Page 1

Form No.

SL3640, SL3840

and SL4240

Skid-Steer

Loaders

917170

Revision A

01/06

Service Manual

®

Page 2

INTRODUCTION

With correct maintenance and proper use, Gehl skid-steer loaders will give years of dependable service. This service

manual is intended to be a guide in the assembly and disassembly, installation and removal, adjustment and testing,

troubleshooting and replacement of components that together make up the Gehl SL3640/3840/4240 family of

skid-steer loaders.

In many of the procedures found within, the installation steps are the exact opposite of the removal steps and vice

versa, and therefore, the opposite procedure is not written. Instead,a note to reverse the procedure will be stated.This

reduces redundancy and excessive pages in the manual. In cases though, where the assembly and disassembly or

removal and installation procedures differ and additional steps or safety concerns are paramount, the entire reverse

procedure will be written out to include the new information.

The Table of Contents and Index can be used to make the procedure you need to find an easier process. Also, there are

black tabs extending off the pages highlighting the chapters for those who prefer to thumb through the manual. Many

schematics, photographs, and line art drawings are used to help perform the necessary repairs, tests, or adjustments

that the SL3640/3840/4240 skid-steer loaders need to keep them in good running condition.

If you have any additional questions, please contact your authorized Gehl dealer or call the Gehl Service Department

for assistance.

Gehl is a registered trademark of the Gehl Company.

Page 3

SL3640/3840/4240 TABLE OF CONTENTS

TABLE OF CONTENTS

Specifications Page 1-1

Specifications ······································································1-1

Tire Options ·······································································1-1

Buckets and Capacities ······························································1-1

General Specifications ·······························································1-2

Safety Page 2-1

General Information ·································································2-1

Signal Words ······································································2-1

Additional Safety Reminders ··························································2-1

Mandatory Safety Shutdown Procedure ·················································2-2

Liftarm Support Device ······························································2-3

Liftarm Support Device Engagement ···················································2-3

Liftarm Support Device Disengagement ·················································2-4

Rollover Protective Structure (ROPS) - Raising ···········································2-4

Rollover Protective Structure (ROPS) - Lowering ·········································2-5

Relieving Hydraulic Pressure··························································2-6

Skid-Steer Loader Raising Procedure ···················································2-6

Skid Loader Lowering Procedure ······················································2-7

Lubrication Page 3-1

General Information ·································································3-1

Hydraulic Oil Reservoir ······························································3-1

Crankcase Oil ······································································3-2

Hydraulic Oil Tank Drain Procedure ····················································3-2

Chaincases········································································3-3

Chaincase Oil Change Procedure·······················································3-3

Grease Fitting Locations ·····························································3-3

Cooling System Drain Procedure·······················································3-4

PRINTED IN USA i 917170/AP0106

Page 4

TABLE OF CONTENTS SL3640/3840/4240

Mainframe Page 4-1

Introduction ·······································································4-1

Engine Access Cover Removal and Installation ···········································4-2

Rollover Protective Structure (ROPS) Removal and Installation ······························4-2

Seat Removal and Installation ·························································4-4

Seat Slide Replacement ······························································4-4

Rollover Protective Structure (ROPS) Rear Window Removal and Installation ··················4-5

Restraint Bar Removal and Installation ··················································4-7

All-Tach™ Bracket Removal and Installation·············································4-9

Liftarm Removal and Installation ······················································4-10

Liftarm Bushing Replacement ·························································4-13

Liftarm Stop Installation and Adjustment ················································4-14

Floor Cover and Kick Plate Removal and Installation ······································4-16

Fuel Level Sender Removal and Installation ··············································4-19

Rear Grille Removal and Installation····················································4-20

Wheel Drives Page 5-1

Introduction ·······································································5-1

Drive Chain Adjustment ·····························································5-2

Drive Chain Removal and Installation···················································5-3

Axle Removal and Installation·························································5-4

Controls Page 6-1

Introduction ·······································································6-1

Control Handle Removal and Installation ················································6-6

Control Handle Position and Tracking Adjustment·········································6-7

Dual Control Weldment Removal and Installation - T-Bar Controls ···························6-9

Neutral Centering Device and Pump Arm Removal and Installation ···························6-10

Neutral Centering Device Adjustment···················································6-11

Lift/Tilt Control Removal and Installation ···············································6-12

Lift/Tilt Control Adjustment ··························································6-13

Auxiliary Hydraulics Removal and Installation ···········································6-14

Auxiliary Hydraulics Adjustment ······················································6-15

Hand Throttle, Hand Throttle Cable and Throttle Rod Removal and Installation ·················6-16

Foot Throttle and Foot Throttle Cable Removal and Installation - T-Bar Controls ················6-18

Hand Throttle Adjustment ····························································6-19

Hand Throttle Tension Adjustment ·····················································6-20

Foot Throttle Adjustment - T-Bar Controls ···············································6-21

917170/AP0106 ii PRINTED IN USA

Page 5

SL3640/3840/4240 TABLE OF CONTENTS

Hydrostatic System Page 7-1

Introduction ·······································································7-1

Troubleshooting Guide·······························································7-3

Charge Pressure Test and Adjustment ···················································7-7

Hydrostatic Pump Relief Valves ·······················································7-8

Drive Motor Hot Oil Shuttle Valve ·····················································7-8

Hydrostatic Pump Removal and Installation ··············································7-9

Hydrostatic Pump Flexible Drive Plate Removal and Installation ·····························7-11

Drive Motor Removal and Installation ··················································7-12

Hydraulic System Page 8-1

Introduction ·······································································8-1

Troubleshooting Guide·······························································8-3

System Pressure Test - Control Valve ···················································8-7

Tilt Cylinder Test ···································································8-9

Self-Leveling Valve Test ·····························································8-11

Self-Leveling Valve Adjustment ·······················································8-12

Lift Cylinder Test···································································8-13

Solenoid Valve Test ·································································8-14

Hydraulic Oil Filter Element Replacement ···············································8-16

Tilt Cylinder Removal and Installation ··················································8-19

Lift Cylinder Removal and Installation ··················································8-21

Lift and Tilt Cylinder Disassembly and Assembly ·········································8-23

Gear Pump Removal and Installation ···················································8-24

Self-Leveling Valve Removal and Installation ············································8-26

Safety Lock Valves - Removal and Installation ···········································8-27

Lift, Tilt and Brake Safety Lock Valves - Disassembly and Assembly ·························8-29

Control Valve Removal and Installation ·················································8-30

Hydraulic/Hydrostatic System Schematic ················································8-32

All-Tach is a trademark of the Gehl Company.

PRINTED IN USA iii 917170/AP0106

Page 6

TABLE OF CONTENTS SL3640/3840/4240

Electrical System Page 9-1

Description of Operation ·····························································9-1

Troubleshooting Guide·······························································9-4

Relay Test and Operation·····························································9-6

Electrical Circuits···································································9-8

Seat Switch Removal and Installation ···················································9-15

Restraint Bar Switch Removal and Installation ············································9-16

Front and Rear Work Light Bulb Replacement ············································9-17

Electrical System Schematic ··························································9-18

Engine Page 10-1

Introduction ·······································································10-1

Troubleshooting Guide·······························································10-2

Engine Oil Filter Element Removal and Installation········································10-4

Air Cleaner Assembly Removal and Installation···········································10-7

Air Filter Element Removal and Installation ··············································10-7

Fuel Filter Removal and Installation ····················································10-8

Water Separator Element Removal and Installation ········································10-8

Electric Fuel Pump Removal and Installation ·············································10-9

Priming Diesel Fuel System···························································10-9

Battery Removal and Installation·······················································10-10

Starter Removal and Installation ·······················································10-11

Exhaust Assembly Removal and Installation ·············································10-11

Fan Belt Adjustment ································································10-12

Radiator/Cooler Removal and Installation················································10-15

Fan Shroud Removal and Installation - 4240 Models ·······································10-16

Fuel Tank Removal and Installation ····················································10-17

Engine Removal and Installation ·······················································10-19

Index

917170/AP0106 iv PRINTED IN USA

Page 7

SL3640/3840/4240 SPECIFICATIONS

SPECIFICATIONS

Engine Make Yanmar Yanmar

Model 3TNV88-XMS2 4TNV88-XMS2

Fuel Diesel Diesel

Displacement 100 CID (1,64 L) 133 CID (2,19 L)

Horsepower - Net (SAE) 35 hp (26 kW) @ 2600 rpm 46 hp (34 kW) @ 2600 rpm

Torque - Maximum 80 ft.-lbs. (108,5 N•m) @ 1200 rpm 103 ft.-lbs. (139,7 N•m) @ 1200 rpm

Rated Operating Load (SAE)* 1050 lbs. (476 kg) 1350 lbs. (612 kg)

Operating Weight 4000 lbs. (1814 kg) 4600 lbs. (2087 kg)

Shipping Weight 3515 lbs. (1594 kg) 4065 lbs. (1844 kg)

Engine Oil 7.6 US qts. (7,2 L) 9.1 US qts. (8,6 L)

Fuel Tank 10.3 US gal. (39 L) 12.4 US gal. (47 L)

Standard Flow Rate 14.5 gpm (55 L/min) 16.5 gpm (62 L/min)

Travel Speed (max) 6.4 mph (10,3 km/h) 6.8 mph (10,9 km/h)

Specifications below apply to all 3640, 3840 and 4240 models

Chaincases (each) 8.0 US qts. (7,6 L)

Hydraulic Reservoir 8.0 US gal. (30 L)

Battery 12-volt DC, 675 CCA

Starter 12-volt DC (2.0 kW)

Alternator 40 A

Main Hydraulic System Pressure 2750 psi (190 bar)

SL3640/3840 SL4240

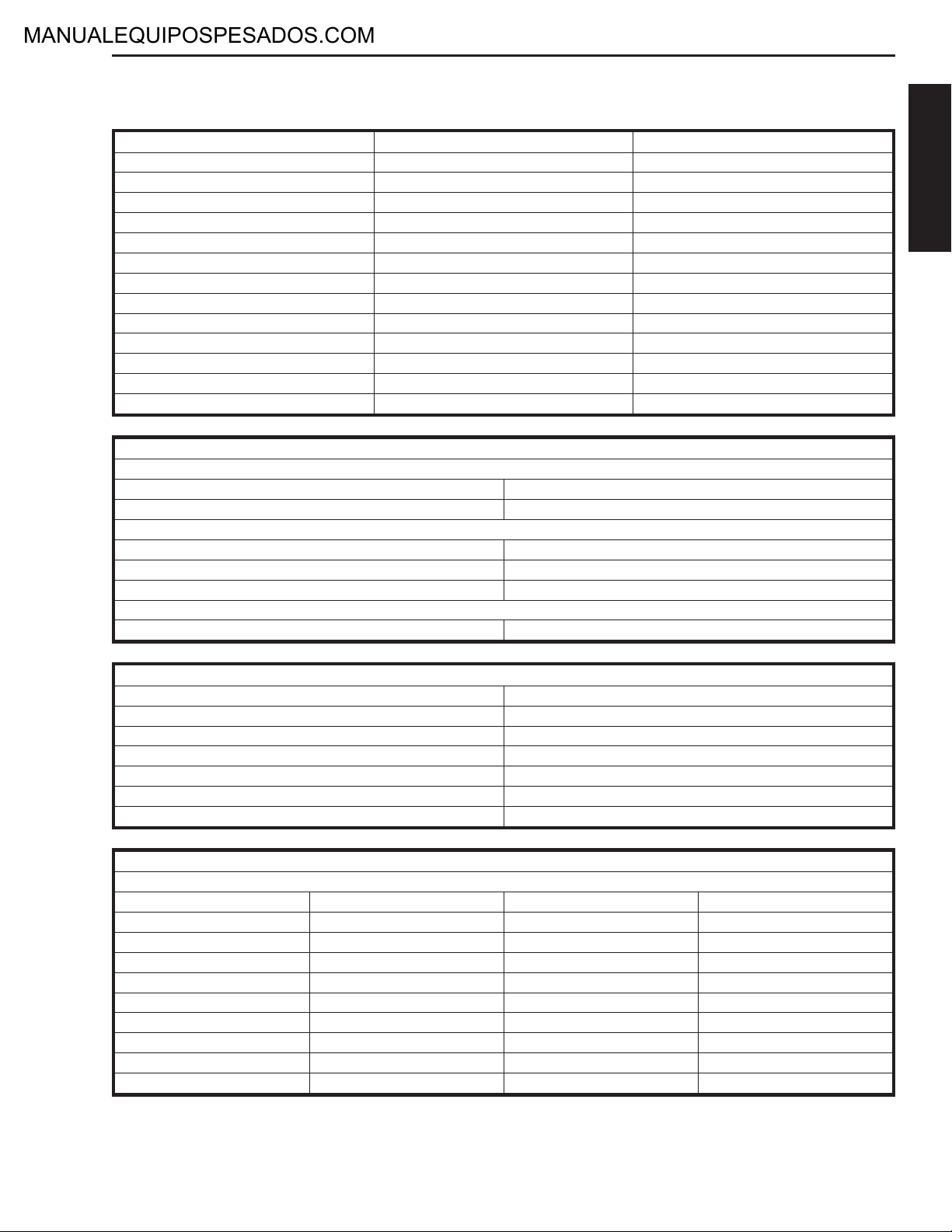

SPECIFICATIONS

Capacities

Electrical

Hydraulic System

Tire Options

7 x 15 SS Narrow

8.5 x 15 - 8 ply Heavy-Duty Flotation

10.50 x 15 - 8 ply Heavy-Duty Flotation

10 x 16.5 - 6 ply Standard Flotation

10 x 16.5 - 8 ply Heavy-Duty Flotation/Foam-Filled

10 x 16.5 - 10 ply Severe-Duty/Severe-Duty Foam-Filled

6.5 x 16 Solid Rubber

Buckets and Capacities

Width Description Capacity (Heaped)

48 inches (1219 mm) Dirt/Construction 9.75 cubic feet 0,27 cubic meters

48 inches (1219 mm) Utility 11.9 cubic feet 0,34 cubic meters

54 inches (1372 mm) Dirt/Construction 9.5 cubic feet 0,27 cubic meters

54 inches (1372 mm) Utility 13.5 cubic feet 0,38 cubic meters

55 inches (1397 mm) Dirt/Construction 10.5 cubic feet 0,30 cubic meters

60 inches (1524 mm) Utility 15.2 cubic feet 0,43 cubic meters

61 inches (1550 mm) Dirt/Construction 11.7 cubic feet 0,33 cubic meters

61.5 inches (1562 mm) Low Profile 12.6 cubic feet 0,36 cubic meters

61.5 inches (1562 mm) Earth & Foundry 13.0 cubic feet 0,37 cubic meters

61.5 inches (1562 mm) Construction 13.0 cubic feet 0,37 cubic meters

3640/3840 SAE Rated Operating Load: Operating load rated with a 54" (1372 mm) dirt/construction bucket in accordance with SAE J818.

4240 SAE Rated Operating Load: Operating load rated with a 60" (1524 mm) dirt/construction bucket in accordance with SAE J818.

PRINTED IN USA 1-1 917170/AP0106

Page 8

SPECIFICATIONS SL3640/3840/4240

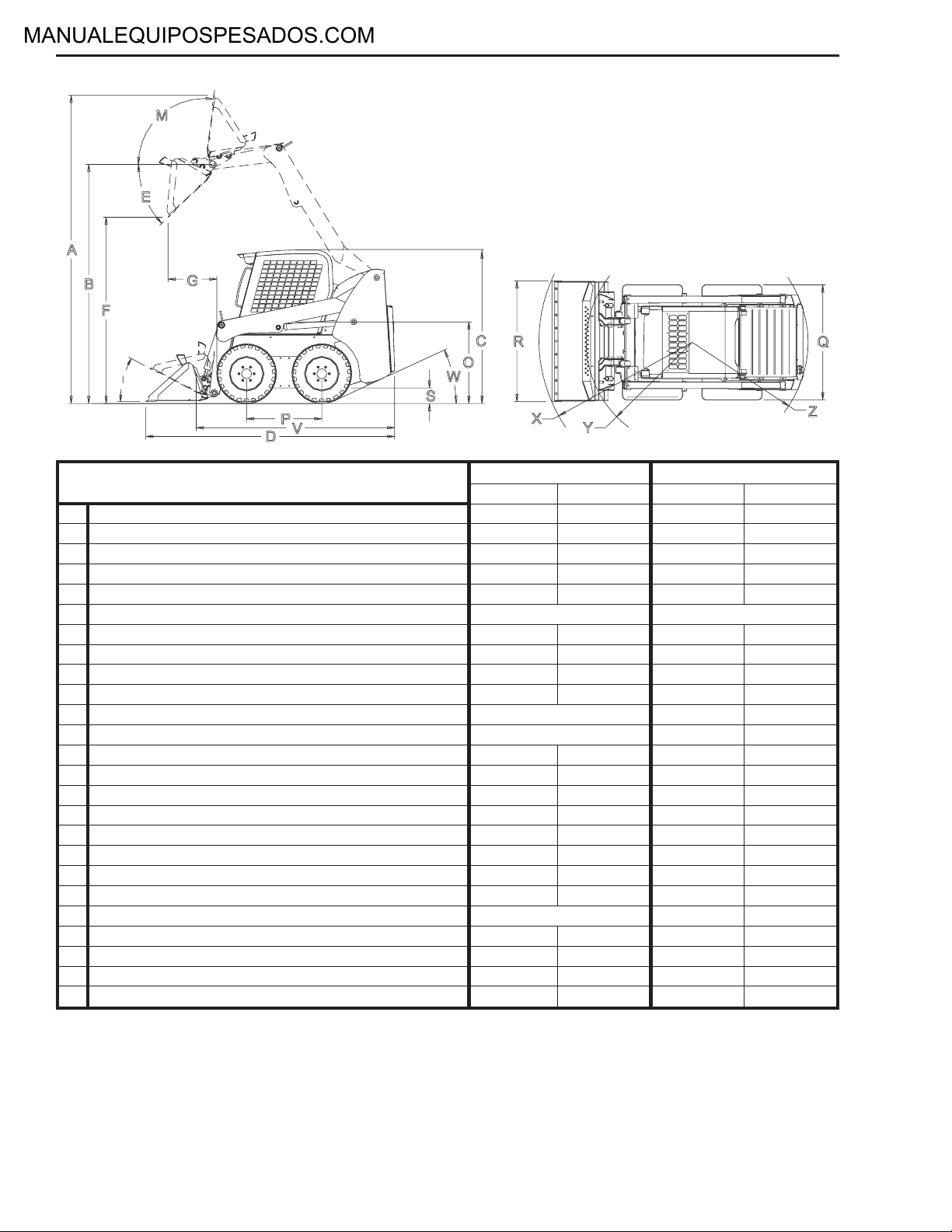

General Specifications

A Overall operation height - fully raised 139.6 3546 141.1 3584

B Height to hinge pin - fully raised 108.1 2746 110 2794

C Overall height - top of ROPS 70.3 1786 71.9 1826

D Overall length (w/54” dirt/construction bucket down) 114.5 2908

Overall length (w/60” dirt/construction bucket down) 116.2 2952

E Dump angle @ full height 42° 42°

F Dump height (w/54” dirt/construction bucket) 84.5 2146

Dump height (w/60” dirt/construction bucket) 86.5 2197

G Dump reach - w/54” dirt/construction bucket (full height) 22.8 578

Dump reach - w/60” dirt/construction bucket (full height) 20.6 523

I Rollback at ground 29° 29°

M Rollback at full height 99° 99°

O Seat-to-ground height 32.6 828 33.6 853

P Wheelbase 34.5 876 36.7 932

Q Overall width - no bucket (w/27 x 8.5 x 15 tires) 48.4/58.2 1229/1428

Overall width - no bucket (w/10 x 16.5 tires) 52.5/58.4 1334/1483

R Overall bucket width - 54” dirt/construction bucket 55.3 1403

Overall bucket width - 60” dirt/construction bucket 60.6 1539

S Ground clearance to mainframe (between wheels) 6 152 8.3 211

V Overall length (no bucket) 88.9 2258 91.1 2314

W Departure angle 26° 29°

X Clearance circle - front (w/54” dirt/construction bucket) 69.4 1763

Clearance circle - front (w/60” utility bucket) 69.2 1758

Y Clearance circle - front (no bucket) 44.1 1120 43.4 1102

Z Clearance circle - rear 54.1 1374 58.4 1484

SL3640/3840 (1) SL4240 (2)

inches millimeters inches millimeters

(1) Dimensions with 27 x 8.50 x 15 HD tires and 54” bucket.

(2) Dimensions with 10.00 x 16.5 HD tires and 60” bucket.

917170/AP0106 1-2 PRINTED IN USA

Page 9

SL3640/3840/4240 SAFETY

General Information

Signal Words

DANGER

“DANGER” indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

The above safety alert symbol means: ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

It stresses an attitude of “Heads Up for Safety” and can

be found throughout this service manual and on the

decals on the machine.

Before operating or working on this machine, read and

study the following safety information. In addition, be

sure that everyone who operates or works on this

equipment is familiar with these safety precautions. It is

essential to have competent and careful operators, who

are not physically or mentally impaired, and who are

thoroughly trained in the safe operation of the machine

and the handling of loads. It is recommended that the

operator be capable of obtaining a valid motor vehicle

operator’s license.

The use ofskid-steer loaders is subject tocertain hazards

that cannot be eliminated bymechanical means, but only

by exercising intelligence, care and common sense.

Such hazards include, but are not limited to, hillside

operation, overloading, instability of the load, poor

maintenance and using the equipment for a purpose for

which it is not intended or designed.

The Gehl Company ALWAYS considers the operator’s

safety when designing its machinery and guards

exposed moving parts for the operator’s protection.

However, some areas cannot be guarded or shielded in

order to assure proper operation. Furthermore, the

Operator’s Manual and the decals on the machine warn

of additional hazards and should be read and observed

closely.

These topics in this chapter include procedures, which,

when followed, will allow safe performance of service

procedures: Mandatory Safety Shutdown Procedure,

Lift Cylinder Liftarm Support Device, Roll-Over

Protective Structure (ROPS)/Falling Object Protective

Structure (FOPS) LockMechanism, Loader Raising and

Lowering Procedures, and Relieving Hydraulic

Pressure.

SAFETY

WARNING

“WARNING” indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

“CAUTION” indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury. May

also alert against unsafe practices.

Additional Safety Reminders

Read and understand the Service Manual

and all decals before maintaining, adjusting

or servicing this equipment.

Doors, Guards and Shields - Some

photographs in this manual may show doors, guards and

shields open or removed for illustrative purposes only.

BE SURE all doors, guards and shields are in their

proper operating positions BEFORE starting engine to

operate unit.

Damaged or Worn-out Parts - For safe operation,

replace damaged or worn-out parts with genuine Gehl

service parts, BEFORE operating this equipment.

Attachments - Gehl skid-steer loaders are designed and

intended to be used only with Gehl Company

attachments or approved referral attachments. The Gehl

Company cannot be responsible for operator safety if the

loader is used with a non-approved attachment.

Battery Safety - To avoid injury from a

spark or short circuit, disconnect the

negative (-) battery cable before servicing

any part of the electrical system. Do not

tip the battery more than 45º to avoid spilling electrolyte.

PRINTED IN USA 2-1 917170/AP0106

Page 10

SAFETY SL3640/3840/4240

Loader Stability - A skid-steer loader’s stability is

determined by its wheelbase and tread width. The

following elements can affect stability: terrain, engine

speed, load being carried or dumped, and sudden control

movements.

DISREGARDING ANY OF THESE FACTORS CAN

CAUSE THE LOADER TO TIP, POSSIBLY

RESULTING IN DEATH OR SERIOUS INJURY.

Therefore, ALWAYS have the operator restraint bar

lowered and wearthe seat belt.Operate the controlsonly

from the operator’s seat. Operate the controls smoothly

and gradually at an appropriate engine speed that

matches the operating conditions.

DO NOT exceed the rated operating load of the

machine. For additional stability when operating on

inclines or ramps, ALWAYS travel with the heavier end

of the loader toward the top of the incline.

ALWAYS look to the rear before backing up.

When parking machine, before leaving seat, check

restraint bar for proper operation. The restraint bar,

when raised, applies the parking brake and deactivates

lift/tilt controls and auxiliary hydraulics.

Keyswitch - NEVER attempt to bypass the keyswitch to

start the engine. Use the jump-starting procedure

detailed in the Service chapter of the Operator’s Manual.

Hydraulic Fluid Leaks - NEVER use

hands to search for hydraulic fluid leaks.

Instead, use paper or cardboard. Fluid under

pressure can be invisible, penetrate the skin

and cause a serious injury. If any fluid is injected into

skin, see a doctor at once. Injected fluid MUST be

surgically removed by a doctor or gangrene may result.

DO NOT drive too close to an excavation or ditch. BE

SURE that the surrounding ground has adequate

strength to support the weight of the loader and the load.

DO NOT smoke or have any

spark-producing equipment in the area

while filling the fuel tank or while working

on the fuel or hydraulic systems.

Exhaust Gases - Exhaust fumes can kill. DO NOT

operate this machine in an enclosed area unless there is

adequate ventilation.

Engine - NEVER use ether or starting fluid.

People - NEVER carry riders. DO NOT allow others to

ride on the machine or attachment, because they could

fall or cause an accident.

BE SURE all persons are away from the machine and

give a warning before starting the engine.

ALWAYS face machine and use handholds and steps

when getting on or off. DO NOT jump off machine.

Wear appropriate ear protection for

prolonged exposure to excessive noise.

ALWAYS perform a daily inspection of the

machine BEFORE using it. Look for

damage, loose or missing parts, leaks, etc.

Remove trash and debris from the machine and engine

compartment each day to minimize risk of fire.

New operators MUST operate loader in an open area

away from bystanders. Practice with controls until

loader can be operated safely and efficiently.

Mandatory Safety Shutdown Procedure

Wear Safety Glasses - ALWAYS wear

safety glasses with side shields when

operating the machine or striking metal

against metal. In addition, it is

recommended that a softer (chip-resistant) material be

used to cushion the blow. Failure to heed could lead to

serious injury to eye(s) or other parts of the body.

ALWAYS wear safety glasses when searching for

hydraulic leaks or when working near batteries.

Loaded Bucket/Fork - DO NOT raise or drop a loaded

bucket or fork suddenly. Abrupt movements under load

can cause serious loader instability.

NEVER push the lift control into the “float” position

with the bucket or attachment loaded or raised, because

this will cause the liftarm to lower rapidly.

917170/AP0106 2-2 PRINTED IN USA

BEFORE cleaning, adjusting, lubricating, or

servicing the unit or leaving it unattended:

1. Move the drive control handle(s) to the

NEUTRAL position.

2. Lower the liftarm and attachment completely.

3. Move the throttle to the low idle position, shut off

the engine and remove the key.

4. However, if the liftarm MUST be left in the

“raised” position, BE SURE to properly engage the

liftarm support device.

Only after these precautions can you be sure it is

safe to proceed. Failure to follow the above

procedure could lead to death or serious injury.

Page 11

SL3640/3840/4240 SAFETY

Fig. 2-1 The lock pin secures the liftarm support device

inside the left liftarm to a welded pin.

Liftarm Support Device

WARNING

BEFORE leaving the operator’s compartment

to work on the loader with the liftarm raised,

ALWAYS engage the liftarm support device.

Turn the keyswitch to OFF, remove the key

and take it with you.

Many service procedures require a raised liftarm to

allow easier access to loader components. For operator

and service personnel safety, a liftarm support device is

standard on Gehl skid-steer loaders. Used as a cylinder

block, it helps prevent a raised liftarm from lowering

unexpectedly.

BE SURE to engage the liftarm support device

whenever the liftarm is raised. When the device is not

being used, secure it tothe anchor on theunderside of the

liftarm using the lock pin and retainer provided.

SAFETY

Fig. 2-2 Pull down and pull out on the lock pin to

release the liftarm support device.

The liftarm support device is a safety device which must

be kept in proper operating condition at ALL times.

The following procedures outline the correct way to

engage and disengage the liftarm support device.

Liftarm Support Device Engagement

1. Lower liftarm until contact with loader frame.

2. Turn the keyswitch to the OFF position to stop the

engine.

3. Leave the operator’s compartment. Pull down on

lock pin button to release its locking mechanism.

Pull out lock pin holding support device up against

liftarm. Allow support device to come down into

contact with lift cylinder. Figs. 2-1, 2-2, 2-3

4. Return to the operator’scompartment and restart the

engine.

5. Use lift control to raise liftarm until the lift arm

support device drops over the end of the lift cylinder

and around cylinder rod. Slowly lower liftarm until

the free end of the support device contacts the top

(rod end) of the lift cylinder. Fig. 2-4

6. Make sure the support device is secure against the

Fig. 2-3 The liftarm support device rests on top of the

lift cylinder base.

PRINTED IN USA 2-3 917170/AP0106

cylinder end. Then, stop the engine, remove the key

and leave the operator’s compartment.

Page 12

SAFETY SL3640/3840/4240

Liftarm Support Device Disengagement

WARNING

NEVER leave the operator’s compartment to

disengage the liftarm support device with the

engine running.

To return the liftarm support device to its storage

position, proceed as follows:

1. Raise liftarm completely.

2. Turn keyswitch to OFF position to stop engine,

remove key and take it with you.

WARNING

BEFORE testing the machine, ALWAYS clear

people from the area.

3. Before leaving operator’s compartment, check to

make sure liftarm is being held in the raised position

by the solenoid valve.

NOTE: With the keyswitch OFF, and the solenoid

valve working, the liftarm will stay raised when the lift

control is moved forward. If the valve does NOT hold

the liftarm and it begins to lower, do NOT leave the

operator’s compartment. Instead, have someone store

the support device for you. Then, contact your Gehl

dealer to determine the reason why the liftarm lowers

while the keyswitch is in the OFF position.

4. To store liftarm support device, lift it up and inside

the liftarm. Insert lock pin through hole in welded

lock pin below the support device. Figs. 2-1, 2-2

Fig. 2-4 Lower liftarm until liftarm support device

contacts the rod end of the lift cylinder.

Fig. 2-5 Front left ROPS mounting area where the

ROPS is secured to the chassis. Right side

same.

ROPS – Raising

For service, the ROPS can be unbolted and tilted back.

Gas-charged springs help tilt it back. A self-actuating

lock mechanism engages to lock the ROPS in a

rolled-back position.

1. The liftarm shouldbe lowered or lockedin the raised

position as per the “Liftarm Support Device

Engagement” procedure in this chapter.

2. Turn the keyswitch to the OFF position to stop the

engine. Remove the key and take it with you.

3. Leave the operator’s compartment.

917170/AP0106 2-4 PRINTED IN USA

Fig. 2-6 Use wrenches to release the front of the ROPS

from the chassis.

Page 13

SL3640/3840/4240 SAFETY

WARNING

DO NOT leave the operator’s compartment

with the engine running. Before leaving the

loader, shut off the engine according to the

“Mandatory Safety Shutdown Procedure”

described in this chapter.

SAFETY

4. Remove two capscrews, six flat washers and two

locknuts securing the ROPS front uprights to the

chassis. Figs. 2-5, 2-6

Fig. 2-7 Location of the self-actuating lock mechanism.

Fig. 2-8 Lowering the ROPS is a two-person operation.

5. Lift ROPS up and tilt it back until the self-actuating

lock mechanism engages. The lock mechanism

locks the ROPS in a rolled-back position. Fig. 2-7

IMPORTANT

BEFORE raising the ROPS, position the seat

as far back as it will go. Avoid damaging

control handles by slowly raising the ROPS.

BE SURE the control handles clear theROPS.

ROPS – Lowering

1. With an assistant's help, apply upward force on the

ROPS while the assistant pulls the lock mechanism

handle toward the front of the loader. Fig. 2-8

2. Lower ROPS until it contacts the chassis. Fig. 2-9

IMPORTANT

Avoid damaging control handles by slowly

lowering the ROPS. BE SURE the control

handles clear the ROPS.

3. Reinstall the two capscrews, six flat washers and

two locknuts that secure the ROPS front uprights to

the chassis. Figs. 2-5, 2-6

Fig. 2-9 BE SURE the ROPS/FOPS clears the control

handles.

PRINTED IN USA 2-5 917170/AP0106

Page 14

SAFETY SL3640/3840/4240

Relieving Hydraulic Pressure

The following procedure should be used to relieve

pressure in the hydraulic system prior to performing

service procedures on hydraulic system components.

1. Completely lower the bucket or attachment.

2. Turn keyswitch to OFF position to shut down

engine.

3. With the operator in the seat and the restraint bar

lowered, turn the keyswitch to the ON position, but

DO NOT start the engine.

4. Move the lift, tilt and auxiliary hydraulics controls

through several cycles. Figs. 2-10, 2-11

5. Turn the keyswitch to the OFF position.

Skid-Steer Loader Raising Procedure

The following procedure is used to raise the skid-steer

loader so that all four tires ARE NOT contacting the

ground.

Lift and Tilt

Auxiliary Hydraulics

Fig. 2-10 On Hand/Foot control models, the lift and tilt

functions are controlled with the foot pedals on

the floor of the ROPS. The auxiliary hydraulics

are controlled by the right control handle.

Auxiliary Hydraulics

Lift and Tilt

WARNING

BEFORE servicing the machine, exercise the

“Mandatory Safety Shutdown Procedure”

described in this chapter.

WARNING

DO NOT rely on a jack or hoist to maintain the

“raised” position without additional blocking

and supports. Serious personal injury could

result from improperly raising or blocking the

skid-steer loader.

1. To raise and block the skid-steer loader, obtain four

jack stands or wooden blocks of sufficient strength

to support the loader.

2. Using a jack or hoist capable of raising the

fully-equipped loader, lift rear of loader until tires

are off the ground. Fig. 2-13

3. Place two jack stands under theflat part of the loader

chassis. Place them parallel with, but not touching,

the rear tires. Fig. 2-14

Fig. 2-11 On T-Bar control models, lift and tilt functions

are controlled with the right control handle.

The auxiliary hydraulics are controlled with

the left foot on the auxiliary hydraulics pedal.

4. Slowly lower loader so its weight rests on the jack

stands or the wooden blocks.

917170/AP0106 2-6 PRINTED IN USA

Page 15

SL3640/3840/4240 SAFETY

5. Repeat steps 2-4 for the front end. When the

procedure is finished, all four tires will be off the

ground, and they can be removed as necessary.

Tie Down Support

Stand Placement Location

Fig. 2-12 View of the jack stand placement area and tie

down support locations.

Skid-Steer Loader Lowering Procedure

When service procedures are complete, the skid-steer

loader can be taken down from the “raised” position. To

lower the loader onto its tires:

1. Using a jack or hoist, raise front of loader until its

weight no longer rests on the jack stands.

2. Carefully remove jack stands or wooden blocks

under front of loader.

3. Slowly lower loaderuntil front tires areon ground.

4. Repeat steps 1-3 for rear of loader.

SAFETY

Fig. 2-13 Locations underneath the skid-steer loader to

position jack stands or blocks at the front and

rear. (View is from the rear of the loader.)

Fig. 2-14 View of jack stands supporting right rear of

skid-steer loader.

PRINTED IN USA 2-7 917170/AP0106

Page 16

SAFETY SL3640/3840/4240

NOTES

917170/AP0106 2-8 PRINTED IN USA

Page 17

SL3640/3840/4240 LUBRICATION

3

2

General Information

WARNING

NEVER service this unit when any part of the

machine is in motion. ALWAYS BE SURE to

exercise the MANDATORY SAFETY

SHUTDOWN PROCEDURE (see Safety

chapter) BEFORE servicing this equipment.

1

Fig. 3-1 Hydraulic oil fill and dipstick (1), hydraulic

filter (2) and engine oil dipstick (43).

Fig. 3-2 Hydraulic oil drain plug located behind the left

rear tire.

Routine lubrication is an important factor in preventing

excessive part wear and early failure. Loader and engine

operation depends on using correct grade, high-quality

lubricating oils. This chapter and the chart below list

locations, temperature ranges and type of recommended

lubricants to be used when servicing this machine. In

addition, refer to the engine manual for specific grades

and ratings as specified by the engine manufacturer.

NOTE: Whenever service is performed on hydraulic

components (valves, cylinders, hoses, etc.), fuel tanks

and lines, care must be taken to prevent discharging

fluid onto the ground. Catch and dispose of fluid per

local waste disposal regulations.

Hydraulic Oil Reservoir

The oil reservoir for hydraulic and hydrostatic systems

has a capacityof eight U.S. gallons (30 liters). A dipstick

built into the reservoir cap provides a visual oil level

indicator (Fig. 3-1) for convenient maintenance of the

hydraulic oil level.

LUBRICATION

Hydraulic System

Reservoir

Use a Petro-Canada

Premium HVI60, or

equivalent which contains

anti-rust, anti-foam, and

anti-oxidation additives &

conforms to ISO VG46.

Capacity:

8 Gallons (30 L)

PRINTED IN USA 3-1 917170/AP0106

Chaincases

Use hydraulic system oil

or SAE grade 15W-40

motor oil.

Capacity (each side):

8 Quarts (7,6 L)

Grease

Fittings

Use lithium-based grease.

Crankcase Oil

(Diesel Engine)

µ Below 32°F (0°C) use

SAE Grade* 10 or 10W-30

µ Above 32°F (0°C) use

SAE Grade* 15W-40

*Service Classification:

API - CF-4/SH

Capacity:

7.6 Quarts (7,2 L) 36/3840

9.1 Quarts (8,6 L) 4240

Antifreeze

Coolant System

Add a mixture of 50%

water, 50% ethylene

glycol to the recovery

tank if coolant level in

recovery tank is low.

Page 18

LUBRICATION SL3640/3840/4240

The hydraulic oil reservoir should be drained (Fig. 3-2)

and filled after every 1000 hours of operation or

annually (whichever occurs first). Use

PETRO-CANADA hydraulic oil (or ISO VG46

equivalent) which contains anti-rust, anti-foam and

anti-oxidation additives. Hydraulic oil filter element

should be replaced after every 500 hours of operation

(See NOTE). For details, refer to “Hydraulic Oil Filter

Element Replacement” procedure in Hydraulic chapter.

NOTE: An initial 50-hour hydraulic oil filter element

replacement is recommended for new skid-steer

loaders.

Hydraulic Oil Tank Drain Procedure

1. Open engine access cover and rear grille.

2. Because the tank is pressurized, slowly remove

hydraulic oil tank cap from filler neck at left side

riser. Fig. 3-1

3. Underneath the left riser, remove drain plug on

hydraulic oil tank. Place a suitable container under

drain plug hole to catch hydraulic oil. Fig. 3-2

5

4

2

1

3

Fig. 3-3 Location of the engine oil filter (1), oil fill (2),

oil drain - not shown (3), dipstick (4) and fuel

filter (5) on left side of engine.

NOTE: Care must betaken to prevent discharging fluid

onto the ground. Catch and dispose of fluid per local

waste disposal regulations.

Crankcase Oil

The Yanmar diesel engine crankcase has a capacity of

7.6 quarts (7,2 L) for 36/3840 skid-steers or 9.1 quarts

(8,6 L) for 4240 skid-steers. The chart below lists

recommended oil viscosity for the engine.

Engine oil should be changed and the filter element

replaced every 250 hours of service. Refer to the engine

operator’s manual (see NOTE) for details on changing

oil and to the “Oil Filter Removal and Installation”

procedure in the Engine chapter. Figs. 3-3, 3-4, 3-5

NOTE: Refer to engine operator’s manual for

additional information on oil change intervals,

including a 50-hour initial oil change interval.

Ambient Temperature Viscosity

Fig. 3-4 Oil filter access location, underneath loader,

near left rear tire.

2

1

Below 32°F (0°C) SAE 10 or 10W-30

Above 32°F (0°C) SAE 15W-40

Fig. 3-5 Location of engine oil fill (1) and oil dipstick

Service classification: API-CF-4/SH

917170/AP0106 3-2 PRINTED IN USA

(2).

Page 19

SL3640/3840/4240 LUBRICATION

Liftarm

Chaincases

Each chaincase requires 8.0 quarts (7,6 L) of SAE motor

oil. This quantity of oilshould be maintained atall times.

The oil in both chaincases should be drained and refilled

every 1000 hours (See NOTE) of operation or annually,

whichever occurs first.

NOTE: A initial 50-hour chaincase oil change is

recommended.

Change Chaincase Oil Procedure

Raise the rear of the loader off the ground following the

“Loader Raising” procedure in this manual.

Fig. 3-6 Location of left chaincase drain plug; right side

is the same. To facilitate draining, lift rear of

loader slightly with a suitable hoist or jack.

Fig. 3-7 Location of chaincase oil fill/check plug.

1. Remove drain plugs and drain oil into a suitable

container. Fig. 3-6

NOTE: Care must betaken to prevent discharging fluid

onto the ground. Catch and dispose of fluid per local

waste disposal regulations.

2. Reinstall drain plugs.

3. Remove fill/level check plug. Fig. 3-7

4. Lower the rear of the loader to return loader to a

level position.

5. Add oil through fill/level check plug until oil starts

to flow out of check plug. Fig. 3-7

6. Reinstall fill/level check plug.

Grease Fitting Locations

Use lithium-based grease on allgrease fittings. Figs. 3-8

through 3-11

Grease every 10 hours of operation (or daily)

LUBRICATION

1. Grease liftarm pivots.

2. Grease lift cylinder pivots.

3. Grease tilt cylinder pivots.

4. Grease All-Tach™ attachment pivots.

Fig. 3-8 Liftarm grease fitting locations.

PRINTED IN USA 3-3 917170/AP0106

Page 20

LUBRICATION SL3640/3840/4240

Cooling System Drain Procedure

Gehl SL36/38/4240 skid-steer loaders use a radiator/

cooler to help keep the engine from overheating. Some

procedures in this Service Manual require partially or

fully draining the radiator/cooler for those procedures.

Coolant / Hydraulic Oil - Drain Procedure

WARNING

BEFORE beginning this service procedure,

perform the following SAFETY procedure:

Shut off the engine and allow to cool.

q

(For detailed instructions, refer to the Safety

chapter of this manual.)

1. Open engine access cover and rear grille.

2. Remove radiator cap.

3. A drain cock is located at bottom rear of radiator.

Open drain cock and drain coolant into a suitable

container. Fig. 3-12

4. Open small access cover (belly pan) located in

chassis behind radiator/cooler, placing a suitable

container underneath the opening.

5. Use two wrenches on lower oil cooler hose (to

prevent damage to fitting), remove lower hose and

drain oil through access cover. Fig. 3-12

NOTE: Care must betaken to prevent discharging fluid

onto the ground. Catch and dispose of fluid per local

waste disposal regulations.

6. Close drain cock, reinstall lower oil cooler hose.

Fig. 3-10 Lower tilt cylinder grease fitting location.

Fig. 3-11 Rod-end lift cylinder grease fitting location.

Radiator Cap

Radiator Side

Fig. 3-12 Radiator/Cooler system drain locations. Left

arrow indicates the radiator drain cock

Fig. 3-9 Attachment bracket grease fitting locations.

917170/AP0106 3-4 PRINTED IN USA

location, the right arrow indicates the lower oil

cooler radiator hose.

Oil Cooler Side

Page 21

SL3640/3840/4240 MAINFRAME

Introduction

Gehl SL36/38/4240 skid-steer loaders have a welded

steel mainframe. Maintenance, service and repair can be

performed through standard access panels. The left rear

mainframe riser serves as the hydraulic reservoir. A

welded steel tank bolted to the mainframe behind the

ROPS/FOPS serves as the fuel tank.

Two side cases provide mounting for the drive motors

and for the front and rear axles. The side cases also serve

Oil is used inside thesecases to ensure the chains always

receive proper lubrication.

The liftarm and the lift and tilt cylinders are mounted

with pivot pins. Capscrews are used to secure the pivot

pins. A Rollover Protective Structure/Falling Object

Protective Structure (ROPS/FOPS) is standard for

operator safety, and both the seat and restraint bar

include safety interlock switches.

as sealed housings for the drive chains and sprockets.

Rollover & Falling Object Protective Structure (ROPS/FOPS) Components

48

45

46

56 11

19

26 5 27

55

8

30

57

50

54

36

37 38

51

13

17

14

24

12

43

44

35

23 22

58

9

21

1

3

4

2

18

33

44 FOAM/SIDE RIGHT

45 GASKET/TOP WINDOW

46 GASKET/TOP WINDOW

47 SPONGE RUBBER/SEAT PLATE

48 WINDOW/TOP

49 SCREW/MACHINE

50 SCREW/CAP

51 SCREW/CAP

47

28

45

53 8 56

46

41

39

40

49

42

32

52 SCREW/CAP

53 SCREW/CAP

54 SCREW/CAP

55 BOLT/CARRIAGE

56 SCREW/MACHINE

57 WASHER/FLAT

58 WASHER/FLAT

29

2 BOLT/SHOULDER

3 BOLT/SHOULDER

4 BUSHING/OILITE

5 TETHER

1 BOLT/SHOULDER

15

6 WASHER/FLAT

51

7 MOUNTING/ISOLATOR

8 NUT/SPEED

9 NUT/LOCK NYLON INSERT

10 NUT/HEX

11 NUT/LOCK SERRATED

12 NUT/LOCK

3452

7

6

34

10

5631

13 NUT/LOCK

14 NUT/LOCK

15 ISOLATOR/ROPS

16 SCREW/WHIZLOCK

17 SUPPORT/ROPS

18 LATCH/ROPS

19 BRACKET/DOME LIGHT

20 ROPS/FOPS

20

16

21 BUSHING

22 TAG/RIP CORD

23 RING

24 GAS SPRING/ROPS

25 HANDLE/GRAB

25

26 NUT/FLAT

27 NUT/SPECIAL

16

28 SCREW/MACHINE

29 PANEL/INSTRUMENT LEFT

30 SHIELD/HARNESS

31 PLATE/HEATER SEAL

32 COVER/SEAT PLATE

33 SPRING/EXTENSION

34 WASHER/FLAT

35 STRIP/LOCKING

36 HOLDER/MANUAL

37 WINDOW/REAR

38 SEAL/WINDOW

39 FOAM/HEADLINER

40 FOAM/REAR PANEL

41 FOAM/SIDE LEFT

42 FOAM/SIDE LEFT

43 FOAM/SIDE RIGHT

MAINFRAME

Fig. 4-1 Assembly view of ROPS/FOPS components.

PRINTED IN USA 4-1 917170/AP0106

Page 22

MAINFRAME SL3640/3840/4240

Engine Access Cover Removal and

Installation

WARNING

BEFORE beginning this service procedure,

perform the following SAFETY procedures:

Shut off the engine.

q

(For detailed instructions, refer to the Safety

chapter of this manual.)

Removal Procedure

1. Open engine access cover until gas spring is

completely extended.

2. Disconnect gas spring from engine access cover by

removing gas spring clip with a small screwdriver,

then pull gas spring off ball stud on access cover.

Lower engine access cover. Fig. 4-2

3. Remove two locknuts securing engine access cover

to ROPS bolt/mainframe and remove cover. Fig.

4-3

Installation Procedure - Follow all warnings first,

then reverse the removal steps.

Spring Clip

Fig. 4-2 Engine access cover gas spring attached to ball

stud on engine access cover.

ROPS Bolt

ROPS Removal and Installation

WARNING

BEFORE beginning this service procedure,

perform the following SAFETY procedures.

q

Shut off the engine.

(For detailed instructions, refer to the Safety

chapter of this manual.)

Removal Procedure

1. Remove the engine access cover per the procedure

in this chapter.

2. Disconnect negative (-) battery cable from battery.

3. Disconnect ROPS wiring harness connector,

secured to mainframe, at right of fuel tank. Also,

disconnect ROPS power connector at same

location. Fig. 4-4

Fig. 4-3 One of two locknuts on ROPS bolt securing

the engine access cover to the mainframe.

Fig. 4-4 The harness bulkhead is where the harness

assembly meets the instrument panel harness.

Remove harness at front of bulkhead.

917170/AP0106 4-2 PRINTED IN USA

Page 23

SL3640/3840/4240 MAINFRAME

Fig. 4-5 Right side gas spring on the ROPS.

4. Raise ROPS per the procedure found in the Safety

chapter.

5. With ROPS tilted back and locked, attach a hoist so

that it is supporting the weight of the ROPS.

WARNING

The hoist MUST BE situated precisely above

the ROPS or else performing the following

steps may cause the ROPS to swing as the

bolts are removed. This could cause serious

bodily injury and/or damage the loader.

6. On right side of ROPS, remove one capscrew and

locknut securing gas spring to ROPS. Fig. 4-5

7. Disassemble ROPS lock mechanism by removing

shoulder bolt and locknut from welded hinge on

ROPS. Remove limiter assembly from ROPS. Fig.

4-6

MAINFRAME

Fig. 4-6 Location of shoulder bolt to remove on the

ROPS lock mechanism.

8. Carefully remove two capscrews and locknuts

securing rear of ROPS to mainframe. Figs. 4-7 and

4-8

9. Lift ROPS off loader.

Installation Procedure - Follow all warnings first,

then reverse the removal steps.

Fig. 4-7 Capscrew through riser where the ROPS

connects to the mainframe.

PRINTED IN USA 4-3 917170/AP0106

Fig. 4-8 Capscrew through riser where the ROPS

connects to the mainframe.

Page 24

MAINFRAME SL3640/3840/4240

Seat Removal and Installation

WARNING

BEFORE beginning this service procedure,

perform the following SAFETY procedures:

Raise liftarm; engage liftarm support

q

device.

Shut off the engine.

q

Tilt back ROPS until lock engages.

q

(For detailed instructions, refer to the Safety

chapter of this manual.)

Removal Procedure

1. Remove four nuts from studs attaching seat to seat

pan underneath ROPS. Fig. 4-9

Fig. 4-9 Location of four nuts securing seat to seat pan.

2. Release lock mechanism and lower ROPS.

Disconnect seat switch from wiring harness. Figs.

4-10, 4-11

3. Lift seat from seat pan.

Installation Procedure - Follow all warnings first,

then reverse the removal steps.

Seat Slide Replacement

Replacement Procedure

1. Remove seat per the procedure in this chapter.

2. Remove four capscrews and flat washers attaching

seat slide to seat. Fig. 4-10

3. Replace with new slides using existing capscrews

and flat washers.

Seat Switch

Seat Pan

Seat Slide

Fig. 4-10 Front seat slide capscrews shown.

Seat

Seat Switch

Fig. 4-11 Seat switch connected to wiring harness,

behind the seat.

917170/AP0106 4-4 PRINTED IN USA

Page 25

Page 26

®

Gehl Company 143 Water Street, P.O. Box 179, West Bend, WI 53095-0179 USA

www.gehl.com

917170/AP0106 © 2006 GEHL COMPANY PRINTED IN USA

All Rights Reserved.

Loading...

Loading...