Page 1

1162/1165

Disc Mower

Form No.

909793

Revision B

OPERATOR’S MANUAL

Page 2

GEHL

NEW AGRICULTURAL EQUIPMENT

DISC MOWER

WARRANTY

GEHL AGRICULTURE DIVISION of the GEHL COMPANY, hereinafter referred to as Gehl,

warrants new Gehl Disc Mowers and attachments, to the Original Retail Purchaser to be free

from defects in material and workmanship for a period of twelve (12) months

for commercial/custom use} from the Warranty Start Date.

GEHL AGRICULTURE WARRANTY INCLUDES:

Genuine Gehl parts and labor costs required to repair or replace equipment at the selling

dealer’s business location.

GEHL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND,

EXPRESS OR IMPLIED (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE), EXCEPT AS

EXPRESSLY STATED IN THIS WARRANTY STATEMENT.

{ninety (90) days

GEHL WARRANTY DOES NOT INCLUDE:

1. Transportation to selling dealer’s business location or, at the option of the Original Retail Purchaser,

the cost of a service call.

2. Used equipment.

3. Components covered by their own non-Gehl warranties, such as tires, trade accessories and

engines.

4. Normal maintenance service and expendable, high wear items.

5. Repairs or adjustments caused by: improper use; non- intended use; failure to follow recommended

maintenance procedures; use of unauthorized attachments; accident or other casualty.

6. Liability for incidental or consequential damages of any type, including, but not limited to lost profits

or expenses of acquiring replacement equipment.

No agent, employee or representative of Gehl has any authority to bind Gehl to any warranty except as

specifically set forth herein. Any of these limitations excluded by local law shall be deemed deleted from this

warranty; all other terms will continue to apply.

Page 3

TABLE OF CONTENTS

Warranty Inside Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Checklists 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Safety 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Controls & Safety Equipment 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Operation 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Adjustments 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Lubrication 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9

Service 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10

Preparing for Field Operation 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 11

Transporting 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 12

Storage 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 13

Troubleshooting 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 14

Set-up & Assembly 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 15

Optional Equipment & Accessories 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 16

Decal Locations 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Hardware Torque Inside Back Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed in U.S.A. 1 909793/BP0805

Page 4

CHAPTER 1

INTRODUCTION

This Operator’s Manual provides information about

maintaining and servicing the DM1162 and DM1165

disc mowers. More important, this manual provides an

operating plan for safe and proper use of the machine.

Major points of safe operation are detailed in the Safety

chapter.

Please read and understand the contents of this manual

completely and become familiar with the machine

before operating it. See your authorized Gehl dealer

with any questions concerning information in the

manual, for additional manuals or for information

concerning availability of manuals in other languages.

Throughout this manual, information is provided that is

set in italic type and introduced by the word NOTE or

IMPORTANT. BE SURE to read carefully and comply

with the message — it will improve operating and

maintenance efficiency, help avoid breakdowns or

damage, and extend machine life.

This Operator’s Manual and an AEM Safety Manual are

provided with the machine. These manuals should stay

with the machine at all times, and should remain with

the machine if it is resold.

If the machine was purchased used, or if the owner’s

address has changed, please provide the Gehl dealer or

Gehl Company Service Department with the current

owner’s name and address, along with the machine

model and serial number. This will allow the owner to

be notified directly in case of an important product

issue, such as a safety update program.

M O D E L N O .

DM116

(Fill In)

S E R I A L N O .

(Fill In)

COMPANY

W E S T B E N D ,

Typical Model & Serial Number Plate

W I 5 3 0 9 5 U S

DO NOT use the machine for any applications or

purposes other that those described in this manual.

Before using the machine with special attachments

other than those approved by Gehl, consult your Gehl

dealer. Any person using non-approved attachments is

responsible for the consequences.

The Gehl dealership network stands ready to provide

any assistance that may be required, including providing genuine Gehl service parts. All service parts should

be obtained from a Gehl dealer. Give complete information about the part and include the model and serial

numbers of machine. Record the serial number in the

space provided above, for quick reference.

The model number and serial number for the machine

are on a plate located on a gusset on the main frame.

“Right” and “left” are determined from a position

standing behind the unit and facing the direction of

travel. From this position, the support leg is on the “left”

side.

A

909793/BP0805 2 Printed in U.S.A.

Gehl Company strives to continuously improve its

products and reserves the right to make changes and

improvements in the design and construction of any part

without incurring the obligation to install such changes

on any machine previously delivered.

Page 5

CHAPTER 2

SPECIFICATIONS

All Dimensions are in Inches (Millimeters) Unless Otherwise Noted

Models & Description:

DM1162 & DM1165 Disc Mower

Cutting Width:

DM1162 94 (2388). . . . . . . . . . . . . . . . . . . .

DM1165 110 (2794). . . . . . . . . . . . . . . . . . .

Minimum Power Required:

DM1162 42 hp (30 kW). . . . . . . . . . . . . . . .

DM1165 50 hp (36 kW). . . . . . . . . . . . . . . .

PTO Drive Speed 540 RPM. . . . . . . . . . . . . . . . . . . .

Hitch Type Category II 3-point. . . . . . . . . . . . . . . . .

Number of Discs:

DM1162 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

DM1165 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disc Speed 2986 RPM. . . . . . . . . . . . . . . . . . . . . . . .

Total Number of Knives:

DM1162 12. . . . . . . . . . . . . . . . . . . . . . . . . .

DM1165 14. . . . . . . . . . . . . . . . . . . . . . . . . .

Transport Width 10 (254) plus width of tractor. . . .

Approximate weight:

DM1162 1180 lbs. (536 kg). . . . . . . . . . . . . .

DM1165 1250 lbs. (568 kg). . . . . . . . . . . . .

Hardware Metric. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Capacities:

Main Drive Gearbox 0.5 U.S. qts. (0.45 Liter). . . . .

Cutterbar 2.1 U.S. qts. (2.0 Liters). . . . . . . . . . . . . . .

Standard Features:

Hydraulic Lift Cylinder & Hoses

Flexible Safety Shield - Supported on Left Side Only

Disc Protection Plates & Skid Shoes

Heavy Duty, Category II, 3-Point Hitch Mount with

Adjustable Lower Link Pins

Heavy Duty PTO with Overrunning Clutch

Six (DM1162) and Seven (DM1165) Disc, Low Pro-

file

Cutterbar with Heavy Duty Gears & Bearings

Easily Replaceable Disc Drive Stations

Right Side Swathing Wheel

Self-supporting when Removed from Tractor

Transport Lock Controlled from Operator’s Seat

Outer Swath Wheel

Optional Features:

Side Deflector Kit

V-type Knives

Printed in U.S.A. 3 909793/BP0805

Page 6

Chapter 2 - Specifications

INTENTIONALLY BLANK

909793/BP0805 4 Printed in U.S.A.

Page 7

CHAPTER 3

CHECKLIST

PRE- DELIVERY

After the disc mower has been completely set-up, the

following inspections MUST be made before delivering it to the customer. Check off each item after it is

completed.

Check that:

Disc mower has been assembled correctly according to

o

instructions in the Set-up & Assembly chapter of the operator’s manual.

The pressure relief valve, which is located in the side of

o

the angle gearbox, is free to operate and not seized up.

All grease fittings have been properly lubricated (see the

o

Lubrication chapter for locations).

The gearbox and cutterbar have been filled to their proper

o

operating levels (see the Lubrication chapter).

All guards, shields and decals are in place and securely at-

o

tached.

All fasteners are properly secured.

o

All adjustments have been made to comply with settings

o

Remove Dealer’s File Copy at Perforation

given in the Adjustments chapter.

Model and serial numbers for the machine are recorded in

o

spaces provided in both checklist pages.

Hook the unit up to a 540 RPM tractor and test

run the unit while making sure that proper

operation is exhibited by all components.

Check that:

The telescoping PTO driveline rotates freely inside the

o

properly chain anchored PTO shields.

All blades and discs are turning freely.

o

All mechanisms are operating smoothly.

o

All hydraulic hose connections are not leaking under pres-

o

sure.

The lift mechanism is operating smoothly and properly.

o

I acknowledge that pre-delivery procedures were performed on the machine as outlined above.

Dealership’s Name

DELIVERY

The following checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time the machine is delivered. Check off

each item as you explain it to the customer.

Check that:

Give the operator’s manual to the customer. Instruct the

o

customer to be sure to read and completely understand the

operator’s manual BEFORE operating the machine.

Explain how to use the Index in the operator’s manual as

o

a quick page number locating guide.

Explain the Safety chapter in the operator’s manual and

o

review it with the customer.

Explain that the machine requires regular lubrication for

o

continued proper operation and long life. Review the Lubrication chapter in the manual with the customer, emphasizing that the oil in the cutterbar and the gearbox MUST

be changed after the first 10 hours of operation.

Explain the function of the PTO slip clutch.

o

Explain the function of the transport lock and how it oper-

o

ates.

Explain the function of the cutterbar breakaway mecha-

o

nism.

Explain the function and value of the PTO safety chain

o

and the flexible sheet cutterbar guard.

Demonstrate the proper use of the spring-loaded PTO

o

locking couplers.

Completely fill out the Owner’s Registration, including

the customer’s signature, and return it to the company.

Customer’s Signature

Date Delivered

(Dealer’s File Copy)

Dealer Representative’s Name

Date Checklist Filled-out

Model Number Serial Number

Printed in U.S.A. 5 909793/BP0805

Page 8

INTENTIONALLY BLANK

(To be removed as Dealer’s File Copy)

909793/BP0805 6 Printed in U.S.A.

Page 9

CHAPTER

CHECKLIST

PRE- DELIVERY

After the disc mower has been completely set-up, the

following inspections MUST be made before delivering

it to the customer. Check off each item after it is

completed.

Check that:

Disc mower has been assembled correctly according to in-

o

structions in the Set-up & Assembly chapter of the operator’s manual.

The pressure relief valve, which is located in the side of

o

the angle gearbox, is free to operate and not seized up.

All grease fittings have been properly lubricated (see the

o

Lubrication chapter for locations).

The gearbox and cutterbar have been filled to their proper

o

operating levels (see the Lubrication chapter).

All guards, shields and decals are in place and securely at-

o

tached.

All fasteners are properly secured.

o

All adjustments have been made to comply with settings

o

Remove Dealer’s File Copy at Perforation

given in the Adjustments chapter.

Model and serial numbers for the machine are recorded in

o

spaces provided on both checklist pages.

Hook the unit up to a 540 RPM tractor and test

run the unit while making sure that proper

operation is exhibited by all components.

Check that:

The telescoping PTO driveline rotates freely inside the

o

properly chain anchored PTO shields.

All blades and discs are turning freely.

o

All mechanisms are operating smoothly.

o

All hydraulic hose connections are not leaking under pres-

o

sure.

The lift mechanism is operating smoothly and properly.

o

I acknowledge that pre-delivery procedures were performed on the machine as outlined above.

DELIVERY

The following Checklist is an important reminder of

valuable information that MUST be passed on to the

customer at the time the machine is delivered. Check off

each item as you explain it to the customer.

Check that:

Give the operator’s manual to the customer. Instruct the

o

customer to be sure to read and completely understand the

operator’s manual BEFORE operating the machine.

Explain how to use the Index in the operator’s manual as

o

a quick page number locating guide.

Explain the Safety chapter in the operator’s manual and

o

review it with the customer.

Explain that the machine requires regular lubrication for

o

continued proper operation and long life. Review the Lubrication chapter in the manual with the customer, empha-

sizing that the oil in the cutterbar and the gearbox MUST

be changed after the first 10 hours of operation.

Explain the function of the PTO slip clutch.

o

Explain to the customer the function of the transport lock

o

and how it operates.

Explain the function of the cutterbar breakaway mecha-

o

nism.

Explain the function and value of the PTO safety chain

o

and the flexible sheet cutterbar guard.

Demonstrate the proper use of the spring-loaded PTO

o

locking couplers.

Completely fill out the Owner’s Registration, including

the customer’s signature, and return it to the company.

Customer’s Signature

Dealership’s Name

Dealer Representative’s Name

Date Checklist Filled-out

Model Number Serial Number

Printed in U.S.A. 7 909793/BP0805

Date Delivered

(Pages 5 & 6 Have Been Removed

at Perforation)

Page 10

CHAPTER 4

SAFETY

The above Safety Alert Symbol means ATTENTION!

BE ALERT! YOUR SAFETY IS INVOLVED! It

stresses an attitude of ‘‘Heads Up for Safety’’ and can be

found throughout this Operator’s Manual and on the

machine itself.

BEFORE YOU ATTEMPT TO OPERATE THE

MACHINE, READ AND STUDY THE FOLLOWING SAFETY INFORMATION. BE SURE THAT

EVERYONE WHO OPERATES OR WORKS

WITH THIS EQUIPMENT IS FAMILIAR WITH

THESE SAFETY PRECAUTIONS.

Gehl Company ALWAYS takes operator safety into

consideration during product design, guarding exposed

moving parts for operator protection wherever possible.

Some areas, however, cannot be guarded or shielded

without adversely effecting operation.

Information in this manual and decals on the machine

warn of hazards. Both this manual and the decals should

be read and observed closely.

DANGER

‘‘DANGER’’ indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

MANDATORY SAFETY SHUTDOWN

PROCEDURE

Work of any type on machinery is always more

hazardous when the machine is in operation.

Therefore, unless expressly instructed to the

contrary, BEFORE unclogging, cleaning, adjusting, lubricating or servicing the machine,

the following MANDATORY SAFETY SHUTDOWN PROCEDURE should ALWAYS be followed:

BEFORE unclogging, cleaning, adjusting, lubricating or servicing the machine:

1. Disengage the tractor PTO.

2. Place the tractor transmission in park and/or

lock brake pedals to prevent tractor movement, then shut off the tractor engine. Lower

the machine until it is resting on firm ground.

3. Remove the tractor ignition key and take it

with you.

4. Wait for all movement to stop.

5. Remove the telescoping PTO drive.

ONLY when you have taken these precautions can

you be sure it is safe to proceed. Failure to follow the

above procedure could lead to death or serious

bodily injury!

WARNING

‘‘WARNING’’ indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

‘‘CAUTION’’ indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. May also alert

against unsafe practices.

909793/BP0805 8 Printed in U.S.A.

SAFETY REMINDERS

It is recommended that the towing tractor be equipped

with an enclosed operator’s cab with safety glass or

polycarbonate windows, or with protective mesh

screens.

Some photographs used in this manual may show doors,

guards and shields open or removed for illustration

purposes ONLY. BE SURE all doors, guards and shields

are in their proper operating positions and securely

attached BEFORE operating the machine.

ALWAYS wear safety glasses with side shields when

striking metal against metal. It is further recommended

that a softer (chip-resistant) material be used to cushion

the blow. Failure to follow these instructions could lead

to serious injury to the eyes or other parts of the body.

Page 11

SAFETY

(Continued)

BEFORE using the disc mower, inspect the cutting

knives, discs and attaching hardware. Do not straighten

bent knives — they must be replaced. Knives MUST be

replaced in pairs.

To ensure continued safe operation, replace damaged or

worn-out parts with genuine Gehl service parts, BEFORE operating the machine.

Regularly inspect the disc mower’s curtain. Replace the

curtain if it is worn or damaged. NEVER operate the

machine unless the protective curtain is in place and

folded down.

NEVER search for hydraulic fluid leaks using your bare

hands — use a piece of cardboard instead. Escaping

fluid under pressure can be invisible and can penetrate

skin and cause serious injury! If any fluid is injected into

the skin, see a doctor at once! Injected fluid MUST BE

surgically removed by a doctor familiar with this type of

injury or gangrene may result.

To avoid injury when changing from the “transport”

position to “operating” position, or “operating” to

“transport” position, BE SURE the immediate area is

clear of people and obstructions BEFORE changing

positions!

Fields to be mowed must be free of obstructions. Keep

people 50 feet (15 m) or more away from the machine

during operation. If an obstruction is encountered

during mowing, stop the unit immediately — follow the

MANDATORY SAFETY SHUTDOWN PROCEDURE! Check the entire disc mower before continuing

use.

DO NOT go near the machine until the discs have

stopped rotating! The mechanism can continue to

operate after the PTO is disengaged!

DO NOT attempt to hand feed or kick any crop or

material into the machine!

DO NOT attempt to mow crop in reverse!

DO NOT mow crop until you ARE SURE that the field

to be mowed is free of obstructions!

REMEMBER, it is the owner’s responsibility to com-

municate information about the safe use and proper

maintenance of the machine.

WARNING

DO NOT use the DM1162 or DM1165 Mower for

roadside cutting. DO NOT operate near

people.

Printed in U.S.A. 9 909793/BP0805

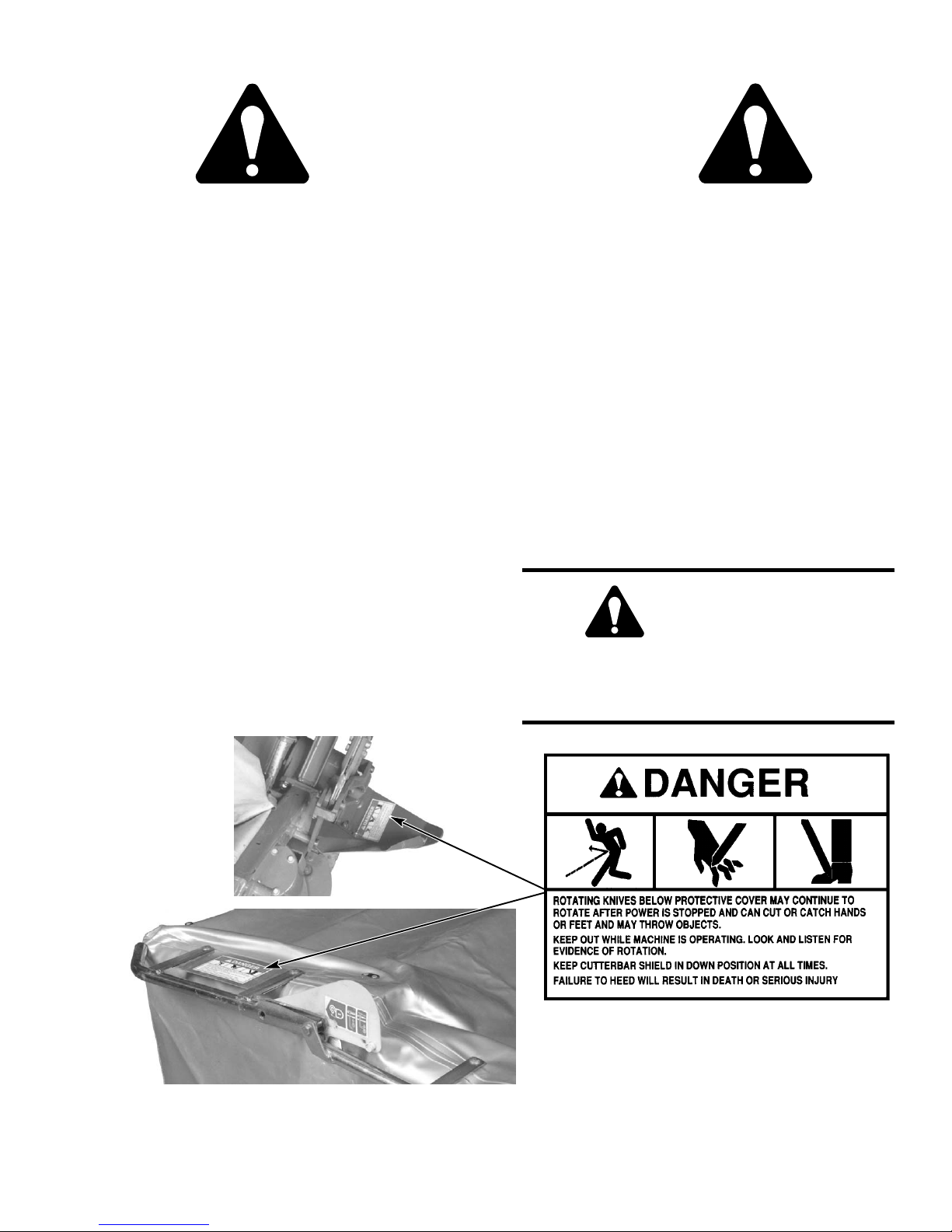

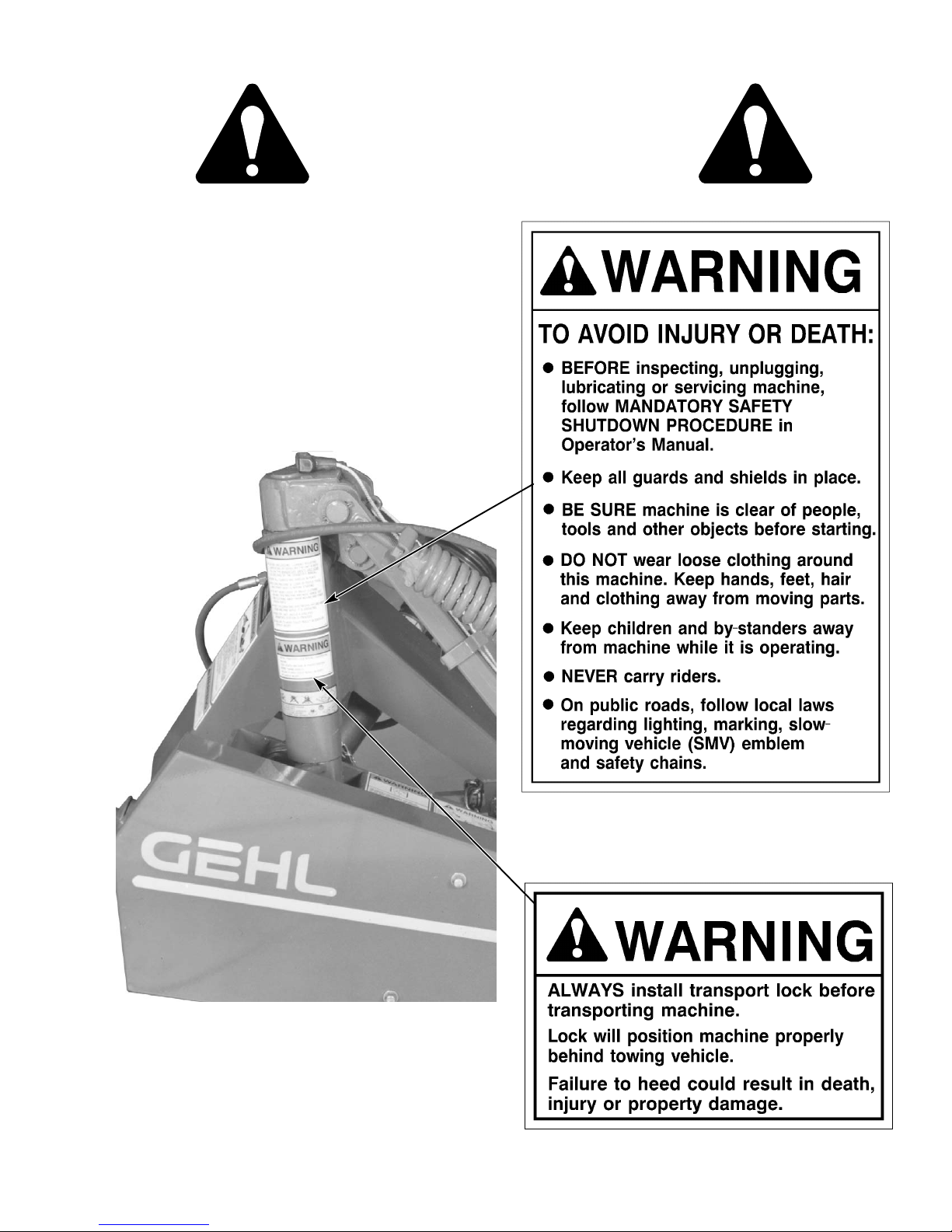

125476

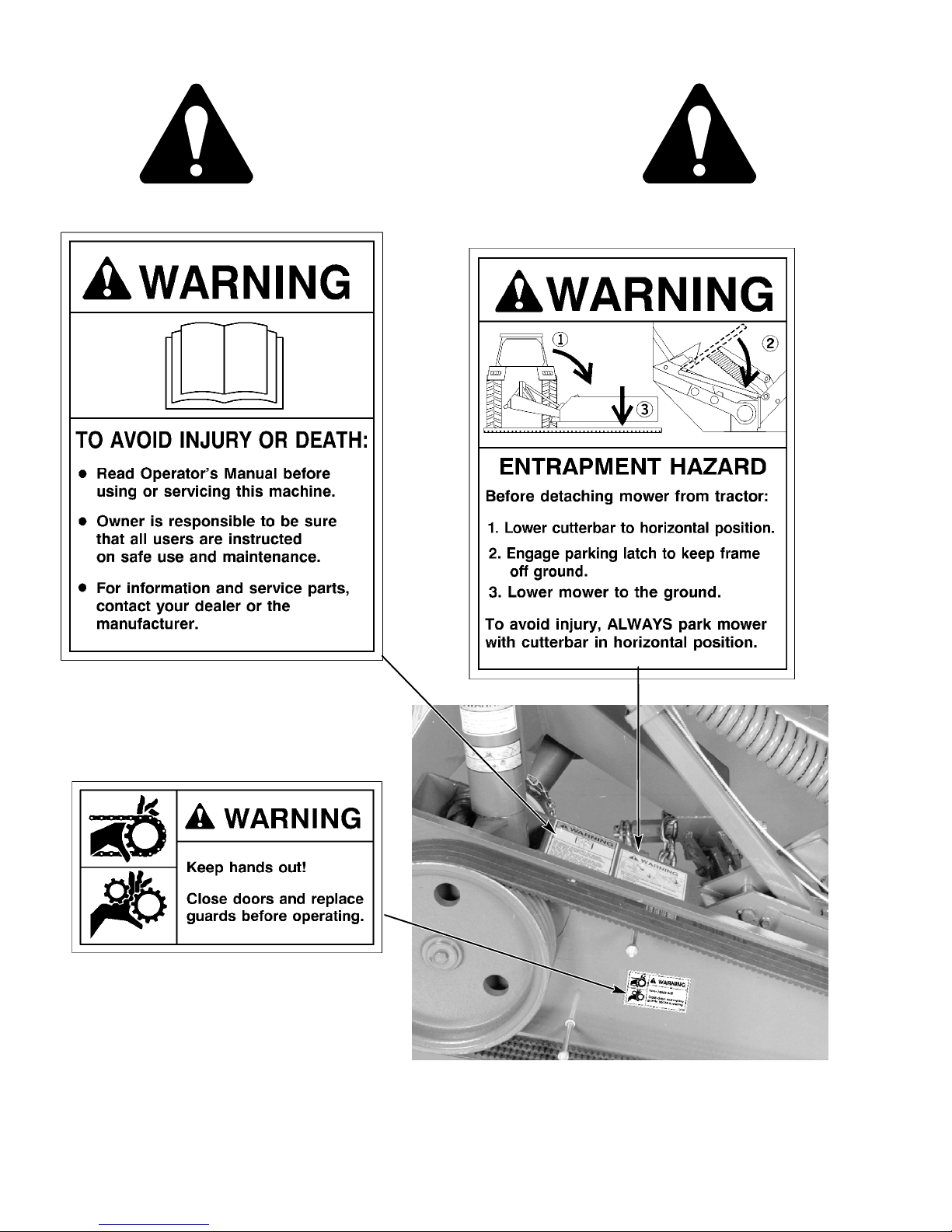

Page 12

SAFETY

(Continued)

093367

163957

142375

909793/BP0805 10 Printed in U.S.A.

Page 13

SAFETY

(Continued)

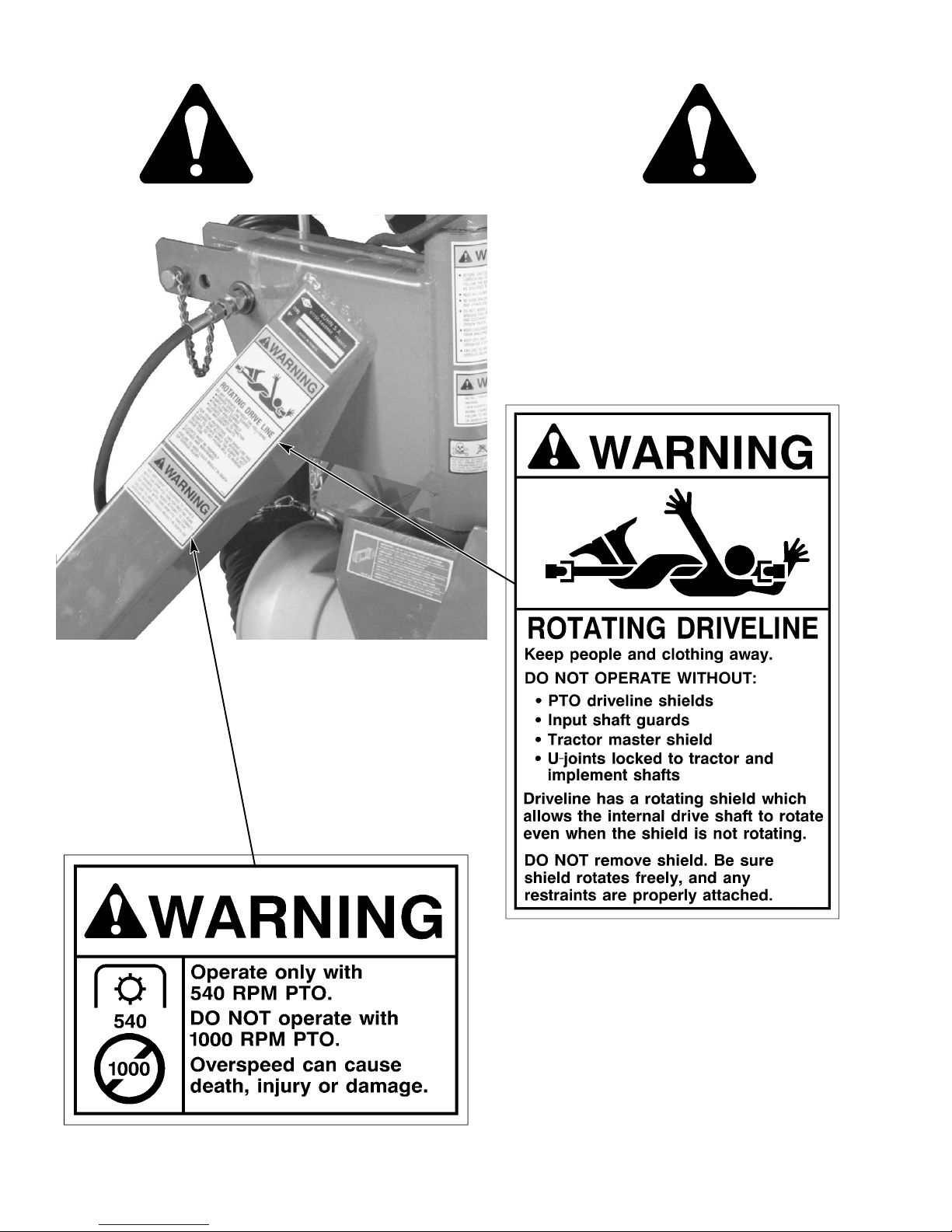

Printed in U.S.A. 11 909793/BP0805

093373

093381

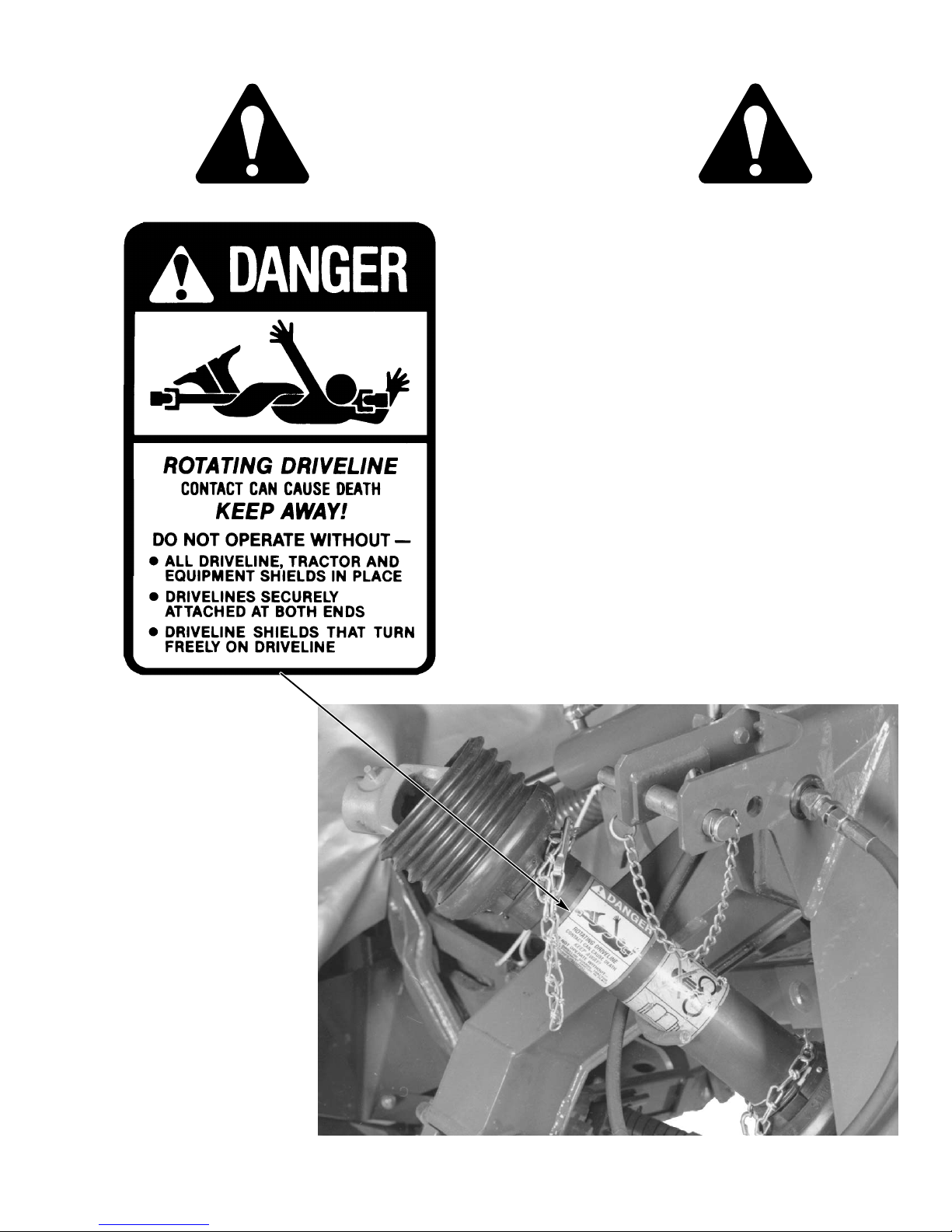

Page 14

SAFETY

(Continued)

909793/BP0805 12 Printed in U.S.A.

093653

093466

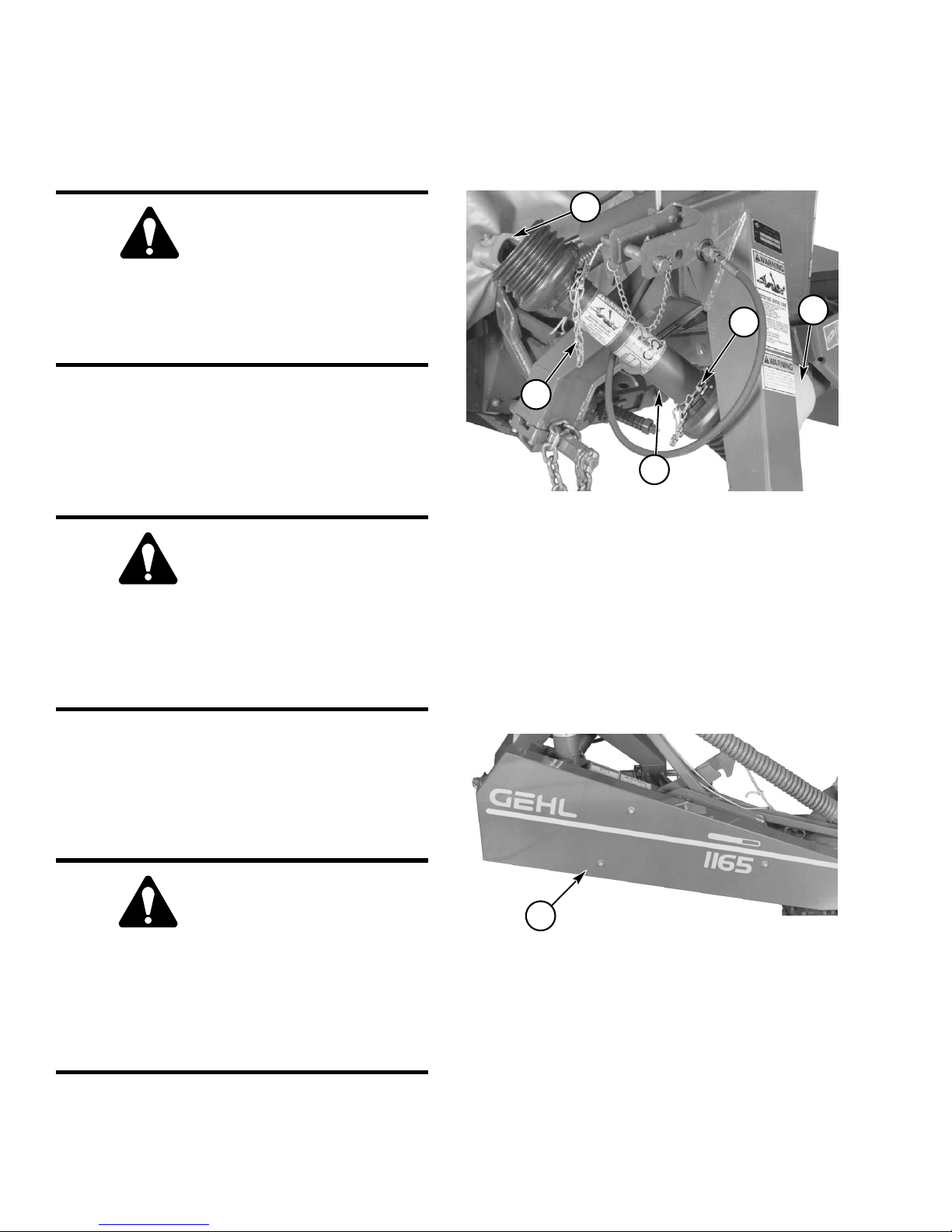

Page 15

SAFETY

(Continued)

091444

Printed in U.S.A. 13 909793/BP0805

Page 16

CHAPTER 5

CONTROLS & SAFETY EQUIPMENT

CAUTION

Become familiar with and know how to use

ALL safety devices and controls on the disc

mower BEFORE operating it. Know how to

stop disc mower operation before starting.

2

4

3

GUARDS, COVERS & SHIELDS

Where possible (without affecting machine operation),

guards, covers and shields are used to protect potentially

hazardous areas. In many places, decals are also

provided to warn of potential hazards as well as to

display special operating procedures.

WARNING

Read and observe ALL warnings on the machine BEFORE operating it. DO NOT operate

the machine unless ALL factory-installed

guards, covers and shields are in place and

properly secured.

Drive Line Shields (Fig . 1)

The telescoping PTO drive, between the disc mower

input shaft and tractor PTO shaft, is equipped with guard

tubes which are held stationary by chains. Be sure the

front chain is attached to tractor and the rear chain is

attached to the disc mower.

3

1

1 - PTO Drive Shield

2 - PTO Drive Coupler

3 - PTO Guard Tube Chain (2 places)

4 - Disc Mower PTO Shield

Fig. 1: Telescoping PTO Driveline Shields

Belt Drive Cover (Fig. 2)

A cover is provided to protect and prevent contact with

the moving drive belts. Be sure the cover is in place and

tightly secured whenever the disc mower is in operation.

WARNING

BEFORE starting the tractor engine, BE SURE

the PTO is properly coupled to the tractor PTO

shaft and mower input shaft. Also, BE SURE

that the PTO guard tubes are properly chained

to the tractor PTO guard and disc mower to

prevent the tubes from turning.

909793/BP0805 14 Printed in U.S.A.

1

1 - Drive Belt Cover

Fig. 2

Page 17

1

2

1 - Protective Cover

2 - Cover Lock Mechanism (Also see Fig. 4)

Fig. 3: Protective Cover in Operating Position

(Folded Down)

Cutterbar Protective Cover (Fig. 3)

WARNING

Chapter 5 - Controls & Safety Equipment

To raise the cover and place it in the transport position:

1. Insert the handle-end of the special box wrench

(Fig. 4, Ref. 3) into the access hole (Fig. 4, Ref.

2). The special box wrench is provided with the

disc mower.

Be sure that the protective cover is in the operating position and properly secured BEFORE starting the tractor engine. The cover

will stop most debris and foreign objects that

might be propelled by the rotating knives and

discs below it, but it may not stop all such material. DO NOT operate near people. NEVER

operate the disc mower with the protective

cover in the raised position.

The protective cover (Fig. 3, Ref. 1) is designed to

contain MOST debris and foreign objects that could be

expelled by the rotating knives and discs below it. This

cover MUST ALWAYS be in the operating position

while the mower is running.

PROTECTIVE COVER LOCK

(Figs. 4 & 5)

The protective cover is provided with a lock (Fig. 4, Ref.

1) which automatically engages when the front half of

the cover is raised and folded over the rear half. This

locking feature secures the cover front half during

transport (when the cutterbar is raised into the vertical

position).

2. Push to release the lock while pulling up on the

cover front half as shown.

3. Fold the cover back until it locks into the transport

position.

1

3

2

1 - Protective Cover Lock Mechanism

2 - Release Access Hole

3 - Special Box Wrench

Fig. 4: Releasing Protective Cover Lock

to Place Cover into Transport Position

Printed in U.S.A. 15 909793/BP0805

Page 18

Chapter 5 - Controls & Safety Equipment

1

1 - Release Lever

Fig. 5: Releasing Protective Cover Lock

To lower the cover and place it in the operating position:

1. Lower the cutterbar into the operating position

(refer to the transport locks section later in this

chapter for proper procedure).

TRANSPORT & OPERATING

POSITION LOCKS (Fig. 6)

Stop lock (Ref. 1) - When in the operating position, this

lock is provided to prevent raising the cutterbar to the

transport position.

Transport hook- type lock (Ref. 2) - When the cutterbar

is moved into the transport position, this lock is

automatically engaged to prevent the cutterbar from

lowering.

Cylinder stroke limiter Lock (Ref. 5) - When in the

operating position and with the hydraulic control set to

“float” position, this lock prevents the cylinder rod

clevis from bottoming against the cylinder packing

gland.

All three of these locks are released by pulling on the

rope release mechanism (Ref. 4).

NOTE: Refer to the Transporting chapter for

proper procedures to place the cutterbar in the

transport and operating positions.

2. Use your fingers or the palm of your hand to apply

pressure on the lever (Fig. 5, Ref. 1) to release the

protective cover lock.

3. While applying pressure to the lever, fold the cover front half forward and down as shown.

4. Release the lever and continue to fold the cover

down until it locks into the operating position.

3

5

4

2

1

3

CAUTION

BEFORE transporting the disc mower on a

public highway or from one field to another,

BE SURE the transport hook lock is properly

engaged.

6

5

4

2

1

1 - Stop Lock

2 - Hook - type Transport Lock

3 - Rope Control Lift Points

Fig. 6: Transport & Operating Position Locks

909793/BP0805 16 Printed in U.S.A.

4 - Rope Control

5 - Cylinder Stroke Limiter

6 - Parking Lock

Page 19

Chapter 5 - Controls & Safety Equipment

PARKING LOCK (See Fig. 6)

The mower is equipped with a parking lock (Fig. 6, Ref.

6) which keeps the 3 - point hitch raised when the mower

is detached from the tractor.

NOTE: Refer to the Transporting chapter for

proper use of the parking lock.

BREAKAWAY LATCH (Fig. 7)

The mower is equipped with a breakaway latch and if an

obstruction is hit, the cutterbar must be free to swing

back. If the latch releases, stop the tractor immediately

and disengage the PTO. To reset the cutterbar, back the

mower until the cutterbar is in its normal position. DO

NOT raise the cutterbar to re-latch the breakaway.

Check for any cutterbar damage before resuming

operation after an obstruction is encountered.

1

2

3

4

IMPORTANT: Before using the mower, BE

SURE all sliding areas (Ref. 1) of the breakaway

latch mechanism are well greased and the

mechanism is operating properly.

Tension on the breakaway latch is determined by the

amount of compression on the spring washer stack (Ref.

3). The tension as set at the factory will be suitable for

most conditions. If the cutterbar continues to break

away, turn the adjustment bolt (Ref. 4) clockwise to

increase the breakaway pressure. (Refer to the Adjustments chapter for additional information.)

IMPORTANT: DO NOT overtighten the

adjustment bolt.

IMPORTANT: In rough field conditions, ground

speed should be reduced to protect the machine

from damage.

TELESCOPING DRIVE COUPLER

(See Fig. 1)

The telescoping drive is equipped with spring-loaded

locking devices to positively lock it onto the tractor PTO

shaft and the disc mower input shaft. Depress the

locking device against the spring tension and slide the

yoke onto the tractor PTO shaft. Release the locking

device and move the yoke ahead or back until the lock

engages into the groove of the PTO shaft. The same

process is used to install the other end of the telescoping

drive line to the disc mower input shaft.

1 - Sliding Area

2 - Latch Mechanism in “Latched” Position

3 - Spring Washer Stack

4 - Adjustment Bolt

Fig. 7: Breakaway Latch

Printed in U.S.A. 17 909793/BP0805

Page 20

CHAPTER 6

OPERATION

FIRST TIME OPERATION

WARNING

If this is the first time you are using the machine, DO NOT start, operate or service it until

you have read and understand the contents of

this manual.

NORMAL OPERATION

CAUTION

BEFORE operating the disc mower, review

and comply with ALL SAFETY recommendations set forth in the SAFETY chapter of this

manual.

WARNING

DO NOT use the DM1162 or DM1165 mower for

roadside cutting. DO NOT operate near

people.

START- UP

WARNING

BE SURE ALL factory- installed guards and

shields are in place and properly secured BEFORE starting the tractor engine. DO NOT operate near people. The protective cover will

contain most debris and foreign objects but

may NOT stop all such material.

When changing the cutterbar from the transport to the

normal operating position and BEFORE engaging the

PTO, ALWAYS allow several minutes for the oil in the

cutterbar to spread. To avoid unnecessary strain on the

disc mower components, ALWAYS engage the tractor

PTO slowly and with the tractor engine at less than half

throttle. Bring the unit to PTO speed BEFORE starting

to cut.

IMPORTANT: Always operate the mower at 540

rpm PTO speed! Operating above 540 rpm could

cause excessive vibration, wear and possible

component failure. Operating the unit below 540

rpm will increase the chances of plugging.

UNPLUGGING

EMERGENCY SHUTDOWN

If crop material is clogging the cutterbar or a foreign

object enters the cutting area, STOP cutting material

IMMEDIATELY by disengaging the tractor PTO and

stopping forward movement. Then, exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE

(page 8) BEFORE leaving the tractor seat to remedy the

problem.

GROUND SPEED

The disc mower can be operated in a wide range of

ground speeds depending on crop conditions and

terrain. Any change in ground speed should be made by

changing tractor gears and NOT by increasing or

decreasing tractor engine RPM.

909793/BP0805 18 Printed in U.S.A.

In certain crop conditions, it is possible for the disc

mower to plug. When plugging occurs, the drive belts

will slip.

To clear a plugging condition in the area of the discs:

1. Disengage the PTO.

2. Raise the mower several inches.

3. Exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8) and apply the

tractor parking brake.

4. Carefully clear the plug from the cutterbar area.

If the plugging occurs frequently, refer to the Troubleshooting chapter for additional directives.

Page 21

Chapter 6 - Operation

ADVERSE FIELD CONDITIONS

WARNING

Use extra caution in fields that may contain

rocks. Use a slower ground speed and tilt cutterbar back towards horizontal. Use of optional v-type knives should be considered.

Extra care and precautions should be taken when

working in rough or difficult terrain. To minimize the

possibility of foreign objects being deflected by the

cutterbar blades, the following adjustments should be

made when operating in adverse field conditions:

1. Adjust the top link (Ref. 1) of the tractor 3-point

hitch to tilt the cutterbar back towards horizontal

and raise the cutting height of the knives.

IMPORTANT: NEVER tilt the cutterbar back past

horizontal as this will lead to premature blade wear.

2. Use a slower ground speed.

3. Be sure the cutting knives can pivot if an obstruction is hit.

1

2

1 - Tractor 3- Point Hitch Top Link

2 - Cutterbar in Horizontal Position

(Maximum Cutting Height - Result when Top

Link is Shorter)

3 - Cutterbar Tilted Forward

(Normal Cutting Height - Result when Top Link

is Longer)

Fig. 8: Cutting Height Adjustment

3

Printed in U.S.A. 19 909793/BP0805

Page 22

CHAPTER 7

ADJUSTMENTS

The DM1162 and DM1165 disc mowers have been

designed and factory adjusted to function properly

under most field operating conditions. However, due to

the wide range of operating conditions that could be

encountered, additional adjustments may be required.

WARNING

BEFORE adjusting the disc mower, exercise

the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8).

4

CUTTING HEIGHT ADJUSTMENT

(Fig. 9)

The cutting height can be changed by tilting the

cutterbar. To tilt the cutterbar, turn the tractor top link on

the 3-point hitch until the desired cutting height is

obtained.

IMPORTANT: If the field being cut is very uneven

or may contain rocks, reduce the cutting angle and

gound speed. Cutting too close to the ground will

cause excessive wear on the cutterbar discs and

knives. In down, tangled and lodged crops, use a

steeper disc angle to obtain a clean cut.

1

1 - 2” (50 mm) Maximum Cutting Height

2 - 1-1/4” (30 mm) Minimum Cutting Height

Fig. 9: Cutting Height Adjustment

3

2

3 - 3-Point Hitch Top Link

4 - Disc Mower Frame

909793/BP0805 20 Printed in U.S.A.

Page 23

DRIVE BELT TENSION (Fig. 10)

The belts MUST be properly tensioned at all times to

prevent slipping. Loose belts will wear out faster and

cause poor cutting.

To tighten the belts:

Use the 18 mm box wrench (Ref. 1 - provided with the

mower) to turn the adjustment bolt until the spacer tube

(Ref. 2) is in contact with the main frame (Ref. 3) and

the washer (Ref. 4).

Chapter 7 - Adjustments

1

NOTE: During initial assembly and when fitting

new V-belts, give two additional complete turns on

the adjustment bolt.

IMPORTANT: It is very important that the belt

tension be checked and adjusted properly,

especially after the first few hours of use. Replace

belts ONLY as a complete set. If one of them

becomes damaged, the whole set must be

replaced.

3

2

1

2

3

4

1 - Sliding Area

2 - Latch Mechanism in “Latched” Position

3 - Spring Washer Stack

4 - Adjustment Nut

Fig. 11: Breakaway Latch

Tension Adjustment

Tension on the breakaway latch is determined by the

length of the spring washer stack (Fig. 12, Ref. 1). The

tension as set at the factory [3-3/4 in. (95 mm)] will be

suitable for most conditions. If the cutterbar continues

to break away, turn the adjustment nut (Fig. 11, Ref. 4)

clockwise to increase the breakaway pressure.

IMPORTANT: The length of the spring stack

(Fig. 11, Ref. 1) MUST NOT be less than 3-9/16 in.

(91 mm).

BE SURE that the spring washers are stacked as shown

in Fig. 12.

2

4

1 - 18 mm Box Wrench

2 - Spacer Tube

3 - Main Frame

4 - Washer

Fig. 10: Drive Belt Tension Adjustment

BREAKAWAY LATCH TENSION

ADJUSTMENT (Figs. 11 & 12)

IMPORTANT: BE SURE all sliding areas (Fig.

11, Ref. 1) of the breakaway latch mechanism are

well greased and the mechanism is operating

properly.

Printed in U.S.A. 21 909793/BP0805

1

1 - Factory Setting 3 - 3/4” (95mm)

2 - Spring Washer Stack

Fig. 12: Breakaway Latch Spring Washer

Stack Detail

Page 24

Chapter 7 - Adjustments

GROUND PRESSURE

ADJUSTMENT (Fig. 13)

The amount of tension on the compensating spring (Ref.

1) determines the mower ground pressure. The ground

pressure can be increased or decreased by making the

distance (Ref. 2) between the lock nut (Ref. 3) and the

center of the anchor pin longer or shorter, respectively.

The distance as set at the factory [3-1/2” (90 mm)] will

be suitable for most conditions.

When the terrain is rough and less ground pressure is

desired, adjust the compensating spring tension as

follows:

1. Raise the cutterbar until the compensating spring

is slack.

2. Loosen the lock nut.

3. Turn the compensating spring to make the lock

nut-to-anchor pin distance (Ref. 2) shorter

4. After making the adjustment, tighten the lock nut.

.

3

2

1

1 - Compensating Spring

2 - Distance - Lock Nut -toAnchor Pin Center

[Factory Setting for Normal Ground Pressure

is 3-1/2 in. (90 mm)]

3 - Lock Nut

Fig. 13: Ground Pressure Adjustment

909793/BP0805 22 Printed in U.S.A.

Page 25

Notes

Chapter 7 - Adjustments

Printed in U.S.A. 23 909793/BP0805

Page 26

CHAPTER 8

LUBRICATION

GENERAL INFORMATION

WARNING

NEVER attempt to lubricate the machine when

any part of the unit is in motion. ALWAYS BE

SURE to exercise the MANDATORY SAFETY

SHUTDOWN PROCEDURE (page 8), BEFORE

lubricating the machine.

Proper lubrication of the disc mower will prevent

excessive part wear and early failure.

IMPORTANT: Whenever service is performed

on hydraulic components (valves, cylinders,

hoses, etc.) or transmission, care must be taken

to prevent discharging fluid onto the ground.

Catch and dispose of fluid according to

environmental law.

BEVEL GEARBOX (Fig. 14)

A plug (Ref. 1) is provided for checking the oil level in

the gearbox when the cutterbar is in the horizonal

position. This plug is also used as a gearbox drain when

the cutterbar is in the vertical transport position. The oil

should be changed every 200 hours of operation or

annually (more often if operated under heavy loads). An

oil fill plug (Ref. 2) is provided on the top of the gearbox

for adding or changing oil. The gearbox holds 0.5 U.S.

qts. (0.45 L). Use SAE 80W90 GL5 EP oil.

A pressure relief valve (Ref. 3) is located on the side of

the gearbox and must be removed and cleaned each time

the gearbox oil is changed. BE SURE that the ball detent

moves freely to relieve pressure.

The gearbox should be checked occasionally for oil

drips and dust accumulation around the seals. Oil drips

or dust accumulation indicate that seals are leaking. Oil

which is tan in color and foams excessively indicates

that it has water present.

IMPORTANT: The oil in the gearbox MUST be

changed after the first 10 hours of operation. BE

SURE to also clean and check the pressure relief

valve at this time.

2

1

3

1 - Check Oil Level & Drain Plug

2 - Oil Fill Plug

3 - Pressure Relief Valve

Fig. 14: Gearbox Lubrication Detail

CUTTERBAR (Fig. 15)

To check the oil in the cutterbar, park the tractor on level

ground and place the cutterbar in the vertical transport

position. A plug (Ref. 1) is provided for checking the oil

level in the cutterbar. The oil level is correct when the

oil just begins to flow out of the hole. The oil should be

changed every 200 hours or annually (more often if

operated under heavy loads). The following procedure

MUST be followed:

1. Operate the disc mower for 10 minutes so that the

cutterbar reaches operating temperature.

2. Raise the disc mower to the vertical transport position and be sure the transport lock is engaged.

3. Exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8).

4. Remove the magnetic drain plug (Ref. 2) and the

oil level/fill plug, allowing the oil to drain completely. Wait for the dripping to stop.

5. BE SURE to clean the magnetic drain plug thoroughly before installation.

6. Refill the cutterbar with SAE 80W90 GL5 oil.

The cutterbar holds 2.1 U.S. qts. (2 L). and reinstall the oil level/fill plug.

909793/BP0805 24 Printed in U.S.A.

Page 27

Chapter 8 - Lubrication

IMPORTANT: The oil in the cutterbar MUST be

changed after the first 10 hours of operation.

The cutterbar should be checked daily for oil drips and

dust accumulation around the seals. Oil drips or dust

accumulation indicate that seals are leaking. Oil which

is tan in color and foams excessively indicates that it has

water present.

NOTE: There will be signs of oil at the overflow

plug. A small amount of oil in this location should

be considered normal.

IMPORTANT: If the cutterbar is to be operated at

angles in excess of ± 20° from horizontal for long

periods of time, the quantity of cutterbar oil should

be reduced by 25%. If the quantity of oil is reduced,

the cutterbar MUST be operated in a horizontal

position for a few minutes every 1/2 hour.

1

GREASING

IMPORTANT: Grease all fittings at the intervals

listed, before and after storage, and as noted. Use

a good grade of lithium- based grease.

Wipe dirt from the fittings BEFORE greasing to prevent

any dirt from being forced into the fittings. Replace any

missing fittings, when noted. To minimize dirt build-up,

avoid excessive greasing.

Grease Fitting Locations (Fig. 16)

Grease Every 8 hours (or Daily)

1. Telescoping PTO drive crosses (2 places)

2. Overrunning clutch

Grease Every 20 hours (or twice

Weekly)

3. Inner telescoping PTO section

Grease Every 40 hours (or Weekly)

2

1 - Check Oil Level & Fill Plug (Cutterbar Vertical)

2 - Magnetic Drain Plug

Fig. 15: Cutterbar Lubrication Detail

SEALED BEARINGS

Sealed bearings are used throughout the disc mower to

provide trouble-free operation. These bearings are

sealed and lubricated for life. Relubrication is NOT

required, NOR should it be attempted.

OILING

4. Telescoping PTO guards (2 places)

5. Spring loaded PTO locking coupler

Grease as Required

6. Grease the inside of the outer guard tube in winter

to prevent freezing.

7. All break-away components

1

5

4

3

4

2

5

1

Oil all linkage and pivot points every 50 hours of

operation using a good grade of motor oil.

Printed in U.S.A. 25 909793/BP0805

Fig. 16: PTO Grease Fitting Locations

Page 28

CHAPTER 9

SERVICE

GENERAL INFORMATION

WARNING

BEFORE servicing the disc mower, exercise

the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8).

NOTE: All services, detailed in this chapter are

owner/operator responsibilities. Where indicated,

certain service routines should only be carried out

by (or under the direction of) an authorized Gehl

equipment dealer.

CUTTERBAR

All service to the internal parts of the cutterbar MUST

be carried out by (or under the direction of) an

authorized Gehl equipment dealer.

DISCS, KNIVES AND HARDWARE

Discs, knives, bolts and nuts are fabricated from high

quality steel and undergo a special heat treatment

process to ensure a tough wear resistance and longer

life.

Knife Hardware (Fig. 17)

If any of the following conditions exist, the knife

retaining hardware MUST be replaced. See Fig. 17 for

details.

1. When a visible deformation is found.

2. When the locking compound on the bolt threads

has worn away or if the locking compound has

become inoperative due to contamination by

water, oil or dirt.

3. When a wear groove deeper than 1/8” (3mm) has

formed on the bearing shoulder of the knife bolt

(Ref. 2).

4. When wear on the bolt head reaches the contact

area of the knife (Ref. 3).

5. When the contact washer of the knife retaining nut

has lost its elasticity or the washer becomes loose

from the nut (Ref. 5).

6. When wear on the nut reaches a depth equal to half

the height of the nut (Ref. 6).

7. When the retaining hardware has been removed 5

times.

WARNING

To avoid creating hazardous out-of-balance

forces, ALWAYS replace missing, damaged or

worn knives and hardware in pairs!

IMPORTANT: Worn or damaged items MUST be

replaced immediately with genuine GEHL service

parts, otherwise the warranty is void.

WARNING

Use ONLY genuine GEHL service parts.

909793/BP0805 26 Printed in U.S.A.

1

4

1 - Acceptable Bolt with Locking Compound Intact

2 - Unacceptable Bolt with Wear Groove

3 - Unacceptable Bolt with Edge Wear

4 - Acceptable Nut with Contact Washer

5 - Unacceptable Nut with Contact Washer Crushed

6 - Unacceptable Nut with Edge Wear

2

5

Fig. 17

3

6

Page 29

Chapter 9 - Service

Knife Removal & Replacement

(See Fig. 18)

Knives should be inspected systematically each time

before the disc mower is operated. Failure to replace

knives as required will result in an increase in the risk

of accidents, a deterioration in the quality of cut and

a risk of damage to the cutterbar. Both knives on each

disc MUST be replaced in pairs to maintain balance

if any of the following conditions exist:

1. If any sign of cracking is found.

2. Refer to Fig. 18. The width of a knife (Ref. 2),

measured at a distance of 3/8” (10 mm) away from

the edge of the disc (Ref. 1), MUST be greater

1-3/8” (34 mm).

3. The hole in the knife for the retaining bolt MUST

NOT be worn oval by more than 1/16” (2 mm).

See Fig. 18, Ref. 3.

1

2

than

When replacing a knife (knives MUST BE replaced in

sets) on the disc mower, the following steps MUST be

followed:

1. Clean around the self-locking nut to be removed.

2. Position the disc to allow the knife retaining bolt

to drop through the access hole in the front, center

of the skid shoe.

3. Remove the self-locking nut with the box wrench

provided with the disc mower (or an 18 mm socket).

4. Fit a new knife or turn the worn knife over to use

second cutting edge. BE SURE that the knife is

positioned with the small arrow pointing in the direction of rotation of the corresponding disc.

5. BE SURE the bolt is in good condition BEFORE

reusing.

6. Torque locknuts to 90 ft.-lbs. (120 Nm).

WARNING

Use ONLY genuine Gehl service parts.

3

1 - 3/8” (10 mm)

2 - 1-3/8” (34 mm)

3 - Maximum Out-of-round 1/16” (2 mm)

Fig. 18

IMPORTANT: To ensure proper knife retention,

the retaining hardware MUST be replaced after

having been removed five times.

WARNING

ALWAYS replace damaged knives in pairs.

NEVER attempt to straighten a bent knife or

replace a single knife.

Printed in U.S.A. 27 909793/BP0805

Page 30

Chapter 9 - Service

Disc Removal & Replacement

(Figs. 19, 20 & 21)

NOTE: Place a block of wood between the discs

so the discs will NOT rotate when removing the

mounting hardware.

Left Disc

1. Remove four self-locking cap screws (Fig. 21,

Ref. 1) to remove the flat cover (Ref. 2).

2. Remove four each cap screws (Ref. 3) and conical

spring washers (Ref. 4).

3. Remove the left disc assembly (Ref. 5); if the disc

is tight, pry up with two levers at opposite sides of

the disc.

4. The spacer (Ref. 6) is only used if the clearance

between the knife mounting bolt head and the cutterbar guard is less than 1/32” (1 mm). Refer to

Fig. 19 for measurement details.

5. Position the new disc and spacer, if required, on

the cutterbar hub. BE SURE the disc is rotated 90°

from the adjacent disc and that each knife is positioned with the small arrow pointing in the direction of disc rotation. Secure the disc with four each

cap screws and conical spring washers. Tighten

the cap screws to 90 ft.-lbs. (120 Nm) torque.

IMPORTANT: BE SURE the conical spring

washers are positioned with the crown up as

shown in Fig. 20.

6. Install the flat cover (Ref. 2) using four self-locking cap screws (Ref. 1). Tighten the cap screws to

65 ft.-lbs. (85 Nm) torque.

1

1 - Conical Spring Washer

Fig. 20

Right Disc

1. Remove four self-locking cap screws (Fig. 21,

Ref. 1) to remove the curved cover (Ref. 9).

2. Remove four each cap screws (Ref. 3) and conical

spring washers (Ref. 4).

3. Remove the right disc assembly (Ref. 10). If the

disc is tight, pry up with two levers at opposite

sides of the disc.

4. The spacer (Ref. 6) is only used if the clearance

between the knife mounting bolt head and the cutterbar guard is less than 1/32” (1 mm). Refer to

Fig. 19 for measurement details.

5. Position the new disc and spacer, if required, on

the cutterbar hub. BE SURE the disc is rotated 90°

from the adjacent disc and that each knife is positioned with the small arrow pointing in the direction of disc rotation. Secure the disc with four each

cap screws and conical spring washers. Tighten

the cap screws to 90 ft.-lbs. (120 Nm) torque.

IMPORTANT: BE SURE the conical spring

washers are positioned with the crown up as

shown in Fig. 20.

6. Install the curved cover (Ref. 9) using four selflocking cap screws (Ref. 1). Tighten the cap

screws to 65 ft.-lbs. (85 Nm) torque

1

1 - 1/32 in. (1 mm) Minimum Clearance

Fig. 19

909793/BP0805 28 Printed in U.S.A.

Flat (Intermediate) Discs

1. Remove two cap screws (Fig. 21, Ref. 3) and conical spring washers (Ref. 4) to remove the conical

cover (Ref. 7).

2. Remove the remaining two cap screws (Ref. 3)

and conical spring washers (Ref. 4) to remove the

disc (Ref. 8). If the disc is tight, pry up with two

levers at opposite sides of the disc.

3. The spacer (Ref. 6) is only used if the clearance

between the knife mounting bolt head and the cutterbar guard is less than 1/32” (1 mm). Refer to

Fig. 19 for measurement details.

Page 31

Chapter 9 - Service

4. Position the new disc and spacer, if required, on

the cutterbar hub. BE SURE the disc is rotated 90°

from the adjacent disc and that each knife is positioned with the small arrow pointing in the direction of disc rotation.

5. Secure the disc with two cap screws and conical

spring washers. Torque the cap screws to 90 ft.lbs. (120 Nm).

2

1

3

IMPORTANT: BE SURE the conical spring

washers are positioned with the crown up as

shown in Fig. 20.

6. Install the conical cover (Ref. 7) using two cap

screws and conical spring washers. Torque the cap

screws to 90 ft.-lbs. (120 Nm).

9

10

7

8

4

5

6

1 - Self-locking Cap Screw (8 used each model)

2 - Flat Cover

3 - Cap Screw (24 used on DM1162, 28 used on DM1165)

4 - Conical Spring Washer

(24 used on DM1162, 28 used on DM1165)

5 - Left Disc Assembly

6 - 1/32″ (1 mm) Spacer

Fig. 21: Disc Replacement (DM1165 Shown)

11

7 - Conical Cover (4 used on DM1162, 5 used on DM1165)

8 - Flat Disc (4 used on DM1162, 5 used on DM1165)

9 - Curved Cover

10 - Right Disc Assembly

11 - Cutterbar Assembly (Reference)

TELESCOPING DRIVES

IMPORTANT: For safety reasons, service on the

telescoping PTO drives should ONLY be

performed by (or under the direction of) an

authorized Gehl equipment dealer.

Printed in U.S.A. 29 909793/BP0805

Over time, the telescoping drive universal joints may

become worn and noisy and require service. As

necessary, remove the drive(s) from the disc mower and

take them to your dealer.

Page 32

CHAPTER 10

PREPARING FOR FIELD OPERATION

TRACTOR REQUIREMENTS

The tractor used to operate the disc mower MUST have:

1. A 540 RPM PTO.

2. A minimum power rating of 42 hp (30 kW) for the

DM1162 and 50 hp (36 kW) for the DM1165.

3. A Category II 3-point hitch.

4. One remote hydraulic output capable of powering

a single-acting cylinder.

5. The tractor should be equipped with a cab.

ADAPTING MOWER TO TRACTOR

The disc mower is provided with adjustable hitch pins

to accommodate various tractor sizes and rear wheel

spacing arrangements.

Refer to Figs. 22 & 23. The mower must be positioned

so that the inside cutting path of the left disc (Ref. 2) is

approximately 2″ (50 mm) to the right of the outside of

the right tractor tire (see Ref. 1). If necessary, loosen the

four cap screws (Fig. 22, Ref. 2) at each lower hitch pin

(Ref. 4) mounting location to slide the mower 3-point

frame left or right. Be sure the distance (Ref. 3) is

maintained. After the correct position is obtained,

tighten the eight cap screws (Ref. 2) to 90 ft.-lbs. (120

Nm) torque.

NOTE: The stop chain (Fig. 22, Ref. 4) is pro-

vided with the mower. This chain is used only when

the tractor IS NOT equipped with 3-point hitch hydraulic positioning control. (Refer to the “Setting

Mower Frame Working Height” topic later in this

chapter.)

1

3

3

2

4

1 - Mower 3-point Hitch Frame

2 - Cap Screw (4 used for each Hitch Pin)

3 - Lower Hitch Pins

4 - Stop Chain (see NOTE, above)

2

Fig. 22

4

1 - 2″ (50 mm)

2 - Cutting Path of Left Disc Assembly

Fig. 23: Mower- to - Tractor Position

909793/BP0805 30 Printed in U.S.A.

1

3

2

4

3 - 32-1/2″ (825 mm)

4 - Lower Hitch Pin (2 used)

Page 33

ATTACHING MOWER TO TRACTOR

1. Clean all paint from the hitch pins.

2. Refer to Fig. 24. Back the tractor to the mower and

attach the lower links to the hitch pins. Secure

links with lynch pins (Ref. 1) provided.

2

3

Chapter 10 - Preparing For Field Operation

1

2

1 - Retainer

2 - Parking Lock

Fig. 25

SETTING MOWER FRAME

WORKING HEIGHT

1

1 - Lynch Pins

2 - Tractor Top Link

3 - Top Link Pin

Fig. 24: Connecting Mower to Tractor

3. Attach the top link to the mower. Secure the link

with the pin provided. Two positions are available

to install the top link retaining pin, depending on

the diameter of the top link ball joint.

4. Connect the hydraulic lift cylinder hose to the

tractor.

5. Raise the mower with the tractor 3-point hitch

system. Fold the mower parking lock (Ref. 2) upward (see arrow) until it engages in the retainer

(Ref. 1). Raise the cutterbar in and out of the transport position several times to purge the air out of

the hydraulic system.

IMPORTANT: ALWAYS position the parking lock

in the upper position while transporting or

operating the disc mower.

For Tractors Equipped with Hydraulic

Position Control of 3-Point Hitch

Refer to Fig. 26. On level ground, adjust the mower with

the tractor hydraulic 3-point lift system so that the

centers of the lower hitch pins are at a height of 15″ (420

mm) from the ground, as shown.

1

2

1 - Center of Lower Hitch Pin

2 - Adjustment Height of 15″ (420 mm)

Fig. 26

Printed in U.S.A. 31 909793/BP0805

Page 34

Chapter 10 - Preparing For Field Operation

For Tractors without 3-Point Hitch

Hydraulic Position Control

Refer to Fig. 27.

1. On level ground, adjust the mower with the tractor

3-point lift system so that the centers of the lower

hitch pins are at a height of 15″ (420 mm) as

shown.

2. Attach the chain to the tractor clevis (or to an

available hole in the tractor top link) with the

chain hook.

3

1

2

1 - Center of Lower Hitch Pin

2 - Adjustment Height of 15″ (420 mm)

3 - Chain

Fig. 27

3. Lower the mower into the working position. the

height adjustment is correct when:

a. the cutterbar is resting on the ground.

b. the chain is tight.

c. the distance between the hitch pins and the

ground is 15″ (420 mm).

NOTE: Use a hairpin cotter to attach the sur-

plus end of the chain to the used portion.

PTO SHAFT

Before the PTO is connected to the tractor, the PTO

driveline MUST be sized.

IMPORTANT: When the PTO driveline is in its

maximum extended position, the drive tubes

MUST overlap a minimum of 10″ (250 mm). Also,

the PTO MUST BE short enough to prevent

bottoming out (see the PTO sizing section, below).

Failure to properly size the PTO WILL result in

premature failure.

PTO Sizing (Fig. 28)

1. Separate the two PTO half shafts. Connect the end

with the free-wheeling hub to the disc mower input shaft (Ref. 2) and the other half to the tractor

PTO (Ref. 1). BE SURE both ends lock in place.

2. Raise or lower the mower to find the position

where the PTO shaft would be in its shortest position.

3. Hold the tractor half of the PTO next to the mower

half.

4. When the PTO is in its maximum retracted position, a 3/8″ (10 mm) gap (Ref. 5) MUST exist be-

tween the end of the tractor-half drive tube (Ref.

7) and the mower-half PTO yoke (Ref. 6). If the

gap is less then specified, shorten both PTO drive

tubes and both guard tubes as follows:

a. Mark off the total length to remove (Ref. A)

so that there is a 3/8″ (10 mm) gap between

the end of the tractor-half PTO drive tube

and the mower-half PTO yoke (shown as

Refs. 5, 6 & 7).

b. Divide the total amount to be removed by

two - so that the same amount will be removed from each PTO half. The result is

Ref. B.

c. Cut off equal amounts (Ref. B) from the

ends of both guard tubes and both drive

tubes.

Remove the sharp edges from the cut tubes and clean out

all chips and filings. Apply grease to the inside of the

outer telescoping tube.

Assemble the two PTO half shafts and connect the

complete PTO assembly to the tractor PTO and the disc

mower input shaft. BE SURE to connect the free end of

the safety chains to a fixed point on the tractor and disc

mower.

909793/BP0805 32 Printed in U.S.A.

Page 35

Chapter 10 - Preparing For Field Operation

1

B

1 - Tractor PTO Shaft

2 - Disc Mower Input Shaft

3 - Guard Tube

4 - Tractor-half Drive Tube

5 - 3/8″ (10mm) Gap

4

3

Fig. 28: Sizing the PTO

3

A

2

4

7

5

6

6 - Mower-half PTO Yoke

7 - Desired Location of Tractor-half Drive Tube

when PTO is Fully Retracted

A - Total Length to Cut Off

B - Cut Off Locations (One - half of “A”)

WARNING

BEFORE operating the disc mower, BE SURE

that the PTO driveline shields are properly

chained to the tractor PTO guard and disc

mower to prevent them from turning.

NOTE: The angle of the Telescoping PTO

MUST NOT exceed 30°. BE SURE to also disen-

gage the PTO when the tractor 3- point hitch is

raised to the maximum height.

BREAK- IN

Before starting to cut, it is recommended that the disc

mower be broken in by running it empty for approximately 30 minutes. This initial run-in MUST be done

with the cutterbar in the cutting position.

The break-in should consist of a 25 minute low-speed,

and a 5 minute high-speed, run-in period. First, run the

machine for 25 minutes with the tractor engine close to

idle RPM. Next, stop the machine and exercise the

MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8) before leaving the tractor seat to inspect

the disc mower. After inspection is complete, reconnect

the PTO, restart the tractor, engage the PTO near engine

idle speed and gradually increase the speed to proper

operating RPM and continue running the machine for 5

minutes. After another inspection, the disc mower is

ready for use.

IMPORTANT: The oil in the cutterbar and the

gearbox MUST be changed after 10 hours of

operation. For details, see the Lubrication chapter.

NOTE: The drive belts MUST be adjusted after

10 hours of operation. For details, see the Adjustments chapter.

TRANSPORTING

BEFORE transporting the disc mower, refer to the

Transporting chapter for transporting information.

Printed in U.S.A. 33 909793/BP0805

Page 36

CHAPTER 11

TRANSPORTING

TRANSPORT LOCK

To transport the mower on the highway or from one field

to another, proceed as follows:

1. Disengage the PTO drive and wait for all movement to stop.

2. Raise the mower off the ground with the tractor

3-point hitch system.

3. Refer to Fig. 29. Use the handle-end of the box

wrench (Ref. 3) provided with the mower to release the protective cover lock (Ref. 1). Then, fold

the cover up and back until it locks in the transport

position.

1

3

IMPORTANT: ALWAYS position the parking lock

in the upper position while transporting or

operating the disc mower.

1

2

1 - Retainer

2 - Parking Lock

Fig. 30

5. Refer to Fig. 31 for steps 5, 6 and 7. Use the tractor

hydraulic control to lower the cutterbar slightly to

allow the stop lock (Fig. 31, Ref. 1) to move away

from the frame stop.

6. Pull on the rope to release the stop lock (Ref. 1)

and use the hydraulic cylinder control to raise the

cutterbar. Maintain tension on the rope until the

stop lock is clear of the frame stop. As the cutterbar nears the vertical position, release the tension

on the rope — the hook-type transport lock (Ref.

2) will automatically engage.

2

1 - Protective Cover Lock Mechanism

2 - Release Access Hole

3 - Special Box Wrench

Fig. 29: Releasing Protective Cover Lock

to Place Cover into Transport Position

4. Refer to Fig. 30. Fold the mower parking lock

(Ref. 2) upward (see arrow) until it engages in the

retainer (Ref. 1).

909793/BP0805 34 Printed in U.S.A.

CAUTION

BEFORE transporting the disc mower on a

public highway or from one field to another,

BE SURE the transport lock is properly engaged.

7. BE SURE the transport lock is fully engaged.

Page 37

Chapter 11 - Transporting

To place the cutterbar into the operating position:

1. Using the tractor hydraulic control, raise the cutterbar slightly (to free the hook lock) while pulling

on the rope to release the hook lock (Ref. 2).

3

5

4

2

1

1 - Stop Lock

2 - Hook-type Transport Lock

3 - Rope Control Lift Points

3

Fig. 31: Transport & Operating Position Locks

2. Keep pulling on the rope while using the tractor

hydraulic control to lower the cutterbar to the horizontal position.

3. Let go of the rope and bring the cutterbar up until

the stop lock is against the frame stop.

6

5

4

2

1

4 - Rope Control

5 - Cylinder Stroke Limiter

6 - Parking Lock

Printed in U.S.A. 35 909793/BP0805

Page 38

CHAPTER 12

STORAGE

After the harvesting season is over, store the disc mower

in a dry place where it is not exposed to weather or

livestock.

BEFORE STORING

Perform the following preparations on the disc mower,

before placing the unit into off-season storage:

1. Remove the drive belts and store them in a dry

place.

2. Wash the entire machine. Take special care to remove gum and accumulated dirt from the cutterbar.

3. Remove trash and debris which may be wrapped

around shafts or lodged against bearings.

4. Drain oil from the cutterbar and gearbox and refill

according to the Lubrication chapter.

5. Brush clean motor oil on the cutterbar.

6. Lubricate the entire machine and apply motor oil

to the adjusting bolt threads.

7. Apply grease to any exposed cylinder rods.

8. Repaint any areas where the paint has been worn

off.

9. Take note of any damaged or missing parts or attaching hardware and order and replace them during the off-season.

10. Check all hydraulic components, hoses and fittings for damage or leaks. Make repairs or corrections, as required.

11. Store the machinewith the cutterbar in the operating position.

AFTER STORING

After taking the disc mower out of storage and before the start

of the harvesting season, carefully check the machine over

and make the following inspections and preparations:

1. Install all removed guards, shields and covers.

2. Review and review all safety precautions according to the Safety chapter.

3. Remove any trash or debris which may have accumulated on the machine during storage.

4. Install the drive belts. Adjust the drive belt tension

according to the Adjustments chapter.

5. Inspect the cutterbar knives.

6. Inspect the break-away latch and be sure that the

components are not rusted tight.

7. Inspect the mower for loose or missing parts or attaching hardware.

8. Lubricate the entire machine according to the Lubrication chapter.

After the above steps have been performed, attach the

disc mower to the tractor and connect the PTO drive.

Start the machine and run it at half speed for about 15

minutes. Then, exercise the MANDATORY SAFETY

SHUTDOWN PROCEDURE (page 8) and make the

following inspections:

• Check for overheated bearings

• Check for excessively worn bearings

• Check for loose attaching hardware

909793/BP0805 36 Printed in U.S.A.

Page 39

CHAPTER 13

TROUBLESHOOTING

NOTE: This Troubleshooting guide presents problems, causes and suggested remedies beyond the ex-

tent of loose, worn or missing parts and it was developed with the understanding that the machine is in

otherwise good operating condition. Refer to the index at the back of this manual for chapter and sectcion

page references. BE SURE to exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8),

BEFORE making any adjustments or repairs.

MISCELLANEOUS PROBLEMS

PROBLEM

Uneven stubble. Cutting height set too low. Adjust top link on tractor 3-point

Low PTO speed. Run PTO at 540 RPM.

Low disc speed. Check drive belts for proper ten-

Excessive forward speed. Reduce forward speed.

Knives NOT installed correctly. Install knives with arrows pointing

Knives dull or broken. Install new Knives.

Stubble too long. Cutting height set too high. Adjust top link on tractor 3-point

Too much cutterbar down pressure.

Soil build-up on front of cutterbar. Very wet conditions. Adjust main frame height to in-

CAUSE REMEDY

hitch to increase cutting height

(see Adjustments chapter).

sion (see Adjustments chapter).

in the direction of disc rotation

(see Service chapter).

hitch to decrease cutting height

(see Adjustments chapter).

Adjust compensating spring tension (see Adjustments chapter).

crease distance between lower

hitch pins and ground (see Preparing for Field Operation chapter).

Cutterbar not floating. Main frame setting incorrect. Adjust main frame to specifica-

Machine breaking back too easily. Insufficient tension on break-

Crop being pushed forward before being cut.

Printed in U.S.A. 37 909793/BP0805

Too much cutterbar down pressure.

away spring.

Wind turbulence created by knives when working in very light

crop.

Adjust compensating spring tension (see Adjustments chapter).

tions (see Preparing for Field Operation chapter).

Adjust break-away spring washer

stack tension (see Adjustments

chapter).

Reduce PTO speed or increase

forward speed.

Page 40

CHAPTER 14

SET- UP & ASSEMBLY

UNCRATE UNIT

The DM1162 or DM1165 disc mowers are shipped from

the factory in two bundles consisting of two

frames and two

divide the components into two DM1162 or DM1165

groups.

cutterbars. Uncrate both bundles and

main

ASSEMBLY

Assemble each disc mower using the following steps:

CAUTION

The main sub-assemblies of the disc mower

are awkward and heavy and an overhead hoist

and wood blocking should be used to assist

in the safe assembly of the disc mowers.

NOTE: Some of the following steps may have

been completed at the factory

Cutterbar Installation

1. Refer to Figure 32. Clean and lubricate the bore of

the bushing (Ref. 1). Remove all protective paint

6

5

from the front cover of the gearbox (Ref. 2) where

the bushing makes contact.

3

1

1 - Bushing

2 - Gearbox

3 - Hinge Plate

Fig. 32

2. Refer to Fig. 33. Block the frame as necessary.

Then, attach the frame (Ref. 1) to the cutterbar

(Ref. 2) using two each self-locking cap screws

and bevel washers (Ref. 3 & 4) as shown. Tighten

the cap screws to 220 ft.-lbs. (300 Nm). If not already preassembled, use a roll pin (Ref. 6) to secure the compensating spring rod (Ref. 5) to the

frame.

2

3

1

1 - Frame

2 - Cutterbar

3 - M16 x 50 Self-locking Cap Screw - Tighten

to 220 ft.-lbs. (300 Nm) (2 places)

909793/BP0805 38 Printed in U.S.A.

4

3

4

3

2

4 - 16.5 mm ID x 60 mm OD Bevel Washer (2 places)

5 - Compensating Spring Rod End

6 - 8 x 50 mm Roll Pin

Fig. 33

Page 41

Chapter 14 - Set-up & Assembly

Break-away Latch Installation

3. Refer to Fig. 34. Use two pins (Ref. 4) and four roll

pins (Ref. 5) to install the break-away latch assembly (Ref. 1) to the mower 3-point hitch frame (Ref.

2) and the main frame (Ref. 3).

2

3

5

1 - Break-away Latch

2 - Mower 3-point Hitch Frame

3 - Main Frame

4 - Pin (2 used)

5 - 6 x 36 mm Roll Pin (4 used)

Fig. 34: Break-away Latch Installation

4

1

5

5. Refer to Fig. 36. To obtain the correct initial belt

tension, use the 18 mm box wrench (Ref 1. — included with the mower) to turn the adjustment bolt

(Ref. 2) clockwise until the spacer tube (Ref. 3) is

in contact with the main frame (Ref. 4). Then, continue to turn the bolt two complete revolutions.

4

3

1

2

1 - 18 mm Box Wrench

2 - Adjustment Bolt

3 - Spacer Tube

4 - Main Frame

Fig. 36: Drive Belt Tension Adjustment

Drive Belts and Shields Installation

4. Refer to Fig. 35. If not already preassembled, use

three spacer bolts (Ref. 3) to install the inner belt

shield (Ref. 2). Then, install the drive belts (Ref.

1). Slide the closing plate (Ref. 4) into position if

it is not already in place as shown.

2

3

4

3

1 - Drive Belts (Matched Set of 4)

2 - Inner Belt Shield

3 - Spacer Bolts (3)

4 - Closing Plate

Fig. 35: Drive Belt Installation

1

3

6. Refer to Fig. 37. Use (three each) washers and cap

nuts (Ref. 2) and a self-locking cap screw (Ref. 3)

to install the outer belt shield (Ref. 1).

3

2

1

1 - Outer Belt Shield

2 - Washers and Cap Nuts (3 each)

3 - M8 x 16 mm Self-lock Cap Screw

Fig. 37: Outer Belt Shield Installation

Printed in U.S.A. 39 909793/BP0805

Page 42

Chapter 14 - Set-up & Assembly

Protective Cover Frame Installation

7. Refer to Fig. 38. Making sure the mating surfaces

are clean, use four M16 x 40 mm cap screws (Ref.

2) to attach the cover frame (Ref. 1) to the gearbox

(Ref. 3). Tighten the cap screws to 155 ft.- lbs.

(210 Nm) torque. Connect the outer link (Ref. 4)

to the pin (Ref. 5) on the cover frame. Use a roll

pin (Ref. 6) to secure the link.

1

6

4

5

2

3

8. Refer to Fig. 39. Use two 8 x 40 mm roll pins (Ref.

3) to attach the compensating spring (Ref. 1) to the

pin (Ref. 2) on the protective cover frame (Ref. 5).

One roll pin goes to the inside of the spring clevis

(Ref. 4) and other to the outside.

1

3

5

2

4

1 - Compensating Spring

2 - Pin

3 - 6 x 36 mm Roll Pin (2 used)

4 - Spring Clevis

5 - Protective Cover Frame

Fig. 39

Inner Shoe and Inner Deflector Shield

Installation

1 - Protective Cover Frame

2 - M16 x 40 mm Cap Screw (4 used)

3 - Gearbox

4 - Outer Link

5 - Pin

6 - 6 x 36 mm Roll Pin

Fig. 38

3

4

9. Refer to Fig. 40. Use four each M10 x 25 mm

carriage bolts and M10 lock nuts (Ref. 2) to

loosely attach the inner shoe (Ref. 1) to the bottom of the cutterbar. Use four each M10 x 20

mm carriage bolts, M10 flat washers and M10

lock nuts (Ref. 4) to attach the inner deflector

shield (Ref. 3) to the bottom of the cutterbar and

inner shoe. Tighten all hardware.

1

3

1

1 - Inner Shoe

2 - M10 x 25 mm CB and LN (2 of 4 shown)

909793/BP0805 40 Printed in U.S.A.

2