Page 1

Form No.

902369

I

I

I

OPERATOR'S

MANUAL

l!I

Page 2

GEHL©COMPANY

HL360

SKID

STEER

Gehl Company (Incorporated), hereinafter referred

since 1859, warrants new GEHL machinery and/or attachments at the time

purchaser, to

accordance with the recommendations set forth in the GEHL Operators Manual.

GEHL's liability for any defect with respect to accepted goods shall be limited to repairing the goods at

an authorized dealer or other GEHL designated location, or replacing them,

above shall be

twelve (12) months/or 500 hours (whichever occurs first) after the delivery

purchaser.

This warranty shall not apply to any machine or attachment which shall have been repaired or altered

outside the GEHL factory or authorized GEHL dealership or in any way

affect its stability or reliability, nor which has been subject to misuse , negligence or accident, nor to

any machine or attachment which shall not have been operated

instructions or beyond the Company recommended machine rated capacity.

be

free from defects in material and workmanship

in

accordance with GEHL warranty adjustment policies. GEHL's obligation shall terminate

LOADER & ATTACHMENTS

to

as

GEHL,

as

manufacturer

if

properly set up and operated

so

in

accordance with GEHL's printed

of

quality machinery

of

delivery to the original

as

GEHL shall elect. The

of

the goods to the original

as

in GEHL's judgement, to

in

This warranty shall

manufacturers. Such items would include but would

batteries , hydraulic components, bearings, tires, belts and other trade accessories.

Except

expressed or implied, AND MAKES

MACHINERY AND/OR ATTACHMENTS AND MAKES

AND/OR ATTACHMENTS ARE FIT FOR ANY PARTICULAR PURPOSE. GEHL shall

for incidental or consequential damages for any breach

inconvenience, rental or replacement equipment, loss

not be liable for, and the buyer assumes

from the handling, possession or

No

representation or warranty concerning its machinery and/or attachments except

herein.

as

otherwise expressly stated herein, GEHL makes no representation or warranty

agent, employee or representative

not

be applicable to items which are subject to the warranties

not

be limited to engines, clutches, universal joints,

EXCLUSION

NO

WARRANTY OF MERCHANTABILITY IN RESPECT

use

all

of

the goods by the buy:er.

of

OF

WARRANTIES

NO

WARRANTY THAT ITS MACHINERY

of

liability for,

GEHL has any authority to bind GEHL to any affirmation,

of

all

warranty, including

profits or other commercial loss. GEHL shall

personal injury and property damage resulting

of

their respective

but

as

specifically set forth

of

any kind,

TO

ITS

not

be

not limited to

liable

2

Page 3

INTRODUCTION

M

r.

Operator:

Your decision

You have made a sound

Company

over a century.

philosophy

Gehl products assure you the performance

you need to make a profit. Your authorized Gehl Skid

Steer

Loader

equipment. They maintain genuine Gehl service parts.

This manual was written for the

find the information which he needs

prepare, adjust, service and understand this unit.

The

operator

the

important

manual

reliability

ed by the knowledge

Each section

divided into smaller sections. The Table

Index can be used

All service parts should be obtained from

through

when ordering service parts.

serial

number

the space provided as a handy record for quick reference.

Numbers for this unit are stamped

located on the left Riser below the Cross

Gehl

Company

provements in the design

without incurring the obligation

on any unit previously delivered.

WEST BEND, WIS. 53095 U.S.A.

"Right"

on

the seat and looking forward.

Traction

T-bar

ill

to

purchase Gehl equipment

and

lasting investment. Gehl

has been building quality equipment for well

Our

entire manufacturing and marketing

is

built

upon

quality.

dealer

should read this manual thoroughly so

facts

are known. The safety

and

performance

of

your

Gehl dealer. Give complete information

should always be given. Record numbers in

is

equipped to service

about

this unit

of

the contents

this manual

to

find the information

reserves the right to ma

The

operator

to

and

of

the

of

this unit will be determin-

is

clearly identified

The

model number

or

construction

to

is

a wise one.

quality built into

and

reliability

your

so

that

he can

know to correctly

the contents

operator

of

this manual.

of

on

a plate which

Frame

ke

install such changes

and

and

Contents and

that

is

needed.

or

ordered

Support.

cha-nges

of

any

GEHL COMPANY

and

"Left" are determined from a position sitting

From

this position, the

T-bar

is

the left-hand

the right-hand Control.

Control

and

the

Lift/Tilt

Gehl

that

of

and

or

part

the

the

is

is

im-

This Symbol . used throughout this manual,

means

to

read carefully and understand the

message that follows.

WARNING:

A

all Door(s), Guard(s) or Shield(s) are in their proper

position, BEFORE machine

Warranty

Introduction

Specification

Check Lists

Warnings - General

Controls

Operation . . . . . .

Adjustments

Lubrication

Transporting

Service

Troubleshooting

Optional Features

Decal Locations

Maintenance Schedule

Index

herein, may show Door(s), Guard(s),or

Shield(s) opened/removed. BE SURE that

TABLE

......................

............

................

...............

& Safety Equipment

..................

............

......................

...........

...

..

.......................

SPECIFI

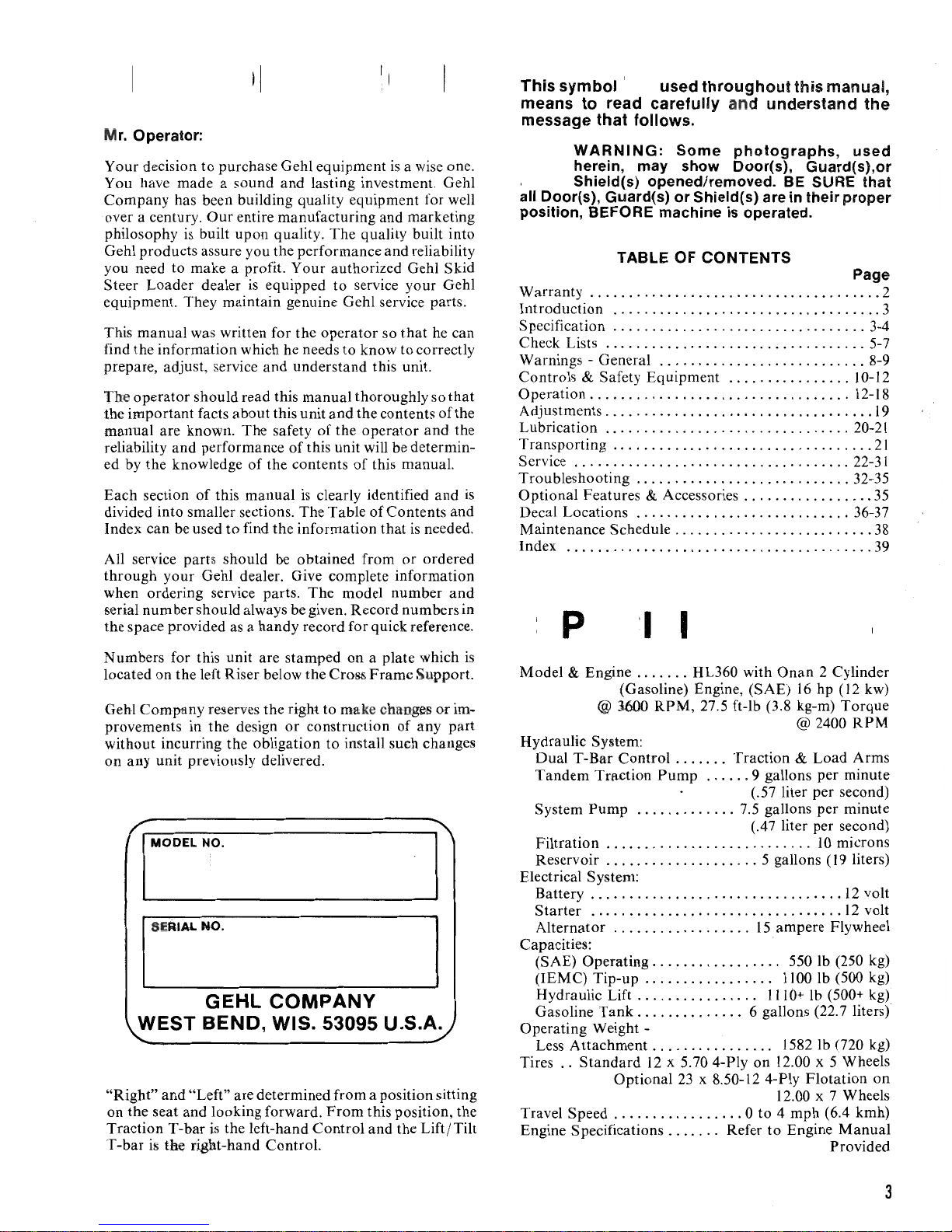

Model & Engine

(Gasoline) Engine, (SAE)

@ 1600

Hydraulic System:

Dual

T-Bar

Control

Tandem

System

Filtration

Reservoir

Electrical System:

Battery

Starter

Alternator

Capacities: .

(SAE) Operating

(lEMC)

Hydraulic Lift . . . . . . . . . . . . . .

Gasoline

Operating Weight -

Less

Tires

Travel Speed

Engine Specifications

Traction

Pump

.....................

....................

.........................

...............................

..............

Tip-up

Tank

Attachment.

..

Standard

Optional

...............

Some

OF

.........

................

.

........................

............................

& Accessories

..............

................

photographs,

is

operated.

CONTENTS

.

...............

.

........ . .............

.

..............

.. . ..

.... . .........

.

.................

..

....... . ......

...

. .

.. .. . ..

.

...

..

...........

.

.... . .. ..

. .

.

..........

.

.............

.

..

...........

. . .

..

..

...

CATIONS

.......

.............

.................

..............

HL360 with

RPM,

27.5 ft-lb (3.8 kg-m)

.......

Pump

.................

12

......

.

.. . 15

. . . . . . . . . . . . .

x 5.70 4-Ply on 12.00 x 5 Wheels

23

x 8.50-12 4-Ply

. . 0 to 4

.......

Refer

Onan

2 Cylinder

16

hp (12 kw)

@ 2400

Traction &

9 gallons per minute

(.57 liter per second)

7.5 gallons per minute

(.47 liter per second)

5 gallons (19 liters)

..

6 gallons (22.7 liters)

..

Load

.

.....

10

.

.......

ampere Flywheel

550 Ib (250 kg)

1100

Ib

1110+

Ib

1582

Ib

Flotation

12.00 x 7 Wheels

mph

to

Engine

used

Page

. . 3-4

5-7

8-9

10-12

12-18

....

20-21

22-31

32-35

...

....

36-37

..

. .

...

... . ..

Torque

RPM

Arms

microns

12

volt

. .

12

volt

(500 kg)

(500+ kg)

(720 kg)

(6.4 kmh)

Manual

Provided

19

21

35

38

39

on

2

3

3

Page 4

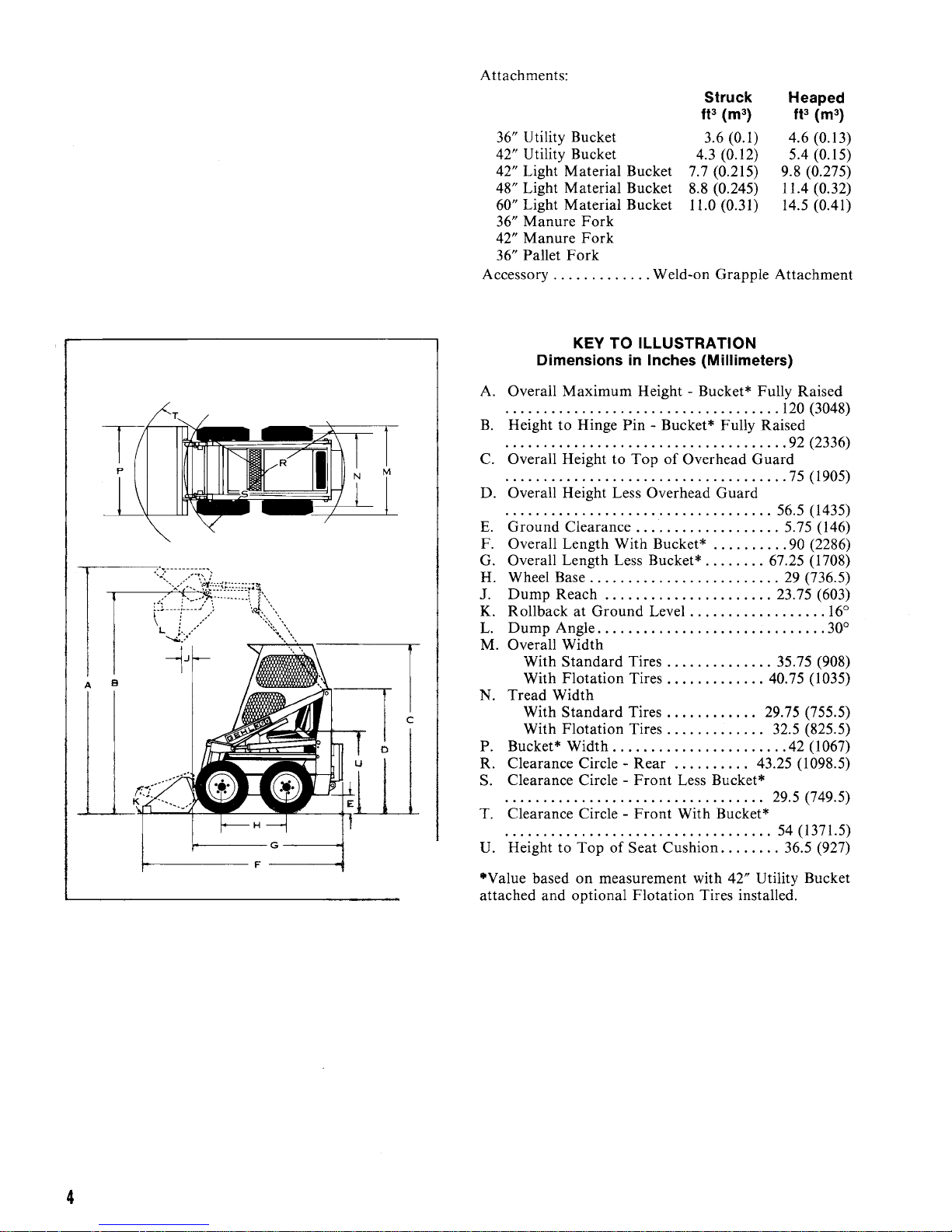

Attachments:

36" Utility Bucket

42" Utility Bucket

42" Light Material Bucket

48" Light Material Bucket

60" Light Material Bucket

Manure

36"

42"

Manure

36" Pallet

Accessory

Fork

Fork

Fork

.............

KEY

TO

Dimensions

in

Struck

fp (m3)

Heaped

fp (m3)

3.6 (0.1) 4.6 (0.

4.3 (0.

12)

5.4 (0.15)

7.7 (0.215) 9.8 (0.275)

8.8 (0.245) 11.4 (0.32)

11.0 (0.31)

14

.5

(0.41)

Weld-on Grapple Attachment

ILLUSTRATION

Inches (Millimeters)

13)

A B

A. Overall

.......................

·

B. Height

·

.... . ..

C. Overall Height

·

....................................

Maximum

to

Hinge

.....

..........

to

Height - Bucket* Fully Raised

.........

Pin

- Bucket* Fully Raised

.. ..

Top

of

Overhead

D. Overall Height Less Overhead

·

..................................

E.

Ground

Clearance

...... . ...........

F. Overall Length With Bucket* .

G. Overall Length Less Bucket* . .

H. Wheel Base .

1.

Dump

K. Rollback

L.

Dump

Reach .

at

Angle

.... . .....

.........

Ground

..............................

....

Level

....

..................

..

M. Overall Width

With

Standard

With

Flotation

N.

Tread

Width

Standard

With

With

Flotation

P. Bucket*

Width . ...

R. Clearance Circle S. Clearance Circle -

.......................

·

T. Clearance Circle -

..... . .. . .....

·

U.

Height to

Top

Tires

Tires

Tires

Tires

........

Rear

Front

Front

...

...... . .....

of

Seat

..............

..... ........

............

.............

..... . .....

. .

.......

Less Bucket*

.

..... . ..

With Bucket*

Cushion

...

....

. . ,

Guard

Guard

... . .....

..

....

.. . ..

...

...

.....

. 43.25 (1098.

. 29.5 (749.5)

..

...

........

120

(3048)

...

92 (2336)

75

(1905)

56.5 (1435)

. 5.75 (146)

90 (2286)

67.25 (1708)

29 (736.5)

23.75 (603)

16

30°

35.75 (908)

40.

75

(1035)

29.75 (755 .

32.5 (825.5)

42 (1067)

54

(1371.5)

36.5 (927)

°

5)

5)

4

·Value

based

on

measurement with 42" Utility Bucket

attached and optional

Flotation

Tires installed.

Page 5

HL360

-::0

(I)

3

o

<

(I)

o

(I)

II)

tD

""t

III

!!

tD

o

o

'<

"

l>

-

"tI

(I)

...

o

-

...

II)

-

0'

:l

-

PRE-DELIVERY

The following Check List

valuable

made before delivering the unit

off each item after prescribed action

Check

__

__

__

__

__

__

__

__

__

__

__

Start the Loader engine and test-run the unit while

checking that proper operation

controls,

Check that:

__

I acknowledge that pre-delivery service was performed

on

By

Da

information

that:

Unit

is

NOT

things as dents

or

replace components as required.

Fuel

Tank,

damaged, leaking or loosely secured.

Battery

Also check

check Electrolyte level

shipment, Battery

Lift

or

Hydraulic

leaking

Hydraulic Hoses

leaking

Oil Filter

attached.

Wheels are securely attached

inflated.

Entire

Hydraulic System, Engine

static Transmission are filled

levels.

All Guards, Shields

properly attached.

Serial number for the unit is recorded in the spaces

provided on this page

Traction

properly and are

this unit

____________________________________

te

Set

is

and

Tilt Cylinders are

loosely attached.

or

or

Loader

as

outlined above .

Dealer's Set-up Man's Signature

-u p

_______________________________

and

damaged in shipment. Check for such

and

Fuel Lines

securely

that

Cable connections are tight. Also

Pump

loosely attached.

loosely attached.

is

NOT

is

T-bar

Dealer's Name

CHECK

is

an

inspections which

to

loose

or

and

mounted

and

is

filled

and

Motor

and

Fittings are

damaged, leaking

properly lubricated

and

Decals are in place

and

and

Lift/Tilt

NOT

damaged

LIST

important

the Customer. Check

missing parts; correct

Fittings are

and

strength (in domestic

at

the factory).

NOT

are

and

Crankcase

page

is

reminder

MUST

is

taken.

NOT

NOT

cracked.

damaged, leaking

NOT

damaged,

NOT

damaged,

or

loosely

Tires

are

properly

and

and

Hydro-

to

the

proper

3.

exhibited

T-bar

or

binding.

by

operate

of

be valuable information

that

oil

and

all

_

_

DELIVERY

The

following Check List

Customer

item

_ Give the

_ Explain

_ Explain and review with him the Controls

_ Explain

_ Explain and review with him the Service section

_ Explain the importance

- Explain

_ Complete

I acknowledge that above points were reviewed with

at the time

Date Delivered

at

the time the unit

as

you explain it to the Customer.

Customer

be

him to

contents

of this Manual.

Equipment section

tinued

him the Lubrication section

this manual.

ing

BEFORE

Operator's

tions,

sure to read and completely understand its

BEFORE attempting to operate the unit.

and

review with him the

that

regular lubrication

proper

of

operation

operation and long life. Review with

and familiarity with the Loader Controls

attempting

that

Manual

Owner

of

delivery.

Customer's Signature

___________________________

CHECK

is

that

M

his Operator's Manual. Instruct

of

this Manual.

of

to operate the Loader.

he

MUST

(provided) for related specifica-

and maintenance instructions.

's Registration

LIST

an

important

UST

be

is

delivered. Check off ea ch

WARNING

is

of

this manual.

his

thorough

consult the Engine

Card

reminder

passed on to the

section

& Safety

required for con-

understand-

.

of

of

me

_

Serial N umber

_____________________________

_

(Dealer's File Copy)

5

Page 6

6

Page 7

HL360

The

following

valuable

made

before delivering

off

eaGh item

Check

__

__

__

__

__

__

__

__

__

__

__

that

Unit

things as

or

replace

Fuel

damaged,

Battery

Also

check

shipment,

Lift

or

loosely

Hydraulic

leaking

Hydraulic

leaking

Oil

attached

Wheels

inflated.

Entire

Hydraulic

static

levels.

All

properly

Serial

provided

PRE-DELIVERY

Check

information

after

:

is

NOT

dents

Tank,

is

check

Electrolyte

and

Tilt

or

or

Filter

.

are

Loader

Transmission

Guards,

attached.

number

on

List

and

prescri bed

damaged

and

components

Fuel Lines

leaking

securely

that

Cable

Battery

Cylinders

attached.

Pump

loosely

Hoses

and

loosely

is

NOT

securely

is

System,

Shields

for

this

page

CHECK

is

an

inspections

the

unit

in

loose

as

or

loosely

mounted

connections

level

and

is

filled

are

and

Motor

attached.

Fittings

attached.

damaged,

attached

properly

Engine

are

and

the

unit

and

to

action

shipment.

or

and

filled

Decals

is

LIST

important

which

the

Customer.

is

taken.

Check

missing parts;

required

at

NOT

Crankcase

page

.

Fittings

secured

and

NOT

are

strength

the

factory).

damaged,

are

NOT

are

NOT

leaking

and

Tires

lubricated

to

the

are

recorded

3.

.

reminder

MUST

Check

for

correct

are

cracked.

tight.

(in

domestic

leaking

damaged,

damaged,

or

loosely

are

properly

and

and

Hydro-

proper

in place

in

the

spaces

of

be

such

NOT

Also

that

oil

and

Start the Loader engine and test-run the unit while

checking that proper operation

is

exhibited

by

all

controls.

Check

that

:

The

following

valuable

Customer

item as

_ Give

_

_

_

_

_

information

you

the

him

to

contents

Explain

of

this

Explain

Equipment

Explain

tinued

him

the

Explain

this

manual.

Explain

ing

of

BEFORE

-

Explain

Operator's

tions,

_

Complete

I

acknowledge

at

the

time

Date

Delivered

DELIVERY

Check

at

the

time

explain

Customer

be

sure

BEFORE

and

review

Manual.

and

review

section

that

regular

proper

Lubrication

and

review

the

importance

and

familiarity

attempting

that

Manual

operation

Owner's

that

of

delivery.

Customer's

_____

List

that

the

unit

it

to

the

his

to

read

and

attempting

with

with

of

lubrication

operation

section

with

to

he

MUST

(provided)

and

maintenance

Registration

above

points

_______

CHECK

is

an

important

MUST

is

delivered.

Customer.

Operator's

completely

him

the

him

the

this

Manual.

and

long

of

him

the

of

his

thorough

with

the

operate

consult

were reviewed

Signature

______

LIST

reminder

be

passed

Manual.

to

operate

WARNING

Controls & Safety

is

required

life. Review

this

Service

Loader

the

for

related

instructions.

Card.

on

Check

off

Instruct

understand

the

for

manual.

section

understand-

Controls

Loader.

the

specifica-

with

______

section

Engine

to

each

unit.

conwith

_

of

the

its

of

me

__

Traction

properly

I

acknowledge

on

this unit as

By

____________

Date

Set-up

Serial Number

T-bar

and

that

outlined

Dealer's

__

___

and

are

NOT

damaged

pre-delivery service was

above.

Dealer's

Set-up

______________________

__________________________

Name

Man's

Lift / Tilt

T-bar

or

binding

__

____

Signature

operate

.

performed

_

____

_

_

(Note: Pages 5 and 6 Have Been Removed at

Perforation)

7

Page 8

WARNING

BEFORE

EQUIPMENT,

FOLLOWING

ADDITION,

INDIVIDUAL

WITH

MEMBER

THESE

Gehl

into

guards

however,

order

operator's

you

of

closely.

Thi"afoty

BECOME

INVOLVED!

for safety

manual

Remember:

Most

precautions must be observed

injury

YOU

ATTEMPT

READ

SAFETY

MAKE

WHO

THIS

EQUIPMENT,

OR EMPLOYEE, IS

SAFETY

Company

consideration

exposed

some

to

assure

manual

further

alec!

PRECAUTIONS.

always

when

moving

areas

cannot

proper

and

decals

danger

and

,ymbol

ALERT!

It

stresses

and

can

be

found

and

on

the

unit itself.

The

careful

accidents are caused

or

damage.

SURE

OPERATES

takes

designing

operation

should

A

an

operator

TO

OPERATE

AND

STUDY

INFORMATION.

THAT

OR

WHETHER

FAMILIAR

the

operator

parts

be

guarded

on

the

be read

mea",

YOUR

attitude

throughout

is

by

human

to

prevent the possibility

and

farm

machinery

for his

or

. In

addition,

machine

A

TTENTI

SAFETY

of

"HEADS

this

the best

error. Certain

protection;

shielded in

and

THIS

THE

IN

EVERY

WORKS

FAMILY

WITH

his safety

and

the

itself

warn

observed

ON!

IS

UP"

operator's

operator.

of

Please read

BEFORE

the

rules listed below for safe

you

operate

this

equipment.

operation

ALWAYS sit in the Seat and fasten your Seat Belt

BEFORE starting the Loader Engine!

Read

and observe ALL Warnings BEFORE oper-

ating this machine!

Know how to STOP the Loader BEFORE starting it!

Keep ALL Guards, Shields and Decals in place and

properly secured!

Rest the Attachment (Bucket) on the ground when

Loader is NOT

ALWAYS use

In

use!

Lift

Cylinder Lock when Load Arms

are raised for servicing the Loader and remove

Ignition Key!

When operating on inclines or ramps, ALWAYS

travel with the heavier end

as

same direction

the top of the incline!

Travel slowly over rough terrain and

abrupt stops, quick starts

of

the Loader in the

NEVER

or

sharp turns with the

make

Load Arms raised.

8

ALWAYS carry the load low, especially on side hills,

inclines and/or when approaching

an

excavation!

Page 9

Carefully inspect

on a regular routine basis; escaping fluid

pressure can cause serious injury!

ALWAYS wear a hard hat when operating the Skid

Steer Loader!

Refuel in a safe place away from open flames and

potential sparks, NEVER refuel the Loader when

the engine is hot! NEVER refuel

engine running!

The Hydrostatic Drive

operates

operating the Loader can move, especially

stopped on

ground

level

contact

DO

service the Loader when any

DO

engine running!

NOT

NOT

with the

mount

Hydraulic

with

Oil Flow. When the Pump is

an

incline. ALWAYS PARK Loader on

with

the

ground

attempt

to

or

dismount

Hoses

of

point

or park

clean, adjust, lubricate

and

a Skid Steer Loader

of the Attachment in

across the incline!

part

is moving!

the Loader

connections

under

with

Loader

NOT

if

or

with

the

DO

NOT

allow minors

Loader unless

Loaders are single Seat NO passenger machines!

DO

NOT

operate the Loader in a closed

area; if necessary, adequate ventillation

provided!

NOT

DO

unless the

engaged!

DO

(Into

loaded and raised

to drop!

DO

the Operator's Platform!

DO

BE SURE surrounding

strength to

DO

turning

DO

leave the Loader

Lift

NOT

push the

"Float" position)

NOT

extend

NOT

drive

NOT

or

NOT

exceed Loader rated operating capacity!

your

too

support

"HOT

reversing Loader directions!

to

operate

properly

Cylinder

LiftITiit T-Bar

as

close

ROD" when starting, stopping,

supervised; Skid Steer

with

with

this

will

feet beyond the

to

an excavation

ground

weight

of

or

be near the

or

confined

MUST

the Load Arms raised

Lock

the Bucket

cause the Load

the Loader and load!

is positively

all the way forward

or

front

edge

or

ditch!

has adequate

be

Fork

Arms

of

9

Page 10

Gehl Company, in compliance with the

Agricultural Engineers, has

adopted

Farm

and Industrial Equipment Institute

and

the American Society

of

as a SAFETY ALERT SYMBOL. When you see this symbol, in this

BE

ALERT! Your Safety

is

involved.

CONTROLS & SAFETY

Whenever and wherever possible

machine operation, Guards and Shields have been used

on this equipment to protect potentially hazardous areas.

In many places, Decals are also provided to warn

potential dangers

proced ures.

WARNING:

A

factory installed Guards and Shields are properly

secured

T -BARS (Fig. 1)

A

bar Controls to their "Neutral" positions, BEFORE

starting the Loader engine.

warning.

DO

in

WARNING:

Seat Belts,

Pump Drive Belt Idler and to return both

Traction

T~Bar

as

well as to display special operating

Read and observe ALL

son

the

NOT

operate this equipment unless

place.

BE

SURE to Fasten and Adjust

to

disengage the Hydrostatic

and

without affecting

of

unit BEFORE operating it.

ALL

T-

manual

or

on the unit itself, you are reminded to

EQUIPMENT

NOTE: When seated

•

Traction

the Lift/Tilt T -bar

Traction T-bar

The

Traction T-bar controls forward

and turning the Skid Steer Loader. With the Hydrostatic

Pump

Drive Belt Idler engaged, a right

out

by twisting the Traction

is

carried-out

clockwise.

power, turns in either direction should only be carriedout

with the Traction T

The

"Neutral" position

movements for turning, forward travel

are displayed on the

Operator's Console.

Lift/Tilt T -bar

The

Lift/Tilt

Load Arms

back. Pushing the

"N

eutral" position lowers the

the

T-bar

straight back raises the

bar

clockwise extends the Tilt Cylinders to roll the

Bucket or

counterclockwise retracts the Tilt Cylinders

Bucket or

T-bar

is

by

twisting the

By

design

and

T-bar

and

rolling the Bucket

Lift/Tilt

Fork

Fork

back .

"Operation"

controls raising and lowering the

forward. Twisting the

on

the Loader Seat, the

is

the "left-hand" control and

the "right-hand" control.

and

reverse motion

turn

in carried-

T-bar

clockwise. A left

Traction

for most efficient use ofLoader

-bar

in the "Neutral" position.

of

the Traction

T-bar

Load

Load

T-bar

counter-

T-bar

and

and

reverse travel

Decal on

or

straight forward from

Arms. Twisting the T-

top

Fork

forward

Arms. Pulling the

to

roll the

turn

T-bar

of

the

or

T-bar

Fig. 1

10

NOTE: The Lift/Tilt T -bar

•

equipped with 3-Spool Control Valves and

Auxiliary Hydraulics connections

with a Float

the T -bar

Information topic

manual for further explanation.

A

when the Load Arms are raised.

pOSition

all

the way forward. Refer

WARNING: On 3-Spool Control Valve

Loader models, NEVER

bar fully forward into the "Float" position

which

in

the Operation section of

on

is

reached

push

Loader models

is

also

to

the Lift/Tilt

equipped

by

pushing

the General

this

T-

Page 11

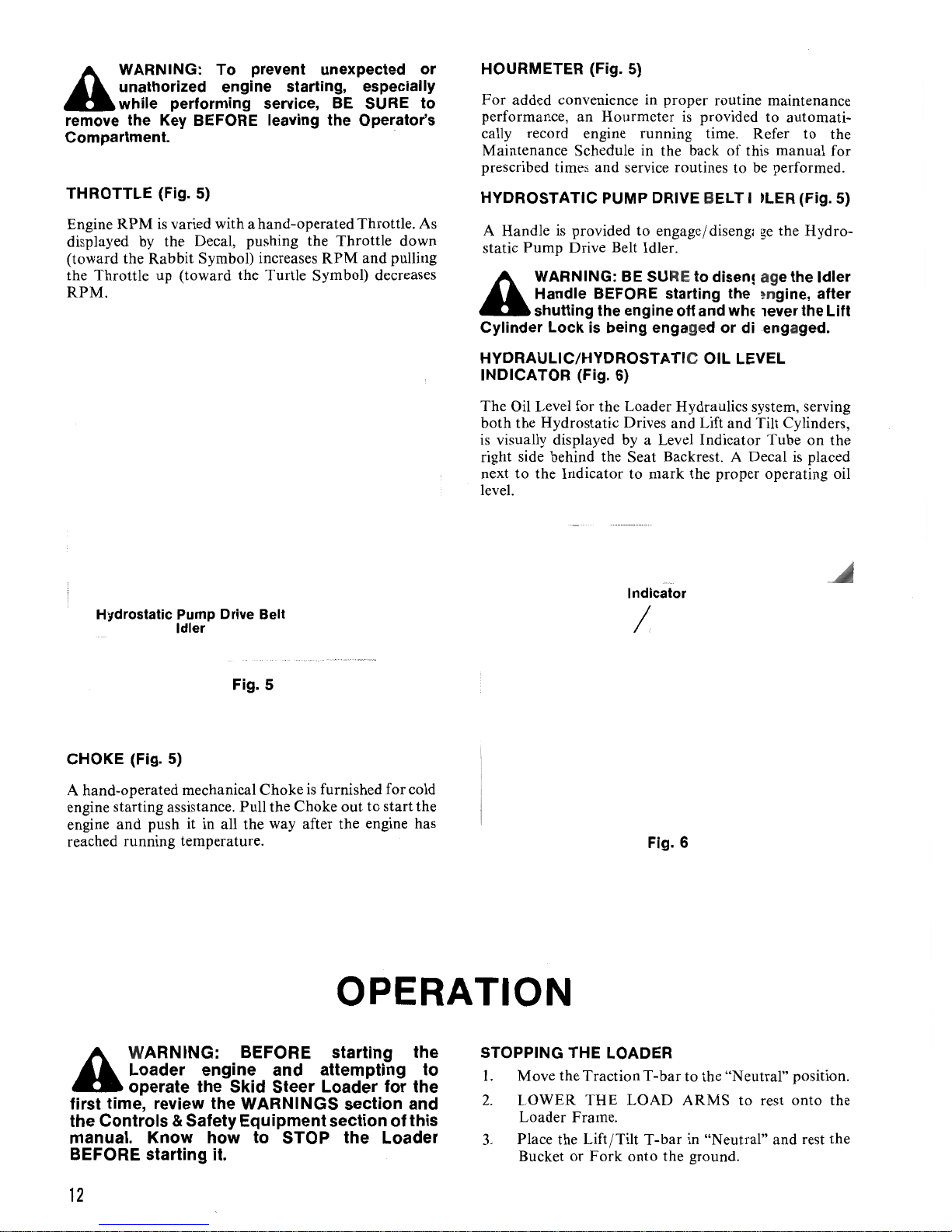

LIFT CYLI NDER LOCK (Figs. 2 & 3)

SEAT BELT (Fig. 4)

WARNING: When it becomes necessary to

on

A

Lock BEFORE shutt

the Operator's Compartment.

The Lift Cylinder Lock

Cylinder. Both the "engaged"

the Lock are shown. Secure the Lock in the "storage"

position with the Lockpin provided. Refer to

section

work

raised,

of

this manual for engage / disengage procedures.

the Load

BE

SURE to engage the Lift Cylinder

er w

ith

the Load Arms

in

g the engine off and leaving

is

located

and

on

the right Lift

"storage" positions

Operation

of

WARNING BEFORE starting the Loader

A

The

1386

automotive equipment use.

Belts to obtain the correct length to match your build

comfort. Correct Belt adjustment

both

completely unwound from the Belt retractors.

engine,

adjust the Seat Belt for a correct snug

Seat Belt furnished

and

J4C

ends

BE

SURE

Regulation approved for construction

of

the Belt are completely extended,

A~

CARRY tOAn

to

fasten and properly

on

all Skid Steer Loaders

BE

SURE to adjust

is

only obtained when

LOW

is

that

fit.

SAE

and

both

and

is,

Fig.

Fig.

3:

2:

Lift Cylinder Lock "Engaged"

lift

Cylinder Lock

in

"Storage"Position

Fig.

4:

Seat Belt (Retracted)

ROLL-OVER PROTECTION - OVERHEAD GUARD

(See Fig. 2)

The Operator's

protected by a high-strength Roll-over

WARNING: NEVER operate the Loader with

A

Channels when mounting

equipment such

LlFTITILT T-BAR GUARD (See Figs. 1

the Overhead Guard removed. In addition,

avoid drilling into the Guard Frame

compartment

as

lights or mirrors.

A WARNING: NEVER remove the Lift/Tilt

"bar

A

Guard

protect from accidentally moving the T-bar while dismounting

T-bar

IGNITION/STARTER KEY (Fig. 5)

The Skid Steer

Ignition

function

Guard.

is

factory installed over the Lift

the

Loader as well as

from outside the Operator's Compartment.

Loader

and

Starter

is

the same as

of

the Skid Steer

Frame

any

kind

to

block-off access

is

furnished with a Key-type

Switch. Switch operation

on

a car or truck.

of

& 2)

/Tilt

Loader

and

special

T -

Cage.

bar

to

the

and

is

T-

to

11

Page 12

WARNING: To prevent unexpected or

A

remove the

Compartment. .

THROTTLE (Fig. 5)

Engine

displayed

(toward the

the Throttle up (toward the Turtle Symbol) decreases

RPM.

unathorized engine starting, especially

while performing service,

Key

BEFORE leaving the Operator's

RPM

is

varied with a hand-operated Throttle. As

by

the Decal, pushing the Throttle down

Rabbit

Symbol) increases

BE

RPM

SURE to

and pulling

HOURMETER (Fig. 5)

For

added convenience in proper routine maintenance

performance, an

cally record engine running time. Refer to the

Maintenance Schedule in the back

prescribed times and service routines

HYDROSTATIC PUMP DRIVE BELT ID

A Handle

Pump

static

WARNING:

A

Cylinder Lock

HYDRAULIC/HYDROSTATIC OIL LEVEL

INDICATOR (Fig. 6)

The Oil Level for the Loader Hydraulics system, serving

both the Hydrostatic Drives and Lift and Tilt Cylinders,

is

right side behind the Seat Backrest . A Decal

next

level.

Handle BEFORE starting the engine, after

shutting the engine off and whenever the

visually displayed by a Level Indicator Tube on the

to

the Indicator to

Hourmeter

is

provided to engage/ disenga

Drive Belt Idler.

BE SURE

is

being engaged or disengaged.

is

provided to automati-

of

this manual for

to

be

ge

to

disengage the Idler

mark

the proper operating oil

performed.

LER

(Fig.

the Hydro-

is

placed

5)

Lift

Fig. 5

CHOKE (Fig. 5)

A hand-operated mechanical Choke

engine starting assistance. Pull the Choke

engine

reached running temperature .

and

push it in all the way after the engine has

is

furnished for cold

out

to start the

OPERATION

WARNING:

A

first time, review the

the Controls & Safety Equipment section of this

manual.

BEFORE

Loader engine and attempting to

operate the Skid Steer Loader for the

Know

starting it.

BEFORE

WARNINGS

how to

STOP

starting the

section and

the Loader

Fig. 6

STOPPING THE LOADER

1.

Move the Traction T

2.

LOWER

Loader Frame.

3.

Place the Lift /Tilt

Bucket

or

THE

Fork

-bar

LOAD

T-bar

onto

the ground.

to

the "N eutral" position.

ARMS

in "Neutral" and rest the

to

rest onto the

12

Page 13

4.

Move the Throttle to the Idle position.

5.

Disengage the Hydrostatic

6.

Turn

the Ignition Key to "OFF" and remove the

Key.

7.

Make sure

has stopped, detach the Seat Belt

the Operator's Compartment.

BEFORE STARTING THE ENGINE

Before actually starting the engine

Loader, familiarize yourself with the T

orient your mind

Grasp the T-bars

directions

Loader, Load Arms and Tilt Cylinders.

that

all movement

and

coordinate your

and

move them in the

to

simulate the various movements

Pump

and

Drive Belt Idler.

Loader motion

and

climb

out

and

running the

-bar

operation

hand

movements.

appropriate

of

of

to

the

Attempt all raise and lower operations, Bucket roll-

and

forward

the two functions before proceeding to operate

bars at the same time.

in

Skill

through proper coordination

and reverse travel with raising and lowering the

Arms

and

back.

To

until they happen naturally and without mistake

hesitation.

A

T-bar operations

caution and good judgement while running this

equipment.

roll-back operations and combinations

Skid Steer Loader operation

of

with rolling the Bucket

gain proficiency, practice all

WARNING: Operation

Loader at full Throttle should only

attempted after complete familiarity with all

is

known. ALWAYS exercise

is

only obtained

the Loader's forward

or

Fork

forward

T-bar

operations

of

the Skid Steer

both

Load

of

T-

or

or

be

STARTING THE ENGINE

I. Step up onto the back

clim b backwards

Compartment.

A

2.

3.

4.

5.

6.

7.

WARNING: FASTEN AND PROPERLY

ADJUST the Seat Belt BEFORE proceeding.

Check

position and check

Drive Belt Idler

Move the Throttle to the midway point ofits travel.

F or cold engine starts, pull the

out.

Turn

Make

the Choke all the way in after the engine reaches

proper operating temperature.

Before attempting

Drive Belt Idler, roll the Bucket

completely

for several seconds

that

both T-bars are in their "Neutral"

the Ignition Key

appropriate

and

of

the Bucket

into

that

the Hydrostatic

is

disengaged.

to

start

Choke

to

hold this Lift / Tilt T

to

readjustments

engage the Hydrostatic

speed-up oil heat-up process.

the

Choke

the

engine.

or

Operator's

or

-bar

Fork

and

Pump

all the way

and

push

Pump

Fork

back

position

NOTE: To prolong Loader component life,

•

avoid "jackrabbit" starts,

bar movements.

LIFT CYLINDER LOCK (Figs. 7

WARNING: When

on

A

Lock BEFORE shutting the engine off and leaving

the Operator's Compartment.

remove the Ignition

work

raised,

the Loader with the Load Arms

BE

SURE

Key.

stops

and

forceful

&

8)

it

becomes neccessary to

to

engage the Lift Cylinder

BE

SURE also

T-

to

FIRST TIME PRACTICE RUNNING

WARNING:

used

A

an

empty Bucket or Fork.

Smoothest and most efficient

achieved while the engine

Throttle. After the engine

engage the Hydrostatic

and deliberately move the Traction T

forward, using a firm left-hand grip

extension. Attempt all forward, reverse and turning

operations before proceeding to operate the Lift /Tilt T-

bar. Leaving your left hand off the Traction T-bar, slowly

and deliberately pull the

using a firm right-hand grip

for test-running

and

obstructions. Operate the Loader with

BE

SURE that the area being

is

being operated

is

sufficiently warmed-up,

Pump

Drive Belt Idler

Lift/Tilt

and

is

clear of spectators

Loader

T-bar

right-arm extension.

opeation

at

half to full

and

-bar

straight

and

left-arm

straight back,

is

slowly

Fig.

7:

Lift Cylinder Lock "Engaged"

13

Page 14

Fig.

8:

Cylinder Lock

Engaging Lock

Before proceeding

to prevent Loader movement, first disengage the Hydrostatic

Pump

to

Drive Belt Idler.

in

"Storage" Position

engage the Lift Cylinder Lock

and

3.

After the Lock

Lock with the left hand and continue to lower the

Load Arms down until they contact the Loader

Frame. With the

off and secure the Lockpin to place the Lift

Cylinder Lock back into the "storage" position.

GENERAL INFORMATION

WARNING: Fasten and properly adjust the

A

BEFORE starting

If

being operated

will stop rising

Lower the Load Arms

before attempting to restart the engine.

engine kills while the Lift/Tilt

lower the Load Arms, the Arms will continue

until they rest against the Frame. Return the T

"N

Braking - Stopping Loader Motion

Seat Belt BEFORE starting the Loader

engine. Know

the Loader engine kills while the Lift / Tilt T

eutral" before attempting to restart the engine.

is

cleared completely, release the

Load

Arms down, shut the engine

how

to

stop

the Loader

it.

to

raise the Load Arms, the Load Arms

and

hold at the level already reached.

and

return the T

T-bar

-bar

to "Neutral"

If

the

is

being operated to

-bar

Loader

to

lower

-bar

is

to

1.

Remove the Lockpin from the Cylinder Lock.

2.

Raise the

to

3.

Lower the Load Arms slightly until the Lock firmly

rests against the Cylinder.

NOTE: DO

•

Lock NOR continue

after the Lock contacts the Cylinder to avoid

damaging the Lock

Disengaging the Cylinder Lock

WARNING:

A

Two methods can be followed

Lock back into its "storage" position.

method

while the Loader Operator raises the

after the Lock

back into "storage".

An alternative method of disengaging the Lock

as

1.

Hydrostatic Pump Drive Belt Idler BEFORE

proceeding.

follows:

Raise the Load Arms slightly away from contact

with the Lift Cylinder Lock.

Load

Arms far enough

drop

down around the Cylinder Rod.

NOT

drop the Load

to

or

the Cylinder.

BE

SURE to disengage the

to

is

to

have a second person disengage the Lock

is

released, the second person also locks it

to

allow the Lock

Arms

lower the Load Arms

disengage

and

The

recommended

Load

Arms. Then,

onto the

secure the

is

to

do

so

of

The Hydrostatic Drive Pumps

control braking and stopping Loader forward

reverse movement. When the Traction T

the straight "Neutral" position, all movement

Wheels

Traction T-bar gradually

and

Load

Positions

HL360 Skid Steer Loaders are available in 2-Spool

3-Spool Control Valve models. Models with 3-Spool

Control Valves are factory equipped with Auxiliary

Hydraulic connections

"detent", on the Lift / Tilt T

position for the Auxiliary Hydraulics connections.

The

pushing the

position causes oil flow to effectively bypass the Lift

Cylinders thus allowing the

following the ground contour.

A

Auxiliary Hydraulics connections), all the way

forward into the "Float" position when the Load

Arms are raised.

is

stopped.

stop the Wheels .

Arm

"Float"

WARNING: NEVER push the LiftlTIIt T-bar,

on

Valve (characterized

By

all means,

and

FLoat & auxiliary Hydraulics "Detent"

and

position for the Lift/Tilt T-bar

T-bar

a unit equipped with 3-Spool Control

all the way forward. This

the Skid Steer Loader

and

-bar

is

moved to

of

the

BE

SURE to move the

deliberately

feature a Load Arm Float,

-bar

as

Load

Arms to "float" while

by

to

slow-down

and

well as a "detent"

is

reached by

T-bar

Foot Pedals and

2.

Using the left hand, reach

of

corner

Lock up so

the Lock can be cleared by the Cylinder when the

Load

the Overhead

that

the Cylinder can be retracted

Arms are lowered.

Guard

around

and

14

the top right

lift

and

hold the

and

The "detent" position for the Auxiliary Hydraulics

is

connections

Foot

Pedal all the way down. The Auxiliary Hydraulics

"detent" position enables operations

accessories, from outside the Operator's Compartment.

reached

by

pushing the "toe" end

of

of

the

special

Page 15

NOTE: HL360

•

2-Spool

T

-bar

Float Position NOR

connections.

Control

Skid

Valves

Steer

do

Loader

NOT

have a

Auxiliary

models

with

Lift/Tilt

Hydraulics

Digging & Loading

To

dig with and load the Bucket, first lower the Load

Arms down in contact with the Loader

(Figs.

9,

10,

11

& 12)

Frame

and

roll

the Bucket Cutting Edge down in contact with the

as

ground. Move the Loader into the material and,

RPM

engine

at

and,

T

-bar

to decrease travel speed while still maintaining

loads-down, roll the Bucket back slowly

the same time, gradually pull back

on

the Traction

the

Wheel torque.

NOTE:

•

when

working

move the

forward,

Loader

working

ability

travel speed is decreased.

ability

from

through

Traction

its

"Neutral"

maximum

T-bar

only a slight

position,

is increased

For

optimum

Wheel torque,

amount

while

filling

a

Bucket.

J""

...

;

J.

,

",,,

..,

"t

."

't

..

-------._

...

_----------------_.

: ' ,

..

' "

\

.\,~

,

to

,

.,:\.", t'"'-

: , ..,'

\:

:

~'''''''''''''~

~

:',':

~

,

~ ,:

~ ;': L'~ '~":' :' ~~,';:

,". ' .

I

\,.-.."

\.

..

-

......

_------------_

__

\.,,~

,I'

""):

t'

I.

'

~ ',',

S

,-",,

',~,"',

.:~~ ,','~"

":'\

"'.~

~

,.'"

n,'l • \.,~:

~~"~~

:~" " ~

'.1

~

~

'.

" ,

... ...

",'

.....

...

_-_

......

I

1

.

I •

1..

",",'.;,'

•••

.'

.

\

'

/

.................................................

· .

•

·

·

•

·

•

•

·

·

:

" "'

s\~

- \ .

..

',

:

.\\\':

· .

· .

· .

i

~

:

~:

i

:

\.~,:

:

~-,~

:

:

~,~\:

· .

\':~~

'-'

~-:

,

.

.

I..

..~,...\,.......

. \

Fig.9

Fig.10

In most hard-packed materials, to fill the Bucket it

necessary

back. Avoid driving onto the material if

to

raise the

Load

Arms while rolling the Bucket

at

is

also

all possible.

With the Bucket filled, back the Loader away from the

material

rest the Load Arms down

onto

the

Frame

and

before proceeding to the dumping area.

WARNING:

or

A

.

incline

(loaded

Fork

the

Loader

or

ramp, ALWAYS travel

Bucket

ALWAYS

LOW

with

Frame. When

end)

toward

carry a loaded

the

Load

Arms

operating

with

the

top

Bucket

resting

on an

the heavier

of

the

incline.

on

end

15

Page 16

,'

...

..........

..................

\:

~ "

\

\.

... .....

1,

\,

...

-

."" '-""~

_----

_.

.....

.....

', " S \

__

..

_-_..

__

...........

,

,

, .

\

.'

I..L_'~" _''''

••••

\

,

,

,

I ,

I ,

I

I

i

~

:

i

~

:

:

,~,:

:

~":

:

~J~:

\':

~-'-'

~

':

S

:'~:.:~;~\..,~"~.

~ ~,\::~:

'L~:'~~ '

','

~ ~.:~'~'~',:

,:. :'~,'

~:

~

-''-1, '

\"-.."".-

,"

..

".',.~

I

\.----_._-------------_

~

~

~

S

...

_---)

I '

I..

c,:;·

.x·

...

....

I

I

I

I

Fig.11

Dumping the Bucket or Fork

Onto

a Pile

Carry

the loaded Bucket

or

Fork

low unt il reaching the

pile. Then, stop forward motion and raise

high enough so

the pile.

Then

the Bucket

Empty the Bucket

while lowering the Load Arms

Fork

back.

Into

a Box

Carry

the loaded Bucket

truck, trailer

box.

Then, stop

of

the

box to raise the

box. Slowly move the

Bucket

or

material

Load

the

that

the Bucket

, slowly move the

or

Fork

to spill the material

or

Fork

or

spreader box squarely with the

or

or

Loader

and

and

Fork

Fork

back the

rolling the Bucket

low and

forward motion well away from

Load

Arms and clear

Loader

Fork

over the inside

is

dumped, back away from the

ahead

of

the box. After the

Arms while rolling the Bucket

ahead

on

the

Load

clears

to position

top

Loader

approach

the

to

position

box

or

Fork

Arms

the

top

of

ofthe

pile.

away

or

the

sideofthe

the

side

side ofthe

the

and

lower

back.

Fig. 12

NOTE: A Bucket can be conveniently used to

•

spread the pile inside the box

by

positioning

the Bucket Cutting Edge against the near side of the

pile and rolling the Bucket back while slowly driving

forward and pushing the top of the pile forward.

Over a Solid

A

Embankment

WARNING: DO

excavation or ditch!

NOT

drive too close

BE

SURE surrounding

ground has adequate strength

to

support

to

an

weight of the Loader and load!

Carry

the

loaded Bucket

the

toward

where

of

the embankment.

forward

After

emb

the Bucket

dumping area.

the

Bucket

and

raise

the

material

ankment while

or

or

the

Fork

or

Fork

Stop

the

Loader

Fork

extends half-way over

Then

, roll

the

Load

Arms to

is

dumped, back away

lowedng tbe

Load

back

low while traveling

at

the position

the

edge

Bucket

dump

or

Fork

the material.

from

the

Arms and rolling

16

Page 17

Scraping with a Bucket (Figs. 13 & 14)

Both HL360 Skid Steer Loader models, units with either

2-Spool

scraping with a Bucket attached

or

3-Spool Control Valves,

to

the

can

be used for

Load

Arms.

For

scraping, the Loader should be operated in the forward

direction. First position the

Load

appropriate level which allows the Bucket

place the Bucket Cutting Edge

at

Arms

to

be tipped to

a slight angle

at

to

the

the

surface being scraped. While traveling forward with the

Bucket in this position, material can flow over the

and

Cutting Edge

collect inside the Bucket.

...

·

•

·

·

·

•

·

·

·

·

·

•

·

·

·

·

..................

.~.

---

..

-

_._.

-----

---_

........

---

---_

.. ----

--- -- - - -

.......

\

\

l _

___

___ __ . __ .

_--_

~

\"

.....................

,'

.. ','

." S

. .

,\,,,-,.,,~

_____ . __

.....

....

..

.

\

\

.l

\,';'

:~

.....

'

Fig.14

· ·

·

· .

· .

· .

:

:

:

:

:

· .

\'::

·

·

,

"""""",''

\'

:

.~\\:

~ l"'

,,\H'-;:\

~

:

~:

\.~,:

~,~:

~~,:

'

~'.~~

-:

~ )~,Y

:

\.,' .\:

:

~''''''''''''~

:

~

:

~

•

·

:

~"_\:~:~

1.._

--- ---------------------

L'~

~:',"~<~,:~T ~ '::~

,,'" ~"l" ~

1,~,1,'v

n

.'l \ "'~:

: '~'~':~:

~\

,',~

~' ~

~,\:

:::~~~',:~

"

I"

~

·:u~

Fig.13

.

,.

~

""

Leveling with a Bucket (Fig. 15)

NOT

.

E:

.

,

.

\

:

,,

:

\

•

Load Arms

equipped with the Float "detent" feature, that

HL360 with 3-Spool Control Valve and Auxiliary

Hydraulics.

Levelin~

First drive the Loader

:

-,

levelled. Then, with the Load Arms down against the

Frame, push the Lift / Tilt T-bar into the Float position

with a Bucket attached to the

is

best accomplished with a Loader

to

the outer edge

of

the area to be

is,

an

and roll the Bucket forward to place the Bucket Cutting

at

Edge

Proceed to level the area

a 30 to 45° angle to the surface to be levelled.

by

driving the Loader

backward.

17

Page 18

( ..................................................\

, ,

, ,

, ,

:

" -~

"

",' ,

:

~"

:

~q;

,

."

:

\~

i~

~

,

,

,

,

,

,

,

:

~~~~

~

\,,~

...

-.~~~~,

~,

..

'.'"

''

.

..

"

.......

"'~

...........~ ..\

s

:

,~'

\

\~

:."

........

:

.~:

,

~

\

.....

~',~}

:

~

,

~.

:'~"

.

\'

"'\ \

1"

, ,

,

\ , '

l"_;~\

.....

:

~

.

~

\

\

':

:

:

\

:

\

,

\

\

\

\

\

\

\

,

\

,

\

·'

Fig. 15

Bucket and Fork Mounting (Figs. 16 & 17)

HL360 Buckets and Forks are designed for quick and

convenient attachment and detachment.

Bucket or Fork, approach

it

from the rear with the Load

To

attach a

Arms resting against the Frame and the Tilt Cylinders

partially extended. Drive the Loader against the back of

the Bucket or

Attachment Plate in front

the Attachment Lip on the back

Fork

head-on and squarely so that the

of

the Load Arms slides under

of

the Bucket. With the

Lip positively engaged, retract the Tilt Cylinders

completely. Then, shut off the Loader engine, leave the

Operator's Compartment and jnstall the Attachment

Pins and Lockpins in the position and direction shown.

To detach the Bucket or Fork, reverse the process.

Fig. 16

Fig.

17

Auxiliary Hydraulics (Fig. 18)

HL360 Loader models with 3-Spool Control Valve and

Auxiliary Hydraulics connections have a

control mechanism to operate a secondary device, such

Foot

Pedal

as

a Grapple Attachment. Pushing the Pedals with the toe

closes the Grapple. Pushing the Pedals with the heel

opens the Grapple. Both Pedals are welded onto a

common Shaft.

all

the

way

NOTE: Pushing the Pedals

•

with the toe engages the "detent" position

oil

enabling continuous

flow.

down

WARNING: ALWAYS install or remove the

A

Attachment

Pins

and

Lockpins with the

engine shut OFF and the Load Arm

LOWERED completely.

18

Fig. 18

Page 19

ADJ

U

STME

NTS

Simplicity

minimum

proper Loader operation.

•

provided, it

day.

A

or when it

ENGINE

All information related

operating settings

Manual

HYDROSTATIC

After break-in and through the course

operation, the Hydrostatic

and stretch .

•

and adjust Drive Belt tension

excessive Belt wear

Sheaves using details provided

Alignment topic

manual. If Belt tension

NOT

slip and wear faster. I mproper Belt tension likewise

causes excessive wear and early failure.

of

HL360 design and functions makes for a

amount

NOTE:

day" basis and since

WARNING: Refuel

open flames and potential sparks. NEVER

refuel the Loader while the engine

is

furnished with the Loader.

NOTE: After the first 10 hours of operation and

at regular 10 hour intervals thereafter, check

disengage. If tension

of

readjustment required to maintain

If

the Loader

is

advisable to refuel before starting the

HOT.

is

PUMP

is

in

is

operated

NO

in

a safe place away from

to

engine adjustments and

detailed in the separate Engine

DRIVE BELT (Fig. 19)

Pumps

noted,

the Service section of this

BE

is

too tight, the Pumps will

is

too loose, the Belt will

on

a "day-to-

gasoline gauge

is

running

of

normal

Drive Belt will wear

as

necessary.

SU

RE

to

realign the

in

the Sheave

is

If

WARNING: The above procedure

A

with the engine running and the Loader

position. Shut the engine off and carefully leave the

Loader to block it up BEFORE attempting

the engine or to perform any adjustment or service

routines. DO

maintain this position without additional blocking

or supporting.

With the Loader Tires off the ground, shut the engine off

and remove the Ignition Key. Next, remove the Seat

assembly for access to the Drive Belt. Then, loosen (bu t

do

Pump

up as far as possible and snug the

the Plate in this positions.

the Loader should only

DO

NOT

leave the Operator's Compartment

NOT

rely on the Loader Hydraulics to

NOT

remove) the (4) bolts which secure the Idler and

Mounting Plate to the

be

used for just

Frame

. Then, pry the Plate

(4)

bolts enough to hold

for

to

raising

that.

in

this

restart

WARNING: Attempt Belt tension readjust-

A

adjust Belt tension, the Loader Wheels

rotate. Refer to Service section for "Neutral"

adjustment.

To readjust the

and properly block the Loader up so

are

Raising the Loader can

first placing two equal height (approximately

solid blocks

rear Wheels and under the rear corners

Frame

Idler disengaged

Loader Frame, extend the Tilt Cylinders to roll the

Bucket and pick the Loader off the ground; stop when all

four

ment ONLY after the correct Traction T -bar

"Neutral" position

Pump

NOT

touching the ground.

of

wood (at least 2 feet long) parallel with the

. Then, with the Hydrostatic

and

Tires are off the ground.

is

established.

Drive Belt tension, first carefully

that

be

conveniently accomplished by

Pump

the

Load

Arms down against the

To

MUST

all

four

5-1 / 2"

of

the Loader

Drive Belt

safely

NOT

Tires

tall)

Fig. 19

Then, making sure

"Neutral" position

start the Loader engine and note

are turning. Next, using a rubber malet

tap the corners

amounts until the

shut

the engine off and remove the Ignition Key and

proceed to tightly secure the (4) bolts to fix the Idler and

Pump

Mounting Plate position.

that

the Traction T-bar

and

with the

of

the Plate down slightly and in equal

Pump

Pump

Idler disengaged,

that

the

or

Sheaves stop turning. Then,

is

Pump

Sheaves

lead hammer,

in the

19

Page 20

LUBRICATION

WARNING: NEVER attempt to lubricate the

A

unauthorized or unexpected starting.

•

GENERAL INFORMATION

•

operation. Repeat lubrication and

regular 50 hour intervals thereafter. Under more

strenuous operation and/or

weather conditions or dusty conditions, change oil

and lubricate the Loader more often

It

grease will prevent excessive component wear and early

failure.

ENGINE OIL

Refer to Engine Manual provided for engine oil

requirements and type recommendations.

basi

replenish

HYDRAULIC & HYDROSTATIC OIL

Skid Steer Loader with the engine running. and Filter after the first 10 hours of operation

Remove the Ignition Key to prevent

NOTE: Log the date of Lubrication in the Maintenance Schedule.

NOTE: Properly lubricate the entire Loader

and replace engine

is

well

to

remember that a sufficient amount

s,

check the Oil Dipstick for level indication and

as

necessary.

011

after the first 25 hours of

011

replacement at

in

extremely cold

as

necessary.

of

On

oil and

a daily

NOTE: Replace the Hydrostatic/Hydraulic Oil

•

and at regular 100 hour intervals thereafter.

Check the Reservoir level on a routine basis every

hours

of

operation; add oil as required. An Oil Level

Indicator

monitoring. Add to or replace Hydraulic/Hydrostatic

Oil with Rando brand HD-AZ Hydraulic Fluid (if available) or otherwise use Type F Automatic Transmission

Fluid.

DRIVE CHAINS

HL360 Drive Chains run continuously in oil. The oil level

should be checked after every

maintained

the Plug in the floor

checking and adding oil.

the oil level. Replace the Drive Chain oil every

of operation. Remove the Plug in the front

to drain the oil. Add to

lOW

OILING

Apply

(at the bases

Linkage

is

provided for continuous visual level

at

a level

40 oil or equivalent.

10

to

15

of

Ball]

of

of

the Operator's Compartment for

drops

of

oil to the T-bar Swivel

the T -bars) and 2 or 3 drops

oints every

50

hours of operation

approximately I" deep. Remove

V

se

the engine Dipstick to check

500

of

the Loader

or

replace Chain Case oil with

Ball]

of

100

hours of operation.

oil

10

and

hours

oints

to

the

The Hydraulic and Hydrostatic systems share the same

fluid and Reservoir. Reservoir capacity

(19 liters). Maintain the oil level

from the top

force oil out the Vent Cap.

1.

Left Tilt Cylinder Pivots (Two Places)

2.

Attachment Plate Pivots (Two Places)

3.

Left Lift Cylinder Pivots (Two Places)

4.

Left Load Arm Pivot

5.

Right Load Arm Pivot

6. Right Lift Cylinder Pivots (Two Places)

7.

Right Tilt Cylinder Pivots (Two Places)

8.

Hydrostatic

of

the Reservoir; do

KEY

TO

LUBRICATION

(Grease each Fitting every 50 hours)

Pump

Idler Arm Pivot

NOT

is 5 V.S.

at

approximately 2"

overfill

as

this will

gallons

GREASE

All Grease Fittings are

found on farm implements and automotive equipment.

FITTINGS

of

a standard style commonly

5

6

20

6 7

Page 21

All HL360 Skid Steer Loaders are equipped with a Because of variation in safety laws for different states and

Bracket, for mounting a Slow-moving Vehicle Emblem

on the rear

of

the unit.

TRANSPORTING

localities,

location. Your Gehl Dealer can aid you in relocating the

Bracket

it

may be necessary to change the emblem

as

necessary.

21

Page 22

SERVIC E

WARNING: Perform

A

outlined.

BOLT TORQUE DATA

The

standard

mended

valVes

markings on the head

routines with the engine shut off, except

where noted within certain procedures

Chart

provided contains information concerning

hardware used on this machine.

that

all fasteners be tightened to the torque

specified. The Grade

of

General Bolt Torque Data

SAE-GRADE 5

BOLT

TORQUE TORQUE

SIZE

DRY LUB.

1/4 -

20

28

1/4 5/16 -18

5/

16 -24

16

3/ 8 3! 8 -

24

7/16-14

7/

16 -20

1/2 -

13

1/2 -

20

5/ 8 - II

5/8 -

18

*Multiply

8

10

17

19

30

35

50

55

75

90

150 110

180

by

(0.1383) for metric kg-m

of

the bolt

the bolt.

6.25

7.

16

13

14

23

25

35

40

55

65

130

all

loader

is

identified by the

in

It

is

Ft-lb*

Service

SAE-GRADE 2

DRY LUB.

5.5 4.17

6.33 4.66

II 8

12

20

23

32

36

50

55

100

110

85

recom-

9

15

17

24

27

35

40

75

Fig. 20

Adding Water

NOTE: loaders sold within th.e United States

O

are shipped

stalled and filled with the proper Electrolyte

Solution.

On

a routine basis after every

remove the Battery Vent Caps

level. The water

high temperatures

level should be

replenish

to

the

from

the factory with Battery in-

50

hours

and

inspect the Electrolyte

in

the

Electrolyte Solution evaporates

or

with excessive charging rates.

to

the

bottom

proper

of

the Filler Neck; if NOT,

level with distilled water.

of

operation,

at

The

Grade

(Plain)

NOTE: The following information

O

in

both the Troubleshooting Guide and the

Maintenance Schedule sections of this manual. It

should

in

Where indicated, certain service routines should

only

Gehl Company representative.

BATTERY (Fig.

The HL360 uses a

Electrical System has negative (-) ground.

also

this

section are Owner-Operator responsibilities.

be

carried-out

2

be

understood that all services covered

by

an

authorized Gehl Dealer or

20)

12

volt wet cell Battery. The

Grade

Marks)

(3

5

is

referred

to

Loader

22

NOTE: Do

O

specific gravity to drop below

NOT

allow the Electrolyte Solution

1.2000

at

80 F

(27 C).

Cleaning Terminals &Cable Connections

The

top

of

the Battery MUST be kept clean. Tighten

Vent Caps

an alkaline solution

water). After the foaming has stopped, flush the

the Battery with clean water.

Clamps are corroded, disconnect the Cables and clean

them with the same alkaline solution.

Jumping a Discharged Battery

If

Loader

sufficient power

can

A

instruction

avoid personal injury.

and

clean the Battery with a brush dipped in

(ammonia

Battery becomes discharged and fails to have

to

be used

to

obtain starting assistance.

WARNING: DO

the

loader

cause

it

in

start the

to

order and completely

Loader

NOT

Battery if it

rupture

or baking soda

If

Terminals

engine,

attempt

or

explode. Follow these

to

is

frozen; this may

and

jumper

jump-start

as

the

and

top

of

Cable

cables

stated to

Page 23

NOTE:

. a 12 volt battery.

•

1.

Turn

cable connections .

2.

Make sure

NOT

3.

Remove the Filler Caps from

check and replenish the Electrolyte levels before

proceeding.

4.

Place a clean cloth over the uncapped Vent Holes

both

A

5.

Interconnect the positive terminals (+)

batteries with one

6.

Interconnect the negative terminal

battery to

Frame

NOTE:

•

of times to make a good electrical contact.

NOT

short the jumper cables or cross them.

negative

be made directly to the Loader Battery to insure that

potential sparks are kept well away from the open

Filler Caps on the discharged Battery which will

tend to produce hydrogen gas.

7.

Proceed to start the Loader. Ifit does

mediately, start the engine

avoid excessive drain on the booster battery.

BE SURE

off both ignition keys before making

touching each other.

batteries

WARNING: If acid contacts your skin, eyes

or clothing, flush the area immediately with

large amounts of water.

an

or

engine block.

Twist the jumper cable clamps a couple

(-)

jumper cable connection should

thatthejumperbattery

that

both vehicles are in neutral

both

batteries

to

prevent boil-over and acid splash.

jumper

unpainted portion

cable.

of

of

NOT

of

the booster vehicle to

is also

jumper

and

and

of

both

the booster

the

Loader

DO

The

NOT