Page 1

503Z / 603

Compact Excavator

Beginning Serial Number: AC02471

®

Form No.

918070

Revision F

Aug. 2011

© 2011 All Rights Reserved. • Printed in USA

Operator’s Manual

Page 2

204937/AP0407

GEHL COMPANY

WARRANTY

GEHL COMPANY, hereinafter referred to as Gehl, warrants new Gehl equipment to the

Original Retail Purchaser to be free from defects in material and workmanship for a

period of twelve (12) months from the Warranty Start Date.

GEHL WARRANTY SERVICE INCLUDES:

Genuine Gehl parts and labor costs required to repair or replace equipment at the

selling dealer’s business location.

GEHL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND,

EXPRESS OR IMPLIED (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE), EXCEPT AS

EXPRESSLY STATED IN THIS WARRANTY STATEMENT.

ANY OF THESE LIMITATIONS EXCLUDED BY LOCAL LAW SHALL BE DEEMED

DELETED FROM THIS WARRANTY; ALL OTHER TERMS WILL CONTINUE TO

APPLY.

SOME STATES DO NOT PERMIT THE EXCLUSION OR LIMITATION OF THESE

WARRANTIES AND YOU MAY HAVE GREATER RIGHTS UNDER YOUR STATE

LAW.

GEHL WARRANTY DOES NOT INCLUDE:

1. Transportation to selling dealer’s business location or, at the option of the

Original Retail Purchaser, the cost of a service call.

2. Used equipment.

3. Components covered by their own non-Gehl warranties, such as tires, batteries,

trade accessories and engines.

4. Normal maintenance service and expendable, high-wear items.

5. Repairs or adjustments caused by: improper use; failure to follow recommended

maintenance procedures; use of unauthorized attachments; accident or other

casualty.

6. Liability for incidental or consequential damages of any type, including, but not

limited to lost profits or expenses of acquiring replacement equipment.

No agent, employee or representative of Gehl has any authority to bind Gehl to any

warranty except as specifically set forth herein.

Page 3

TABLE OF CONTENTS

Chapter 1 - General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ownership Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Excavator Component Indentification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Fluid Capacities/Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Undercarriage and Swing System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Fuse Box in Instrument Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Main Fuse Box and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Sound Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Coolant Compound Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

503Z General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

603 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Fields of Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Load Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Chapter 2 - Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unauthorized Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Attachment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mandatory Safety Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Before Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Exposure to Crystalline Silica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Parking the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

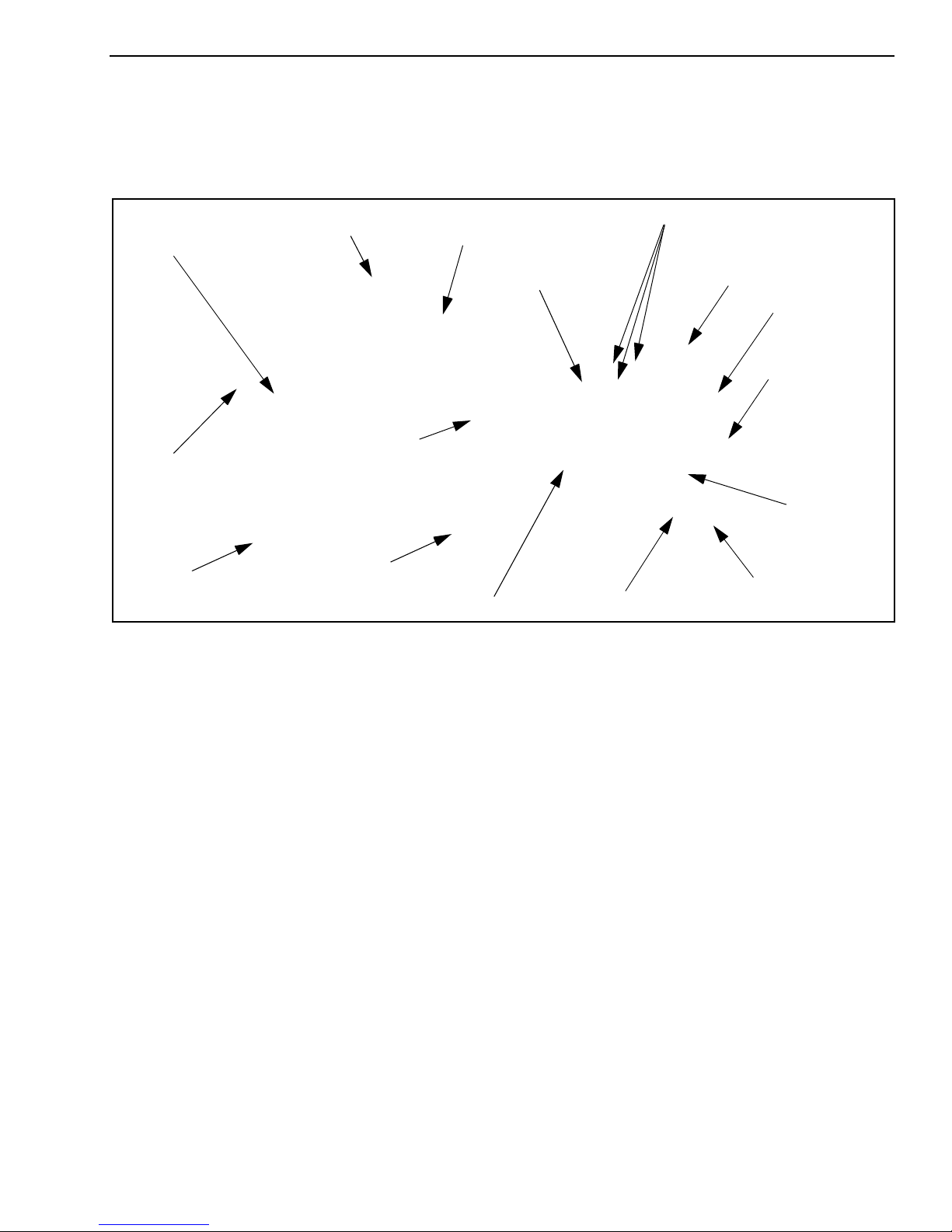

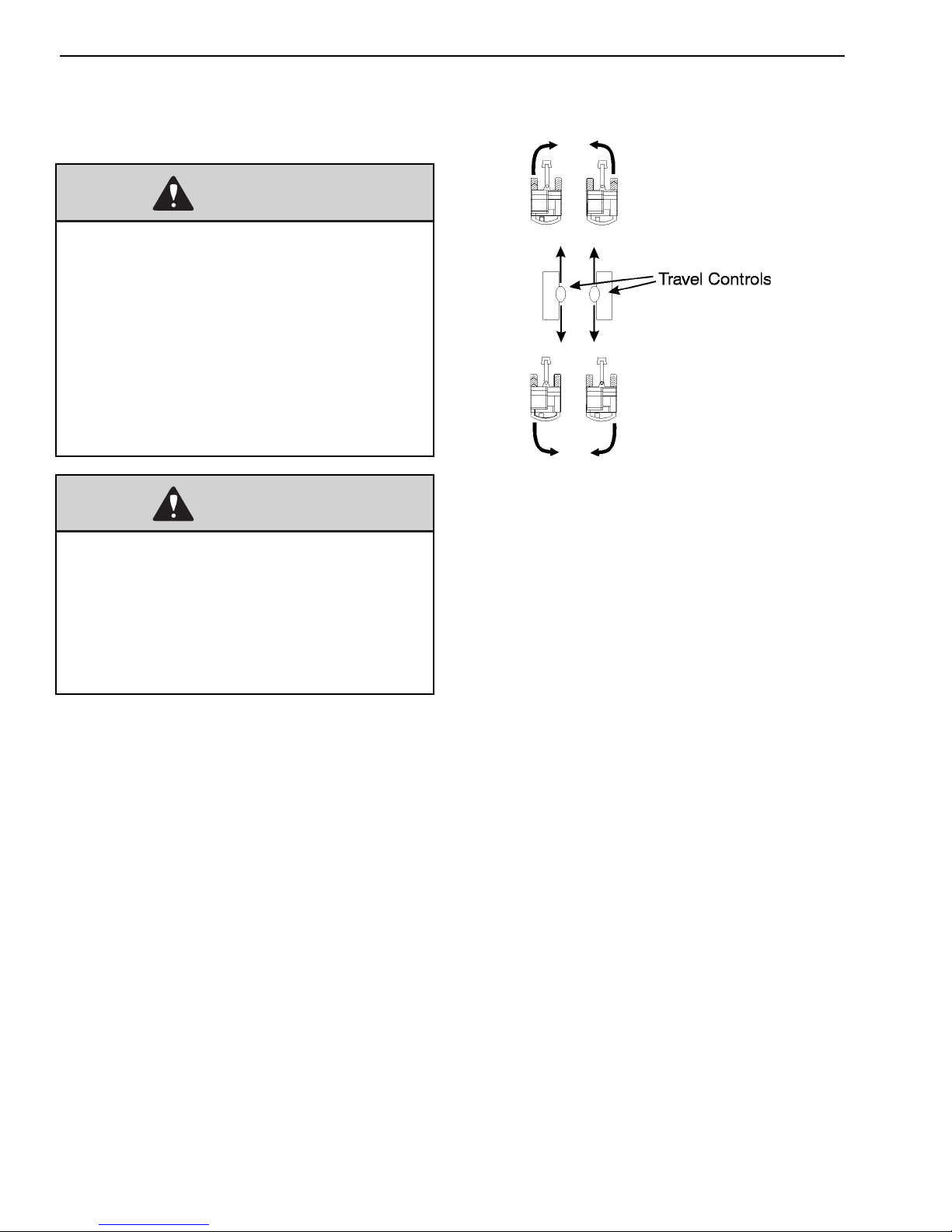

Travel Controls May Produce Reversed Travel Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Additional Travel Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Snow, Ice and Cold Temperature Operation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fire Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fire Extinguisher Recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Additional Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Hydraulic Cylinder Seal Periodic Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

High Pressure Hydraulic Lines Store Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Operator’s Cab and Swing Frame Deck Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Battery Electrolyte and Explosive Gas Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

918070/FP0811 i Printed in U.S.A.

Page 4

Battery Disconnection Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Jump-starting or Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Lifting the Machine with a Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

New Decal Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

ISO-Style Safety Decal Locations (Serial Numbers AJ02993 and Up) . . . . . . . . . . . . . . . . . . 2-11

ISO-Style Information Decal Locations (Serial Numbers AJ02993 and Up). . . . . . . . . . . . . . 2-14

ANSI-Style Safety Decal Locations (Serial Numbers AH02282 and Before) . . . . . . . . . . . . . 2-16

Chapter 3 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

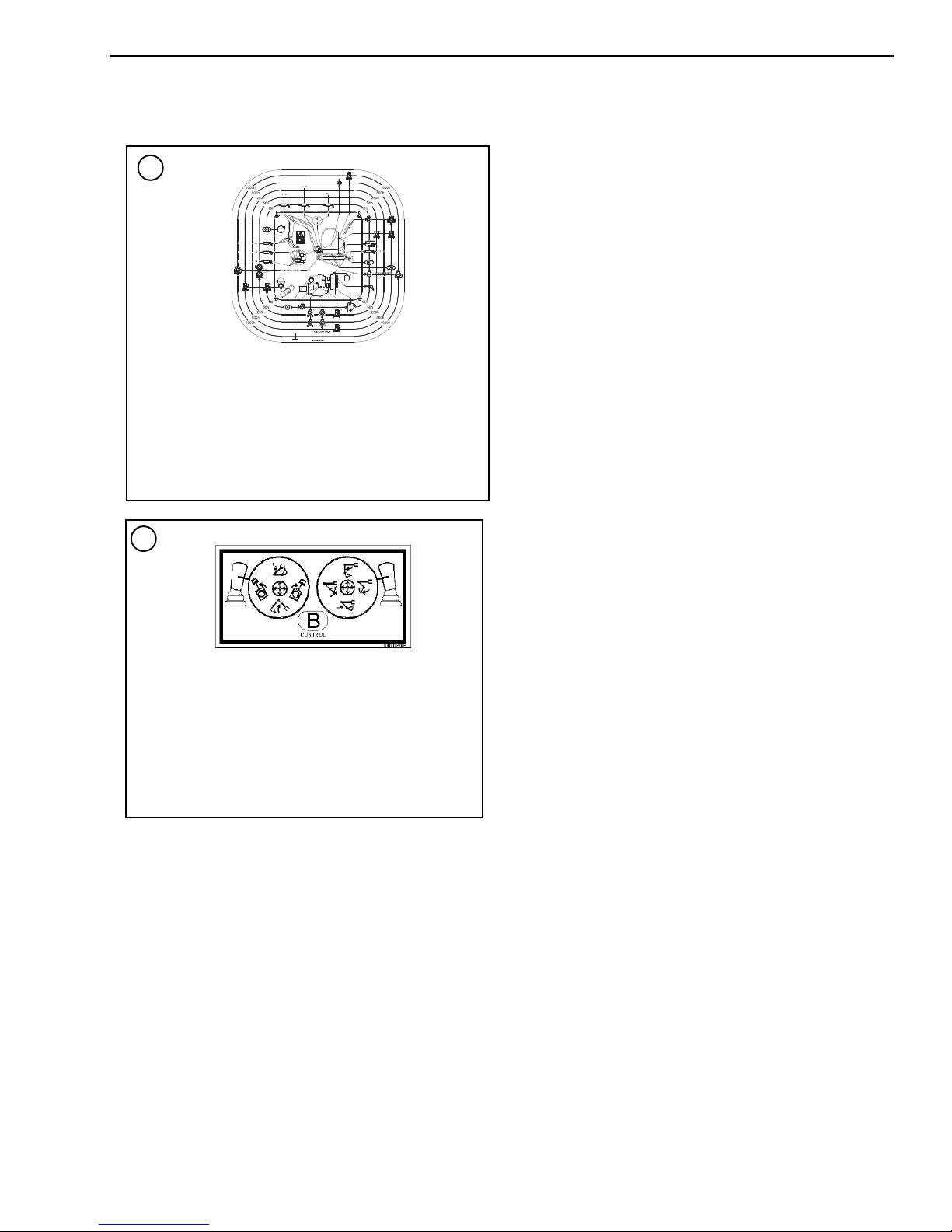

Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Machine Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ignition Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Battery Disconnect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Travel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Tilting the Cab or Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

SAE Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

ISO Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Boom Swivel/Auxiliary Hydraulics Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Throttle Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Optional Auto-Idle Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Operator’s Seat Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Arm rests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Seat Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Mounting/Removing Buckets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Auxiliary Hydraulics Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Pre-Operation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Engine Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Operating on Slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Cold Weather Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Operating in Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Swiveling the Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Grading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Excavation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Excavating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Loading Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Optional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Proportional Auxiliary Hydraulic

Joystick Control (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Two-Speed Variable Auxiliary Hydraulic Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Printed in U.S.A. ii 918070/FP0811

Page 5

Auxiliary Hydraulic Hammer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Chapter 4 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Care and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Maintenance Label Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Maintenance Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Check, Clean and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Fluid and Filter Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cab Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cab Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Leakage Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Recommended Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Changing Engine Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Air Cleaner Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Cooling System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Checking and Adjusting V-Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Checking and Adjusting Air Conditioning V-Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Track System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Windshield Washer Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Long-Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Before Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

After Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Chapter 5 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Seals and Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Traveling Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Bucket, Boom and Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Engine Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Error Diagnostic Code Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Engine Diagnostic Codes Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Chapter 6 - index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

918070/FP0811 iii Printed in U.S.A.

Page 6

NOTES

Printed in U.S.A. iv 918070/FP0811

Page 7

CHAPTER 1 – GENERAL

1

2

INFORMATION

INTRODUCTION

The information in this Operator’s Manual was written

to give the owner/operator assistance in preparing,

adjusting, maintaining and servicing the Compact

Excavator. More important, this manual provides an

operating plan for safe and proper use of the machine.

Major points of safe operation are detailed in Chapter 2

– Safety.

Read and understand the contents of this manual com-

pletely and become familiar with the machine before

attempting to operate it. Contact your dealer to obtain

additional manuals.

Throughout this manual, information is introduced by

the word Note or IMPORTANT. Be sure to read the

message carefully and comply with the message. Fol-

lowing this information will improve operating and

maintenance efficiency, help to avoid breakdown and

damage and extend the service life of the machine.

Do not use the machine for any application or purpose

other than described in this manual. Consult your

dealer before using special attachments or equipment

not approved for use with the machine. Any person

making unauthorized modifications is responsible for

the consequences.

The Gehl dealer network stands ready to provide any

assistance you may require, including genuine Gehl

service parts. All service parts should be obtained from

your dealer. Give complete information about the part

and include the model and serial number of the

machine. Record the serial number in the following

space, as a handy reference.

Purchased from:______________________________

Date of Purchase: ____________________________

Model No.: _________________________________

Serial No.: __________________________________

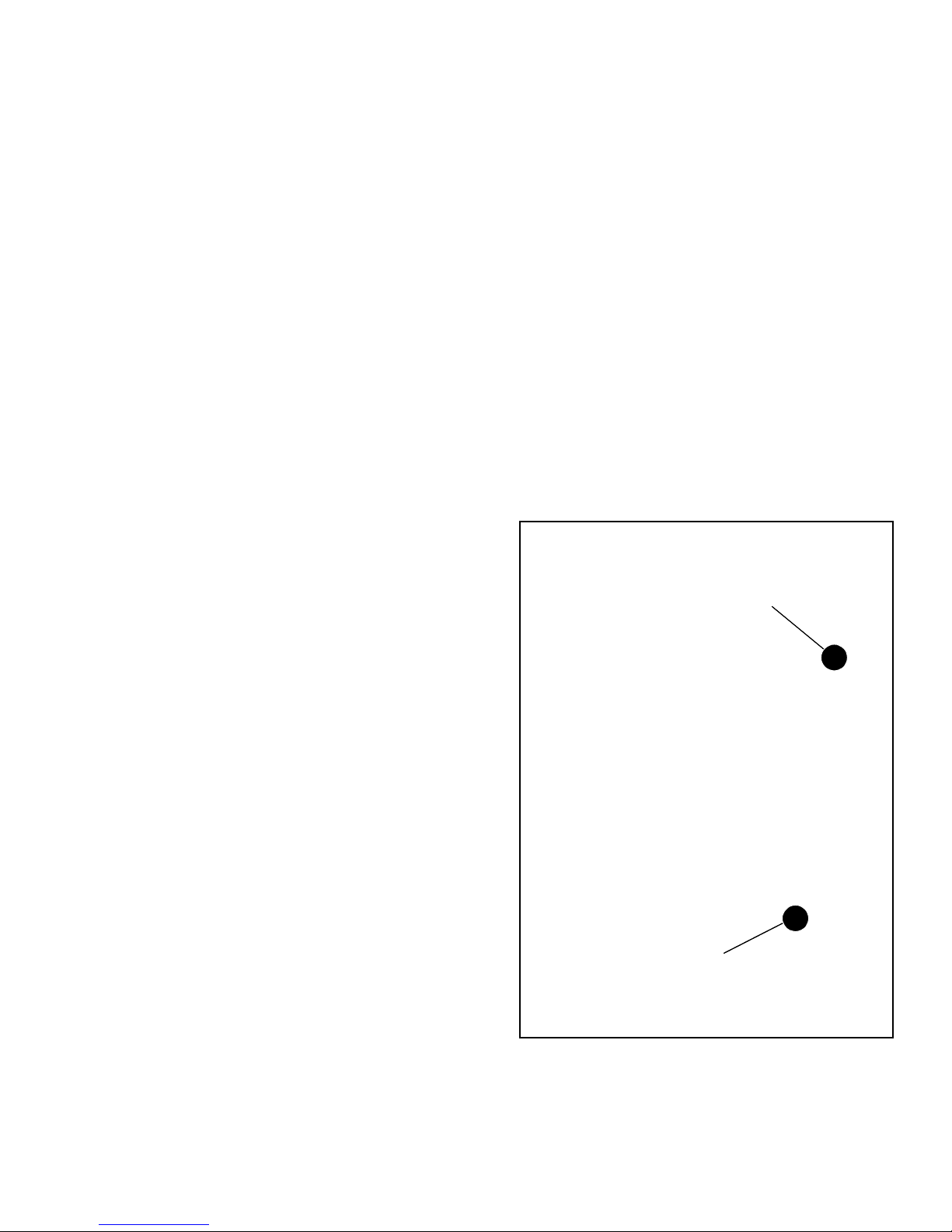

Serial Number Location

The machine serial number plate (1, Figure 1-1) is

located on the front frame, below the operator’s cab.

The cab/canopy serial number (2) is located on the right

rear of the frame next to the rear window.

The use of the machine is subject to certain hazards

that cannot be eliminated by mechanical means - only

by exercising intelligence, care, and common sense.

Such hazards include, but are not limited to: hillside

operation, overloading, instability of the load, poor

maintenance and using the equipment for purposes for

which it was not intended or designed.

It is essential to have competent and careful operators,

not physically or mentally impaired, who are thor-

oughly trained in safe operation and proper load han-

dling.

It is recommended that operators be capable of obtain-

ing a valid motor vehicle operator’s license.

Some illustrations in this manual may show doors,

guards and shields open or removed for illustrative pur-

poses only. BE SURE all doors, guards and shields are

in their proper operating positions BEFORE starting

the engine to operate the machine.

Manitou Americas, Inc. reserves the right to make

changes and improvements in the design and construc-

tion of any part without incurring the obligation to

install such changes on any unit previously delivered.

Figure 1-1 Serial Number Plate Locations

918070/FP0811 1-1 Printed in U.S.A.

Page 8

Engine Serial Number Location

Engine serial number label

Model 503Z: Serial numbers AH00579 and up

Model 603: Serial numbers AH00645 and up

Engine serial number label

Model 503Z: Serial numbers AH00578 and before

Model 603: Serial numbers AH00644 and before

The engine serial number label is located on the cylinder head cover

Ownership Change

If this machine was purchased “used,” or if the owner’s

address has changed, please provide your GEHL dealer

or GEHL Company Service Department with the

owner’s name and current address, along with the

machine model and serial numbers. This will allow the

registered owner information to be updated, so that the

owner can be notified directly in case of an important

product issue, such as a safety update program.

Printed in U.S.A. 1-2 918070/FP0811

Page 9

Excavator Component Indentification

Dipper Arm Cylinder

Boom

Bucket

Bucket Cylinder

Dipper Arm

Boom Cylinder

Dozer Blade

Track Frame

Travel Drive Motor

Swing Frame/

Superstructure

Hydraulic/Fuel

Tank Cover

Counterweight

Operator ’s Seat

Operati o n C o nt rols

Swing Cylinder

Engine Cover

Figure 1-2 Component Names

918070/FP0811 1-3 Printed in U.S.A.

Page 10

SPECIFICATIONS

Fluid Capacities/Lubricants

Note: Capacities i ndicated are approximate.

Component/Applica-

tion

Diesel Engine

Travelling Drive Gearbox Oil

Hydraulic Oil Tank

Lubricant Specification Season/Temper-

ature

SAE 10W-40 (according to

Engine Oil

b

DIN 51502); API: CD, CF,

CF-4, CI-4

-4°F (-20°C)

+104°F (+40°C)

SAE E3, E4, E5

Q8 T 55, SAE80W-90

Gearbox Oil

c

FINA PONTONIC GLS

Year-round

SAE80W-90

HVLP46 (according to DIN

Hydraulic Oil

Biodegradable Oil

d

51524 section 3)

PANOLIN HLP Synth 46

e

FINA BIOHYDRAN SE 46

Year-round 11.9 gal. (45 L)

Capacity

Model 503Z: 8.2

qts. (7.8 L)

Model 603: 10.8

qts. (10.2 L)

About 0.3 gal.

(1.3 L) each

a

BP BIOHYD SE-46

Grease

Grease Fittings

Battery Terminals

Roller and Friction

Bearings

Open Gear (live

ring gears)

Multipurpose

Grease

f

Acid-proof Grease

FINA Energrease L21M

Year-round As Required

BP Energrease MP-MG2

FINA Energrease L21M Year-round As Required

g

FINA Marson L2 Year-round As Required

No. 2-D, DIN 51601 grade Over 39°F (4°C)

Diesel FuelTank Diesel Fuel

Engine and Hydraulic

Oil Cooler

Coolant Water + antifreeze; SP-C Year-round 1.8 gal. (5.5 L)

Refrigerating Agent R134a

Air Conditioning

Compressor Oil Sanden SP10

No. 1-D, DIN 51601 grade

Below 39°F

(4°C)

Year-round

20.6 gal. (78 L)

1.7 lbs. (750 g)

3

7.1 in

(116.5 cm3)

Windshield Washer Cleaning Agent Water + Antifreeze Year-round 5.3 gal. (2 L)

a. Capacities shown are approximate; use only oil level check to determine correct oil level

b. BP Vanellus MG 15W40, BP Vanellus C-Extra 10W30, Chevron Delo 400 15W40 or equivalent; Refer to engine operator’s manual for more

detailed information about recommended oil grade type use depending upon ambient temperature.

c. Hypoid gearbox oil based on basic mineral oil (API GL-4, GL-5)

d. Mobile DTE15M, Amoco Rykon 46, BP Energol HLP-HD 46 or equivalent

e. Hydraulic ester oils (HEES)

f. FINA Energrease 21M, Chevron RPM Heavy-Duty Grease No. 2, Mobilgrease Moly 52, or BP Energrease Moly EP2

g. Standard acid-proof grease

Printed in U.S.A. 1-4 918070/FP0811

Page 11

Engine

Engine 503Z 603

Engine Model Serial Numbers AH00579 and up:

Yanmar 4TNV88-BPNS

EPA Tier III

S/N AC02471-AH00578:

Yanmar 4TNV88-PNS

EPA Tier II

Type Water-cooled 4-stroke, 4 cylinder diesel engine

Displacement 134 cu. in. (2.19 L) 202 cu. in. (3.32 L)

Bore and Stroke 3.5 x 3.5 in. (88 x 90 mm) 3.9 x 4.3 in. (98 x 110 mm)

Horsepower (DIN) 37.8 hp (28.2 kW) @ 2400 rpm 57.0 hp (42.5 kW) @ 2100 rpm

Max. Torque 102 lb.-ft. (138 Nm) @ 1100 rpm 184 lb.-ft. (249 Nm) @ 1400 rpm

Max. Engine Speed (with no load) 2575 +/- 50 rpm 2275 +/- 50 rpm

Idle Engine Speed 1050 +/- 50 rpm

Fuel Injection System Direct injection

Starting Aid Glow plug (Preheating time 10-15 seconds)

Max. Inclined Angle (engine still sup-

plied with oil)

Note: The machine’s theoretical climbing ability

25° in all directions

(30°/ 58%) exceeds this angle!

Exhaust Emission Compliance 97/68 EC; U.S. EPA

Engine Oil Capacity 8.2 qts. (7.8 L) 10.7 qts. (10.1 L)

Engine Coolant Capacity 7.4 qts. (7.0 L)

Serial Numbers AH00645 and up:

Yanmar 4TNV98-ZVNS

EPA Tier III

S/N AC02513-AH00644:

Yanmar 4TNV98-VNS

EPA Tier II

Hydraulic System

Hydraulic System 503Z 603

Pump Two variable-displacement + two gear pumps

Flow Rate 2 x 14.2 gpm + 10.9 gpm + 3.0

gpm @ 2590 rpm

(2 x 53.6 L/min + 41.4 L/min

+11.6 L/min) @ 2590 rpm

Operating Pressure (working and driving) 3408 psi (235 bar) 3553 psi (245 bar)

Operating Pressure (swing unit) 3336 psi (230 bar) 3480 psi (240 bar)

Hydraulic Fluid Cooler Standard

Hydraulic Reservoir (system capacity) 21.1 gal. (80 L)

Filter Return filter

2 x 15.7 gpm + 11.8 gpm + 2.5

gpm @ 2290 rpm

(2 x 59.6.1 L/min + 44.7 L/min +

9.6 L/min) @ 2130 rpm

918070/FP0811 1-5 Printed in U.S.A.

Page 12

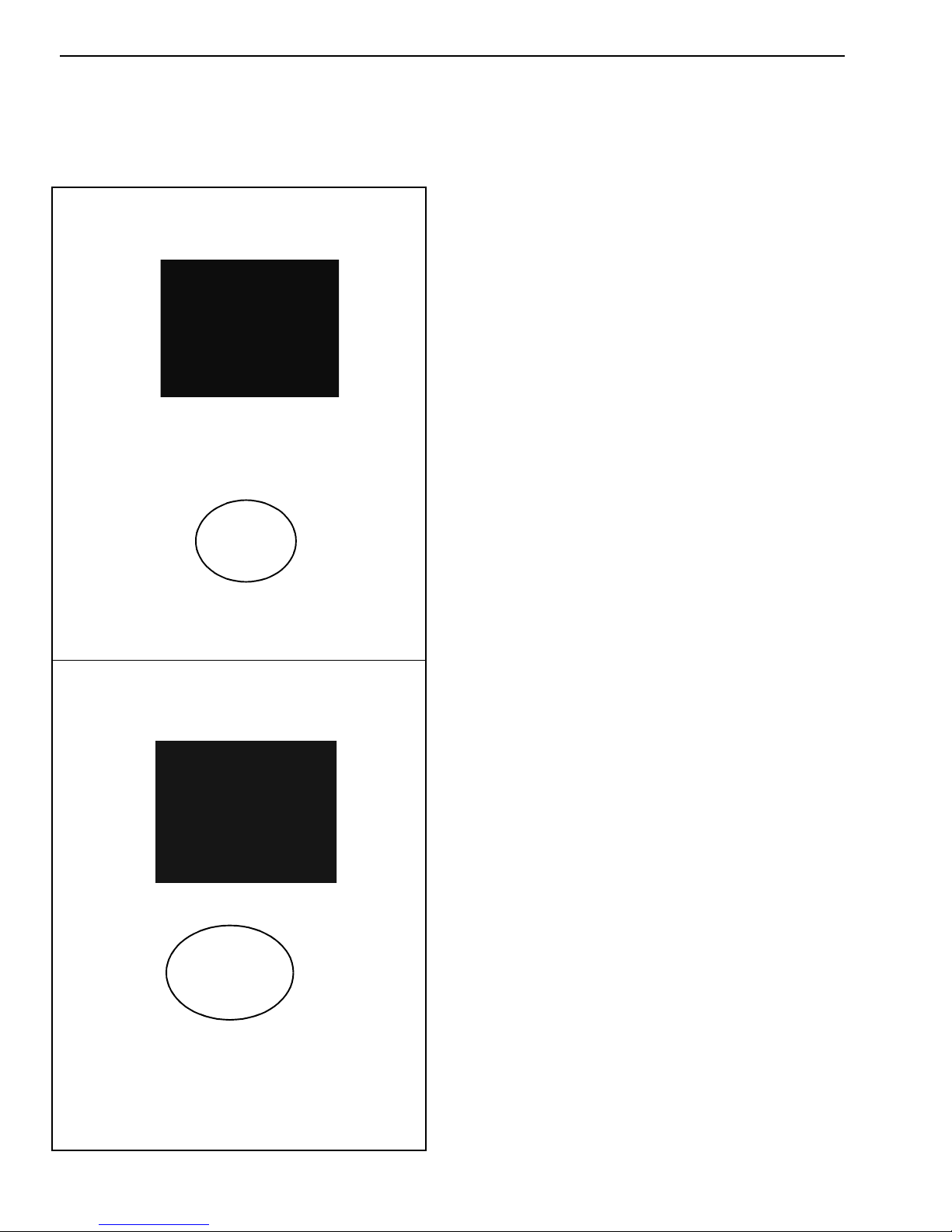

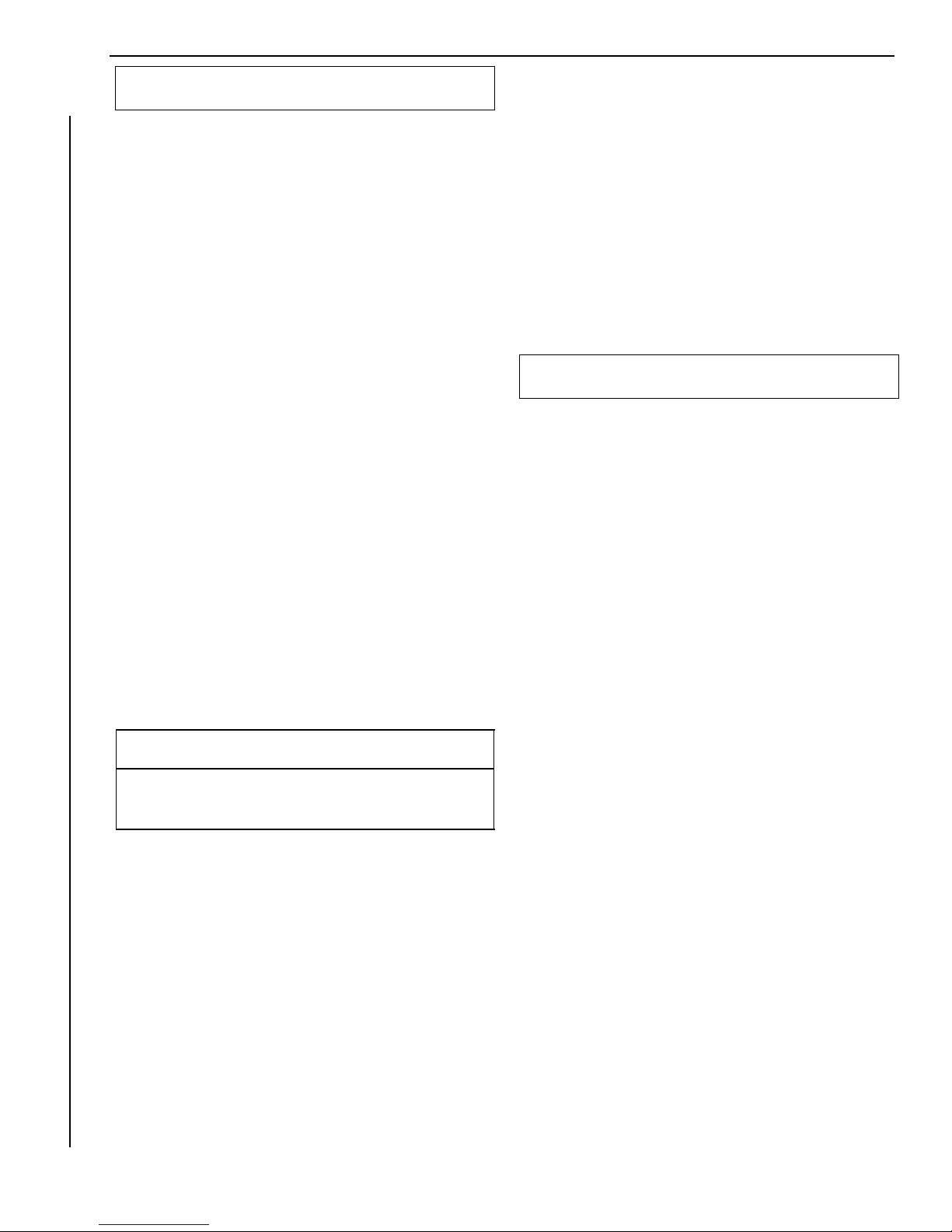

Undercarriage and Swing System

F3

F4

F8

F9

F10

F5 F6 F7

Serial Numbers to

AH02282

Located on top of right

inside cab/canopy

interior trim.

Serial Numbers

AJ02993 and up

Located on inside of

right cab/canopy

interior trim

Undercarriage and Swing System 503Z 603

Travel Speed

Low Speed 1.7 mph (2.74 km/h) 1.7 mph (2.76 km/h)

High Speed 2.8 mph (4.56 km/h) 3.0 mph (4.76 km/h)

Ground Clearance 11.8” (300 mm) 13.2” (335 mm)

Swing Speed 8.7 rpm 9.0 rpm

Gradability 30

° (58%)

Rubber Track Width 15.7” (400 mm)

Number of Track Rollers 4 per side 5 per side

Average Ground Pressure

3.84 psi (0.28 kg/cm

2

)

Dozer Blade

Dozer Blade 503Z 603

Width 78.3” (1990 mm) 78.3” (1990 mm)

Height 15.0” (380 mm) 16.7” (425 mm)

Maximum Lift Above Ground 15.2” (385 mm) 15.3” (390 mm)

Maximum Depth Below Ground 15.4” (390 mm) 15.7” (400 mm)

Electrical System

Alternator 12-V, 55-A

Starter 12-V, 2.3-kW

Battery 12-V, 88-Ah, BCI group size 49 (93 opt.), 680 CCA

Socket 15-A max. - Cigarette lighter

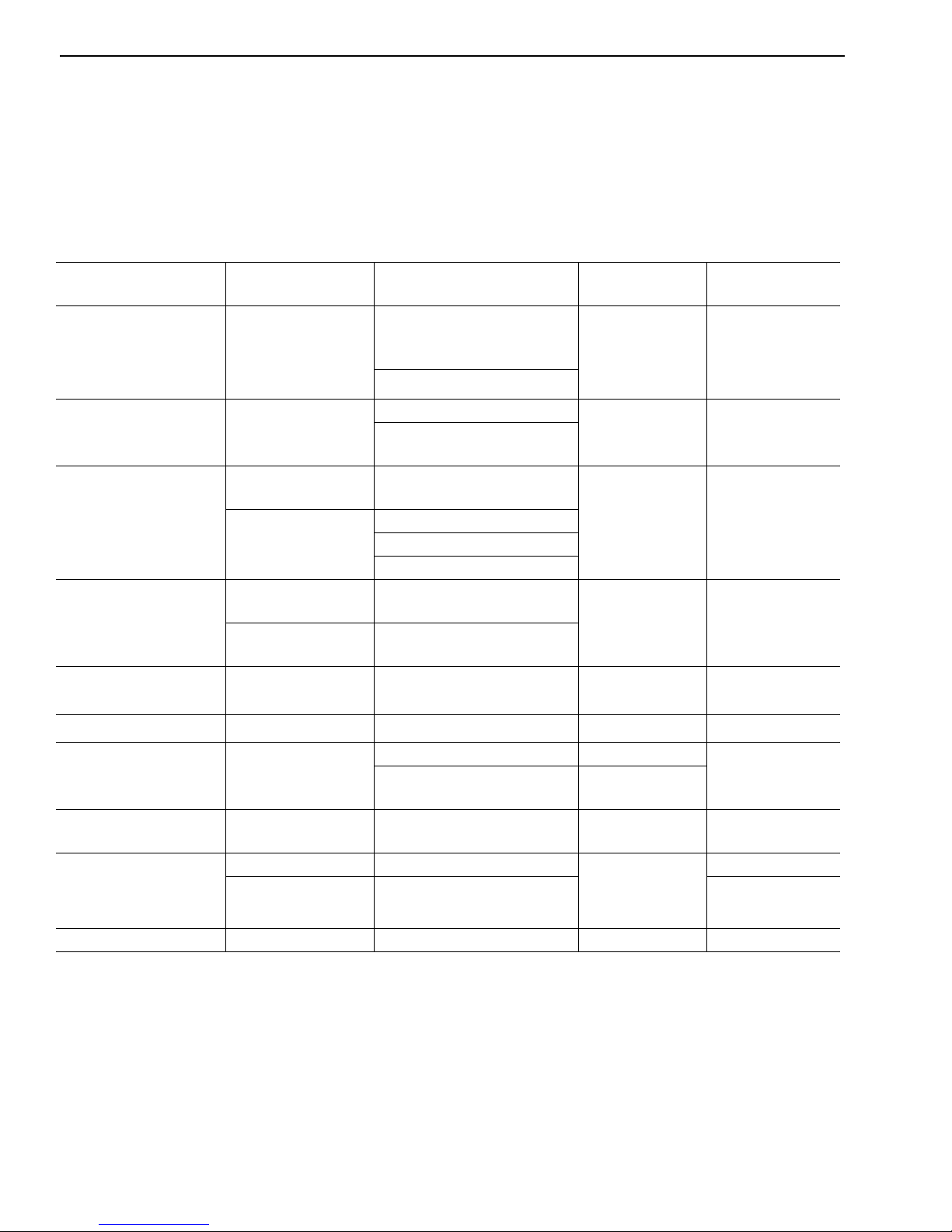

Fuse Box in Instrument Panel

Fuse

No.

F3 10 Amp Indicators, cut-off solenoid, relays

F4 10 Amp Boom light

F5 15 Amp Roof lights

F6 10 Amp Valves, horn

F7 15 Amp Heating, air conditioning

F8 10 Amp Windshield wiper, interior light

F9 10 Amp Rotating beacon, radio

F10 15 Amp Socket, cigarette lighter

Rated

Current

Protected Circuit

Printed in U.S.A. 1-6 918070/FP0811

Page 13

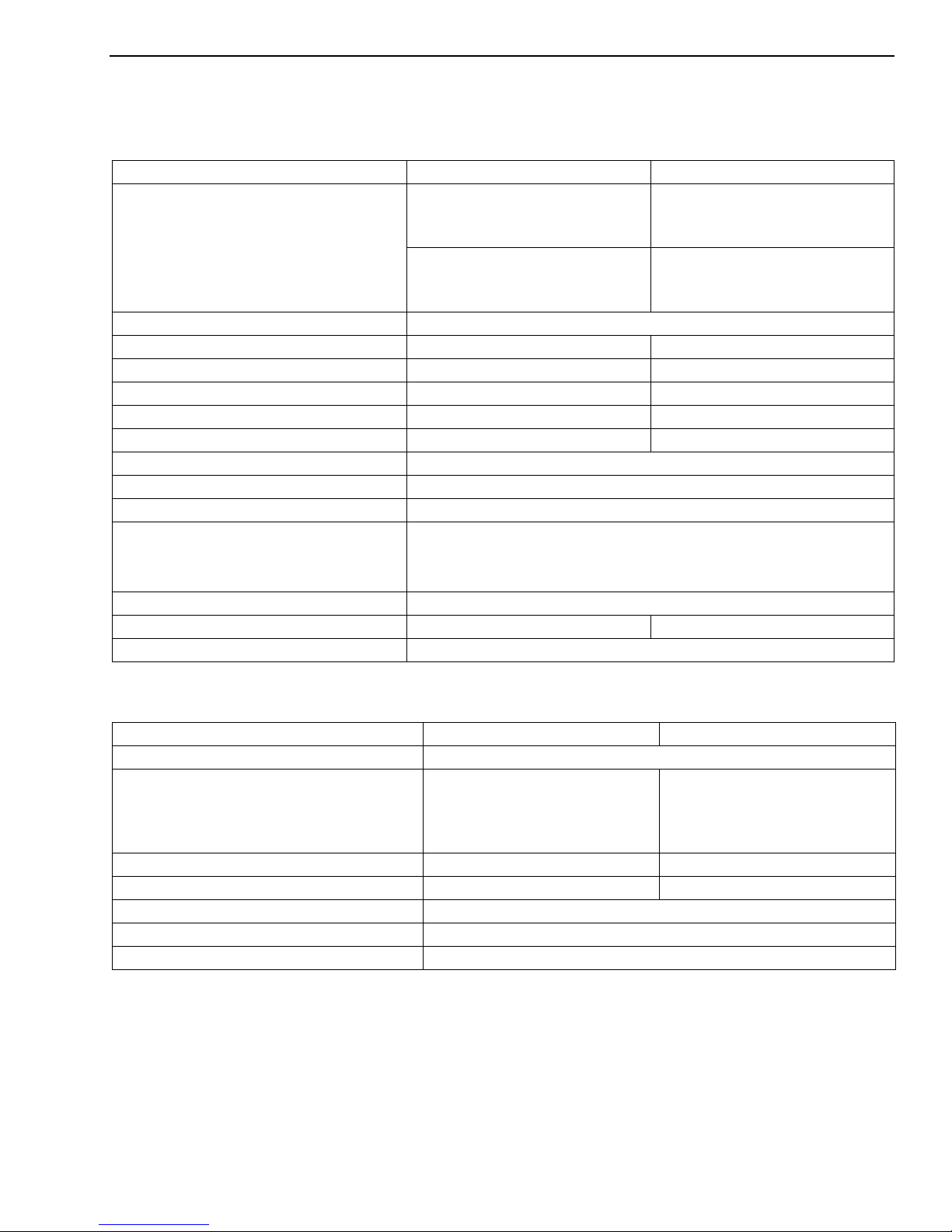

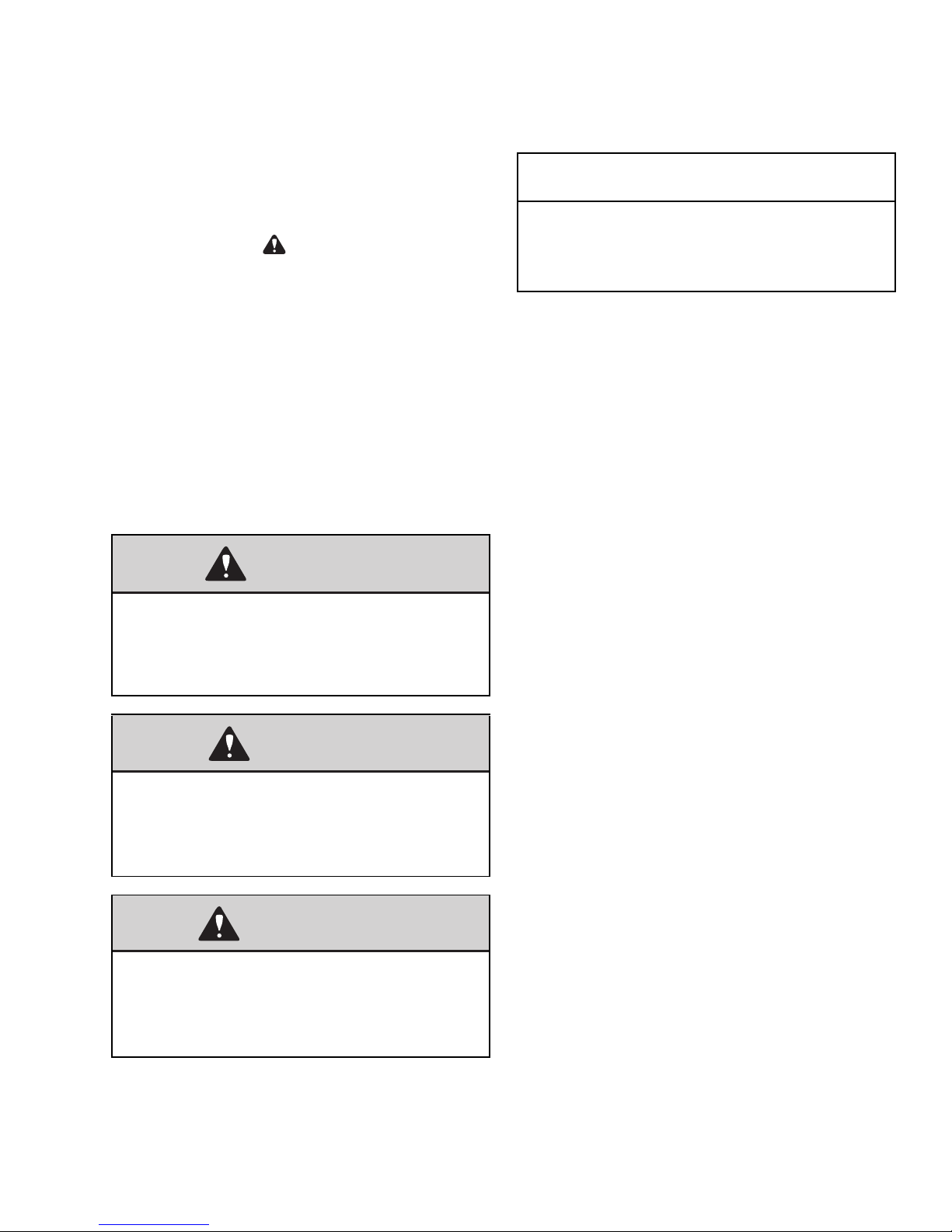

Main Fuse Box and Relays

K9

K5

F1

F2

K7

K6

K8

V1

Relays

Fuse No. Rated Curren t Protected Circuit

F1 40 Amp Start, preheat, cut-off solenoid

F2 50 Amp Main fuse, ignition lock

Relay No. Protected Circuit

K9 Cut-off solenoid

K5 Preheating

Relay No. Protected Circuit

K6 Preheating timer

K7 Starting relay

K8 Cut-off solenoid

V1 Diode

918070/FP0811 1-7 Printed in U.S.A.

Page 14

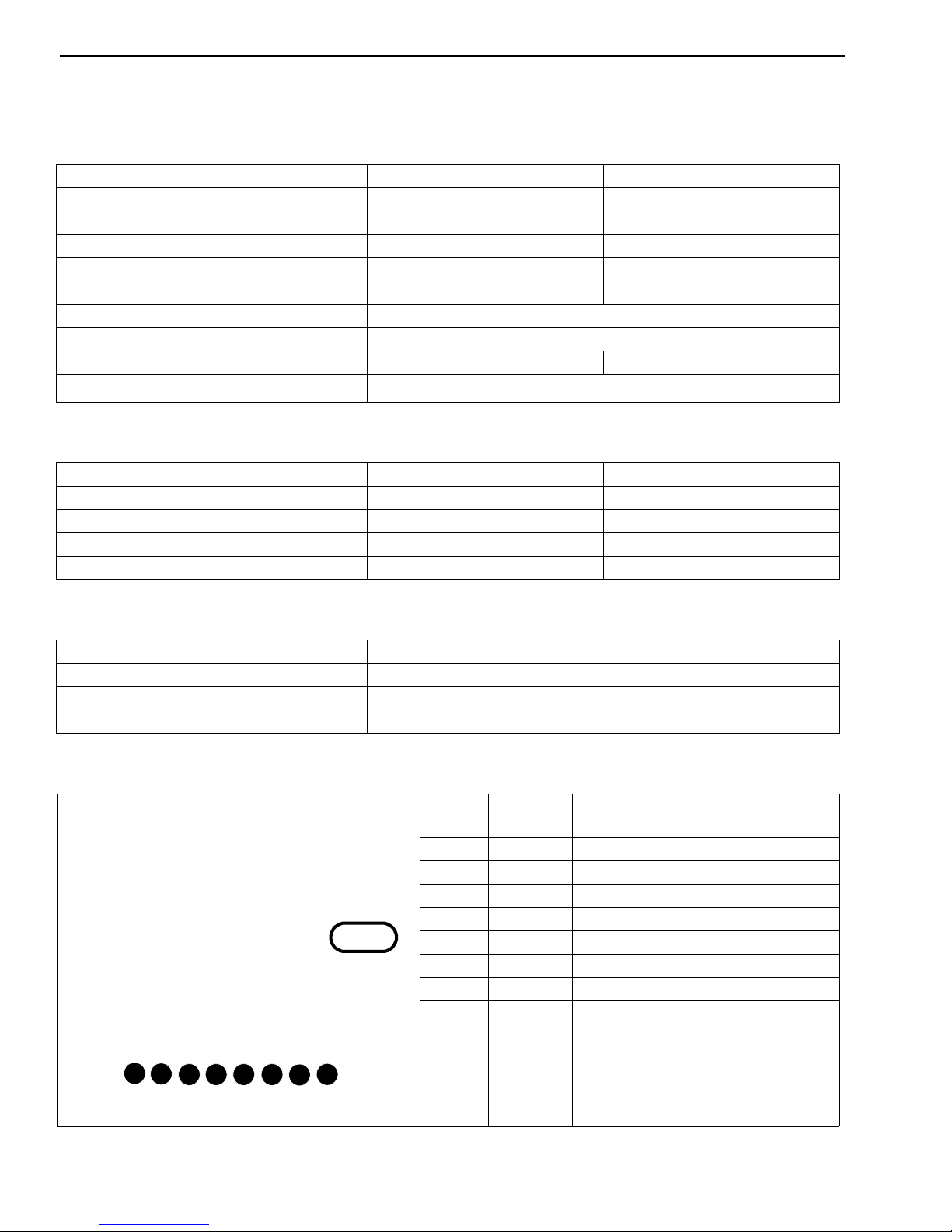

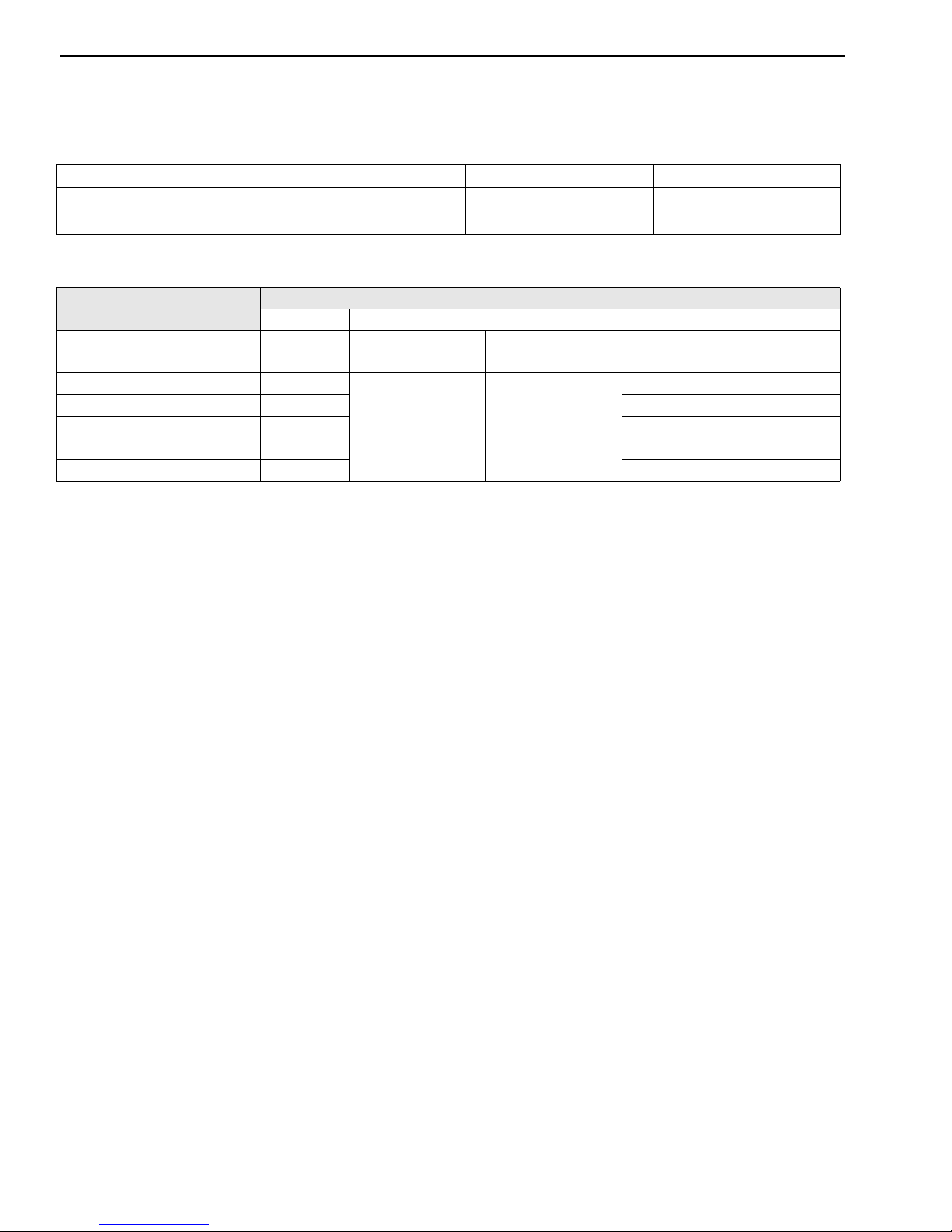

Sound Levels

503Z 603

Sound Power 96 dB(A) 98 dB(A)

Sound Pressure 76 dB(A) 74 dB(A)

Coolant Compound Table

Outside temperature

Up to °F (°C)

39 (4) 99

14 (-10) 79 20

-4 (-20) 65 34

-13 (-25) 59 40

-22(-30) 55 44

Water Anticorrosion agent Antifreeze agent

% by vol-

ume

Coolant: Halvoline XLC (based on ethylene glycol)

in³/gal (cm³/L) % by volume % by volume

2.6 (10) 1

–

Printed in U.S.A. 1-8 918070/FP0811

Page 15

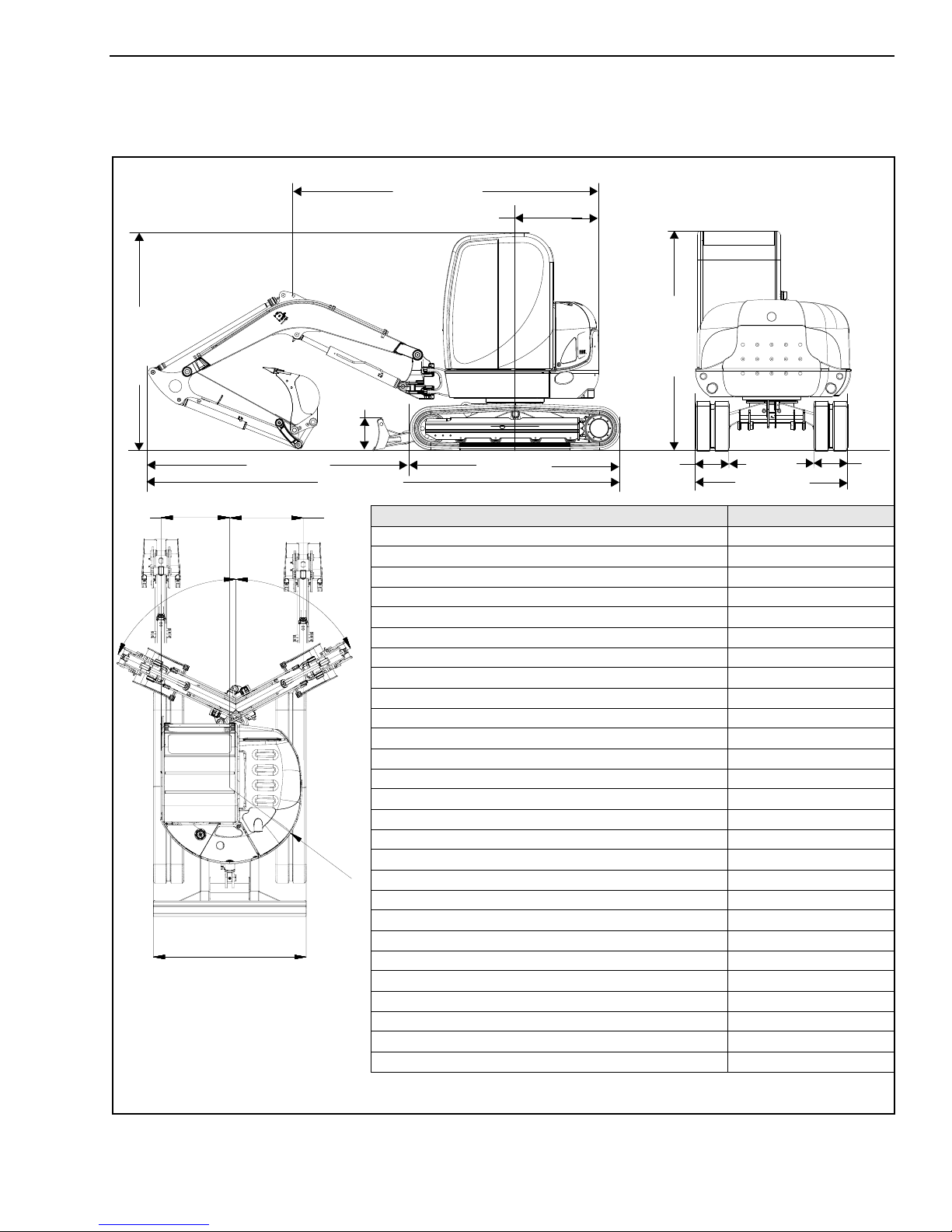

503Z General Specifications

8’2” (2500 mm)

12’ 2” (3097 mm)

8’5” (2570 mm)

6’6” (1990 mm)

1’3”

3’10”

18’4” (5600 mm)

3’3” (995 mm)

11’9” (3583 mm)

8’5” (2570 mm)

1’3” (380 mm)

(400 mm)

(1190 mm)

(400 mm)

1’3”

General Specifications

503Z

Weight 10,582 lbs. (4800 kg)

Height 8’5” (2570 mm)

Width 6’6” (1990 mm)

Transport length 18’4” (5600 mm)

Dipper arm length (Standard Arm) 4’9” (1450) mm

Dipper arm length (Optional Long Arm) 5’9” (1750 mm)

Max. digging depth w/ Standard Arm 11’9” (3570 mm)

Max. digging depth w/ Optional Long Arm 12’8” (3870 mm)

Max. vertical digging depth w/ Standard Arm 8’8” (2630 mm)

Max. vertical digging depth w/ Optional Long Arm 9’7” (2915 mm)

Max. digging height w/ Standard Arm 17’5” (5320 mm)

Max. digging height w/ Optional Long Arm 18’1” (5500 mm)

Max. dump height w/ Standard Arm 12’2” (3720 mm)

Max. dump height w/ Optional Long Arm 12’10” (3900 mm)

Max. digging radius w/ Standard Arm 19’9” (6030 mm)

Max. digging radius w/ Optional Long Arm 20’8” (6300 mm)

Max. reach at ground level w/ Standard Arm 19’4” (5900 mm)

Max. reach at ground level w/ Optional Long Arm 20’3” (6185 mm)

Max. breakout force at bucket tooth 7,599 lbf (33.8 kN)

Max. tearout force (Standard Arm) 5,980 lbf (26.6 kN)

Max. tearout force (Optional Long Arm) 5,283 lbf (23.5 kN)

Min. tail end slewing radius 3’3” (995 mm)

Max. tail end lateral projection over tracks 0’0” (0 mm)

Max. boom distance to bucket center (right side) 3’1” (960 mm)

Max. boom distance to bucket center (left side) 2’11” (895 mm)

Max. boom slew angle (left side) 65°

Max. boom slew angle (right side) 61°

3’1”

6

1°

6

5

°

R

3

’

3

”

(

9

9

5

m

m

)

6’6” (1990 mm)

(956 mm)

2’11”

(893 mm)

918070/FP0811 1-9 Printed in U.S.A.

Page 16

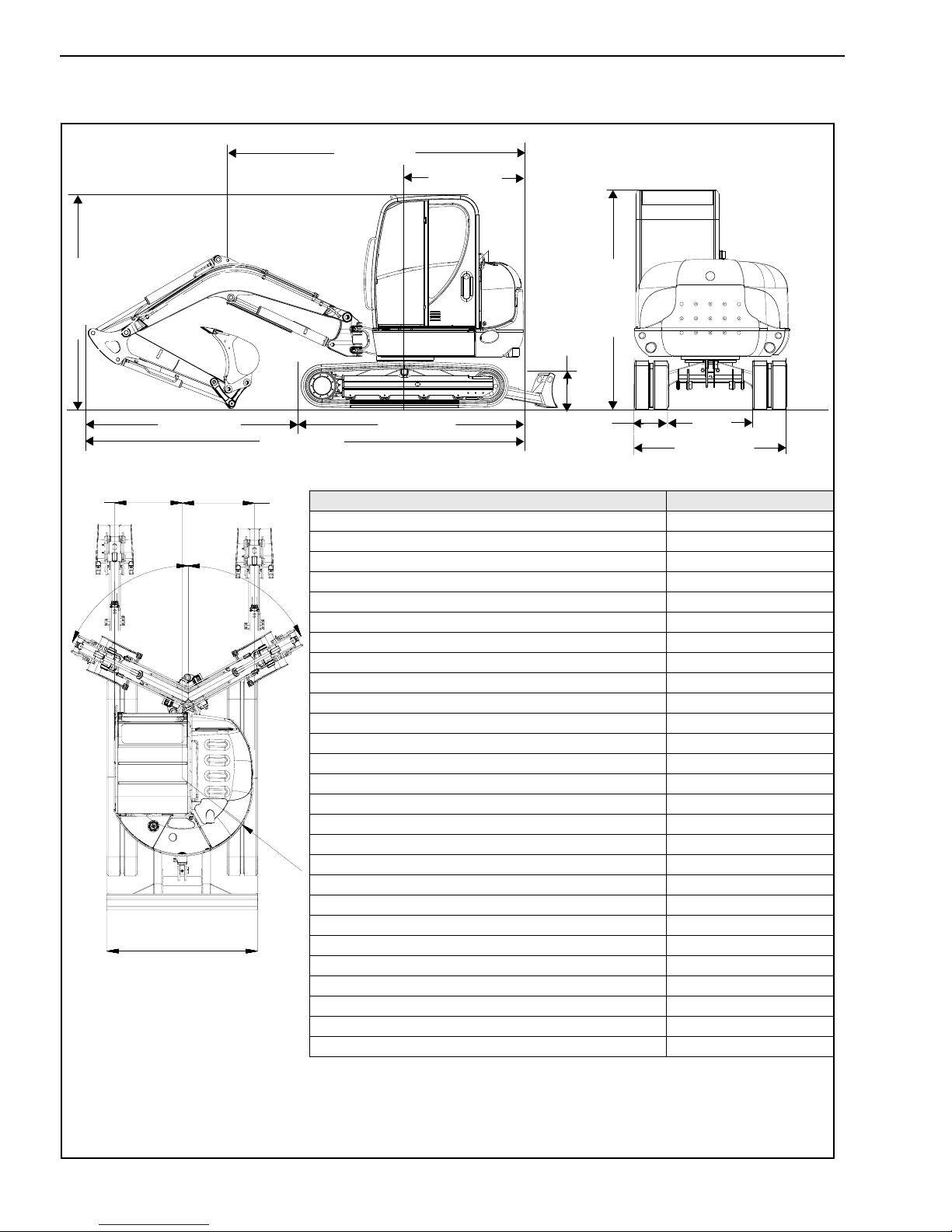

603 General Specifications

8’5” (2570 mm)

19’2” (5800 mm)

8’2” (2500 mm)

10’9” (3280 mm )

13’0” (3967 mm)

4’9” (1465 mm)

1’5” (425 mm)

6’6” (1990 mm)

1’3”

3’10”

(400 mm)

(1190 mm)

8’5” (2570 mm)

1’9”

(535 mm)

°

5

7

6’6” (1990 m m )

2’5”

(745 mm)

5

1

°

R

(

4

1

’

4

9

6

”

5

m

m

)

General Specifications 603

Weight 12,566 lbs. (5700 kg)

Height 8’5” (2570 mm)

Width 6’6” (1990 mm)

Transport length 19’0” (5800 mm)

Dipper arm length (Standard Arm) 5’6” (1685 mm)

Dipper arm length (Optional Long Arm) 6’6” (1985 mm)

Max. digging depth w/ Standard Arm 12’7” (3845 mm)

Max. digging depth w/ Optional Long Arm 13’7” (4140 mm)

Max. vertical digging depth w/ Standard Arm 9’4” (2855 mm)

Max. vertical digging depth w/ Optional Long Arm 10’3” (3135 mm)

Max. digging height w/ Standard Arm 18’6” (5660 mm)

Max. digging height w/ Optional Long Arm 19’2” (5850 mm)

Max. dump height w/ Standard Arm 13’1” (3995 mm)

Max. dump height w/ Optional Long Arm 13’8” (4185 mm)

Max. digging radius w/ Standard Arm 20’ 4” (6210 mm)

Max. digging radius w/ Optional Long Arm 21’3” (6490 mm)

Max. reach at ground level w/ Standard Arm 19’11” (6090 mm)

Max. reach at ground level w/ Optional Long Arm 20’11” (6380 mm)

Max. breakout force at bucket tooth 8,925 lbf (39.7 kN)

Max. tearout force (Standard Arm) 6,317 lbf (28.1 kN)

Max. tearout force (Optional Long Arm) 5,642 lbf (25.1 kN)

Min. tail end slewing radius 4’9” (1465 mm)

Max. tail end lateral projection over tracks 1’6” (470 mm)

Max. boom distance to bucket center (right side) 2’5” (745 mm)

Max. boom distance to bucket center (left side) 1’9” (535 mm)

Max. boom slew angle (left side) 75°

Max. boom slew angle (right side) 51°

Printed in U.S.A. 1-10 918070/FP0811

Page 17

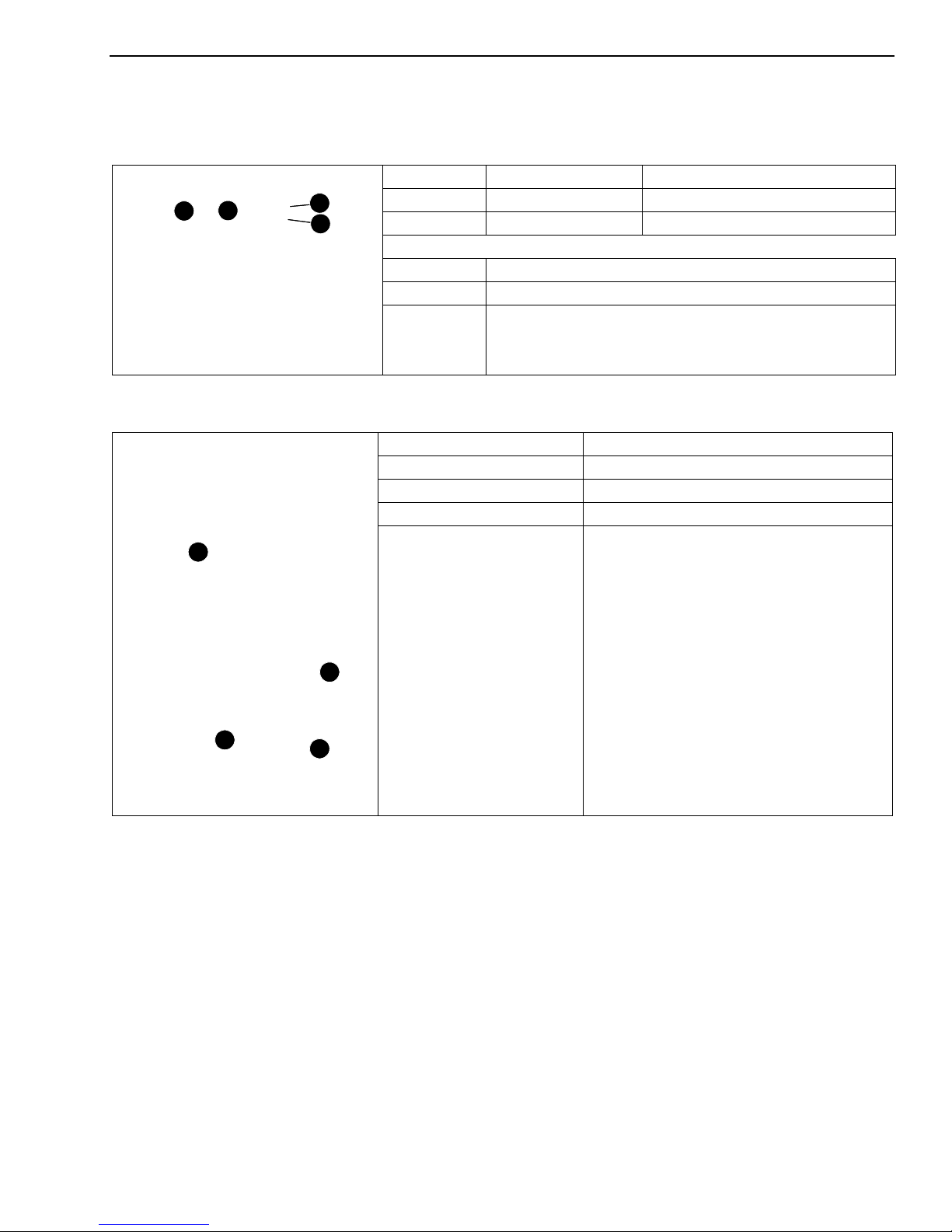

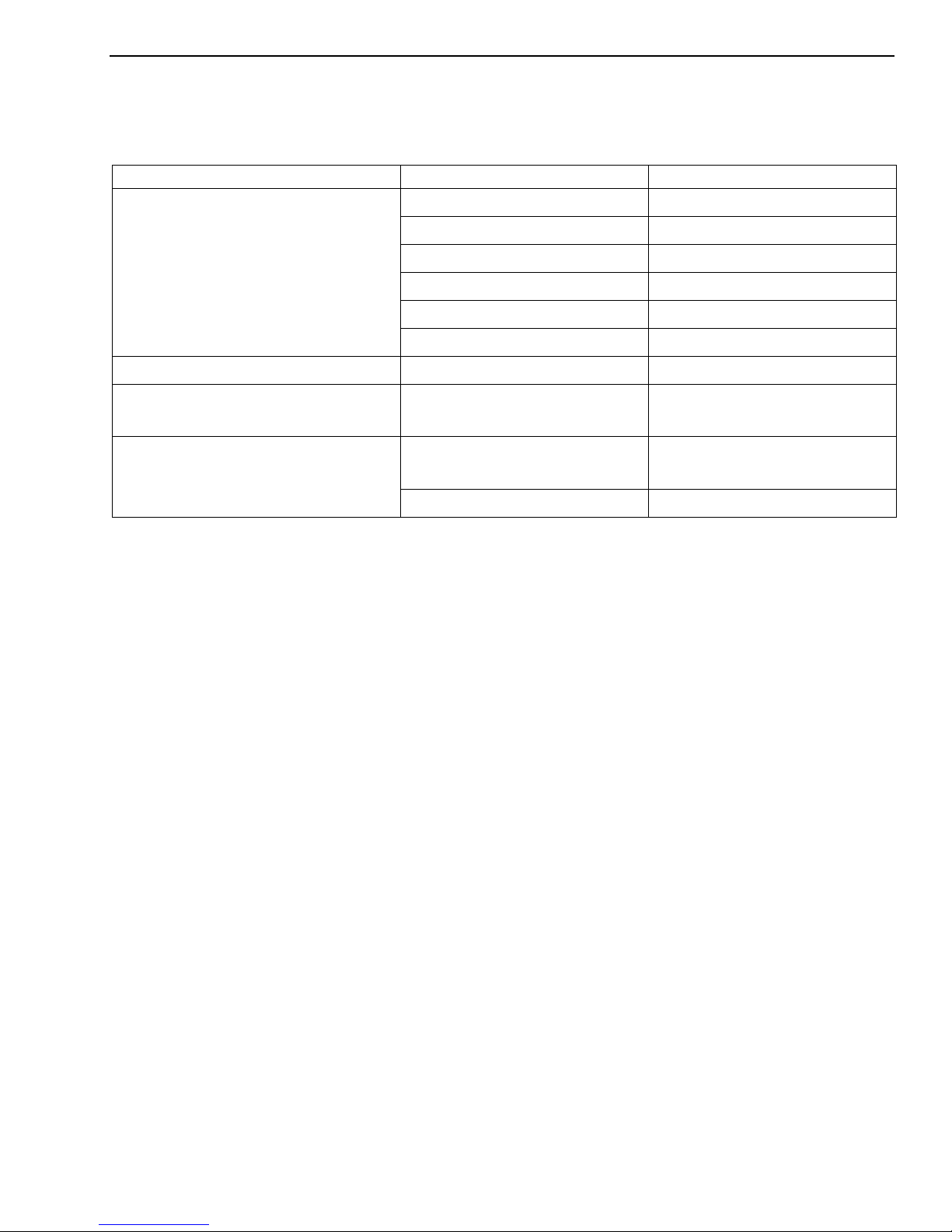

Fields of Applications

Attachment Size Capacity

Heavy-Duty Bucket 10 in. (250 mm)

16 in. (400 mm)

20 in. (500 mm)

24 in. (600 mm)

30 in. (700 mm)

36 in. (900 mm)

Ditching Bucket 48 in. (1000 mm)

Ditch Bucket (503Z only) 48 in. (1000 mm)

55 in. (1400 mm)

Swivel Bucket 48 in. (1200 mm)

55 in. (1400 mm)

2.5 ft

3.3 ft

3.7 ft

6.4 ft

8.8 ft

9.8 ft

5.9 ft

7.0 ft

8.4 ft

5.9 ft

7.0 ft

5.9 ft

3

3

3

3

3

3

3

3

3

3

3

3

(0.070 M3)

(0.093 M3)

(0.104 M3)

(0.181 M3)

(0.249 M3)

(0.278 M3)

(0.167 M3)

(0.196 M3)

(0.238 M3)

(0.167 M3)

(0.198 M3)

(0.167 M3)

918070/FP0811 1-11 Printed in U.S.A.

Page 18

Load Diagrams

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

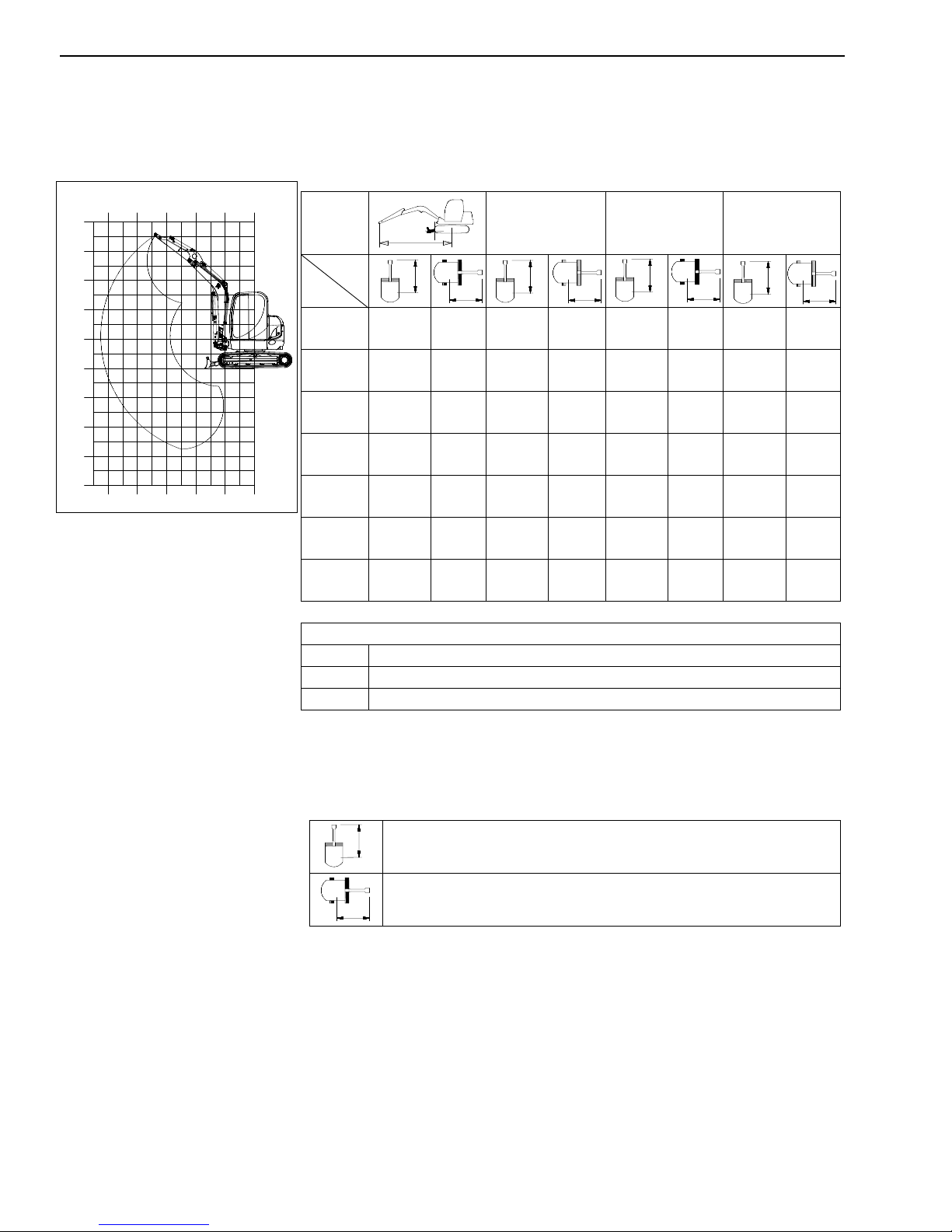

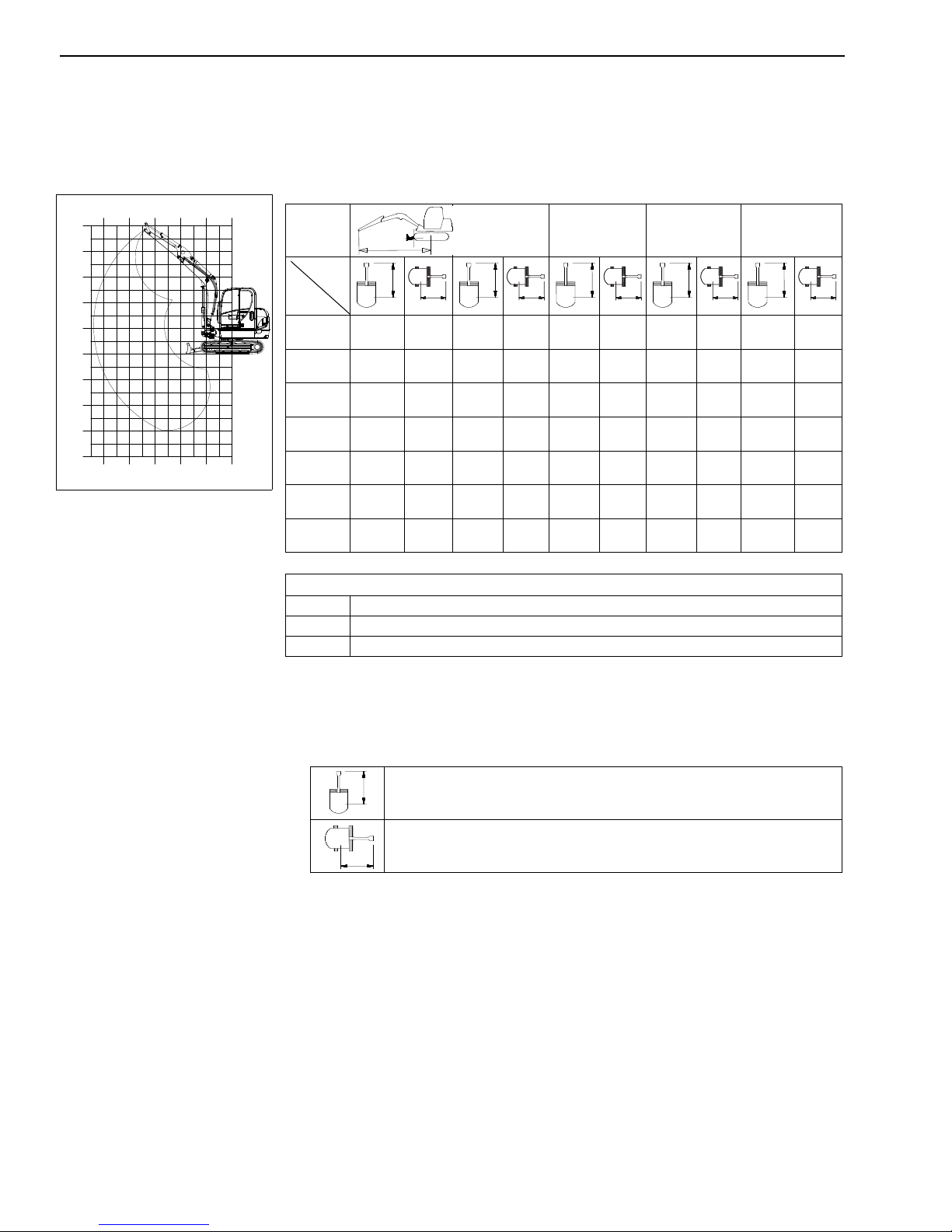

503Z Load Diagram - Standard Dipper Arm Maximum Permissible Loads

13’0”

A

B

13’0”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2,337*

(1060*)

2,260*

(1025*)

2,304*

(1045*)

2,403*

(1090*)

2,524*

(1145*)

2,668*

(1210*)

2,767*

(1255*)

1,786

(810)

1,290

(585)

1,080

(490)

1,003

(455)

1,014

(460)

1,135

(515)

1,554

(705)

(4.0 m)

2,227*

(1010*)

2,612*

(1185*)

3,120*

(1415*)

3,428*

(1555*)

3,329*

(1510*)

1,720

(780)

1,609

(730)

1,477

(670)

1,378

(625)

1,345

(610)

(3.0 m)

3,483*

(1580*)

4,905

(2225*)

5,368*

(2435*)

5,049*

(2290*)

3,924*

(1780*)

Maximum permissible load on standard dipper arm

A Overhang from the center of the turntable

B Height of load fixing point

* Lifting capacity hydraulically limited

9’9”

2,535

(1150)

2,183

(990)

2,028

(920)

2,017

(915)

2,094

(950)

(2.0 m)

8,973*

(4070*)

6,614*

(3000*)

6’6”

3,946

(1790)

4,101

(1860)

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Printed in U.S.A. 1-12 918070/FP0811

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

Page 19

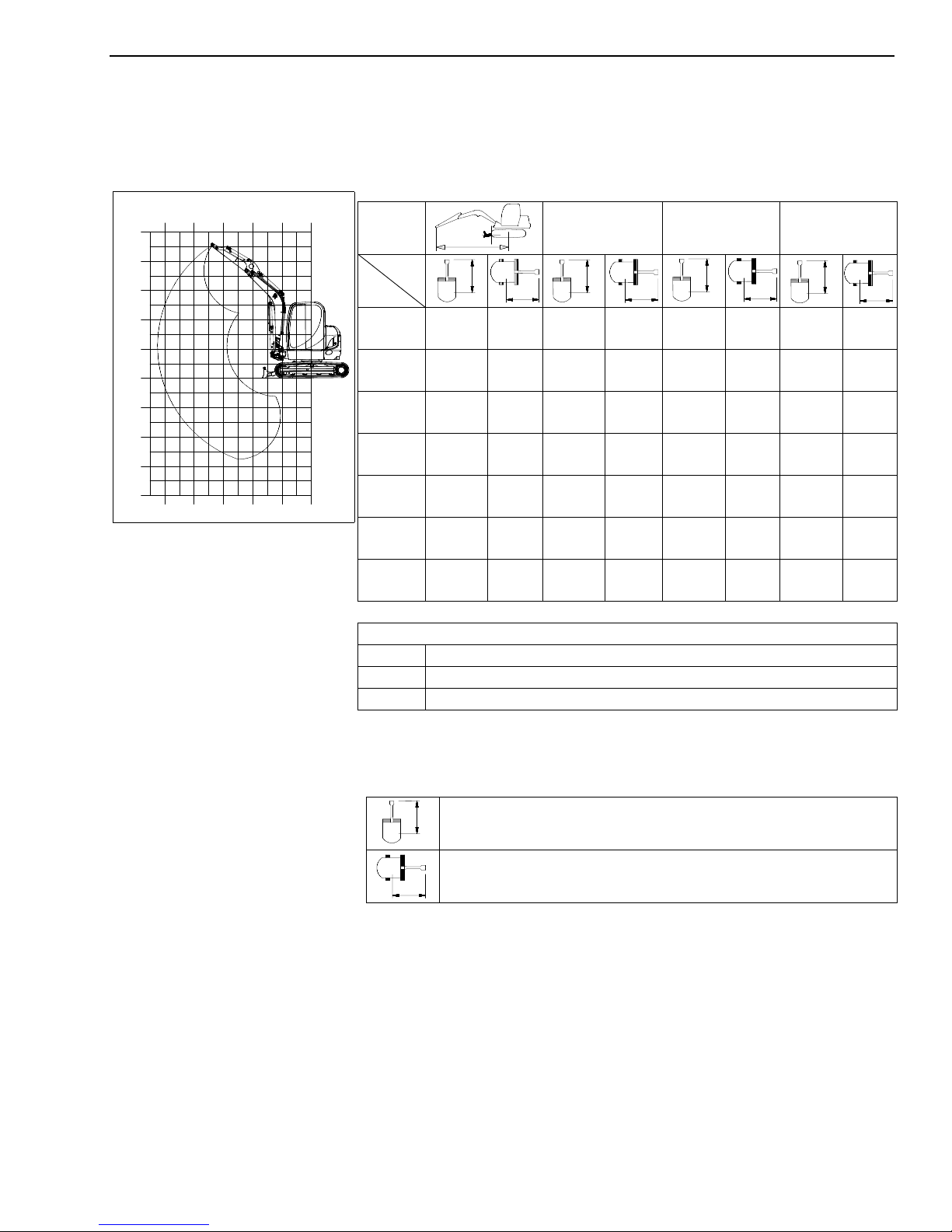

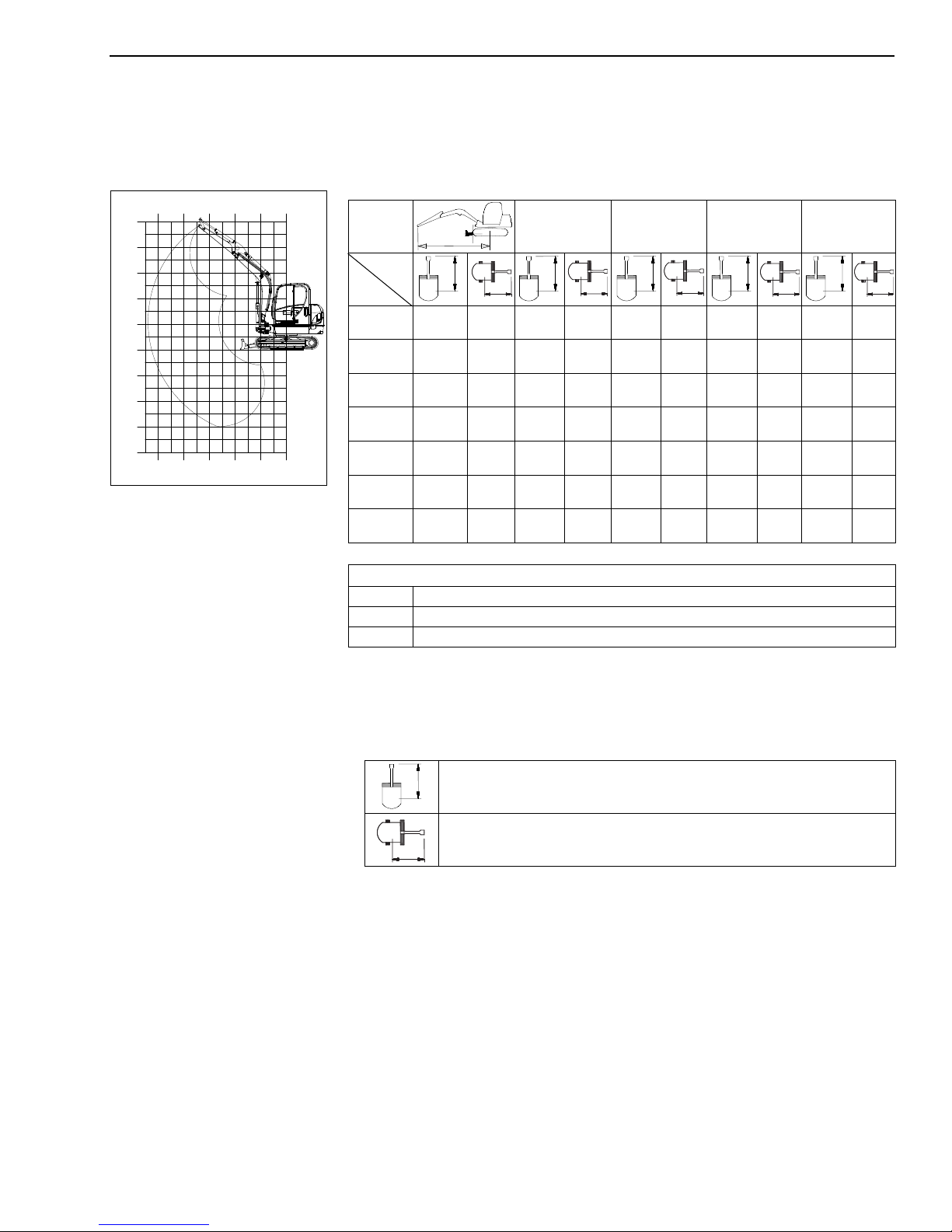

503Z Load Diagram - Extended Dipper Arm (Option)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads

13’0”

A

B

13’0”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2,028*

(920*)

2,017*

(915*)

2,061*

(935*)

2,138*

(970*)

2,238*

(1015*)

2,348*

(1065*)

2,447*

(1110*)

1,455

(660)

1,102

(500)

937

(425)

871

(395)

882

(400)

970

(440)

1246

(565)

(4.0 m)

1,951*

(855*)

1,907*

(865*)

2,315*

(1050*)

2,888*

(1310)

3,296*

(1495*)

3,340*

(1515*)

2,756*

(1250*)

1,731

(785)

1,720

(780)

1,609

(730)

1,466

(665)

1,345

(610)

1,301

(590)

1,323

(600)

(3.0 m)

2,899*

(1315*)

4,464*

(2025*)

5,258*

(2385*)

5,181*

(2350*)

4,343*

(1970*)

Maximum permissible load on extended dipper arm

A Overhang from the center of the turntable

B Height of load fixing point

* Lifting capacity hydraulically limited

9’9”

2,579

(1170)

2,227

(1010)

2,017

(915)

1,962

(890)

2,006

(910)

6’6”

(2.0 m)

10,075*

(4570*)

7,915*

(3590*)

3,858

(1750)

3,979

(1805)

918070/FP0811 1-13 Printed in U.S.A.

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Page 20

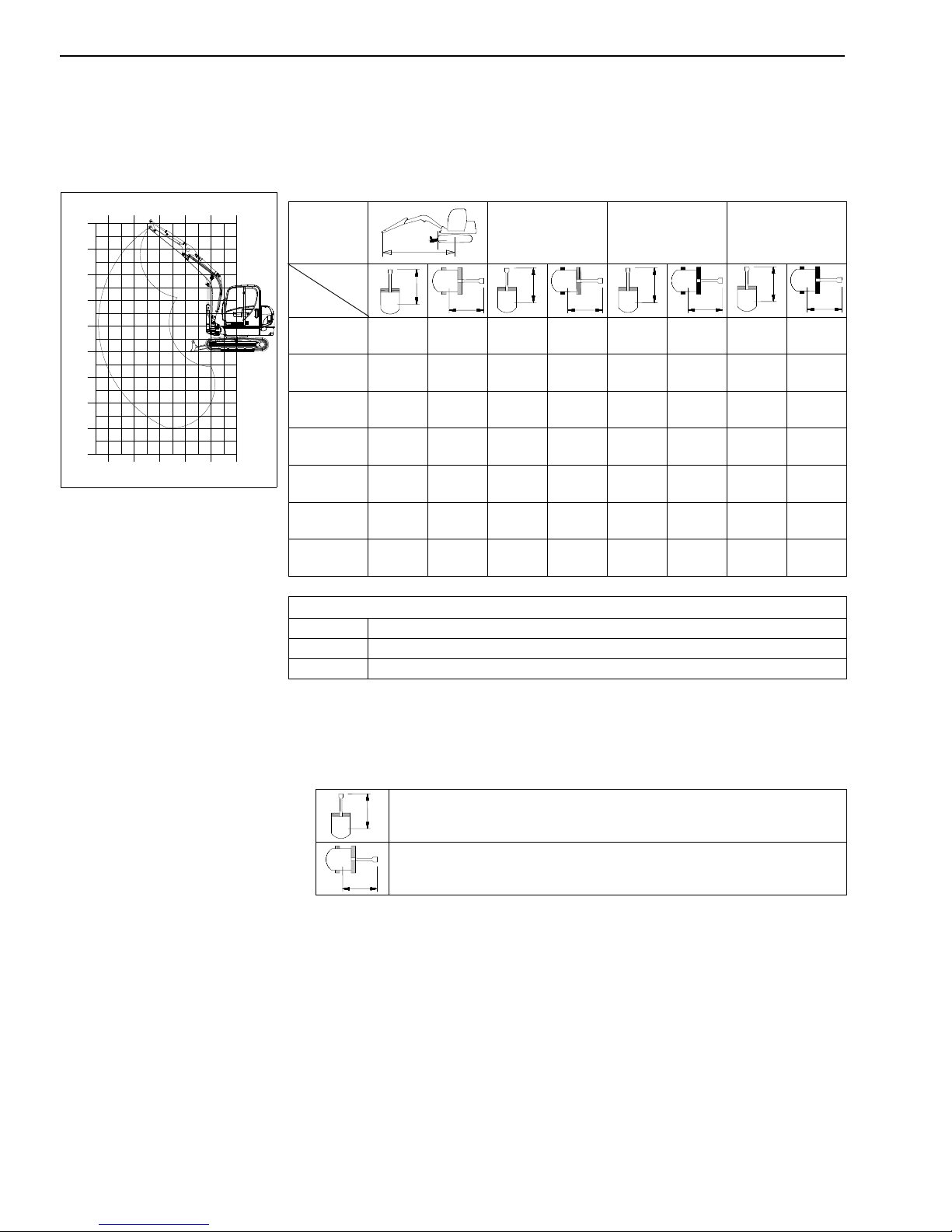

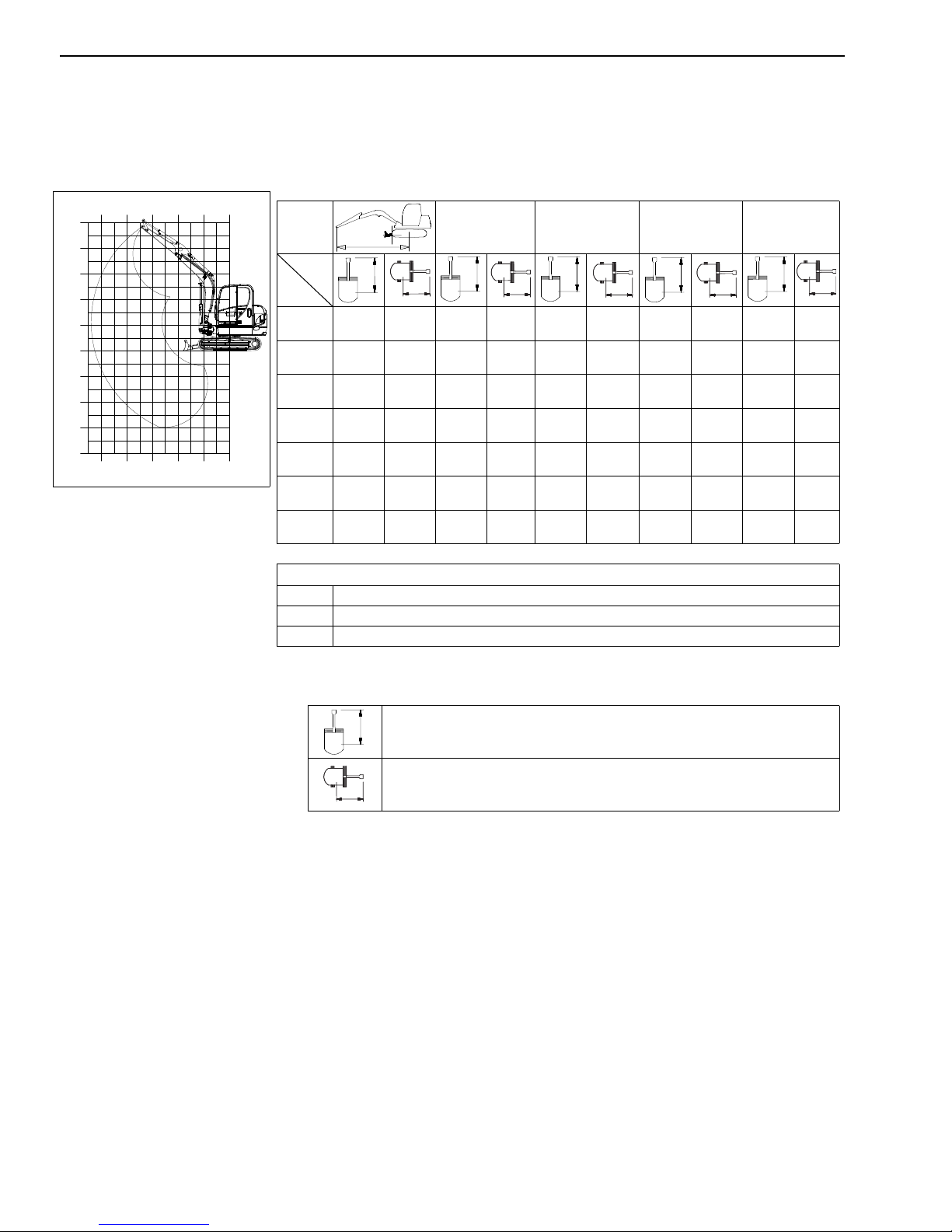

503Z Load Diagram - Standard Dipper Arm with Counterweight

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads

13’0”

(4.0 m)

A

B

13’3”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2337*

(1060*)

2260*

(1025*)

2304*

(1045*)

2403*

(1090*)

2524*

(1145*)

2668*

(1210*)

2767*

(1255*)

2017

(915)

1488

(675)

1279

(580)

1202

(545)

1213

(550)

1367

(620)

1830

(830)

2227*

(1010*)

2612*

(1185*)

3120*

(1415*)

3428*

(1555*)

3329*

(1510*)

2006

(910)

1907

(865)

1775

(805)

1676

(760)

1642

(745)

3483*

(1580*)

4905*

(2225*)

5368*

(2435*)

5049*

(2290*)

3924*

(1780*)

Maximum permissible load on standard dipper arm

A Reach from live ring center

B Load hook height

* Lift capacity limited by hydraulics

9’9”

(3.0 m)

(1345)

(1185)

(1115)

(1110)

(1140)

2965

2612

2458

2447

2513

(2.0 m)

8973*

(4070*)

6614*

(3000*)

6’6”

4751

(2155)

4905

(2225)

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

If equipped with a bucket or other implements, lift capacity or tilt load is

Printed in U.S.A. 1-14 918070/FP0811

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

Page 21

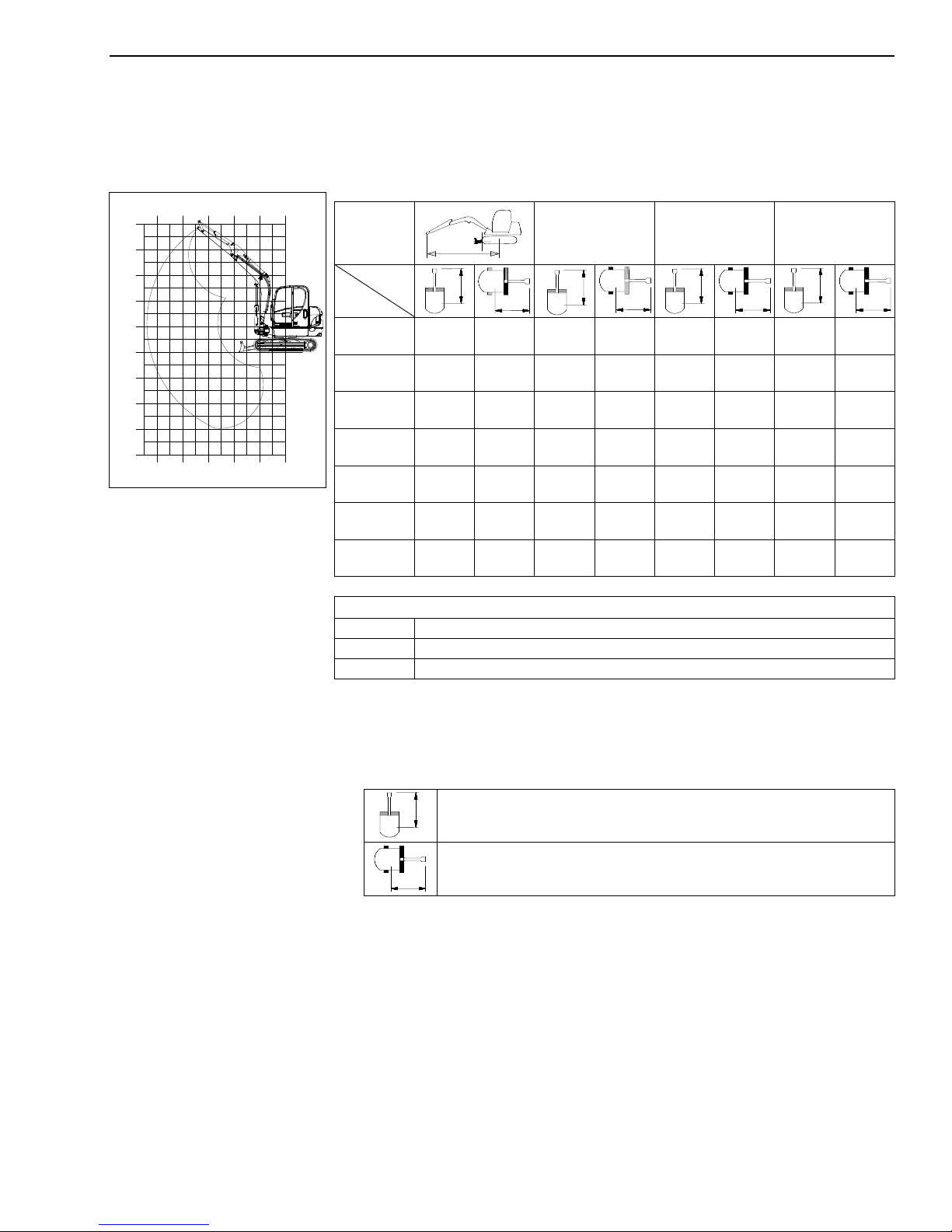

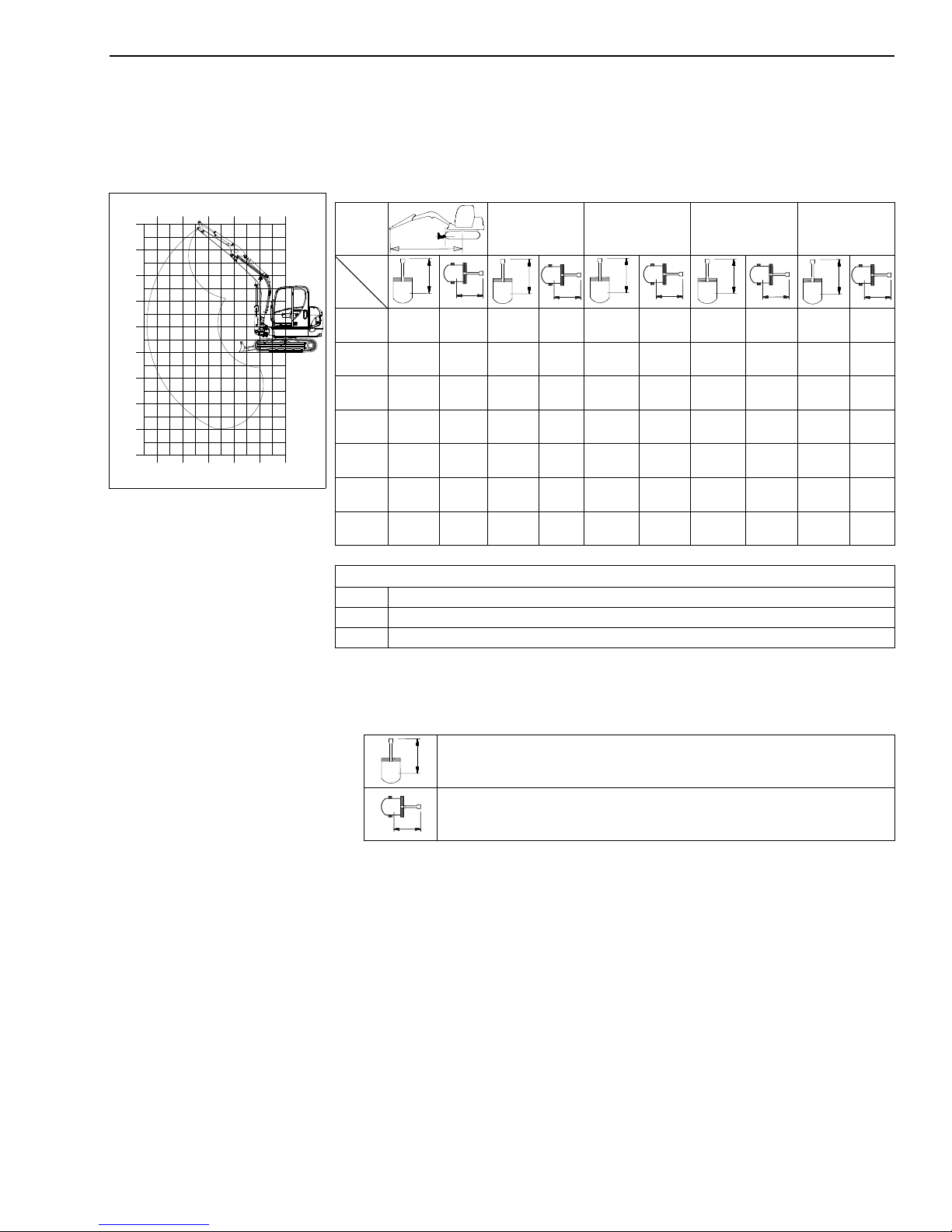

503Z Load Diagram - Extended Dipper Arm with Counterweight

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads

13’0”

(4.0 m)

A

B

13’3”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2028*

(920*)

2017*

(915*)

2061*

(935*)

2138*

(970*)

2238*

(1015*)

2348*

(1065*)

2447*

(1110*)

1720

(780)

1323

(600)

1146

(520)

1069

(485)

1080

(490)

1190

(540)

1521

(690)

1885*

(855*)

1907*

(865*)

2315*

(1050*)

2888*

(1310*)

3296*

(1495*)

3340*

(1515*)

2756*

(1250*)

1885*

(855*)

1907*

(865*)

1907*

(865*)

1764

(800)

1642

(745)

1587

(720)

1620

(735)

2899*

(1315*)

4464*

(2025*)

5258*

(2385*)

5181*

(2350*)

4343*

(1970*)

Maximum permissible load on extended dipper arm

A Reach from live ring center

B Load hook height

* Lift capacity limited by hydraulics

9’9”

(3.0 m)

(1315*)

2899*

2657

(1205)

2447

(1110)

2392

(1085)

2436

(1105)

(2.0 m)

10,075*

(4570*)

7915*

(3590*)

6’6”

4663

(2115)

4663

(2115)

918070/FP0811 1-15 Printed in U.S.A.

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Page 22

603 Load Diagram - Standard Dipper Arm

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads (standard arm)

16’0”

(5.0 m)

13’0”

(4.0 m)

A

B

13’0”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2,888*

(1310*)

2,866*

(1300*)

2,911*

(1320*)

2,998*

(1360*)

3,109*

(1410*)

3,230*

(1465*)

3,296*

(1495*)

2,249

(1020)

1,775

(805)

1,565

(710)

1,488

(675)

1,521

(690)

1,676

(760)

2,127

(965)

2,932*

(1330*)

3,164*

(1435*)

3,296*

(1495*)

1,709

(775)

1,654

(750)

1,609

(730)

2,745*

(1245*)

2,789*

(1265*)

3,285*

(1490*)

3,913*

(1775*)

4,343*

(1970*)

4,332*

(1965*)

2,546

(1155)

2,524

(1145)

2,425

(1100)

2,282

(1035)

2,183

(990)

2,138

(970)

Maximum permissible load on standard dipper arm

A Overhang from the center of the turntable

B Height of load fixing point

* Lifting capacity hydraulically limited

9’9”

(3.0 m)

4,156*

(1885*)

5,765*

(2615*)

6,548*

(2970*)

6,415*

(2910*)

5,401*

(2450*)

3,748

(1700)

3,417

(1550)

3,241

(1470)

3,197

(1450)

3,252

(1475)

6’6”

(2.0 m)

11,045*

(5010*)

8829*

(4005*)

6162

(2795)

6294

(2855)

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Printed in U.S.A. 1-16 918070/FP0811

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

Page 23

603 Load Diagram - Extended Dipper Arm (Option)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads (extended arm)

16’0”

(5.0 m)

13’0”

(4.0 m)

A

B

13’0”

(4.0 m)

9’9”

(3.0 m)

6’6”

(2.0 m)

3’3”

(1.0 m)

0’0”

(0.0 m)

-3’3”

(-1.0 m)

-6’6”

(-2.0 m)

2,623*

(1190*)

2,623*

(1190*)

2,690*

(1220*)

2789*

(1265*)

2899*

(1315*)

3031*

(1375*)

3142*

(1425*)

2,183

(990)

1,411

(640)

628

(285)

1,168

(530)

1,290

(585)

1,466

(665)

1,819

(825)

2,745*

(1245*)

3,042*

(1380*)

3,274*

(1485*)

1,576

(715)

1,598

(725)

1,554

(705)

2,315*

(1050*)

2,469*

(1120*)

3,031*

(1375*)

3,726*

(1690*)

4,244*

(1925*)

4,387*

(1990*)

1907

(865)

2,326

(1055)

2,392

(1085)

2,271

(1030)

2,161

(980)

2,039

(955)

Maximum permissible load on extended dipper arm

A Overhang from the center of the turntable

B Height of load fixing point

* Lifting capacity hydraulically limited

(3.0 m)

3,682*

(1670*)

5,291*

(2400*)

6,184*

(2805*)

6,294*

(2855*)

5,688*

(2580*)

9’9”

3,682

(1670)

3,461

(1570)

3,230

(1465)

3,142

(1425)

3,175

(1440)

6’6”

(2.0 m)

10,075*

(4570*)

8,775*

(3980*)

6,140

(2785)

6,173

(2800)

918070/FP0811 1-17 Printed in U.S.A.

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Page 24

603 Load Diagram - Standard Dipper Arm with Counterweight

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads (standard dipper w/counterweight)

16’ 3"

(5.0 m)

13’ 0"

(4.0 m)

A

B

13’

(4.0 m)

9’, 9"

(3.0 m)

6,’ 6"

(2.0 m)

3’, 3"

(1.0 m)

0’

(0.0 m)

-3’, 3”

(-1.0 m)

-6’, 6”

(-2.0 m)

2888

(1310*)

2866

(1300*)

2910

(1320*)

2998

(1360*)

3109

(1410*)

3230

(1465*)

3296

(1495*)

2590

(1175)

2061

(935)

1830

(830)

1753

(795)

1786

(810)

1973

(895)

2491

(1130)

2932

(1330*)

3164

(1435*)

3296

(1495*)

1995

(905)

1940

(880)

1874

(850)

2745

(1245*)

2789

(1265*)

3285

(1490*)

3913

(1775*)

4343

(1970*)

4332

(1965*)

2745

(1245*)

2789

(1265*)

2789

(1265)

2657

(1205)

2546

(1155)

2513

(1140)

Maximum permissible load on standard dipper arm

A Reach from live ring center

B Load hook height

* Lift capacity limited by hydraulics

9’ 9"

(3.0 m)

4156

(1885*)

5766

(2615*)

6548

(2970*)

6445

(2910*)

6504

(2450*)

4156

(1885*)

3957

(1795)

3781

(1715)

3737

(1695)

3792

(1720)

6’ 6"

(2.0 m)

11045

(5010*)

8830

4005*)

(

7165

(3250)

7297

(3310)

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Printed in U.S.A. 1-18 918070/FP0811

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

Page 25

603 Load Diagram - Extended Dipper Arm with Counterweight

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

0'0"

(0.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

16'3"

(5.0 m)

3'3"

(1.0 m)

6'6"

(2.0 m)

9'9"

(3.0 m)

13'0"

(4.0 m)

-13'0"

(-4.0 m)

16'3"

(5.0 m)

-3'3"

(-1.0 m)

-6'6"

(-2.0 m)

-9'9"

(-3.0 m)

0'0"

(0.0 m)

Maximum permissible loads (extended dipper w/counterweight)

16’ 3"

(5.0 m)

13’ 0"

(4.0 m)

A

B

13’

(4.0 m)

9’, 9"

(3.0 m)

6,’ 6"

(2.0 m)

3’, 3"

(1.0 m)

(0.0 m)

-3’, 3”

(-1.0 m)

-6’, 6”

(-2.0 m)

2623

(1190*)

2623

(1190*)

2690

(1220*)

2789

(1265*)

0’

2899

(1315*)

3031

(1375*)

3142

(1425*)

2491

(1130)

1676

(760)

871

(395)

1411

(640)

1543

(700)

1731

(785)

2138

(970)

2745

(1245*)

3042

(1380*)

3274

(1485*)

1863

(845)

1874

(850)

1841

(835)

2315

(1050*)

2469

(1120*)

3031

(1375*)

3726

(1690*)

4244

(1925*)

4387

(1990*)

2282

(1035)

2469

(1120*)

2756

(1250)

2646

(1200)

2524

(1145)

2469

(1120)

Maximum permissible load on extended dipper arm

A Reach from live ring center

B Load hook height

* Lift capacity limited by hydraulics

(3.0 m)

3682

(1670*)

5241

(2400*)

6184

(2805*)

6294

(2855*)

5688

(2580*)

9’ 9"

3682

(1670*)

40011

(1815)

3770

(1710)

3682

(1670)

3715

(1685)

6’ 6"

(2.0 m)

10075

(4570*)

8774

3980*)

(

7143

(3240)

7187

(3260)

918070/FP0811 1-19 Printed in U.S.A.

All table values are in lbs. (kg) and for a machine in a horizontal position on

firm ground without bucket.

Dozer blade support in drive direction

Dozer blade support 90° to drive direction

If equipped with a bucket or other implements, lift capacity or tilt load is

reduced by bucket or implement weight.

Calculation basis: According to ISO 10567.

The excavator's lift capacity is restricted by the settings of the pressure relief

valves and the hydraulic system's stabilizing features.

Neither 75% of the static tilt load nor 87% of the hydraulic lift capacity is

exceeded.

Page 26

IMPORTANT

CHECKLISTS

Pre-Delivery Checklist

The following checklist is an important reminder of

valuable information and inspections that MUST be

made before delivering the machine to the customer.

Check off each item after the prescribed action is taken.

CHECK THAT:

Machine has not been damaged in shipment. Check for

such things as dents and loose or missing parts; correct

or replace components as required.

Battery is securely mounted and not cracked. Be sure

cable connections are tight.

Cylinders, hoses and fittings are not damaged, leaking

or loosely connected.

Coolant/radiator hoses and fittings are not damaged,

leaking or loosely connected. Coolant system is filled to

the proper level and has proper antifreeze protection.

Filters are not damaged, leaking or loosely secured.

Machine is properly lubricated and no grease fittings are

missing or damaged.

Hydraulic system reservoir, engine crankcase and drive

motors are filled to their proper levels.

All adjustments are made to comply with settings

provided in Chapter 4 – Maintenance of this manual.

All guards, shields and decals are in place and secured.

Model and serial numbers for the machine are recorded

in the space provided on this page.

Start the engine and test run the unit while

checking that all controls operate properly.

I acknowledge the pre-delivery procedures were performed

on this unit as outlined on this page.

_______________________________________________

Dealership’s Name

_______________________________________________

Dealer Representative’s Name

_______________________________________________

Date Checklist Filled Out

_______________________________________________

Model & Serial Number

Delivery Checklist

The following checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time of delivery. Check off each item

as you explain it to the customer.

EXPLAIN:

The Safety and Operation chapters of this manual,

regarding the safe operation of this machine.

The Maintenance and Troubleshooting chapters for

information regarding the proper maintenance of this

machine. Explain that regular lubrication and

maintenance is required for continued safe operation

and long machine life.

Give this Operator’s Manual and the AEM Compact

Excavator Safety Manual to the customer and instruct

the customer to read and completely understand the

contents before operating the machine.

Completely fill out the Owner’s Registration, including

customer’s signature and return it to the Gehl Company.

CHECK THAT:

Drive controls and boom/arm/bucket/dozer blade/swing/

pivot controls operate properly and are not damaged or

binding.

Drive controls are properly adjusted for correct neutral

position.

The parking and travelling gear brake, along with the

lock-out devices, are activated with the machine

stationary (no pilot control pressure).

All hydraulic functions are NOT operational with the

left control console in the raised lock-out position.

All instrument panel gauges, indicator lights, etc.

function properly and all installed lights, such as work

lights, function properly.

Printed in U.S.A. 1-20 918070/FP0811

Explain that a copy of the product warranty is included

on the inside front cover of this Operator’s Manual.

_______________________________________________

Customer’s Signature

_______________________________________________

Date Delivered

RETAIN FOR CUSTOMER’S RECORDS

Page 27

IMPORTANT

CHECKLISTS

Remove dealer’s file copy at perforation.

Pre-Delivery Checklist

The following checklist is an important reminder of

valuable information and inspections that MUST be

made before delivering the machine to the customer.

Check off each item after the prescribed action is taken.

CHECK THAT:

Machine has not been damaged in shipment. Check for

such things as dents and loose or missing parts; correct

or replace components as required.

Battery is securely mounted and not cracked. Be sure

cable connections are tight.

Cylinders, hoses and fittings are not damaged, leaking

or loosely connected.

Coolant/radiator hoses and fittings are not damaged,

leaking or loosely connected. Coolant system is filled to

the proper level and has proper antifreeze protection.

Filters are not damaged, leaking or loosely secured.

Machine is properly lubricated and no grease fittings are

missing or damaged.

Hydraulic system reservoir, engine crankcase and drive

motors are filled to their proper levels.

All adjustments are made to comply with settings

provided in Chapter 4 – Maintenance of this manual.

All guards, shields and decals are in place and secured.

Model and serial numbers for the machine are recorded

in the space provided on this page.

Start the engine and test run the unit while

checking that all controls operate properly.

I acknowledge the pre-delivery procedures were performed

on this unit as outlined on this page.

_______________________________________________

Dealership’s Name

_______________________________________________

Dealer Representative’s Name

_______________________________________________

Date Checklist Filled Out

_______________________________________________

Model & Serial Number

Delivery Checklist

The following checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time of delivery. Check off each item

as you explain it to the customer.

EXPLAIN:

The Safety and Operation chapters of this manual,

regarding the safe operation of this machine.

The Maintenance and Troubleshooting chapters for

information regarding the proper maintenance of this

machine. Explain that regular lubrication and

maintenance is required for continued safe operation

and long machine life.

Give this Operator’s Manual and the AEM Compact

Excavator Safety Manual to the customer and instruct

the customer to read and completely understand the

contents before operating the machine.

Completely fill out the Owner’s Registration, including

customer’s signature and return it to the Gehl Company.

CHECK THAT:

Drive controls and boom/arm/bucket/dozer blade/swing/

pivot controls operate properly and are not damaged or

binding.

Drive controls are properly adjusted for correct neutral

position.

The parking and travelling gear brake, along with the

lock-out devices, are activated with the machine

stationary (no pilot control pressure).

All hydraulic functions are NOT operational with the

left control console in the raised lock-out position.

All instrument panel gauges, indicator lights, etc.

function properly and all installed lights, such as work

lights, function properly.

918070/FP0811 1-21 Printed in U.S.A.

Explain that a copy of the product warranty is included

on the inside front cover of this Operator’s Manual.

_______________________________________________

Customer’s Signature

_______________________________________________

Date Delivered

RETAIN FOR DEALER’S RECORDS

Page 28

INTENTIONALLY BLANK

(To be removed as dealer’s file copy)

Printed in U.S.A. 1-22 918070/FP0811

Page 29

CHAPTER 2 – SAFETY

DANGER

WARNING

CAUTION

IMPORTANT

SAFETY ALERTS

Manitou Americas, Inc., in cooperation with the Society of Automotive Engineers (SAE), has adopted this

safety alert symbol: This warning symbol, used

with a “signal word,” indicates situations or conditions

that can cause injury or death if precautions are not followed. The signal words used with the safety alert symbol are:

“IMPORTA NT” is used to draw atten tion to

a procedure that must to be followed to prevent machine damage.

GENERAL SAFETY RULES

“CAUTION,” “WARNING,” and “DANGER,”

which indicate the level of risk and severity of hazards.

All three levels indicate that safety is involved.

Observe the precautions whenever you see the safety

alert symbol, no matter which signal word is used.

The following signal words are used throughout this

manual and on decals on the machine to warn of potential hazards:

The word “DANGER” indicates an imminently hazardous situation that, if not

avoided, will result in serious injury or

death.

The word “WARNING” indicates a potentially hazardous situation that, if not

avoided, could result in serious injury or

death.

Before operating the machine, first read and study the

safety information in this manual. Be sure that anyone

who operates or works on the machine is familiar with

the safety precautions. This includes providing

translations of the warnings and instructions for

operators who are not fluent in reading English.

It is essential that operators be thoroughly trained in the

safe operation of the machine and handling loads.

Operators must not be physically or mentally impaired.

Do not allow minors or unqualified personnel to

operate the machine, or to be near the machine unless

they are properly supervised. It is recommended that

the operator be capable of obtaining a valid motor

vehicle operator’s license.

Only trained and authorized personnel, with a full

awareness of safe procedures, should be allowed to

operate or perform maintenance or service on the

excavator.

Read the operator’s manual provided with each attachment before using it.

Use of the machine is subject to certain hazards that

cannot be eliminated by mechanical means, but only by

exercising intelligence, care and common sense. Such

hazards include: hillside operation, overloading, load

instability, poor maintenance, and using the machine

for a purpose for which it was not intended or designed.

The word “CAUTION” indicates a potentially hazardous situation that, if not

avoided. may result in minor or moderate

injury.

918070/FP0811 2-1 Printed in U.S.A.

Manitou Americas, Inc, always takes operator’s safety

into consideration during the design process. Guards

and shields are provided, which protect the operator

and bystanders from moving parts and other hazards.

Operators must be alert, however, because some areas

cannot be guarded or shielded without preventing or

interfering with proper operation.

Page 30

Different applications may require optional safety

equipment. Users must evaluate the worksite hazards

and equip the machine and the operator as necessary.

The information in this manual does not replace any

applicable safety rules and laws. Before operating the

machine, learn the rules and laws for the local area.

Make sure the machine is equipped as required

according to these rules/laws.

Remember that some risks to your health may not be

immediately apparent. Exhaust gases and noise

pollution may not be visible, but these hazards can

cause permanent injuries.

Some photographs in this manual may show doors,

guards and shields open or removed for the purposes of

illustration only. Be sure all doors, guards, shields and

panels are in the proper operating positions before

starting the engine to operate the machine.

Do not modify the Falling Object Protective Structure

(“FOPS”) unless instructed to do so in approved installation instructions. Modifications, such as welding,

drilling or cutting, can weaken the structure and reduce

the protection it provides. A damaged protective structure cannot be repaired – it must be replaced.

For safety reasons, use only genuine service parts. For

example, using incorrect fasteners could lead to a condition in which the safety of critical assemblies is dangerously compromised.

The machine is designed and intended to be used only

with approved attachments. To avoid possible personal

injury, equipment damage or performance problems,

use only attachments that are approved for use on and

within the rated operating capacity of the machine.

Contact your dealer or the Manitou Americas, Inc. service department for information about attachment

approval and compatibility with specific machine models. Manitou Americas, Inc. cannot be responsible if

the machine is used with non-approved attachments.

For safety reasons, use only genuine replacement service parts. For example, using incorrect fasteners could

lead to a condition in which the safety of critical

assemblies is dangerously compromised.

Attachment Precautions

Optional kits are available through your dealer. Contact

your dealer or the Manitou Americas, Inc. service

department for information on available one-way (single-acting) and two-way (double-acting) piping/valving/auxiliary control kits. Because Manitou Americas,

Inc. cannot anticipate, identify and test all of the attachments that owners may want to install on their

machines, please contact Manitou Americas, Inc. for

information on approval of attachments, and their compatibility with optional kits.

MANDATORY SAFETY

SHUTDOWN PROCEDURE

Before leaving the machine:

1. Bring the machine to a complete stop on a level

surface. Avoid parking on an incline or a hillside,

but if this is not possible, park across the slope.

2. Lower the working equipment to the ground and

support it securely.

3. Run the engine at idle speed for a few minutes to

allow systems to cool after operation at full speed.

4. Turn the key fully counter-clockwise to shut off the

engine. Wait for all movement to stop.

5. Move the joysticks in all directions to verify the

hydraulic system is de-pressurized.

6. Lock out controls by raising left control console.

7. Remove the ignition key and take it with you. Exit

the machine using the hand-holds.

Do not use the machine for any application or purpose

other than described in this manual.

Unauthorized Modifications

Any machine modification made without authorization

from Manitou Americas, Inc. could create a safety hazard, for which the machine owner would be responsible.

Printed in U.S.A. 2-2 918070/FP0811

OPERATION SAFETY

Before Operation

Contact the proper local authorities for utility line locations BEFORE starting to dig. In North America, contact the North American One-Call Referral System at

8-1-1 in the U.S., or 1-888-258-0808 in the U.S. and

Canada.

Page 31

Remove all trash and debris from the machine every

day, especially in the engine compartment, to minimize

the risk of fire.

The operator’s area, steps and hand holds must be kept

free of oil, dirt, ice and unsecured objects.

Never use ether starting aids. Glow plugs are used for

cold weather starting. Glow plugs can cause ether or

other starting fluid to detonate, causing injury or damage.

Walk around the machine and inspect it before using it.

Look for damage, loose or missing parts, leaks, etc.

Repair as required before using the machine.

Check the tracks for damage at regular intervals.

Repair or replace as necessary.

Warn all nearby personnel before starting the machine.

Below-ground hazards also include water mains, tunnels and buried foundations. Know what is underneath

the work site before starting to dig.

Before working near power lines (either above-ground

or buried cable-type), always contact the power utility

and establish a safety plan with them.

Be aware of height obstacles. Any object in the vicinity

of the boom could represent a potential hazard, or

cause the operator to react suddenly and cause an accident. Use a spotter or signal person when working near

bridges, phone lines, work site scaffolds, or other

obstructions.