Page 1

OPERATOR’S MANUAL

418T Wheel

Loader

Form No.

909879

Page 2

GEHL CONSTRUCTION

WARRANTY

GEHL CONSTRUCTION DIVISION of the GEHL COMP ANY , hereinafter referred to as Gehl,

warrants new Gehl construction equipment to the Original Retail Purchaser to be free from

defects in material and workmanship for a period of twelve (12) months from the Warranty

Start Date:

GEHL CONSTRUCTION WARRANTY INCLUDES:

Genuine Gehl parts and labor costs required to repair or replace equipment at the selling

dealer’s business location.

GEHL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND,

EXPRESS OR IMPLIED (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANT ABILITY AND FITNESS FOR P ARTICULAR PURPOSE), EXCEPT AS

EXPRESSLY STATED IN THIS WARRANTY STATEMENT.

GEHL WARRANTY SERVICE DOES NOT INCLUDE:

1. Transportation to selling dealer’s business location or , at the option of the Original Retail Purchaser,

the cost of a service call.

2. Used equipment.

3. Components covered by their own non-Gehl warranties, such as tires, trade accessories and

engines.

4. Normal maintenance service and expendable, high wear items.

5. Repairs or adjustments caused by: improper use; failure to follow recommended maintenance

procedures; use of unauthorized attachments; accident or other casualty .

6. Liability for incidental or consequential damages of any type, including, but not limited to lost profits

or expenses of acquiring replacement equipment.

No agent, employee or representative of Gehl has any authority to bind Gehl to any warranty except as

specifically set forth herein. Any of these limitations excluded by local law shall be deemed deleted from this

warranty; all other terms will continue to apply.

Page 3

The complete documentation consists of:

Description Part number

Operator’s Manual 909879

Operator’s Manual (Engine)

Spare parts catalogue 909880

Legend

Edition Issued

A September 2002

© Copyright – 2002 Gehl Company

Printed in the United States of America

All rights reserved

Nopartofthis publication maybereproduced,translated or usedinanyformorby any means–graphic, electronic

or mechanical includingphotocopying,recording,tapingorinformationstorageor retrieval systems – without prior

permission in writing.

Thecover featuresthe machine withpossible optionalequipment.

Gehl Company

P.O.Box179

West Bend, WI 53095 U.S.A.

Document: 909879

Part no.: 909879

Edition: A

Page 4

AP0902 I-1

Table of contents

I

Introduction

Introduction ....................................................................................................................1-1

Notes on this operator’s manual ............................................................................. 1-1

Machine: Overview................................................................................................... 1-2

Brief description........................................................................................................ 1-3

Applications.............................................................................................................. 1-4

Regulations............................................................................................................... 1-5

Machine data............................................................................................................ 1-6

Type labels and component numbers....................................................................... 1-7

Safety signs and symbols ....................................................................................... 1-8

Safety instructions

Safety instructions .......................................................................................................... 2-1

Identification of warnings and dangers ................................................................... 2-1

Designated uses....................................................................................................... 2-2

General conduct and safety instructions................................................................... 2-3

Safety instructions regarding operation.................................................................... 2-5

Safety instructions for service and maintenance...................................................... 2-9

Warning of special hazards ................................................................................... 2-11

Operation

Operation .......................................................................................................................3-1

Overview of cab ....................................................................................................... 3-2

Overview: Multifunctional lever and consoles ......................................................... 3-4

Placing into service .................................................................................................. 3-5

Safety instructions ............................................................................................. 3-5

Placing the machine into service for the first time ............................................. 3-5

Checklists .......................................................................................................... 3-6

Driving the machine.................................................................................................. 3-8

Overview of controls: ........................................................................................ 3-8

Warning Lights: overview ................................................................................ 3 -13

Before starting the engine ............................................................................... 3-16

Starting the engine .......................................................................................... 3-16

Before driving the machine............................................................................... 3-20

Driving ............................................................................................................. 3-22

Drive ranges..................................................................................................... 3-23

Differential lock................................................................................................. 3-25

Stopping the machine ...................................................................................... 3-25

Parking the machine......................................................................................... 3-26

Light system..................................................................................................... 3-27

Signalling system.............................................................................................. 3-28

Cab heating and ventilation.............................................................................. 3-29

Window wash system....................................................................................... 3-30

Seat adjustment................................................................................................ 3-31

Seat belt ........................................................................................................... 3-33

Driver's door and side window.......................................................................... 3-35

Other controls................................................................................................... 3-38

Towing and transporting the m achine.............................................................. 3-39

Working with the machine ...................................................................................... 3-42

General safety instructions .............................................................................. 3-42

Load diagram ................................................................................................... 3-42

Safe load indicator............................................................................................ 3-43

Control valve for the telescopic unit: overview................................................. 3-45

Table of contents

Page 5

I-2 AP0902

Table o f contents

Lowering the telescopic unit with the engine switched off................................ 3-47

Relieving pressure the quick couplers on the telescopic unit ......................... 3-47

Installing an attachment ................................................................................... 3-48

Connecting pressurized quick couplers ........................................................... 3-51

Operation of the telescopic unit........................................................................ 3-53

Safety device “Hose burst valve“...................................................................... 3-55

Working with standard bucket and pallet forks................................................. 3-58

Working with pallet forks................................................................................... 3-66

Troubleshooting

Troubleshooting ............................................................................................................. 4-1

Engine trouble .......................................................................................................... 4-2

Possible causes for malfunctions....................................................................... 4-3

Maintenance

Maintenance ................................................................................................................... 5-1

Introduction .............................................................................................................. 5-1

Fuel system .............................................................................................................. 5-1

Specific safety instructions ................................................................................ 5-1

Refuelling............................................................................................................ 5-2

Cleaning the fuel tank ........................................................................................ 5-3

Changing the fuel filter........................................................................................ 5-4

Cleaning the fuel/water separator....................................................................... 5-5

Bleeding the fuel system..................................................................................... 5-6

Engine lubrication system......................................................................................... 5-7

Checking the engine oil level ............................................................................. 5-7

Topping up the engine oil .................................................................................. 5-7

Changing the engine oil...................................................................................... 5-8

Changing the engine oil filter cartridge............................................................... 5-9

Engine and hydraulics cooling system.................................................................... 5-10

Specific safety instructions .............................................................................. 5-10

Checking the coolant level/topping up the coolant level .................................. 5-11

Cleaning the cooling fins .................................................................................. 5-12

Air filter ................................................................................................................... 5-13

V-belt....................................................................................................................... 5-15

Checking the V-belt tension ............................................................................. 5-15

Re-tensioning the V-belt .................................................................................. 5-15

Hydraulic system..................................................................................................... 5-16

Specific safety instructions .............................................................................. 5-16

Checking the hydraulic oil level ....................................................................... 5-16

Topping up the hydraulic oil.............................................................................. 5-17

Changing the hydraulic oil ............................................................................... 5-17

Hydraulic oil return filter.................................................................................... 5-20

Replacing the breather filter ............................................................................. 5-21

Hydraulic pressure lines .................................................................................. 5-21

Gearboxes and axles ............................................................................................. 5-22

Rear axle transfer gearbox .............................................................................. 5-22

Front and rear axle differentials........................................................................ 5-24

Front and rear axle planetary drives ................................................................ 5-25

Lubricating the rear axle oscillation-type bearing............................................. 5-26

Page 6

AP0902 I-3

Table of contents

Maintenance of the brake system........................................................................... 5-27

Specific safety instructions .............................................................................. 5-27

Checking/topping up brake fluid ...................................................................... 5-27

Telescopic unit........................................................................................................ 5-28

Lubricating the pivot points of the telescopic unit ............................................ 5-28

Lubricating the telescopic unit ......................................................................... 5-28

Adjusting the wear pads................................................................................... 5 -29

Tire care ................................................................................................................. 5-30

Inspection work ................................................................................................ 5-30

Wheel change................................................................................................... 5-31

Heating................................................................................................................... 5-32

Cleaning the dust filter of the heating system .................................................. 5-32

Electrical system..................................................................................................... 5-33

Specific safety instructions .............................................................................. 5-33

Service and maintenance work at regular intervals ......................................... 5-33

Instructions concerning specific components................................................... 5-34

General maintenance work..................................................................................... 5-36

Cleaning .......................................................................................................... 5-36

Bolted connections........................................................................................... 5-38

Pivots and hinges ............................................................................................ 5-38

Engine fluids and lubricants .................................................................................. 5-39

Maintenance kits .................................................................................................... 5-40

Helpful information for using the service parts list

Helpful information for using the service parts list ......................................................... 6-1

Introduction .............................................................................................................. 6-1

Composition of service parts list .............................................................................. 6-1

Groups ............................................................................................................... 6-1

Group overview.................................................................................................. 6-2

Figures................................................................................................................ 6-3

Number index .................................................................................................... 6-3

Symbols and abbreviations ...................................................................................... 6-4

Description of symbols ...................................................................................... 6-4

Abbreviations...................................................................................................... 6-6

Machine data ........................................................................................................... 6-6

Helpful information for ordering service parts........................................................... 6-7

Order information ............................................................................................... 6-7

Address for your servicepart order.................................................................... 6-8

Specifications

Specifications ................................................................................................................. 7-1

Frame ...................................................................................................................... 7-1

Engine ..................................................................................................................... 7-1

Power train ............................................................................................................... 7-2

Axles ....................................................................................................................... 7-2

Brakes ..................................................................................................................... 7-3

Steering .................................................................................................................. 7-3

Work hydraulics ...................................................................................................... 7-3

Telescopic unit ........................................................................................................ 7-4

Electrical system ...................................................................................................... 7-5

Fuse boxes in side console ............................................................................... 7-5

Main fuses in engine compartment .................................................................... 7-6

Relays ................................................................................................................ 7-6

Tires.......................................................................................................................... 7-7

Page 7

I-4 AP0902

Table o f contents

Weights ................................................................................................................... 7-7

Noise levels ............................................................................................................. 7-7

Vibration ................................................................................................................... 7-8

Dimensions ............................................................................................................. 7-8

Coolant table............................................................................................................. 7-9

Tightening torques ................................................................................................... 7-9

General tightening torques ................................................................................ 7-9

Specific tightening torques ................................................................................ 7-9

Conversion tables .................................................................................................. 7-10

Conversion factors ........................................................................................... 7-10

Specific converted values ................................................................................ 7-11

Annex

Proofs of maintenance .................................................................................................. A-1

Maintenance plan model 418T (overview) .................................................................... A-3

Maintenance plan model

418T (maintenance label) ............................................................................................. A-5

Explanation of symbols used in maintenance plan.................................................. A-5

Legend for hydraulics diagram,

model 418T

❙➜418T 0001 ..................................................................................... A-6

Hydraulics diagram model 418T ................................................................................... A-7

Electrical diagram 418T ................................................................................................ A-9

Page 8

AP0902 I-5

Index

A

Abbreviations .........................................................................................1-1

Accelerator pedal ...................................................................................3-9

Applications

Attachments ....................................................................................1-4

B

Backup warning system (option) ..........................................................3-24

Biodegradable oil .................................................................................5-19

Brake inching pedal ...............................................................................3-9

Brake system .......................................................................................5-27

Brake fluid .....................................................................................5-27

Safety instructions .........................................................................5-27

C

Changing direction ...............................................................................3-24

Changing direction, Tip switch for ........................................................3-24

Checklists ..............................................................................................3-6

Control elements ....................................................................................3-8

Control lever for attachments and 3rd control circuit ...........................3-46

Conversion factors ...............................................................................7-10

Converted values .................................................................................7-11

D

Designated use and exemption from liability .........................................2-2

Differential lock ....................................................................................3-25

Documents .............................................................................................1-5

Driving direction selector switch ............................................................3-8

Driving licence .......................................................................................1-5

Driving on public roads ........................................................................3-20

Driving the machine ...............................................................................3-8

Dust filter ..............................................................................................5-32

E

Electrical diagram ................................................................................. A-9

Engine coolant preheater (option) .......................................................3-18

Engine preheater (option) ....................................................................3-18

Equipment of the machine .....................................................................1-5

F

Fields of application

Possible attachments ......................................................................1-4

Fuel level indicator ...............................................................................3-15

Fuel preheater (option) ........................................................................3-18

G

General conduct ....................................................................................2-3

H

Hazard warning system .......................................................................3-28

Heating ................................................................................................3-29

High beam ...........................................................................................3-27

Hydraulic oil preheater (option) ............................................................3-18

J

Jump-starting the engine .....................................................................3-19

L

Light system .........................................................................................3-27

Load diagram ............................................................................. 1-12, 3-42

Loader unit

Checking the tilt position of the bucket .........................................3-58

Lock for driving on public roads ...........................................................3-46

Lowering the telescopic unit with the engine switched off ...................3-47

M

Machine

Brief description ..............................................................................1-3

Data ................................................................................................1-7

Fields of application ........................................................................1-4

Overview ........................................................................................1-2

Machine inspections ..............................................................................1-5

Maintenance

Air filter .........................................................................................5-13

Biodegradable oil ..........................................................................5-19

Bleeding the fuel system ................................................................5-6

Brake system ................................................................................5-27

Changing the

Engine oil .............................................................................5-8

Engine oil filter cartridge ......................................................5-9

Fuel filter ..............................................................................5-4

Hydraulic oil .......................................................................5-17

Checking the

Coolant level ......................................................................5-11

Engine oil level .....................................................................5-7

Hydraulic oil level ...............................................................5-16

Cleaning .......................................................................................5-36

Cleaning the

Fuel tank ..............................................................................5-3

Cleaning the cooling ribs ..............................................................5-12

Cleaning the fuel/water separator ..................................................5-5

Differentials ..................................................................................5-24

Electrical diagram ...........................................................................A-9

Electrical system ..........................................................................5-33

Engine and hydraulics cooling system .........................................5-10

Engine lubrication system ..............................................................5-7

Fuel system ....................................................................................5-1

Gearboxes and axles ...................................................................5-22

General maintenance work ..........................................................5-36

Heating .........................................................................................5-32

Hydraulic oil return filter ................................................................5-20

Hydraulic pressure lines ...............................................................5-21

Hydraulic system ..........................................................................5-16

Instructions concerning specific components ...............................5-34

Lubricating the oscillation-type bearing ........................................5-26

Lubricating the telescopic unit ......................................................5-28

Maintenance plan ...........................................................................A-3

Pivots and hinges .........................................................................5-38

Planetary drives ............................................................................5-25

Proofs of maintenance ...................................................................A-1

Replacing the filler and breather filters on the hydraulic oil tank ..5-21

Screw connections .......................................................................5-38

Service and maintenance work at regular intervals ......................5-33

Telescopic unit .............................................................................5-28

Topping up the

Coolant level ......................................................................5-11

Engine oil .............................................................................5-7

Hydraulic oil .......................................................................5-17

Transfer gearbox ..........................................................................5-22

Tire care .......................................................................................5-30

V-belt ............................................................................................5-15

Wheel change ..............................................................................5-31

Index

I

Page 9

I-6 AP0902

Index

Maintenance kits ..................................................................................5-40

Multifunctional lever .............................................................................3-11

O

Operation ...............................................................................................3-1

Backup warning system (option) ...................................................3-24

Before moving off ..........................................................................3-20

Before starting the engine .............................................................3-16

Changing direction ........................................................................3-24

Drive ranges .................................................................................3-23

Moving off .....................................................................................3-22

Overview of cab ..............................................................................3-2

Overview of instrument panel, multifunctional and drive lever ........3-4

Parking the machine .....................................................................3-26

Selecting drive range ....................................................................3-23

Starting the engine ........................................................................3-16

Stopping the machine ...................................................................3-25

Operation manual

Notes ..............................................................................................1-1

P

Pallet forks ...........................................................................................3-66

Approaching the material ..............................................................3-66

Loading the material .....................................................................3-67

Safety instructions ........................................................................3-66

Setting down the material .............................................................3-68

Parking brake .......................................................................................3-10

Preheating start switch ..........................................................................3-8

R

Refuelling ...............................................................................................5-2

Regulations ............................................................................................1-5

Rotating beacon (option) .....................................................................3-28

Running-in period ..................................................................................3-5

S

Safe load indicator ...............................................................................3-43

Adjusting signal volume ................................................................3-44

Overview .......................................................................................3-43

What to do if ... ..............................................................................3-44

Safety instructions .................................................................................2-1

Identification ....................................................................................2-1

Operation ........................................................................................2-6

Special hazards ............................................................................2-13

Seat adjustment ...................................................................................3-31

Armrest setting ..............................................................................3-32

Backrest setting ............................................................................3-32

Height setting ................................................................................3-31

Longitudinal setting .......................................................................3-32

Weight setting ...............................................................................3-31

Seat belt ...............................................................................................3-33

Service brake .......................................................................................3-22

Signalling system .................................................................................3-28

Signs and symbols .................................................................................1-9

Specifications .........................................................................................7-1

Axles ...............................................................................................7-2

Brakes .............................................................................................7-3

Conversion factors ........................................................................7-10

Coolant compound table .................................................................7-9

Dimensions .....................................................................................7-8

Electrical system .............................................................................7-5

Engine .............................................................................................7-1

Frame .............................................................................................7-1

Noise levels ....................................................................................7-7

Power train ..................................................................................... 7-2

Specific converted values ............................................................. 7-11

Steering ..........................................................................................7-3

Telescopic unit ...............................................................................7-4

Tightening torques ..........................................................................7-9

Tires ............................................................................................... 7-7

Vibration .........................................................................................7-8

Weights .......................................................................................... 7-7

Work hydraulics ..............................................................................7-3

Starting with starting aid ......................................................................3-24

Steering ...............................................................................................3-21

Symbols ................................................................................................1-1

T

Taking into service ................................................................................3-5

Checklists .......................................................................................3-6

Overview of the control elements ...................................................3-8

Safety instructions ..........................................................................3-5

Taking the machine into service for the first time ...........................3-5

Telescopic unit

Checking the transport position of the bucket ..............................3-58

Depressurizing the quick couplers on the telescopic unit .............3-47

Lowering the telescopic unit with the engine switched off ............3-47

Lubrication ....................................................................................5-28

Re-equipping the telescopic unit ..................................................3-48

Warning Lights ....................................................................................3-13

Towing and transporting the machine ................................................. 3-39

Transporting with a full bucket ............................................................3-59

Turn indicators .................................................................................... 3-28

Type labels and component numbers ...................................................1-8

Tire care ..............................................................................................5-30

Tire inflation pressure table .................................................................1-11

Tires ......................................................................................................7-7

V

Ventilation ........................................................................................... 3-29

Ventilation, fresh air ......................................................................3-29

W

Warning identification (option) ...............................................................1-5

Warranty ................................................................................................2-1

Washer pump ......................................................................................3-30

Washer system

Tank ............................................................................................. 3-30

Wheel change .....................................................................................5-31

Wheel synchronization position ...........................................................3-21

Window wash system ..........................................................................3-30

Wipers .................................................................................................3-30

Working

... with pallet forks .........................................................................3-66

Approaching the material ............................................................. 3-66

Loading the material .....................................................................3-67

Safety device "Hose burst valve" ................................................. 3-55

Setting down the material .............................................................3-68

Working light (option) ..........................................................................3-27

Workingwiththemachine

Freeing the machine .....................................................................3-65

Grading .........................................................................................3-65

Loading heaped material .............................................................. 3-64

Loading loose material .................................................................3-60

Practical hints ...............................................................................3-65

Removing material/digging in hard soil ........................................3-63

Removing material/digging in soft soil ..........................................3-62

Page 10

Section 1

Introduction

1

Page 11

Page 12

AP0902 1–1

1

1Introduction

1.1 Notes on this operator’s manual

Thisoperator’s manualcontains importantinformation on how to worksafely, correctlyand

economically with the wheel loader model 418T. Therefore, it aims not only at new operators,but it is also areference for experienced ones. It helps to avoid dangerous situations,

and reduce repair costs and downtimes. Furthermore, the reliability and the service life of

themachine will be increased by following theinstructions in the operator’s manual.This is

why the operator’s manual must always be kept in the machine.

Your own safety, as well as the safety of others, depends to a great extent on how the

machine is moved and operated. Therefore, carefully read and understand this operator’s

manual prior to the first use. This operator’s manual will help to fami liarize yourself more

easily with the machine, thereby enabling you to use it more safely and efficiently.

General safety instructions are given in Part 2 of this operator’s manual. Carefully read

and understand them prior to the first drive. As a rule, keep the following in mind:

Careful and prudent working is the best way to avoid accidents!

Special safety instructions with direct reference to service, function and operator’s of the

machine are given before the procedure to follow in the respective chapters. These safety

instructions must always be observed and followed.

Operationalsafety and readiness of the machine do not only dependon your skill, but also

on maintenance and service of the machine. This is why regular maintenance and service

work is absolutely necessary. Extensive maintenance and repair work should always be

carried out by an expert with appropriate training. Insist on using original service parts

when performing maintenance and repair work. This ensures operational safety and readiness of your machine, and maintains its value.

Your dealer will be pleased to answer any further questions regarding the machine or the

operator’s manual.

Abbreviations/symbols

• This symbol stands for a list

• This symbol stands for the subdivision of an enumeration or an activity. Follow the

steps in the recommended sequence.

☞ This symbol requires you to carry out the activity described.

➥ Description of the effects or results of an activity.

n.s. = not shown

SO = option

Stated whenever controlsor other components of the machine are installed as an option.

This symbol shows the direction oftravel – for better orientation in figures and

graphics.

Introduction

Page 13

1–2 AP0902

Introduction

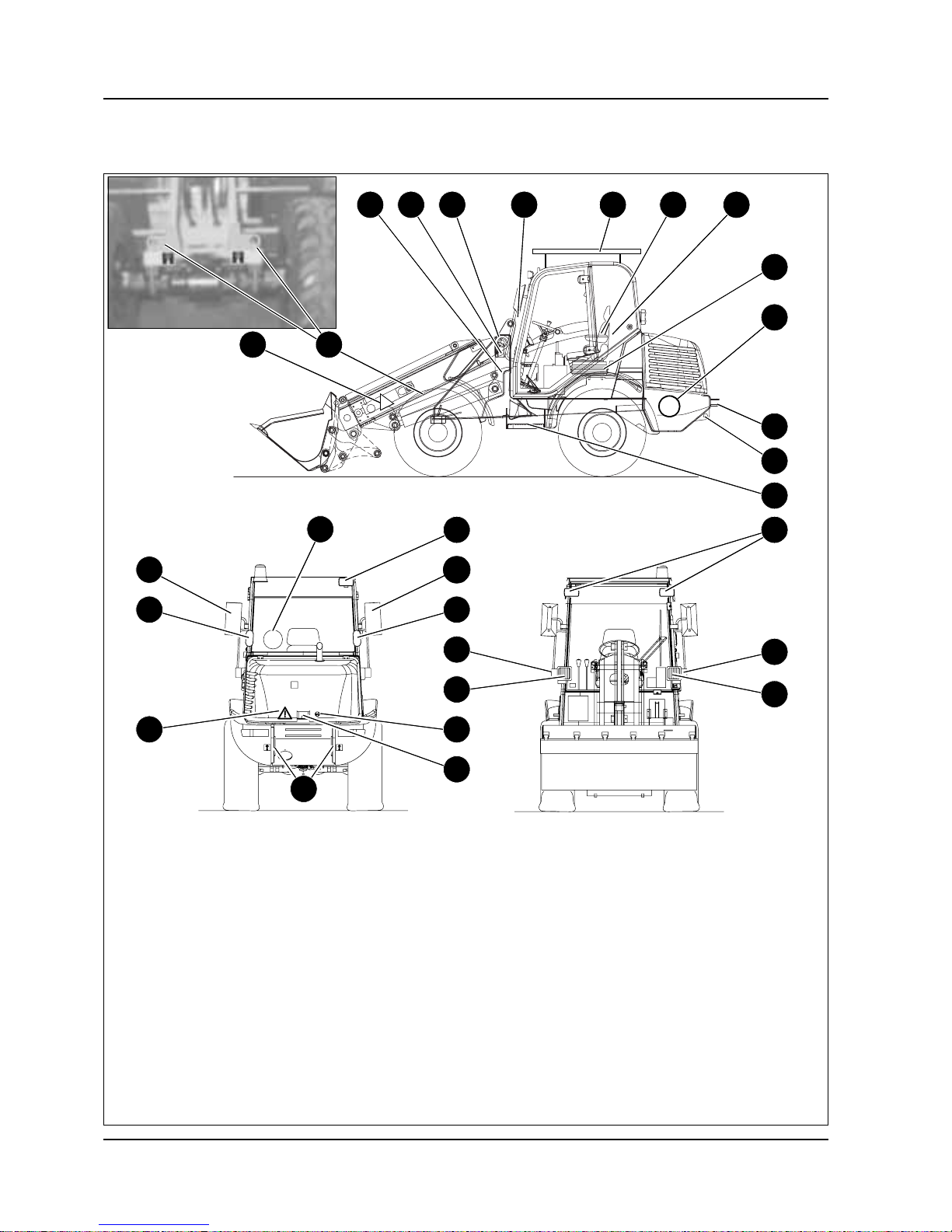

1.2 Machine: Overview

31100b0190.eps

308b0070.ep

s

308b0060.ep

s

Fig.1: Machineoutside views

1 Working light (option)

2 Danger label

3 Front eye hooks – lifting and strapping down the machine

4 Wheel chock

5 Horn

6 Mark – telescopic unit position for long-haul travel

7 Access handle

8 Protective FOPS screen

9 Noise emission label

10 EC sign

11 Maximum driving speed label

12 Fuel filler inlet

13 Drawbar pin

14 Rear eye hooks – lifting and strapping down the machine

15 Step

16 Working light (option)

17 Turn indicator

18 Headlights

19 Engine cover lock

20 Label –“Do not open engine cover before engine is at a

standstill!”

Do not touch any moving or turning parts!

21 Brake light, rear light, turn indicator

22 Rearview mirror

2

20

6 8 9

4

5

10

11

13

14

21

21

2

20

11 1

16

22

17

18

17

18

7

15

19

12

22

3

20

14

!

Page 14

AP0902 1–3

Introduction

1.3 Brief description

The wheel loader model 418T is a self-propelled work machine.

Thismachine is aversatile and powerful helper for moving earth,gravel and debrison construction sites and elsewhere. The wide range of attachments accounts for the numerous

applications of the machine: as a fork lift, a snow plow, a spreader for sand, salt etc., a

sweeper or a tree replanter. See part 1.4 Applications for further applications. Fit the

machine with the respective safety devices when using it as a lifting machine (see “Applications with lifting accessories” in Part 2 Safety Instructions).

The main components of the wheel loader model 418T are:

• ROPS tested operator’s cab

• Water-cooled four cylinder PERKINS diesel engine, 58 hp (43.1 kW) at 2400 rpm (as

per DIN ISO 9249)

• Sturdy steel sheet frame in torsion-resistant box-type design

• Hydrostatic drive with electronic control, inching; 12 mph (20 km/h) max. speed

• Hydrostatic four-wheel steering with emergency steering features

• Front and rear planetary axles, rear axle with oscillation

• Service brake (mechanical or hydrostatic), mechanical disk-type parking brake

• Telescopic unit with safe load indicator

Hydrostatic drive The diesel engine drives a hydraulic pump, whose oil flow is sent to a hydraulic motor con-

nected to the rear axle. The force of the hydraulic motor is transmitted to the rear axle via

the transfer gearbox. At the same time, the front axle is driven by the cardan shaft, ensuring permanent four wheel drive.

Work hydraulics and hydro st at ic four wheel steering

Thediesel engine also drives the joint gear pump for work hydraulics and hydrostatic fourwheel steering. The oil flow of this pumpdepends on the diesel engine speed only.

Whenthe machine is in operation,the entire diesel engine outputcan be transmitted to the

gearpump forwork hydraulics and steering. Thisis madepossible by theso-called inching

whichresponds as soon as theinching brake is used, reducingor cutting off power inputof

the drive. Therefore, engine output is fully available for the telescopic unit by pressing the

accelerator pedal and the i nching brake pedal at the same time.

Cooling system A combined oil/water cooler (for the diesel engine and the hydraulic oil) is located at the

rear of the machine. The warning lights in the instrument panel 17 ensure constant monitoringof the coolant and hydraulic oil temperature. In addition, an audible signal sounds in

the machine cab as soon as there is danger of coolant or hydraulic oil overheating and in

case of low engine oil pressure.

Page 15

1–4 AP0902

Introduction

1.4 Applications

The attachments will determine where and how the machine can be used.

The following table gives an overview of the possible attachments.

Description and Model Model No. Use

Standard bucket w/ teeth

– normal material 418T

810136 Loosening, picking up, transporting and loading loose or

solid material (material density ≤ 2700 lbs/yd³ (18 kg/m³))

Pallet forks 418T 810135 Picking up and transporting pallets per load diagram

Page 16

AP0902 1–5

Introduction

1.5 Regulations

Driving license

Earth moving machinery should be driven on public roads only ifthe driver has a drivers

license.

Get informed on and follow the legal regulations of your country.

Equipment

The highway regulations of your state/province may require you to equip your machine

with:

• Slow-Moving Vehicle (SMV) emblem

• warning lights

Become informed on and follow the local highwayregulations.

Gehl will send you the original copy of this Declaration of Manufacturer at your request.

Please state name of product, model and identification number (see type label of the

attachment).

Page 17

1–6 AP0902

Introduction

1.6 Machine data

The following data provide a detailed description of your machine. Please supply your

dealer with these data for all correspondence or telephone inquiries.

Please read the data valid for your machine off the serial number plates, and enter this

data in the list. They will immediately be at hand for all inquiries or service parts orders.

Machine model: ......................................................................................................................................

Date of registration: ......................................................................................................................................

Service hours/kilometerreading: ......................................................................................................................................

Serial number: ......................................................................................................................................

Cab number: ......................................................................................................................................

Engine no.: ......................................................................................................................................

Variable displacement pump model –

identificationno.:

......................................................................................................................................

Variable displacement motor model –

identificationno.:

......................................................................................................................................

Front axle no.: ......................................................................................................................................

Rear axle no.: ......................................................................................................................................

Cab no.: ......................................................................................................................................

Optional attachments: ......................................................................................................................................

Your local dealer:

• Address:

• Telephone:

Page 18

AP0902 1–7

Introduction

1.7 Type labels and component numbers

Type label

The type label (Fig. 3) is located at the front right of the machine frame (Fig. 2/1)

Serial number

The serial number is stamped on the machine frame (Fig. 2/2). It is also stamped on the

type label (Fig.3)

Example for wheel loader model 418T:

418T 0005

Engine number

The engine number is located on the label atthe front of the engine block (arrow, Fig. 4)

Example:

073 305

Number of hydraulic pump

The type label (arrow, Fig. 5) islocated on the pump, below the air filter

Hydraulic m otor number

Thetype label (arrow,Fig. 6) is located on the lower side of the hydraulicmotor, above the

cardan shaft

Fhzg-Typ

Model

Modèle

308

311 10

311 10 0003

2001

Typ / Ausf.

Version

Version

Fg.-Nr.

Serial no.

No. de sé rie

Baujahr

Model year

Année fabr.

Zul. Achslast vorn

Front GAWR

PNBE AV

Zul. Achslast hinten

Rear GAWR

PNBE AR

Zul. Ges. Gew.

GWR

PTAC

Leistung

Output

Performance

[ kg ]

[ kg ]

[ kg ]

[ kW ]

3750

3750

6000

43,5

31100b0230.eps

Fig.2: Type label:location

Fig.3: Type labelmodel 418T

1

2

Fig.4: Dieselengine number

Fig.5: Hydraulicpump: type label

Fig.6: Hydraulicmotor: type label

Page 19

1–8 AP0902

Introduction

Front/rear a xle number

The axle number is located on the type label, on the right side of each axle (arrow, Fig. 7)

1.8 Safety signs and symbols

The following explains signs and symbols that do not contain explanatory text.

...on the outside of th e machine

Meaning

General indication of danger:

This sign (Fig. 9) warns persons standing or working near the machine of increased danger around the machine.

Location

Front left and right of machine frame, and at rear of machine (Fig. 8/3)

Meaning

Eye hooks/limit (Fig. 10)stops on the machine. The eye hooks are used for liftingor strapping down the machine.

Location

At the rear of the counterweight (Fig. 8/2), as well as

at the front above the front axle, left and right on the frame

Meaning

1 (Fig. 11) Do not open engine cover before engine is stopped!

2 (Fig. 11)Do not touch any movi ng or turning parts!

Location

At the rear on the engine cover (Fig. 8/1), as well as on the engine block.

Fig.7: Type labelon the front axle

Fig.8: Decalsat the rear

3

3

2

308b0360.eps

Fig.9: Dangersign

308b0680.ep

s

Fig.10: Decal: eyehooks

Fig.11: Prohibitory sign

Page 20

AP0902 1–9

Introduction

Meaning

Read and observe the operator’s manual before carrying out maintenance work!

Location

On the engine block (Fig. 12)

Fig.12: Please referto operator’smanual

Page 21

1–10 AP0902

Introduction

...inside t he operator’s compa rt ment

Meaning

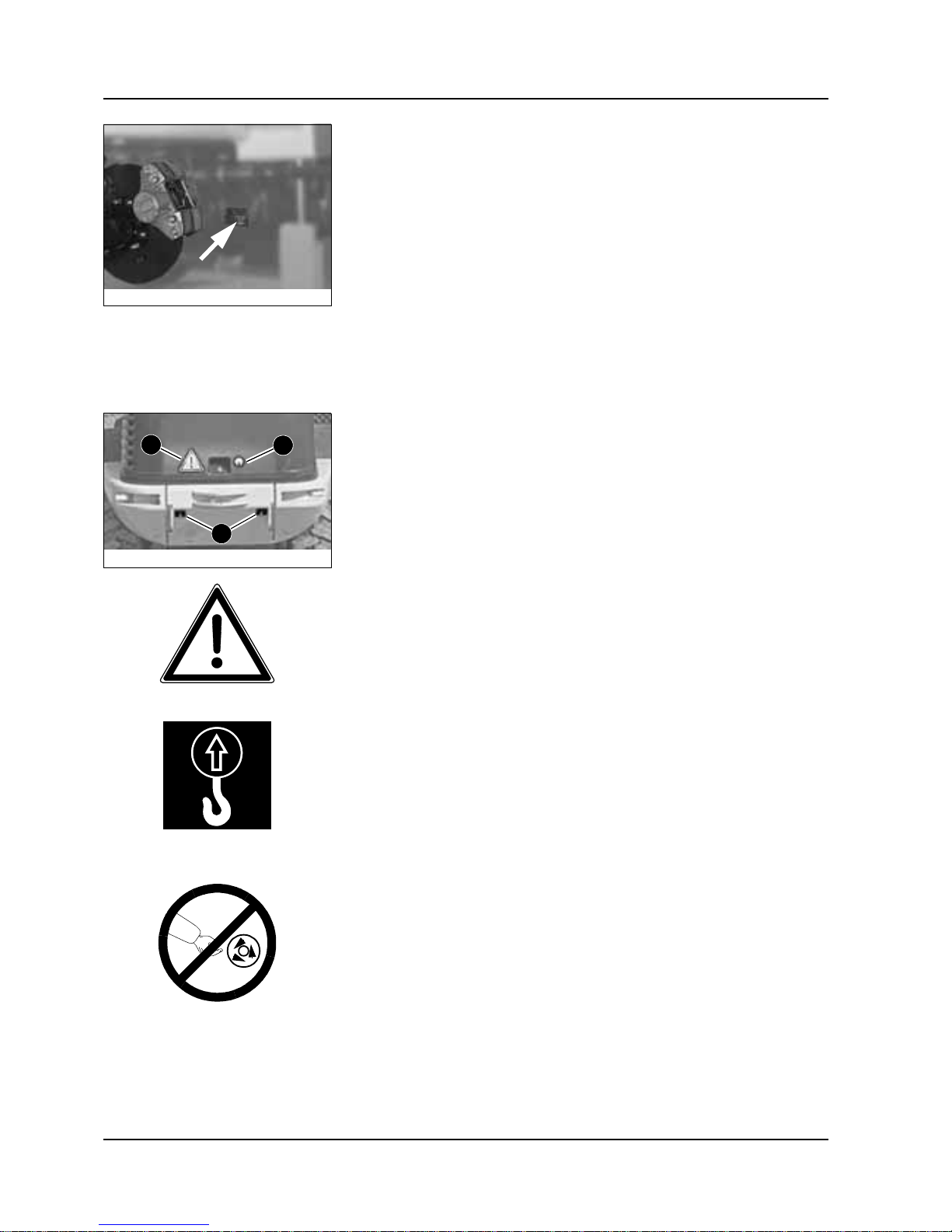

Cab type label (Fig. 13)

Location

On left side of B-column

Meaning

Tire inflation pressure table (Fig. 14)

List of authorized types of tires with prescribed tire inflation pressure

Location

Inside the cab, on left side of front window

Meaning

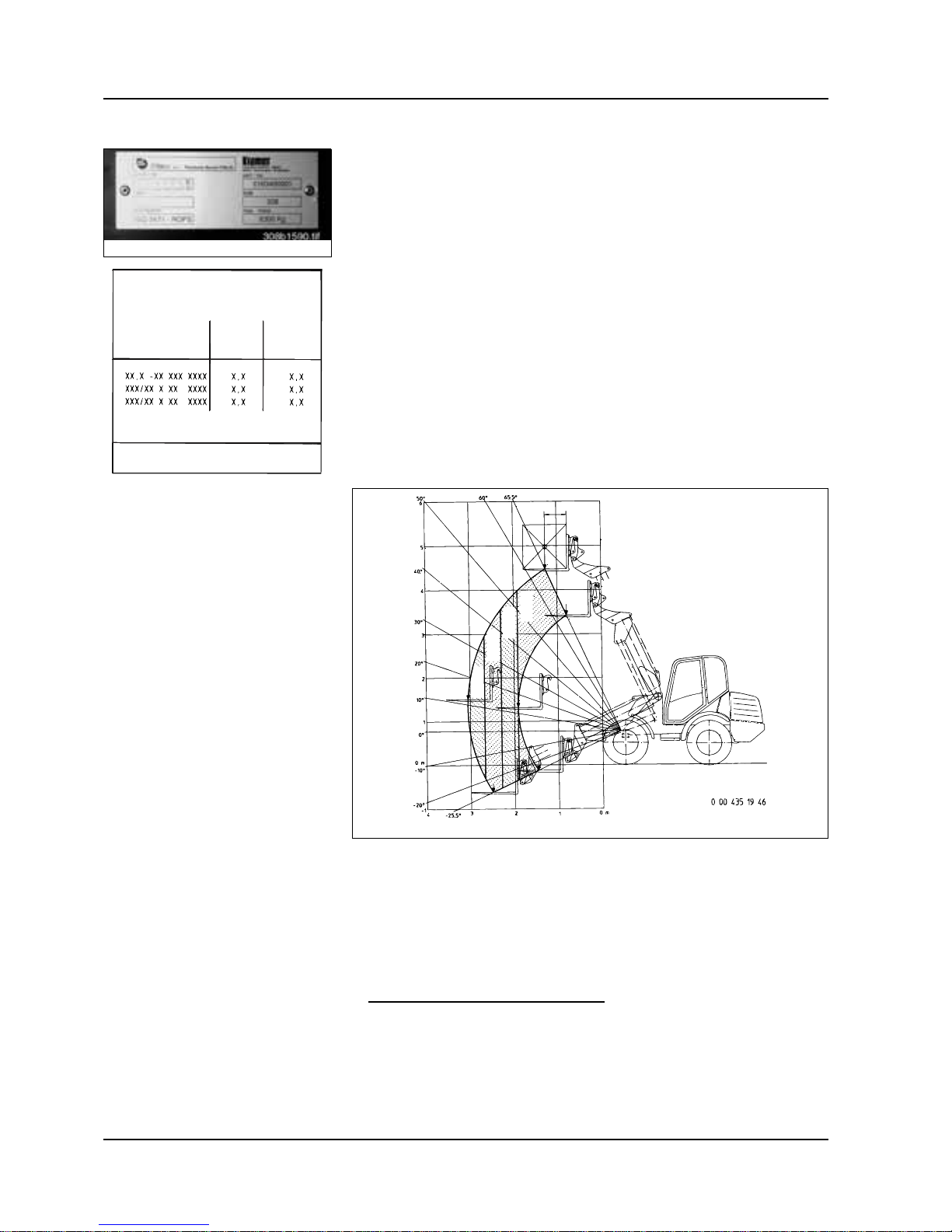

Load diagram (Fig. 15 for operation with pallet forks (fork arms):

The framednumbers indicate the maximum authorized load on the fork arms for industrial

(S=1.25) and off-road (S=1.67)applications respectively. The maximum load varies

accordingto the horizontal and vertical distance ofthe load center,in thediagram depicted

onthe fork armswith a distance of 500 mm to the rear of the fork arms. The telescopic unit

with fork arms moves within the dotted range.

Reading example for attachment no. 810135

:

Off-road application

➝ safetyfactor S=1.67

Distance of load to rear of fork arms = 20 inches (500 mm)

Height of fork arm above tire contact area = 61 inches (1.56 m)

Distance to tire front = 132 inches (3.36 m)

Maximum load is 2061 lbs (935 kg)!

Fig.13: Cab inspectionlabel

31100b0010.ep

s

Reifenluftdrucktabelle

Tire pressure

Reifenbezeichnung

vorn (bar)

front (bar)

AV (bar)

hinten (bar)

rear (bar)

AR (bar)

Tires

Pneumatiques

Pression pneumatiques

Bei Stapelbetrieb Luftdruck vorne um 0,5bar erhöhen!

Increase tire pressure by 0,5 bar during pallet forks operation!

Augmenter la pression pneumatique de 0,5bar en service porte-palette

!

Fig. 14: Tyre inflation pressure table model 311 00

Fig. 15: Load diagram

31100b0210.eps

S=1,25/ 1100 kg

S=1,67/ 820 kg

S=1,25/ 1270 kg

S=1,67/ 950 kg

S=1,25/ 1500 kg

S=1,67/ 1120 kg

S=1,25/ 1800 kg

S=1,67/ 1345 kg

311-00

311-10

Traglastdiagramm

Load diagram

Diagramme de charges

Gültig für Anbaugerät

Valid for attachment

Valable pour équipement

Nr. 10103-00

Nr. 10149-00

Nr. 10162-00

Nr. 10165-00

Page 22

Section 2

Safety instructions

2

Page 23

Page 24

AP0902 2–1

2

2 Safety instructions

2.1 Identification of warnings and dangers

Importantindications regarding the safety of the operating personnel and the machine are

indicated in this operator’s manual with the following terms and symbols:

DANGER!/WARNING!/CAUTION!

Failure to observe the instructions identified by this symbol may result in

personal injury or deathfor the operator or other persons.

☞Measures for avoiding danger

IMPORTANT

Failure to observe the instructions identified by this symbol may result in

damage to the machine.

☞Measures for avoiding danger for the machine

NOTE:

This symbol identifies instructions for a more efficient and economical use of the

machine.

Environment!

Failure to observe the instructions identified by this symbol may result in damage to the

environment.

The environment is in danger ifenvironmentally hazardous material (e.g. waste oil) is not

subject to proper use or disposal.

Safety instructions

Page 25

2–2 AP0902

Safety instructions

2.2 Designated uses

• The machine is intended for:

• Moving earth, gravel, coarse gravel or ballast and rubble as well as

• Working with the attachment mentioned in the present operator’s manual

Every other applicationis regarded as not designated for the use of the machine. Gehl

will not be liable for damage resulting from use other than mentioned above. The user

alone will bear the risk.

Designated use also includes observing the instructions in the operator’s manual and

observing the conditions of maintenance and service

• Observe the pertinent regulations relevant to accident prevention, other generally

acknowledged regulations regarding safety and occupational medicine, as well as the

regulations and standards relevant to motor machines and traffic. The manufacturer is

not liable for damage resulting from the failure to observe these regulations

• Thesafety of the machine canbe negatively affected by carrying out machine modifica-

tions without proper authority and by using spare parts, equipment, attachments and

optional equipment which have not been checked and approved by the manufacturer.

The manufacturer will not be liable for damage resulting from this

• The manufacturer will not be liable for personal injury and/or damage to property

caused by failure to observe the safety instructions and the operator’s manual, and by

the failure to exercise due care when:

• Handling

• Operating

• Servicing and carrying out maintenance work

• Repairing

the machine. This is also applicable in those cases in which special attention has not

been drawn to the duty to exercise due care, in the safety instructions as well as in the

operator’s and maintenance manuals (machine/engine).

Read and understand the operator’s manual before starting, servicing or repairing the

machine. Observe the safety instructions!

• The machine may not be used for transport jobs on public roads

• In applications with lifting accessories, the machine is to be used according to its desig-

nated use only if the required safety devices areinstalled and functional

Page 26

AP0902 2–3

Safety instructions

2.3 General conduct and safety instructions

Organization al measures • The machine has been designed and built in accordance with current standards and

therecognized safety regulations.Nevertheless, its use may constitute a risk to life and

limb of the user or of third parties, or cause damage to the machine and to other

material property if it is not used properly.

• The machine must only be used in mechanically good condition in accordance with its

designated use(s) and the instructions set out in the operator’s manual, and only by

safety-conscious persons who are fully aware of the risks involved in operating the

machine. Any malfunctions, especially those affecting the safety of the machine, must

therefore be corrected immediately!

Basic rule:

Before starting the machine, i nspect the machine for safety in work androad operation!

• Careful and prudent operation is the best way to avoid accidents!

• The operating instructions must always be available, and must therefore be kept in the

storage compartment provided for in the cab.

Immediately complete or replace an incomplete or illegible operator’s manual.

• In addition to the operating instructions, observe and instruct the operator in all appli-

cable legal and mandatory regulations relevant to accident prevention and environmental protection.

These compulsory regulations may also deal with the handling of hazardous

substances, issuing and/or wearing of personal protective equipment, or traffic regulations.

• With regard to specific operational features, e.g. those relevant to job organization,

work sequences or the persons doing the work, supplement the operator’s manual by

correspondinginstructions, including those relevant tosupervising and reporting duties.

• Persons who with work on the machine must have read and understood the operator’s

manual and in particular, Section 2 “Safety Instructions” before beginning work. This

applies especially to persons working only occasionally on the machine, e.g. set-up or

maintenance.

• The user/owner must check – at least from time to time – whether the persons doing

operationor maintenance ofthe machine are workingin compliance with the operator’s

manual and are aware of risks and safety factors.

• The user/owner commits himself to operate and keep the machine in a good operating

condition, and, if necessary or required by law, to require the operating or servicing

persons to wear protective clothing etc.

• In the event of safety-relevant modifications or changes on the machine or of its

behavior, stop the machine immediately and report the malfunction to the competent

authority/person.

Safety-related damage or malfunctions of the machine must be corrected immediately.

• Never make any modifications, additions or conversions to the machine and its super-

structure (cab, telescopic unit etc.), as well as to the attachments, which might affect

safety without the approval of the manuufacturer! This also applies to the i n stallation

and the adjustment of safety devices and valves, as well as to welding work on loadbearing elements.

• Service parts must comply with the technical requirements specified by the manuufac-

turer. Original service parts from the manuufacturer can be relied to do so.

• Replace hydraulic hoses within stipulated and appropriate intervals even if no safety-

related defects have been detected.

Page 27

2–4 AP0902

Safety instructions

• Before working on or withthe machine, take off jewelry, such as rings, wristwatches,

bracelets, etc., and tie back long hair, and do not wear loose-fitting garments, such as

unbuttoned or unzipped jackets, ties or scarves.

Injury may result from beingcaught up in the machinery or from rings catching on

moving parts!

• Keep the machine clean. This reduces:

• Fire hazard, e.g. due to oil-soaked rags lying around

• Danger of injury, e.g. due to dirt or debris on the steps, and

• Danger of accident e.g. due to dirt or debris on the brake or accelerator pedal!

• Observe all safety, warning and information signs and decals on the machine.

• Adhere to prescribed intervals or those specified in the operator’s manual for routine

checks/inspections and maintenance work!

• For service, inspection, maintenance or repair work, tools and workshop equipment

adapted to the task involved are absolutely indispensable.

Selection and qualification of personnel, basic responsibilities

• Any work on or with the machine must be performed by reliable personnel only. Do not

let unauthorized persons drive or work with the machine! Observe statutory minimum

age limits!

• Employ only trained or instructed staff on the machine, and set out clearly and unequiv-

ocallythe individual responsibilities of the personnel for operation, set-up,maintenance

and repair!

• Define the machine operator's responsibilities – including observing traffic regulations.

Give the operator the authority to refuse instructions by third parties that are contrary to

safety.

• Do not allow persons to be trained or instructed, or persons taking part in a general

training course, to work on or with the machine without being supervised by an experienced person!

• Work on the electrical system and equipment, on the chassis and onthe steering and

brake systems may be carried out only by skilled personnel who has been specially

trained for such work.

Work on the hydraulic system of the machine must be carried out only bypersonnel

with special knowledge and experience of hydraulic equipment!

• Seal off the area of danger should it not be possible to keep a safe distance.

Stop work if persons do not leave the area of danger in spite of w arning! Keep out of

the area of danger!

Area of danger:

Thearea of danger is the areain which persons are in dangerdue to themovements of

the

• Machine

• Work equipment

• Additional equipment, or

• Material

This also includes the area affected by falling material, equipment, or by parts that are

thrown.

Page 28

AP0902 2–5

Safety instructions

2.4 Safety instructions regarding operation

Normal operat ion • Before beginning work, familiarize yourself with the surroundings and circumstances of

the work site. These are, e.g., obstacles in the working and travelling area, the soil

bearingcapacity and any necessarybarriers separating the work site from publicroads.

• Takethe necessary precautionsto ensure thatthe machine isused only when in a safe

and reliable condition!

• Operate the machine only if all protective and safety-related devices, e.g., removable

safety-devices, soundproofing elements and mufflers etc., are in place and fully

functional!

• Check the machine at least once daily/per working shift for visible damage and defects.

Report any changes (such aschanges in the machine’s working behavior) to the

competent organization/person immediately! If necessary, stop the machine immediately and lock it!

• In the event of malfunctions, stop the machine immediately and lock it! Have any

defects corrected immediately!

• Start and operate the machine from theoperator’s seat only!

• Carryout start-upand shut-down procedures in accordancewith theoperator’s manual,

and observe the warning lights!

• Before putting the machine/attachment into operation (start-up/moving), make sure

nobody is at risk!

• Before driving the machine, and also after stopping work, check whether the brakes,

steering, signalling and light systems are functional!

• Before moving the machine always check whether the supplementary equipment and

the attachments have been safely stowed away or attached!

• When driving on public roads, observe the traffic regulations and, if necessary, make

sure beforehand that the machine is in compliance w ith these regulations!

• In conditions of poor visibility and after dark always switch on the lights!

• No lifting, lowering or carrying of persons in the

work equipment/attachments!

• No mounting of a man basket or personal work platform!

• When crossing underpasses, bridges and tunnels, or when passing under overhead

lines, always make sure there is sufficient clearance!

• Always keep at a safe distance from the edges of excavations and slopes!

• When working in buildings or in enclosed areas, look out for the

• Height of the ceiling/clearances

• Width of the entrances and

• Maximum load of ceilings and floors

Provide for sufficient room ventilation – danger of poisoning!

Page 29

2–6 AP0902

Safety instructions

• Avoid any operation that might be a risk to stability!

• During operation on slopes, drive or work uphill or downhill. If driving across a slope

cannot be avoided, bear in mind the stability limit of the machine!

Always keep the attachments/work tool close to the ground. This also applies when

driving downhill!

When driving or working across a slope, the load must be on the uphill side of the

machine.

• On sloping terrain always adapt your driving speed to the prevailing ground conditions.

Never change to a lower gear on a slope, but always before reaching it!

• Before leaving the machine

• Lower the work tool/attachments to the ground

• Before leaving the operator seat, always secure the machine against inadvertent

movement and unauthorized use!

• Before starting work, check whether

• All safety devices are properly installed and functional

• Slow Moving Vehicle (SMV) emblem installed as needed

• Warning lights installed as needed, and

• A First-aid kit is on hand

• Before moving the machine or before starting work:

• Make sure visibility is sufficient (do not forget rearview mirrors!)

• Adjust correct seat position (brake pedal must be depressed to the limit).

Never adjust the operator seat when driving or working!

• Fasten your seat belt

• Inspect the immediate area (children!). In the work area the operator is responsible

for third parties!

• Caution when handling fuel – increased danger of fire!

Make sure fuel does not come into contact with hot parts!Stop the engine during refuelling! Do not smoke during refuelling, and avoid fire and sparks!

• Never get on or off a moving machine! Never jump off the machine!

• If the lights of the machine are not sufficient for the safe execution of certain work

processes, provide additional lighting of the work area.

• Installed rear work lights must not be switched on for travel on public roads. They can

be switched on in work operation if users of public roads are not dazzled.

• Hydrostatic four-wheel steering takestime getting used to. Therefore, adjustthe driving

speed to your abilities and the circumstances. Selection and change steering mode of

machine at standstill only!

WARNING!

Exposure to crystalline silica (found in sand, soil and rocks) has been

associated with silicosis, a debilitating and often fatal lung disease. A

Hazard Review (Pub. No. 2002-129) by the U.S. National Institute for

Occupational Safety and Health (NIOSH) indicates a significant risk (at

least 1 in 100) of chronic silicosis for workers exposed to inhaled crystalline silica over a working lifetime. NIOSH recommends an exposure limit

of 0.05 mg/m

3

as a time-weighted average for up to a 10-hr workday during a 40-hr workweek. NIOSH also recommends substituting less hazardous materials when feasible, using respiratory protection, and regular

medical examinations for exposed workers.

Page 30

AP0902 2–7

Safety instructions

Applicationswith lifting accessories Definition:

Applications with lifting accessories are understood as procedures involving the lifting,

transporting and lowering of loads with help of slings and load-securing devices (e.g.

ropes, chains). In doing so, the help of persons is necessary for securingand detaching

the load. This applies, for example, to lifting and lowering of pipes, shaft rings or containers.

• Themachine may beused for applicationswith lifting accessories onlyif the prescribed

safety devices are in place and functional.

These are, e.g.:

• Accessories for slinging and securing a lifting attachment (load hook)

• Load diagrams

• The load must be secured so as to prevent it from falling or slipping.

• Persons guiding the load or securing it must stay in visual contact with the machine

operator.

• Themachine operatormust guidethe load as near aspossible tothe ground,and avoid

any oscillating or swinging movements.

• The machine may be moved with a raised load only if the path of the machine is level.

• The persons attaching or securing loads may approach the boom from the side only,

and only after the machine operator has given permission. The machine operator may

give his permission only after the machine is at a standstill and the tool/attachment is

not moving.

• Do not use any damaged lifting attachments or such lifting accessories (ropes, chains)

that are not sufficiently sized. Always wear protective gloves when working with lifting

accessories.

Page 31

2–8 AP0902

Safety instructions

Trailers and attachments • It is not permitted to use a trailer withthe towing device of the machine!

• Attachments and counterweights affect handling, as well as the steering and brake

capability of the machine!

• Fit the attachments with the specially required devices only!

• Before uncoupling or coupling hydraulic lines (hydraulic quick couplers):

• Turn off the engine, and

• Relieve the oil pressure in the hydraulic system by moving the control levers of the

hydraulic control units backand forth a couple times.

• Coupling of attachments requires special care!

• Secure the attachments against inadvertent movement!

• Operate the machine only if all safety devices are installed and are functional, and if all

brake, light and hydraulic connections are connected!

• If optional equipment is installed, all additionally required light installations, warning

lights, etc., must be provided for and functional.

• Mount the attachments only if the engine is stopped and the drive system is switched

off.

• Relievepressure in the hydraulic system before connecting or disconnecting hydraulic

lines.

• Especially when driving or working with machines with a quick hitch facility for the

attachments, be sure that the attachment is securely locked in the quick hitch facility.

The lock pin must be visible on both sides of the bores on the attachment. Check

before starting work.

• Prior to connecting attachments to the loader, secure the control lever of the hydraulic

control against unintentional movement.

• Be careful when connecting attachments to the loadert: because of the danger of

personal injury due to crushing and shearing. Be sure nobody is between the machine