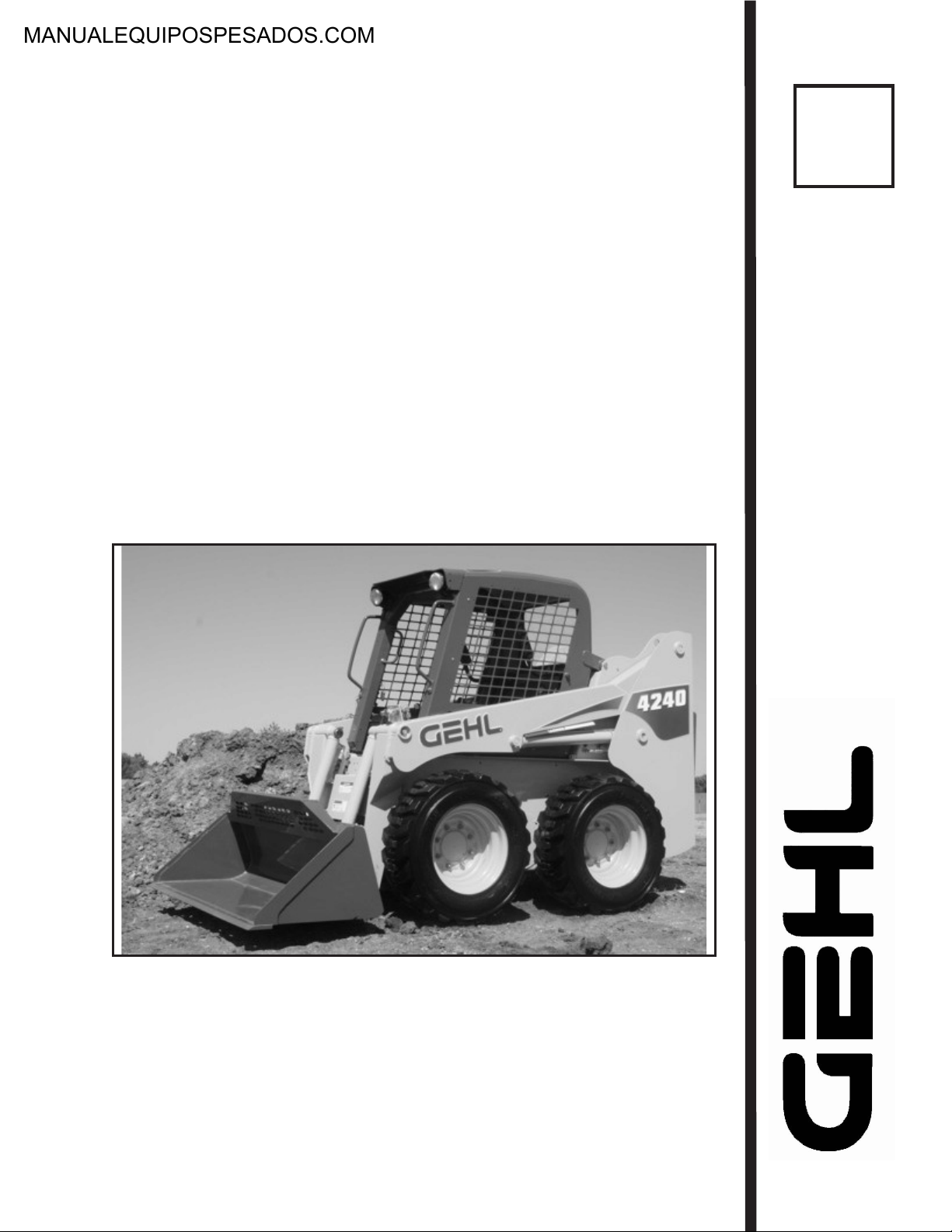

GEHL SL3640, SL3840, SL4240 SERVICE MANUAL

Form No.

SL3640, SL3840

and SL4240

Skid-Steer

Loaders

917170

Revision A

01/06

Service Manual

®

INTRODUCTION

With correct maintenance and proper use, Gehl skid-steer loaders will give years of dependable service. This service

manual is intended to be a guide in the assembly and disassembly, installation and removal, adjustment and testing,

troubleshooting and replacement of components that together make up the Gehl SL3640/3840/4240 family of

skid-steer loaders.

In many of the procedures found within, the installation steps are the exact opposite of the removal steps and vice

versa, and therefore, the opposite procedure is not written. Instead,a note to reverse the procedure will be stated.This

reduces redundancy and excessive pages in the manual. In cases though, where the assembly and disassembly or

removal and installation procedures differ and additional steps or safety concerns are paramount, the entire reverse

procedure will be written out to include the new information.

The Table of Contents and Index can be used to make the procedure you need to find an easier process. Also, there are

black tabs extending off the pages highlighting the chapters for those who prefer to thumb through the manual. Many

schematics, photographs, and line art drawings are used to help perform the necessary repairs, tests, or adjustments

that the SL3640/3840/4240 skid-steer loaders need to keep them in good running condition.

If you have any additional questions, please contact your authorized Gehl dealer or call the Gehl Service Department

for assistance.

Gehl is a registered trademark of the Gehl Company.

SL3640/3840/4240 TABLE OF CONTENTS

TABLE OF CONTENTS

Specifications Page 1-1

Specifications ······································································1-1

Tire Options ·······································································1-1

Buckets and Capacities ······························································1-1

General Specifications ·······························································1-2

Safety Page 2-1

General Information ·································································2-1

Signal Words ······································································2-1

Additional Safety Reminders ··························································2-1

Mandatory Safety Shutdown Procedure ·················································2-2

Liftarm Support Device ······························································2-3

Liftarm Support Device Engagement ···················································2-3

Liftarm Support Device Disengagement ·················································2-4

Rollover Protective Structure (ROPS) - Raising ···········································2-4

Rollover Protective Structure (ROPS) - Lowering ·········································2-5

Relieving Hydraulic Pressure··························································2-6

Skid-Steer Loader Raising Procedure ···················································2-6

Skid Loader Lowering Procedure ······················································2-7

Lubrication Page 3-1

General Information ·································································3-1

Hydraulic Oil Reservoir ······························································3-1

Crankcase Oil ······································································3-2

Hydraulic Oil Tank Drain Procedure ····················································3-2

Chaincases········································································3-3

Chaincase Oil Change Procedure·······················································3-3

Grease Fitting Locations ·····························································3-3

Cooling System Drain Procedure·······················································3-4

PRINTED IN USA i 917170/AP0106

TABLE OF CONTENTS SL3640/3840/4240

Mainframe Page 4-1

Introduction ·······································································4-1

Engine Access Cover Removal and Installation ···········································4-2

Rollover Protective Structure (ROPS) Removal and Installation ······························4-2

Seat Removal and Installation ·························································4-4

Seat Slide Replacement ······························································4-4

Rollover Protective Structure (ROPS) Rear Window Removal and Installation ··················4-5

Restraint Bar Removal and Installation ··················································4-7

All-Tach™ Bracket Removal and Installation·············································4-9

Liftarm Removal and Installation ······················································4-10

Liftarm Bushing Replacement ·························································4-13

Liftarm Stop Installation and Adjustment ················································4-14

Floor Cover and Kick Plate Removal and Installation ······································4-16

Fuel Level Sender Removal and Installation ··············································4-19

Rear Grille Removal and Installation····················································4-20

Wheel Drives Page 5-1

Introduction ·······································································5-1

Drive Chain Adjustment ·····························································5-2

Drive Chain Removal and Installation···················································5-3

Axle Removal and Installation·························································5-4

Controls Page 6-1

Introduction ·······································································6-1

Control Handle Removal and Installation ················································6-6

Control Handle Position and Tracking Adjustment·········································6-7

Dual Control Weldment Removal and Installation - T-Bar Controls ···························6-9

Neutral Centering Device and Pump Arm Removal and Installation ···························6-10

Neutral Centering Device Adjustment···················································6-11

Lift/Tilt Control Removal and Installation ···············································6-12

Lift/Tilt Control Adjustment ··························································6-13

Auxiliary Hydraulics Removal and Installation ···········································6-14

Auxiliary Hydraulics Adjustment ······················································6-15

Hand Throttle, Hand Throttle Cable and Throttle Rod Removal and Installation ·················6-16

Foot Throttle and Foot Throttle Cable Removal and Installation - T-Bar Controls ················6-18

Hand Throttle Adjustment ····························································6-19

Hand Throttle Tension Adjustment ·····················································6-20

Foot Throttle Adjustment - T-Bar Controls ···············································6-21

917170/AP0106 ii PRINTED IN USA

SL3640/3840/4240 TABLE OF CONTENTS

Hydrostatic System Page 7-1

Introduction ·······································································7-1

Troubleshooting Guide·······························································7-3

Charge Pressure Test and Adjustment ···················································7-7

Hydrostatic Pump Relief Valves ·······················································7-8

Drive Motor Hot Oil Shuttle Valve ·····················································7-8

Hydrostatic Pump Removal and Installation ··············································7-9

Hydrostatic Pump Flexible Drive Plate Removal and Installation ·····························7-11

Drive Motor Removal and Installation ··················································7-12

Hydraulic System Page 8-1

Introduction ·······································································8-1

Troubleshooting Guide·······························································8-3

System Pressure Test - Control Valve ···················································8-7

Tilt Cylinder Test ···································································8-9

Self-Leveling Valve Test ·····························································8-11

Self-Leveling Valve Adjustment ·······················································8-12

Lift Cylinder Test···································································8-13

Solenoid Valve Test ·································································8-14

Hydraulic Oil Filter Element Replacement ···············································8-16

Tilt Cylinder Removal and Installation ··················································8-19

Lift Cylinder Removal and Installation ··················································8-21

Lift and Tilt Cylinder Disassembly and Assembly ·········································8-23

Gear Pump Removal and Installation ···················································8-24

Self-Leveling Valve Removal and Installation ············································8-26

Safety Lock Valves - Removal and Installation ···········································8-27

Lift, Tilt and Brake Safety Lock Valves - Disassembly and Assembly ·························8-29

Control Valve Removal and Installation ·················································8-30

Hydraulic/Hydrostatic System Schematic ················································8-32

All-Tach is a trademark of the Gehl Company.

PRINTED IN USA iii 917170/AP0106

TABLE OF CONTENTS SL3640/3840/4240

Electrical System Page 9-1

Description of Operation ·····························································9-1

Troubleshooting Guide·······························································9-4

Relay Test and Operation·····························································9-6

Electrical Circuits···································································9-8

Seat Switch Removal and Installation ···················································9-15

Restraint Bar Switch Removal and Installation ············································9-16

Front and Rear Work Light Bulb Replacement ············································9-17

Electrical System Schematic ··························································9-18

Engine Page 10-1

Introduction ·······································································10-1

Troubleshooting Guide·······························································10-2

Engine Oil Filter Element Removal and Installation········································10-4

Air Cleaner Assembly Removal and Installation···········································10-7

Air Filter Element Removal and Installation ··············································10-7

Fuel Filter Removal and Installation ····················································10-8

Water Separator Element Removal and Installation ········································10-8

Electric Fuel Pump Removal and Installation ·············································10-9

Priming Diesel Fuel System···························································10-9

Battery Removal and Installation·······················································10-10

Starter Removal and Installation ·······················································10-11

Exhaust Assembly Removal and Installation ·············································10-11

Fan Belt Adjustment ································································10-12

Radiator/Cooler Removal and Installation················································10-15

Fan Shroud Removal and Installation - 4240 Models ·······································10-16

Fuel Tank Removal and Installation ····················································10-17

Engine Removal and Installation ·······················································10-19

Index

917170/AP0106 iv PRINTED IN USA

SL3640/3840/4240 SPECIFICATIONS

SPECIFICATIONS

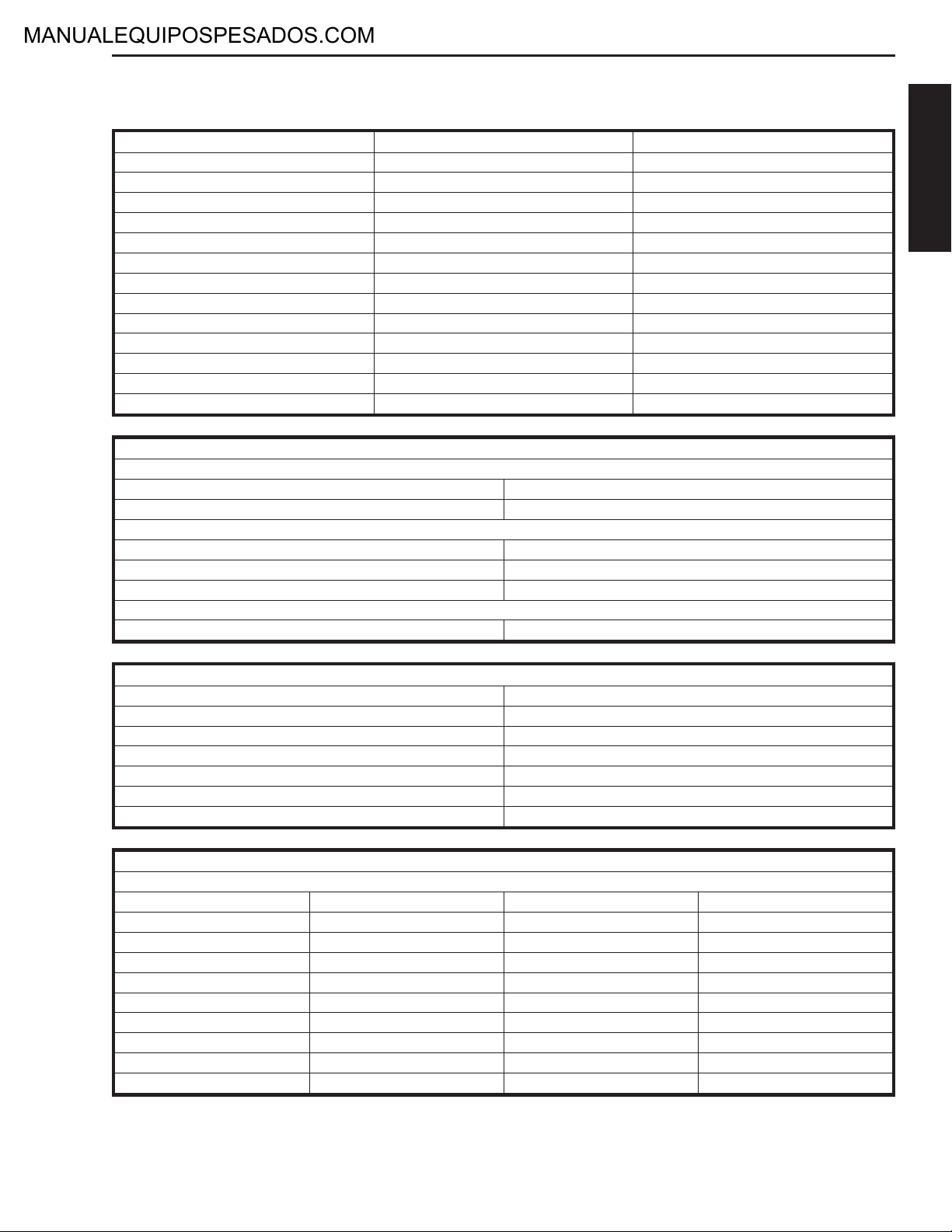

Engine Make Yanmar Yanmar

Model 3TNV88-XMS2 4TNV88-XMS2

Fuel Diesel Diesel

Displacement 100 CID (1,64 L) 133 CID (2,19 L)

Horsepower - Net (SAE) 35 hp (26 kW) @ 2600 rpm 46 hp (34 kW) @ 2600 rpm

Torque - Maximum 80 ft.-lbs. (108,5 N•m) @ 1200 rpm 103 ft.-lbs. (139,7 N•m) @ 1200 rpm

Rated Operating Load (SAE)* 1050 lbs. (476 kg) 1350 lbs. (612 kg)

Operating Weight 4000 lbs. (1814 kg) 4600 lbs. (2087 kg)

Shipping Weight 3515 lbs. (1594 kg) 4065 lbs. (1844 kg)

Engine Oil 7.6 US qts. (7,2 L) 9.1 US qts. (8,6 L)

Fuel Tank 10.3 US gal. (39 L) 12.4 US gal. (47 L)

Standard Flow Rate 14.5 gpm (55 L/min) 16.5 gpm (62 L/min)

Travel Speed (max) 6.4 mph (10,3 km/h) 6.8 mph (10,9 km/h)

Specifications below apply to all 3640, 3840 and 4240 models

Chaincases (each) 8.0 US qts. (7,6 L)

Hydraulic Reservoir 8.0 US gal. (30 L)

Battery 12-volt DC, 675 CCA

Starter 12-volt DC (2.0 kW)

Alternator 40 A

Main Hydraulic System Pressure 2750 psi (190 bar)

SL3640/3840 SL4240

SPECIFICATIONS

Capacities

Electrical

Hydraulic System

Tire Options

7 x 15 SS Narrow

8.5 x 15 - 8 ply Heavy-Duty Flotation

10.50 x 15 - 8 ply Heavy-Duty Flotation

10 x 16.5 - 6 ply Standard Flotation

10 x 16.5 - 8 ply Heavy-Duty Flotation/Foam-Filled

10 x 16.5 - 10 ply Severe-Duty/Severe-Duty Foam-Filled

6.5 x 16 Solid Rubber

Buckets and Capacities

Width Description Capacity (Heaped)

48 inches (1219 mm) Dirt/Construction 9.75 cubic feet 0,27 cubic meters

48 inches (1219 mm) Utility 11.9 cubic feet 0,34 cubic meters

54 inches (1372 mm) Dirt/Construction 9.5 cubic feet 0,27 cubic meters

54 inches (1372 mm) Utility 13.5 cubic feet 0,38 cubic meters

55 inches (1397 mm) Dirt/Construction 10.5 cubic feet 0,30 cubic meters

60 inches (1524 mm) Utility 15.2 cubic feet 0,43 cubic meters

61 inches (1550 mm) Dirt/Construction 11.7 cubic feet 0,33 cubic meters

61.5 inches (1562 mm) Low Profile 12.6 cubic feet 0,36 cubic meters

61.5 inches (1562 mm) Earth & Foundry 13.0 cubic feet 0,37 cubic meters

61.5 inches (1562 mm) Construction 13.0 cubic feet 0,37 cubic meters

3640/3840 SAE Rated Operating Load: Operating load rated with a 54" (1372 mm) dirt/construction bucket in accordance with SAE J818.

4240 SAE Rated Operating Load: Operating load rated with a 60" (1524 mm) dirt/construction bucket in accordance with SAE J818.

PRINTED IN USA 1-1 917170/AP0106

SPECIFICATIONS SL3640/3840/4240

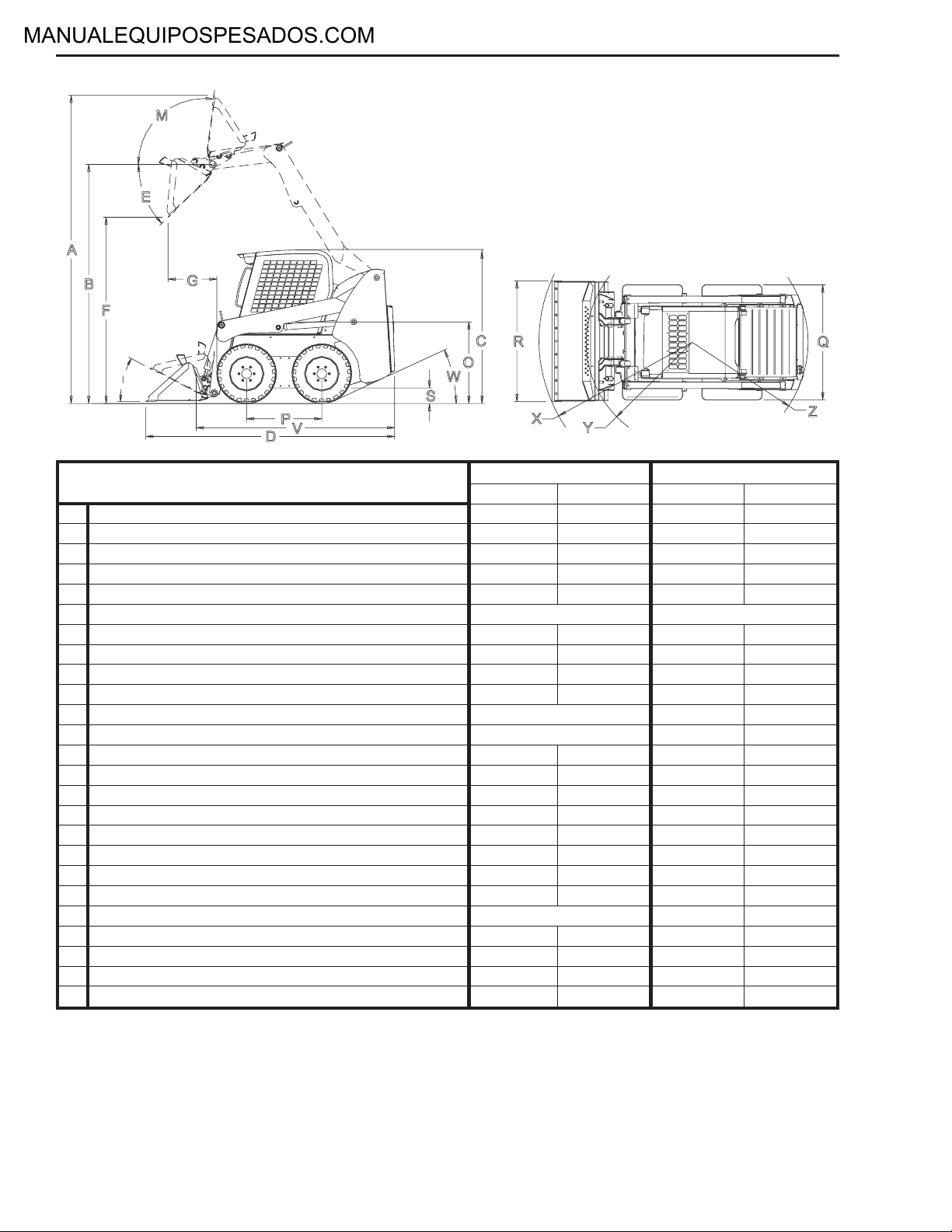

General Specifications

A Overall operation height - fully raised 139.6 3546 141.1 3584

B Height to hinge pin - fully raised 108.1 2746 110 2794

C Overall height - top of ROPS 70.3 1786 71.9 1826

D Overall length (w/54” dirt/construction bucket down) 114.5 2908

Overall length (w/60” dirt/construction bucket down) 116.2 2952

E Dump angle @ full height 42° 42°

F Dump height (w/54” dirt/construction bucket) 84.5 2146

Dump height (w/60” dirt/construction bucket) 86.5 2197

G Dump reach - w/54” dirt/construction bucket (full height) 22.8 578

Dump reach - w/60” dirt/construction bucket (full height) 20.6 523

I Rollback at ground 29° 29°

M Rollback at full height 99° 99°

O Seat-to-ground height 32.6 828 33.6 853

P Wheelbase 34.5 876 36.7 932

Q Overall width - no bucket (w/27 x 8.5 x 15 tires) 48.4/58.2 1229/1428

Overall width - no bucket (w/10 x 16.5 tires) 52.5/58.4 1334/1483

R Overall bucket width - 54” dirt/construction bucket 55.3 1403

Overall bucket width - 60” dirt/construction bucket 60.6 1539

S Ground clearance to mainframe (between wheels) 6 152 8.3 211

V Overall length (no bucket) 88.9 2258 91.1 2314

W Departure angle 26° 29°

X Clearance circle - front (w/54” dirt/construction bucket) 69.4 1763

Clearance circle - front (w/60” utility bucket) 69.2 1758

Y Clearance circle - front (no bucket) 44.1 1120 43.4 1102

Z Clearance circle - rear 54.1 1374 58.4 1484

SL3640/3840 (1) SL4240 (2)

inches millimeters inches millimeters

(1) Dimensions with 27 x 8.50 x 15 HD tires and 54” bucket.

(2) Dimensions with 10.00 x 16.5 HD tires and 60” bucket.

917170/AP0106 1-2 PRINTED IN USA

Loading...

Loading...