Lighting Contactors

Section Updated 07 / 2016

Lighting Contactors Electrical Features and Benefits .........3-2

Lighting Contactors Mechanical Features and Benefits .....3-3

Lighting Contactors CR460 Series ...........................................3-4

Application Information..........................................................................3-4

The Choice is yours: Three ways to order......................................3-5

Components ................................................................................................3-6

Enclosure Accessories.............................................................................3-7

Project Submittal Form...........................................................................3-8

Lighting Contactors CR463L .....................................................3-9

Standard Assembled Forms.................................................................3-9

Modified Assembled Forms - Electrically Held..........................3-11

Lighting Contactors CR463M ..................................................3-13

Standard Assembled Forms ..............................................................3-13

Modified Assembled Forms - Mechanically Held ....................3-15

Lighting Contactors CR460, CR463 .......................................3-17

Technical Data ..........................................................................................3-17

Lighting Contactors CR463L, CR463M ..................................3-18

Wiring Diagrams .....................................................................................3-18

Outlines and Dimensions For Estimating Only .........................3-19

Lighting Contactors CR360L ...................................................3-22

Application Information.......................................................................3-22

Selection......................................................................................................3-23

Technical Data .........................................................................................3-25

Outlines and Dimensions For Estimating Only .........................3-26

Lighting Contactors CR160MC................................................3-28

Application Information.......................................................................3-28

Modified Assembled Forms - Mechanically Held ....................3-29

Technical Data .........................................................................................3-32

Outlines and Dimensions For Estimating Only .........................3-33

Section 3

Rev. 4/16

change without notice

data subject to

Control Catalog

3-1

Lighting Contactors Section 3

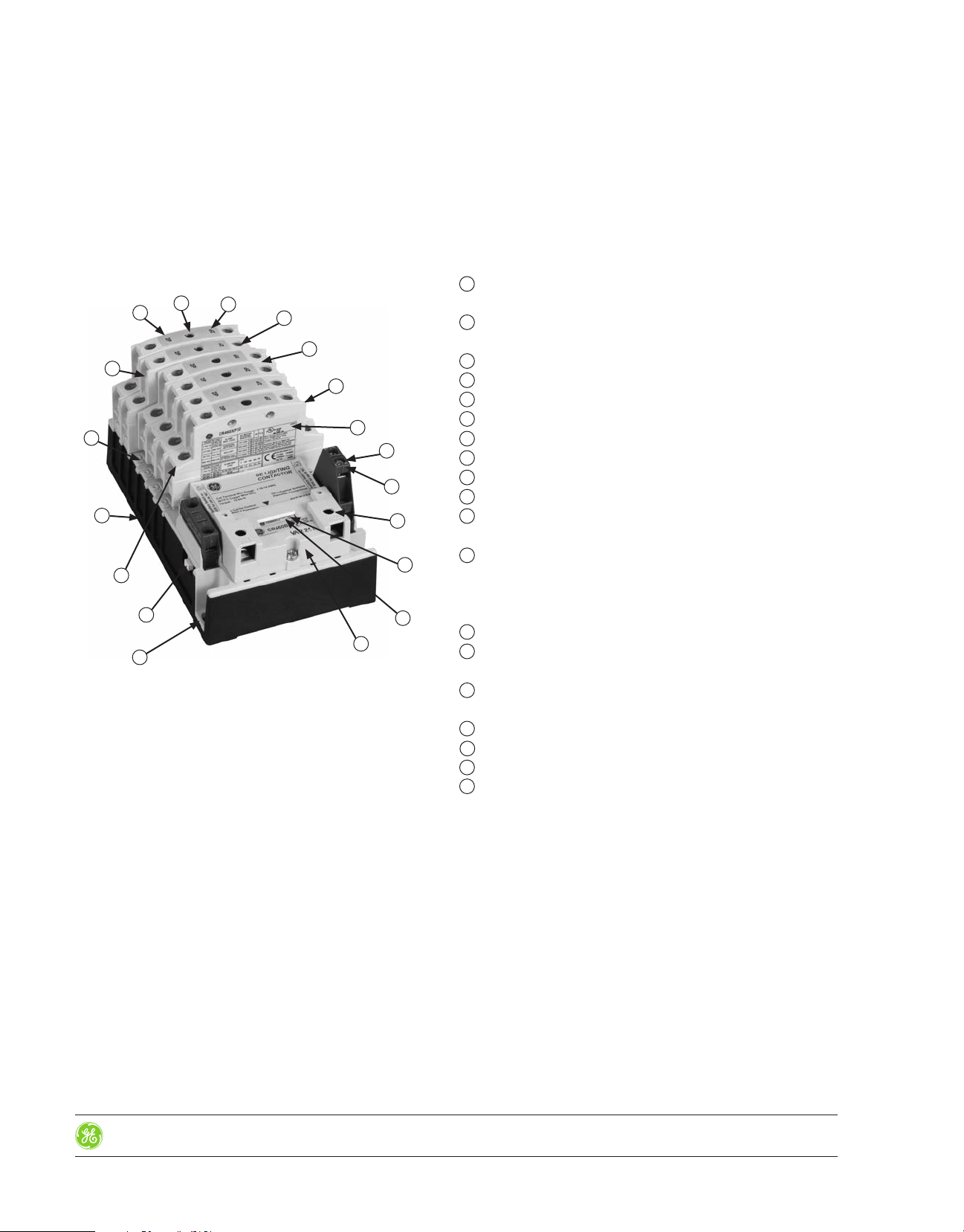

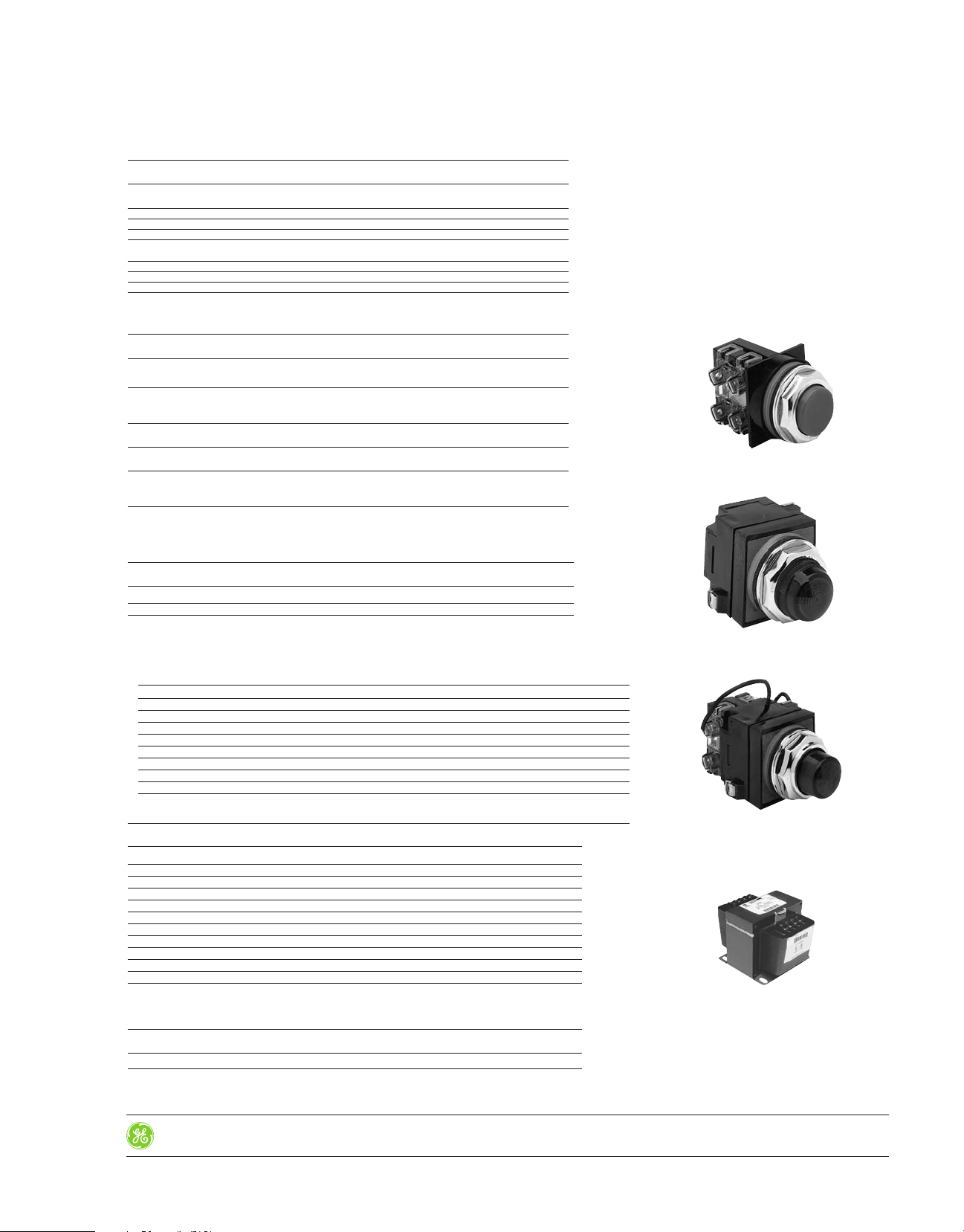

Electrical Features and Benefits

GE’s CR460 Series lighting contactors deliver unprecedented

versatility in application, simplicity in configuration and

performance in operation. Ingenious design, rugged construction

and a host of truly useful features make them uniquely appealing

to all those who use them.

A Contact position indication—when button protrudes,

A

B

C

D

E

F

G

H

Electrically H el d Cont ac tor

I

J

K

L

M

N

O

P

Q

R

S

contact is closed.

B Power poles are available as single or double poles,

creating 74 different circuit combinations.

C Convenient side access field power wiring

D Contact configuration indicator

E Standard base for all pole configurations

F Robust pole terminals accept up to two #8 AWG wires

G Manual operator

H Fast, sure three-point mounting

I Enclosed contacts resist contaminants for greater reliability

J Combination slotted/#2 Phillips screws

K Common, easily installed power poles change from NO to

NC (or vice versa) simply by unlatching and rotating 180°.

L Power poles rated for the range of tasks:

—30A rated contacts

—15A motor rated

—A600 Pilot duty rated

M Easy-to-read rating label

N Auxiliary contacts, rated A600, are suitable for use on low

level circuits down to 12V, 5mA

O Plug-in auxiliary contacts are NO when installed on the left

side of the base, NC on the right

P Finger and back-of-hand safe power terminals

Q Quick-view coil voltage

R Easy-change coil

S Low magnetic noise results in quiet operation

3-2

Control Catalog

Rev. 4/16

data subject to

change without notice

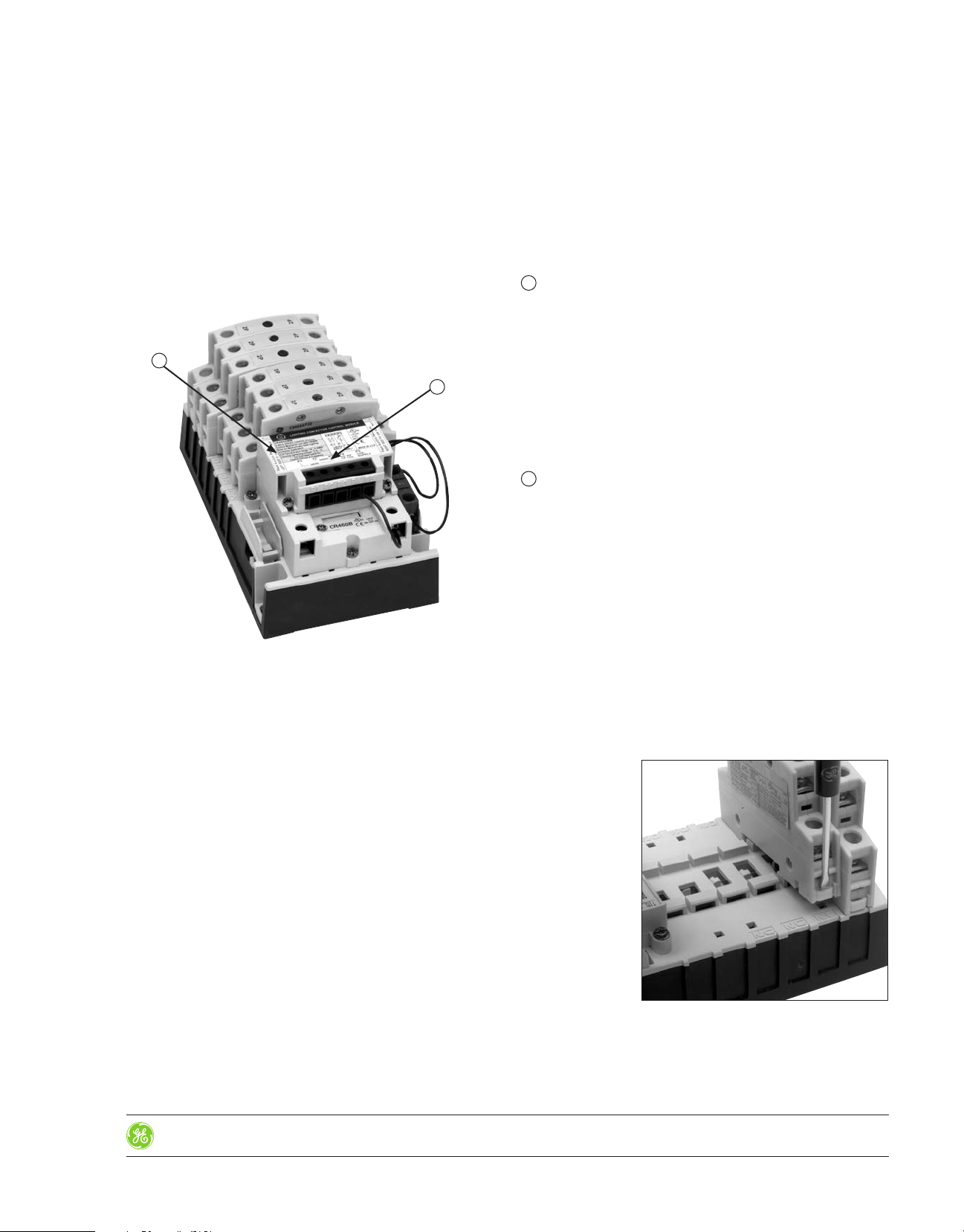

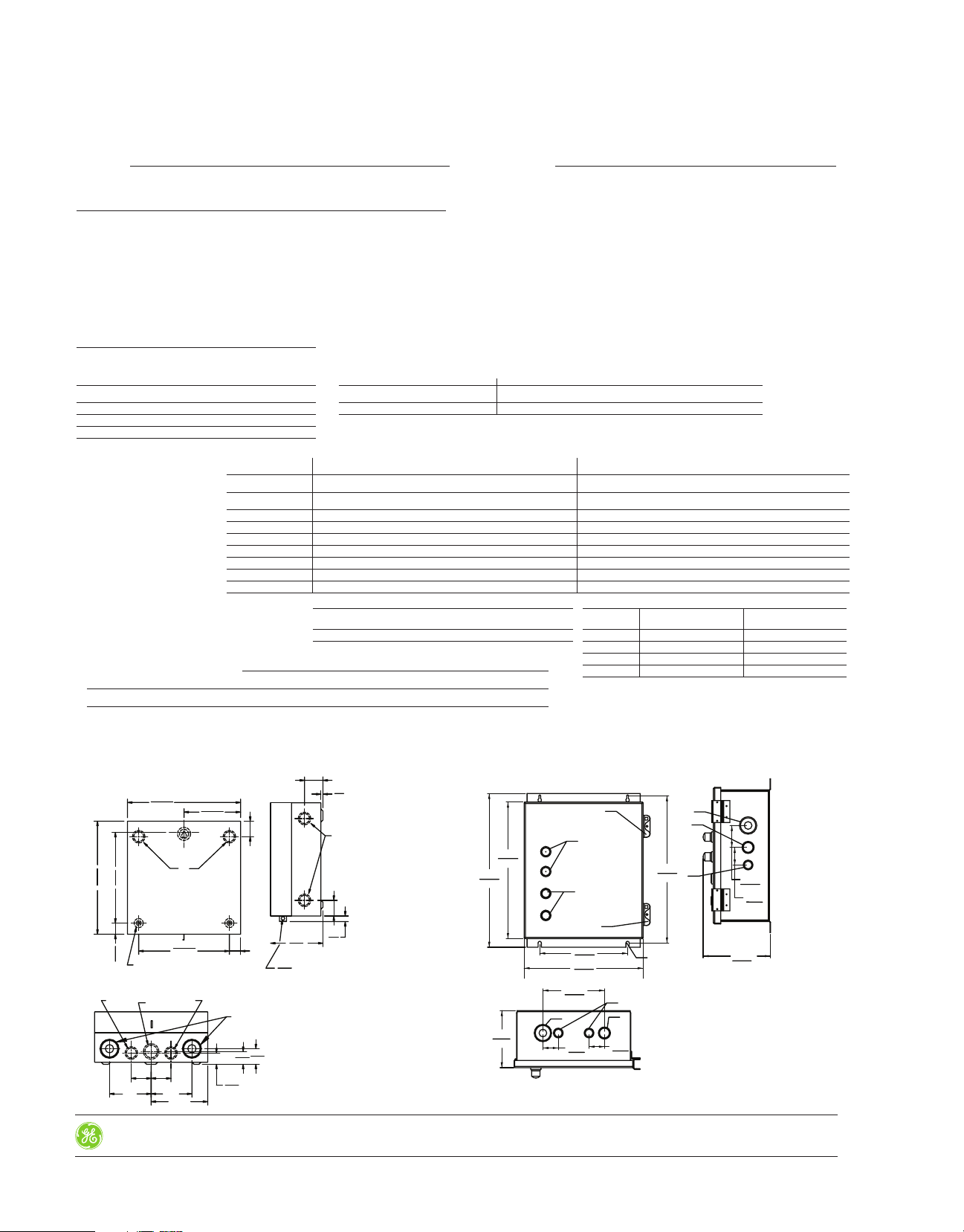

Mechanical Features and Benefits

Mechanically held contactors also feature:

A

B

Section 3Lighting Contactors

A Two-or-three-wire control module:

—low input VA permits long wire runs

—verifies contact status and has

built-in delays that minimize

excessively frequent signals from

faulty controllers

—come in a wide range of input

voltages. Four modules cover input

voltages from 24-277 VAC and 12-24

VDC. All modules may be used with

coil voltage from 24 VAC-277 VAC.

B Clear labeling shows control module rating,

wire size and torque

Field configurable from standard electrically held contactor with

simple, easy-to-install kits of control modules, latch mechanisms

and auxiliary contacts.

Mechanically H el d Cont ac tor

The ultimate in versatility, simplicity and performance

All CR460 Series lighting contactors deliver unprecedented versatility in application,

simplicity in configuration

unique features meet most lighting control needs better than ever before.

—Modular design permits fast , on-site configuration

—2-12 power poles

—30 amp rating

—Snap-in auxiliary contacts

—Common components for both electrically and mechanically held versions

—Continuously rated, interchangeable coils

—Finger-safe terminals

and performance in operation. Their revolutionary design and

Rev. 4/16

data subject to

change without notice

Power poles latch e as il y onto the ba se,

and de si gn at in g them as N O or NC i s a

simple m at ter of left or r ig ht positioning.

Additional p ol es may be added

at a ny time.

Control Catalog

3-3

Lighting Contactors

CR460 Series

Application Information

CR460 lighting contactors switch ballast (fluorescent or HID), tungsten and general use

loads and carry motor load, resistive and pilot duty ratings as well.

CR463L Electrically Held Contactors

Operational Mode

• 3-wire control is typically used when control is desired from multiple locations. The

contactor is operated

to be used as a holding interlock.

• 2-wire control is used for single location control with power continuously supplied to

the coil for contactor operation.

CR463M Mechanically Held Contactors

A mechanical latch with a 2- or 3-wire electronic control module delivers reliable

performance and protection from such application abnormalities as line noise,

leakage currents from controller outputs, or short repetitive commands burst from

faulty controllers.

Mechanical Operation

• Latches after contactor command and removes coil from circuit for

noise-free operation

• Eliminates all coil losses after contactor is latched

Control Module

• Coil operation and control circuit at same or different voltages

• Allows longer control wiring runs

• Microprocessor validates control signal before operation

—will not respond to momentary voltage spikes or noise

—operation command has built in delay (0.4 sec) to avoid multiple short-term

commands that can cause contact fatigue or failure

—feedback loop prevents contactor from getting out of sequence with switches,

even after power failures

Operational Modes

• 3 wire control is the choice for use with momentary devices allowing operation from

multiple locations

—a momentary pulse of energy operates contactor; a second pulse on alternate

leg returns contactor to original state

• 2-wire control is the choice for single-output automatic operation or for operation

from single-pole devices

—latches contactor into position when voltage is applied to input terminals (coil is

removed from circuit while control voltage is continuously supplied); disengages

latch and returns contactor to original state when control voltage is removed.

from a momentary pilot device and requires an auxiliary contact

Section 3

CR463L E le ct ri ca ll y Held

CR463M M ec ha ni ca ll y Held

3-4

Control Catalog

Rev. 4/16

data subject to

change without notice

Lighting Contactors

CR460 Series

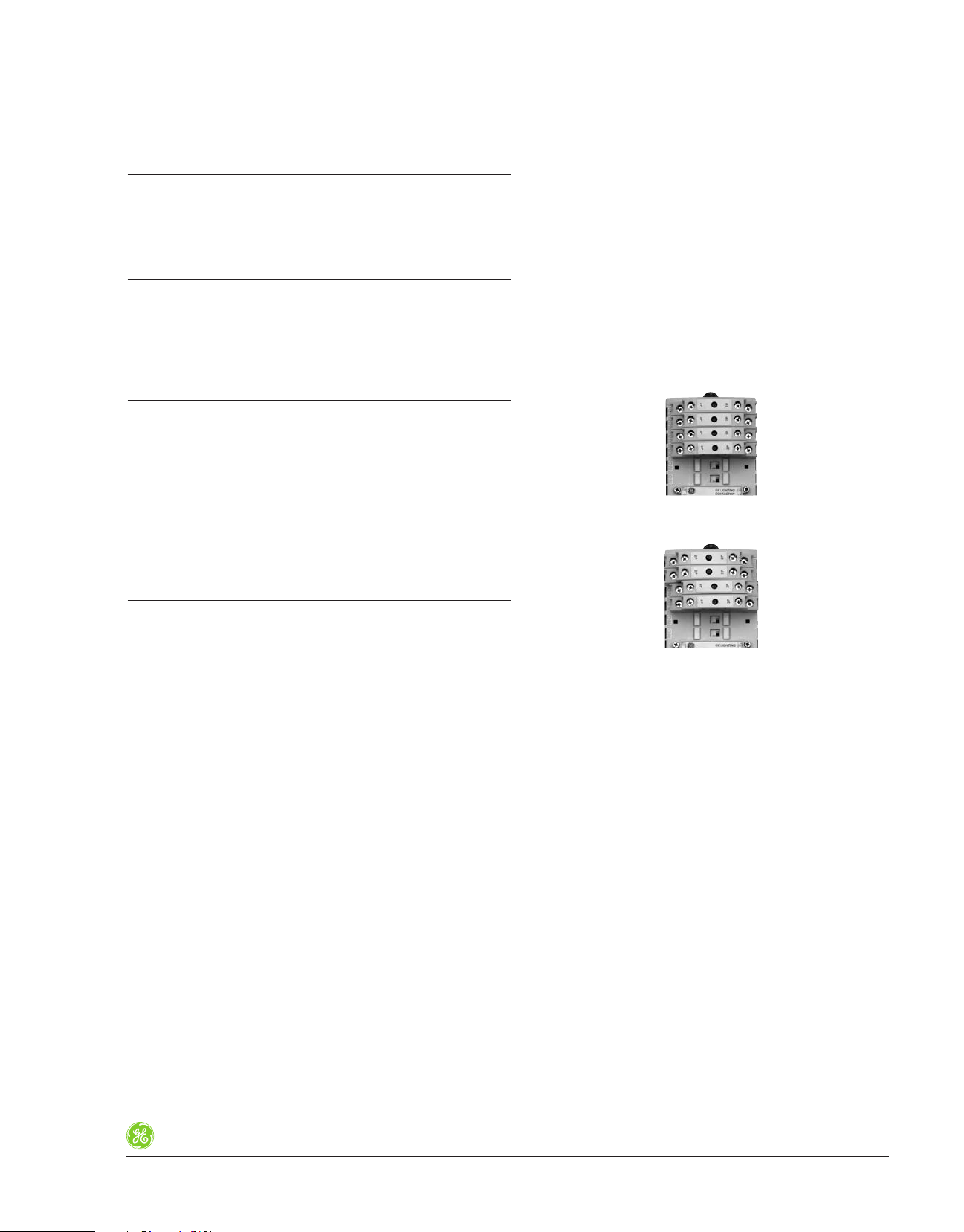

The choice is yours:

3 ways to order CR460 Series Lighting Contactors

Ordering the correct contactor for your application may be

accomplished in any

for you.

1. Order components and assemble in minutes

(see pages 3-6 and 3-7).

—Cost-effective

—Allows late-point configuration

—Greatest flexibility

—Parts in stock for immediate delivery

2. Order standard assembled contactor and rotate poles to meet

pole requirements (see pages 3-9, 3-10, 3-13 and 3-14).

—Available from stock or short cycle for timely delivery

—Single product number to order

—Allows local stocking of most common assembled forms via

pole reconfiguration

When you receive the contactor, simply reconfigure it to the NO-NC

arrangement you require by rotating the appropriate power plates.

It just takes a minute.

Example: 4NO-4NC required. Order CR463L80AJA.

of three ways. Choose the one that’s right

Section 3

CR463L80AJA (8NO)

3. Order assembled contactor configured to the exact

application need (see pages 3-11, 3-12, 3-15 and 3-16)

—Order contactor as required by application

—Arrives fully assembled, ready to install

Contactor re co nf ig ured as 4NO-4NC

Rev. 4/16

data subject to

change without notice

Control Catalog

3-5

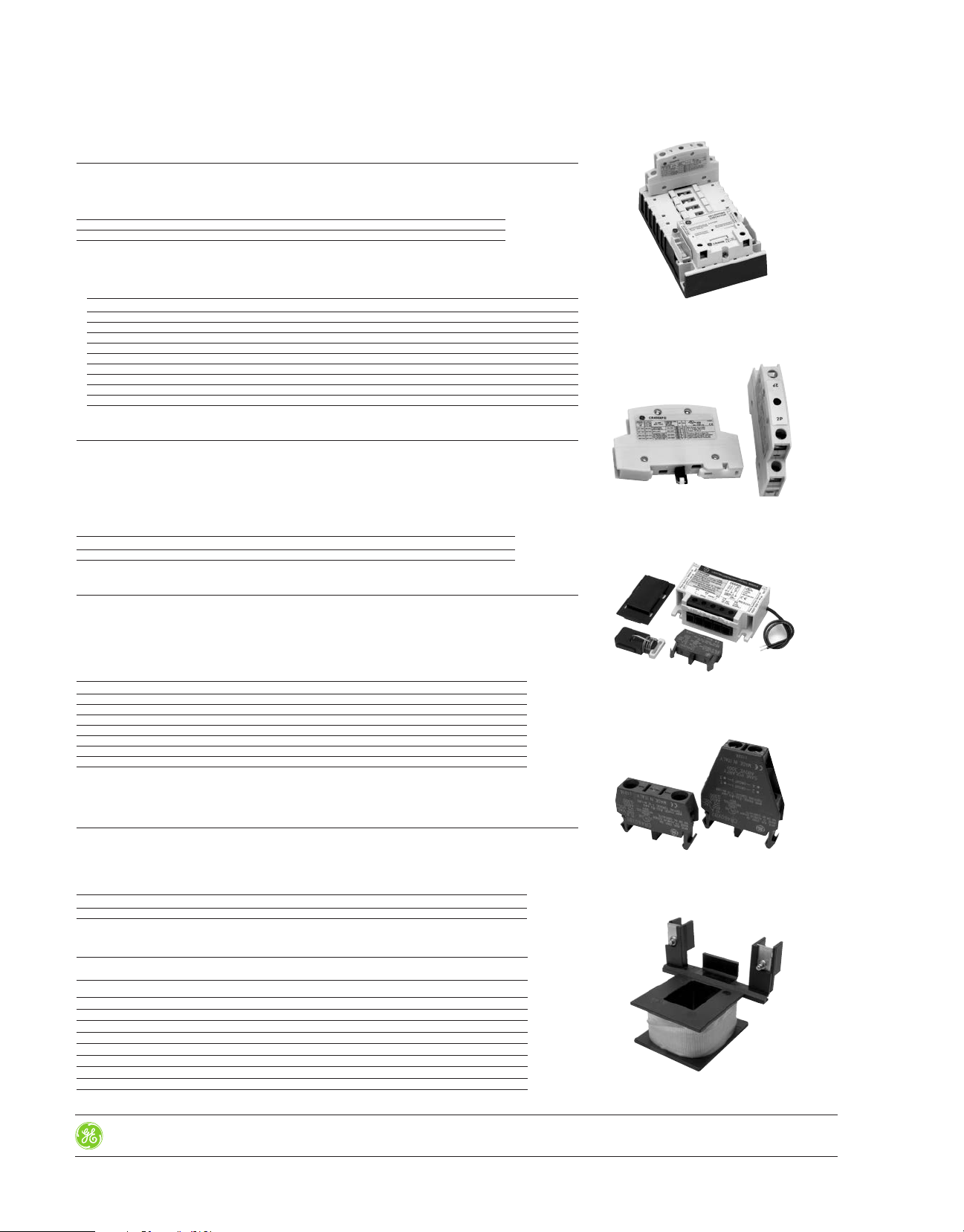

Lighting Contactors

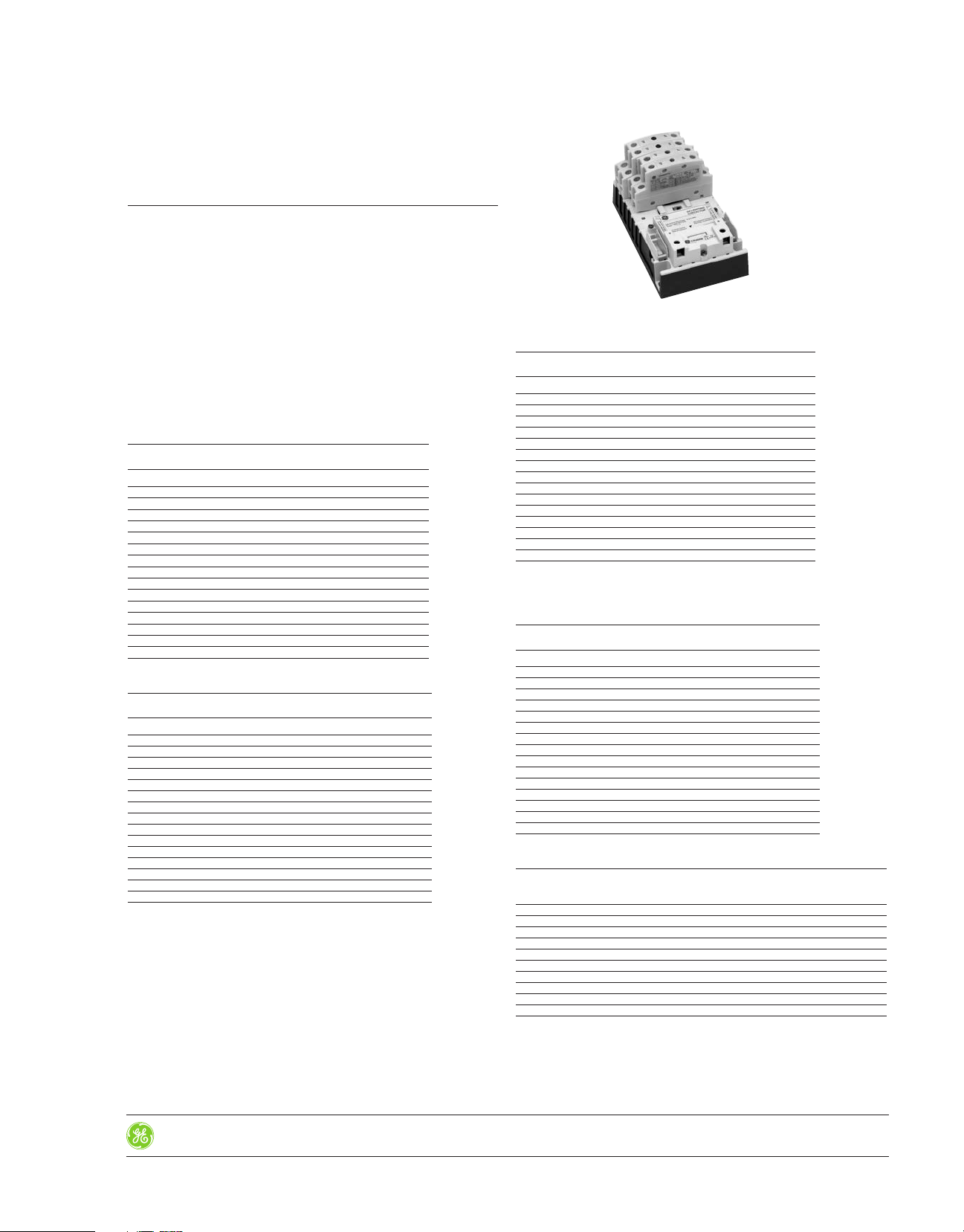

CR460

Components

Basic Contactor

Combined with other appropriate components, basic contactors allow configuration into

any available electrically or mechanically held model. Includes two power poles.

Contact Configuration Product Number

1NO-1NC CR463L11A*A

2NO CR463L20A*A

Replace * in the product number with the appropriate digits from the Coil Voltage table. The resulting product

number will be for an assembled contactor with no additional auxiliary contacts, pilot devices, pilot lights,

control circuit fuses or CPTs. There is no list price adder to Coil Selection.

Coil Voltage

AC, 60Hz AC, 50Hz Electrically Held Mechanically Held Coil Digit

24V 20V √√C

28V 24V √√D

115-120V 110V √√J

200-208V —√ √ L

230-240V 220V √√S

277V 240V √√N

347V —√

460-480V 440V √

575-600V 550V √

1

Control module switching device rated 277V max; use CPT for higher voltage

1

1

1

T

U

Y

Power Poles

CR460 Series basic contactors accept up to 6 single- or double-pole power poles. These

can be used to form up to:

—12 NO poles when 6 double-poles are used in the NO positions (1-6) or

—8 NC poles with 4 double-poles in the NC positions (1-4) + 4 NO poles with 2

double-poles in the 2 NO positions (5-6)

Type Product Number

Single Pole CR460XP31

Double Pole CR460XP32

Packaged individually and overpacked in multiple of 5.

Conversion Kits for Mechanically Held Contactors

Kits for converting electrically held contactors to a mechanically held version. Kits

includes control module, latch, latch cover and auxiliary contact(s) plus installation

instructions. Conversion kits are suitable for coil voltages 277V and below. Use CPT to

reduce coil voltage if line voltage is higher than 277V.

Coil Voltage Control Circuit Auxiliary Control Circuit

Range Wiring Contacts

24-277 Vac 2-wire (1) 1 Pole 24 Vac CR460XMB

24-277 Vac 2-wire (1) 1 Pole 110-120 Vac CR460XMC

24-277 Vac 2-wire (1) 1 Pole 200-277 Vac CR460XMD

24-277 Vac 2-wire (1) 1 Pole 12-28 Vdc CR460XME

24-277 Vac 3-wire (2) 1 Pole 24 Vac CR460XMM

24-277 Vac 3-wire (2) 1 Pole 110-120 Vac CR460XMN

24-277 Vac 3-wire (2) 1 Pole 200-277 Vac CR460XMP

24-277 Vac 3-wire (2) 1 Pole 12-28 Vdc CR460XMR

1

Auxiliary contact block required for feedback loop, alternate 2 pole blocks may be required for status feedback

and/or pilot lights. See Fuse and Transformer Kits table on page 3-7 for CPT selection. See wiring diagrams on

page 3-17.

1

Voltage Product Number

Auxiliary Contacts

Each contactor may use one single or one double auxiliary contact block on each side of

the base. When installed on the left side the contacts are NO, when installed on the right

side the contacts are NC. This allows a total of 2NO + 2NC contacts maximum.

Type Product Number

Single Pole CR460XB1

Double Pole CR460XB2

See Additional Auxiliary Contacts tables on pages 3-12 and 3-16 for contact selection data.

Spare Coils

Coil Voltage @ 60 Hz Coil Voltage @ 50 Hz Product Number

24 20 CR460XCC

28 24 CR460XCD

115-120 110 CR460XCJ

200-208 — CR460XCL

230-240 220 CR460XCS

277 240 CR460XCN

347 — CR460XCT

460-480 440 CR460XCU

575-600 550 CR460XCY

CR463L—Basic C on ta ct or

CR460XM—Conversion K it s

CR460XB—Auxiliary Contacts

Section 3

CR460XP—Power Poles

CR460XC Spare Co il s

3-6

Control Catalog

Rev. 4/16

data subject to

change without notice

Lighting Contactors

CR460

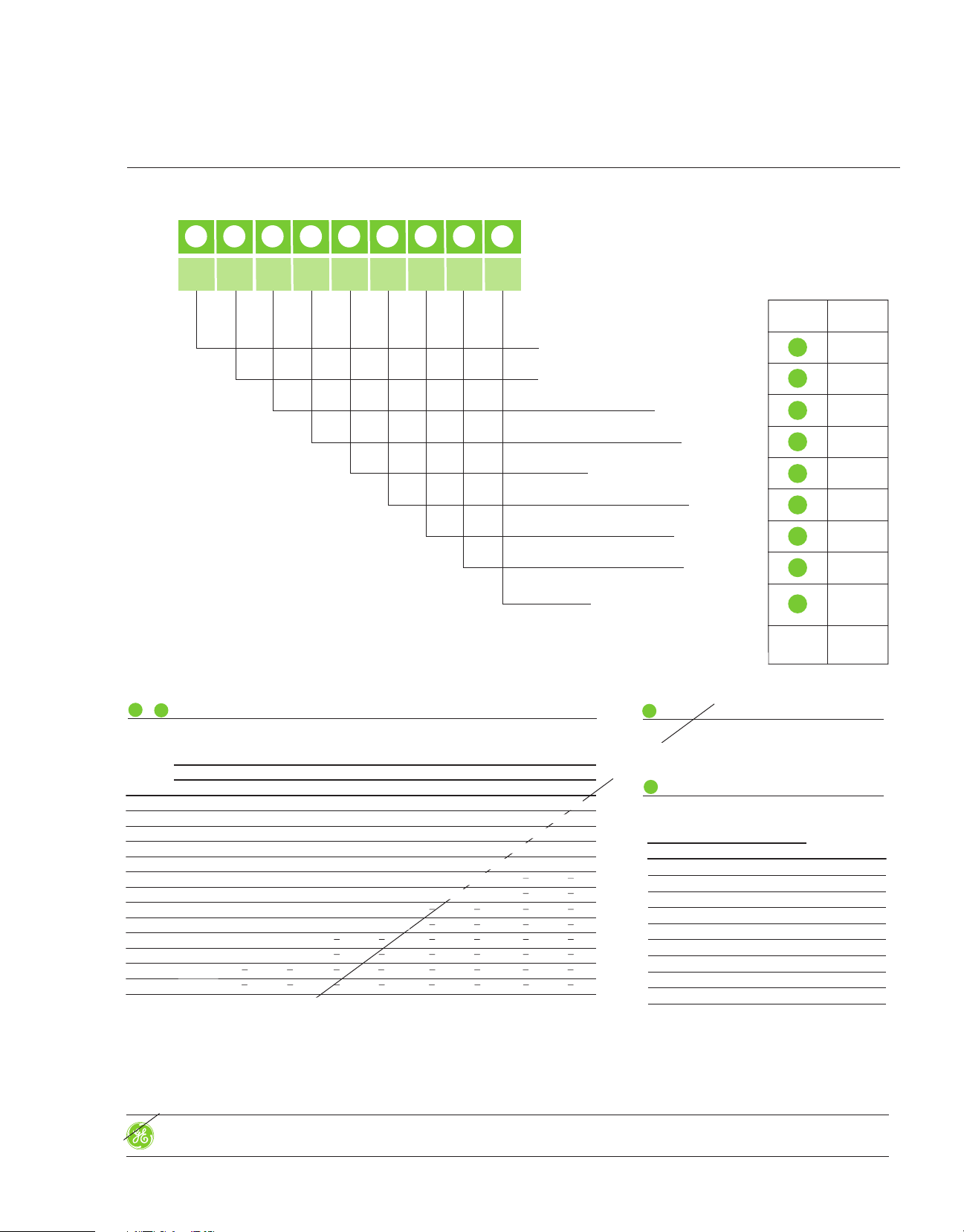

Enclosure Accessories

Enclosure Kits (with no CPT or pilot light devices, lights)

Description Enclosure Type Product Number

Standard

With no CPT or pilot device NEMA Type 1 CR460XE1B

With no CPT or pilot device NEMA Type 1 Flush Mount CR460XE8B

With no CPT or pilot device NEMA Type 12/3R CR460XE2B

Oversized

With provision for CPT and/or pilot devices, lights NEMA Type 1 CR460XE1D

With provision for CPT and/or pilot devices, lights NEMA Type 12/3R CR460XE2D

With provision for CPT and/or pilot devices, lights NEMA Type 4 CR460XE4D

See pages 3-20 to 3-21 for enclosure dimensions.

Pilot Devices (Requires oversize enclosure)

Pilot Device Type For Use With Product Number

Momentary ON/OFF Push Button Electrically Held with Interlock Aux. CR460XP1

Maintained ON/OFF or OFF/AUTO Electrically Held w/o Interlock Aux. CR460XP2

Selector Switch Mechanically Held 2-wire Control Module

Momentary ON/OFF Selector Switch, Electrically Held with Interlock Aux. CR460XP3

Spring Return to Center Mechanically Held 3-wire Control Module

Maintained H-O-A or ON/OFF/AUTO Electrically Held w/o Interlock Aux. CR460XP4

Keyed Selector Switch Mechanically Held 3-wire Control Module

Maintained H-O-A or ON/OFF/AUTO Electrically Held w/o Interlock Aux. CR460XP5

Keyed Selector Switch Mechanically Held 3-wire Control Module

(Key Removal All Positions)

Enclosure accessory kits contain accessory and complete installation wiring and hardware. Some kits contain

multiple nameplates for alternate markings.

Mechanically Held 3-wire Control Module

Mechanically Held 3-wire Control Module

Section 3

Extended Button

Pilot Lights (Requires oversize enclosure)

Pilot Light Type Nameplate Product Number

Standard ON or OFF CR460XLB*

Push-to-Test ON or OFF CR460XLD*

Pilot light kits come with interchangeable red and green lenses. Pilot lights may require auxiliary contacts.

Replace * in pilot light product number with appropriate voltage digit from the table below.

See extra contact limitations in the Additional Auxiliary Contacts tables on pages 3-12 and 3-16.

Pilot Light Voltage

Voltage Digit

24 Vac/dc C

120 Vac J

208 Vac L

240 Vac S

277 Vac N

347 Vac T

480 Vac U

600 Vac Y

Transformer Kits - Includes 2 primary and 2 secondary fuse. (Requires oversize enclosure)

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

100VA CPT Kit

1

May be reconnected in field for 440-480 volts; requires substitution of two 0.5 amp primary fuses.

1

1

1

1

1

1

1

1

1

1

1

CPT Primary Volts CPT Secondary Volts Product Number

208V 120V CR460X TB

220-240V 120V CR460XTC

277V 120V CR460XTD

1

440-480V

600V 120V CR460XTF

120V 24V CR460XTL

208V 24V CR460XTM

1

220-240V

277V 24V CR460XTP

440-480V 24V CR460X TR

600V 24V CR460XTS

120V CR460XTE

24V CR460XTN

Control Circuit Fuse Kit

For Use With Product Number

Contactor Without CPT CR460XF

Standard

Push-to-Test

Control Power

Transformer

Rev. 4/16

data subject to

change without notice

Control Catalog

3-7

Lighting Contactors

4.62

.50

1.38

1.63

35.1

12.7

1.38

35.1

1.00

8.00

254

41.4

25.4

203.2

10.00

1.0

25.4

117.3

1.13

1.00

1.75

1.75

44.4

44.4

A

B

A

K.O.'s SAME TOP & BOTTOM

28.7

25.4

ÿ.25

ÿ6.4

HOLE FOR PADLOCK

3 POINT MTG.

FOR #10 SCREWS

A

A

(BACK)

(BOTH

SIDES)

ACOMBINATION KNOCKOUT FOR

1/2 or 3/4-INCH CONDUIT

COMBINATION KNOCKOUT FOR

3/4 or 1-INCH CONDUIT

B

10.00

D

4.8

.19

3.5

88.9

3.5

88.9

1.5

38.1

COMBINATION KNOCKOUT FOR

1/2, 1 1/4 OR 1 1/2 INCH CONDUI

T

C

254.0

5.00

127.0

203.2

8.00

C (PART 1 ONLY)

13.54

343.9

10.00

254.0

16.75

425.5

17.50

444.5

6.50

165.1

7.67

194.7

2.50

63.5

2.00

50.8

7.00

177.8

1.75

44.5

1.75

44.5

15.54

394.7

PILOT LIGHTS

PUSH BUTTONS

HOLE FOR PADLOCK

HOLE FOR PADLOCK

4 PT. MTG FOR

1/4-20 SCREWS

C*

B*

A

C

B

A

A- COMBINATION KNOCKOUT FOR

1/2 OR 3/4 INCH CONDUIT

B- COMBINATION KNOCKOUT FOR

3/4 OR 1 INCH CONDUIT

C- COMBINATION KNOCKOUT FOR

1/2, 1-1/4 OR 1-1/2 INCH CONDUIT

* NOTE : KNOCKOUTS REVERSED ON BOTTOM

CR460 Series Lighting Contactors – Project Submittal Form

Item No. Proposition No.

CR460 Series lighting contactors feature:

—A modular design that permits fast, on-site configuration

—2-12 power poles that latch easily onto the base as either

NO or NC and that can be added at any time

—30 amp rating

—Snap-in auxiliary contacts

Main Power Pole Ratings

Maximum AC Voltage and Amp Ratings

Load Type Amps Continuous 1 Phase 3 Phase

Ballast 30 347 Vac 600 Vac

General Use 30 600 Vac 600 Vac

Tungsten 20 277 Vac 480 Vac

AC Resistive 30 600 Vac 600 Vac

Power pole

configuration Electrically Held Contactor Mechanically Held Contactor

NO NC Standard Type 1 Enclosure Oversized Type 1 Enclosure Standard Type 1 Enclosure Oversized Type 1 Enclosure

2 0 ❐ CR463L20A*A10A0 ❐ CR463L20A*A10AA ❐ CR463M20##A10A0 ❐ CR463M20##A10AA

3 0 ❐ CR463L30A*A10A0 ❐ CR463L30A*A10AA ❐ CR463M30##A10A0 ❐ CR463M30##A10AA

4 0 ❐ CR463L40A*A10A0 ❐ CR463L40A*A10AA ❐ CR463M40##A10A0 ❐ CR463M40##A10AA

6 0 ❐ CR463L60A*A10A0 ❐ CR463L60A*A10AA ❐ CR463M60##A10A0 ❐ CR463M60##A10AA

8 0 ❐ CR463L80A*A10A0 ❐ CR463L80A*A10AA ❐ CR463M80##A10A0 ❐ CR463M80##A10AA

10 0 ❐ CR463LB0A*A10A0 ❐ CR463LB0A*A10AA ❐ CR463MB0##A10A0 ❐ CR463MB0##A10AA

12 0 ❐ CR463LD0A*A10A0 ❐ CR463LD0A*A10AA ❐ CR463MD0##A10A0 ❐ CR463MD0##A10AA

___ ___ __________________ __________________ __________________ __________________

Maximum Horsepower Rating (Normal Starting Duty)

1 Pole Single Phase 3 Poles, Three Phase

Volts 110-120V 220-240V 200-208V 220-240V 440-480V 550-600V

HP 1 2 3 5 10 15

* 60Hz Coil Voltage (✓) for Electrically Held

115- 200- 230- 460- 575-

24V 120V 208V 240V 277V 488V 600V

❐ C ❐ J ❐ L ❐ S ❐ T ❐ U ❐ Y

Extended description (if any):

—Common components for both electrically and mechanically

held versions

—Continuously rated, interchangeable coils

—Finger-safe terminals

## Control Module (✓) for Mechanically Held

Control Volts 115-120V 277V 115-120V 277V

24-28V ❐ BJ ❐ BN ❐ MJ ❐ MN

110-120V ❐ CJ ❐ CN ❐ NJ ❐ NN

200-277V ❐ DJ ❐ PN ❐ PJ ❐ PN

2-wire Control 3-wire Control

Coil Voltage Coil Voltage

Section 3

Type 1, Standard Enclosure Type 1, Oversized Enclosure

Control Catalog

3-8

Rev. 4/16

data subject to

change without notice

Lighting Contactors

CR463L

Electrically Held Contactors

CR463L - 30A (2-12 pole)

Standard Assembled Forms

Product Number Selection Instructions

Replace * in the product number with the appropriate digits from

the Coil Voltage table. The resulting product number will be for

an assembled contactor with no additional auxiliary contacts,

pilot devices, pilot lights, control circuit fuses or CPTs. There

For modified assembled forms with those modifications, see

pages 3-11 and 3-12.

—Items listed here are the most common pole configurations.

—Poles may be reconfigured by the user into alternative combi-

nations of NO and NC contacts.

—All configurations are available as factory-assembled forms.

Open

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A

2 2NO CR463L20A*A

3 3NO CR463L30A*A

4 3NO-1NC CR463L31A*A

4 4NO CR463L40A*A

5 5NO CR463L50A*A

6 5NO-1NC CR463L51A*A

6 6NO CR463L60A*A

7 7NO CR463L70A*A

8 7NO-1NC CR463L71A*A

8 8NO CR463L80A*A

9 9NO CR463L90A*A

10 9NO-1NC CR463L91A*A

10 10NO CR463LB0A*A

11 11NO CR463LC0A*A

12 12NO CR463LD0A*A

Enclosed NEMA Type 1 Surface Mount

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A10A0

2 2NO CR463L20A*A10A0

3 3NO CR463L30A*A10A0

4 3NO-1NC CR463L31A*A10A0

4 4NO CR463L40A*A10A0

5 5NO CR463L50A*A10A0

6 5NO-1NC CR463L51A*A10A0

6 6NO CR463L60A*A10A0

7 7NO CR463L70A*A10A0

8 7NO-1NC CR463L71A*A10A0

8 8NO CR463L80A*A10A0

9 9NO CR463L90A*A10A0

10 9NO-1NC CR463L91A*A10A0

10 10NO CR463LB0A*A10A0

11 11NO CR463LC0A*A10A0

12 12NO CR463LD0A*A10A0

Section 3

Enclosed NEMA Type 1 Surface Mount (Oversize)

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A10AA

2 2NO CR463L20A*A10AA

3 3NO CR463L30A*A10AA

4 3NO-1NC CR463L31A*A10AA

4 4NO CR463L40A*A10AA

5 5NO CR463L50A*A10AA

6 5NO-1NC CR463L51A*A10AA

6 6NO CR463L60A*A10AA

7 7NO CR463L70A*A10AA

8 7NO-1NC CR463L71A*A10AA

8 8NO CR463L80A*A10AA

9 9NO CR463L90A*A10AA

10 9NO-1NC CR463L91A*A10AA

10 10NO CR463LB0A*A10AA

11 11NO CR463LC0A*A10AA

12 12NO CR463LD0A*A10AA

1

Oversize enclosures required for field installed pilot devices, pilot lights and control

power transformers.

Enclosed NEMA Type 1 Flush Mount

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A80A0

2 2NO CR463L20A*A80A0

3 3NO CR463L30A*A80A0

4 3NO-1NC CR463L31A*A80A0

4 4NO CR463L40A*A80A0

5 5NO CR463L50A*A80A0

6 5NO-1NC CR463L51A*A80A0

6 6NO CR463L60A*A80A0

7 7NO CR463L70A*A80A0

8 7NO-1NC CR463L71A*A80A0

8 8NO CR463L80A*A80A0

9 9NO CR463L90A*A80A0

10 9NO-1NC CR463L91A*A80A0

10 10NO CR463LB0A*A80A0

11 11NO CR463LC0A*A80A0

12 12NO CR463LD0A*A80A0

Coil Voltage

Insert coil digit in place of * in digit 10.

Coil Voltage

AC, 60Hz AC, 50Hz Coil Digit

24V 20V C

28V 24V D

115-120V 110V J

200-208V —L

230-240V 220V S

277V 240V N

347V —T

460-480V 440V U

575-600V 550V Y

1

Rev. 4/16

data subject to

change without notice

Control Catalog

3-9

CR463L

Electrically Held Contactors

CR463L - 30A (2-12 pole)

Standard Assembled Forms

Section 3Lighting Contactors

Enclosed NEMA Type 12/3R

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A20A0

2 2NO CR463L20A*A20A0

3 3NO CR463L30A*A20A0

4 3NO-1NC CR463L31A*A20A0

4 4NO CR463L40A*A20A0

5 5NO CR463L50A*A20A0

6 5NO-1NC CR463L51A*A20A0

6 6NO CR463L60A*A20A0

7 7NO CR463L70A*A20A0

8 7NO-1NC CR463L71A*A20A0

8 8NO CR463L80A*A20A0

9 9NO CR463L90A*A20A0

10 9NO-1NC CR463L91A*A20A0

10 10NO CR463LB0A*A20A0

11 11NO CR463LC0A*A20A0

12 12NO CR463LD0A*A20A0

Enclosed NEMA Type 12/3R (Oversize)

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A20AA

2 2NO CR463L20A*A20AA

3 3NO CR463L30A*A20AA

4 3NO-1NC CR463L31A*A20AA

4 4NO CR463L40A*A20AA

5 5NO CR463L50A*A20AA

6 5NO-1NC CR463L51A*A20AA

6 6NO CR463L60A*A20AA

7 7NO CR463L70A*A20AA

8 7NO-1NC CR463L71A*A20AA

8 8NO CR463L80A*A20AA

9 9NO CR463L90A*A20AA

10 9NO-1NC CR463L91A*A20AA

10 10NO CR463LB0A*A20AA

11 11NO CR463LC0A*A20AA

12 12NO CR463LD0A*A20AA

1

Oversize enclosures required for field installed pilot devices, pilot lights and control

power transformers.

1

Enclosed NEMA Type 4/4X

No. of Poles Contact Configuration Product Number

2 1NO-1NC CR463L11A*A40A0

2 2NO CR463L20A*A40A0

3 3NO CR463L30A*A40A0

4 3NO-1NC CR463L31A*A40A0

4 4NO CR463L40A*A40A0

5 5NO CR463L50A*A40A0

6 5NO-1NC CR463L51A*A40A0

6 6NO CR463L60A*A40A0

7 7NO CR463L70A*A40A0

8 7NO-1NC CR463L71A*A40A0

8 8NO CR463L80A*A40A0

9 9NO CR463L90A*A40A0

10 9NO-1NC CR463L91A*A40A0

10 10NO CR463LB0A*A40A0

11 11NO CR463LC0A*A40A0

12 12NO CR463LD0A*A40A0

Coil Voltage

Insert coil digit in place of * in digit 10.

Coil Voltage

AC, 60Hz AC, 50Hz Coil Digit

24V 20V C

28V 24V D

115-120V 110V J

200-208V —L

230-240V 220V S

277V 240V N

347V —T

460-480V 440V U

575-600V 550V Y

3-10

Control Catalog

Rev. 4/16

data subject to

change without notice

Lighting Contactors

AC, 60Hz AC, 50Hz

24V 20V C

28V 24V D

115-12 0V 110V J

200-208V

—

L

230-240V 220V S

277V 240V N

347V

—

T

460-480V 440V U

575-600 V 550V Y

Coil Voltage

Digit 4

0 1 2 3 4 5 6 7 8

0

— —

1

—

2

3

4

5

6

7

8

9

10 (B)

11 (C)

12 (D)

NO

Contacts

Digit 1

NC Contacts Digit 2

1

1

1

For digit 1 with 10 NO contacts, use B;

for 11 NO contacts, use C; for 12 NO contacts, use D.

Section 3

CR463L

Modified Assembled Forms – Electrically Held

CR463L Electrically Held Contactors

Follow the diagram and tables below to select the options and corresponding product number digits for your modified contactor.

1 2 3 4 5 6 7 8 9

CR463L

A

NO Power Pole Contact Configuration

NC Power Pole Contact Configuration

Standard Control

Coil Voltage

Additional Auxiliary Contacts

Enclosures

Pilot Devices

Pilot Lights

Control Circuit Fuses/

Control Power Transformers

Total

1

2

3

4

5

6

7

8

9

1

2

& Power Pole Contact Configuration

The number of NO contacts is digit 1 and the number of NC contacts is digit 2.

1

For digit 1 with 10 NO contacts use B; for 11 NO contacts, use C; for 12 NO contacts, use D.

Rev. 4/16

change without notice

data subject to

3

Standard Control

Digit 3: A

4

Coil Voltage

There is no price adder to coil selection.

Control Catalog

3-11

Loading...

Loading...