Page 1

Page 2

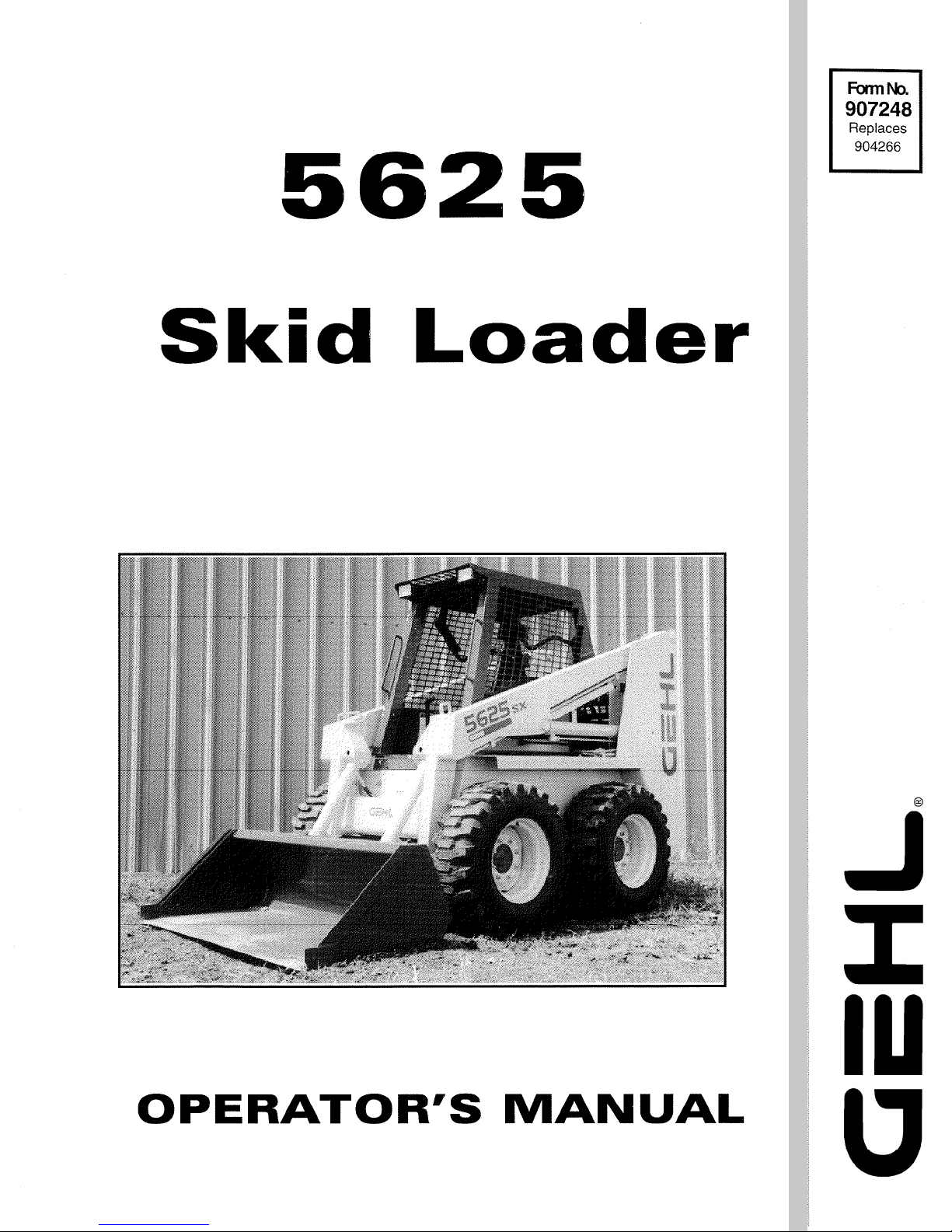

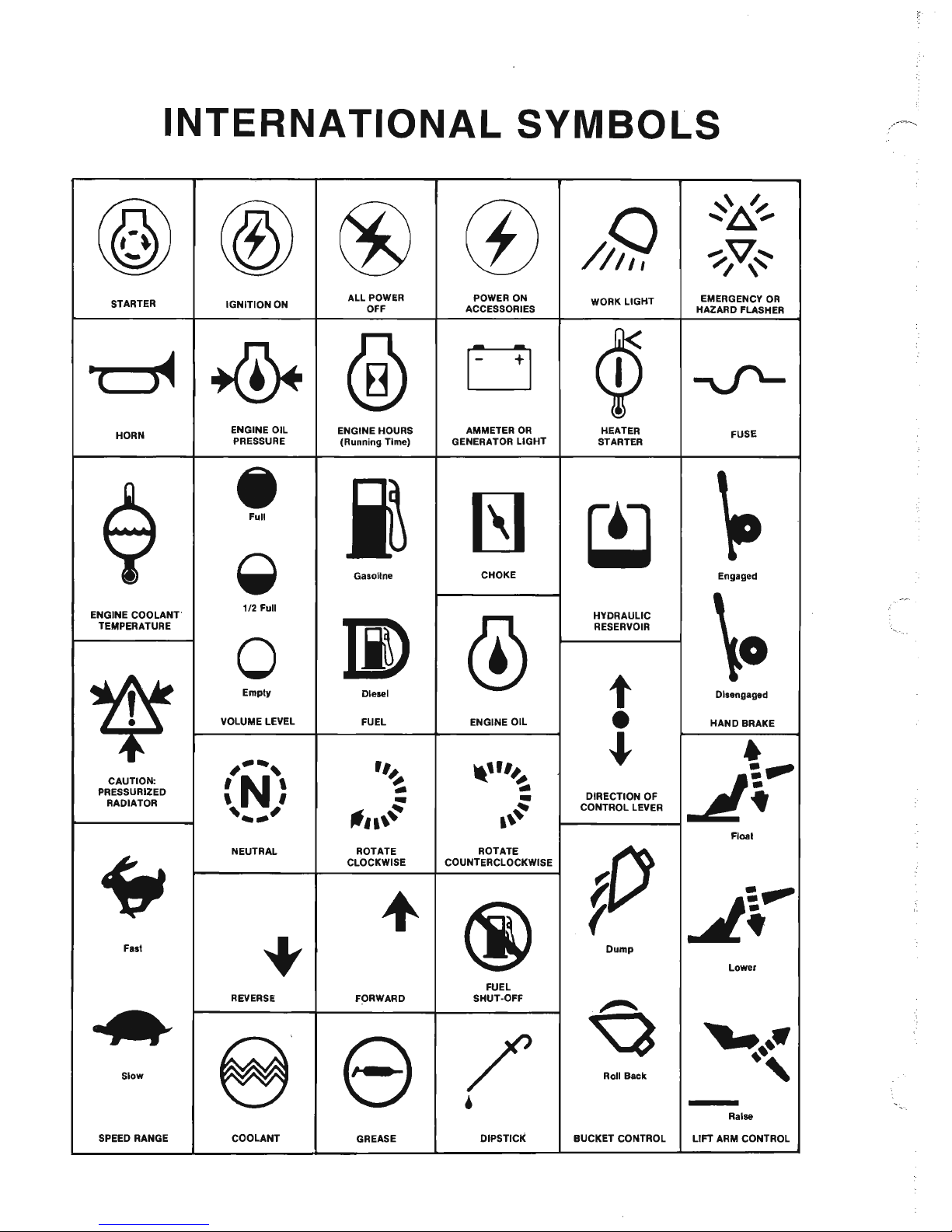

INTERNATIONAL

SYMBOLS

@ @

®

(£)

Q

'6/

......

,.

'/v~

///11

I \

STARTER

IGNITION ON

ALL POWER

POWER ON

WORK LIGHT

EMERGENCY

OR

OFF

ACCESSORIES

HAZARD FLASHER

~

~

®

0

c15

-v'-

HORN

ENGINE OIL

ENGINE HOURS

AMMETER

OR

HEATER

FUSE

PRESSURE

(Running Time) GENERATOR LIGHT STARTER

A

•

~~

IS]

c::J

~

Full

y

~

Gasoline

CHOKE

Engaged

ENGINE COOLANT'

1/2

Full

HYDRAULIC

\0

TEMPERATURE

JI)

(j)

RESERVOIR

*

0

t

Empiv

Diesel

Disengaged

VOLUME LEVEL

FUEL ENGINE OIL

•

HAND BRAKE

,--,

~

•

r"

,,-U/#.

~r-

CAUTION:

'N'

~

~

PRESSURIZED

..

, ,

-

-

DIRECTION OF

RADIATOR

'--'

4Itt

~

CONTROL LEVER

"n\'

.\~

Floal

NEUTRAL ROTATE ROTATE

C

if'

CLOCKWISE COUNTERCLOCKWISE

+

@

~:.~

r

•

Faal

+

Dump

Lower

FUEL

REVERSE

FORWARD

SHUT-OFF

~

....,

8

/'

'-.-

~~,

e

Slow

,

Roll Back

•

Raise

SPEED RANGE COOLANT

GREASE

DIPSTICK BUCKET CONTROL

LIFT ARM CONTROL

Page 3

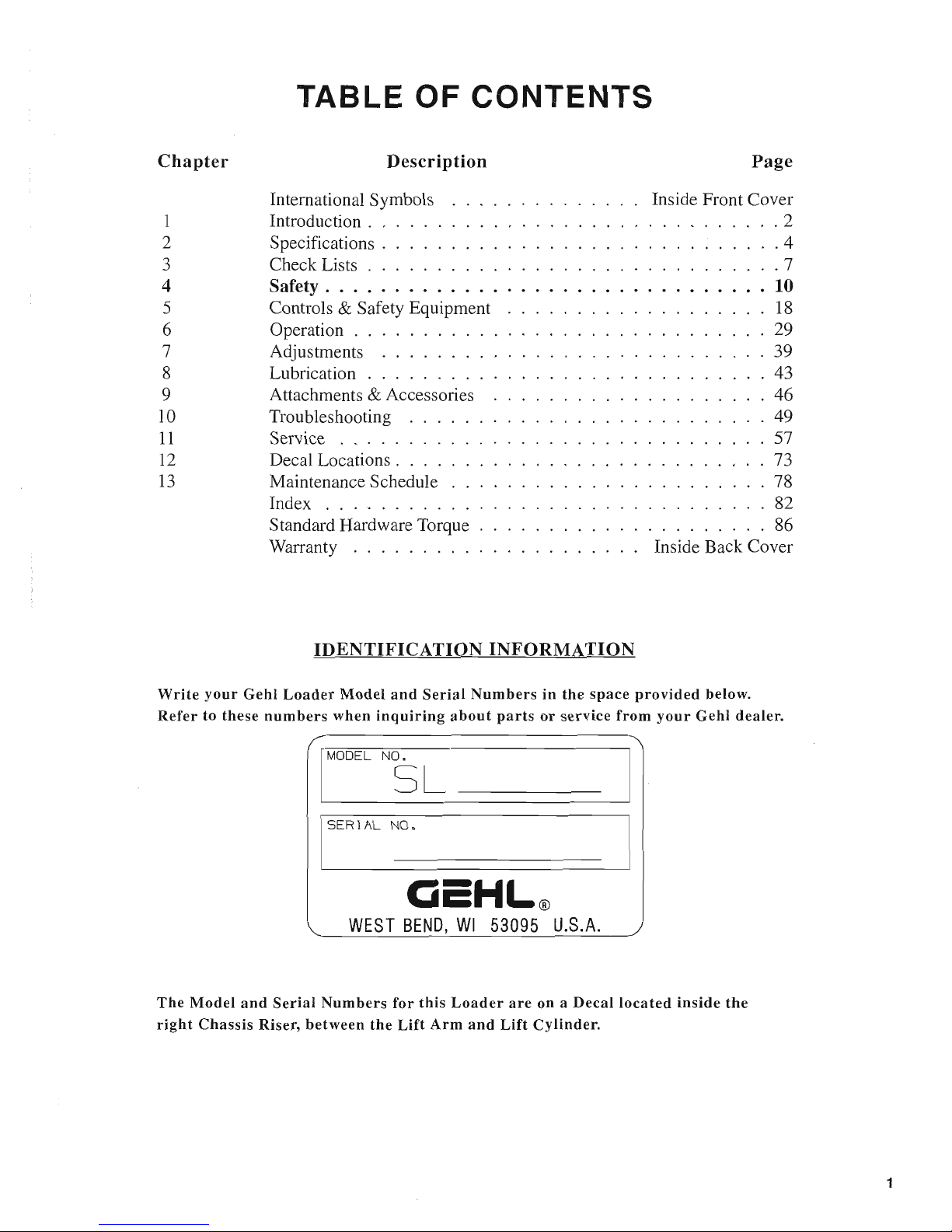

Chapter

1

2

3

4

5

6

7

8

9

10

11

12

13

TABLE OF

CONTENTS

Description

International Symbols

Introduction.

.

Specifications .

Check Lists . .

Safety

.....

.

Controls & Safety Equipment

Operation

..

Adjustments

.......

.

Lubrication . . . . . . . . .

Attachments

& Accessories

Troubleshooting

Service

.......

.

Decal

Locations.

. . .

Maintenance Schedule

Index

........

.

Standard Hardware Torque

Warranty

........

.

IDENTIFICATION

INFORMATION

Page

Inside Front Cover

.2

.4

.7

10

18

29

39

43

46

49

57

73

78

82

86

Inside

Back

Cover

Write your Gehl Loader Model and Serial Numbers in the space provided below.

Refer to these numbers when inquiring about parts or

service

from your Gehl dealer.

jMOOEL

N5

L

jSERIAL

N_O_o

________________

__

CicHL®

WEST

BEND,

WI

53095

U.S.A.

The Model and Serial Numbers for this Loader are on a Decal located inside the

right Chassis Riser, between the

Lift

Arm and

Lift

Cylinder.

1

Page 4

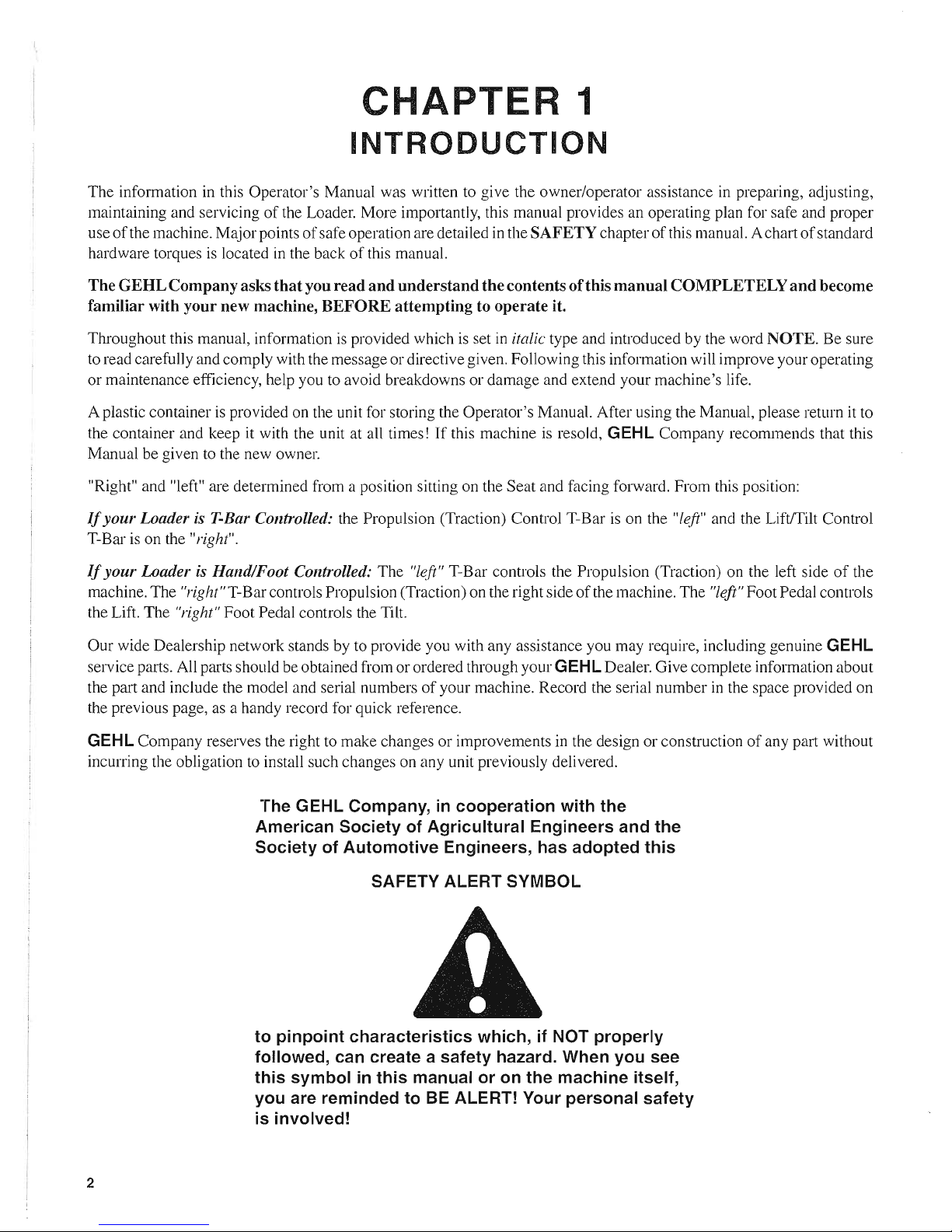

HAPTER

1

INTRODUCTION

The information in this Operator's Manual was written to give the owner/operator assistance in preparing, adjusting,

maintaining and servicing

of

the Loader. More importantly, this manual provides an operating plan for safe and proper

use

of

the machine. Major points

of

safe operation are detailed in the

SAFETY

chapter

of

this manual. A chart

of

standard

hardware torques

is

located in the back

of

this manual.

The

GEHL

Company

asks

that

you

read

and

understand

the

contents

of

this

manual

COMPLETELY

and

become

familiar

with

your

new

machine,

BEFORE

attempting

to

operate

it.

Throughout this manual, information

is

provided which is set in italic type and introduced by the word

NOTE.

Be sure

to read carefully and comply with the message or directive given. Following this information will improve your operating

or maintenance efficiency, help you to avoid breakdowns or damage and extend your machine's life.

A plastic container

is

provided on the unit for storing the Operator's Manual. After using the Manual, please return it to

the container and keep it with the unit at all times!

If

this machine

is

resold, GEHL Company recommends that this

Manual be given

to

the new owner.

"Right" and "left" are determined from a position sitting on the Seat and facing forward. From this position:

If

your

Loader is T-Bar Controlled: the Propulsion (Traction) Control T-Bar is on the "left" and the Liftffilt Control

T-Bar

is

on the "right".

If

your

Loader is Hand/Foot Controlled: The "left" T-Bar controls the Propulsion (Traction) on the left side

of

the

machine. The

"right"

T-

Bar controls Propulsion (Traction) on the right side

of

the machine. The "leji" Foot Pedal controls

the Lift. The

"right" Foot Pedal controls the Tilt.

Our wide Dealership network stands by to provide you with any assistance you may require, including genuine

GEHL

service parts. All parts should be obtained from or ordered through your GEHL Dealer. Give complete information about

the

PaIt and include the model and serial numbers

of

your machine. Record the serial number in the space provided on

the previous page, as a handy record for quick reference.

GEHL Company reserves the right to make changes or improvements in the design or construction

of

any part without

incurring the obligation to install such changes on any unit previously delivered.

2

The GEHL Company,

in

cooperation

with

the

American

Society

of

Agricultural

Engineers and

the

Society

of

Automotive

Engineers,

has

adopted

this

SAFETY ALERT SYMBOL

to

pinpoint

characteristics

which,

if

NOT

properly

followed,

can create a

safety

hazard. When

you

see

this

symbol

in

this

manual

or

on

the

machine

itself,

you

are reminded

to

BE ALERT! Your

personal

safety

is

involved!

Page 5

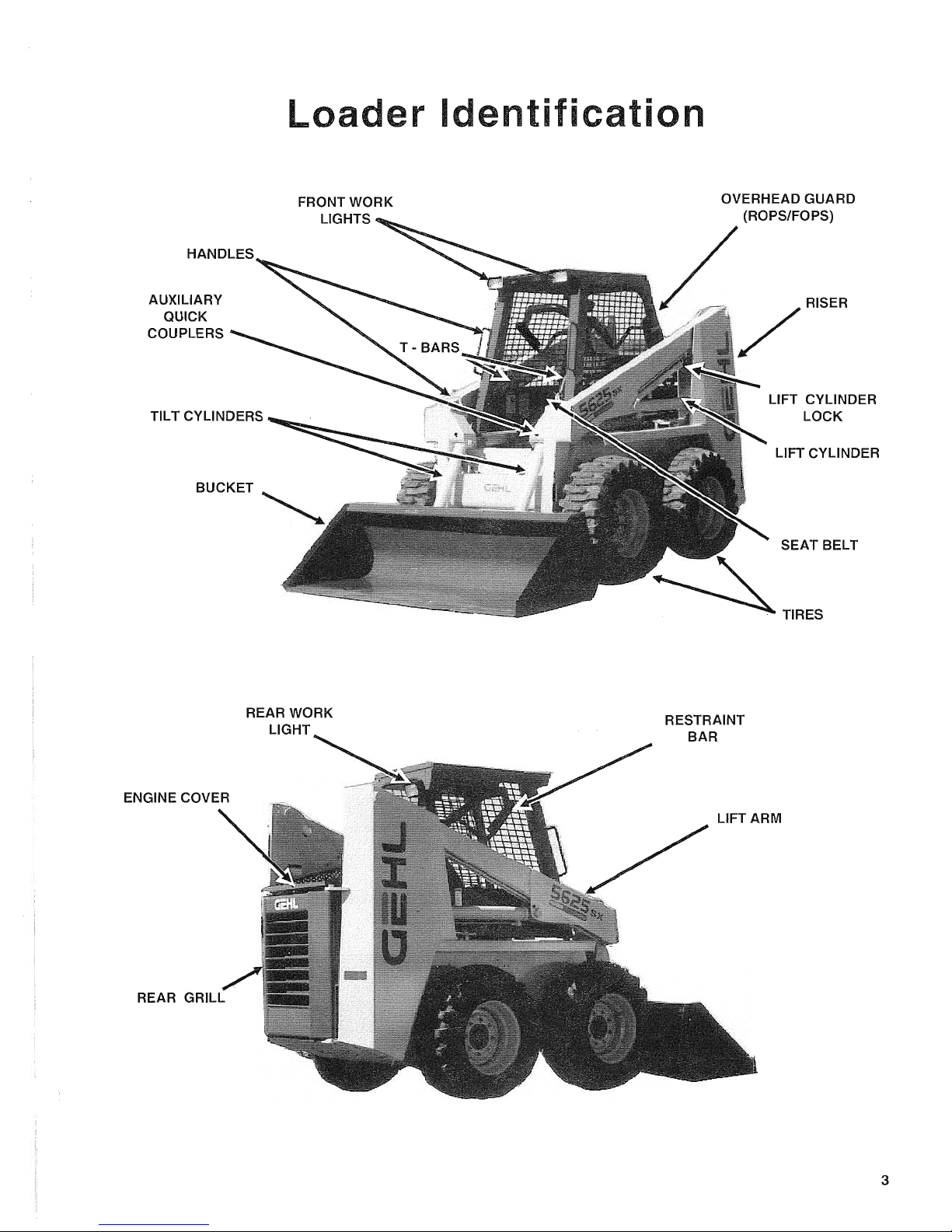

Loader

Identification

AUXILIARY

QUICK

COUPLERS

FRONT WORK

LIGHTS

TILT CYLINDERS

BUCKET

REAR GRILL

REAR WORK

LIGHT

RESTRAINT

BAR

LIFT CYLINDER

LOCK

LIFT CYLINDER

SEAT BELT

TIRES

LIFT ARM

3

Page 6

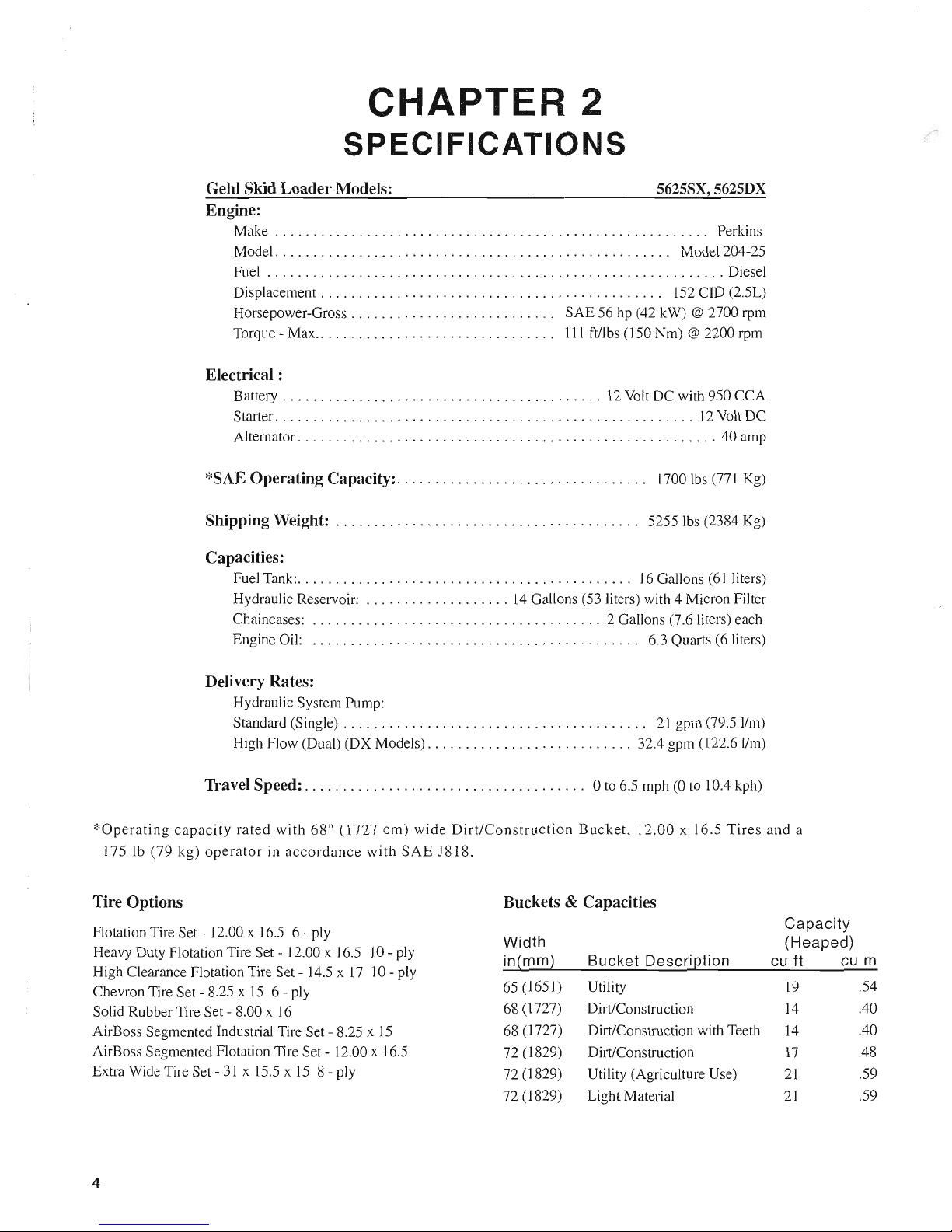

CHAPTER

2

SPECIFICATIONS

Gehl Skid Loader Models:

Engine:

5625SX,5625DX

Make . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

Perkins

Model

...................................................

, Model 204-25

Fuel

............................................................

Diesel

Displacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

152

cm (2.5L)

Horsepower-Gross

...........................

SAE 56 hp (42 kW) @ 2700 rpm

Torque - Max.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

111

ftllbs (150 Nm) @ 2200 rpm

Electrical :

Battery

..........................................

12

Volt

DC with 950 CCA

Starter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

Volt

DC

Alternator

.......................................................

40 amp

*SAE Operating Capacity:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1700

Ibs

(77 I Kg)

Shipping Weight:

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5255

Ibs

(2384 Kg)

Capacities:

Fuel Tank:

............................................

16

Gallons

(61

liters)

Hydraulic Reservoir:

...................

14

Gallons (53 liters) with 4 Micron Filter

Chaincases:

......................................

2 Gallons (7.6 liters) each

Engine Oil:

...........................................

6.3 Quarts (6 liters)

Delivery Rates:

Hydraulic System Pump:

Standard (Single) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2 I gpm (79.5 IIm)

High Flow (Dual) (DX Models)

...........................

32.4 gpm (122.6

11m)

Travel Speed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

0 to 6.5 mph (0 to 10.4 kph)

*Operating

capacity

rated

with

68"

(1727

cm)

wide

Dirt/Construction

Bucket,

12.00

x 16.5

Tires

and

a

175 Ib (79 kg)

operator

in

accordance

with

SAE

J818.

Tire Options

Buckets & Capacities

Flotation Tire Set - 12.00 x 16.5 6 - ply

Capacity

Width

(Heaped)

Heavy Duty Flotation Tire Set - 12.00 x 16.5

10

- ply

High Clearance Flotation Tire Set - 14.5 x

17

10

- ply

Chevron Tire Set - 8.25 x

15

6 - ply

in(mm}

Bucket

Descri[2tion cu ft cu m

Solid Rubber Tire Set - 8.00 x

16

AirBoss Segmented Industrial Tire Set - 8.25 x

15

AirBoss Segmented Flotation Tire Set - 12.00 x 16.5

Extra Wide Tire Set -

31

x 15.5

xiS

8 - ply

4

65 (1651)

68 (1727)

68 (1727)

72 (1829)

72 (1829)

72 (1829)

Utility

Dirt/Construction

Dirt/Construction with Teeth

Dirt/Construction

Utility (Agriculture Use)

Light Material

19

.54

14

.40

14

.40

17

.48

21

.59

21

.59

Page 7

Standard

Features

e Side-Mount "Load Trak" T-Bar Controls

e Power-Assist Controlled Hydrostatic Drive

e ROPS-FOPS ISO Level 2 Approved Overhead Guard

e Self-Level Lift Action

.. Independent Hydraulic Reservoir

.. Operator Restraint Bar with Armrests

e Seat and Operator Restraint Bar Interlock for Starter,

Lift Cylinders, and Tilt Cylinders

e Adjustable Contoured Seat with Seat Belt

.. Mechanical Lift Cylinder Lock

.. Integral Belly Plate with Cleanout

• Hourmeter

.. Coolant Temperature Gauge

.. Fuel Gauge

• Oil Pressure, Battery Charge Indicators

..

Hand and Foot Throttle-Hand Controls

III Glow Plug Statting Assist

III Disc Type Handbrake

e Operational Lights - 2 Front, I Rear

III Spark Arrestor Muffler

• Locking Fuel Cap

• Dual Element Air Cleaner

III Front Auxiliary Hydraulics with 3/4" Couplers

• Gehl Quick-Lock Attachment Mounting

III Sound Deadening Package

• 50/50 Anti-Freeze Protection

Accessories

•

3"

Seat Belt -Where required by Law

III Centrifugal Pre-Cleaner

III All Weather Rigid Cab Enclosure with Door Kit

III Vinyl Cab Enclosure Kit

..

Wiper Kit

..

HeaterlDefroster Kit

..

Back-Up Alarm

III Dual Flasher Kit

..

Strobe Light

..

Horn Kit

..

Lift Kit

..

Hydraulic Reservoir Heater

..

Enclosed Alternator -

12

Volt,

30 Amp

• Suspension Seat

• Engine Heater - Block -400 Watt

..

Engine Auto-Shutdown System Kit

• Battery Disconnect Switch

5

Page 8

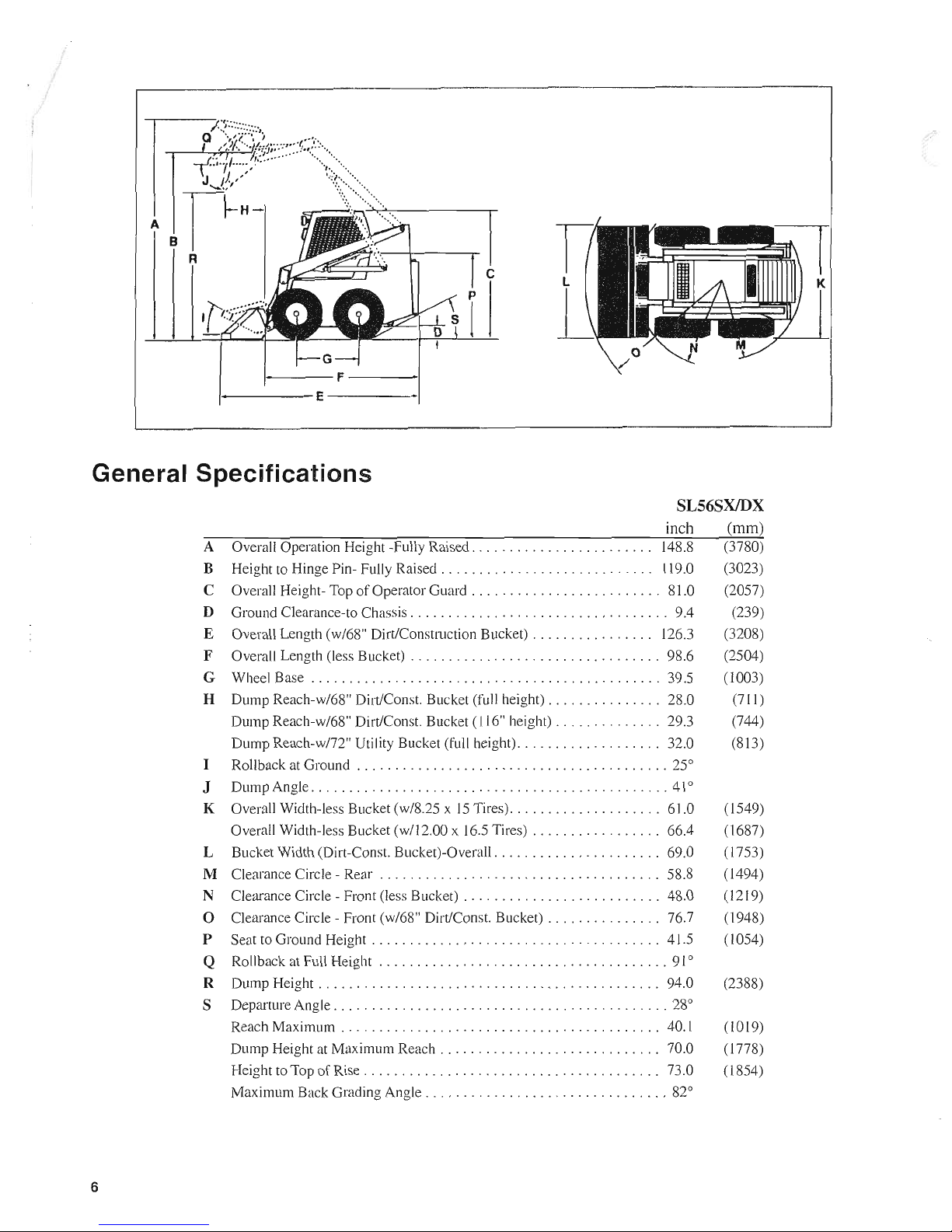

A

General Specifications

SL56SX/DX

6

inch

A Overall Operation Height -Fully Raised

........................

14S.S

B Height to Hinge Pin- Fully

Raised.

. . . . . . . . . . . . . . . . . . . . . . . . .

..

119.0

C Overall Height-Top

of

Operator

Guard.

. . . . . . . . . . . . . . . . . . . . . .

..

SI.O

D Ground Clearance-to Chassis

..................................

9.4

E Overall Length (w/6S" DirtlConstruction Bucket)

................

126.3

F Overall Length (less Bucket)

.................................

9S.6

G Wheel Base

..............................................

39.5

H Dump Reach-w/6S" Dirt/Const. Bucket (full height)

...............

2S.0

Dump Reach-w/6S" Dirt/Const. Bucket (116" height)

..............

29.3

Dump

Reach-w/72" Utility Bucket (full height)

...................

32.0

I Rollback at Ground

.........................................

25°

J Dump Angle

...............................................

41°

K Overall Width-less Bucket

(w/S.25

x

15

Tires)

....................

61.0

Overall Width-less Bucket (wI12.00 x 16.5 Tires)

.................

66.4

L Bucket Width (Dirt-Const. Bucket)-Overall

......................

69.0

M Clearance Circle - Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5S.S

N Clearance Circle - Front (less Bucket) . . . . . . . . . . . . . . . . . . . . . . . . . . 4S.0

o Clearance Circle - Front (w/6S" Dirt/Const. Bucket)

...............

76.7

P Seat to Ground Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.5

Q Rollback at Full Height

......................................

91

°

R Dump

Height.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

94.0

S Departure Angle

............................................

2So

Reach Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.1

Dump Height at Maximum

Reach.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

70.0

Height to Top

of

Rise

.......................................

73.0

Maximum Back Grading Angle

................................

S2°

(mm)

(37S0)

(3023)

(2057)

(239)

(320S)

(2504)

(1003)

(711)

(744)

(SI3)

(1549)

(16S7)

(1753)

(1494)

(1219)

( 1945)

(1054)

(23SS)

(1019)

(l77S)

(lS54)

Page 9

c

o

:;::::;

~

o

't:

Q)

a.

-

ctS

~

o

()

~

ii:

~C/)

...

Q)

C6

Q)

c

Q)

>

o

E

Q)

a:

CHAPTER

3

CHECKLISTS

PRE-DELIVERY

The following Checklist

is

an important reminder

of

valuable information and inspections which MUST be

made before delivering the Loader

to

the Customer.

Check off each item after prescribed action

is

taken.

Check that:

D Unit has NOT been damaged

in

shipment. Check for such

things

as

dents and loose or missing parts; con-ect or

replace components

as

required .

D Battery is securely mounted and

NOT

cracked, cable con-

nections are tight, and Battery Disconnect Switch (if

equipped)

is

in

the "ON" position.

D Lift and Tilt Cylinders, Hoses and Fittings are

NOT

dam-

aged, leaking or loosely connected.

D Radiator Hoses and Fittings are

NOT

damaged, leaking or

loosely connected.

D Filters are NOT damaged, leaking or loosely secured.

D Wheels are properly and securely attached and Tires are

properly inflated.

D Loader

is

properly lubricated and NO Grease Fittings are

missing or damaged.

D Hydraulic System Reservoir, Engine Crankcase and Drive

Chaincases are filled to their proper levels.

D All adjustment are made

to

comply with settings given

in

the Adjustments chapter

of

this manual.

D All Guards, Shields and Decals are in place and securely

attached.

D Model and Serial Numbers, for this unit,

m'e

recorded in

space provided on this page and page

I.

Start Loader Engine and test-run the unit while

checking that proper operation is exhibited by all

controls.

Check that:

D

Propulsion

Control

and Lift/Tilt Control T-bars

or

Hand/Foot Controls operate properly and are NOT damaged or binding.

D Propulsion Control T-bar or HandlFoot Controls are prop-

erly adjusted for a correct "neutral" position so that Loader

does NOT creep.

D Lift Cylinder and Starter Interlock system functions prop-

erly. By design, the Engine will NOT start unless the

Operator is sitting on the Seat and the Restraint Bar

is

"lowered". Furthermore, the Lift and Tilt Circuits will not

operate unless the Operator is sitting on the Seat, the

Restraint Bar is "lowered", and the Starter Key Switch is

in the "Run" position.

I acknowledge that pre-delivery procedures were performed on this unit at outlined above.

Dealership

Name

Dealer

Representative's

Name

Date

Checklist

Filled-out

Loader

Model#

Loader

Serial#

Engine

Serial#

Delivery

Check that:

The following Checklist is an important reminder

of

valuable information that MUST be passed on to the

Customer at the time the unit

is

delivered. Check off each

item as you explain it to the Customer.

Review with the Customer the contents

of

this manual;

especially:

D The INDEX at the back, for quickly locating topics;

D The SAFETY, CONTROLS & SAFETY EQUIPMENT

and OPERATION Chapters, for information regarding

safe use

of

the machine;

D The ADJUSTMENTS, LUBRICATION, SERVICE and

TROUBLESHOOTING Chapters, for information regarding proper maintenance

of

the machine. Explain that regular lubrication and maintenance are required for continued

safe operation and long life.

D Give this Operator's Manual to the Customer and instruct

the Customer to be sure to read and completely understand

its contents BEFORE operating the unit.

D Explain that the Customer

MUST

consult the Engine

Manual (provided) for related specifications, operating

adjustments and maintenance instructions.

D Completely fill out the Owner's Registration, including

Customer's signature and, return it to the company.

Customer's

Signature

Date

Delivered

(Dealer's

File

Copy)

7

Page 10

INTENTIONALLY

BLANK

(To

be

removed

as

Dealer's

file

copy)

8

Page 11

CHAPTER

3

CHECKLISTS

PRE-DELIVERY

The following Checklist

is

an important reminder

of

valuable information and inspections which MUST be

made before delivering the Loader

to

the Customer.

Check off each item after prescribed action

is

taken.

Check that:

D Unit has NOT been damaged

in

shipment. Check for such

things as dents and loose or missing parts;

COlTect

or

replace components

as

required.

D Battery

is

securely mounted and NOT cracked, cable con-

nections are tight, and Battery Disconnect Switch (if

equipped) is

in

the "ON" position.

D Lift and Tilt Cylinders, Hoses and Fittings are NOT dam-

aged, leaking or loosely connected.

D Radiator Hoses and Fittings are NOT damaged, leaking or

loosely connected.

D Filters are NOT damaged, leaking or loosely secured.

D Wheels are properly and securely attached and Tires are

properly inflated.

D Loader is properly lubricated and NO Grease Fittings are

missing or damaged.

D Hydraulic System Reservoir, Engine Crankcase and Drive

Chain cases are filled to their proper levels.

D All adjustment are made to comply with settings given

in

the Adjustments chapter

of

this manual.

D All Guards, Shields and Decals are

in

place and securely

attached.

D Model and Serial Numbers, for this unit, are recorded

in

space provided on this page and page

1.

Start Loader Engine and test-run the unit while

checking that proper operation is exhibited by all

controls.

Check that:

D

Propulsion

Control and Lift/Tilt Control T-bars or

HandlFoot Controls operate properly and are NOT damaged or binding.

D Propulsion Control T-bar or Hand/Foot Controls are prop-

erly adjusted for a correct "neutral" position so that Loader

does NOT creep.

D Lift Cylinder and Starter Interlock system functions prop-

erly. By design, the Engine will NOT start unless the

Operator is sitting on the Seat and the Restraint Bar

is

"lowered". FUlthermore, the Lift and Tilt Circuits will not

operate unless the Operator

is

sitting on the Seat, the

Restraint Bar is "lowered", and the Starter Key Switch is

in the "Run" position.

I acknowledge that pre-delivery procedures were performed on this unit at outlined above.

Dealership

Name

Dealer

Representative's

Name

Date

Checklist

Filled-out

Loader

Model#

Loader

Serial#

Engine

Serial#

Delivery

Check that:

The following Checklist is an important reminder

of

valuable information that MUST be passed on to the

Customer at the time the unit

is

delivered. Check off each

item as you explain it

to

the Customer.

Review with the Customer the contents

of

this manual;

especially:

D The INDEX at the back, for quickly locating topics;

D The SAFETY, CONTROLS & SAFETY EQUIPMENT

and OPERATION Chapters, for information regarding

safe use

of

the machine;

D The ADJUSTMENTS, LUBRICATION, SERVICE and

TROUBLESHOOTING Chapters, forinfonnation regarding proper maintenance

of

the machine. Explain that regular lubrication and maintenance are required for continued

safe operation and long life.

D Give this Operator's Manual to the Customer and instruct

the Customer to be sure to read and completely understand

its contents BEFORE operating the unit.

D Explain that the Customer MUST consult the Engine

Manual (provided) for related specifications, operating

adjustments and maintenance instructions.

D Completely fill out the Owner's Registration, including

Customer's signature and, return

it

to the company.

Customer's

Signature

Date

Delivered

(Pages 7 & 8 have been removed at Perforation)

9

Page 12

CHAPTER

4

The above Safety Alert Symbol means

ATTENTION!

BECOME

ALERT!

YOUR

SAFETY

IS

IN-

VOLVED! It stresses an attitude

of

"Heads Up for

Safety" and can be found throughout this Operator's

Manual and on the machine itself.

BEFORE

YOU

ATTEMPT

TO

OPERATE

THIS

EQUIPMENT,

READ

AND

STUDY

THE

FOL-

LOWING

SAFETY

INFORMATION.

IN

ADDI-

TION,

MAKE

SURE

THAT

EVERY

INDIVIDUAL

WHO

OPERATES

OR

WORKS

WITH

THIS

EQUIPMENT,

WHETHER

FAMILY

MEMBER

OR

EMPLOYEE,

IS

FAMILIAR

WITH

THESE

SAFETY

PRECAUTIONS.

Our Company ALWAYS takes the operator's safety

into consideration when designing its machinery, and

guards exposed moving parts for the operator's protection. However, some areas can NOT be guarded or

shielded in order to assure proper operation. In addition, this Operator's Manual, and Decals on the machine, warn

of

further danger and should be read and

observed closely.

DAN

ER

"DANGER" indicates

an

imminently hazardous

situation which,

if

not avoided, will result

in

death or serious injury.

WARNING

"WARNING" indicates a potentially hazardous situ-

ation which,

if

not avoided, could result

in

death

or

serious injury.

CAUTI

N

"CAUTION"

indicates a potentially

hazardous situation which, if not avoided, may result

in

minor

or

moderate

injury. May also

alert

against unsafe practices.

10

MANDATORY SAFETY SHUTDOWN

PROCEDURE

BEFORE

unclogging, cleaning, adjusting, lubricat-

ing or servicing the unit:

1. Move the Propulsion Control T-bar(s)

to

the "neutral"

position.

2. Lower the Lift Arm and Attachment completely.

Also, see Step 5, below.

3. Move the Throttle

to

the low idle position, shut the

Engine off and remove the

Key.

4. Apply the Parking Brake.

S.

If

the Lift Arm MUST be left

in

the "raised" position,

BE SURE

to

properly engage the Lift Cylinder Me-

chanical Lock instead

of

performing step

2.

ONLY when you have taken these precautions can

you be sure it is safe to proceed. Failure to follow

the above procedure, could lead to death or serious

injury.

ADDITIONAL SAFETY REMINDERS

e

Some

photographs

in this manual may

show

Doors, Guards and Shields open or removed for

illustrative purposes

ONLY.

BE SURE that all

Doors, Guards and Shields are in their proper

operating positions BEFORE starting the engine

to operate the unit.

e To ensure safe operation, replace damaged

or

worn-out parts with genuine Gehl service parts,

BEFORE attempting to operate this equipment.

e GEHL Skid Loaders are designed and intended to

be used ONLY with GEHL Company Attachments

or

approved Referral Attachments. The GEHL

Company can NOT be responsible for operator

safety

if

the Loader is used with a non-approved

Attachment.

Page 13

SA

ETV

(CONTINUED)

• The stability

of

a Skid Loader is determined by its

short wheel base. The following elements: the

terrain,

Engine

speed,

load

being

carried

or

dumped, and/or abrupt Control movements, can

affect stability.

IF

MISUSED, ANY

OF

THE

ABOVE

FACTORS

CAN

CAUSE

THE

LOADER TO TIP, THROWING YOU FORWARD

OR

OUT

OF

THE

UNIT, CAUSING

DEATH

OR

SERIOUS INJURY. Therefore,

ALWAYS have the Operator Restraint Bar

"low-

ered"

and wear the Seat Belt. Operate the Controls

smoothly and gradually at an appropriate Engine

speed which matches the operating conditions.

• For additional stability when operating on inclines

or ramps, ALWAYS travel with the heavier end

of

the Loader to the top

of

the incline.

• NEVER attempt to by-pass the Keyswitch to start

the Loader Engine. Only use the jump-starting

procedure detailed in the service chapter

of

this

manual.

• Do NOT attempt to remove the Radiator Cap after

the Engine has reached operating temperature or

has overheated because the Engine Coolant will be

extremely

HOT

and under pressure. ALWAYS

wait for the Engine to cool down BEFORE attempting to relieve pressure and remove the Radiator Cap. Failure to heed could result in severe

burns.

• NEVER use your hands to search for hydraulic

fluid leaks, use a piece

of

paper or cardboard.

Escaping fluid under pressure can be invisible and

can penetrate the skin and cause a serious injury.

If

any fluid is injected into your skin, see a doctor

at once. Injected fluid MUST be surgically removed by a doctor or gangrene may result.

•

ALWAYS

wear safety glasses with side shields

when striking metal against metal. In addition, it

is also recommended that a softer (non-chipable

material) be used to cushion the blow. Failure

to

heed could lead to serious injury to the eyes or

other parts

of

the body.

• DO NOT raise or drop a loaded Bucket or Fork

suddenly. Abrupt movements under load can cause

serious instability.

•

DO

NOT push the Lift Control all the way forward

(into the

"float"

position) with the Attachment

loaded and the Lift Arm raised as this will cause

the Lift Arm to drop, very rapidly.

• DO NOT drive too close to an excavation

or

ditch;

BE SURE that the surrounding ground has ade-

quate strength to support the weight

of

the Loader

and the load.

• DO NOT smoke or have any spark producing

equipment in the area while filling the Fuel Tank

or

while working on the fuel

or

hydraulic systems.

11

Page 14

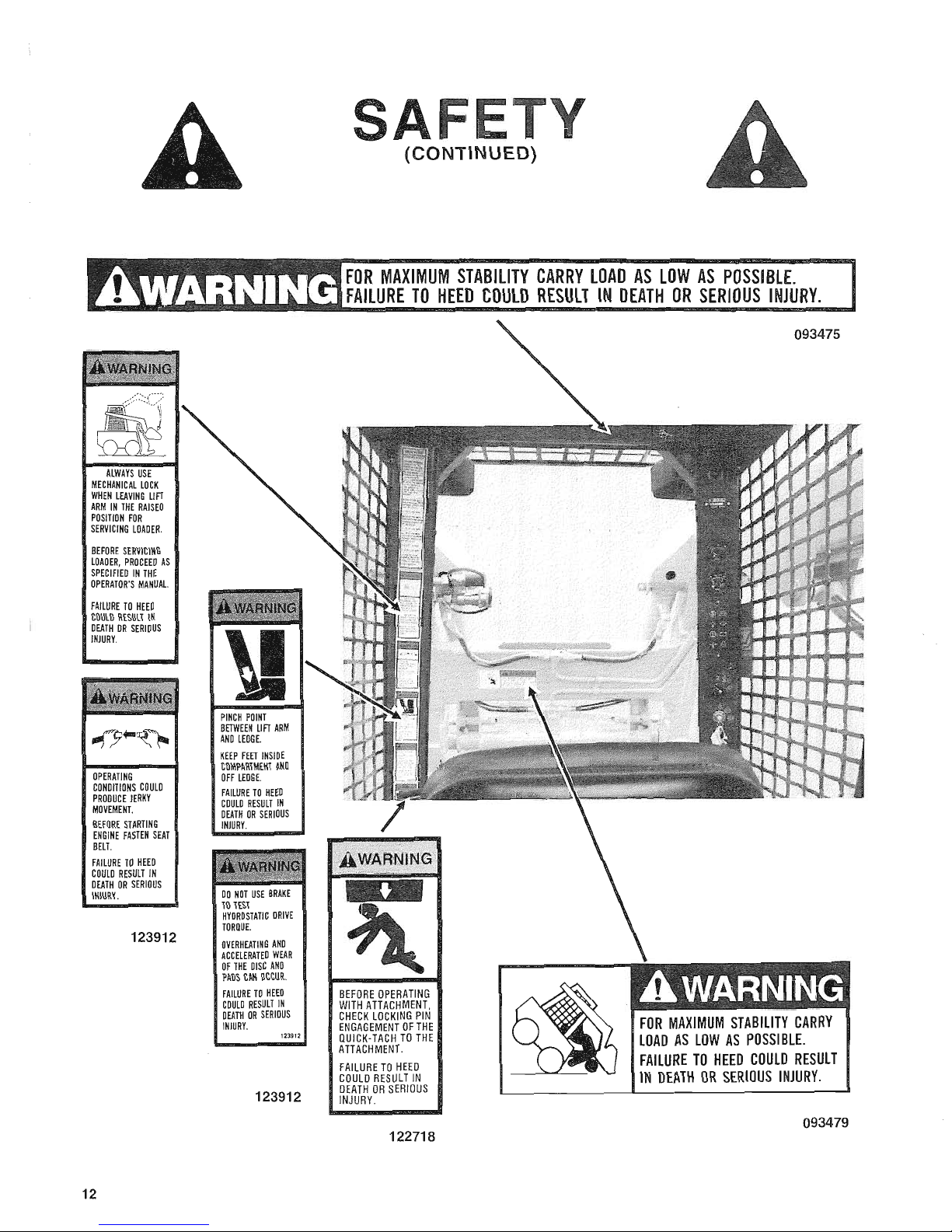

ALWAYS

USE

MECHANICAL

LOCK

WHEN

LEAVING

LIFT

ARM

IN

THE

RAISED

POSITION

FOR

SERVICING

LOAOER.

BEFORE

SERVICING

LOADER,

PROCEED

AS

SPECIFIED

IN

THE

OPERATOR'S

MANUAl.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

OPERATING

CONDITIONS

COULD

PRODUCE

JERKY

MOVEMENT.

BEFORE

STARTING

ENGINE

FASTEN

SEAT

BELT.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

123912

12

KEEP

FEET

INSIDE

COMPARTMENT

AND

OFF

LEDGE.

FAILURE

TO

HEED

COULO

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

DO

NOT

USE

BRAKE

TO

TEST

HYDROSTATIC

DRIVE

TORQUE.

OVERHEATING

AND

ACCELERATED

WEAR

OF

THE

DISC

AND

PADS

CAN

OCCUR.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

123912

123912

(CONTINUED)

OR

MAXIMUM

STABILITY

CARRY

LOAD

AS

LOW

AS

POSSIBLE.

AlLURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

BEFORE

OPERATING

WITH

ATTACHMENT,

CHECK

LOCKING

PIN

ENGAGEMENT

OF

THE

QUICK-TACH

TO

THE

ATTACHMENT.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

122718

093475

FOR

MAXIMUM

STABILITY

CARRY

LOAD

AS

LOW

AS

POSSIBLE.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

093479

Page 15

DO

NOT

BYPASS

ENGINE

KEYSWITCH

BY

CONNECTING

AT

THE

STARTER

TERMINALS

TO

JUMP

START.

FOLLOW

RECOMMENDED

PROCEDURE

IN

THE

OPERATOR'S

MANUAL

FOR

JUMP

STARTING

USING

THE

ENGINE

KEYSWITCH.

STARTING

IN

GEAR

COULD

OCCUR

IF

THE

STARTING

CONTROL

CIRCUIT

IS

BYPASSED.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

091033

IMPROPERLY

GROUNDED

HEATING

UNIT

CAN

CAUSE

ELECTRIC

SHOCK

OR

ElECTROCUTION.

MAKE

SURE

LOADER

IS

GROUNDED

WHEN

USING

ELECTRIC

HEATER.

FAILURE

TO

HEED

WILL

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

093484

(CONTINUED)

ROTATING

COMPONENTS

CAN

CUT

HANDS.

FAILURE

TO

HEED

WILL

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

091050

091050

PRESSURE

CAP

072798

13

Page 16

14

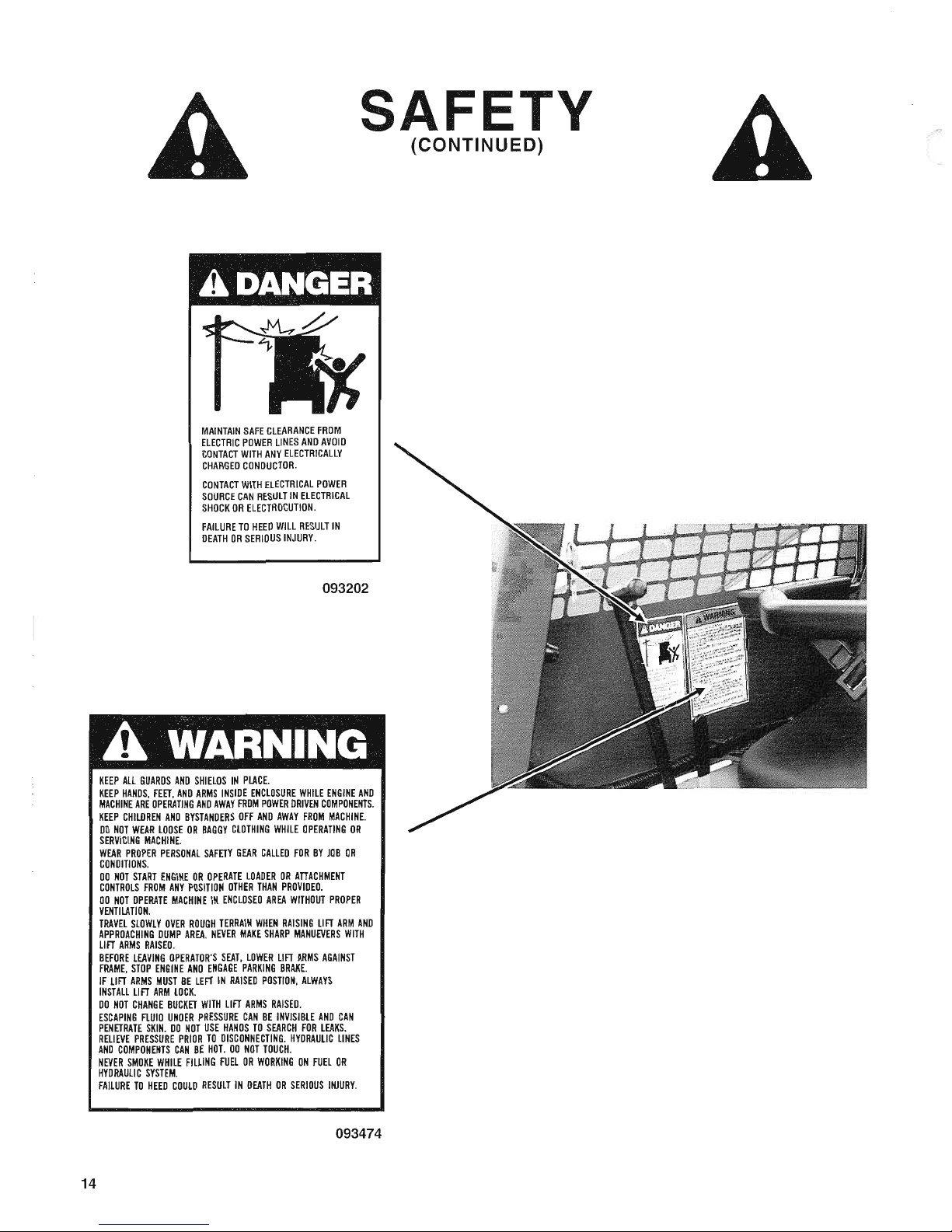

SAFETY

MAINTAIN

SAFE

CLEARANCE

FROM

ELECTRIC

POWER

LINES

AND

AVOID

CONTACT

WITH

ANY

ELECTRICALLY

CHARGED

CONDUCTOR.

CONTACT

WITH

ELECTRICAL

POWER

SOURCE

CAN

RESULT

IN

ELECTRICAL

SHOCK

OR

ELECTROCUTION.

FAILURE

TO

HEED

WILL

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

093202

KEEP

ALL

GUARDS

AND

SHIELDS

IN

PLACE.

KEEP

HANDS,

FEET,

AND

ARMS

INSIDE

ENCLOSURE

WHilE

ENGINE

AND

MACHINE

ARE

OPERATING

AND

AWAY

FROM

POWER

DRIVEN

COMPONENTS.

KEEP

CHILDREN

AND

BYSTANDERS

OFF

AND

AWAY

FROM

MACHINE.

DO

NOT

WEAR

LOOSE

OR

BAGGY

CLOTHING

WHILE

OPERATING

DR

SERVICING

MACHINE.

WEAR

PROPER

PERSONAL

SAFETY

GEAR

CALLED

FOR

BY

JOB

OR

CONDITIONS.

DO

NOT

START

ENGINE

OR

OPERATE

LOADER

OR

ATTACHMENT

CONTROLS

FROM

ANY

POSITION

OTHER

THAN

PROVIDED.

DO

NOT

OPERATE

MACHINE

IN

ENCLOSED

AREA

WITHOUT

PROPER

VENTILATION.

TRAVEL

SLOWLY

OVER

ROUGH

TERRAIN

WHEN

RAISING

LIFT

ARM

AND

APPROACHING

DUMP

AREA.

NEVER

MAKE

SHARP

MANUEVERS

WITH

LIFT

ARMS

RAISED.

BEFORE

LEAVING

OPERATOR'S

SEAT,

LOWER

LIFT

ARMS

AGAINST

FRAME,

STOP

ENGINE

AND

ENGAGE

PARKING

BRAKE.

IF

LIFT

ARMS

MUST

BE

LEFT

IN

RAISED

POSTlON,

ALWAYS

INSTALL

LIFT

ARM

LOCK.

DO

NOT

CHANGE

BUCKET

WITH

LIFT

ARMS

RAISED.

ESCAPING

flUID

UNDER

PRESSURE

CAN

BE

INVISIBLE

AND

CAN

PENETRATE

SKIN.

DO

NOT

USE

HANDS

TO

SEARCH

FOR

LEAKS.

RELIEVE

PRESSURE

PRIOR

TO

DISCONNECTING.

HYDRAULIC

LINES

AND

COMPONENTS

CAN

BE

HOT.

DO

NOT

TOUCH.

NEVER

SMOKE

WHILE

FIlliNG

FUEL

OR

WORKING

ON

FUEl

OR

HYDRAULIC

SYSTEM.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

093474

(CONTINUED)

Page 17

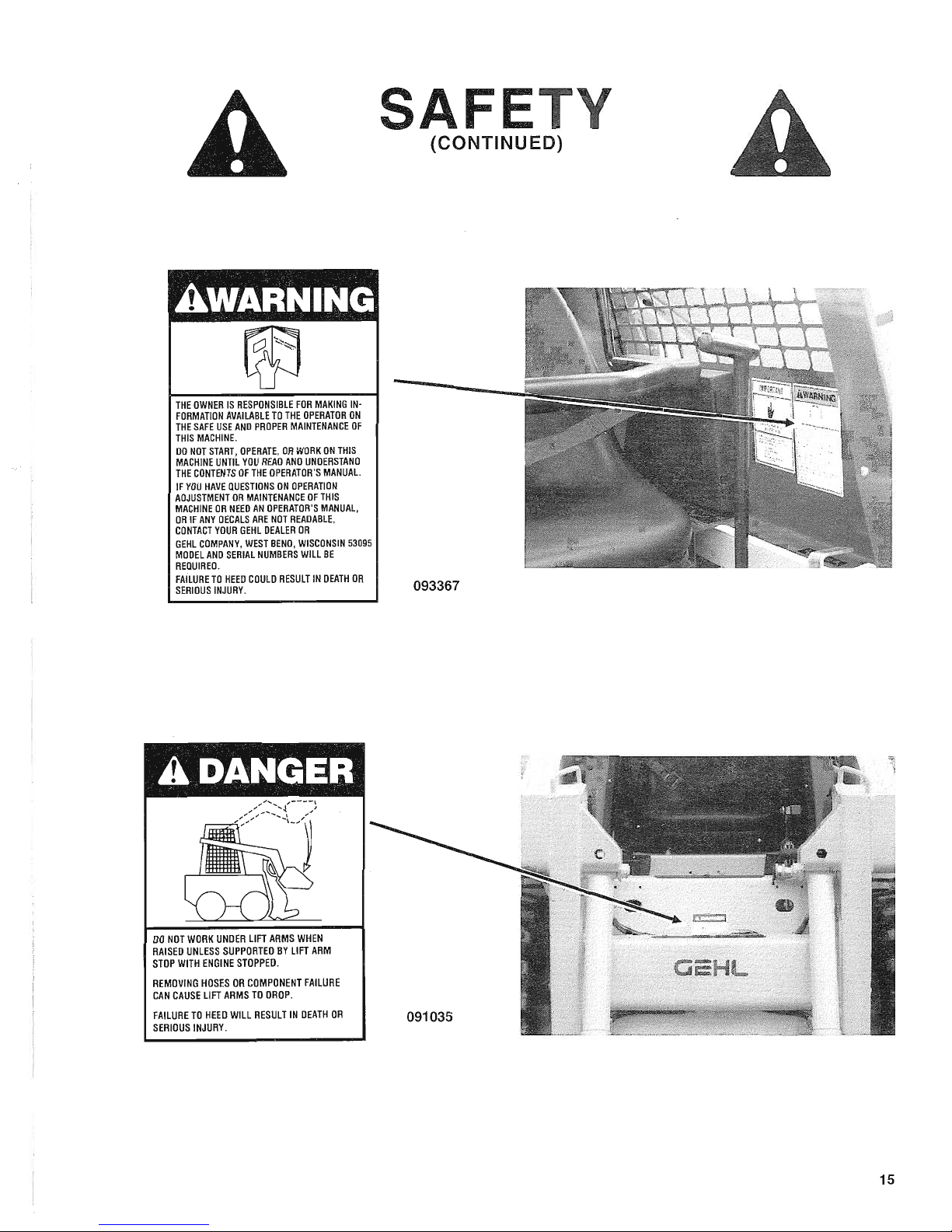

THE

OWNER

IS

RESPONSIBLE

FOR

MAKING

IN·

FORMATION

AVAILABLE

TO

THE

OPERATOR

ON

THE

SAFE

USE

AND

PROPER

MAINTENANCE

OF

THIS

MACHINE.

DO

NOT

START,

OPERATE,

OR

WORK

ON

THIS

MACHINE

UNTIL

YOU

READ

AND

UNDERSTAND

THE

CONTENTS

OF

THE

OPERATOR'S

MANUAl.

IF

YOU

HAVE

QUESTIONS

ON

OPERATION

ADJUSTMENT

OR

MAINTENANCE

OF

THIS

MACHINE

OR

NEED

AN

OPERATOR'S

MANUAL,

OR

IF

ANY

DECALS

ARE

NOT

READABLE,

CONTACT

YOUR

GEHL

DEALER

OR

GEHL

COMPANY,

WEST

BEND,

WISCONSIN

53095

MODEL

AND

SERIAL

NUMBERS

WILL

BE

REQUIRED.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

DO

NOT

WORK

UNDER

LIFT

ARMS

WHEN

RAISED

UNLESS

SUPPORTED

BY

LIFT

ARM

STOP

WITH

ENGINE

STOPPED.

REMOVING

HOSES

OR

COMPONENT

FAILURE

CAN

CAUSE

LIFT

ARMS

TO

DROP.

FAILURE

TO

HEED

WILL

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

(CONTINUED)

093367

091035

15

Page 18

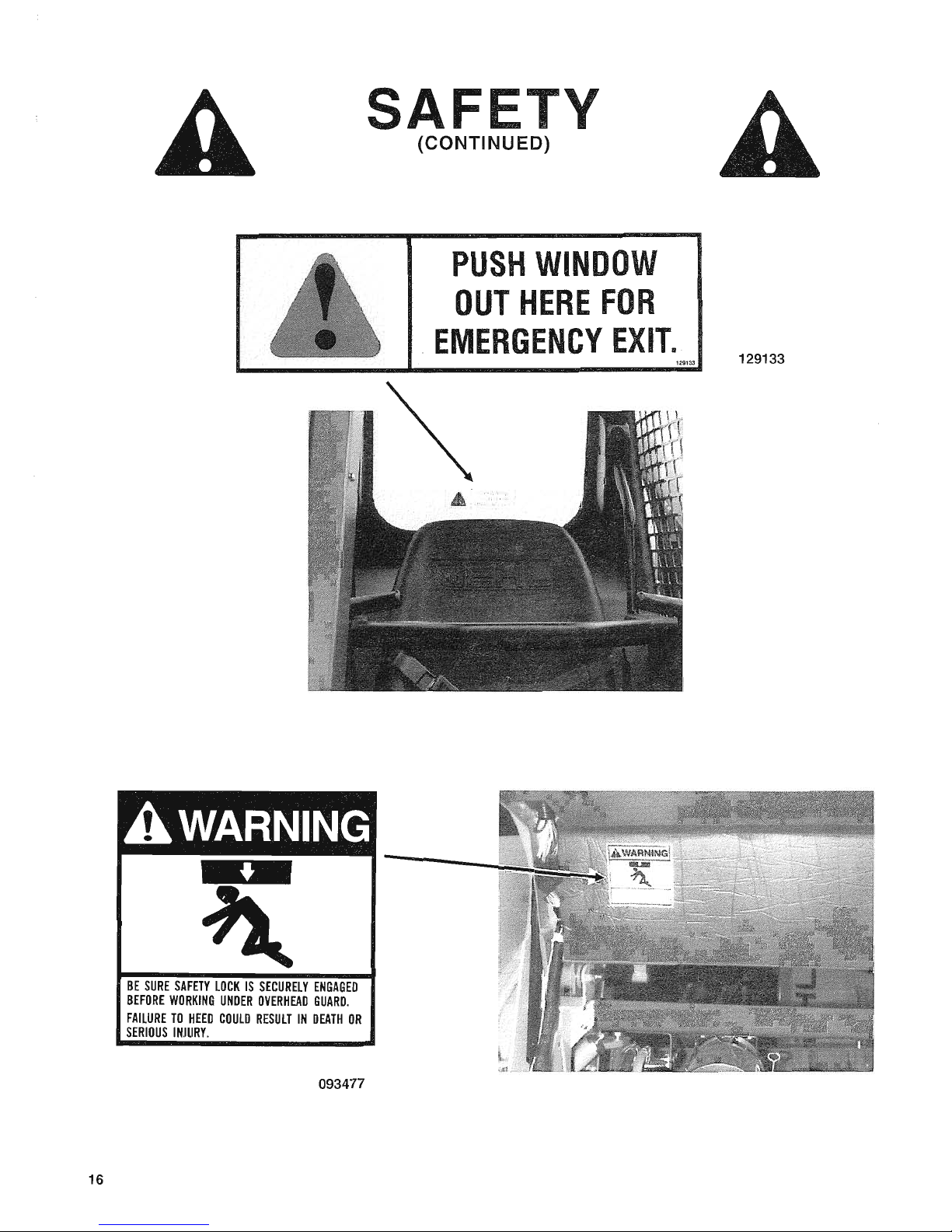

16

BE

SURE

SAFETY

LOCK

IS

SECURELY

ENGAGED

BEFORE

WORKING

UNDER

OVERHEAD

GUARD.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

093477

F

(CONTINUED)

129133

Page 19

ROTATING

OR

HOT

COMPONENTS

CAN

CAUSE

INJURY

KEEP

ENGINE

COVER

CLOSED

WHilE

ENGINE

IS

RUNNING

fAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

iNJURY

(CONTINUED)

129130

129130

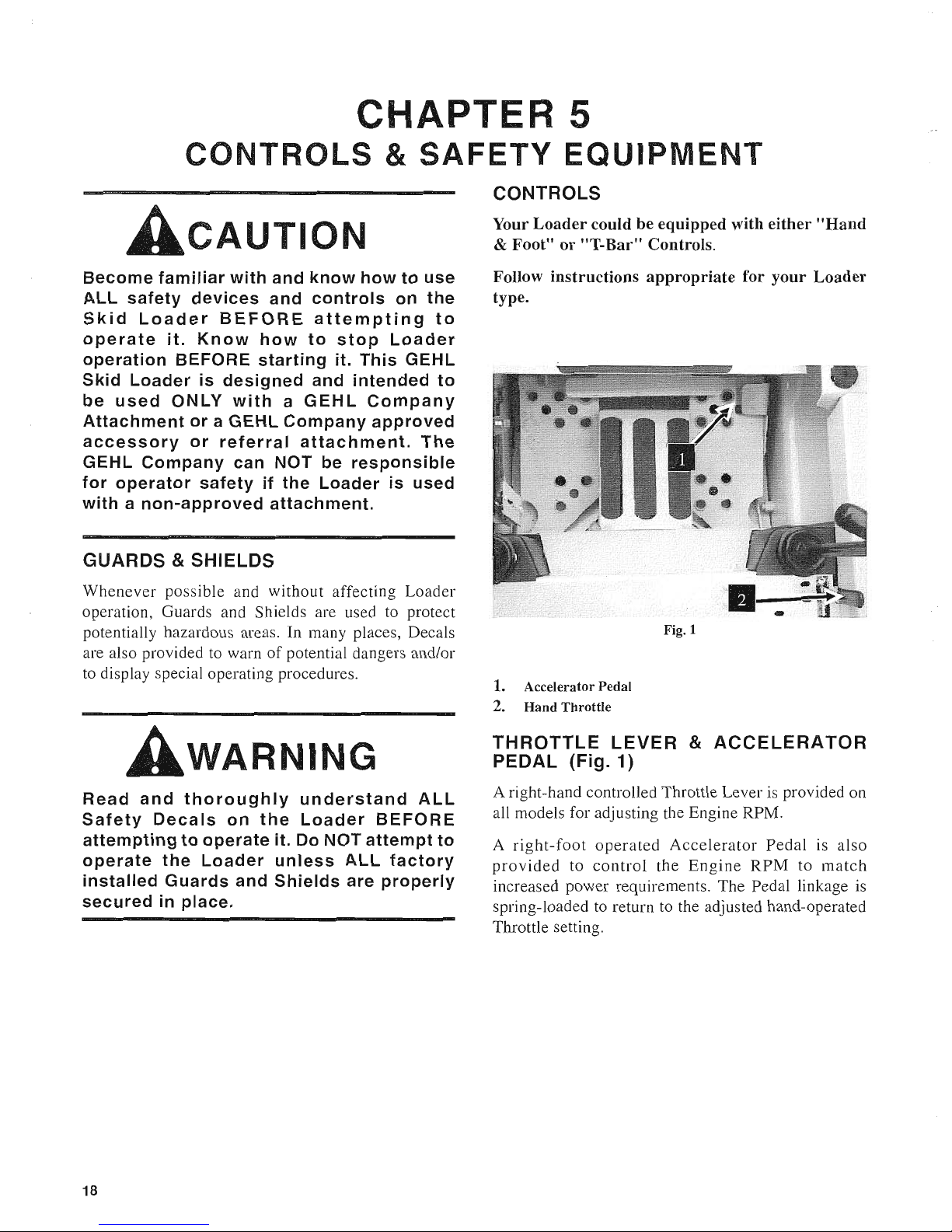

GAS-CHARGED

SPRING

CYLINDERS

ARE

USED

ON

THIS

MACHINE.

SEE

OPERATOR'S

MANUAL

FOR

LOCATIONS.

CYLINDERS

HAVE

HIGH

INTERNAL

PRESSURE.

DO

NOT

DISASSEMBLE.

DISASSEMBLY

COULD

RElEASE

PARTS

WITH

GREAT

FORCE.

FAILURE

TO

HEED

COULD

RESULT

IN

DEATH

OR

SERIOUS

INJURY.

122745

REMOVING

HOSES

OR

COMPONENT

FAILURE

CAN

CAUSE

LIFT

ARMS

TO

OROP

USE

MECHANICAL

LOCK

WHEN

LEAVING

LIFT

ARM

IN

RAISEO

POSITION

FOR

SERVICE

FAILURE

TO

HEED

WILL

RESULT

IN

DEATH

OR

SERIOUS

INJURY

129132

17

Page 20

CHAPTER

5

CONTROLS

&

SAFETY

EQUIPMENT

CAUTION

Become

familiar

with

and

know

how

to

use

ALL

safety

devices

and

controls

on

the

Skid

Loader

BEFORE

attempting

to

operate

it.

Know

how

to

stop

Loader

operation

BEFORE

starting

it.

This

GEHL

Skid

Loader

is

designed

and

intended

to

be

used

ONLY

with

a

GEHL

Company

Attachment

or a GEHL

Company

approved

accessory

or

referral

attachment.

The

GEHL

Company

can

NOT

be

responsible

for

operator

safety

if

the

Loader

is

used

with a non-approved

attachment.

GUARDS & SHIELDS

Whenever

possible and without affecting Loader

operation, Guards and Shields are used to protect

potentially hazardous areas. In many places, Decals

are also provided to warn

of

potential dangers and/or

to display special operating procedures.

WARNING

Read

and

thoroughly

understand

ALL

Safety

Decals

on

the

Loader

BEFORE

attempting

to

operate

it.

Do NOT

attempt

to

operate

the

Loader

unless

ALL

factory

installed

Guards

and

Shields

are

properly

secured

in

place.

18

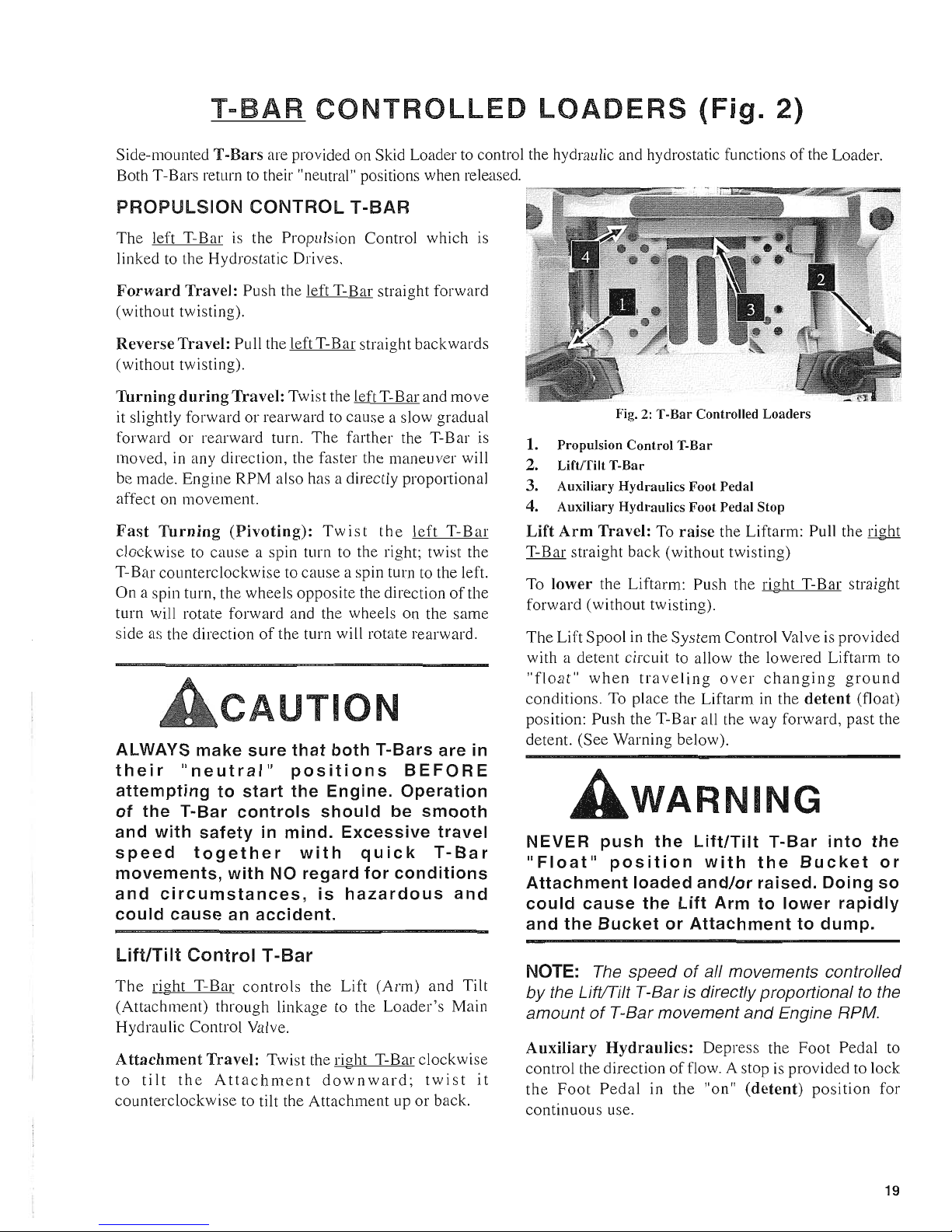

CONTROLS

Your

Loader

could be

equipped

with

either

"Hand

&

Foot"

or

"T-Bar"

Controls.

Follow

instructions

appropriate

for

your

Loader

type.

Fig. 1

1.

Accelerator Pedal

2.

Hand

Throttle

THROTTLE

LEVER

&

ACCELERATOR

PEDAL

(Fig.

1)

A right-hand controlled Throttle Lever is provided on

all models for adjusting the Engine RPM.

A

right-foot

operated

Accelerator

Pedal

is also

provided

to

control

the

Engine

RPM

to

match

increased power requirements. The Pedal linkage is

spring-loaded to return to the adjusted hand-operated

Throttle setting.

Page 21

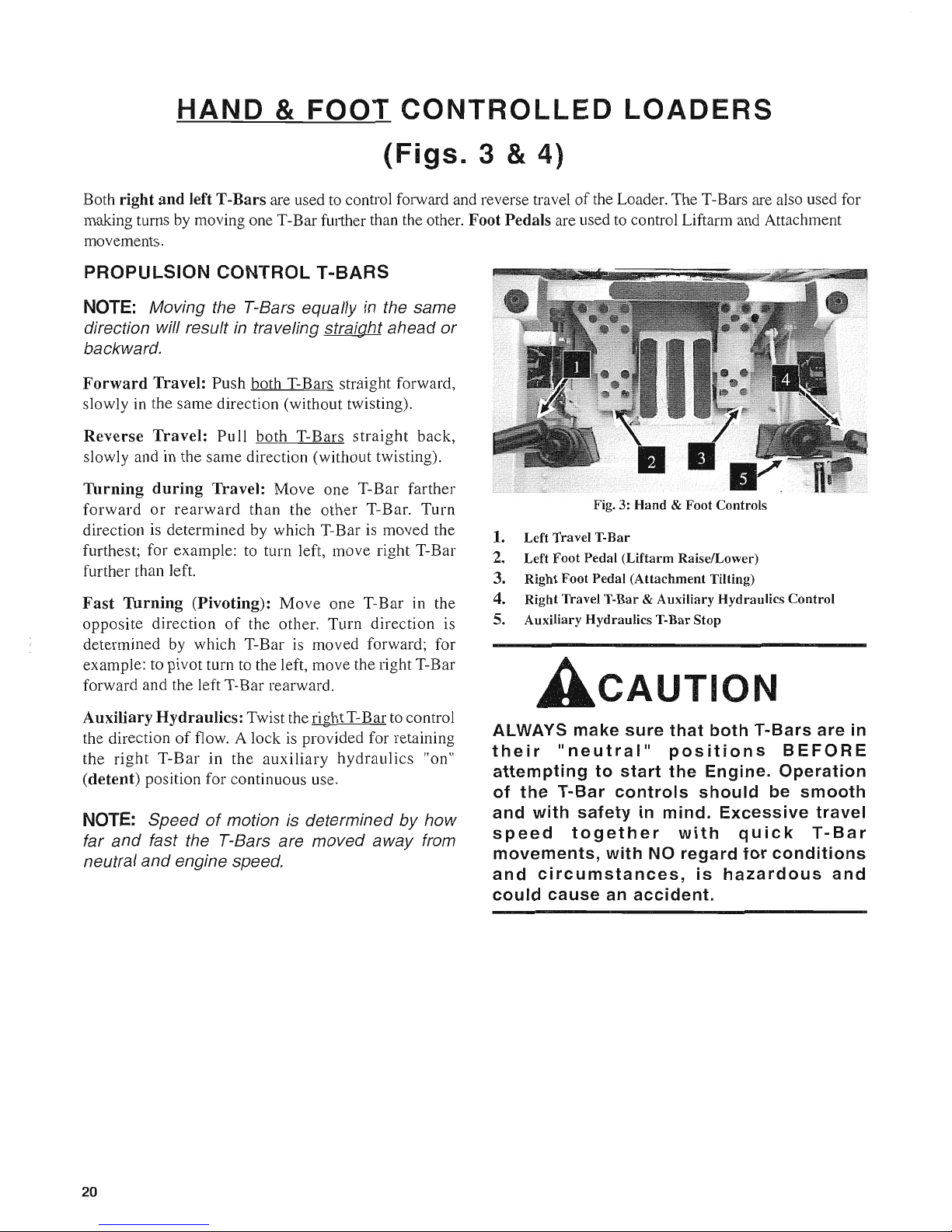

T",BAR

CONTROLLED

LOADERS

(Fig.

2)

Side-mounted T

-Bars

are provided on Skid Loader

to

control the hydraulic and hydrostatic functions

of

the Loader.

Both T-Bars return to their "neutral" positions when released.

PROPULSION CONTROL

T-BAR

The left T-Bar

is

the Propulsion Control which is

linked to the Hydrostatic Drives.

Forward

Travel:

Push the left T-Bar straight forward

(without twisting).

Reverse

Travel:

Pull the left T-Bar straight backwards

(without twisting).

Turning

during

Travel:

Twist the left T-Bar and move

it slightly forward or rearward to cause a slow gradual

forward or rearward turn. The farther the T-Bar

is

moved, in any direction, the faster the maneuver will

be made. Engine RPM also has a directly proportional

affect on movement.

Fast

Turning

(Pivoting):

Twist

the

left

T-Bar

clockwise to cause a spin turn to the right; twist the

T-Bar counterclockwise

to

cause a spin turn to the left.

On a spin turn, the wheels opposite the direction

of

the

turn will rotate forward and the wheels on the same

side as the direction

of

the turn will rotate rearward.

CAUTI

N

ALWAYS

make

sure

that

both

T-Bars

are

in

their

"neutral"

positions

BEFORE

attempting

to

start

the

Engine.

Operation

of

the

T-Bar

controls

should

be

smooth

and

with

safety

in

mind.

Excessive

travel

speed

together

with

quick

T-Bar

movements,

with

NO

regard

for

conditions

and

circumstances,

is

hazardous

and

could

cause

an

accident.

Lift/Tilt

Control

T-Bar

The

right T-Bar controls the Lift (Arm) and Tilt

(Attachment) through linkage to the Loader's Main

Hydraulic Control Valve.

Attachment

Travel:

Twist the right T-Bar clockwise

to

tilt

the

Attachment

downward;

twist

it

counterclockwise to tilt the Attachment up

or

back.

-"llll~-

Fig.

2:

T-Bar Controlled Loaders

1. Propulsion Control T-Bar

2.

Lift/Tilt T-Bar

3. Auxiliary Hydraulics Foot Pedal

4. Auxiliary Hydraulics Foot Pedal Stop

Lift

Arm

Travel:

To

raise

the Liftarm: Pull the right

T-Bar straight back (without twisting)

To

lower

the Liftarm: Push the right T-Bar straight

forward (without twisting).

The Lift Spool in the System Control Valve is provided

with a detent circuit to allow the lowered Liftarm to

"float"

when

traveling

over

changing

ground

conditions. To place the Liftarm in the

detent

(float)

position: Push the T-Bar all the way forward, past the

detent. (See Warning beloW).

WARNING

NEVER

push

the

Lift/Tilt

T-Bar

into

the

"Float"

position

with

the

Bucket

or

Attachment

loaded

and/or

raised.

Doing

so

could

cause

the

Lift

Arm

to

lower

rapidly

and

the

Bucket

or

Attachment

to

dump.

NOTE:

The speed

of

aI/ movements control/ed

by

the LiftlTilt T-Bar is directly proportional

to

the

amount

of

T-Bar movement and Engine RPM.

Auxiliary

Hydraulics:

Depress the Foot Pedal to

control the direction

of

flow. A stop is provided to lock

the

Foot

Pedal

in the "on"

(detent)

position

for

continuous use.

19

Page 22

HAND

&

FOOT

CONTROLLED

LOADERS

(Figs.

3 &

4)

Both right

and

left T-Bars are used

to

control forward and reverse travel of the Loader. The T-Bars are also used for

making turns by moving one T-Bar fmther than the other. Foot Pedals are used

to

control Liftarm and Attachment

movements.

PROPULSION CONTROL

T-BARS

NOTE:

Moving the T-Bars equally in the same

direction will result

in

traveling straight ahead

or

backward.

Forward

Travel: Push both T-Bars straight forward,

slowly

in

the same direction (without twisting).

Reverse

Travel:

Pull

both T-Bars straight back,

slowly and

in

the same direction (without twisting).

Turning

during

Travel: Move one T-Bar farther

forward

or

rearward

than the other T-Bar. Turn

direction is determined by which

T-

Bar

is

moved the

furthest; for example: to turn left, move right

T-

Bar

further than left.

Fast

Turning

(Pivoting): Move one T-Bar in the

opposite direction

of

the other. Turn direction is

determined by which

T-

Bar

is

moved forward; for

example: to pivot turn to the left, move the right T-Bar

forward and the left T-Bar rearward.

Auxiliary

Hydraulics:

Twist the right T-Bar to control

the direction

of

flow. A lock

is

provided for retaining

the right T-Bar in the auxiliary hydraulics "on"

(detent) position for continuous use.

NOTE:

Speed

of

motion is determined

by

how

far

and

fast the T-Bars are moved away from

neutral

and

engine speed.

20

Fig. 3: Hand & Foot Controls

1. Left Travel T-Bar

2.

Left Foot Pedal (Liftarm RaiselLower)

3. Right Foot Pedal (Attachment Tilting)

4. Right Travel T-Bar & Auxiliary Hydraulics Control

5. Auxiliary Hydraulics T-Bar Stop

ACAUTION

ALWAYS

make

sure

that

both

T-Bars

are

in

their

"neutral"

positions

BEFORE

attempting

to

start

the

Engine.

Operation

of

the

T-Bar

controls

should

be

smooth

and

with

safety

in

mind.

Excessive

travel

speed

together

with

quick

T-Bar

movements,

with

NO

regard

for

conditions

and

circumstances,

is

hazardous

and

could

cause

an

accident.

Page 23

HAND

&

FOOT

CONTROLLED

LOADERS

(continued)

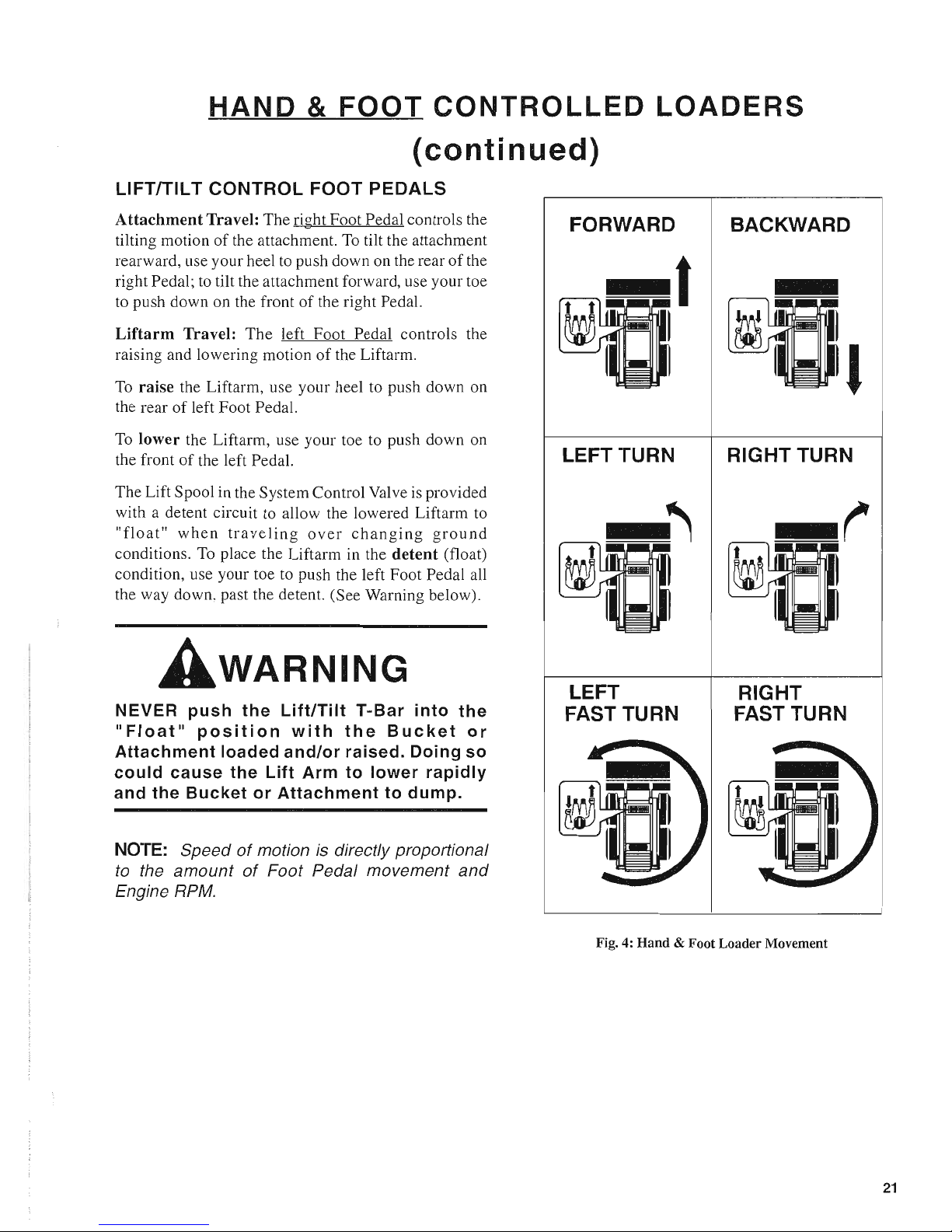

LlFTITIL T CONTROL FOOT PEDALS

Attachment

Travel: The right Foot Pedal controls the

tilting motion

of

the attachment.

To

tilt the attachment

rearward, use your heel to push down on the rear

of

the

right Pedal; to tilt the attachment forward, use your toe

to push down on the front

of

the right Pedal.

Liftarm

Travel: The left Foot Pedal controls the

raising and lowering motion

of

the Liftarm.

To

raise the Liftarm, use your heel to push down on

the rear

of

left Foot Pedal.

To

lower the Liftarm, use your toe to push down on

the front

of

the left Pedal.

The Lift Spool in the System Control Valve

is

provided

with a detent circuit to allow the lowered Liftarm

to

"float"

when

traveling

over

changing

ground

conditions.

To

place the Liftarm in the

detent

(float)

condition, use your toe to push the left Foot Pedal all

the way down, past the detent. (See Warning below).

AWARNING

NEVER

push

the

Lift/Tilt

T-Bar

into

the

"Float"

position

with

the

Bucket

or

Attachment

loaded

and/or

raised.

Doing

so

could

cause

the

Lift

Arm

to

lower

rapidly

and

the

Bucket

or

Attachment

to

dump.

NOTE:

Speed

of

motion

is

directly proportional

to

the amount

of

Foot Pedal movement

and

Engine RPM.

FORWARD

t

LEFT TURN

LEFT

FAST TURN

BACKWARD

I

RIGHT TURN

RIGHT

FAST TURN

Fig. 4:

Hand

& Foot Loader Movement

21

Page 24

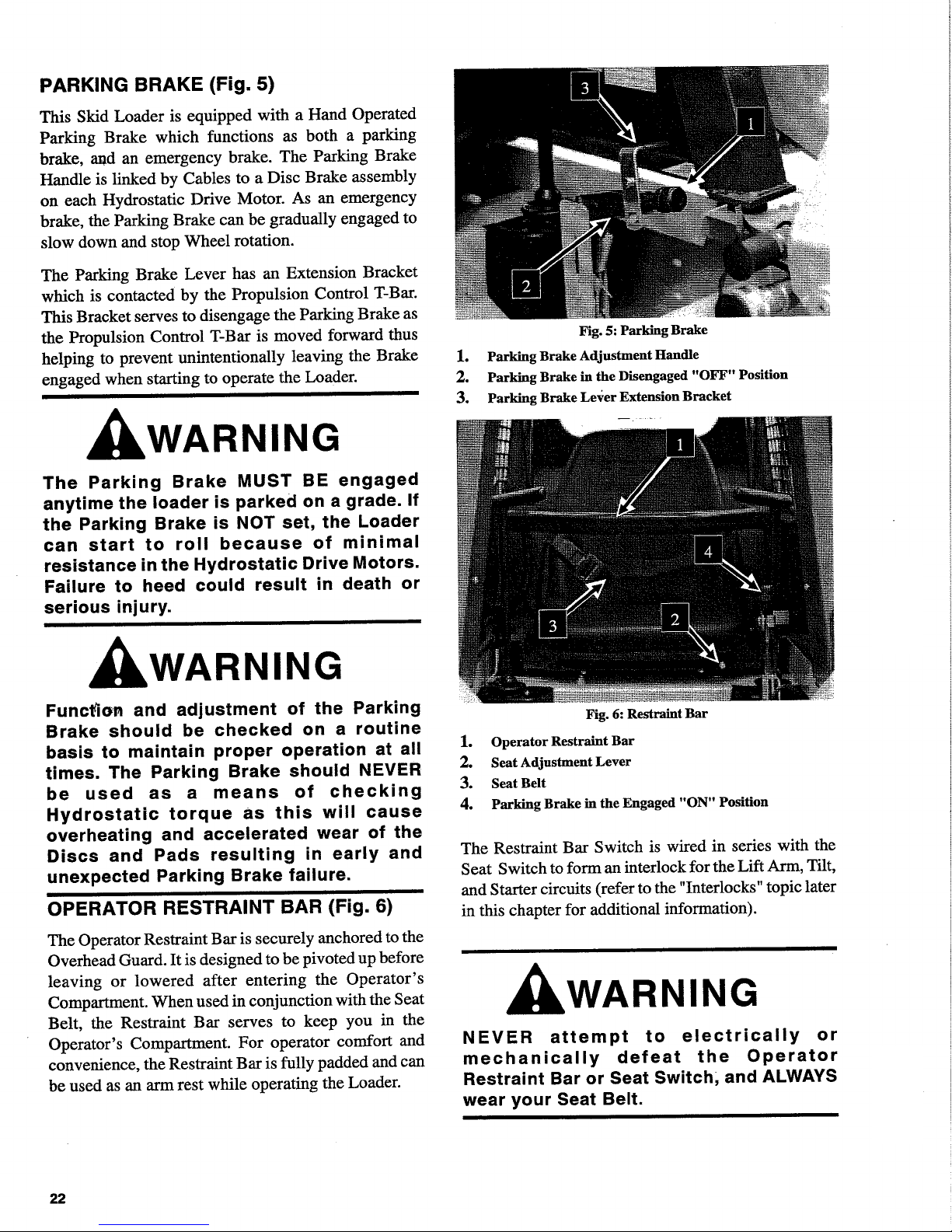

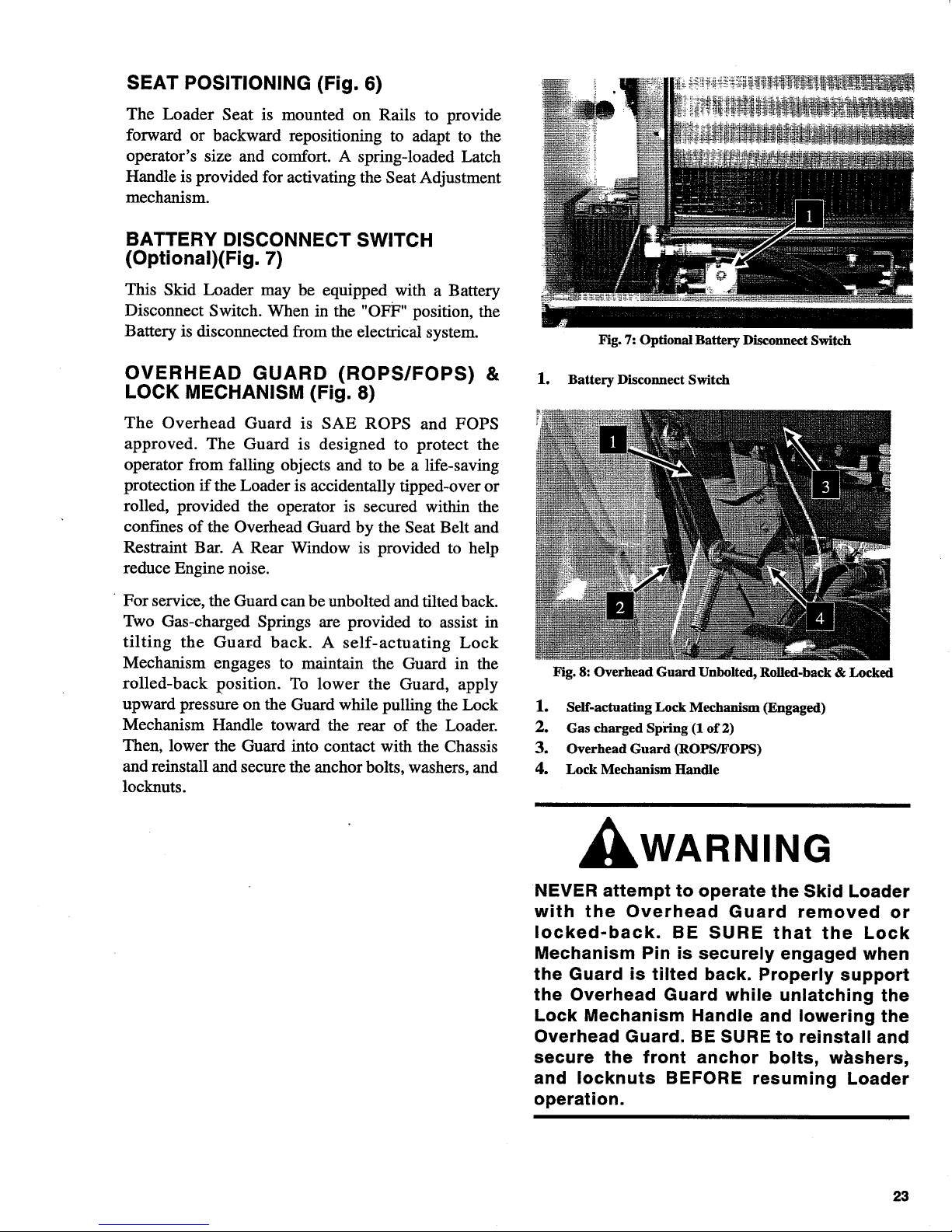

Page 25

Page 26

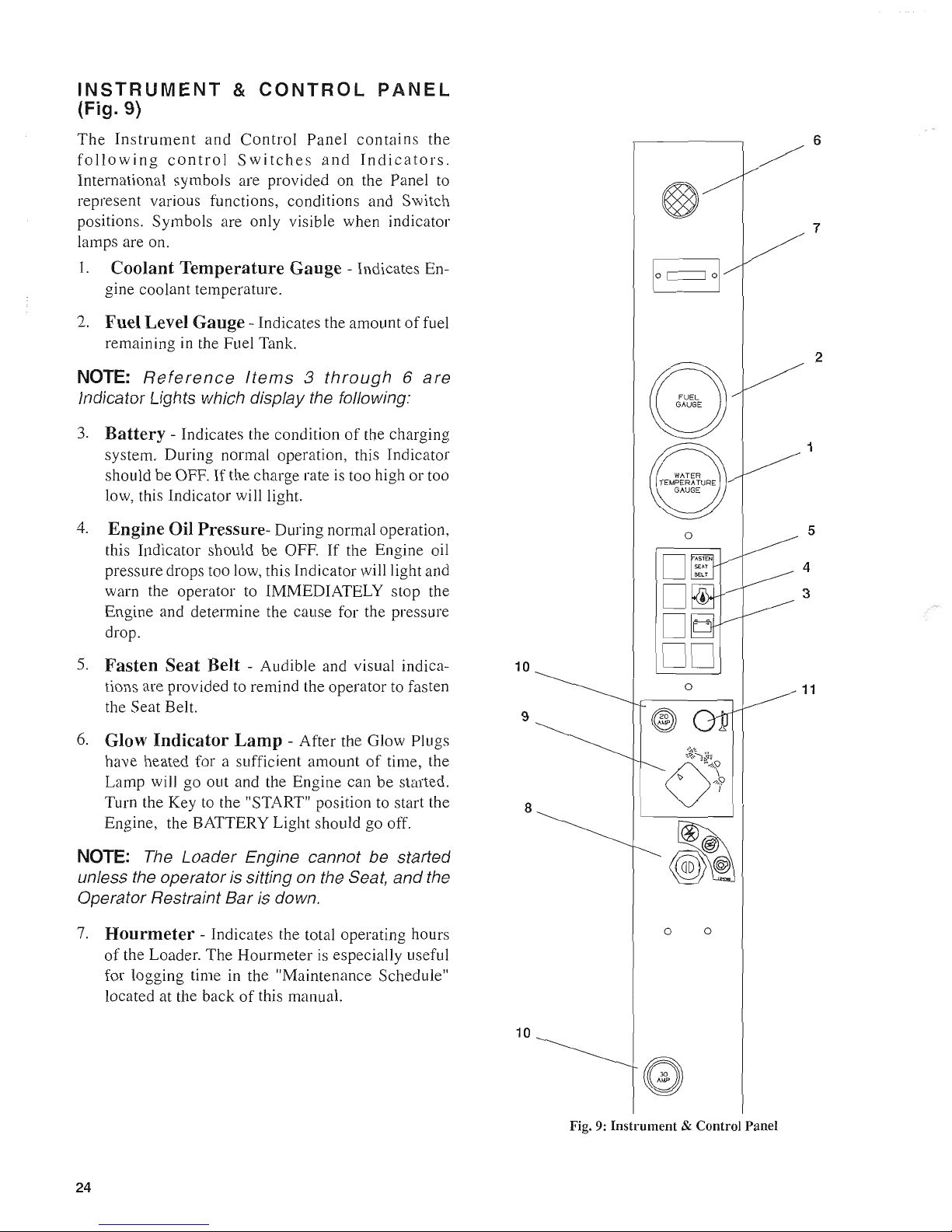

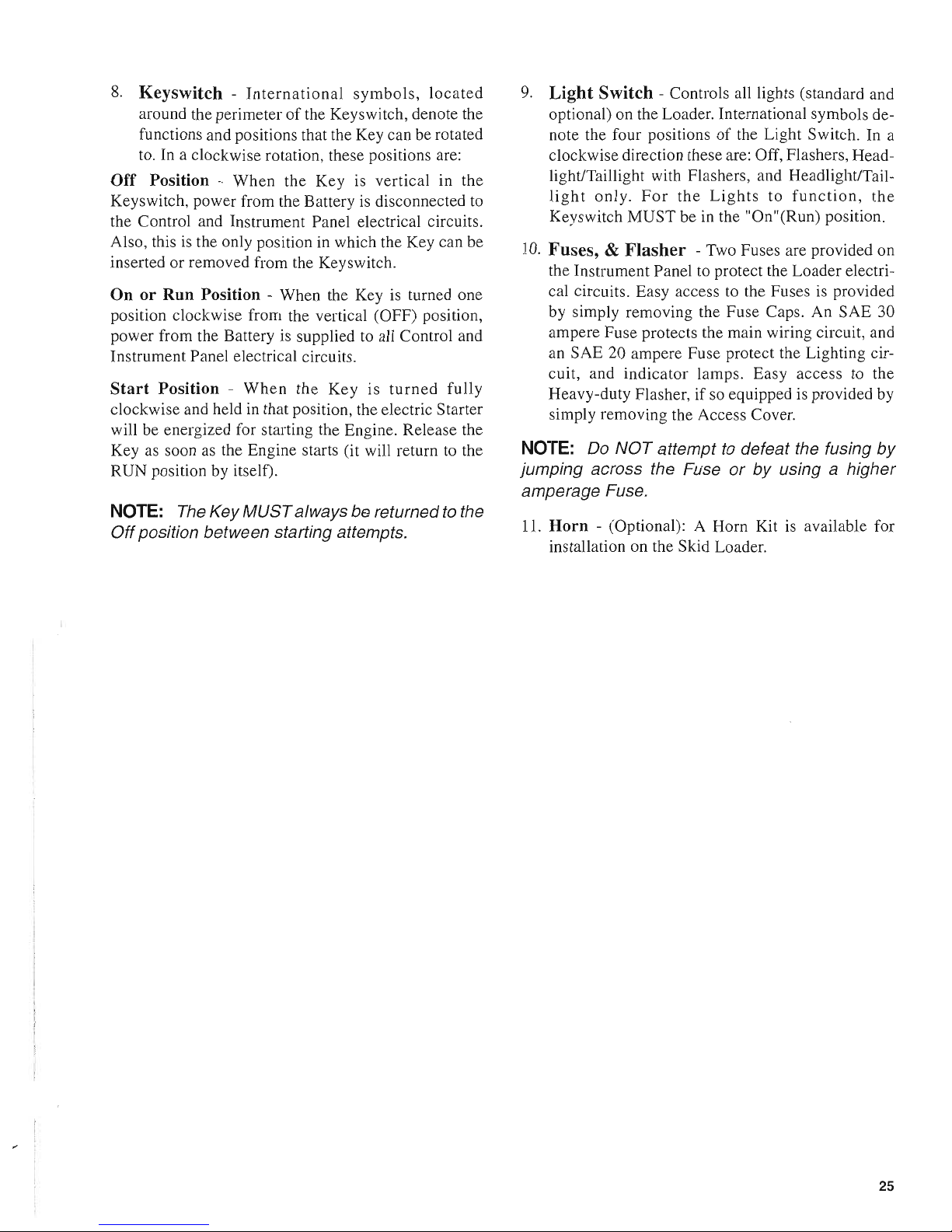

INSTRUMENT

&

CONTROL

PANEL

(Fig. 9)

The

Instrument

and

Control

Panel

contains

the

following

control

Switches

and

Indicators.

International symbols are provided on the Panel to

represent various functions, conditions and Switch

positions. Symbols are only visible when indicator

lamps are on.

1.

Coolant Temperature Gauge - Indicates En-

gine coolant temperature.

2.

Fuel Level Gauge -Indicates the amount

offuel

remaining in the Fuel Tank.

NOTE:

Reference

Items 3 through 6 are

Indicator Lights which display the following:

3.

Battery -Indicates the condition

of

the charging

system. During normal operation, this Indicator

should be OFF.

If

the charge rate is too high or too

low, this Indicator will light.

4.

Engine Oil Pressure- During normal operation,

this Indicator should be OFF.

If

the Engine oil

pressure drops too low, this Indicator will light and

warn the operator to IMMEDIATELY stop the

Engine and determine the cause for the pressure

drop.

5.

Fasten Seat Belt - Audible and visual indica- 10

tions are provided to remind the operator to fasten

the Seat Belt.

6.

Glow

Indicator

Lamp

- After the Glow Plugs

have heated for a sufficient amount

of

time, the

Lamp will go out and the Engine can be started.

Turn the Key to the "START" position to start the

Engine, the BATTERY Light should go off.

NOTE:

The

Loader Engine cannot be started

unless the operator is sitting on the Seat,

and

the

Operator Restraint

Bar

is down.

7.

Hourmeter

- Indicates the total operating hours

of

the Loader. The Hourmeter is especially useful

for logging time in the "Maintenance Schedule"

located at the back

of

this manual.

24

9

8

10

o

o

o o

Fig.

9:

Instrument & Control Panel

6

7

2

1

5

4

3

11

Page 27

8.

Keyswitch -

International

symbols,

located

around the perimeter

of

the Keyswitch, denote the

functions and positions that the Key can be rotated

to. In a clockwise rotation, these positions are:

Off

Position - When the Key is vertical in the

Keyswitch, power from the Battery

is

disconnected

to

the Control and Instrument Panel electrical circuits.

Also, this

is

the only position in which the Key can be

inserted or removed from the Keyswitch.

On

or

Run

Position - When the Key is turned one

position clockwise from the vertical (OFF) position,

power from the Battery

is

supplied to all Control and

Instrument Panel electrical circuits.

Start

Position -When

the

Key

is

turned

fully

clockwise and held in that position, the electric Starter

will be energized for starting the Engine. Release the

Key

as

soon

as

the Engine starts (it will return to the

RUN position by itself).

NOTE: The Key

MUST

a/ways be returned

to

the

Off

position between starting attempts.

9.

Light

Switch - Controls all lights (standard and

optional) on the Loader. International symbols denote the four positions

of

the Light Switch. In a

clockwise direction these are: Off, Flashers, Headlight/Taillight with Flashers, and Headlight/Tail-

light

only.

For

the

Lights

to

function,

the

Keyswitch MUST be in the "On"(Run) position.

1

O.

Fuses, &

Flasher

- Two Fuses are provided on

the Instrument Panel to protect the Loader electrical circuits. Easy access to the Fuses

is

provided

by simply removing the Fuse Caps. An SAE 30

ampere Fuse protects the main wiring circuit, and

an SAE 20 ampere Fuse protect the Lighting circuit, and indicator lamps. Easy access to the

Heavy-duty Flasher,

if

so equipped is provided by

simply removing the Access Cover.

NOTE: Do

NOT

attempt

to

defeat the fusing

by

jumping across the Fuse

or

by

using a higher

amperage Fuse.

11.

Horn

- (Optional): A Horn Kit is available for

installation on the Skid Loader.

25

Page 28

INTERLOCKS

ACAUTION

NEVER

attempt

to

defeat

the

interlock

system

functions

by

mechanically

or

electrically

bypassing

any

Switches,

Relays or Solenoid Valves.

With operator safety in mind, interlock systems are

used on the Loader. Together with Solenoid Valves

Switches and Relays, the interlocks:

Prevent starting

of

the Engine unless the operator

is sitting on the Seat, and the Operator Restraint

Bar

is down.

Disable Lift Arm and Attachment Tilt anytime the

operator leaves the Seat, turns the Keyswitch to

"Off" or raises the Restraint Bar.

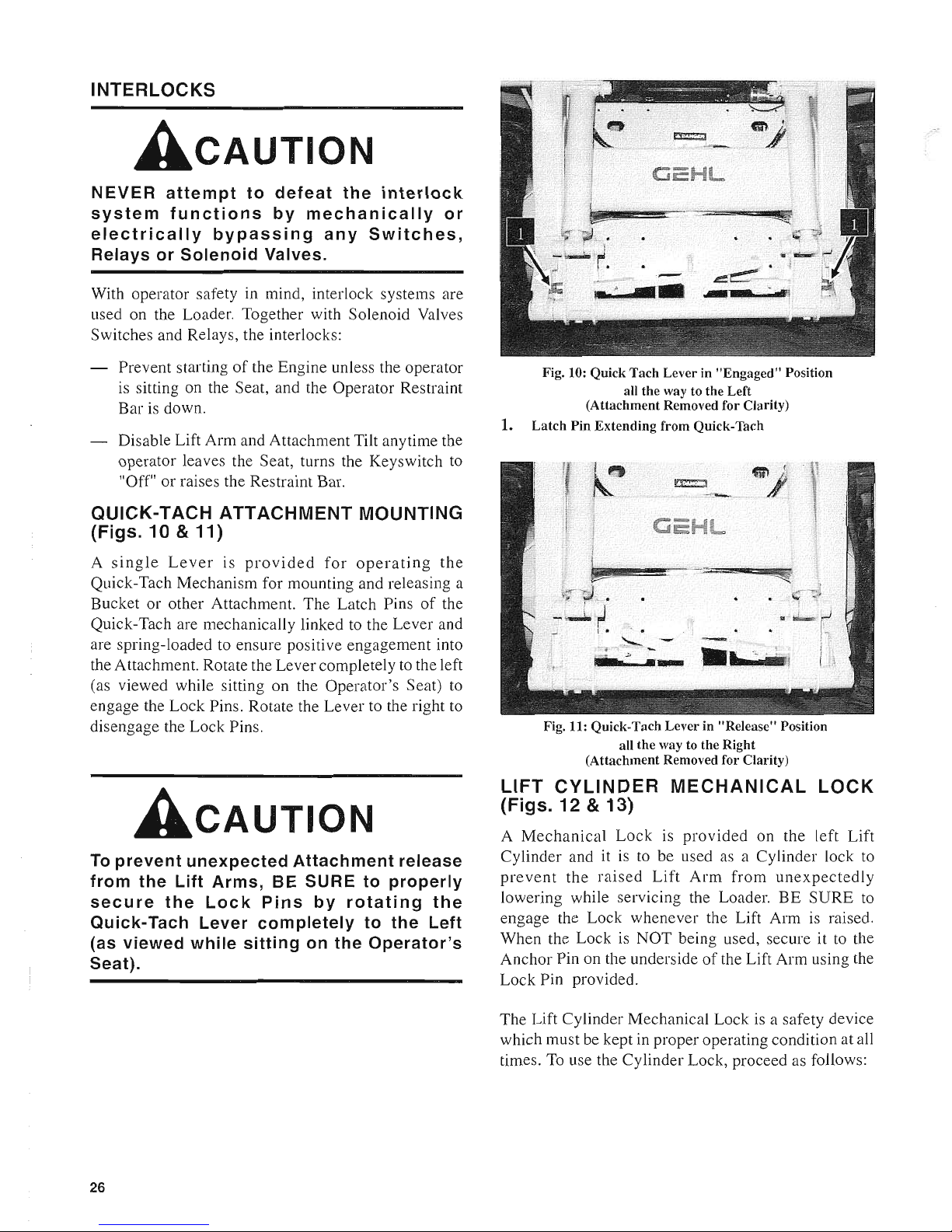

QUICK-TACH ATTACHMENT MOUNTING

(Figs. 10

& 11)

A

single

Lever

is

provided

for

operating

the

Quick-Tach Mechanism for mounting and releasing a

Bucket or other Attachment. The Latch Pins

of

the

Quick-Tach are mechanically linked

to

the Lever and

are spring-loaded to ensure positive engagement into

the Attachment. Rotate the Lever completely to the left

(as viewed while sitting on the Operator's Seat) to

engage the Lock Pins. Rotate the Lever to the right to

disengage the Lock Pins.

ACAUTION

To

prevent

unexpected

Attachment

release

from the Lift Arms, BE SURE to properly

secure

the

Lock

Pins

by

rotating

the

Quick-Tach Lever

completely

to the Left

(as viewed while sitting on

the

Operator's

Seat).

26

1.

Fig. 10: Quick Tach Lever in "Engaged" Position

all the way to the Left

(Attachment Removed for Clarity)

Latch Pin Extending from Quick-Tach

! • •

"-

_~'

411'_

.In·

mi

Fig. 11: Quick-Tach Lever in "Release" Position

all the way to the Right

(Attachment Removed for Clarity)

LIFT

CYLINDER

MECHANICAL

LOCK

(Figs. 12 & 13)

A

Mechanical

Lock

is

provided

on the left

Lift

Cylinder and it is to be used as a Cylinder lock to

prevent

the

raised

Lift

Arm

from

unexpectedly

lowering while servicing the Loader.

BE

SURE

to

engage the Lock whenever the Lift Arm

is

raised.

When the Lock

is

NOT being used, secure it to the

Anchor Pin on the underside

of

the Lift Arm using the

Lock Pin provided.

The Lift Cylinder Mechanical Lock is a safety device

which must be kept in proper operating condition at all

times. To use the Cylinder Lock, proceed as follows:

Page 29

AWARNING

BEFORE

leaving

the

Operator's

Compartment

to

work

around the

outside

of

the

Loader

with

the

Lift Arm

raised,

ALWAYS

engage

the

Lift

Cylinder

Mechanical Lock. Also, turn

the

Keyswitch

to

the

Off position, remove the Key and

take

it with you.

Lock Engagement

To engage the Lift Cylinder Mechanical Lock, proceed

as follows:

I. Apply the Parking Brake.

2.

Lower the Lift Arm into contact with the Loader

Frame.

3.

Turn the Keyswitch to the

Off

position to Stop the

Engine, remove the Key and take it with you.

4.

Leave the Operator's Compartment and remove

the Lock Pin which holds the Lock up against the

Lift Arm. Allow the Lock to come down into

contact with the Lift Cylinder.

5.

Return to the Operator's Compartment and restart

the Engine.

6.

Move the Lift Control to raise the Lift

Arm

until

the Lock drops over the end

of

the Lift Cylinder

and around the Cylinder Rod. Then, slowly lower

the Lift Arm until the free-end

of

the Lock contacts

the top end

of

the Lift Cylinder.

7.

Look to make sure that the Lock is secure against

the Cylinder End. Then, stop the Loader Engine

and leave the Operator's Compartment.

Jt"11

Fig. 12: Lift

Arm

raised & Lock

"Engaged"

1.

LiftArm

2. Lift Cylinder Mechanical Lock

"Engaged"

3. Lock Pin

4. Left Side Lift Cylinder

5.

Anchor

Pin

Lock Disengagement

WARNING

NEVER

attempt

to

disengage

the

Lift

Cylinder

Lock by leaving

the

Operator's

Compartment

while

the

Engine is running.

To return the Lift Cylinder Mechanical

Lock

to its

"storage" position, proceed as follows:

1.

Apply the Parking Brake.

2.

Raise the Lift Arm completely.

3.

Turn the Keyswitch to the

Off

position to Stop the

Engine, remove the Key and take it with you.

ACAUTION

BEFORE

performing

Step 4, below, MAKE

SURE

the

area BELOW the Lift Arm and

Attachment

is clear.

4.

Before

leaving

the

Operator's

Compartment,

check to make sure that the Lift Arm is being held

in the raised position by the Solenoid Valve (See

the following NOTE).

27

Page 30

NOTE: With the Keyswitch OFF,

and

if

the

Solenoid Valve is working properly, the Arm

should remain in the raised position when the Lift

Control is moved forward.

If

the Valve does

NOT

hold the Arm and the Arm begins

to

lower, do NOT

leave the Operator's Compartment. Instead, have

another person place the Lock into the "storage"

position for you. Then, contact your Gehl dealer

to

determine the reason why the Lift Arm lowers

while the Keyswitch

is

in

the "off" position.

5.

To

store the Lock, raise it up until it contacts the

Lift Arm and install the Lock Pin through the hole

in

the Lock Anchor Pin under the Lift Arm.

AUXILIARY HYDRAULICS

Standard

Flow

Auxiliary

Hydraulics

(Fig. 14)

Loaders are shipped from the factory with standard

flow Auxiliary Front Hydraulic connections. A pair

of

Quick-disconnect Fittings, located at the left, inside

corner

of

the Lift Arm, can be used for operating

Attachments (Grapple, Backhoe, etc.).

T-Bar Controlled Loaders: A Footpedal

is

used to

control the direction

of

oil flow. A stop is provided

to

lock the footpedal for continuous operation.

Hand/Foot Controlled Loaders: the right T-Bar

is

twisted to control the direction

of

oil flow. A stop

is

provided to lock the T-Bar for continuous operation.

High

Flow

Auxiliary

Hydraulics

(Fig. 15)

In addition to standard flow Auxiliary Front Hydraulic

connections, model 5625DX Loaders are shipped from

the factory with High Flow Auxiliary Hydraulics. An

additional pair

of

Quick-disconnect Fittings, located

at

right and left front corners

of

the Lift Arm, can be used

for operating high hydraulic oil flow Attachments

(Cold Planer, Snowblower, etc.).

A two-position, Toggle Switch is used to control the

operation

of

the High Flow Hydraulics. The two

positions on the Toggle Switch are:

OFF

- which disables output to the Quick-disconnect

Fittings.

ON

- which pressurizes the Top Male Port.

28

Fig. 13: Lift Arm Lowered & Lock "Stored"

1.

Lift Cylinder Mechanical Lock in

"Storage"

Position

2.

Lock Pin

3.

Left Side Lift Cylinder

Fig. 14:

Standard

Flow Auxiliary Hydraulics

1.

Standard

Flow Quick-disconnects

Fig.

15:

High Flow Auxiliary Hydraulics

1.

High Flow Auxiliary Hydraulics Control Switch

2.

High Flow Quick-disconnects

3. Case

Drain

Line

Page 31

CHAPTER

6

OPERATION

GENERAL

INFORMATION

(Fig. 16)

CAUTION

BEFORE

starting

the

Engine

and

operating

the

Loader,

review

and

comply

with

ALL

safety

recommendations

set

forth

in

the

SAFETY

chapter

of

this

manual.

Know

how

to

STOP

the

Loader

BEFORE

starting

it.

Also,

BE

SURE

to

fasten

and

properly

adjust

the

Seat

Belt

and

lower

the

Operator

Restraint

Bar.

BEFORE STARTING ENGINE

Before

starting the Engine and running the Loader,

refer to the "Controls & Safety Equipment"

Chapter

and

familiarize

yourself

with the various operating

controls, Indicators and safety devices on the Loader.

Fig. 16: Operator's Compartment

1.

Operator's

Seat

2.

Operator

Restraint

Bar

3. Seat Belt

4. Parking Brake in the Engaged

"ON"

Position

STARTING THE ENGINE

WARNING

ALWAYS

fasten

your

Seat

Belt

and

lower

the

Restraint

Bar

BEFORE

starting

the

Loader

Engine.

Leave

the

Parking

Brake

"engaged"

until

the

Engine

is

running

and

you

are

ready

to

operate

the

Loader.

The

following

procedure

is

recommended

for starting

the

Loader

Engine:

1.

Carefully step up onto the

back

of

the

Bucket

or

Attachment

while grasping the Handles to

get

into

the

Operator's

Compartment.

2.

Fasten

the

Seat

Belt

and

lower

the Restraint Bar.

3.

Check

that both Control T-Bars are in their "Neu-

tral" positions.

4.

Push

the Throttle forward to

half

of

full speed.

NOTE:

When the Key

is

turned

to

liON

II

position,

a Buzzer will sound momentarily.

5.

Turn

the Keyswitch to the "ON" position.

Wait

for

the

Glow

Indicator

Light

to go out, then turn the

key

to the start position.

NOTE:

Crank the Starter until the Engine is

started.

If

the Engine fails

to

start within

15

sec-

onds, return the key

to

the "Off" position, wait 2

minutes,

and

try

to

restart

the

Engine.

Cranking the engine for longer than 15 seconds

will result in premature failure

of

the Starter.

After

the

Engine

starts, allow a sufficient

warm-up

time

before

attempting to operate the Controls.

COLD

STARTING PROCEDURES

A

Block

Heater

or

Lower

Radiator

Hose

Heater

is

recommended

for starting in temperatures

of

20°F

or

lower.

See

your

Gehl

Dealer

for

recommended

Heater.

29

Page 32

STOPPING THE LOADER

The following procedure is the recommended sequence for stopping the Loader:

1.

Check that Propulsion Control T-Bar(s) are in the

"Neutral" position.

2.

Using the Lift/Tilt Control, lower the Lift Arm and

rest the Attachment on the ground.

3.

Pull the Throttle Lever back to the Idle position

(and/or take

your

foot

off

the Accelerator Pedal

for

T-Bar controlled machines).

4.

Turn the Keyswitch Key

to

the

Off

position

to

shut

the Engine off.

5.

Apply the Parking Brake, Raise the Restraint Bar,

unlatch the Seat Belt and grasp the Handles while

climbing out

of

the Operator's Compartment.

AWARNING

The

Parking

Brake

MUST

BE

engaged

anytime

the Loader is parked on a grade. If

the Parking Brake

is

NOT

set, the Loader

can

start

to

roll

because

of

minimal

resistance in the

Hydrostatic

Drive Motors.

Failure to heed could result in death or

serious injury.

30

LOADER MOVEMENT

The Hydrostatic Drive

of

the Skid Loader controls

forward and reverse direction and speed. As rapidly as

the Propulsion Control(s) are moved to the straight

"N

eutral" position, movement

of

the Wheels

is

slowed

accordingly.

ACAUTION

A

combination

of high heat and

excessive

loads may

cause

the

engine

to

overheat.

See

the

Troubleshooting

chapter

in this

manual

for

further

instruction.

ACAUTION

Operate

the Propulsion Controls

gradually

and

smoothly

when

starting,

stopping,

turning and reversing Loader

directions.

Excessive

speed

can

be

hazardous.

ALWAYS

exercise

caution

and

good

judgment

while

operating

the

Skid Loader.

Page 33

First

Time

Operation

CAUTION

BE

SURE

the

area

being

used

for

test-running

is

clear

of

spectators

and

obstructions.

For

the

first

time,

operate

the

Loader

with

an

empty

Bucket.

Smoothest and most efficient Loader operation is

achieved while running the Engine at half-throttle.

Make sure the Engine is warm and then, follow instructions appropriate for your type

of

Loader.

T-Bar Controlled Loaders (Fig. 17): Using your right

hand, slowly and smoothly pull straight back on the

Lift/Tilt Control T-Bar to raise the Lift Arm. Twist the

T-Bar to roll the Bucket forward or back. Attempt all

raising and lowering functions, and combinations

of

the two functions before proceeding to operate the

Propulsion Control T-Bar. ALWAYS lower the Lift

Arm and roll the Bucket back

BEFORE

proceeding to

operate the Propulsion T-Bar.

Using your left hand, slowly and smoothly move the

Propulsion Control T-Bar straight forward to travel

ahead. Then, slowly pull the T-Bar backward to "Neutral" to stop forward movement.

To

travel backwards,

slowly and smoothly move the T-Bar straight back.

Then, return the Propulsion Control T -

Bar

to the "Neutral" position to stop reverse movement. Next, twist the

Propulsion T-Bar slowly clockwise to turn right and

counterclockwise to turn left. Attempt all forward,

reverse and turning movements before proceeding to

operate both T -Bars at the same time.

Fig.

17:

T-Bar Controlled Loaders

1. Propulsion Control

T-Bar

2. Auxiliary Hydraulics Control Footpedal

3. Foot Throttle

4.

Hand

Throttle

5. LiftlTilt Control

T-Bar

6.

Parking

Brake

Fig. 18: Hand

& Foot Controls

1. Left Propulsion Control T-Bar

2. Right Propulsion Control T-Bar & Auxiliary Hydraulics

3. Hand Throttle

4. Attachment Tilting (right foot pedal)

5. Attachment Lifting (left foot pedal)

6.

Parking

Brake

31

Page 34

Hand & Foot Controlled Loaders (Fig. 18): To raise

the Liftarm, use your heel to push down on the rear

of

the left Foot Pedal. To lower the Liftarm, use your toe

to push down on the front

of

the left Pedal.

The right Foot Pedal controls the tilting motion

of

the

attachment. To tilt the attachment rearward, use your

heel to push down on the rear

of

the right Pedal: to tilt

the attachment forward, use your toe to push down on

the front

of

the right Pedal.

Attempt all raising and lowering functions, and combinations

of

the two functions before proceeding to

operate the Propulsion Control T -Bars. AL WAYS

lower the Lift Arm and roll the Bucket back before

proceeding to operate the Propulsion T-Bars.

Using both hands, slowly and smoothly move the

Propulsion Control T -Bars straight forward to travel

ahead. Then, slowly pull the T-Bars backward to "Neutral" to stop forward movement. To travel backwards,

slowly and smoothly move the T-Bars straight back.

Then, return the T-Bars to the "Neutral" position to

stop reverse movement.

To Turn during Travel: Move the right T-Bar further

forward then the left to turn left. Move the left T -Bar

further forward than the right to turn right.

To Pivot: Move the right T-Bar forward and the left

T -Bar rearward to pivot to the left. Move the left T -Bar

forward and the right T-Bar rearward to pivot to the

right.

Skid Loader operating skills are only obtained through

proper coordination

of

the Loader's forward and re-

verse movements, with raising and lowering the Lift

Arm and with rolling the Bucket forward and back. To

gain proficiency, practice all Control T-Bar operations

until you are capable

of

performing the movements

without mistake or hesitation.

NOTE:

If

the Loader Engine kills while either

T-Bar

is

being operated, the T-Bar must be re-

turned

to

its "Neutral" position before the Engine

can be restarted.

32

ACAUTION

BEFORE

leaving

the

Operator's

Compartment,

engage

the

Parking

Brake.

BE SURE

to

lower

the

Lift

Arm

or

engage

the

Lift

Cylinder

Mechanical

Lock,

as

appropriate.

Shut

the

Engine

off,

and

remove

the

Key.

NOTE:

If

the Loader will not start, the Uftarm can

be lowered

by

sitting in the Operator's Seat with

the Restraint Bar down, and turning the Key

to

the

"ON" position, then lowering the Uftarm.

PARKING

BRAKE

(Figs.

16, 17, & 18)

AWARNING

Function

and

adjustment

of

the

Parking

Brake

should

be

checked

on a routine

basis

to

maintain

proper

operation

at

all

times.

NEVER

use

the

Parking

Brake

as

a

means

of

checking

Hydrostatic

torque

as

this

will

cause

overheating

and