Page 1

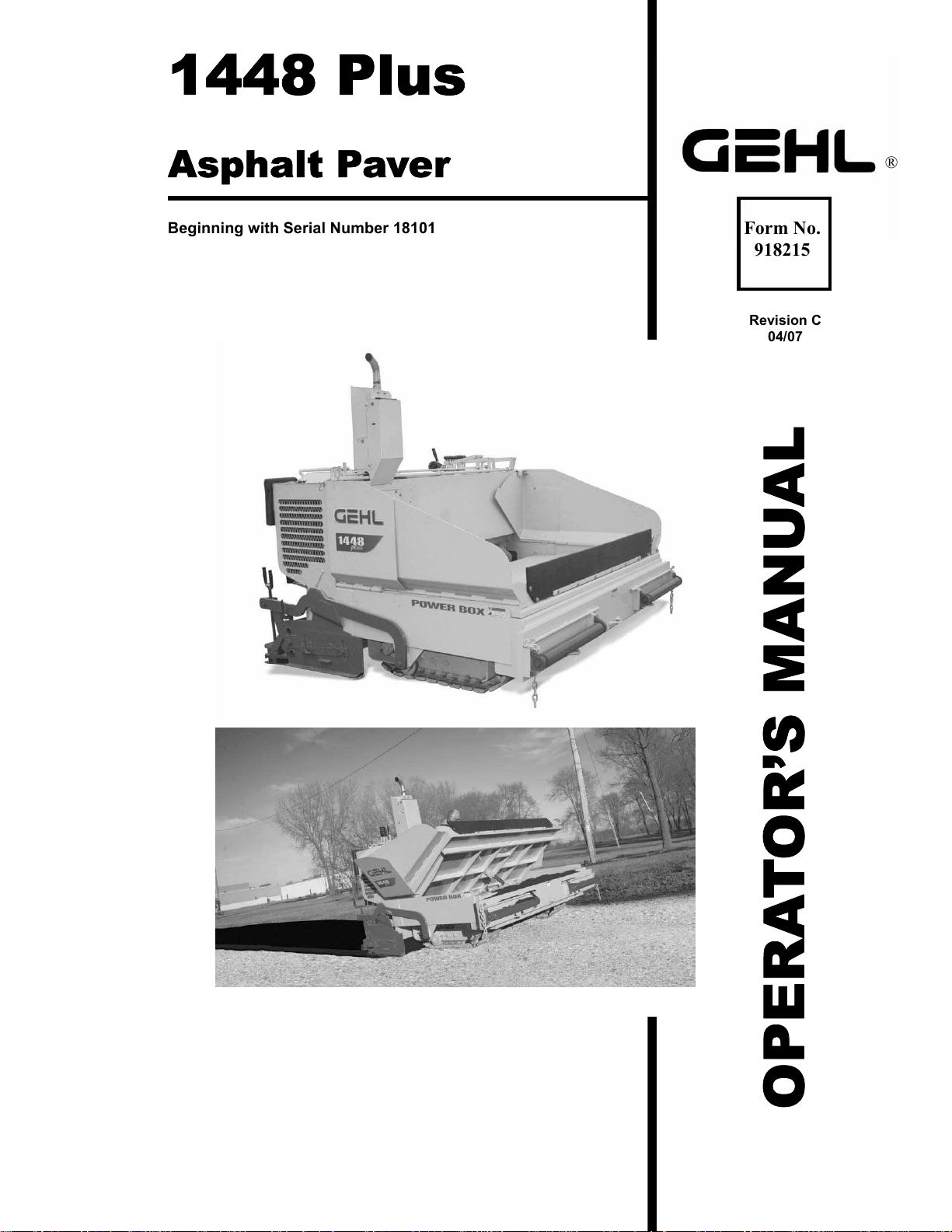

1448 Plus

Asphalt Paver

Beginning with Serial Number 18101

®

Form No.

918215

Revision C

04/07

OPERATOR’S MANUAL

Courtesy of Machine.Market

Page 2

GEHL COMPANY

WARRANTY

GEHL COMPANY, hereinafter referred to as Gehl, warrants new Gehl equipment to the

Original Retail Purchaser to be free from defects in material and workmanship for a period of

twelve (12) months from the Warranty Start Date.

GEHL WARRANTY SERVICE INCLUDES:

Genuine Gehl parts and labor costs required to repair or replace equipment at the selling dealer's

business location.

GEHL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND,

EXPRESS OR IMPLIED (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE), EXCEPT AS

EXPRESSLY STATED IN THIS WARRANTY STATEMENT.

ANY OF THESE LIMITATIONS EXCLUDED BY LOCAL LAW SHALL BE DEEMED

DELETED FROM THIS WARRANTY; ALL OTHER TERMS WILL CONTINUE TO APPLY.

SOME STATES DO NOT PERMIT THE EXCLUSION OR LIMITATION OF THESE

WARRANTIES AND YOU MAY HAVE GREATER RIGHTS UNDER YOUR STATE LAW.

GEHL WARRANTY DOES NOT INCLUDE:

1. Transportation to selling dealer's business location or, at the option of the Original Retail

Purchaser, the cost of a service call.

2. Used equipment.

3. Components covered by their own non-Gehl warranties, such as tires, batteries, trade

accessories and engines.

4. Normal maintenance service and expendable, high-wear items.

5. Repairs or adjustments caused by: improper use; failure to follow recommended

maintenance procedures; use of unauthorized attachments; accident or other casualty.

6. Liability for incidental or consequential damages of any type, including, but not limited

to lost profits or expenses of acquiring replacement equipment.

No agent, employee or representative of Gehl has any authority to bind Gehl to any warranty

except as specifically set forth herein.

Courtesy of Machine.Market

Page 3

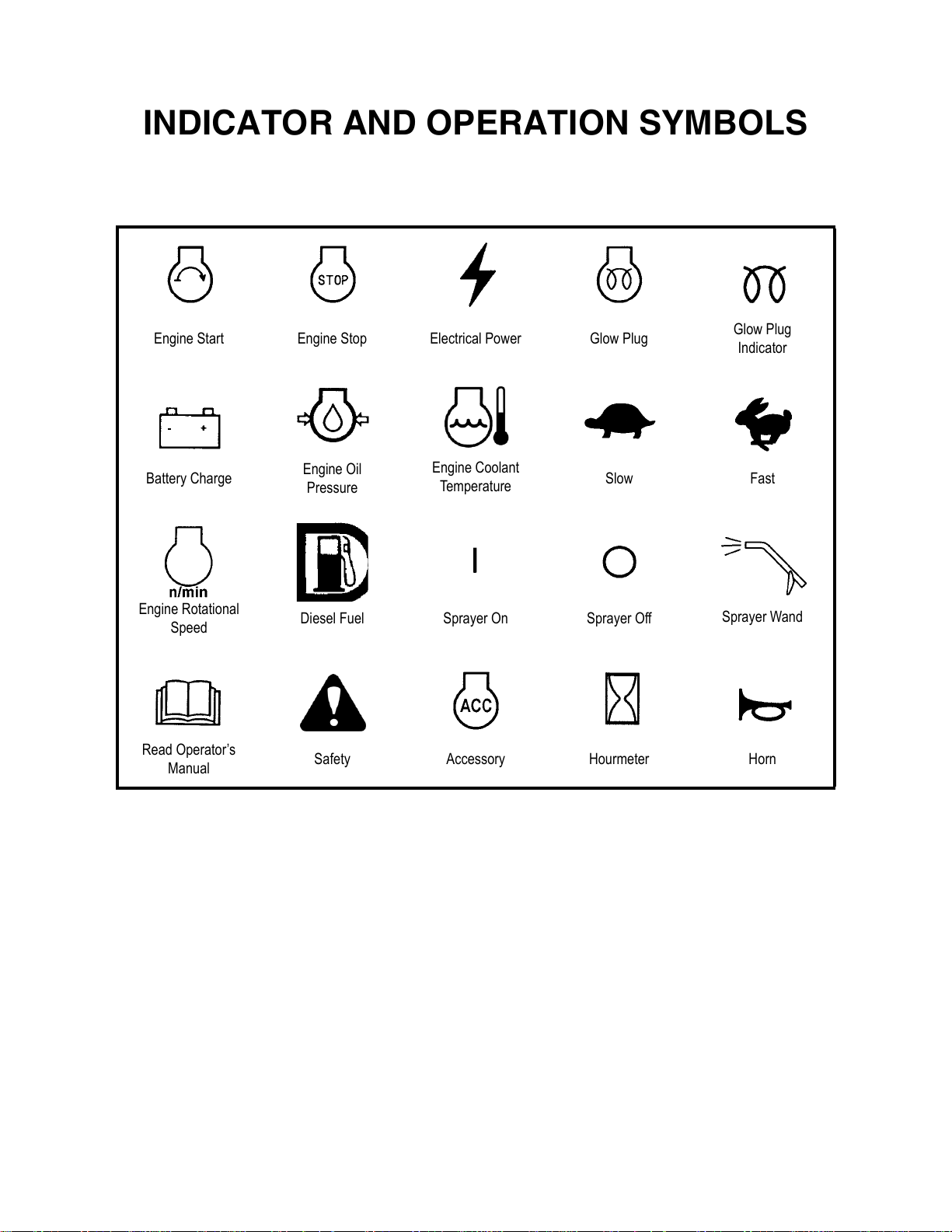

INDICATOR AND OPERATION SYMBOLS

Engine Start Engine Stop Electrical Power Glow Plug

Battery Charge

Engine Rotational

Speed

Read Operator’s

Manual

Engine Oil

Pressure

Diesel Fuel Sprayer On Sprayer Off

Safety Accessory Hourmeter Horn

Engine Coolant

Temperature

Glow Plug

Indicator

Slow Fast

Sprayer Wand

Courtesy of Machine.Market

Page 4

NOTES

Courtesy of Machine.Market

Page 5

TABLE OF CONTENTS

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model/Serial Number Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Paver Controls/Components Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3

Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mandatory Safety Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pre-operation Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Screed Propane Heater Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Modifications, Nameplates, Markings and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Protective Guards and Warning Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 5

Indicators and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Guards and Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Circuit Breaker and In-line Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Indicator and Control Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ignition Keyswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Instrument Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Engine Throttle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fuel Level Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Engine Coolant Temperature Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hourmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Washdown Sprayer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hydraulic Fluid Reservoir Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Paving Alignment Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Travel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hydraulic Pump Variable-Speed Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Travel Control Levers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hopper Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Hopper Floor Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Flow Gate Control Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Printed in U.S.A 1 918215/CP0407

Courtesy of Machine.Market

Page 6

TABLE OF CONTENTS 1448 PLUS

Feed Auger Control Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Screed Platform Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Screed Lift Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Vibrator Control Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Screed Extension Control Levers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Screed Depth Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Side Shoe Plate Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mat Crown Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Screed Propane Heater Kit (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Engine Break-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Before Starting Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Starting the Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

First Time Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Stopping the Paver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

General Paver Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Walk-around Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hands-on Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Screed Propane Heater Kit Operation (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Paving at the Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Positioning the Paver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Filling the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Laying the Asphalt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Precautions while Paving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Handling Asphalt Spills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Highway Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Transporting Between Jobsites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Unloading with Ramps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Towing for More Than One Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Transporting for More Than One Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Theft Deterrents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

918215/CP0407 2 Printed in U.S.A

Courtesy of Machine.Market

Page 7

1448 PLUS TABLE OF CONTENTS

Chapter 8

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Greasing and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Hydraulic Fluid Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

All Grease Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Engine Crankcase Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Torque Hubs Gear Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grease Fitting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 9

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Chapter 10

Service and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Dealer Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Engine Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Hydraulic System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Electrical Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operator Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Service Every 10 Hours or Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Spraying Asphalt Contact Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Check Fuel Tank Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check Radiator Coolant Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check Instrument Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check Paver Operation and Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Service Every 50 Hours or Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Check Fan Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Check Hydraulic Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Check Battery Connections/Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Air Cleaner Element Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Lubricate Grease Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Service Every 250 Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Check Screed Bottom Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Change Hydraulic Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Change Engine Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Check Torque Hub Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Service Every 500 Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Change Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Service Every 1000 Hours

or Each Season. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Change Radiator Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Printed in U.S.A 3 918215/CP0407

Courtesy of Machine.Market

Page 8

TABLE OF CONTENTS 1448 PLUS

Replace Hydraulic Oil and Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Check Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Adjusting Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Before Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

During Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

After Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

General Paver Problems During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Paver-Related Mat Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Material-Delivery, Compaction-Related Mat Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Drive and Main Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Hydraulic Pump and Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 12

Decal Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

New Decal Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

918215/CP0407 4 Printed in U.S.A

Courtesy of Machine.Market

Page 9

Chapter 1

INTRODUCTION

The information in this Operator’s Manual was written to give the owner/operator assistance in preparing,

adjusting, maintaining and servicing of the paver. More important, this manual provides an operating plan

for safe and proper use of the machine. Major points of safe operation are detailed in the SAFETY chapter

of this manual.

GEHL Company asks that you read and understand the contents of this manual COMPLETELY and

become familiar with the machine, before operating it.

The use of this asphalt paver (referred to as paver throughout the rest of the manual) is subject to certain

hazards that cannot be eliminated by mechanical means, but only by the exercise of intelligence, care and

common sense. It is therefore essential to have competent and careful operators, who are not physically or

mentally impaired, and who are thoroughly trained in the safe operation of the equipment.

Throughout this manual information is provided that is set in italic type and introduced by the word

IMPORTANT or NOTE. Be sure to read carefully and comply with the message or directive given. Fol-

lowing this information will improve operating and maintenance efficiency, help to avoid breakdowns and

damage, and extend the machine’s life. A chart of standard hardware torques is located in the back of this

manual. “Right” and “left” are determined from a position standing on the screed and facing forward.

A storage compartment is provided on the unit for storing the Operator’s Manual. After using the manual,

please return it to the storage compartment and keep it with the unit at all times! If the machine is resold,

GEHL Company recommends that this manual be given to the new owner.

If this machine was purchased "used," or if the owner's address has changed, please provide your GEHL

dealer or GEHL Company Service Department with the owner's name and current address, along with the

machine model and serial number. This will allow the registered owner information to be updated, so that

the owner can be notified directly in case of an important product issue, such as a safety update program.

The wide GEHL dealership network stands ready to provide any assistance that may be required, including

genuine GEHL service parts. All parts should be obtained from or ordered through your GEHL dealer.

Give complete information about the part and include the model and serial number of the machine. Record

the serial number in the space provided in “Model/Serial Number Information” on page 6, as a handy

record for quick reference.

GEHL Company reserves the right to make changes or improvements in the design or construction of any

part without incurring the obligation to install such changes on any unit previously delivered.

GEHL Company, in cooperation with the Society of Automotive

Engineers, has adopted this

Safety Alert Symbol

to identify potential safety hazards, which, if not properly avoided, could

result in injury. When you see this symbol in this manual or on the

machine itself, you are reminded to BE ALERT! Your personal safety is

involved!

Printed in U.S.A 5 918215/CP0407

Courtesy of Machine.Market

Page 10

INTRODUCTION 1448 PLUS

Model/Serial Number Information

As a handy reference, record the purchase informa-

tion, and the model and serial numbers in the fol-

lowing spaces.

Purchased from: ________________________

Date of Purchase: _______________________

Model No.: ____________________________

Serial No.: _____________________________

Fig. 1 - Serial Number Decal

918215/CP0407 6 Printed in U.S.A

Courtesy of Machine.Market

Page 11

1448 PLUS INTRODUCTION

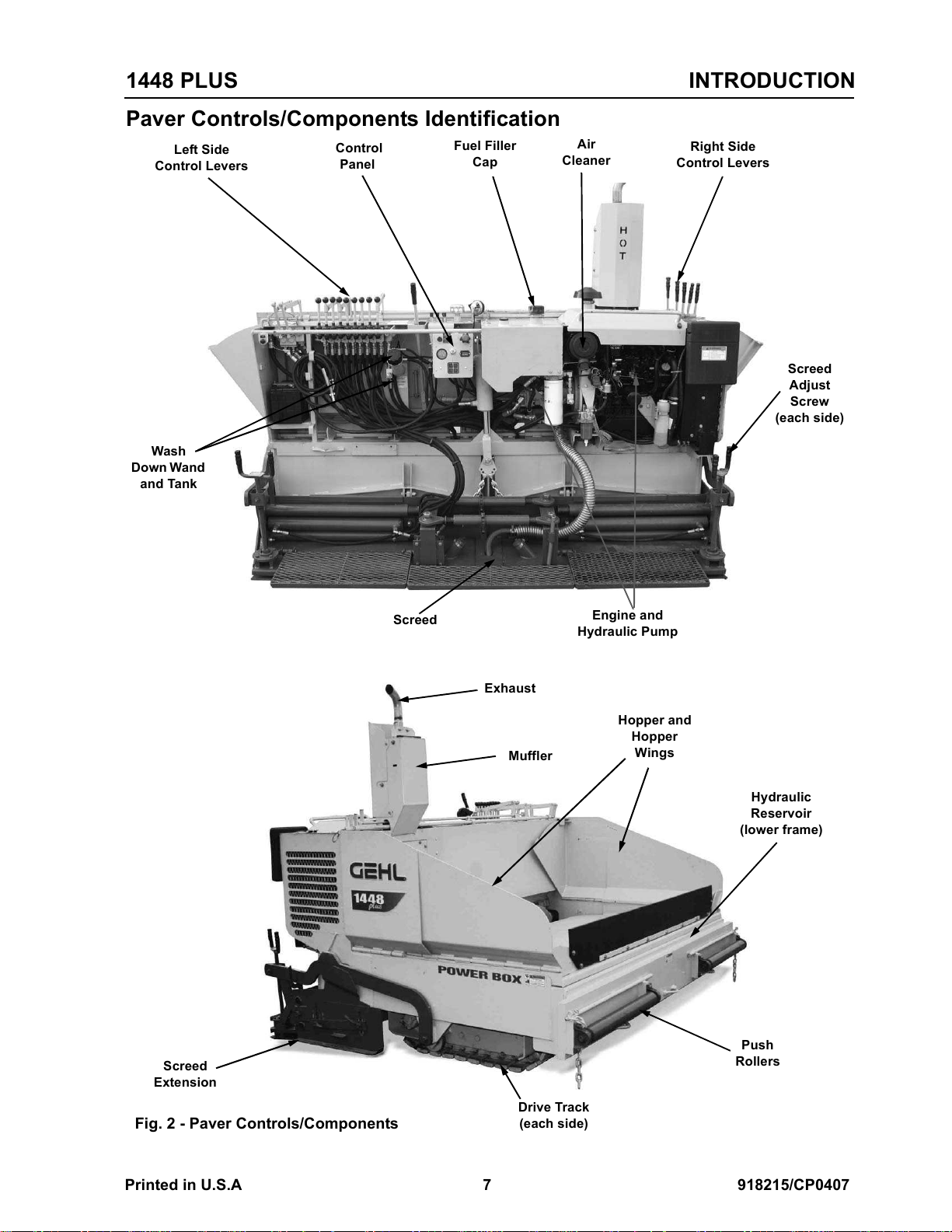

Paver Controls/Components Identification

Left Side

Control Levers

Wash

Down Wand

and Tank

Control

Panel

Fuel Filler

Cap

Air

Cleaner

Right Side

Control Levers

Screed

Adjust

Screw

(each side)

Screed

Extension

Fig. 2 - Paver Controls/Components

Screed

Exhaust

Muffler

Drive Track

(each side)

Engine and

Hydraulic Pump

Hopper and

Hopper

Wings

Hydraulic

Reservoir

(lower frame)

Push

Rollers

Printed in U.S.A 7 918215/CP0407

Courtesy of Machine.Market

Page 12

INTRODUCTION 1448 PLUS

NOTES

918215/CP0407 8 Printed in U.S.A

Courtesy of Machine.Market

Page 13

Chapter 2

SPECIFICATIONS

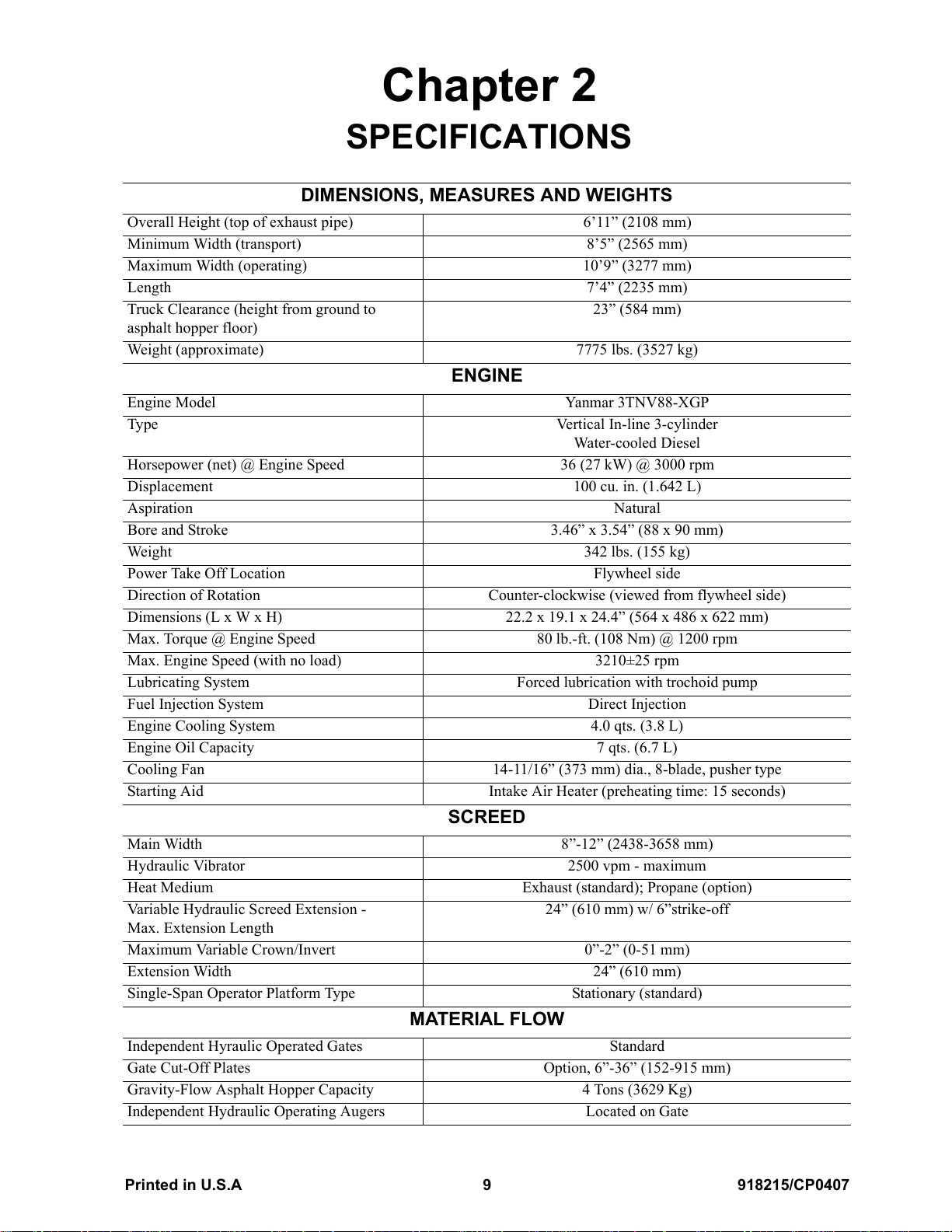

DIMENSIONS, MEASURES AND WEIGHTS

Overall Height (top of exhaust pipe) 6’11” (2108 mm)

Minimum Width (transport) 8’5” (2565 mm)

Maximum Width (operating) 10’9” (3277 mm)

Length 7’4” (2235 mm)

Truck Clearance (height from ground to

asphalt hopper floor)

Weight (approximate) 7775 lbs. (3527 kg)

ENGINE

Engine Model Yanmar 3TNV88-XGP

Type Vertical In-line 3-cylinder

Horsepower (net) @ Engine Speed 36 (27 kW) @ 3000 rpm

Displacement 100 cu. in. (1.642 L)

Aspiration Natural

Bore and Stroke 3.46” x 3.54” (88 x 90 mm)

Weight 342 lbs. (155 kg)

Power Take Off Location Flywheel side

Direction of Rotation Counter-clockwise (viewed from flywheel side)

Dimensions (L x W x H) 22.2 x 19.1 x 24.4” (564 x 486 x 622 mm)

Max. Torque @ Engine Speed 80 lb.-ft. (108 Nm) @ 1200 rpm

Max. Engine Speed (with no load) 3210±25 rpm

Lubricating System Forced lubrication with trochoid pump

Fuel Injection System Direct Injection

Engine Cooling System 4.0 qts. (3.8 L)

Engine Oil Capacity 7 qts. (6.7 L)

Cooling Fan 14-11/16” (373 mm) dia., 8-blade, pusher type

Starting Aid Intake Air Heater (preheating time: 15 seconds)

23” (584 mm)

Water-cooled Diesel

SCREED

Main Width 8”-12” (2438-3658 mm)

Hydraulic Vibrator 2500 vpm - maximum

Heat Medium Exhaust (standard); Propane (option)

Variable Hydraulic Screed Extension -

Max. Extension Length

Maximum Variable Crown/Invert 0”-2” (0-51 mm)

Extension Width 24” (610 mm)

Single-Span Operator Platform Type Stationary (standard)

24” (610 mm) w/ 6”strike-off

MATERIAL FLOW

Independent Hyraulic Operated Gates Standard

Gate Cut-Off Plates Option, 6”-36” (152-915 mm)

Gravity-Flow Asphalt Hopper Capacity 4 Tons (3629 Kg)

Independent Hydraulic Operating Augers Located on Gate

Printed in U.S.A 9 918215/CP0407

Courtesy of Machine.Market

Page 14

SPECIFICATIONS 1448 PLUS

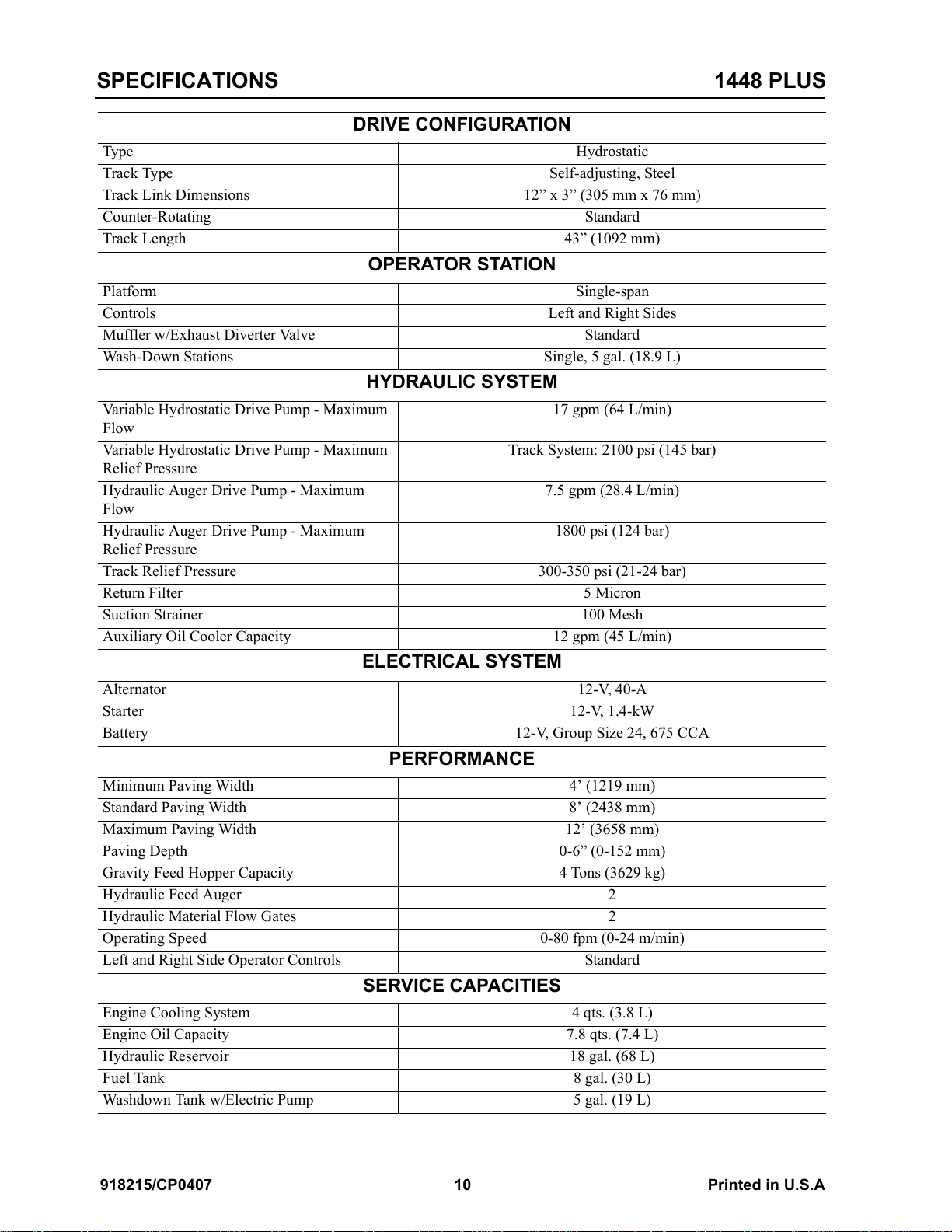

DRIVE CONFIGURATION

Type Hydrostatic

Track Type Self-adjusting, Steel

Track Link Dimensions 12” x 3” (305 mm x 76 mm)

Counter-Rotating Standard

Track Length 43” (1092 mm)

OPERATOR STATION

Platform Single-span

Controls Left and Right Sides

Muffler w/Exhaust Diverter Valve Standard

Wash-Down Stations Single, 5 gal. (18.9 L)

HYDRAULIC SYSTEM

Variable Hydrostatic Drive Pump - Maximum

Flow

Variable Hydrostatic Drive Pump - Maximum

Relief Pressure

Hydraulic Auger Drive Pump - Maximum

Flow

Hydraulic Auger Drive Pump - Maximum

Relief Pressure

Track Relief Pressure 300-350 psi (21-24 bar)

Return Filter 5 Micron

Suction Strainer 100 Mesh

Auxiliary Oil Cooler Capacity 12 gpm (45 L/min)

17 gpm (64 L/min)

Track System: 2100 psi (145 bar)

7.5 gpm (28.4 L/min)

1800 psi (124 bar)

ELECTRICAL SYSTEM

Alternator 12-V, 40-A

Starter 12-V, 1.4-kW

Battery 12-V, Group Size 24, 675 CCA

PERFORMANCE

Minimum Paving Width 4’ (1219 mm)

Standard Paving Width 8’ (2438 mm)

Maximum Paving Width 12’ (3658 mm)

Paving Depth 0-6” (0-152 mm)

Gravity Feed Hopper Capacity 4 Tons (3629 kg)

Hydraulic Feed Auger 2

Hydraulic Material Flow Gates 2

Operating Speed 0-80 fpm (0-24 m/min)

Left and Right Side Operator Controls Standard

SERVICE CAPACITIES

Engine Cooling System 4 qts. (3.8 L)

Engine Oil Capacity 7.8 qts. (7.4 L)

Hydraulic Reservoir 18 gal. (68 L)

Fuel Tank 8 gal. (30 L)

Washdown Tank w/Electric Pump 5 gal. (19 L)

918215/CP0407 10 Printed in U.S.A

Courtesy of Machine.Market

Page 15

Chapter 3

CHECKLISTS

Pre-Delivery

The following Checklist is an important reminder of

valuable information and inspections that MUST be

made before delivering the machine to the customer.

Check off each item after the prescribed action is

taken.

Check That:

R No parts of Paver have been damaged in shipment.

Check for such things as dents and loose or missing

parts; correct or replace components as required.

R Battery is securely mounted and not cracked. Cable

connections are tight.

R Cylinders, hoses and fittings are not damaged, leaking

or loosely secured.

R Oil, fuel and air filters are not damaged leaking or

loosely secured.

R All grease fittings have been properly lubricated and no

fittings are missing; see Lubrication chapter of this

manual.

R Hydraulic system reservoir, engine crankcase, and

engine coolant are filled to the proper operating levels.

I acknowledge that pre-delivery procedures were

performed on this unit as outlined on this page.

____________________________________________

Dealership’s Name

____________________________________________

Dealer Representative’s Name

____________________________________________

Date Checklist Filled Out

____________________________________________

Paver Model # Serial # Engine Serial #

Delivery

The following Checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time the unit is delivered. Check off

each item as you explain it to the customer.

Check That:

Review with the customer the contents of this manual;

especially:

R All adjustments have been made to comply with the

settings given in this manual and in the separate engine

manual.

R All guards, shields and decals are in place and securely

attached.

R Model and serial number for this unit are recorded in

space provided on this page and page 6.

Start the engine and test run the unit while

checking that all controls operate properly.

Check That:

R All indicators (lamps, meters, etc.) function properly.

R Proper operation of all hopper and screed controls.

R Dynamic braking in effect with drive motors in neutral.

R No hydraulic system leaks when under pressure.

R Listen for abnormal noises or vibrations; if detected,

determine their cause and repair as necessary.

R The index at the back, for quickly locating topics;

R The Safety, Indicators and Controls and Operation

chapters for information regarding safe use of the

machine.

R The Lubrication, Service and Storage and

Troubleshooting chapters, for information regarding

proper maintenance of the machine. Explain that regular

lubrication and maintenance are required for continued

safe operation and long life.

R Give this Operator’s Manual and the AEM Safety

Manual to the customer and instruct them to be sure to

read and completely understand the contents before

operating the unit.

R Explain that the customer must consult the engine

manual (provided) for related specifications, operating

adjustments and maintenance instructions.

R Completely fill out the Owner’s Registration, including

customer’s signature, and return it to the Company.

R Explain that a copy of the product warranty is included

on the inside front cover of this operator’s manual.

____________________________________________

Customer’s Signature

____________________________________________

Date Delivered

Printed in U.S.A 11 918215/CP0407

Courtesy of Machine.Market

Page 16

CHECKLISTS 1448 PLUS

NOTES

918215/CP0407 12 Printed in U.S.A

Courtesy of Machine.Market

Page 17

CHECKLISTS

Pre-Delivery

The following Checklist is an important reminder of

valuable information and inspections that MUST be

made before delivering the machine to the customer.

Check off each item after the prescribed action is

taken.

Check That:

R No parts of Paver have been damaged in shipment.

Check for such things as dents and loose or missing

parts; correct or replace components as required.

R Battery is securely mounted and not cracked. Cable

connections are tight.

R Cylinders, hoses and fittings are not damaged, leaking

or loosely secured.

R Oil, fuel and air filters are not damaged leaking or

loosely secured.

R All grease fittings have been properly lubricated and no

fittings are missing; see Lubrication chapter of this

manual.

R Hydraulic system reservoir, engine crankcase, and

engine coolant are filled to the proper operating levels.

I acknowledge that pre-delivery procedures were

performed on this unit as outlined on this page.

____________________________________________

Dealership’s Name

____________________________________________

Dealer Representative’s Name

____________________________________________

Date Checklist Filled Out

____________________________________________

Paver Model # Serial # Engine Serial #

Delivery

The following Checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time the unit is delivered. Check off

each item as you explain it to the customer.

Check That:

Review with the customer the contents of this manual;

especially:

R All adjustments have been made to comply with the

settings given in this manual and in the separate engine

manual.

R All guards, shields and decals are in place and securely

attached.

Remove dealer’s file copy at this line.

R Model and serial number for this unit are recorded in

space provided on this page and page 6.

Start the engine and test run the unit while

checking that all controls operate properly.

Check That:

R All indicators (lamps, meters, etc.) function properly.

R Proper operation of all hopper and screed controls.

R Dynamic braking in effect with drive motors in neutral.

R No hydraulic system leaks when under pressure.

R Listen for abnormal noises or vibrations; if detected,

determine their cause and repair as necessary.

R The index at the back, for quickly locating topics;

R The Safety, Indicators and Controls and Operation

chapters for information regarding safe use of the

machine.

R The Lubrication, Service and Storage and

Troubleshooting chapters, for information regarding

proper maintenance of the machine. Explain that regular

lubrication and maintenance are required for continued

safe operation and long life.

R Give this Operator’s Manual to the customer and

instruct them to be sure to read and completely

understand the contents before operating the unit.

R Explain that the customer must consult the engine

manual (provided) for related specifications, operating

adjustments and maintenance instructions.

R Completely fill out the Owner’s Registration, including

customer’s signature, and return it to the Company.

R Explain that a copy of the product warranty is included

on the inside front cover of this operator’s manual.

____________________________________________

Customer’s Signature

____________________________________________

Date Delivered

Printed in U.S.A 13 918215/CP0407

Courtesy of Machine.Market

Page 18

CHECKLISTS 1448 PLUS

NOTES

918215/CP0407 14 Printed in U.S.A

Courtesy of Machine.Market

Page 19

Chapter 4

SAFETY

The above safety alert symbol means

ATTENTION! BE ALERT! SAFETY IS

INVOLVED! It stresses an attitude of “safety

awareness” and can be found throughout this

operator’s manual and on the paver.

Before operating the paver, read and study the

following safety information. In addition,

anyone who operates or works with the paver

must be familiar with these safety precautions.

Gehl Company always takes operator’s safety into

consideration during the design process. Guards

and shield are provided, protecting the operator

and bystanders from moving parts or other hazards.

Owners and operators must be alert, however,

because some areas cannot be guarded or shielded

without preventing or interfering with proper

operation. Additionally, this operator’s manual and

decals on the paver warn of additional hazards and

should be read and observed closely.

DANGER

REMEMBER: It is the owner’s responsibility to

communicate information about the safe use and

proper maintenance of the paver! This includes

providing understandable interpretations of these

instructions for operators who are not fluent in

reading English.

Pavers should be operated only by qualified

operators. It is the responsibility of the operator to

read and understand this operator’s manual and to

follow correct operating procedures.

MANDATORY SAFETY

SHUTDOWN PROCEDURE

BEFORE cleaning, adjusting, lubricating or

servicing the paver:

1. Bring paver to full stop on a level surface.

NEVER park on a slope or hillside, but if it

is not possible to avoid, park across the

slope and block the tracks at both ends.

2. Place all controls in neutral.

3. Move the throttle to low idle.

“DANGER” indicates an imminently hazardous

situation that, if not avoided, will result in death

or serious injury.

WARNING

“WARNING” indicates a potentially hazardous

situation that, if not avoided, could result in

death or serious injury.

CAUTION

“CAUTION” indicates a potentially hazardous

situation that, if not avoided, may result in

minor injury or property damage. It also alerts

users to unsafe practices.

4. Shut off the engine and remove the key.

5. Lower the hopper and screed assembly to

the “full down” position. Allow the screed

to cool before lowering for transport.

ONLY when you have taken these precautions

can you be sure it is safe to proceed. Failure to

follow the above procedure could lead to death

or serious injury.

Safety Reminders

• User/operator safety practices are included in

this operator’s manual and are intended to

promote the safe operation of the paver. These

guidelines do not preclude the use of good

judgment, care and common sense as indicated

by the specific jobsite work conditions.

• It is essential that operators be physically and

mentally fit and free of mind-altering drugs

and chemicals.

Printed in U.S.A 15 918215/CP0407

Courtesy of Machine.Market

Page 20

SAFETY

(Continued)

• It is essential that operators be thoroughly

trained in the safe operation of the paver. Such

training should be presented completely to all

new operators and not condensed for those

claiming previous experience.

• Some illustrations in this manual may show

doors, guards and shields open or removed.

This is for illustration purposes only. Be sure

that all doors, guards and shields are in their

proper operating positions before starting the

engine to operate the paver.

Pre-operation Safety Reminders

• Always wear personal protective equipment

appropriate for the job and working conditions.

Hard hats, safety glasses, protective shoes,

gloves, reflective vests, respirators and ear

protection are examples of types of equipment

that may be required. Do not wear loose-fitting

clothing, long hair, jewelry or loose personal

items while operating or servicing the paver.

• Always check the job site for obstructions and

bystanders.

• Always perform a daily inspection of the paver

before using it. Look for damage, loose or

missing parts, leaks, etc.

• Walk around the paver and warn all nearby

personnel before starting the paver.

Operation Safety Reminders

• Do not use ether or other starting fluids to start

the paver engine. Doing so may void the

engine warranty.

• Do not attempt to move hot asphalt mix with

your hands or feet. Contact with hot asphalt

can cause serious skin burns.

• Do not allow minors or any unqualified

personnel to operate or be near the paver

unless properly supervised.

• Do not operate the paver in an enclosed area

without adequate ventilation. Internal

combustion engines deplete the oxygen supply

within enclosed spaces and may create a

serious hazard unless the oxygen is replaced.

• Do not leave the paver unattended with the

engine running. Always lower the hopper to

“full down” position, shut off the engine, and

place all controls in neutral before leaving the

paver.

• Do not jump off the paver. Do not dismount

from the paver while it is moving.

• Check paver for proper functioning of controls

before operating. Observe all gauges and

instruments, and correct any malfunctions

before operating.

• Do not lift the hopper if pushing a dump truck

with the paver. Damage to the paver/truck may

result.

Service Safety Reminders

• Never use your hands to search for hydraulic

fluid leaks. Use a piece of paper or cardboard

instead. Escaping fluid under pressure can be

invisible and can penetrate the skin and cause

serious injury. If any fluid is injected into your

skin, see a doctor at once. Injected fluid must

be surgically removed by a doctor familiar

with this type of injury or gangrene may result.

• Never attempt to bypass the keyswitch to start

the engine. Only use the jump starting

procedure described in this manual. See

“Jump-starting” on page 57.

• Never use fuel for cleaning purposes.

• Always position the safety props up when

leaving the hopper raised for inspection,

cleaning or service.

918215/CP0407 16 Printed in U.S.A

Courtesy of Machine.Market

Page 21

SAFETY

(Continued)

• Always wear safety glasses with side shields

when striking metal against metal. In addition,

it is recommended that a softer (chip-resistent)

material be used to cushion the blow, such as a

brass drift. Failure to follow could lead to

serious injury to the eyes or other parts of the

body.

• Do not refill the fuel tank when the engine is

hot. Allow engine to cool before refilling to

prevent the hot engine from igniting any

spilled or splashed fuel.

• Do not smoke while filling the fuel tank, while

working on the fuel or hydraulic systems, or

while working around the battery or propane

heater.

• Do not attempt to loosen or disconnect any

hydraulic lines, hoses or fittings without first

relieving hydraulic circuit pressure. Also, be

careful not to touch any hydraulic components

that have been in recent operation, because

they can be extremely hot and can cause burns.

• Before performing any service/maintenance on

the paver, always disconnect the battery to

prevent unintentional starting.

• Do not attempt to remove the radiator cap after

the engine has reached operating temperature

or if it is overheated. At operating

temperatures, engine coolant is extremely hot

and under pressure. Always wait for the engine

to cool before attempting to relieve pressure

and remove the radiator cap. Failure to heed

this warning could result in severe burns.

• Dispose of all petroleum-based oils and fluids

properly. Used motor oil may pose a health

risk. Wipe oil from your hands promptly and

wash off any residue. Used motor oil is an

environmental contaminant and may only be

disposed of at approved collection facilities.

Never drain any petroleum-based product on

the ground, dispose of in municipal waste

collection containers, or in metropolitan sewer

systems or landfills. Check state and local

regulations for other requirements.

Screed Propane Heater Safety

Reminders

WARNING

Do not smoke in the area around a paver

equipped with propane burners.

ALWAYS be sure a suitable fire extinguisher is

readily available.

ALWAYS light ignitor with a striker. NEVER use

a cigarette lighter or a match.

Ignitor flame may be invisible in sunlight. Do

not place ignitor near your skin or clothing.

Severe burns will result.

ALWAYS allow the screed to cool before lower-

ing it for transport. Fires could result.

• Only use propane gas with the screed propane

heater.

• Wrench-tighten all fittings.

• Never use oil or grease for lubrication.

• Keep the propane supply cylinder upright at all

times.

• Keep the paver free of dirt and oil.

• Use a regulator valve on the propane supply

cylinder.

• Check the screed propane heater equipment

carefully each time before lighting.

• Do not operate the screed propane heater in an

enclosed area or near flammable material.

• Close all valves when not in use.

• Comply with all federal, state and local

regulations during operation.

Printed in U.S.A 17 918215/CP0407

Courtesy of Machine.Market

Page 22

SAFETY

(Continued)

Modifications, Nameplates,

Markings and Capacities

Modifications and additions that affect capacity or

safe operation of the paver must not be performed

without the prior written approval of the Gehl

Company.

Protective Guards and Warning

Devices

The paver is fitted with protective covers over the

engine area in accordance with industry standards.

They are intended to offer protection to the

operator from physical injury.

A horn is provided, which can be activated from

either side of the paver.

Replacement Parts

To ensure continued safe operation, replace

damaged or wornout parts with genuine GEHL

service parts, before operating the paver. If there is

a decal on a part that is to be replaced, be sure that

the replacement part has the decal applied to it.

918215/CP0407 18 Printed in U.S.A

Courtesy of Machine.Market

Page 23

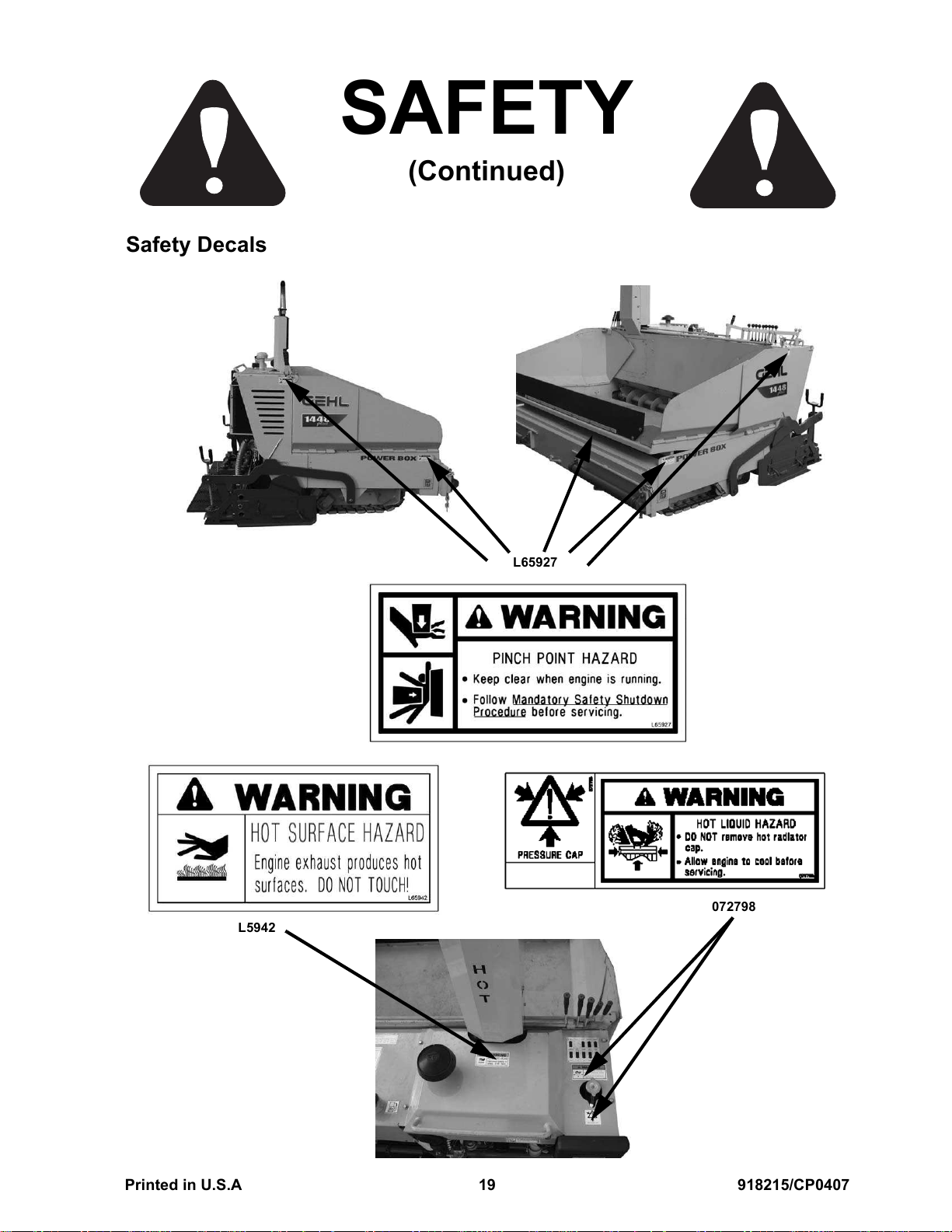

Safety Decals

SAFETY

(Continued)

L65927

072798

L5942

Printed in U.S.A 19 918215/CP0407

Courtesy of Machine.Market

Page 24

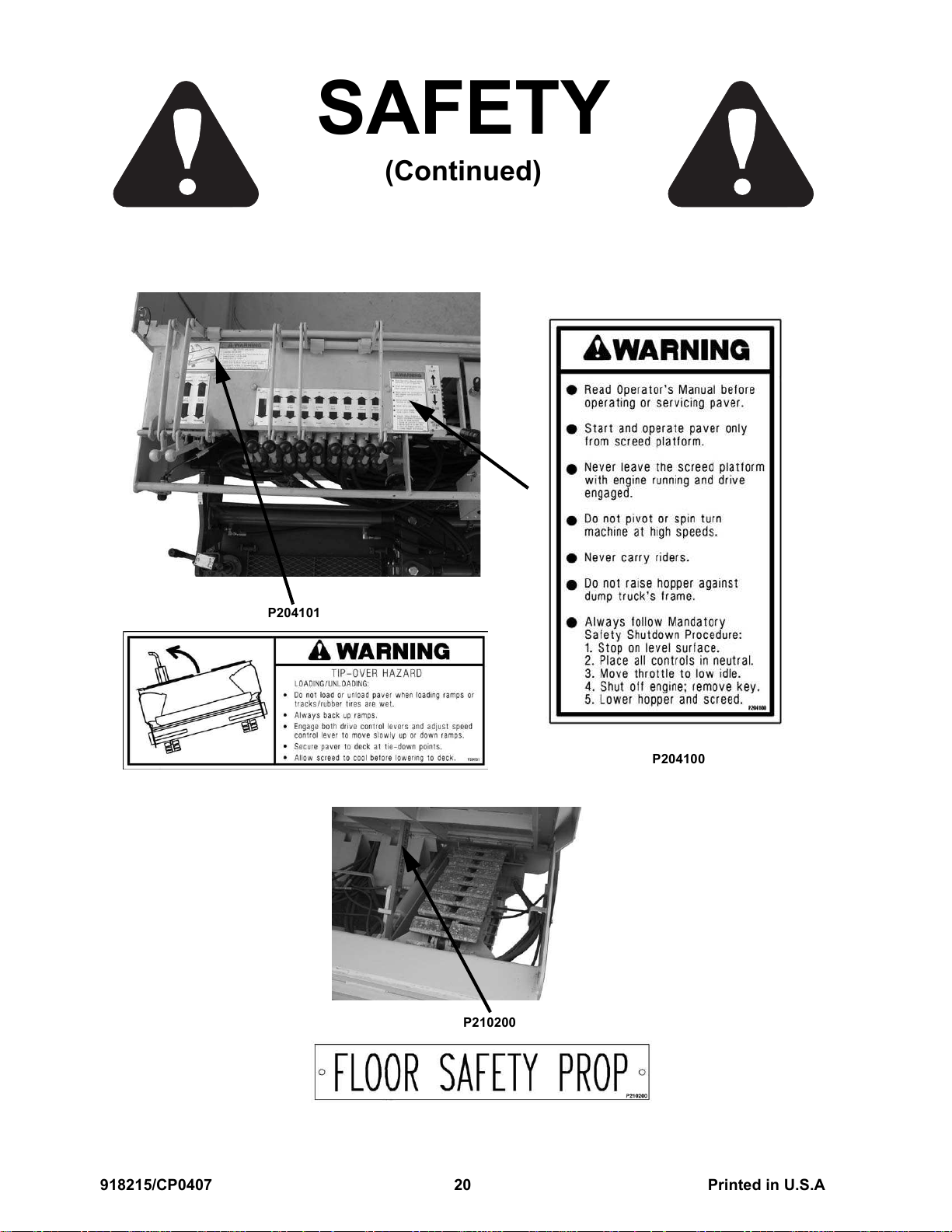

SAFETY

(Continued)

P204101

P204100

P210200

918215/CP0407 20 Printed in U.S.A

Courtesy of Machine.Market

Page 25

SAFETY

(Continued)

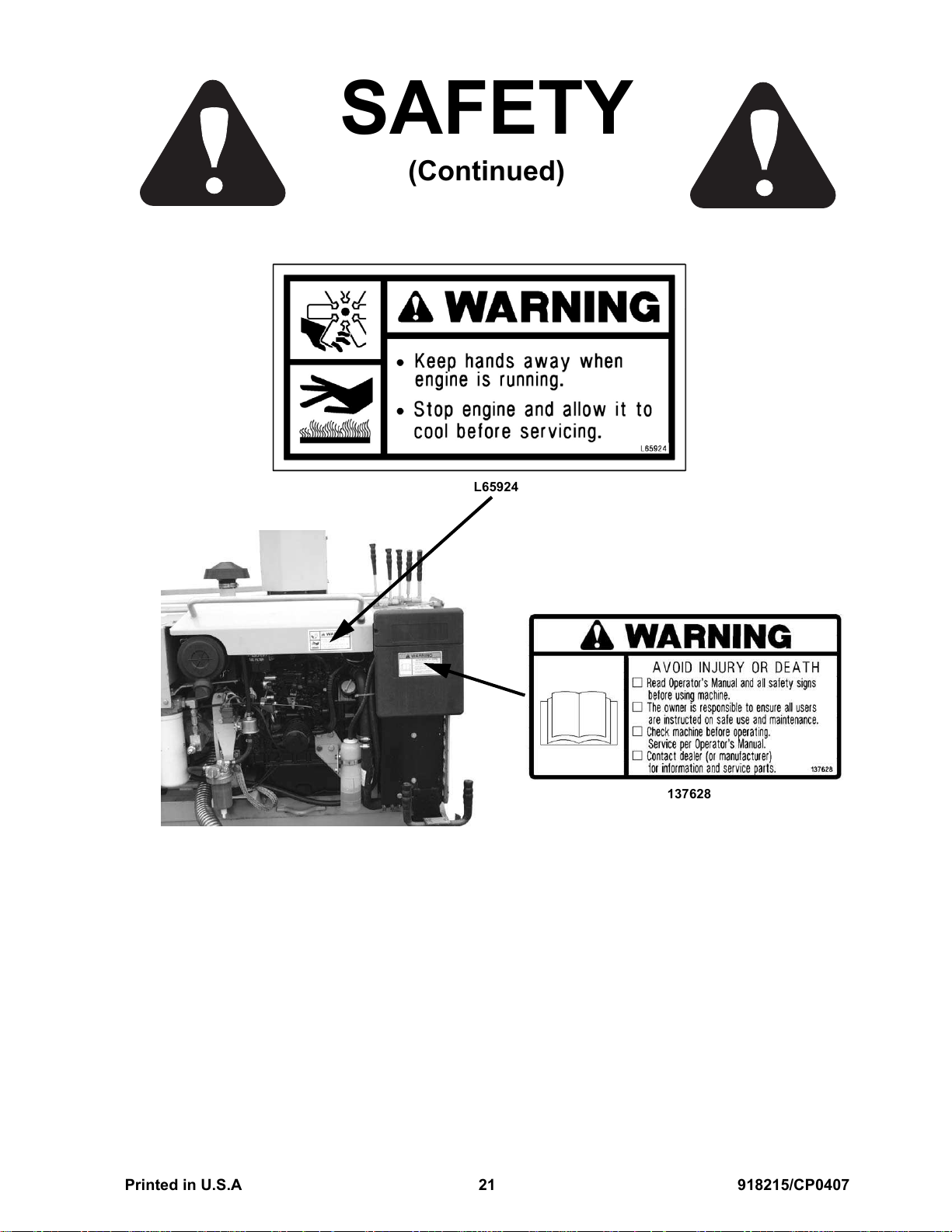

L65924

137628

Printed in U.S.A 21 918215/CP0407

Courtesy of Machine.Market

Page 26

SAFETY

(Continued)

NOTES

918215/CP0407 22 Printed in U.S.A

Courtesy of Machine.Market

Page 27

Chapter 5

INDICATORS AND CONTROLS

Left Control Panel

(backwall)

2

3

1

14

12

13

9 10

8

7

6

5

4

2

5

7

3

11

12

22

15

21

24

16

17

18

19

20

1

Paver Front

23

Right Control Panel

(backwall)

1Horn

2 Left Travel Control

3 Right Travel Control

4 Screed Vibrator Control

5 Hopper Floor Control

6 Left Auger Control

7 Right Auger Control

8 Screed Lift Control

9 Left Flow Gate Control

10 Right Flow Gate Control

11 Left Screed Extension

12 Right Screed Extension

13 Variable Speed Control

14 Fuel Level Indicator

15 Engine Coolant Temperature

16 Engine Throttle

17 Hourmeter

18 Ignition Switch

19 Instrument Module

20 Washdown Sprayer Switch

21 Releasing Agent Reservoir Fill

22 Hydraulic Fluid Reservoir Fill

23 Paving Alignment Guide

24 Exhaust Diverter

Fig. 3 - Indicators and Controls

Printed in U.S.A 23 918215/CP0407

Courtesy of Machine.Market

Page 28

INDICATORS AND CONTROLS 1448 PLUS

Indicator and Control

CAUTION

Before operating the paver, become familiar

with, and know how to use, all safety devices

and controls. Know how to stop the paver

before starting it — refer to “Mandatory Safety

Shutdown Procedure” on page 15.

Descriptions

(Refer to Fig. 3, page 23 for locations)

Ignition Keyswitch

(Item 18, Fig. 3)

Guards and Shields

Whenever possible and without affecting paver

operation, guards and shields are used to protect

potentially hazardous areas. In many places, decals

are also used to warn of potential dangers and to

communicate special operating procedures.

WARNING

Read and thoroughly understand all safety

decals on the paver before operation. Do not

operate the paver unless all factory-installed

guards and shields are properly secured in

place.

Circuit Breaker and In-line Fuses

1

Fig. 4 - Circuit Breaker

The circuit breaker (1, Fig. 4) provides protection

for the entire electrical system. If activated, the

indicator will be extended out. Push in to reset.

In-line fuses, located behind the control panel,

are provided to protect individual components.

Fig. 5 - Keyswitch

STOP Position ( ): When the key is vertical in

the keyswitch, power from the battery is

disconnected from the paver electrical circuits

(except the horn).

NOTE: This is the only position the ignition

key can be inserted or removed from the key

switch.

RUN Position ( ): When the key is rotated

clockwise one position from vertical, power from

the battery is connected to the paver electrical

circuits.

NOTE: The battery charge and engine oil

pressure indicators activate when the key is in

the RUN position. If the engine is below 40° F

(5° C), engine pre-heating is activated (see

item D in “Instrument Module” on page 25).

START Position ( ): Rotating the key clockwise

two positions from vertical activates the engine

starter. The key will automatically return to the

RUN position when the key is released.

NOTE: If ambient temperature is below 40° F

(5° C) or cold engine does not start, turn key

to RUN position and wait 15 seconds or until

preheat indicator light is off. Then start engine.

See item D in “Instrument Module” on

page 25.

918215/CP0407 24 Printed in U.S.A

Courtesy of Machine.Market

Page 29

1448 PLUS INDICATORS AND CONTROLS

ACC (Accessory) Position ( ): When the key is

rotated counter-clockwise one position from

vertical. The paver accessory electrical circuit is

activated when the key is in this position.

Instrument Module

(Item 19, Fig. 3)

The instrument module is a multi-function

indicator monitoring four engine/system functions.

During power-up, the instrument module performs

a diagnostic self-test. During the self-test, the

module beeps for 3 seconds and the indicator lights

activate. When the self-test is complete, the lights

deactivate unless an error condition is detected.

A

C

IMPORTANT: If the engine oil pressure

indicator activates during normal operation,

STOP the engine immediately. Loss of engine

oil pressure could be an indication of

insufficient engine oil. See “Check Engine Oil

Level” on page 55.

Engine Throttle

(Item 16, Fig. 3)

G

F

E

B

Fig. 6 - Instrument Module

Indicator Description

A - Battery

Charge

B - Engine

Coolant

Temperatu re

C - Engine Oil

Pressure

D - Engine

Pre-Heat

Indicator is activated if a

charge system fault is

detected. Activates if

system voltage is below

12V or over 15V.

Indicator is activated if

engine coolant temperature

exceeds 220° F (104° C).

Once activated, indicator

deactivates when coolant

temperature falls below

210° F (99° C).

Indicator is activated if a

significant loss in engine

oil pressure is detected.

Indicator is activated

during pre-heat. Pre-

heating is required under

cold starting conditions.

Fig. 7 - Engine Throttle

D

The throttle controls engine speed.

To place the throttle into idle position, loosen

the throttle lock ring (G) by rotating it counter-

clockwise, push the red throttle release button (E)

and move the throttle control knob (F) all the way

in against the lock ring (G).

To increase engine speed, loosen the throttle lock

ring (G), press the red throttle release button (E)

and pull the throttle control knob (F) out.

For fine adjustment of the throttle, rotate the

throttle control knob (F) counter-clockwise to

increase engine speed; clockwise to decrease

engine speed.

To lock the throttle in position, rotate the throttle

lock ring (G) clockwise until it is tightened/

engaged.

NOTE: The throttle can be quickly placed into

the idle position by firmly pushing against the

throttle release button.

For normal operation, move the throttle release

button (E) and the throttle control knob (F) as a

unit to prevent undue wear to the throttle

mechanism.

Printed in U.S.A 25 918215/CP0407

Courtesy of Machine.Market

Page 30

INDICATORS AND CONTROLS 1448 PLUS

Horn

(Item 1, Fig. 3)

Fig. 8 - Horn (Either Side of Control Panel)

The horn is activated by pressing the button on

either side of the control panel.

Fuel Level Indicator

(Item 14, Fig. 3)

The exhaust diverter diverts engine exhaust. Pull

the knob OUT to divert engine exhaust through the

screed. This heats up the bottom of the screed

surface when paving. Push the knob IN to divert

engine exhaust out through the muffler.

Engine Coolant Temperature Indicator

(Item 15, Fig. 3)

Fig. 11 - Temperature Indicator

Fig. 9 - Fuel Level Indicator

The fuel level gauge shows the amount of fuel

remaining in the fuel tank.

Exhaust Diverter

(Item 24, Fig. 3)

Fig. 10 - Exhaust Diverter

The engine coolant temperature indicator shows

engine coolant temperature. Normal operating

temperature is 180-200° F (82-93° C).

Hourmeter

(Item 17, Fig. 3)

Fig. 12 - Hourmeter

The hourmeter indicates total paver operating time

and is activated whenever the paver is running. Use

the hourmeter to determine paver maintenance

intervals. See “Maintenance” on page 33.

918215/CP0407 26 Printed in U.S.A

Courtesy of Machine.Market

Page 31

1448 PLUS INDICATORS AND CONTROLS

Washdown Sprayer System

(Items 20 & 21, Fig. 3)

Washdown

Reservoir Fill

and Switch

Washdown

Spray

Nozzle

Hydraulic Fluid Reservoir Fill

(Item 22, Fig. 3)

H

Fig. 14 - Hydraulic Fluid Reservoir Fill

Remove the hydraulic reservoir fill plug to check

the hydraulic fluid level or to add hydraulic fluid.

NOTE: Before removing the hydraulic

reservoir fill plug (H), allow the fluid to cool

for 10-15 minutes. Slowly loosen the breather

cap on the backwall top console to release

system pressure (shown in “Change Hydraulic

Filter” on page 59).

Fig. 13 - Washdown Fill and Spray Nozzle

The washdown sprayer system is used periodically

each day to wash down parts of the paver with an

asphalt releasing agent.

IMPORTANT: Use only releasing agents

approved for use according to environmental

regulations applicable to the area of paver

operation.

WARNING

Do NOT spray releasing agent on a hot engine.

Paving Alignment Guide

(Item 23, Fig. 3)

I

Fig. 15 - Paving Alignment Guide

The adjustable paving alignment guide (I) is used

to align the paver with a curb or the edge of a

previously laid mat of asphalt.

Printed in U.S.A 27 918215/CP0407

Courtesy of Machine.Market

Page 32

INDICATORS AND CONTROLS 1448 PLUS

Travel Controls

The travel controls are used to maneuver the paver

around on the jobsite and for road travel. Decals on

the backwall top console area provide graphic

representation of the various control actions.

Hydraulic Pump Variable-Speed Control

Lever

(Item 13, Fig. 3)

NOTE: Variable-Speed Control Lever

Shown in Neutral Position

These two levers control forward, rearward and

turning travel. The travel levers are mechanically

linked together on both sides of the paver to

provide control from either side.

Travel Type Lever Position

Forward Both levers forward

Reverse Both levers back

Stop both levers returned to

neutral

Left Turn Right lever forward

Right Turn Left lever forward

Spin (paver spins

around its center)

Right/left levers in opposite

directions

NOTE: Turn and/or spin the paver at slow

speeds only.

Fig. 16 - Variable-Speed Control Lever

This lever increases or decreases oil flow to the

drive motors. Push the lever forward to increase

speed; pull rearward to decrease speed. Place the

lever in neutral when not operating to prevent

creating excess heat in the hydraulic system.

NOTE: Lever must be all the way back

(neutral position) to start the engine.

If the paver does not completely stop traveling

when the speed control lever is in the neutral

position, adjustment is required. See “Adjusting

Variable Speed Control” on page 62.

Travel Control Levers

(Items 2 & 3, Fig. 3)

Fig. 18 - Travel Controls

Fig. 17 - Travel Control

918215/CP0407 28 Printed in U.S.A

Courtesy of Machine.Market

Page 33

1448 PLUS INDICATORS AND CONTROLS

Hopper Controls

HOPPER CONTROLS — LEFT SIDE

6

75

HOPPER CONTROLS — RIGHT SIDE

7

Fig. 19 - Hopper Controls

Screed Platform Controls

SCREED CONTROLS — LEFT SIDE

8

10

9

5

Fig. 20 - Screed Platform Controls

4

SCREED CONTROLS — RIGHT SIDE

12

11

12

Hopper Floor Control Lever

(Item 5, Fig. 3 and Fig. 19)

Move the hopper control lever rearward to raise

hopper, forward to lower the hopper. These hopper

control levers are mechanically linked together on

both sides of the paver.

Flow Gate Control Levers

(Items 9 and 10, Fig. 3 and Fig. 19)

The right and left flow gate control levers control

the flow of asphalt out of the hopper. One lever

controls each gate.

Move the levers rearward to open the gates,

forward to close the gates.

Feed Auger Control Levers

(Items 6 and 7, Fig. 3 and Fig. 19)

The feed auger controls are used only with screed

extensions “out.” On the left side of the paver, one

lever controls either the right or left auger with the

right feed auger control lever mechanically linked

to another lever on the right side of the paver.

Move the levers rearward to activate the augers.

Move the levers to “neutral” to deactivate the

augers.

Screed Lift Control Lever

(Item 8, Fig. 3 and Fig. 20)

Move the screed lift control lever rearward to

lower the screed into the paving position. Make

sure the cylinder is fully extended. Move the lever

forward to raise the screed.

Vibrator Control Lever

(Item 4, Fig. 3 and Fig. 20)

The screed vibrator assists in compacting the

asphalt mat passing under the screed. Move the

vibrator control lever rearward to turn the vibrator

on, forward to turn the vibrator off.

Screed Extension Control Levers

(Items 11 and 12, Fig. 3 and Fig. 20)

The screed extensions allow paving an area wider

than eight feet.

On the left side of the paver, one lever controls

either the right or left screed extension with the

right screed extension control lever mechanically

linked to another lever on the right side of the

paver.

Printed in U.S.A 29 918215/CP0407

Courtesy of Machine.Market

Page 34

INDICATORS AND CONTROLS 1448 PLUS

Move the levers forward to move the extensions

inward, rearward to move the extensions outward.

Screed Depth Adjustment

A

Fig. 21 - Screed Depth Adjustment

Screed depth adjustment is controlled with

manually operated adjustment screws (A, Fig. 21)

on both sides of the screed. The adjustment screws

set the thickness of the asphalt mat. Rotate the

screws clockwise to increase the depth, counter-

clockwise to decrease the depth.

NOTE: Indicators on the adjustment screws

provide a reference for mat thickness, but

actual mat thickness must be measured with a

depth gauge.

Mat Crown Adjustment

D

C

Fig. 23 - Mat Crown Adjustment

Mat crown adjustment is controlled by moving the

rod ends (C, Fig. 23) inward or outward using a

ratchet handle (D, Fig. 23). Mat crown is increased

when the rod ends move outward. Mat crown is

decreased when the rod ends move inward.

Screed Propane Heater Kit (Option)

CAUTION

Side Shoe Plate Adjustment

B

Fig. 22 - Side Shoe Plate

Wing nuts (B, Fig. 22) are used to adjust the side

shoe plates on both sides of the screed. Loosen the

wing nuts to adjust the side shoe plates and

re-tighten when the adjustment is complete.

Do NOT smoke in the area around the paver

when equipped with propane burners.

F

Fig. 24 - Screed Propane Heater

A propane heater for the screed is available as an

option. It provides even heating across the bottom

of the screed.

918215/CP0407 30 Printed in U.S.A

Courtesy of Machine.Market

Page 35

1448 PLUS INDICATORS AND CONTROLS

The propane tank regulator (F, Fig. 24) controls

and indicates the pressure of the propane gas

flowing out of the propane tank.

For information about using the propane screed

heating system, see “Screed Propane Heater Kit

Operation (Option)” on page 39.

Accessories

Gehl offers special accessories such as hopper

cut-off and block-off plates, and bolt-on screed

extensions. Contact your area Gehl dealer for

specifications and ordering information.

NOTE: All accessories are field-installed

unless otherwise noted. Information and parts

for field installation of all accessories are

provided by the factory or Gehl paver dealers.

Printed in U.S.A 31 918215/CP0407

Courtesy of Machine.Market

Page 36

INDICATORS AND CONTROLS 1448 PLUS

NOTES

918215/CP0407 32 Printed in U.S.A

Courtesy of Machine.Market

Page 37

Chapter 6

MAINTENANCE

The Maintenance Interval Chart contains the main-

tenance intervals for the service procedures located

in “Service and Storage” on page 53. The “Mainte-

nance Log” on page 34 is for recording the service

procedures performed.

MAINTENANCE INTERVAL CHART

SERVICE

PROCEDURE

Check Fuel Tank Level

Check Fuel Filter

Check Engine Oil

Check Radiator

Coolant Level

Check Fan Belt Tension

Check Instruments

Operation

Clean Areas Contacting

Asphalt

Check General Machine

Operation and Condition

Lubricate Appropriate

Grease Points

Check Hydraulic

Oil Level

Check Battery

Every 10

Hours

(or

Daily)

•

•

•

•

•

•

•

Every 50

Hours

(or

Weekly)

•

•

•

•

IMPORTANT:Under extreme operating

conditions, more frequent maintenance than

the recommended intervals may be required.

Every

1000

Hours

(or Yearly)

First 50

Hours

Every

250

Hours

Every

500

Hours

Change Engine Oil

and Filter

Check Screed Bottom

Plate Wear

Change Hydraulic Filter

Elements

Change Air Cleaner

Element

Printed in U.S.A 33 918215/CP0407

••

•

••

•

Courtesy of Machine.Market

Page 38

MAINTENANCE 1448 PLUS

SERVICE

PROCEDURE

Change Engine Oil

and Filter

Check Torque Hubs

Oil Level

Change Fuel Filter

Inspect Fuel Injection

System

Change Air Cleaner

Element

Change Radiator Coolant

Check Exhaust System

Change Hydraulic Reser-

voir Oil & Sump Strainer

Check Engine

Compression

Every 10

Hours

(or

Daily)

Every 50

Hours

(or

Weekly)

First 50

Hours

Every

250

Hours

•

•

Every

500

Hours

•

•

Every

1000

Hours

(or Yearly)

•

•

•

•

•

NOTE: Recording the 10-hour (or daily) service intervals in the Maintenance Log is not

recommended.

MAINTENANCE LOG

Date Hours Service Procedure

918215/CP0407 34 Printed in U.S.A

Courtesy of Machine.Market

Page 39

1448 PLUS MAINTENANCE

Date Hours Service Procedure

Printed in U.S.A 35 918215/CP0407

Courtesy of Machine.Market

Page 40

MAINTENANCE 1448 PLUS

Date Hours Service Procedure

918215/CP0407 36 Printed in U.S.A

Courtesy of Machine.Market

Page 41

Chapter 7

OPERATION

GENERAL INFORMATION

CAUTION

BEFORE starting the engine and operating the

paver, review and comply with all safety

recommendations in the SAFETY chapter of

this manual. Know how to stop the paver

before starting it.

ENGINE BREAK-IN

IMPORTANT: Do not suddenly change

engine speed or carry heavy loads during the

first 50 hours of operation because this may

damage the engine and shorten engine life.

The paver does not use a special engine "break-in"

oil. Do not add special additives or "break-in"

components to the crankcase. The oil in the engine

crankcase is the same as used for regular oil

changes. Check the oil level frequently and refill as

necessary. See “Check Engine Oil Level” on

page 55. Change the oil and the oil filter at the

intervals in “Service Every 250 Hours” on page 58.

BEFORE STARTING ENGINE

Complete the following steps to start the engine:

1. Turn the keyswitch to the STOP position.

2. Set the throttle control to 1/3 open.

NOTE: If starting a cold engine and the

outside temperature is below 40° F (4° C), turn

the keyswitch to the RUN position and leave it

there for 15 seconds before starting the

engine. Turn key to START position to start

engine. See item D in “Instrument Module” on

page 25.

3. Turn the keyswitch to the START position.

If the engine does not start, turn the keyswitch

to the STOP position. Wait 30 seconds to

allow battery voltage to recover and follow the

cold start procedure noted above.

IMPORTANT: Do not crank the starter for

longer than 15 seconds because the starter

motor overheats. Do not crank the starter if the

engine is either not completely stopped or in

operation because the starter motor pinion or

ring gear will be damaged.

4. After the engine starts, release the keyswitch.

The keyswitch moves to the RUN position.

Before starting the engine and running the paver,

see “Indicators and Controls” on page 23.

STARTING THE ENGINE

Before mounting the screed platform, walk

completely around the paver to make sure no one

is on or close to it. Let others near the paver know

you are going to start the engine and do not start

the engine until everyone has moved away from

the paver.

Place all hydraulic function controls and the

hydraulic pump speed control lever in "neutral"

position.

Printed in U.S.A 37 918215/CP0407

5. Run the engine at a low, consistent speed for

five minutes before operating any controls.

Listen for any abnormal sounds during this

time.

IMPORTANT: Do not run the engine with a

load while the engine is cold because black

smoke is emitted and the life of the engine

may be shortened.

6. Check that indicators are in normal condition.

7. Check the color of the exhaust gas. It should be

light blue or colorless.

8. Check that there are no fuel, oil or engine

coolant leaks.

9. Check that there are no abnormal noises or

vibrations.

Courtesy of Machine.Market

Page 42

OPERATION 1448 PLUS

If the battery is discharged and cannot start the

engine, either charge the battery or jump start the

paver. See “Jump-starting” on page 57.

CAUTION

BEFORE starting the engine and operating the

paver, review and comply with all safety

recommendations in the SAFETY chapter of

this manual. Know how to stop the paver

before starting it.

FIRST TIME OPERATION

Complete the following steps if you are operating

the paver for the first time:

1. Be sure the engine is warm.

2. Learn the control levers.

3. Raise the screed.

4. Move the paver travel control levers

forward and rearward.

5. Make left and right turns using the

travel control levers.

6. Stop the paver, lower the screed, and

activate the vibrator.

7. Divert the exhaust down to the screed.

8. Position the side gates and extensions

in and out.

9. Raise and lower the hopper.

10. Turn the auger motors on and off.

5. Run the engine at a low, consistent speed for

five minutes. Listen for any abnormal sounds

during this time.

6. Shut off the engine and remove the key. Refer

to the “Mandatory Safety Shutdown Proce-

dure” on page 15.

WARNING

Do not turn the keyswitch to “STOP” position

before completing step 5. Turning the key-

switch to “STOP” position before completing

step 5 causes the engine temperature to rise

rapidly and this may cause fire and injury.

IMPORTANT: Do not stop the engine

immediately after removing the load because

the temperature of the engine rises suddenly

when this occurs. If the coolant system is not

allowed to cool the engine before it is shut

down, the engine may be damaged.

GENERAL PAVER OPERATION

Walk-around Inspection

1. Inspect the hydraulic suction hose to be sure it

is firm and not soft.

2. Check for hydraulic leaks.

3. Check the hopper sides and floor clearance.

4. Inspect the screed.

5. Check that safety guards and covers are

in place.

STOPPING THE PAVER

1. Bring paver to full stop on a level surface.

NEVER park on a slope or hillside, but if it is

not possible to avoid, park across the slope and

block the tracks at both ends.

2. Place all controls in neutral.

3. Move the throttle to low idle.

4. Lower the hopper and screed assembly to the

“full down” position. Allow the screed to cool

before lowering for transport.

918215/CP0407 38 Printed in U.S.A

Hands-on Check

1. Check the fuel gauge. Fill the tank before

paving and when necessary.

2. Check the engine oil level and add oil

if necessary.

Courtesy of Machine.Market

Page 43

1448 PLUS OPERATION

IMPORTANT: Follow the manufacturer's

recommendations regarding the use of fuel,

lubricants and oil.

WARNING

To prevent a fire or explosion, allow the engine

to cool down before refilling the fuel tank. A hot

engine could ignite spilled fuel and burn you.

Also, do not smoke while refilling the fuel tank.

3. Check the cooling air intake on the radiator.

4. Check the air cleaner for cleanliness and make

sure that components are tight to prevent

intake of unfiltered air.

5. Check the hourmeter against the fuel filter

change schedule in the maintenance log. See

“Maintenance” on page 33.

6. Check the pump speed control lever for full

travel movement.

If the paver needs repair, is unsafe, or contributes

to an unsafe condition, inform the appropriate

person immediately. Do not operate the machine

until it is repaired or the unsafe condition is

corrected.

Screed Propane Heater Kit Operation

(Option)

1. Check propane heating equipment carefully

each time before lighting.

2. Do NOT operate the propane heater in

enclosed areas or near flammable materials.

CAUTION

Do NOT smoke in the area around the paver

when equipped with propane burners.

E

WARNING

Clean external surface of tracks with asphalt

releasing agent, using the washdown sprayer.

Do not spray releasing agent into tracks imme-

diately before loading or unloading the paver

on a truck/trailer. Wet tracks can slip and lose

traction.

7. Clean the external area of both tracks three to

four times during the work day.

8. Clean all asphalt buildup in the screed platform

exhaust ports located on each end of the

screed.

9. Clean all asphalt buildup inside the tracks.

10. Inspect the paver for loose hardware and

components.

11. Be sure safety guards and covers are in place.

WARNING

F

Fig. 25 - Screed Propane Heater

3. Close the tank valve (E, Fig. 25) and the valves

on the “Y” valve (F, Fig. 25).

4. Slowly open the tank valve.

5. Adjust regulator 15-20 psi (103-138 kPa).

CAUTION

Always light the burners with a striker. NEVER

use a match.

NEVER operate the paver with safety guards or

covers removed.

Printed in U.S.A 39 918215/CP0407

Courtesy of Machine.Market

Page 44

OPERATION 1448 PLUS

• Hopper, augers, and underside of the screed

• Push rollers

• Hydraulic fluid reservoir

G

• Asphalt depth adjustment screws

• External track and sprockets

• Any part of the paver that contacts asphalt

H

Fig. 26 - Burner and Support Tubes

6. Remove one burner (G, Fig. 26) from the

burner support tube (H, Fig. 26) and light with

a striker. Place the burner back into the burner

support tube.

7. Light the second burner in the same way.

8. Re-adjust the regulator to 15-20 psi

(103-138 kPa).

CAUTION

The burner flame may be invisible in sunlight.

Do NOT place the burner near your skin or

clothing. Severe burns may result.

WARNING

Do NOT spray tracks before loading or unload-

ing paver on a truck or trailer, because this

could cause loss of traction.

Positioning the Paver

1. Warm-up the engine.

2. Place throttle in full “open” position. See

“Indicators and Controls” on page 23.

3. Pull out the exhaust diverter knob. The exhaust

will preheat the screed in preparation to lay

asphalt. The throttle should always be at full

speed. The exhaust can be periodically re-

diverted through the muffler.

4. Use the travel control levers to move the paver

into position for laying asphalt.

5. Move the screed control lever to "down" and

hold it until the screed lift cylinder fully

extends (this allows the screed to float freely).

Screed surfaces will be HOT. Do NOT touch.

Severe burns will result.