential Hazards

A skid steer loader operator must

ALWAYS be conscious of the working

environment. Operator actions, the environmental conditions and the job at

hand require thefull attention ofthe operator sothat safetyprecautions can be

taken.

ALWAYS maintaina safe distance from electric power lines andavoid contact

with any electrically charged conductor or gas line. Accidental contact or

rupture can result in electrocution or an explosion. Contact the North

American One CallReferral System at(888) 258-0808 forthe local "Digger's

Hotline" number or the proper local authorities for utility line locations

BEFORE starting to dig!

Exposure to crystalline silica (found in sand, soil and rocks) has been

associated with silicosis,a debilitating andoften fatal lung disease. A Hazard

Review (Pub. No. 2002-129) by the U.S. National Institute for Occupational

Safety and Health(NIOSH) indicates a significant risk of chronicsilicosis for

workers exposed to inhaled crystalline silica over a working lifetime.

NIOSH recommends an exposure limit of 0.05 mg/m

3

as a time-weighted

average for up to a 10-hr workday during a 40-hr workweek. NIOSH also

recommends substituting less hazardous materials when feasible, using

respiratory protection and regular medical examinations for exposed

workers.

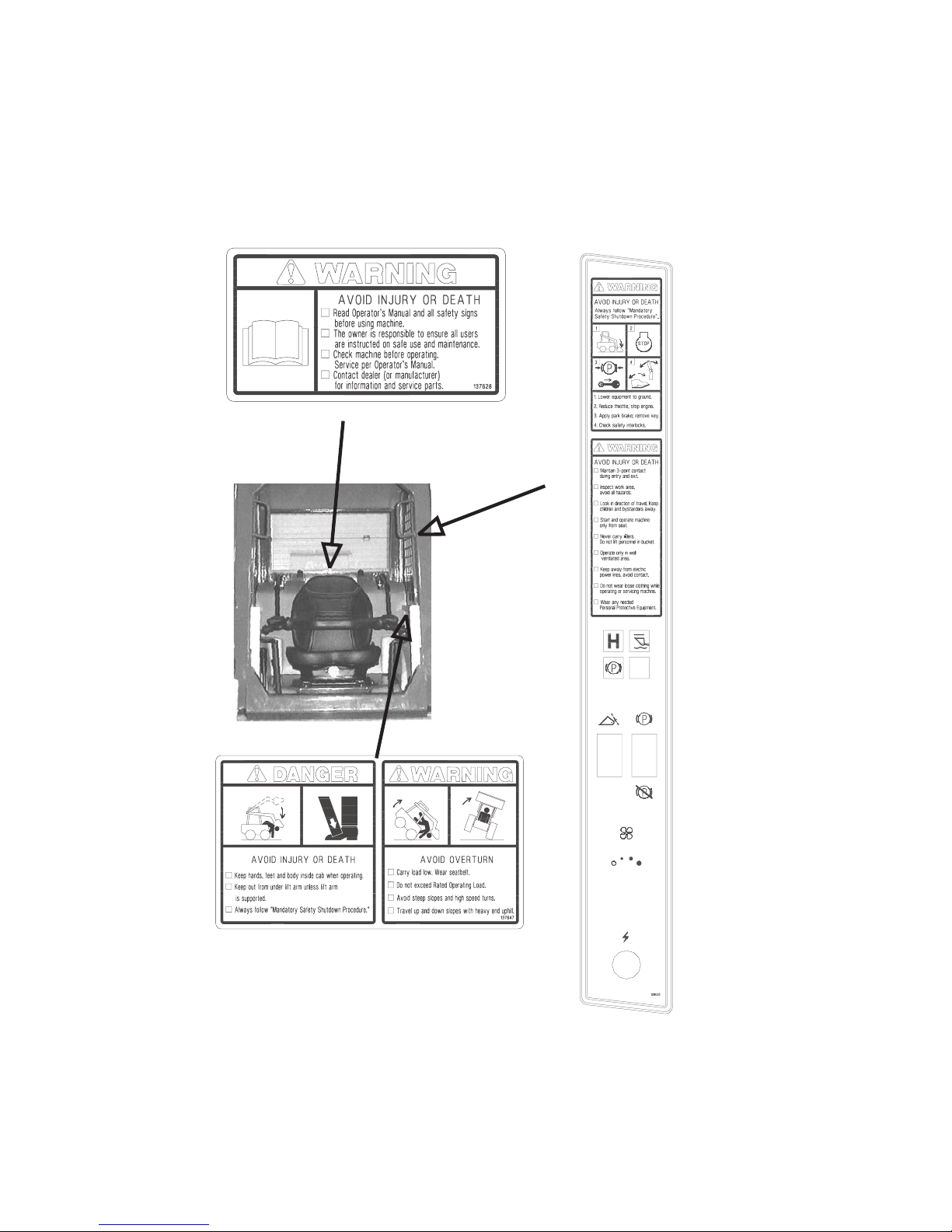

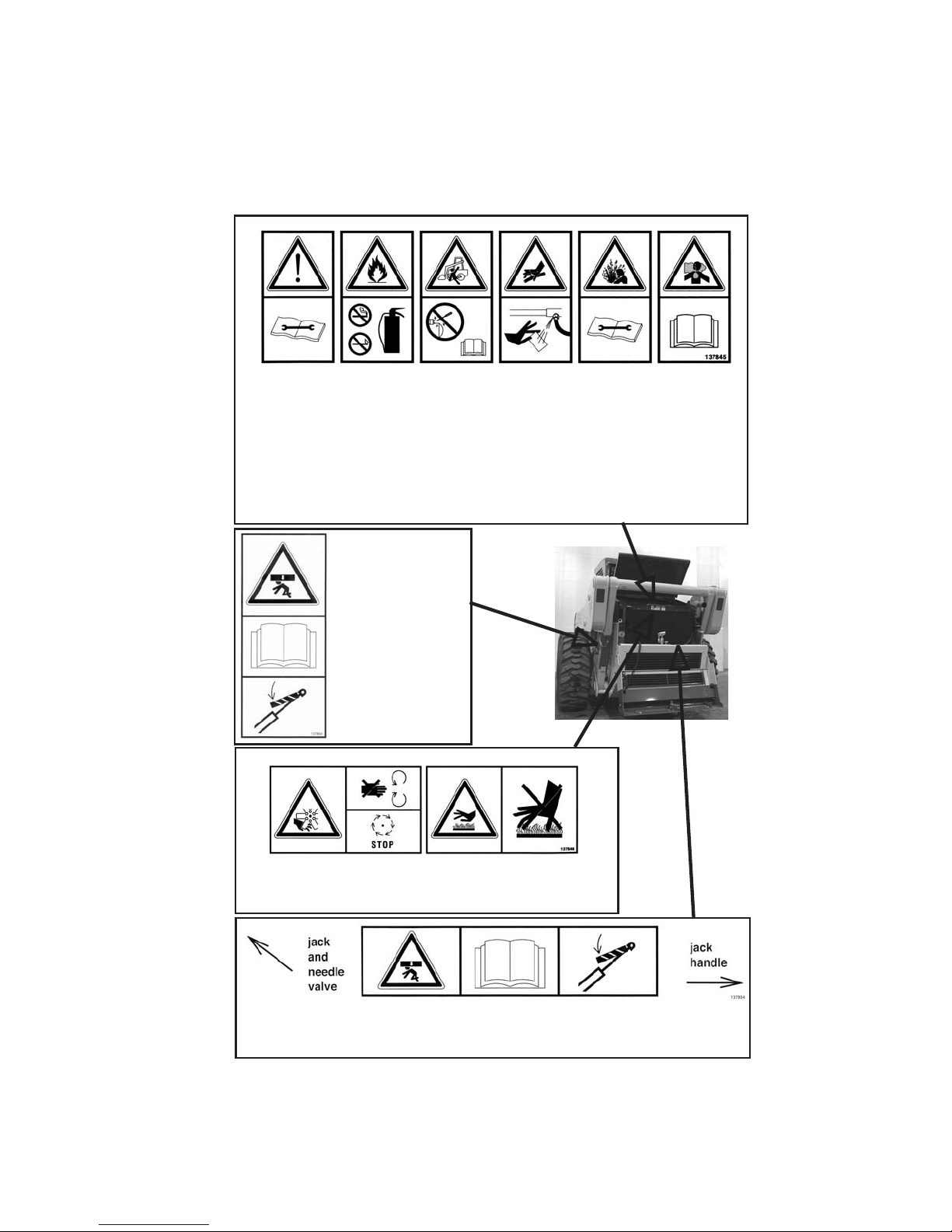

Safety Decals

The skid steer loader has decals that provide safety information and

precautions around the loader. These decals must be kept legible. If missing

or illegible, they must be replaced promptly. Replacements may be obtained

from your Gehl dealer. New equipment must have all decals specified by the

manufacturer affixed to their proper place.

New Decal Application

Surfaces must be free of dirt, dust, grease and foreign material before

applying the decal. Remove the smaller portion of the decal backing paper

and apply the exposed adhesive to the clean surface, maintaining proper

position and alignment. Peel the rest of the backing paper and apply hand

pressure to smooth out the decal surface. Refer to the following pages for

proper decal location. Text decals begin on page 9; no-text decals begin on

page 12.

908274/BP1202 8

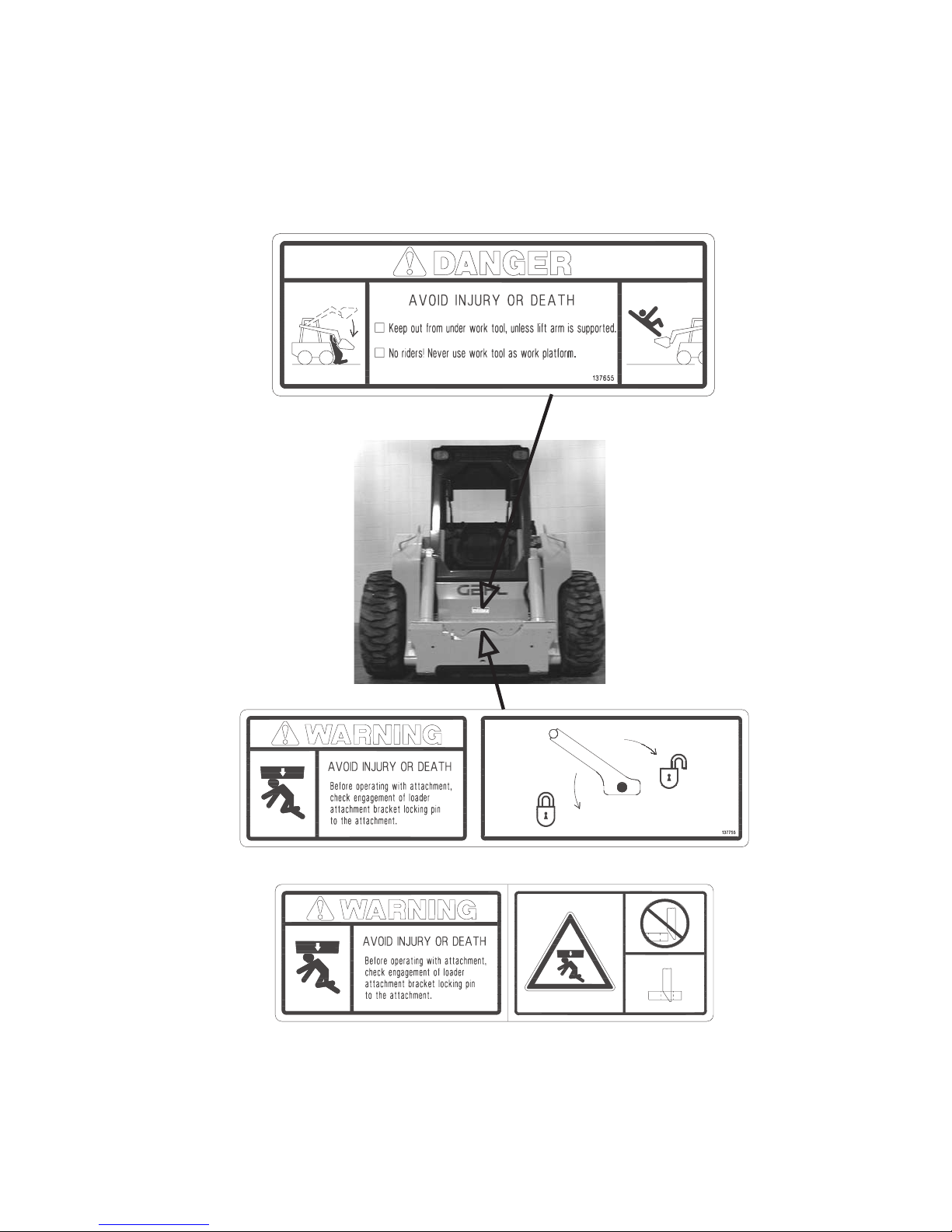

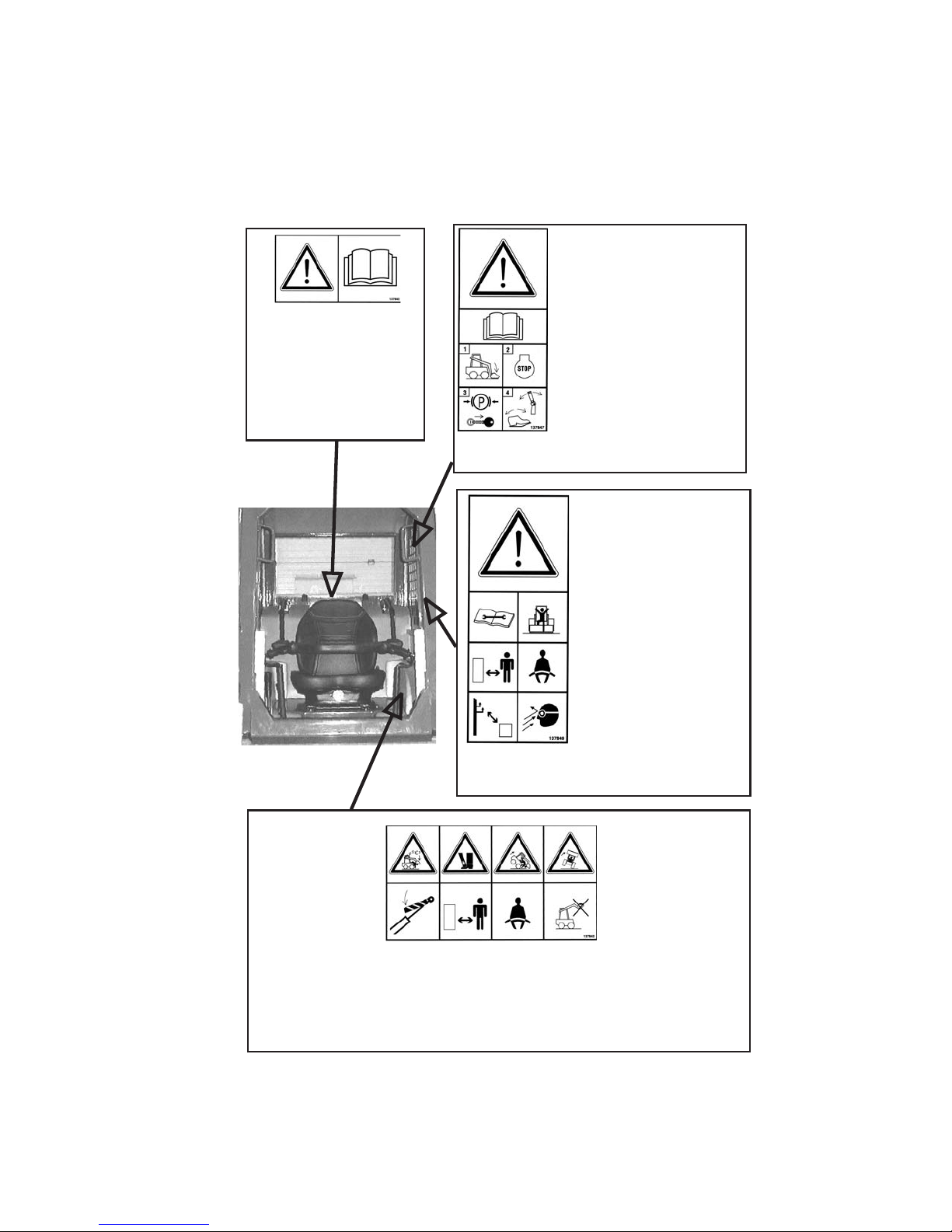

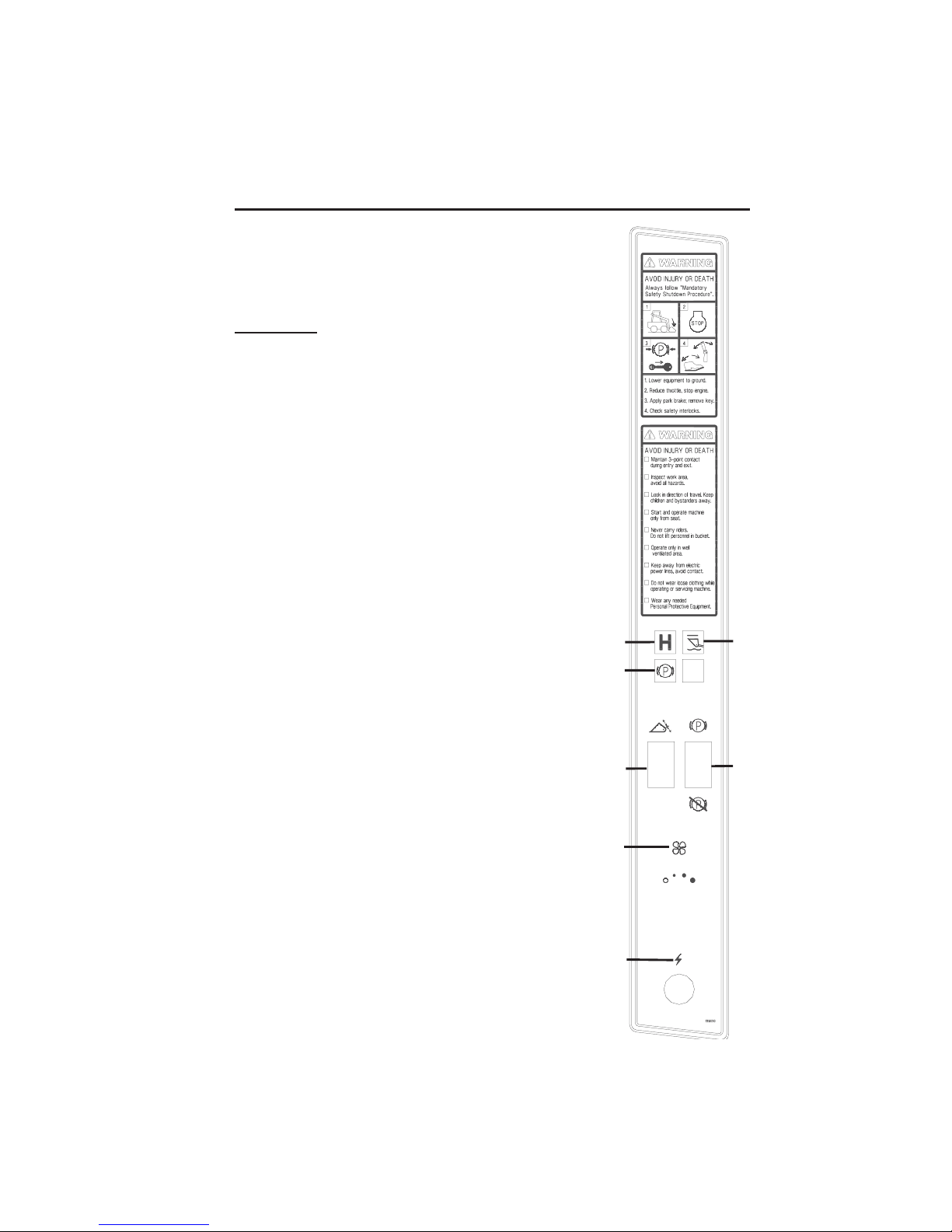

Safety Decals inside the ROPS

137628 - Located on manual box, behind seat

137647 - Located on operator’s lower left side

9 908274/BP1202

Part of left instrument panel

Safety Decals on the Outside of the Skid Loader

137655 - Located on front of loader

137755 - Located on hitch (manual hitch loaders only)

139101 - Located on hitch (power hitch loaders only)

908274/BP1202 10

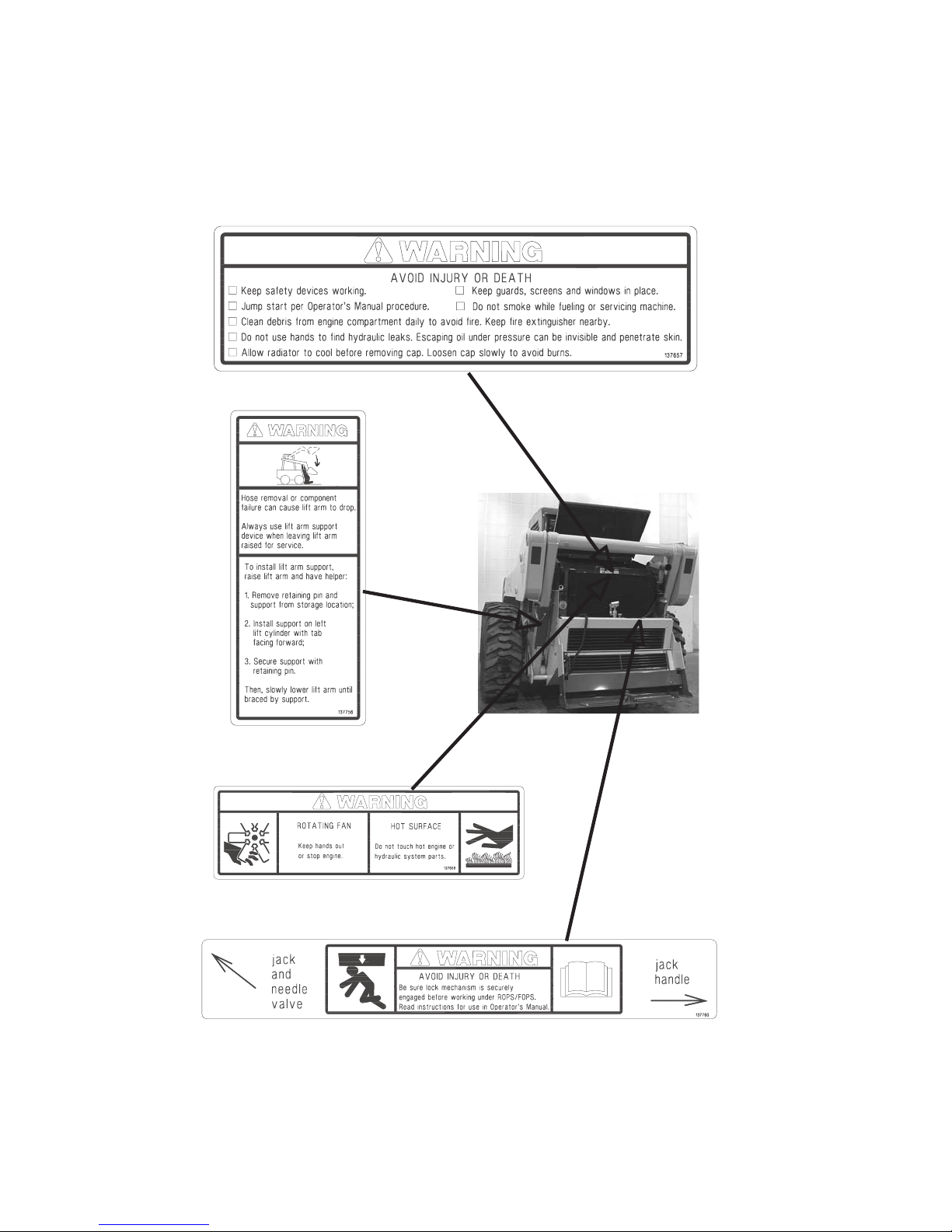

Safety Decals in the Engine Compartment

137657 - Located on radiator

137756 - Located on lift arm

support device

137658 - Located on radiator

137760 - Located on rear door

11 908274/BP1202

Safety Decals inside the ROPS

137842 - Located on manual

box, behind seat

Safety alert: Read Operator’s

Manual and all safety signs

before using machine. The

owner is responsible to

ensure all users are

instructed on safe use and

maintenance.

Safety alert: Always follow

“Mandatory Safety Shutdown

Procedure” in Operator’s Manual.

1-Lower equipment to ground.

2-Reduce throttle, stop engine.

3-Apply parking brake; remove

key.

4-Check safety interlocks.

137847 – Part of left

instrument panel

A

E

137849 – Part of

left instrument

panel

B

C

D

F

Safety alert:

A-Check machine before

operating; Service per

Operator’s Manual; Contact

dealer (or manufacturer) for

information and service

parts.

B-Maintain 3-point contact

during entry and exit.

C-Inspect work area; Avoid

all hazards; Look in direction

of travel; Keep children and

bystanders away.

D-Start and operate

machine only from seat.

E-Keep away from power

lines; Avoid contact.

F-Wear any needed

Personal Protective

Equipment; Do not wear

loose clothing while

operating or servicing

machine.

137843 - Located on operator’s lower left side

A-Crush hazard: Keep out from under lift arm unless lift arm is supported.

B-Crush hazard: Keep hands, feet and body inside cab when operating.

C-Forward tip hazard: Fasten seat belt; Carry load low; Do not exceed Rated

Operating Load.

D-Side tip hazard: Avoid steep slopes and high speed turns; Travel up and down

slopes with heavy end uphill.

908274/BP1202 12

A

B

C

D

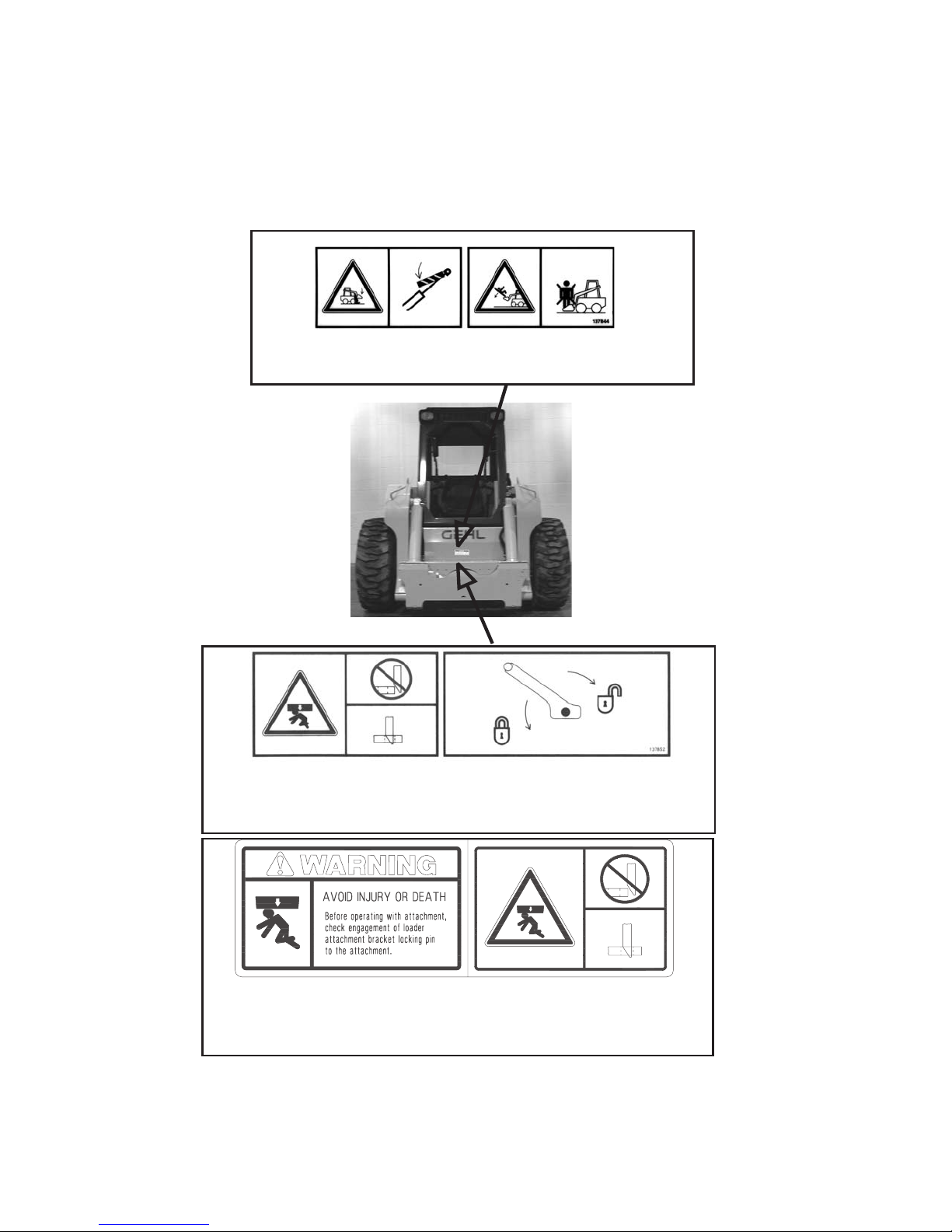

Safety Decals on the Outside of the Skid Loader

A

137844 – Located on front of loader

A-Crush hazard: Keep out from under worktool unless lift arm is supported.

B-Fall hazard: No riders; Never use work tool as work platform.

A

B

B

137852 – Located on hitch (manual hitch loaders only)

Crush hazard: Before operating with attachment, check engagement of hitch locking pin to

the attachment:

A-Incorrect attachment engagement C-Lock hitch lever

B-Correct attachment engagement D-Unlock hitch lever

139101 - Located on hitch (power hitch loaders only)

Crush hazard: Before operating with attachment, check engagement of hitch locking pin to

the attachment:

A-Incorrect attachment engagement

B-Correct attachment engagement

13 908274/BP1202

C

D

A

B

Safety Decals in the Engine Compartment

AB C D E F

137845 – Located on radiator

A-Safety alert: Keep safety devices in place and in working order; Keep guards,

screens and windows in place.

B-Fire hazard: Do not smoke while fueling or servicing machine; Clean debris from

engine compartment daily to avoid fire; Keep fire extinguisher nearby.

C-Run-over hazard: Jump-start per Operator’s Manual procedure.

D-Oil injection hazard: Do not use hands to find hydraulic leaks; Escaping oil under

pressure can be invisible and penetrate skin; Use a piece of cardboard to find leaks.

E-Burn hazard: Allow radiator to cool before removing cap; Loosen cap slowly to avoid

burns.

F-Suffocation hazard: Operate only in a well-ventilated area.

137853 Located on lift

arm support

device

Crush hazard: Hose

removal or component

failure can cause lift

arm to drop. Always

use lift arm support

device when leaving

lift arm raised for

service.

A

137846 – Located on radiator

A-Rotating fan: Keep hands out or stop engine.

B-Hot surface: Do not touch hot engine or hydraulic system parts.

137854 - Located on rear door

Crush hazard: Be sure lock mechanism is securely engaged before working under

ROPS/FOPS.

908274/BP1202 14

B

CONTROLS and SAFETY EQUIPMENT

CAUTION

Become familiar with and know how to use all

safety devices and controls on the skid steer loader before

operating it. Know how to stop loader operation before starting it.

This Gehl loader is designed and intended to be used only with a

Gehl attachment or a Gehl-approved referral attachment or

accessory. Gehl cannot be responsible for operator safety if the

loader is used with a non-approved attachment.

Guards and Shields

Whenever possible and without affecting loader operation, guards and

shields are provided to protect against potentially hazardous areas. In many

places, safety decals are also provided to warn of potential hazards and/or to

display special operating procedures.

WARNING

Read and thoroughly understand all safety

decals on the loader before operating it. Do not operate the loader

unless all factory-installedguards and shields are properly secured

in place.

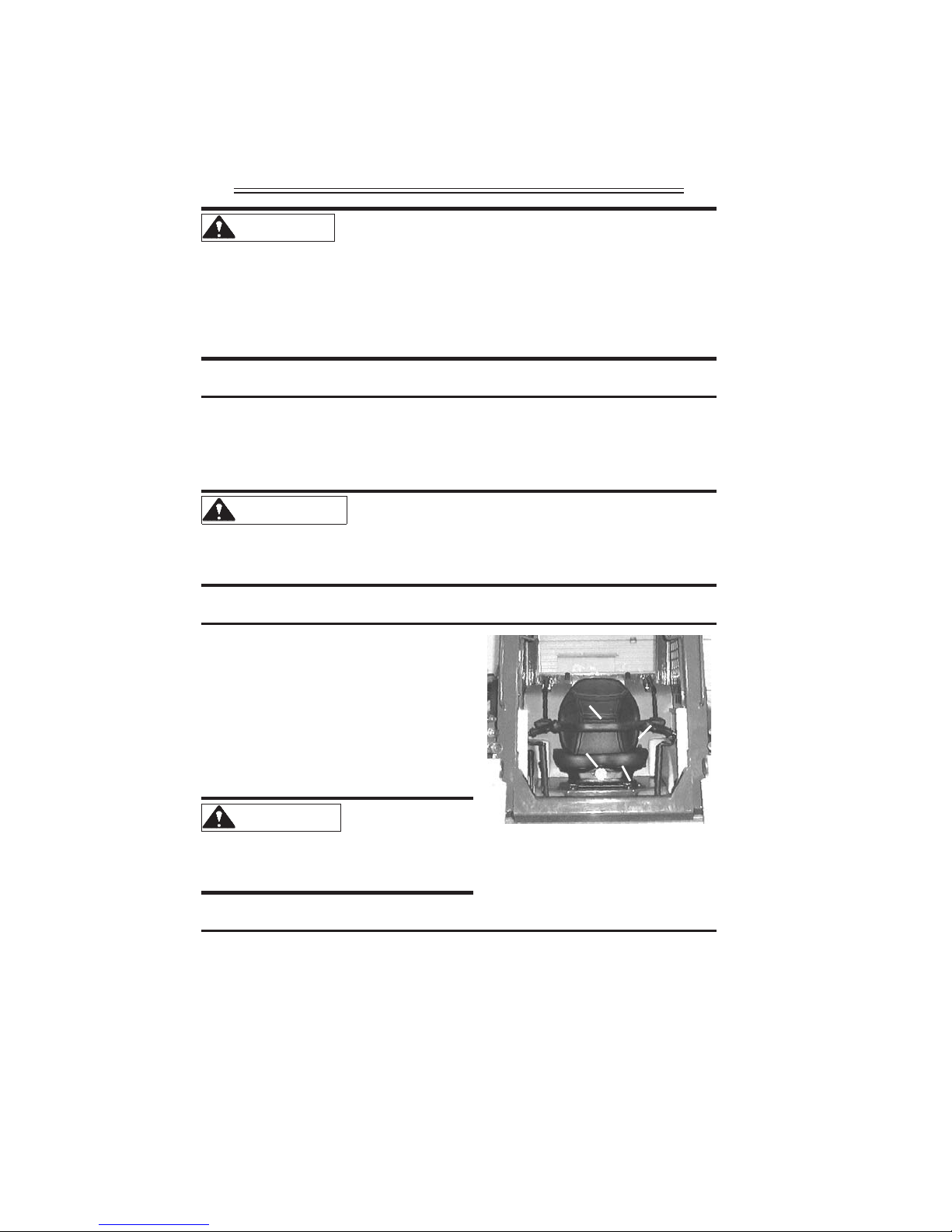

Operator Restraint Bar

Lower the restraint bar after entering the

operator’s compartment. The restraint

bar is securely anchored to the ROPS.

The restraint bar switch and the seat

switch form an interlock for the lift arm,

tilt, drive and starter circuits (refer to the

“Safety Interlock System” topic on

1

2

4

3

page 16 for more information).

WARNING

operator restraint bar or seat

switch electrically or mechanically.

Always wear your seatbelt.

Operator’s Seat

The seat is mounted on rails for backward or forward repositioning. A

spring-loaded latch handle activates the seat adjustment mechanism.

Suspension seat (optional): A weight adjustment knob is provided with this

seat for operator comfort.

15 908274/BP1202

Never defeat the

Fig. 1: Operator’s Seat

1. Restraint Bar

2. Seatbelt

3. Seat Adjustment Lever

4. Suspension Seat Knob

(optional)

Battery Disconnect

A battery disconnect switch is located in the rear

of the skid loader. Turn the switch to the

OFF

position to disconnect the battery from the

electrical system.

Safety Interlock System

Fig. 2: Battery Disconnect

Switch

WARNING

NEVER defeat the safety interlock system by

mechanically or electrically bypassing any switches, relays or

solenoid valves.

An interlock system is provided on the loader for operator safety. Together

with solenoid valves, switches and relays, the interlock system:

» Prevents the engine from starting unless the operator is sitting on the seat

and the operator restraint bar is down.

» Disables the lift arm, auxiliary hydraulics, attachment tilt and wheel drives

anytime the operatorleaves the seat, turns thekeyswitch to

OFF or raisesthe

restraint bar.

Testing the Safety Interlock System

Before leaving a parked machine, check the safety interlock system for

proper operation:

Restraint Bar

With the engine running, raise the restraint bar. Test each of the controls.

There should be no more than a slight movement of the lift arm, hitch and

machine. If there is any significant movement, troubleshoot and correct

the problem immediately. Contact your dealer if necessary.

Seat Switch

With the engine off and the restraint bar lowered, unfasten your seatbelt.

Lift your weight off the seat. Try to start the engine. If the engine starts,

turn off the engine, and troubleshoot and correct the problem. Contact

your dealer if necessary.

908274/BP1202 16

ROPS/FOPS

The ROPS/FOPS (Roll Over/Falling Object ProtectiveStructure) is designed

to provide protection for the operator from falling objects and in case the

loader tips or rolls over, provided the operator is secured inside the ROPS by

the seatbelt and restraint bar.

WARNING

Never operate the loader with the ROPS

removed or locked back.

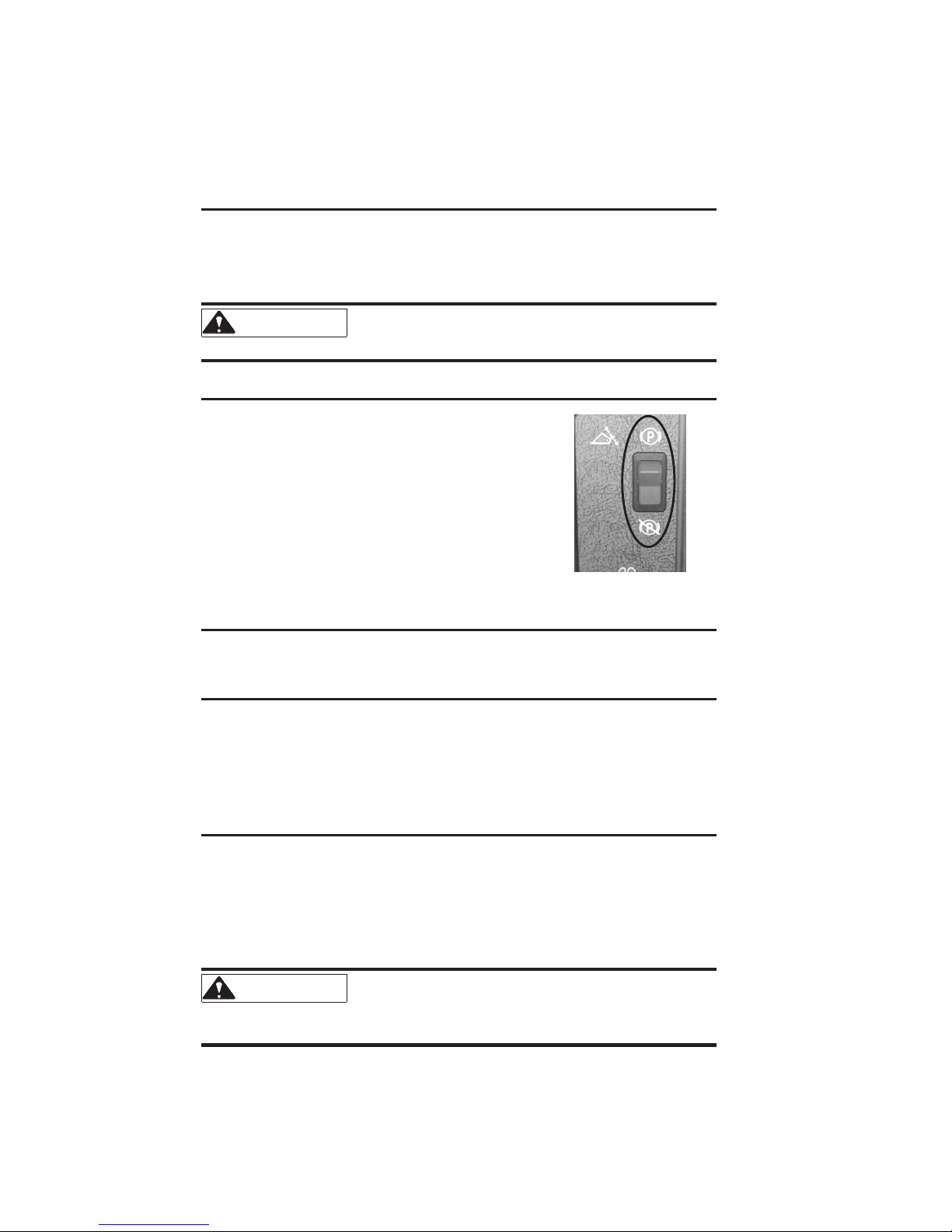

Parking Brake

This skid loader is equipped with a

spring-applied, hydraulic-released parking

brake. The parking brake engages when the

operator lifts the restraint bar, leaves the

operator’s seat or shuts off the engine. The

brake can also be applied manually by using

the switch located on the left control panel of

the ROPS. A red indicator on the left control

panel lights whenthe parking brake is applied.

Fig. 3: Parking Brake Switch

Horn

Pressing the

BLUE button on the left control handle sounds the horn.

Rear Window Emergency Exit

The ROPS rear window has three functions: noise reduction, falling objects

barrier and emergency exit.

To use the emergency exit, unlatch the two latches, push out the window and

exit.

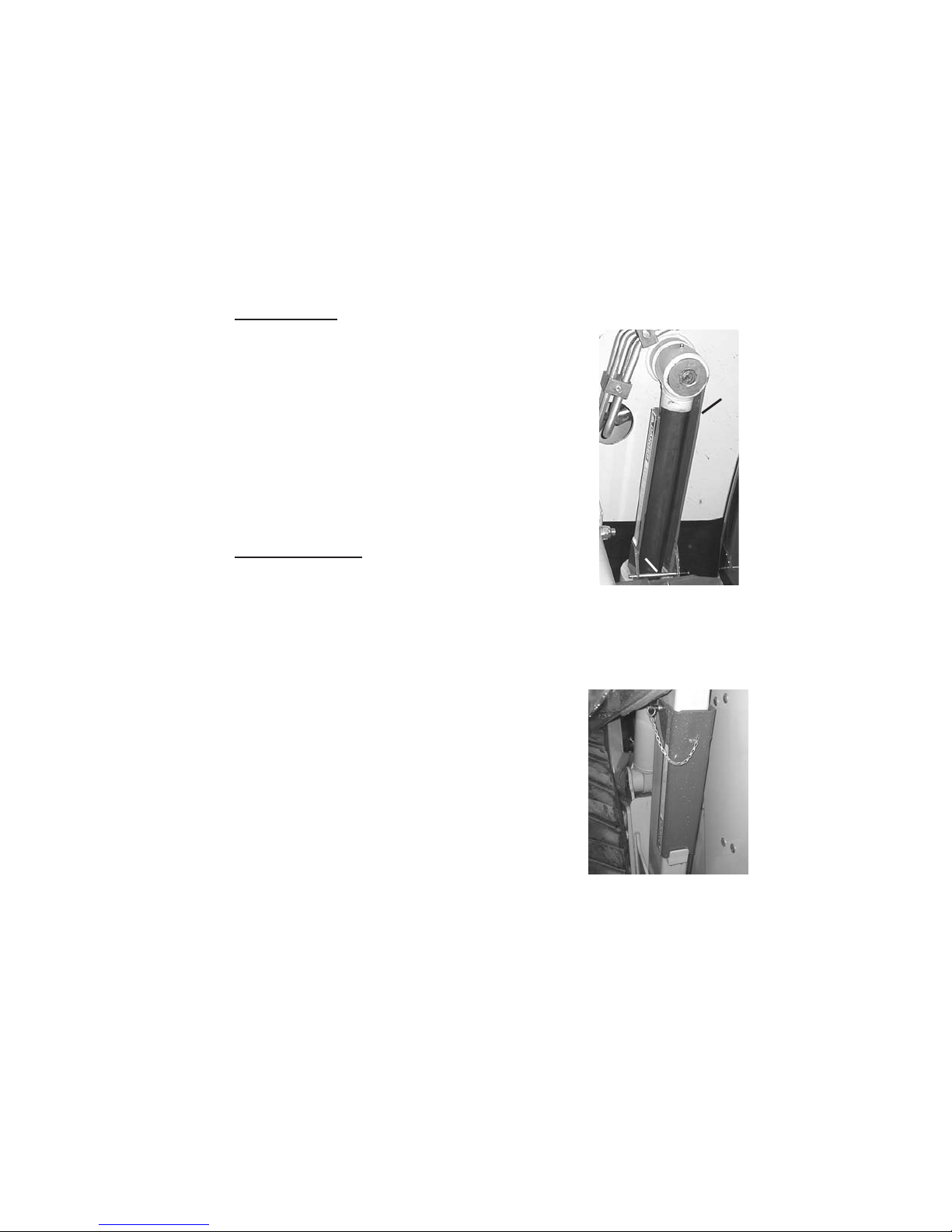

Lift Arm Support Device

The lift arm support device is used as a cylinder lock to prevent the raised lift

arm from unexpectedly lowering. Be sure to engage the support device when

the lift arm is raised for service. When the support device is not being used,

return it to its storage position. The support deviceis a safety device that must

be kept in proper operating condition at all times. The following steps ensure

correct usage:

WARNING

support device requires two people - one person inside the loader

and another person to engage the support device.

17 908274/BP1202

The safest method of engaging the lift arm

Important: With the keyswitch OFF and the solenoid valve functioning

properly, the lift arm will stay raised when the lift control is moved to lower

the lift arm. If the valve does not hold the lift arm, lower the lift arm

completely. Contact your Gehl dealer immediately to determine why the lift

arm lowers while the keyswitch is

OFF.

Engagement

To engage the lift arm support device:

1. Raise the lift arm fully.

2. Stop the engine.

2

3. Remove the lift arm support device from its

storage location on the left rear link.

4. Place the supportdevice on theleft liftcylinder

with the long end of the support device facing

the front of the loader (Fig. 4).

5. Secure the support device with the lock pin.

Disengagement

To disengage the lift arm support device:

1. Raise the lift arm completely.

2. Stop the engine.

3. Remove the support device from the lift

cylinder and return it to its storage position on

the left rear link (Fig. 5).

4. Secure the support device with the lock pin.

1

Fig. 4:Lift Arm Support

Device Engaged

1. Lock Pin

2. Long End of Support

Device

Fig. 5: Lift Arm Support

Device Stored

908274/BP1202 18

Accessory Plug (Optional)

The optional accessory plug is located at the bottom of the left instrument

panel.

Heater (Optional)

Loaders with the optional heater have a dial on the left instrument panel to

control the fan operation of the heater.

Heater and Air Conditioner (Optional)

Loaders with the combined heater/air conditioner

have three controls on the left instrument panel:

fan speed, airconditioner on/off and temperature.

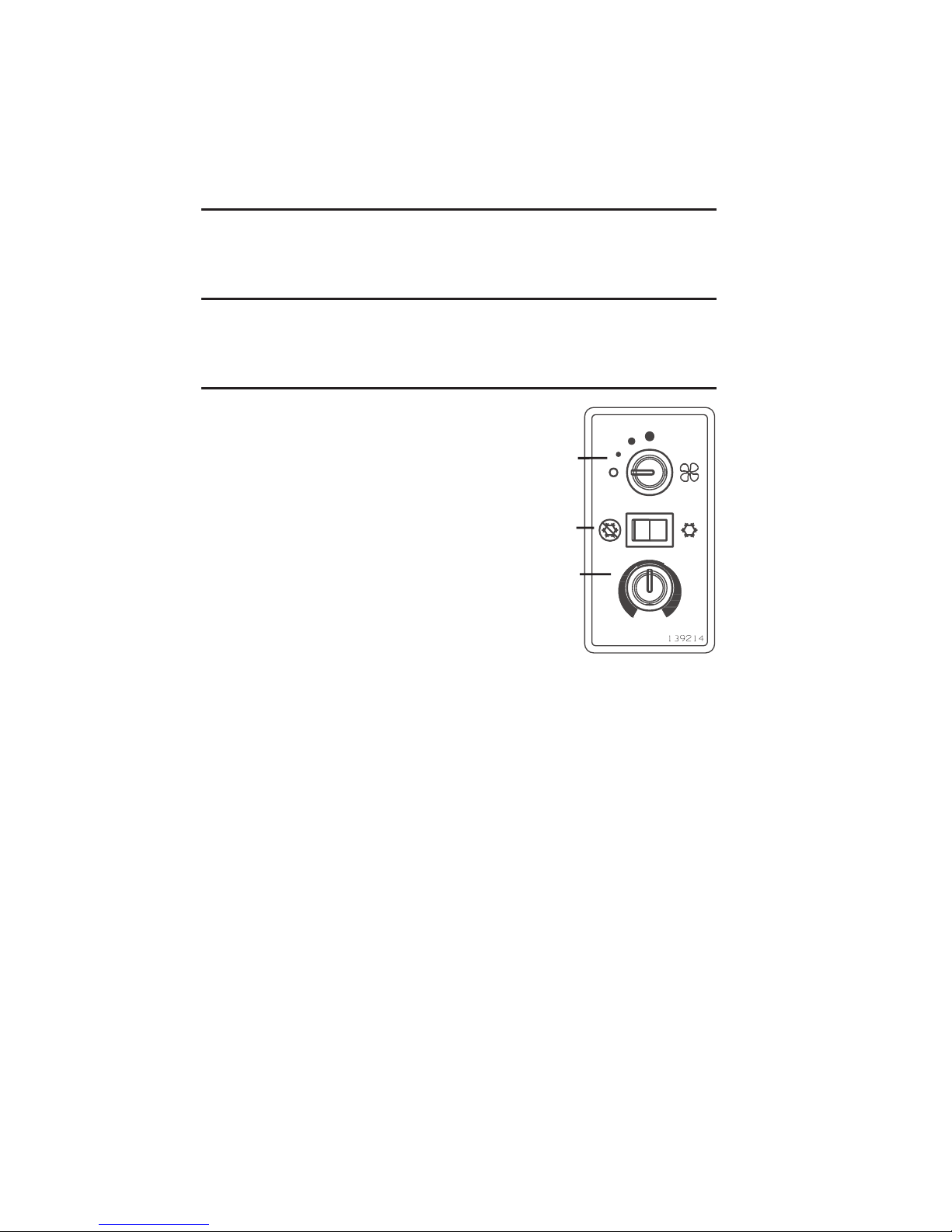

1

1. Fan Speed: Controls the rate at which air

exits the vents

2. Air Conditioner On/Off: Turns the air

conditioner unit

ON and OFF

3. Temperature: Controls the temperature of

the air exiting the vents

Hint: The operator will feelcooler withjust the two

front vents opened and aimed at the upper body.

2

3

Fig. 6: Heater/

Air Conditioner Controls

19 908274/BP1202

Speed Control

A right-hand controlled throttle lever is provided

on all models for adjusting the engine speed.

Move the control forward to increase the engine

speed and rearwardto decrease the engine speed.

T-Bar and Dual Hand Controls Only: A

right-foot operated accelerator pedal is provided

to control the engine RPM. The pedal linkage is

spring-loaded to return to the adjusted

hand-operated throttle setting.

Fig. 8: Foot Pedal (T-Bar & Dual Hand)

Fig. 7: Throttle Lever

Two-Speed Transmission (optional)

Loaders with two-speed transmissions have a

YELLOW button on the left

control handle for shifting between High (H) and Low (L). Shifting to High

allows the operator to exceed the standard 8 mph (13 km/h) upto a maximum

speed of 14 mph (22.5 km/h).

Note: Loaders sold to European Union nations can exceed the standard speed

up to a maximum speed of 12.4 mph (20 km/h).

Hydraglide™ Ride Control System (optional)

Loaders with the optional ride control feature have a

BLUE button on the right

control handle for shifting between normal mode and ride control mode. The

ride control system provides a smoother ride over uneven surfaces. Press the

button once to activate and again to deactivate. The ride control system is

automatically deactivated when the machine shuts down.

Note: The lift arm will drop slightly when ride control is activated.

908274/BP1202 20

Attachment Mounting

Your Gehl loader may be equipped with either a manual All-Tach™

attaching mechanism (hitch) or power All-Tach™ hitch for mounting a

bucket or other attachment.

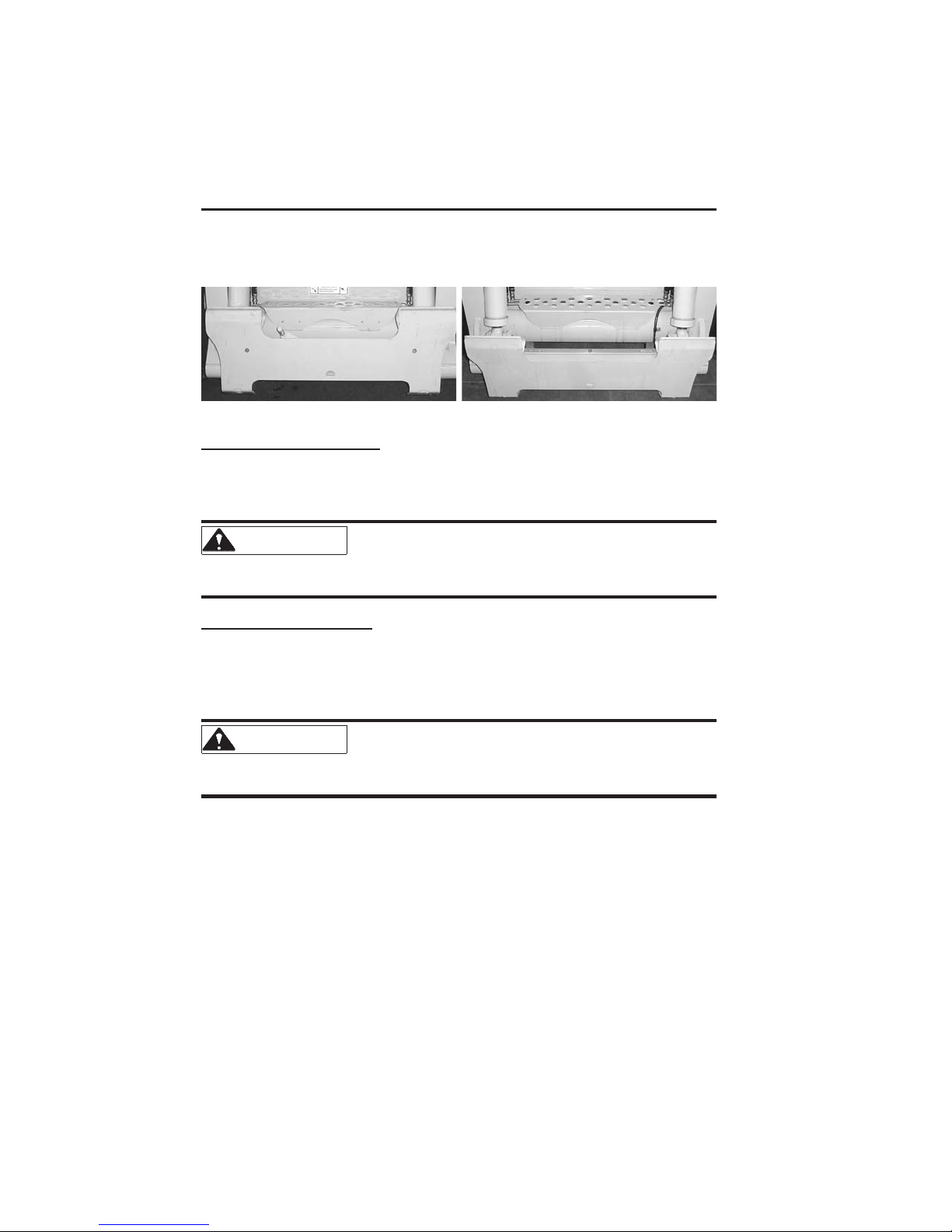

Fig. 9: Manual All-Tach Hitch

Fig. 10: Power All-Tach Hitch

Manual All-Tach Hitch

A manual latchlever engages the latch pins. Rotate the lever all theway to the

left to engage the latch pins. Rotate the lever all the way to the right to

disengage the latch pins. Refer to page 37 for more information.

WARNING

To prevent unexpected attachment release

from the hitch, be sure to secure the latch pins by rotating the lever

all the way to the left.

Power All-Tach Hitch

A switch on the left control panel activates the latch pins. Flags on the pins

indicated their position; the pin flags will move towards the outside of the

hitch when engaging the pins and towards the inside of the hitch when

disengaging the pins. Refer to page 37 for more information.

WARNING

To prevent unexpected attachment release

from the hitch, be sure the latch pins are secure by verifying that the

pin flags havemoved as faras possibleto theoutside ofthe hitch.

21 908274/BP1202

Instrument Panel

The instrument panel contains the following

switches and indicators. Symbols on the panel

represent various functions and conditions, and are

visible only when indicator lamps are on.

Left Panel

Note: Items 1 through 3 are indicator lights which

display the following:

1. Two-Speed High (optional) – Lights when high

speed is engaged.

2. Parking Brake – Lights when the parking brake

is applied.

3. Ride Control System (optional) – Lights when

the ride control system is activated.

4. Parking Brake Switch– Used tomanually apply

the parking brake.

5. Fan (optional) – Used to manually control the

fan for the air conditioner or heater.

6. Accessory Plug (optional) – A 12 VDC power

outlet.

7. Power All-Tach Hitch (optional) – Used to

operate the power All-Tach hitch.

1

2

3

7

5

6

Fig. 11: Left Panel

908274/BP1202 22

4

Right Panel

Note: Items 1 through 8 are indicator lights which

display the following:

1. Air Filter Restriction (optional) -Lights if

the air filter becomes restricted, warning the

operator to stop the engine. Inspect the air

cleaner filters and replace if necessary. During

normal operation, thisindicator should be

2. Engine Coolant Temperature – Lights if the

OFF.

9

engine coolant gets too hot, warning the

operator to stop the engine. Allow the engine

to cool, determine the cause for the high

10

temperature and correct the problem before

restarting the engine. During normal

operation, this indicator should be

OFF.

11

3. Hydraulic Oil Filter Restriction– Lights if

the hydraulic return filter becomes restricted,

warning the operator to stop the engine. Allow

the engine tocool then change the oiland filter.

1

5

During normal operation, this indicator should

be

OFF.

4. Hydraulic Oil Temperature – Lights if the

hydraulic oil becomes too hot, warning the

2

3

4

6

7

8

operator to stop engine. Allow the hydraulic

system to cool and determine the cause of the

high temperature. During normal operation,

this indicator should be

OFF.

12

5. Fasten Seatbelt – A momentary visual (and

audible) indicator to remind the operator to

fasten the seatbelt.

6. Engine Oil Pressure – Lights if the engine oil

13

pressure drops toolow, warning theoperator to

immediately stop theengine and determine the

cause for the pressure drop. During normal

operation, this indicator should be

OFF.

14

7. Battery – Lights if the charging voltage is too

high or too low. During normal operation, this

indicator should be

OFF.

8. Preheat Indicator Lamp – Lights when the

preheat is active. During normal operation,

this indicator should be

23 908274/BP1202

OFF.

Fig. 12: Right Panel

9. Hourmeter – Indicates the total operating hours of the loader.

10. Fuel Level Gauge – Indicates the amount of fuel in the tank.

11. Engine Coolant Temperature Gauge – Indicates the engine coolant

temperature.

12. Light Switch – Controls all the lights (standard and optional) on the

loader. Symbols denote the four positions of the light switch. In a

clockwise direction these are: Off, Flashers (Hazards), Work Lights with

Flashers, and Tail Lights. For thelights to function,the keyswitch must be

in the

RUN position.

13. Keyswitch – In a clockwise rotation, these positions are:

Off Position – With the key vertical (

OFF) in the keyswitch, power from

the battery is disconnected from the controls and instrument panel

electrical circuits. This is the only position the key can be inserted or

removed from the keyswitch.

On or Run Position – With the key turned one position clockwise (

from the vertical (

OFF) position, power from the battery is supplied to all

RUN)

control and instrument panel electrical circuits.

Start Position – With the key turned fully clockwise (

START) and held in

position, the electric starter energizes, startingthe engine. Releasethe key

after the engine starts (it returns to the

RUN position by itself).

Note: The engine cannot be started unless the operator sits in the seat and the

restraint bar is lowered.

14. Circuit Breakers – Four circuit breakers on the instrument panel protect

the loader’s electrical circuits.

Important: Do not attempt to defeat the circuit protection by jumping

across a circuit breaker or by using a higher amperage circuit breaker.

908274/BP1202 24

Loading...

Loading...