GE Consumer & Industrial

Electrical Distribution

AF-650 GP

TM

General Purpose Drive

Design Guide

Contents

AF-650 GP Design Guide

1 How to Read this Design Guide

How to Read this Design Guide 5

Symbols 5

Abbreviations 6

Definitions 6

2 Safety and Conformity

Safety Precautions 11

Aggressive Environments 14

3 Introduction to AF-650 GP

Product Overview 15

Control Principle 17

AF-650 GP Controls 17

Control Structure in Advanced Vector Control 18

Control Structure in Flux Sensorless 19

Control Structure in Flux with Motor Feedback 20

Internal Current Control in Advanced Vector Control Mode 20

5

11

15

Local (Hand) and Remote (Auto) Control 21

Reference Limits 23

Scaling of Preset References and Bus References 23

Scaling of Analog and Pulse References and Feedback 24

Dead Band Around Zero 24

Speed PID Control 27

Process PID Control 30

Ziegler Nichols Tuning Method 34

EMC Test Results 36

PELV - Protective Extra Low Voltage 38

Brake Functions in AF-650 GP 40

Mechanical Holding Brake 40

Dynamic Braking 40

Selection of Brake Resistor 40

Mechanical Brake Control 43

Hoist Mechanical Brake 44

Safe Stop of AF-650 GP 48

4 AF-650 GP Selection

Electrical Data - 200-240 V 53

Electrical Data - 380-480 V

Electrical Data - 525-600 V 61

Electrical Data - 525-690 V 64

53

55

1

AF-650 GP Design Guide

General Specifications 71

Acoustic Noise 77

du/dt Conditions 77

Special Conditions 81

Automatic Tuning to Ensure Performance 88

5 Mechanical Installation - Unit Sizes 1, 2 and 3

6 Mechanical Installation - Unit Size 4, 5 and 6

Pre-installation 93

Planning the Installation Site 93

Receiving the Frequency Converter 93

Transportation and Unpacking 93

Lifting 94

Mechanical Dimensions 96

Mechanical Installation 103

Terminal Locations - Unit Size 4X 105

Terminal Locations - Unit Size 5X 106

Terminal Locations - Unit Sizes 6X 108

Cooling and Airflow 111

7 Electrical Installation

Connections- Unit Sizes 1x, 2x and 3x 117

Connection to Mains and Earthing 118

89

93

117

Motor Connection 121

Relay Connection 124

Connections - Unit Sizes 4, 5 and 6 125

Power Connections 125

Fuses 133

Disconnectors, Circuit Breakers and Contactors 140

Motor Bearing Currents 141

Control Cables and Terminals 141

Control Cable Routing 142

Control Terminals 143

Switches S201, S202, and S801 144

Electrical Installation, Control Terminals 145

Basic Wiring Example 146

Electrical Installation, Control Cables 147

Additional Connections 149

How to Connect a PC to the Frequency Converter 151

The AF-650 GP PC Software 151

Residual Current Device 156

2

AF-650 GP Design Guide

Final Setup and Test 157

8 Application Examples

Encoder Connection 160

Encoder Direction 160

Closed Loop Drive System 161

Programming of Torque Limit and Stop 161

Advanced Mechanical Brake Control for Hoisting Applications 162

Auto Tune 163

Logic Controller Programming 163

LC Application Example 164

Torque Control Open Loop 165

9 Options and Accessories

Mounting of Option Modules in Slot A 167

Mounting of Option Modules in Slot B 167

General Purpose Input Output Module OPCGPIO 168

OPCENC Encoder Option Module 171

OPCRES Resolver Option Module 173

OPCRLY Relay Option Module 174

159

167

OPC24VPS 24V DC External Supply Module 176

Brake Resistors 177

Remote Mounting Kit for Keypad 177

IP21/IP 4X/ TYPE 1 Unit Kit 179

Sine-wave Filters 180

10 RS-485 Installation and Set-up

RS-485 Installation and Set-up 181

Network Configuration 183

Drive Protocol Message Framing Structure - AF-650 GP 183

Examples 188

Modbus RTU Overview 190

Modbus RTU Message Framing Structure 191

How to Access Parameters 195

GE Drive Control Profile 196

Index

181

206

3

1

AF-650 GP Design Guide

4

AF-650 GP Design Guide

1 How to Read this Design Guide

1.1.1 How to Read this Design Guide

This Design Guide will introduce all aspects of your AF-650 GP.

Available literature for AF-650 GP

- The AF-650 GP Operating Instructions DET-607 provide the neccessary information for getting the drive up and running.

- The AF-650 GP High Power Operating Instructions DET-608

- The AF-650 GP Design Guide DET-619 entails all technical information about the drive and customer design and applications.

- The AF-650 GP Programming Guide DET-618 provides information on how to programme and includes complete parameter descriptions.

- The AF-650 GP Profibus Operating Instructions DET-629 provide the information required for controlling, monitoring and programming the drive via a

Profibus network.

- The AF-650 GP DeviceNet Operating Instructions DET-623 provide the information required for controlling, monitoring and programming the drive via

a DeviceNet network.

GE technical literature is also available online at www.geelectrical.com/drives

1.1.2 Symbols

1

Symbols used in this guide.

NB!

Indicates something to be noted by the reader.

Indicates a general warning.

Indicates a high-voltage warning.

Indicates default setting

*

5

1.1.3 Abbreviations

AF-650 GP Design Guide

1

Alternating current AC

American wire gauge AWG

Ampere/AMP A

Current limit I

Degrees Celsius °C

Direct current DC

Drive Control Tool PC Software DCT 10

Drive Dependent D-TYPE

Electro Magnetic Compatibility EMC

Electronic Thermal Overload Elec. OL

Gram g

Hertz Hz

Kilohertz kHz

Meter m

Millihenry Inductance mH

Milliampere mA

Millisecond ms

Minute min

Nanofarad nF

Newton Meters Nm

Nominal motor current I

Nominal motor frequency f

Nominal motor power P

Nominal motor voltage U

Parameter par.

Protective Extra Low Voltage PELV

Printed Circuit Board PCB

Rated Inverter Output Current I

Revolutions Per Minute RPM

Regenerative terminals Regen

Second s

Synchronous Motor Speed n

Torque limit T

Volts V

LIM

M,N

M,N

M,N

M,N

INV

s

LIM

1.1.4 Definitions

Frequency converter:

Coast

The motor shaft is in free mode. No torque on motor.

I

DRIVE,MAX

The maximum output current.

I

DRIVE,N

The rated output current supplied by the frequency converter.

U

DRIVE, MAX

The maximum output voltage.

Input:

Control command

Start and stop the connected motor by means of Keypad and the digital in-

puts.

Functions are divided into two groups.

Functions in group 1 have higher priority than functions in group 2.

Motor:

f

JOG

The motor frequency when the jog function is activated (via digital terminals).

Group 1

Group 2 Start, Pulse start, Reversing, Start reversing,

Reset, Coasting stop, Reset and Coasting stop,

Quick-stop, DC braking, Stop and the "Off" key.

Jog and Freeze output

6

AF-650 GP Design Guide

f

M

Motor frequency. Output from the frequency converter. Output frequency is related to the shaft speed on motor depending on number of poles and slip frequency.

f

MAX

The maximum output frequency the frequency converter applies on its output. The maximum output frequency is set in limit par. F-16, F-17 and F-03.

f

MIN

The minimum motor frequency from frequency converter. Default 0 Hz.

f

M,N

The rated motor frequency (nameplate data).

I

M

The motor current.

I

M,N

The rated motor current (nameplate data).

n

M,N

The rated motor speed (nameplate data).

n

s

Synchronous motor speed

2×

par. F

n

=

s

P

M,N

par

− 04 × 60

. P− 01

The rated motor power (nameplate data).

s

1

T

M,N

The rated torque (motor).

U

M

The instantaneous motor voltage.

U

M,N

The rated motor voltage (nameplate data).

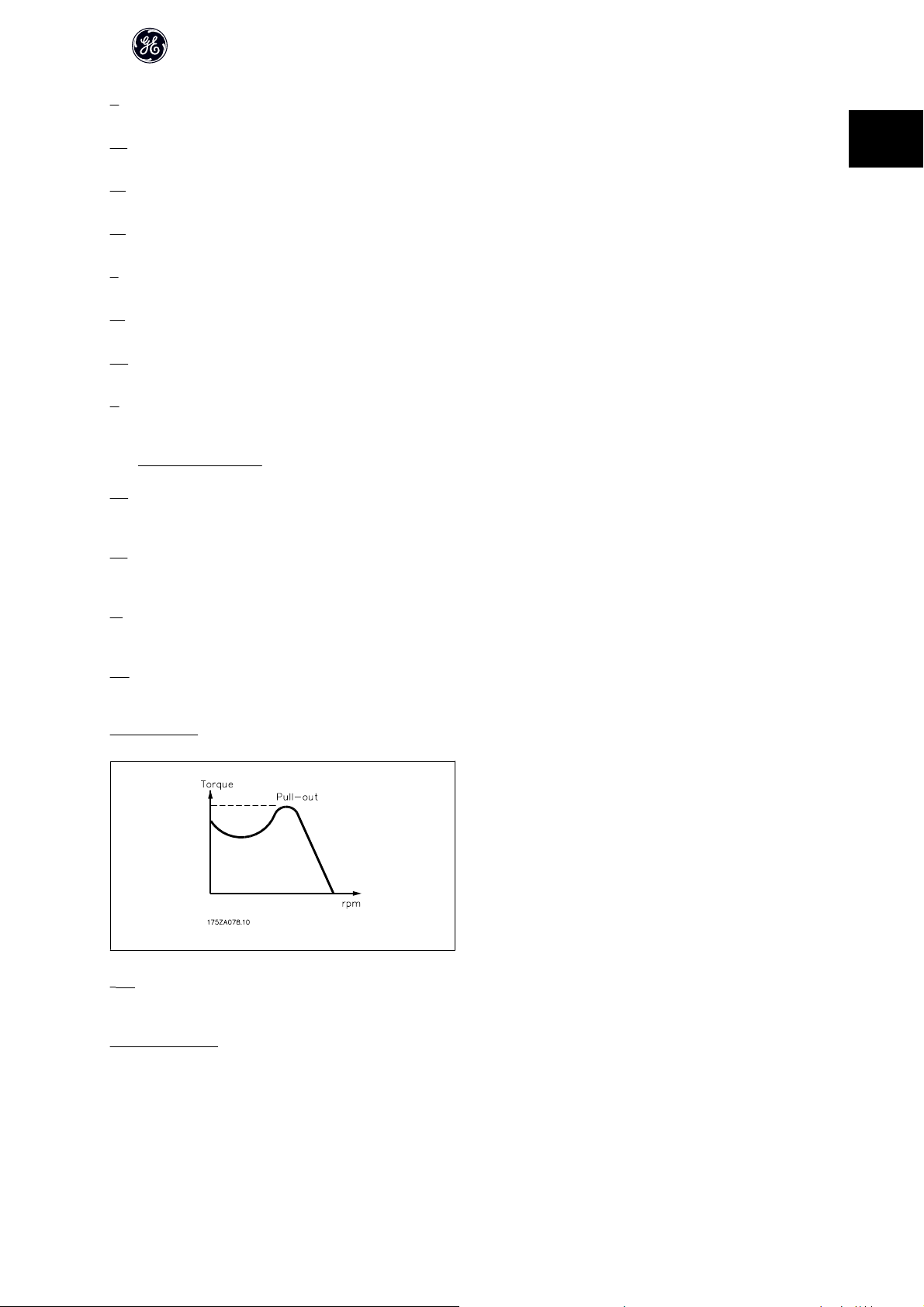

Break-away torque

DRIVE

The efficiency of the frequency converter is defined as the ratio between the power output and the power input.

Start-disable command

A stop command belonging to the group 1 control commands - see this group.

7

AF-650 GP Design Guide

Stop command

See Control commands.

1

References:

Advanced Vector Control

If compared with standard voltage/frequency ratio control, Adv. Vector Control) improves the dynamics and the stability, both when the speed reference is changed

and in relation to the load torque.

Analog Reference

An analog signal applied to input 53 or 54. The signal can be either Voltage 0-10V or -10 -+10V. Current signal 0-20 mA or 4-20 mA.

Binary Reference

A signal applied to the serial communication port (RS 485 term 68 – 69).

Preset Reference

A defined preset reference to be set from -100% to +100% of the reference range. Selection of eight preset references via the digital terminals.

Pulse Reference

A pulse reference applied to term 29 or 33, selected by par. E-04 or E-06 [32]. Scaling in par. group E-6#.

Ref

MAX

Determines the relationship between the reference input at 100% full scale value (typically 10 V, 20mA) and the resulting reference. The maximum reference value

set in par. F-53 Maximum Reference.

Ref

MIN

Determines the relationship between the reference input at 0% value (typically 0V, 0mA, 4mA) and the resulting reference. The minimum reference value set in

par. F-52 Minimum Reference.

Miscellaneous:

Analog Inputs

The analog inputs are used for controlling various functions of the frequency converter.

There are two types of analog inputs:

Current input, 0-20 mA and 4-20 mA

Voltage input, 0-10 V DC

Voltage input, -10 - +10 V DC.

Analog Outputs

The analog outputs can supply a signal of 0-20 mA, 4-20 mA.

Auto Tuning

The Auto Tune algorithm determines the electrical parameters for the connected motor at standstill.

Brake Resistor

The brake resistor is a module capable of absorbing the brake power generated in regenerative braking. This regenerative braking power increases the intermediate

circuit voltage and a brake chopper ensures that the power is transmitted to the brake resistor.

CT Characteristics

Constant torque characteristics used for all applications such as conveyor belts, displacement pumps and cranes.

Digital Inputs

The digital inputs can be used for controlling various functions of the frequency converter.

Digital Outputs

The frequency converter features two Solid State outputs that can supply a 24 V DC (max. 40 mA) signal.

DSP

Digital Signal Processor.

Electronic Thermal Overload

The Electronic Overload is a thermal load calculation based on present load and time. Its purpose is to estimate the motor temperature.

®

Hiperface

Hiperface® is a registered trademark by Stegmann.

Intermittent Duty Cycle

An intermittent duty rating refers to a sequence of duty cycles. Each cycle consists of an on-load and an off-load period. The operation can be either periodic duty

or non-periodic duty.

8

AF-650 GP Design Guide

Keypad

The Keypad makes up a complete interface for control and programming of the frequency converter. The Keypad is detachable and can be installed up to 10ft/

3M from the frequency converter, i.e. in a front panel with the optional Remote Keypad Mounting Kit (RMKYPDAC)..

Logic Controller (LC)

The LC is a sequence of user defined actions executed when the associated user defined events are evaluated as true by the Logic Controller. (Parameter group

LC-##).

lsb

Least significant bit.

msb

Most significant bit.

MCM

Short for Mille Circular Mil, an American measuring unit for cable cross-section. 1 MCM = 0.5067 mm

On-line/Off-line Parameters

Changes to on-line parameters are activated immediately after the data value is changed. Changes to off-line parameters are not activated until you enter [OK]

on the Keypad.

Process PID

The PID regulator maintains the desired speed, pressure, temperature, etc. by adjusting the output frequency to match the varying load.

PCD

Process Data

Pulse Input/Incremental Encoder

An external digital sensor used for feedback information of motor speed and direction. Encoders are used for high speed accuracy feedback and in high dynamic

applications. The encoder connection is either via term 32 and 32 or encoder option OPCENC.

RCD

Residual Current Device.

Set-up

You can save parameter settings in four Set-ups. Change between the four parameter Set-ups and edit one Set-up, while another Set-up is active.

SFAVM

Switching pattern called

Slip Compensation

The frequency converter compensates for the motor slip by giving the frequency a supplement that follows the measured motor load keeping the motor speed

almost constant..

STW

Status Word

Drive Standard Bus

Includes RS 485 bus with Drive protocol or MC protocol. See par. O-30 Protocol.

Thermistor:

A temperature-dependent resistor placed where the temperature is to be monitored (frequency converter or motor).

THD

Total Harmonic Distortion state the total contribution of harmonic.

Trip

A state entered in fault situations, e.g. if the frequency converter is subject to an over-temperature or when the frequency converter is protecting the motor,

process or mechanism. Restart is prevented until the cause of the fault has disappeared and the trip state is cancelled by activating reset or, in some cases, by

being programmed to reset automatically. Trip may not be used for personal safety.

Trip Locked

A state entered in fault situations when the frequency converter is protecting itself and requiring physical intervention, e.g. if the frequency converter is subject

to a short circuit on the output. A locked trip can only be cancelled by cu tting off mains, removing the cause of the fault, and reconnecting th e frequency converter.

Restart is prevented until the trip state is cancelled by activating reset or, in some cases, by being programmed to reset automatically. Trip may not be used for

personal safety.

Stator Flux oriented Asynchronous Vector Modulation (par. F-37 Adv. Switching Pattern).

2

.

1

9

VT Characteristics

Variable torque characteristics used for pumps and fans.

60° AVM

1

Switching pattern called 60°

Asynchronous Vector Modulation (par. F-37 Adv. Switching Pattern).

AF-650 GP Design Guide

Power Factor

The power factor is the relation between I

The power factor for 3-phase control:

The power factor indicates to which extent the frequency converter imposes

a load on the mains supply.

The lower the power factor, the higher the I

In addition, a high power factor indicates that the different harmonic currents are low.

All frequency converters have built-in DC link reactor in the DC link to have a high power factor and to reduce the THD on the main supply.

and I

.

1

RMS

for the same kW performance.

RMS

Power factor

I1 x cos

=

I

RMS

I

=

RMS

I

ϕ1

2

1

=

=

+

3 x U x

3 x U x

I

RMS

2

I

+

5

I

1

2

I

7

I

cos

1

I

RMS

since cos

+ .. +

ϕ

ϕ1 = 1

2

I

n

10

2 Safety and Conformity

2.1 Safety Precautions

AF-650 GP Design Guide

2.1.1 Safety Precautions

The voltage of the drive is dangerous whenever connected to mains. Incorrect installation of the motor, drive or network may cause damage

to the equipment, serious personal injury or death. Consequently, the instructions in this manual, as well as national and local rules and safety

regulations, must be complied with.

Safety Regulations

1. The mains supply to the drive must be disconnected whenever repair work is to be carried out. Check that the mains supply has been disconnected and

that the necessary time has elapsed before removing motor and mains supply plugs.

2. The [OFF] button on the Keypad of the driver does not disconnect the mains supply and consequently it must not be used as a safety switch.

3. The equipment must be properly earthed, the user must be protected against supply voltage and the motor must be protected against overload in

accordance with applicable national and local regulations.

4. The earth leakage current exceeds 3.5 mA.

5. Protection against motor overload is not included in the factory setting. If this function is desired, set par. F-10 Electronic Overload to data value Elec.

OL trip 1 [4] or data value Elec. OL warning 1 [3].

6. Do not remove the plugs for the motor and mains supply while the drive is connected to mains. Check that the mains supply has been disconnected

and that the necessary time has elapsed before removing motor and mains plugs.

7. Please note that the drive has more voltage sources than L1, L2 and L3, when load sharing (linking of DC intermediate circuit) or external 24 V DC are

installed. Check that all voltage sources have been disconnected and that the necessary time has elapsed before commencing repair work.

Warning against unintended start

1. The motor can be brought to a stop by means of digital commands, bus commands, references or a local stop, while the drive is connected to mains. If

personal safety considerations (e.g. risk of personal injury caused by contact with moving machine parts following an unintentional start) make it

necessary to ensure that no unintended start occurs, these stop functions are not sufficient. In such cases the mains supply must be disconnected.

2. The motor may start while setting the parameters. If this means that personal safety may be compromised (e.g. personal injury caused by contact with

moving machine parts), motor starting must be prevented by disconnection of the motor connection.

3. A motor that has been stopped with the mains supply connected, may start if faults occur in the electronics of the drive, through temporary overload

or if a fault in the power supply grid or motor connection is remedied. If unintended start must be prevented for personal safety reasons (e.g. risk of

injury caused by contact with moving machine parts), the normal stop functions of the drive are not sufficient. In such cases the mains supply must be

disconnected.

4. Control signals from, or internally within, the drive may in rare cases be activated in error, be delayed or fail to occur entirely. When used in situations

where safety is critical, e.g. when controlling the electromagnetic brake function of a hoist application, these control signals must not be relied on

exclusively.

2

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as external 24 V DC, load sharing (linkage of DC intermediate circuit), as well as the motor

connection for kinetic back up.

Systems where frequency converters are installed must, if necessary, be equipped with additional monitoring and protective devices according to the valid safety

regulations, e.g law on mechanical tools, regulations for the prevention of accidents etc. Modifications on the frequency converters by means of the operating

software are allowed.

Protection Mode

Once a hardware limit on motor current or dc-link voltage is exceeded the drive will enter “Protection mode”. “Protection mode” means a change of the PWM

modulation strategy and a low switching frequency to minimize losses. This continues 10 sec after the last fault and increases the reliability and the robustness

of the drive while re-establishing full control of the motor.

11

AF-650 GP Design Guide

The “Protection mode” can be disabled by setting par. SP-26 Trip Delay at Drive Fault to ze ro w hich mea ns that the drive will trip immediately if one of the hardware

limits is exceeded.

The DC link capacitors remain charged after power has been disconnected. To avoid electrical shock hazard, disconnect the frequency con-

verter from mains before carrying out maintenance. When using a PM-motor, make sure it is disconnected. Before doing service on the

frequency converter wait at least the amount of time indicated below:

2

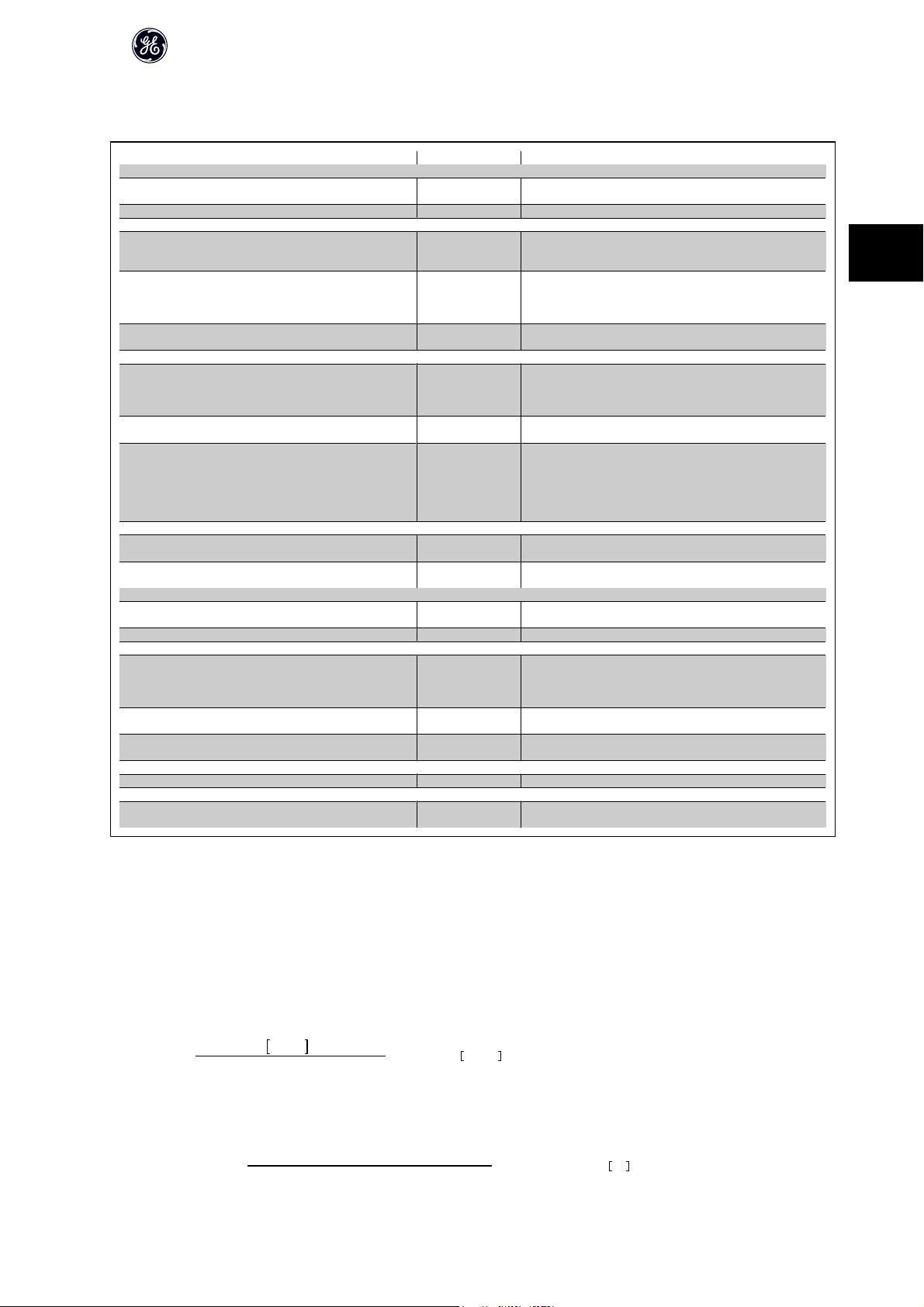

Voltage Power Waiting Time

380 - 480 V 0.25 - 7.5 kW 4 minutes

11 - 75 kW 15 minutes

90 - 200 kW 20 minutes

250 - 800 kW 40 minutes

525 - 690 V 11-75 kW (unit size 2x and 3x) 15 minutes

37 - 315 kW (unit size 4x) 20 minutes

355 - 1000 kW 30 minutes

2.2.1 Disposal Instruction

Equipment containing electrical components may not be disposed of together with domestic waste.

It must be separately collected with electrical and electronic waste according to local and currently

valid legislation.

AF-650 GP

Design Guide

Software version: 1.xx

This Design Guide can be used for all AF-650 GP frequency converters with software version 1.xx.

The software version number can be seen from par. ID-43 Software Version.

2.4.1 CE Conformity and Labelling

What is CE Conformity and Labelling?

The purpose of CE labelling is to avoid technical trade obstacles within EFTA and the EU. The EU has introduced the CE label as a simple way of showing whether

a product complies with the relevant EU directives. The CE label says nothing about the specifications or quality of the product. Frequency converters are regulated

by three EU directives:

The machinery directive (98/37/EEC)

All machines with critical moving parts are covered by the machinery directive of January 1, 1995. Since a frequency converter is largely electrical, it does not fall

under the machinery directive. However, if a frequency converter is supplied for use in a machine, we provide information on safety aspects relating to the

frequency converter. We do this by means of a manufacturer's declaration.

The low-voltage directive (73/23/EEC)

Frequency converters must be CE labelled in accordance with the low-voltage directive of January 1, 1997. The directive applies to all electrical equipment and

appliances used in the 50 - 1000 V AC and the 75 - 1500 V DC voltage ranges. GE CE-labels in accordance with the directive and issues a declaration of conformity

upon request.

The EMC directive (89/336/EEC)

EMC is short for electromagnetic compatibility. The p resence of electromagnetic compatibility means that the mutual interference between different components/

appliances does not affect the way the appliances work.

The EMC directive came into effect January 1, 1996. GE CE-labels in accordance with the directive and issues a declaration of conformity upon request. To carry

out EMC-correct installation, see the instructions in this Design Guide. In addition, we specify which standards our products comply with. We offer the filters

presented in the specifications and provide other types of assistance to ensure the optimum EMC result.

12

AF-650 GP Design Guide

The frequency converter is most often used by professionals of the trade as a complex component forming part of a larger appliance, system or installation. It

must be noted that the responsibility for the final EMC properties of the appliance, system or installation rests with the installer.

2.4.2 What Is Covered

The EU "Guidelines on the Application of Council Directive 89/336/EEC" outline three typical situations of using a frequency converter. See below for EMC coverage

and CE labelling.

1. The frequency converter is sold directly to the end-consumer. The frequency converter is for example sold to a DIY market. The end-consumer is a

layman. He installs the frequency converter himself for use with a hobby machine, a kitchen appliance, etc. For such applications, the frequency converter

must be CE labelled in accordance with the EMC directive.

2. The frequency converter is sold for installation in a plant. The plant is built up by professionals of the trade. It could be a production plant or a heating/

ventilation plant designed and installed by professionals of the trade. Neither the frequency converter nor the finished plant has to be CE labell ed und er

the EMC directive. However, the unit must comply with the basic EMC requirements of the directive. This is ensured by using components, appliances,

and systems that are CE labelled under the EMC directive.

3. The frequency converter is sold as part of a complete system. The system is being marketed as complete and could e.g. be an air-conditioning system.

The complete system must be CE labelled in accordance with the EMC directive. The manufacturer can ensure CE labelling under the EMC directive either

by using CE labelled components or by testing the EMC of the system. If he chooses to use only CE labelled components, he does not have to test the

entire system.

2

2.4.3 GE Frequency Converter and CE Labelling

CE labelling is a positive feature when used for its original purpose, i.e. to facilitate trade within the EU and EFTA.

However, CE labelling may cover many different specifications. Thus, you have to check what a given CE label specifically covers.

The covered specifications can be very different and a CE label may therefore give the installer a false feeling of security when using a frequency converter as a

component in a system or an appliance.

GE CE labels the frequency conve rters in accordance with the low-voltage directive. This mea ns that if the frequency converter is installed correctly, we guarantee

compliance with the low-voltage directive. GE issuesWe issue a declaration of conformity that confirms our CE labelling in accordance with the low-voltage

directive.

The CE label also applies to the EMC directive provided that the instructions for EMC-correct installation and filtering are followed. On this basis, a declaration of

conformity in accordance with the EMC directive is issued.

The Design Guide offers detailed instructions for installation to ensure EMC-correct installation. Furthermore, GE specifies which our different products comply

with.

GE provides other types of assistance that can help you obtain the best EMC result.

2.4.4 Compliance with EMC Directive 89/336/EEC

As mentioned, the frequency converter is mostly used by professionals of the trade as a complex component forming part of a larger appliance, system, or

installation. It must be noted that the responsibility for the final EMC properties of the appliance, system or installation rests with the installer. As an aid to the

installer, GE has prepared EMC installation guidelines for the Power Drive system. The standards and test levels stated for Power Drive systems are complied with,

provided that the EMC-correct instructions for installation are followed, see the section EMC Immunity.

The frequency converter has been designed to meet the IEC/EN 60068-2-3 standard, EN 50178 pkt. 9.4.2.2 at 50°C.

13

AF-650 GP Design Guide

2.5.1 Aggressive Environments

A frequency converter contains a large number of mechanical and electronic components. All are to some extent vulnerable to environmental effects.

2

Liquids can be carried through the air and condense in the frequency converter and may cause corrosion of components and metal parts. Steam, oil, and salt

water may cause corrosion of components and metal parts. In such environments, use equipment with Unit Size rating IP 54/55. As an extra protection, coated

printed circuit boards can be ordered as an option.

Airborne

particles is dust particles around the frequency converter fan. In very dusty environments, use equipment with Unit Size rating IP 54/55 or a cabinet for IP 00/IP

20/TYPE 1 equipment.

In environments with high temperatures and humidity,

frequency converter components.

Such chemical reactions will rapidly affect and damage the electronic components. In such environments, mount the equipment in a cabinet with fresh air

ventilation, keeping aggressive gases away from the frequency converter.

An extra protection in such areas is a coating of the printed circuit boards, which can be ordered as an option.

NB!

Mounting frequency converters in aggressive environments increases the risk of stoppages and considerably reduces the life of the converter.

The frequency converter should not be installed in environments with airborne liquids, particles, or gases capable of affecting and damaging

the electronic components. Failure to take the necessary protective measures increases the risk of stoppages, thus reducing the life of the

frequency converter.

Particles such as dust may cause mechanical, electrical, or thermal failure in the frequency converter. A typical indicator of excessive levels of airborne

corrosive gases such as sulphur, nitrogen, and chlorine compounds will cause chemical processes on the

Before installing the frequency converter, check the ambient air for liquids, particles, and gases. This is done by observing existing installations in this environment.

Typical indicators of harmful airborne liquids are water or oil on metal parts, or corrosion of metal parts.

Excessive dust particle levels are often found on installation cabinets and existing electrical installations. One indicator of aggressive airborne gases is blackening

of copper rails and cable ends on existing installations.

Unit Sizes 4x and 5x have a stainless steel back-channel option to provide additional protection in aggressive environments. Proper ventilation is still required for

the internal components of the drive. Contact GE for additional information.

The frequency converter has been tested according to the procedure based on the shown standards:

The frequency converter complies with requirements that exist for units mounted on the walls and floors of production premises, as well as in panels bolted to

walls or floors.

IEC/EN 60068-2-6: Vibration (sinusoidal) - 1970

IEC/EN 60068-2-64: Vibration, broad-band random

NB!

Unit Sizes 4x and 5x have a stainless steel backchannel option to provide additional protection in aggressive environments. Proper ventilation is still required

for the internal components of the drive. Contact factory for additional information.

14

3 Introduction to AF-650 GP

3.1 Product Overview

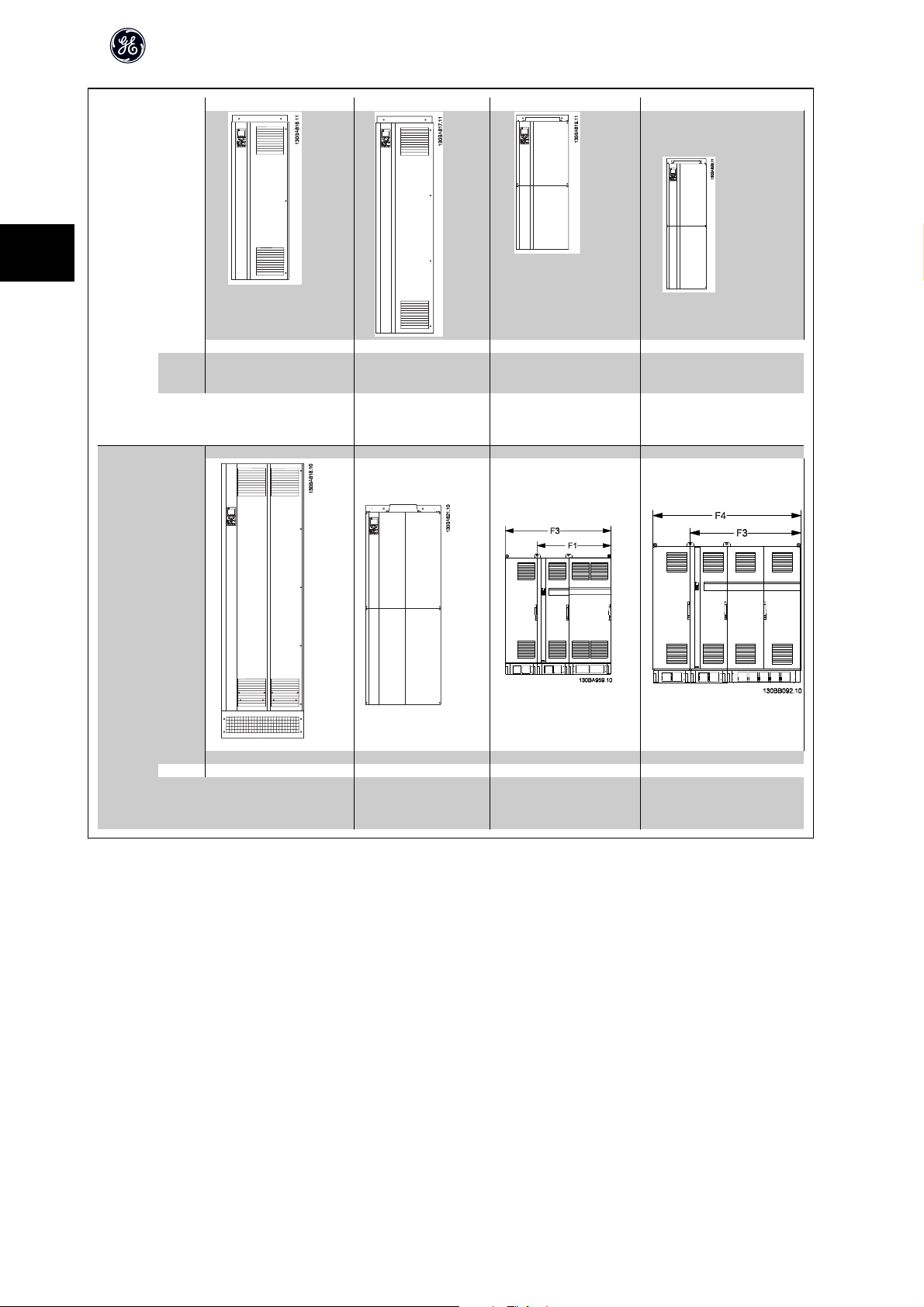

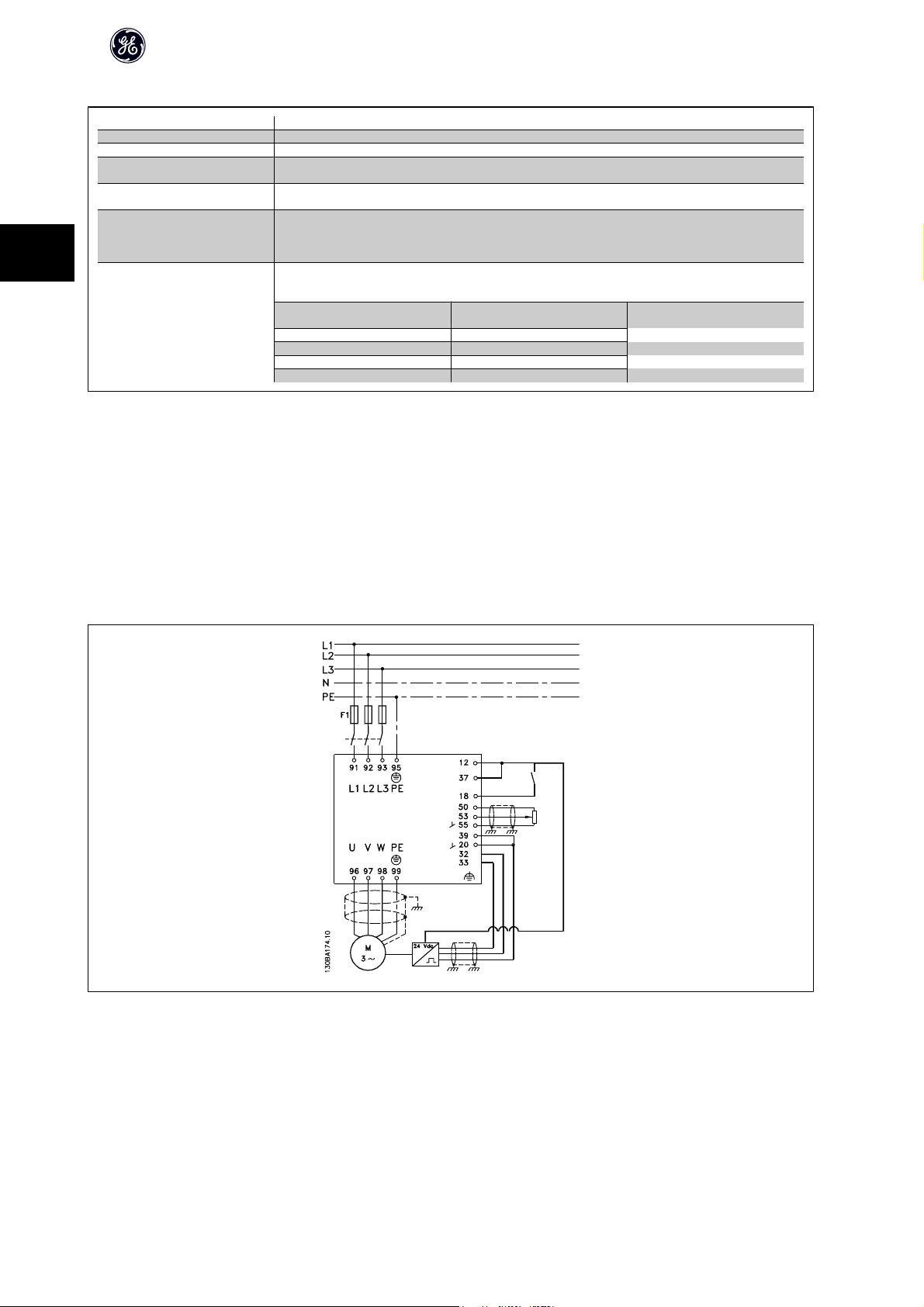

Frame size depends on Unit Size, power range and mains voltage

Unit Size 12 13 15

130BA810.10

AF-650 GP Design Guide

3

Unit Size

protection

Heavy duty (HD) rated power - 160%

overload torque

Unit Size

Unit Size

protection

Heavy duty (HD) rated power - 160%

overload torque

Unit Size

IP 20/21 20/21 55/66

NEMA Chassis/ Type 1 Chassis/ Type 1 Type 12

IP 55/66 55/66 20 20

NEMA Type 1/Type 12 Type 1/Type 12 Chassis Chassis

0.25-3 kW (200–240 V)

0.37-4.0 kW (380-480V)

21

5.5-7.5 kW (200-240 V)

11-15 kW (380-480V)

11-15 kW (525-600 V)

31 32 33 34

0.75-4 kW (525-600 V)

22 23 24

11 kW (200-250 V)

18.5-22 kW (380-480V)

18.5-22 kW (525-600 V)

11-22 kW (525-690 V)

3.7 kW (200-240 V)

5.5-7.5 kW (380-480 V)

5.5-7.5 kW (525-600 V )

5.5-7.5 kW (200-240 V)

11-15 kW (380-480 V)

11-15 kW (525-600 V)

0.25-3.7 kW (200-240 V)

0.37-7.5 kW (380-480 V)

0.75 -7.5 kW (525-600 V)

11-15 kW (200-240 V)

18.5-30 kW (380-480 V)

18.5-30 kW (525-600 V)

Unit Size

protection

Heavy duty (HD) rated power - 160%

overload torque

IP 55/66 55/66 20 20

NEMA Type 1/Type 12 Type 1/Type 12 Chassis Chassis

15-22 kW (200-240 V)

30-45kW (380-480V)

30-45 kW (525-600 V)

30-37 kW (200-240 V)

55-75 kW (380-480V)

55-90 kW (525-600 V)

30-75 kW (525-690 V)

18.5-22 kW (200-240 V)

37-45 kW (380-480 V)

37-45 kW (525-600 V)

30-37 kW (200-240 V)

55-75 kW (380-480 V)

55-90 kW (525-600 V)

15

3

AF-650 GP Design Guide

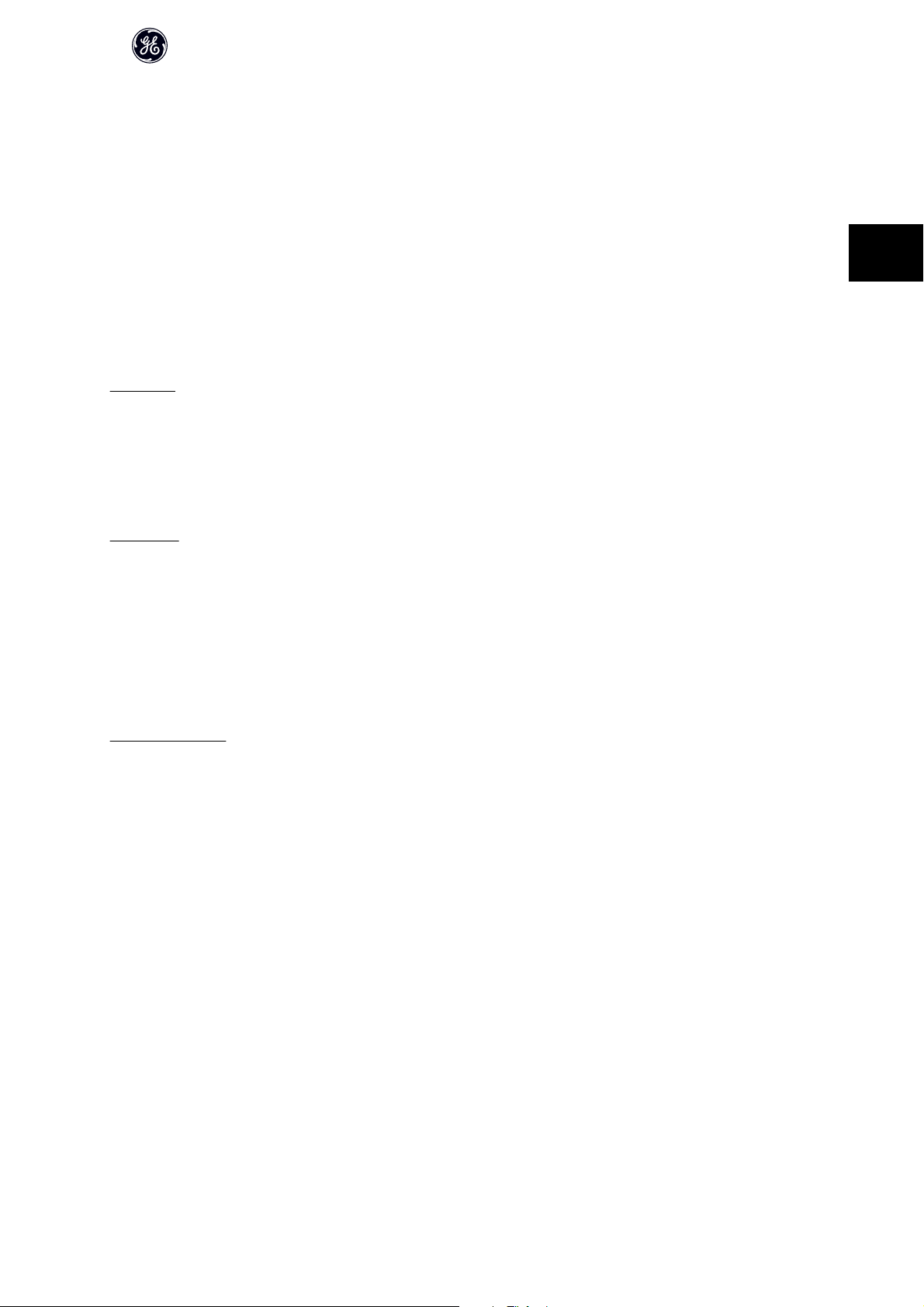

Unit Size 41 42 43 44

Unit Size

protection

Heavy duty (HD) rated

power - 160% overload torque

Unit Size 51 52 61/63 62/64

Unit Size

protection

Heavy duty (HD) rated

power - 160% overload torque

IP 21/54 21/54 00 00

NEMA Type 1/ Type 12 Type 1/ Type 12 Chassis Chassis

90-110 kW at 400 V

(380-480 V)

37-132 kW at 690 V

(525-690 V)

IP 21/54 00 21/54 21/54

NEMA Type 1/ Type 12 Chassis Type 1/ Type 12 Type 1/ Type 12

250-400 kW at 400 V

(380-480 V)

355-560 kW at 690 V

(525-690 V)

132-200 kW at 400 V

(380-480 V)

160-315 kW at 690 V

(525-690 V)

250-400 kW at 400 V

(380-480 V)

355-560 kW at 690 V

(525-690 V)

90-110 kW at 400 V

(380-480 V)

37-132 kW at 690 V

(525-690 V)

450 - 630 kW at 400 V

(380 - 480 V)

630 - 800 kW at 690 V

(525-690 V)

132-200 kW at 400 V

(380-480 V)

160-315 kW at 690 V

(525-690 V)

710 - 800 kW at 400 V

(380 - 480 V)

900 - 1000 kW at 690 V

(525-690 V)

16

AF-650 GP Design Guide

3.2.1 Control Principle

A frequency converter rectifies AC voltage from mains into DC voltage, after which this DC voltage is converted into a AC current with a variable amplitude and

frequency.

The motor is supplied with variable voltage / current and frequency, which enables infinitely variable speed control of three-phased, standard AC motors and

permanent magnet synchronous motors.

3.2.2 AF-650 GP Controls

The frequency converter is capable of controlling either the speed or the torque on the motor shaft. Setting par. H-40 Configuration Mode determines the type of

control.

Speed control:

There are two types of speed control:

• Speed open loop control which does not require any feedback from motor (sensorless).

• Speed closed loop PID control requires a speed feedback to an input. A properly optimised speed closed loop control will have higher accuracy than a

speed open loop control.

Selects which input to use as speed PID feedback in par. PI-00 Speed PID Feedback Source.

3

Torque control:

The torque control function is used in applications where the torque on motor output shaft is controlling the application as tension control. Torque control can

be selected in par. H-40, either in Advanced Vector Control open loop [4] or Flux control closed loop with motor speed feedback [2]. Torque setting is done by

setting an analog, digital or bus controlled reference. When running torque control it is recommended to make a full Auto tune procedure as the correct motor

data are of high importance for optimal performance.

• Closed loop in Flux mode with encoder feedback offers superior performance in all four quadrants and at all motor speeds.

• Open loop in Advanced Vector Control mode. The function is used in mechanical robust applications, but the accuracy is limited. Open loop torque

function works basically only in one speed direction. The torque is calculated on basic of current measurement internal in the frequency converter. See

Application Example Torque open Loop

Speed / torque reference:

The reference to these controls can either be a single refrence or be the sum of various references including relatively scaled references. The handling of refe rences

is explained in detail later in this section.

17

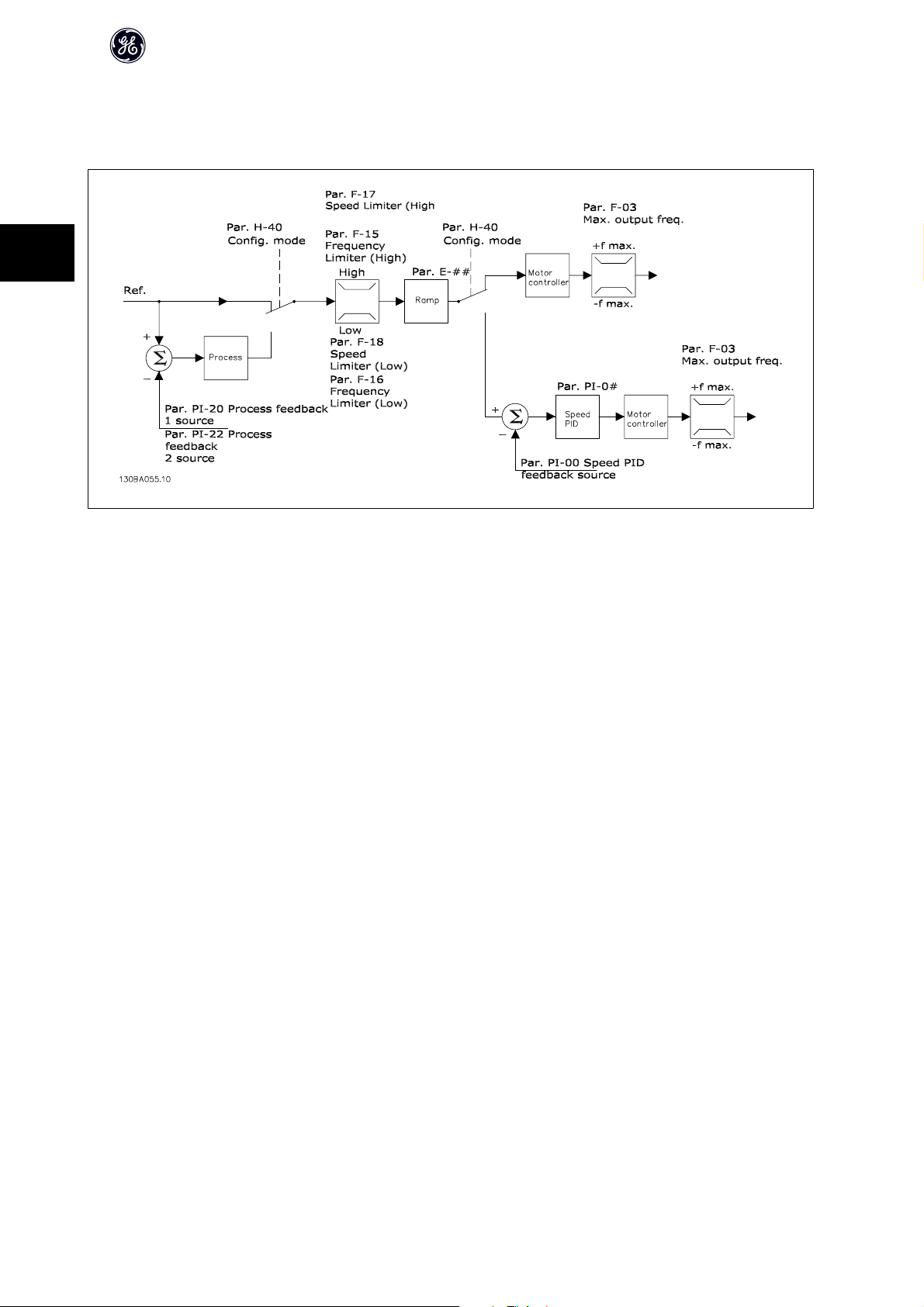

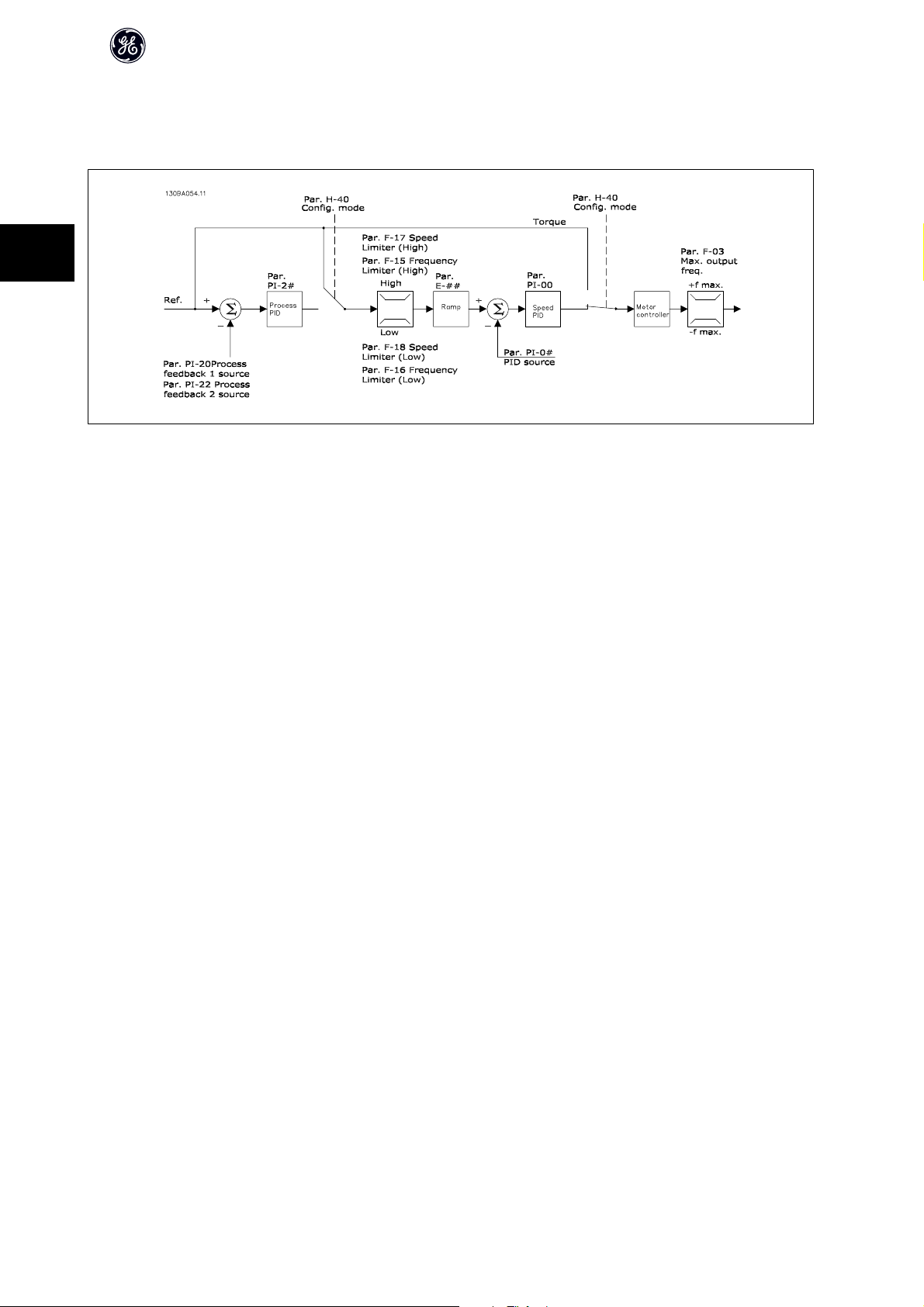

3.2.3 Control Structure in Advanced Vector Control

Control structure in Advanced Vector Control open loop and closed loop configurations:

3

AF-650 GP Design Guide

In the configuration shown in the illustration above, par. H-41 Motor Control Principle is set to “Advanced Vector Control [1]” and par. H-40 Configuration Mode is

set to “Speed open loop [0]”. The resulting reference from the reference handling system is received and fed through the ramp limitation and speed limitation

before being sent to the motor control. The output of the motor control is then limited by the maximum frequency limit.

If par. H-40 Configuration Mode is set to “Speed closed loop [1]” the resulting reference will be passed from the ramp limitation and speed limitation into a speed

PID control. The Speed PID control parameters are located in the par. group PI-0#. The resulting reference from the Speed PID control is sent to the motor control

limited by the frequency limit.

Select “Process [3]” in par. H-40 Configuration Mode to use the process PID control for closed loop control of e.g. speed or pressure in the controlled application.

The Process PID parameters are located in par. group PI-2# and PI-3#.

18

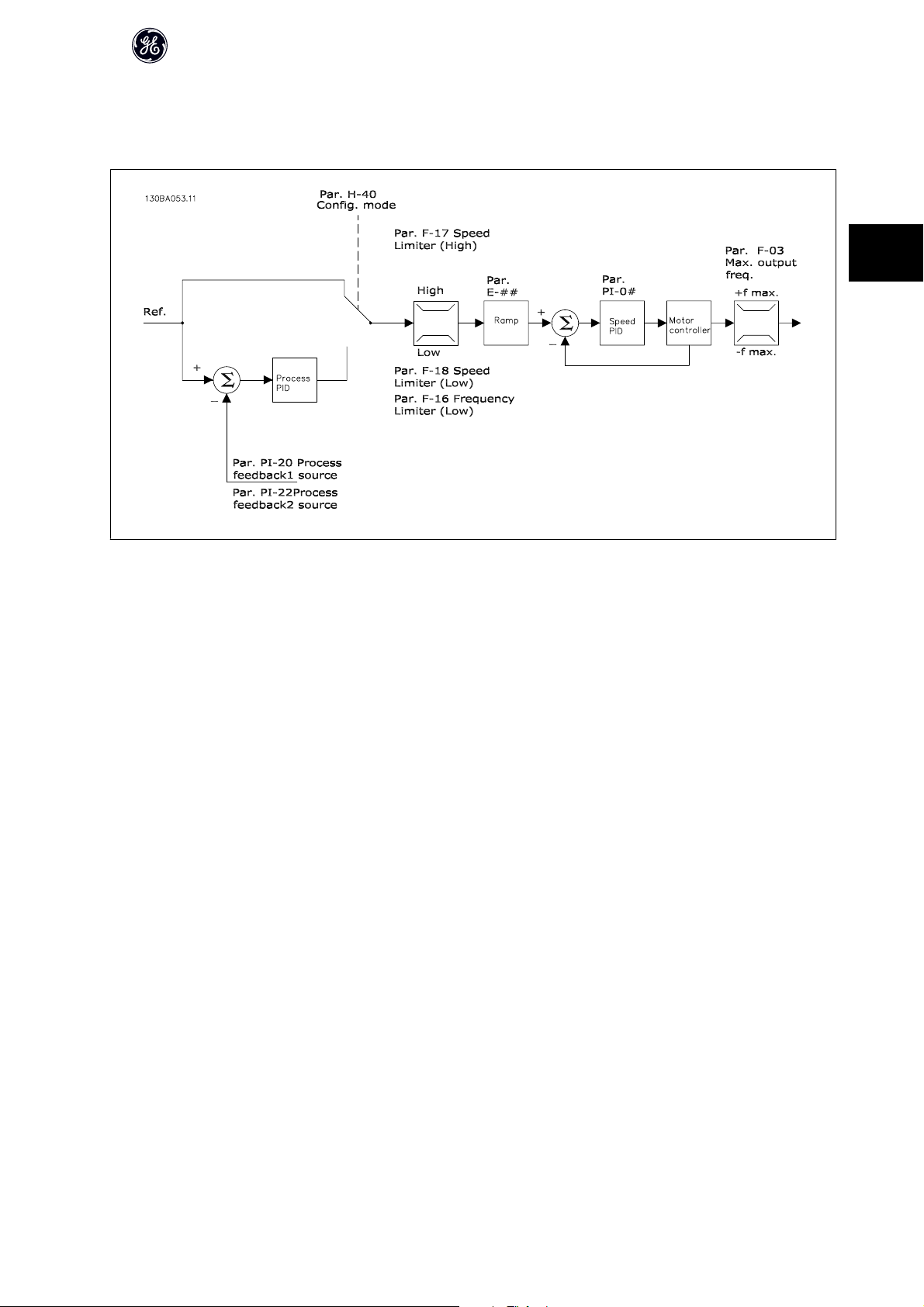

3.2.4 Control Structure in Flux Sensorless

Control structure in Flux sensorless open loop and closed loop configurations.

AF-650 GP Design Guide

3

In the shown configuration, par. H-41 Motor Control Principle is set to “Flux sensorless [2]” and par. H-40 Configuration Mode is set to “Speed open loop [0]”. The

resulting reference from the reference handling system is fed through the ramp and speed limitations as determined by the parameter settings indicated.

An estimated speed feedback is generated to the Speed PID to control the output frequency.

The Speed PID must be set with its P,I, and D parameters (par. group PI-0#).

Select “Process [3]” in par. H-40 Configuration Mode to use the process PID control for closed loop control of i.e. speed or pressure in the controlled application.

The Process PID parameters are found in par. group PI-2# and PI-3#.

19

AF-650 GP Design Guide

3.2.5 Control Structure in Flux with Motor Feedback

Control structure in Flux with motor feedback configuration (only available in AF-650 GP):

3

In the shown configuration, par. H-41 Motor Control Principle is set to “Flux w motor feedb [3]” and par. H-40 Configuration Mode is set to “Speed closed loop [1]”.

The motor control in this configuration relies on a feedback signal from an encoder mounted directly on the motor (set in par. H-42 Flux Motor Feedback

Source).

Select “Speed closed loop [1]” in par. H-40 Configuration Mode to use the resulting reference as an input for the Speed PID control. The Speed PID control parameters

are located in par. group PI-0#.

Select “Torque [2]” in par. H-40 Configuration Mode to use the resulting reference directly as a torque reference. Torque control can only be selected in the Flux

with motor feedback (par. H-41 Motor Control Principle) configuration. When this mode has been selected, the reference will use the Nm unit. It requires no torque

feedback, since the actual torque is calculated on the basis of the current measurement of the frequency converter.

Select “Process [3]” in par. H-40 Configuration Mode to use the process PID control for closed loop control of e.g. speed or a process variable in the controlled

application.

3.2.6 Internal Current Control in Advanced Vector Control Mode

The frequency converter features an integral current limit control which is activated when the motor current, and thus the torque, is higher than the torque limits

set in par. F-40 Torque Limiter (Driving), par. F-41 Torque Limiter (Braking) and par. F-43 Current Limit.

When the frequency converter is at the current limit during motor operation or regenerative operation, the frequency converter will try to get below the preset

torque limits as quickly as possible without losing control of the motor.

20

AF-650 GP Design Guide

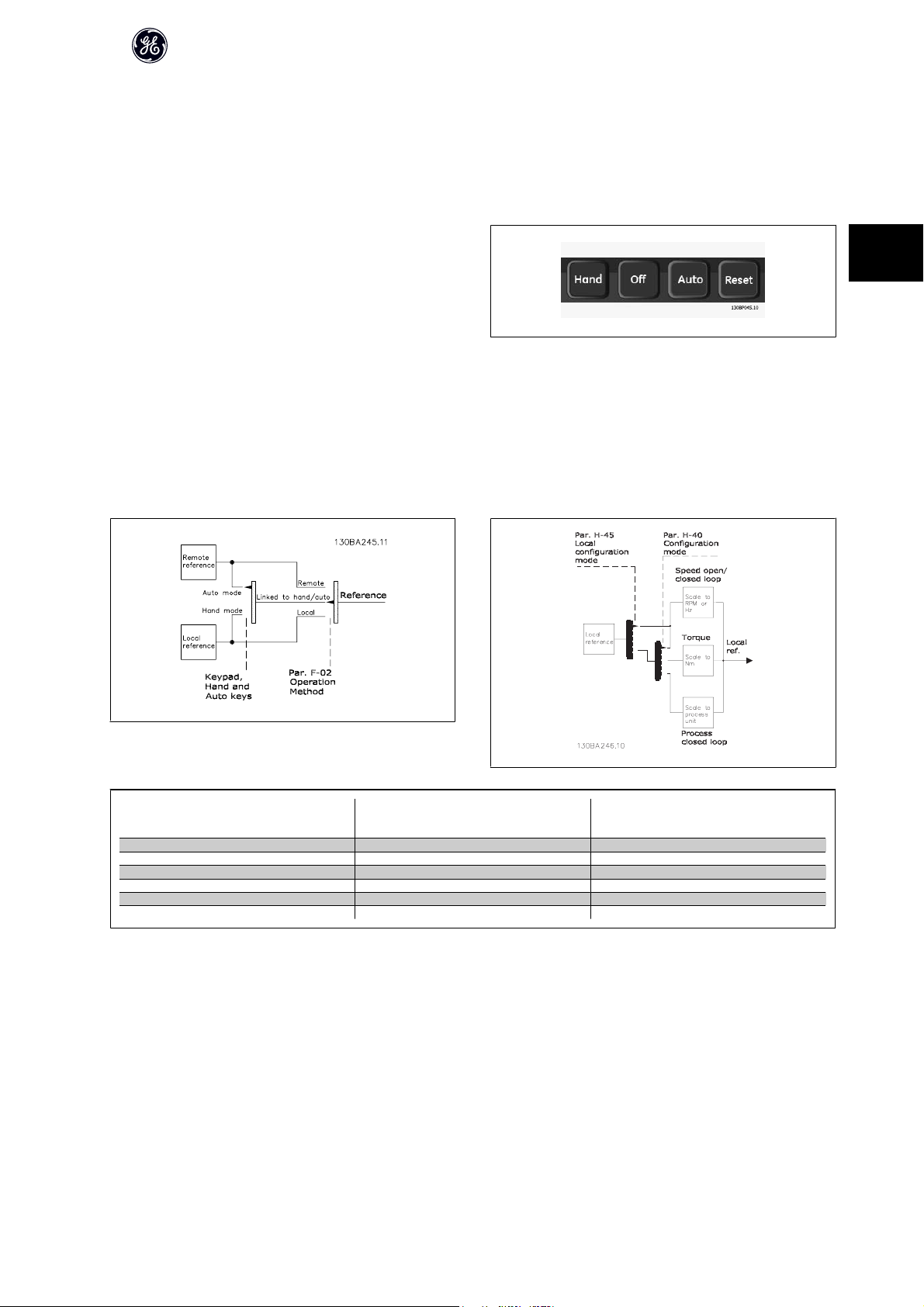

3.2.7 Local (Hand) and Remote (Auto) Control

The frequency converter can be operated manually via the local control panel (Keypad) or remotely via analog and digital inputs and serial bus.

If allowed in par. K-40 [Hand] Button on Keypad, par. K-41 [Off] Button on Keypad, par. K-42 [Auto] Button on Keypad, and par. K-43 [Reset] Button on Keypad, it is

possible to start and stop the frequency converter via the Keypad using the [Hand] and [Off] keys. Alarms can be reset via the [RESET] key. After pressing the

[Hand] key, the frequency converter goes into Hand mode and follows (as default) the Local reference that can be set using arrow key on the Keypad.

After pressing the [Auto] key, the frequency converter goes into Auto mode

and follows (as default) the Remote reference. In this mode, it is possible to

control the frequency converter via the digital inputs and various serial in-

terfaces (RS-485, USB, or an optional network). See more about starting,

stopping, changing ramps and parameter set-ups etc. in par. group E-0#

(digital inputs) or par. group O-5# (serial communication).

Active Reference and Configuration Mode

The active reference can be either the local reference or the remote reference.

In par. F-02 Operation Method the local reference can be permanently selected by selecting Local [2].

To permanently select the remote reference select Remote [1]. By selecting Linked to Hand/Auto [0] (d efault) the reference site will depend on which mode i s active.

(Hand Mode or Auto Mode).

3

Hand

Auto

Keypad Keys

Hand Linked to Hand / Auto Local

Hand -> Off Linked to Hand / Auto Local

Auto Linked to Hand / Auto Remote

Auto -> Off Linked to Hand / Auto Remote

All keys Local Local

All keys Remote Remote

The table shows under which conditions either the Local reference or the Remote reference is active. One of them is always active, but both can not be active at

the same time.

Par. H-40 Configuration Mode determines what kind of application control principle (i.e. Speed, Torque or Process Control) is used when the Remote reference is

active (see table above for the conditions).

Par. H-45 Local Mode Configuration determines the kind of application control principle that is used when the Local reference is made active.

Par. F-02 Operation Method Active Reference

21

3.3 Reference Handling

Local Reference

The local reference is active when the drive is operated with ‘Hand On’ bottom active. Adjust the reference by up/down and left/right arrows respectively.

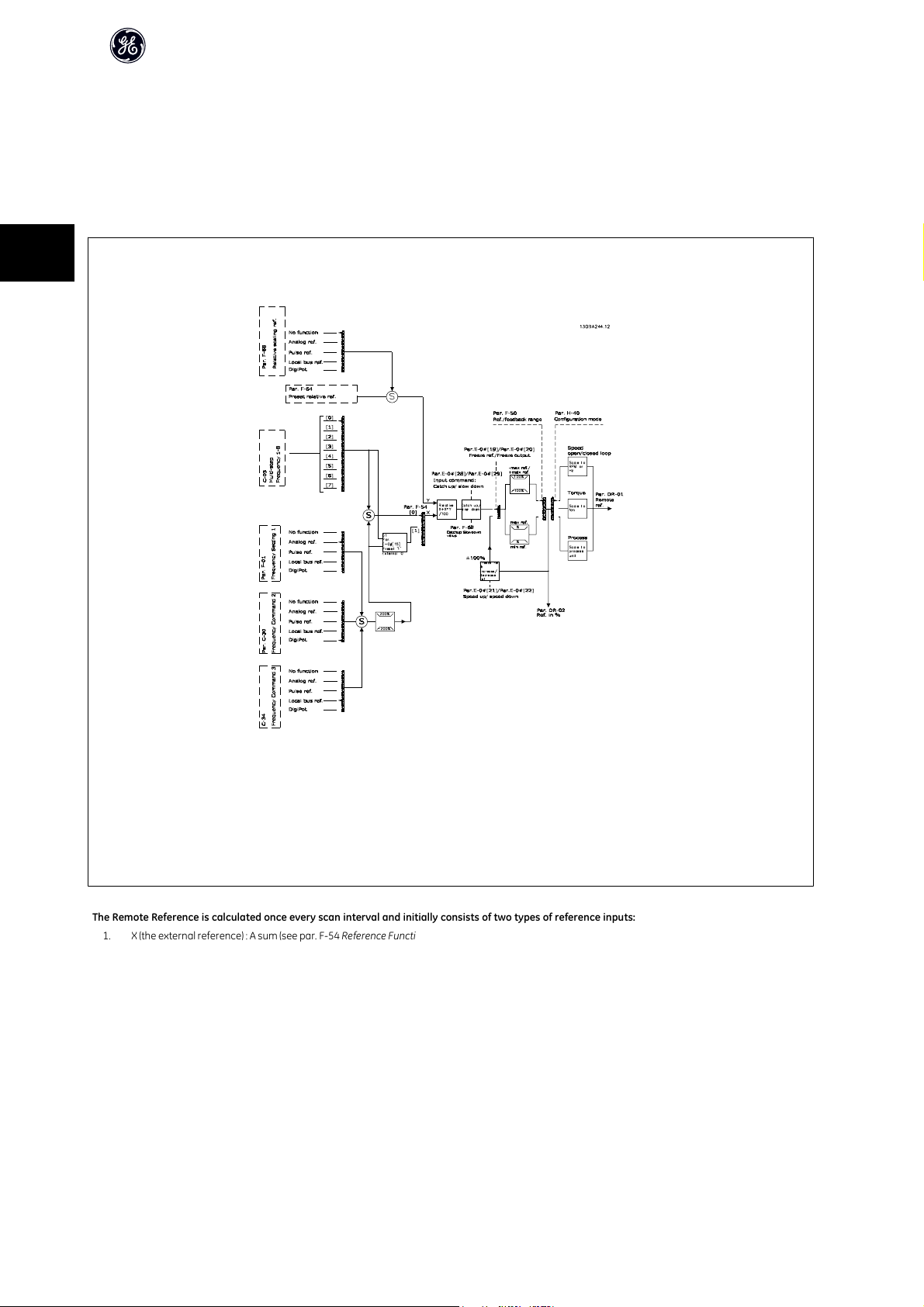

Remote Reference

The reference handling system for calculating the Remote reference is shown in the illustration below.

3

!"

#

$

-

./012

33

.433

%

&'&()

*+$#

,,

AF-650 GP Design Guide

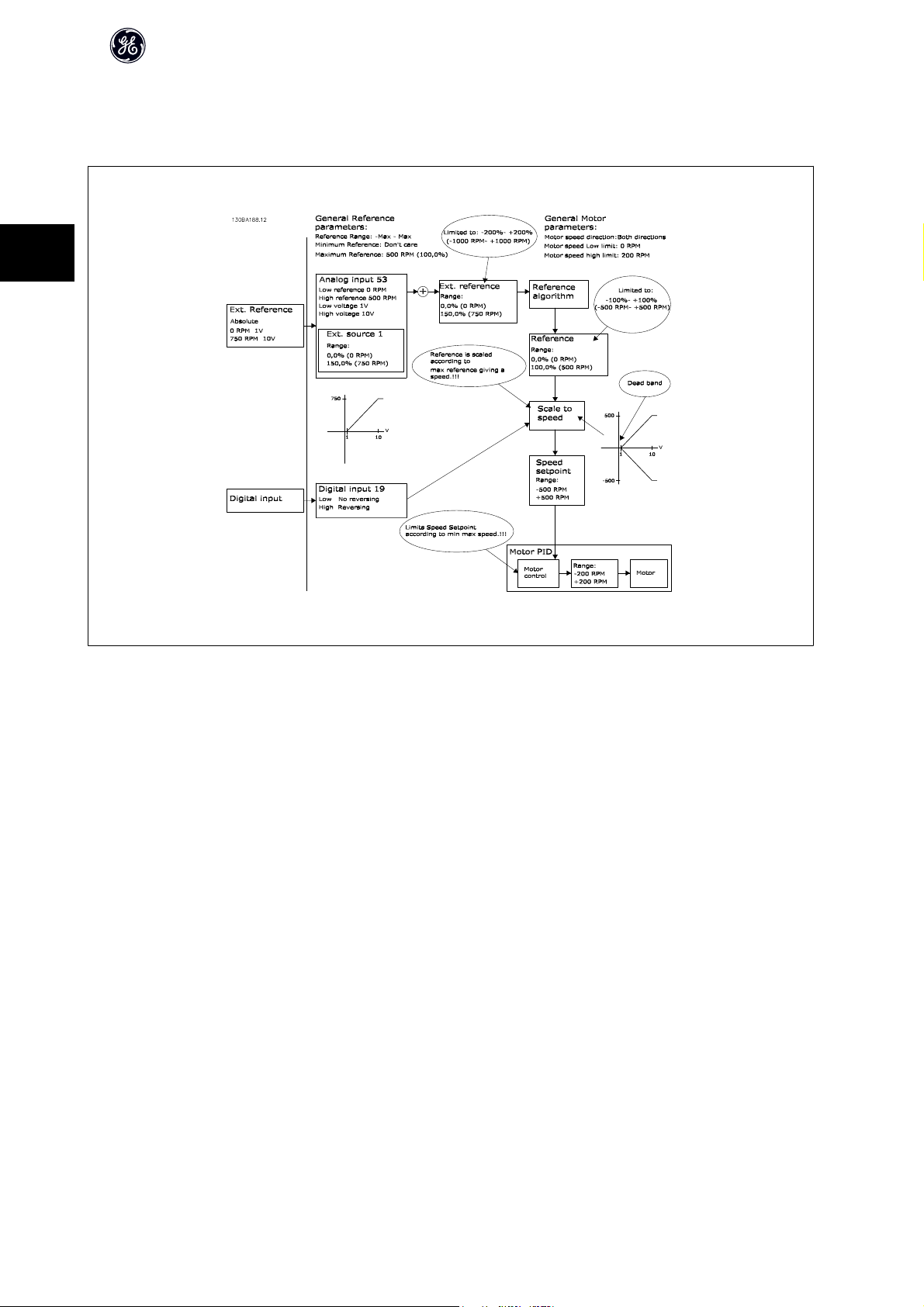

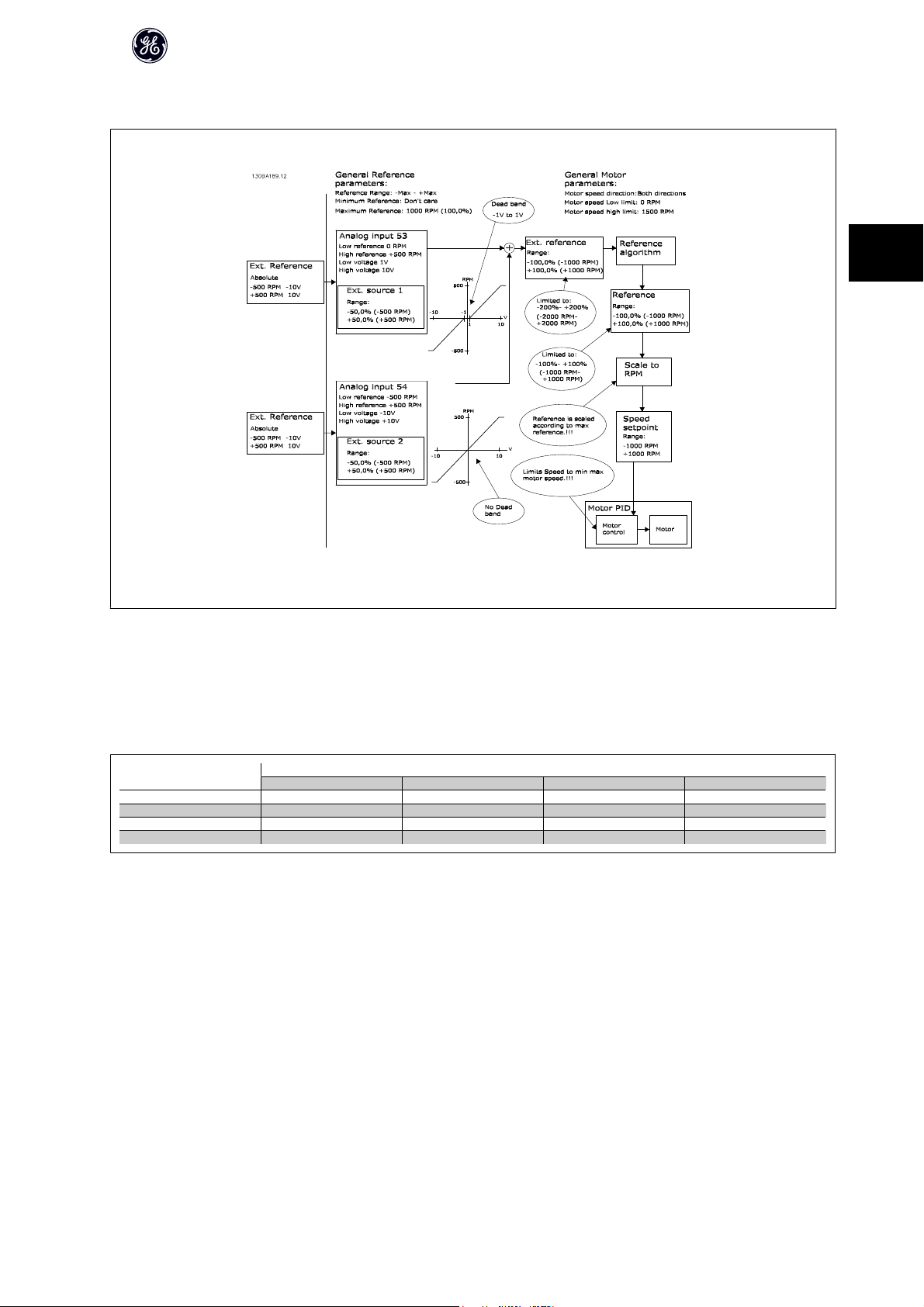

The Remote Reference is calculated once every scan interval and initially consists of two types of reference inputs:

1. X (the external reference) : A sum (see par. F-54 Reference Function) of up to f our externally selected references, comprising any combi nation (determined

by the setting of par. F-01 Frequency Setting 1, par. C-30 Frequency Command 2 and par. C-34 Frequency Command 3) of a fixed preset reference

(par. C-05 Multi-step Frequency 1 - 8 ), variable analog references, variable digital pulse references, and various serial bus references in whatever unit

the frequency converter is controlled ([Hz], [RPM], [Nm] etc.).

2. Y- (the relative reference): A sum of one fixed preset reference (par. F-64 Preset Relative Reference) and one variable analog reference (par. F-68 Relative

Scaling Reference Resource) in [%].

The two types of reference inputs are combined in the following formula: Remote reference = X + X * Y / 100%. If relative reference is not used par. F-68 must be

set to No function and par. F-64 to 0%. The catch up / slow down function and the freeze reference function can both be activated by digital inputs on the

frequency converter. The functions and parameters are described in the Programming Guide, DET-618

The scaling of analog references are described in par. groups AN-1# and AN-2#, and the scaling of digital pulse references are described in par. group E-6#.

Reference limits and ranges are set in par. group F-5#.

22

AF-650 GP Design Guide

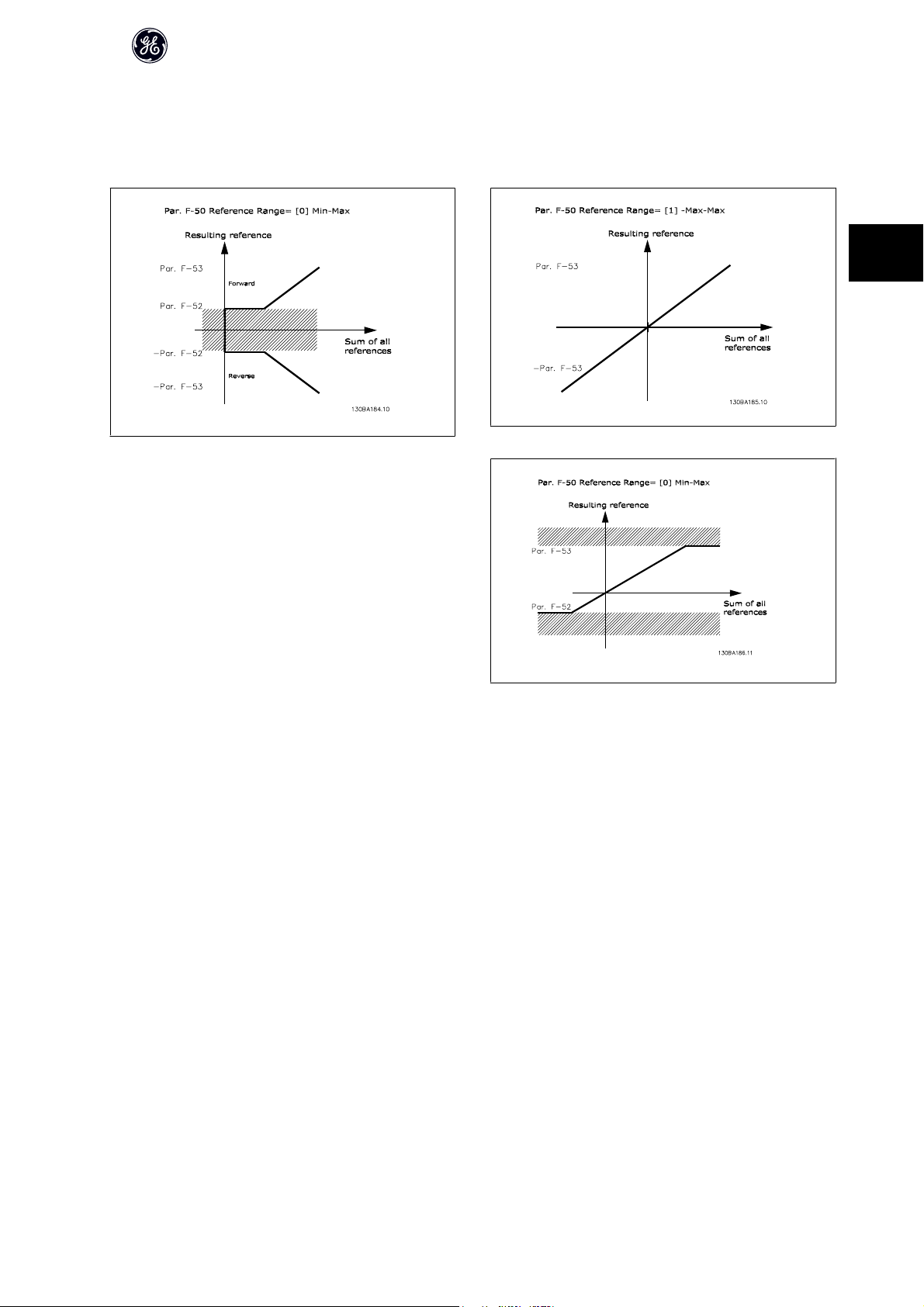

3.3.1 Reference Limits

Par. F-50 Reference Range, par. F-52 Minimum Reference and par. F-53 Maximum Reference together define the allowed range of the sum of all references. The

sum of all references are clamped when necessary. The relation between the resulting reference (after clamping) and the sum of all references is shown below.

The value of par. F-52 Minimum Reference can not be set to less than 0, unless

the par. H-40 Configuration Mode is set to [3] Process. In that case the fol-

lowing relations between the resulting reference (after clamping) and the sum

of all references is as shown to the right.

3

3.3.2 Scaling of Preset References and Bus References

Preset references are scaled according to the following rules:

• When par. F-50 Reference Range : [0] Min - Max 0% reference equals 0 [unit] where unit can be any unit e.g. rpm, m/s, bar etc. 100% reference equals

the Max (abs (par. F-53 Maximum Reference ), abs (par. F-52 Minimum Reference)).

• When par. F-50 Reference Range : [1] -Max - +Max 0% reference equals 0 [unit] -100% reference equals -Max Reference 100% reference equals Max

Reference.

Bus references are scaled according to the following rules:

• When par. F-50 Reference Range: [0] Min - Max. To obtain max resolution on the bus reference the scaling on the bus is: 0% reference equals Min

Reference and 100% reference equals Max reference.

• When par. F-50 Reference Range: [1] -Max - +Max -100% reference equals -Max Reference 100% reference equals Max Reference.

23

AF-650 GP Design Guide

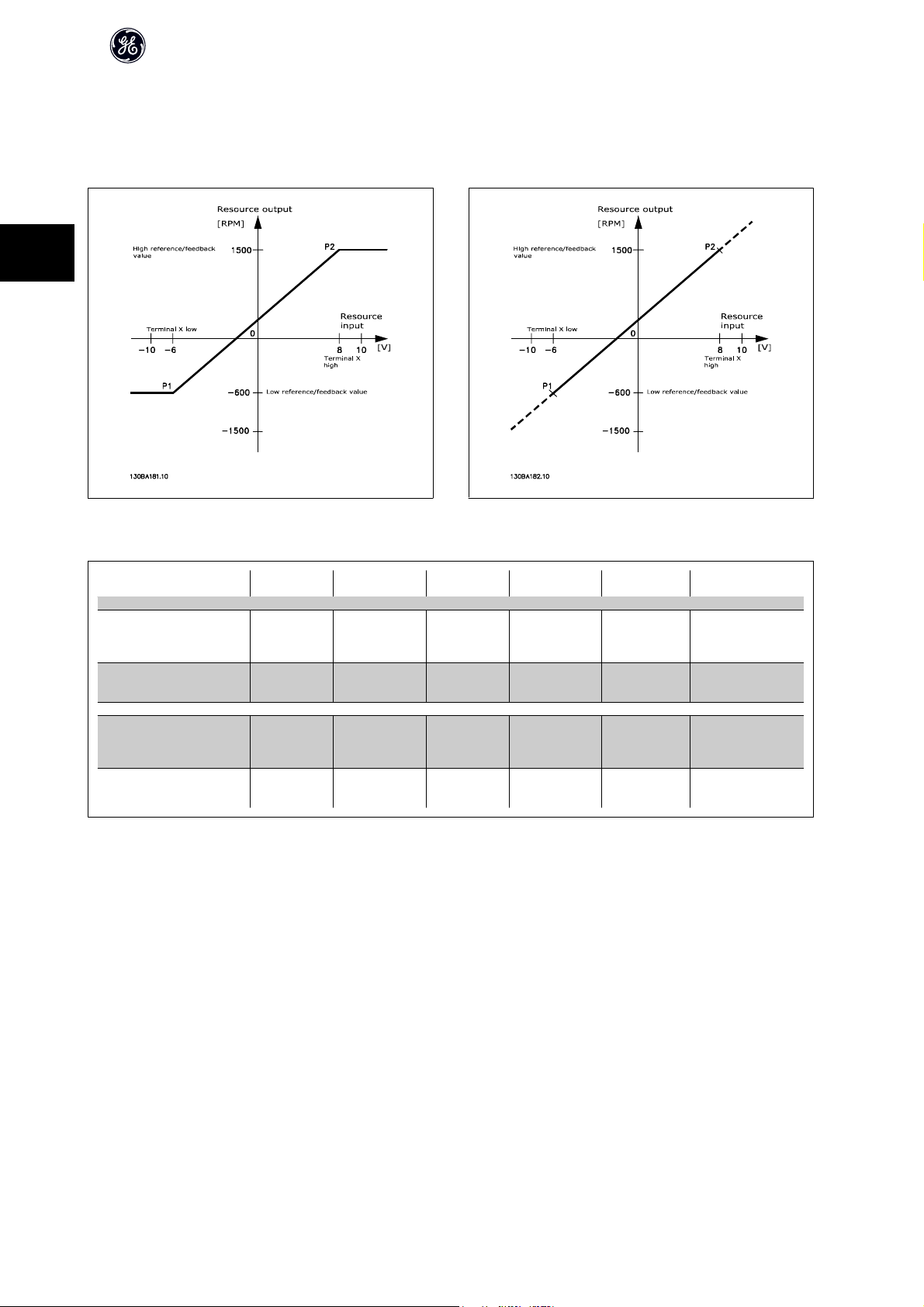

3.3.3 Scaling of Analog and Pulse References and Feedback

References and feedback are scaled from analog and pulse inputs in the same way. The only difference is that a reference above or below the specified minimum

and maximum “endpoints” (P1 and P2 in the graph below) are clamped whereas a feedback above or below is not.

3

The endpoints P1 and P2 are defined by the following parameters depending on which analog or pulse input is used

Analog 53

P1 = (Minimum input value, Minimum reference value)

Minimum reference value

Minimum input value Par. AN-10 Ter-

P2 = (Maximum input value, Maximum reference value)

Maximum reference value Par. AN-15 Ter-

Maximum input value Par. AN-11 Ter-

S201=OFF

Par. AN-14 Ter-

minal 53 Low

Ref./Feedb. Value

minal 53 Low

Voltage [V]

minal 53 High

Ref./Feedb. Value

minal 53 High

Voltage [V]

Analog 53

S201=ON

Par. AN-14 Termi-

nal 53 Low Ref./

Feedb. Value

Par. AN-12 Terminal 53 Low Current

[mA]

Par. AN-15 Termi-

nal 53 High Ref./

Feedb. Value

Par. AN-13 Terminal 53 High Current [mA]

Analog 54

S202=OFF

Par. AN-24 Ter-

minal 54 Low

Ref./Feedb. Value

Par. AN-20 Terminal 54 Low

Voltage [V]

Par. AN-25 Terminal 54 High

Ref./Feedb. Value

Par. AN-21 Terminal 54 High

Voltage[V]

Analog 54

S202=ON

Par. AN-24 Termi-

nal 54 Low Ref./

Feedb. Value

Par. AN-22 Terminal 54 Low Current [mA]

Par. AN-25 Terminal 54 High Ref./

Feedb. Value

Par. AN-23 Terminal 54 High Current[mA]

Pulse Input 29 Pulse Input 33

Par. E-62 Term. 29

Low Ref./Feedb.

Value

Par. E-60 Term. 29

Low Frequency

[Hz]

Par. E-63 Term. 29

High Ref./Feedb.

Value

Par. E-61 Term. 29

High Frequency

[Hz]

Par. E-67 Term. 33 Low

Ref./Feedb. Value

Par. E-65 Term. 33 Low

Frequency [Hz]

Par. E-68 Term. 33 High

Ref./Feedb. Value

Par. E-66 Term. 33 High

Frequency [Hz]

3.3.4 Dead Band Around Zero

In some cases the reference (in rare cases also the feedback) should have a Dead Band around zero (i.e. to make sure the machine is stopped when the reference

is “near zero”).

To make the dead band active and to set the amount of dead band, the following settings must be done:

• Either Minimum Reference Value (see table above for relevant parameter) or Maximum Reference Value must be zero. In other words; Either P1 or P2

must be on the X-axis in the graph below.

• And both points defining the scaling graph are in the same quadrant.

24

AF-650 GP Design Guide

The size of the Dead Band is defined by either P1 or P2 as shown in the graph below.

Thus a reference endpoint of P1 = (0 V, 0 RPM) will not result in any dead band, but a reference endpoint of e.g. P1 = (1V, 0 RPM) will result in a -1V to +1V dead

band in this case provided that the end point P2 is placed in either Quadrant 1 or Quadrant 4.

3

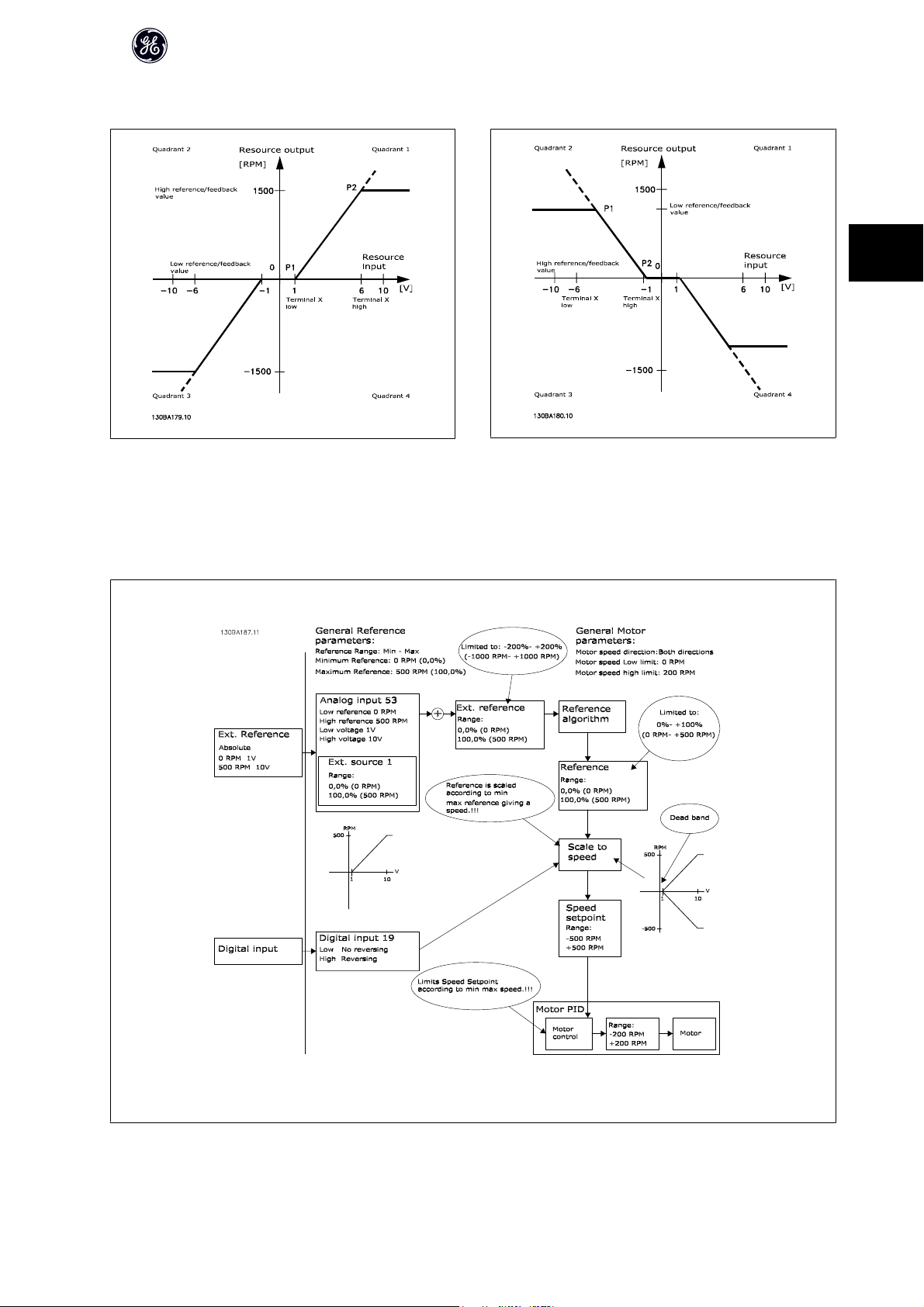

Case 1: Positive Reference with Dead band, Digital input to trigger reverse

This Case shows how Reference input with limits inside Min – Max limits clamps.

25

AF-650 GP Design Guide

Case 2: Positive Reference with Dead band, Digital input to trigger reverse. Clamping rules.

This Case shows how Reference input with limits outside -Max – +Max limits clamps to the inputs low and high limits before addition to External reference. And

how the External reference is clamped to -Max – +Max by the Reference algorithm.

3

26

Case 3: Negative to positive reference with dead band, Sign determines the direction, -Max – +Max

AF-650 GP Design Guide

3

3.4 PID Control

3.4.1 Speed PID Control

The table shows the control configurations where the Speed Control is active.

Par. H-40 Configuration Mode

[0] Speed open loop Not Active Not Active ACTIVE N.A.

[1] Speed closed loop N.A. ACTIVE N.A. ACTIVE

[2] Torque N.A. N.A. N.A. Not Active

[3] Process Not Active ACTIVE ACTIVE

Note: “N.A.” means that the specific mode is not available at all. “Not Active” means that the specific mode is available but the Speed Control is not active in that

mode.

Note: The Speed Control PID will work under the default parameter setting, but tuning the parameters is highly recommended to optimize the motor control

performance. The two Flux motor control principles are specially dependant on proper tuning to yield their full potential.

Par. H-41 Motor Control Principle Motor Control Principle

U/f Advanced Vector Control Flux Sensorless Flux w/ enc. feedb

27

AF-650 GP Design Guide

The following parameters are relevant for the Speed Control:

Parameter

Par. PI-00 Speed PID Feedback Source Select from which input the Speed PID should get its feedback.

Par. PI-02 Speed PID Proportional Gain The higher the value - the quicker the control. However, too high value may lead to oscillations.

Par. PI-03 Speed PID Integral Time Eliminates steady state speed error. Lower value means quick reaction. However, too low value may lead to oscilla-

Par. PI-04 Speed PID Differentiation

Time

Par. PI-05 Speed PID Diff. Gain Limit If there are quick changes in reference or feedback in a given application - which means that the error changes

3

Par. PI-06 Speed PID Lowpass Filter

Time

Below is given an example of how to programme the Speed Control:

In this case the Speed PID Control is used to maintain a constant motor speed regardless of the changing load on the motor.

The required motor speed is set via a potentiometer connected to terminal 53. The speed range is 0 - 1500 RPM corresponding to 0 - 10V over the potentiometer.

Description of function

tions.

Provides a gain proportional to the rate of change of the feedback. A setting of zero disables the differentiator.

swiftly - the differentiator may soon become too dominant. This is because it reacts to changes in the error. The

quicker the error changes, the stronger the differentiator gain is. The differentiator gain can thus be limited to allow

setting of the reasonable differentiation time for slow changes and a suitably quick gain for quick changes.

A low-pass filter that dampens oscillations on the feedback signal and improves steady state performance. However,

too large filter time will deteriorate the dynamic performance of the Speed PID control.

Practical settings of par. PI-06 taken from the number of pulses per revolution on from encoder (PPR):

Encoder PPR Par. PI-06 Speed PID Lowpass Filter

Time

512 10 ms

1024 5 ms

2048 2 ms

4096 1 ms

Starting and stopping is controlled by a switch connected to terminal 18.

The Speed PID monitors the actual RPM of the motor by using a 24V (HTL) incremental encoder as feedback. The feedback sensor is an encoder (1024 pulses per

revolution) connected to terminals 32 and 33.

28

In the parameter list below it is assumed that all other parameters and switches remain at their default setting.

The following must be programmed in order shown - see explanation of settings in the Programming Guide.

AF-650 GP Design Guide

Function

1) Make sure the motor runs properly. Do the following:

Set the motor parameters using name plate data

Have the frequency converter makes an auto tune Par. P-04 Auto Tune [1] Enable complete auto tune

2) Check the motor is running and the encoder is attached properly. Do the following:

Press the “Hand” Keypad key. Check that the motor is running

and note in which direction it is turning (henceforth referred to as

the “positive direction”).

Go t o pa r . D R -2 0 Motor Angle. Turn the motor slowly in the positive

direction. It must be turned so slowly (only a few RPM) that it can

be determined if the value in par. DR-20 Motor Angle is increasing

or decreasing.

If par. DR-20 Motor Angle is decreasing then change the encoder

direction in par. E-81 Term 32/33 Encoder Direction.

3) Make sure the drive limits are set to safe values

Set acceptable limits for the references. Par. F-52 Minimum

Check that the ramp settings are within drive capabilities and

allowed application operating specifications.

Set acceptable limits for the motor speed and frequency. Par. F-18 Motor Speed

4) Configure the Speed Control and select the Motor Control principle

Activation of Speed Control Par. H-40 Configura-

Selection of Motor Control Principle Par. H-41 Motor Con-

5) Configure and scale the reference to the Speed Control

Set up Analog Input 53 as a reference Source

Scale Analog Input 53 0 RPM (0 V) to 1500 RPM (10V) AN-1# Not necessary (default)

6) Configure the 24V HTL encoder signal as feedback for the Motor Control and the Speed Control

Set up digital input 32 and 33 as encoder inputs Par. E-05 Terminal 32

Choose terminal 32/33 as motor feedback Par. H-42 Flux Motor

Choose terminal 32/33 as Speed PID feedback Par. PI-00 Speed PID

7) Tune the Speed Control PID parameters

Use the tuning guidelines when relevant or tune manually PI-0# See the guidelines below

8) Finished!

Save the parameter setting to the Keypad for safe keeping Par. K-50 Keypad

Par. no. Setting

P-02 to P-07

F-04 & F-05

Set a positive reference.

Par. DR-20 Motor An-

gle

Par. E-81 Term 32/33

Encoder Direction

Reference

par. F-53 Maximum

Reference

Par. F-07 Accel Time 1

par. F-08 Decel Time 1

Low Limit [RPM]

par. F-17 Motor Speed

High Limit [RPM]

par. F-03 Max Output

Frequency 1

tion Mode

trol Principle

Par. F-01 Frequency

Setting 1

Digital Input

par. E-06 Terminal 33

Digital Input

Feedback Source

Feedback Source

Copy

As specified by motor name plate

N.A. (read-only parameter) Note: An increasing value overflows at

65535 and starts again at 0.

[1] Counter clockwise (if par. DR-20 Motor Angle is decreasing)

0 RPM (default)

1500 RPM (default)

default setting

default setting

0 RPM (default)

1500 RPM (default)

60 Hz (default 132 Hz)

[1] Speed closed loop

[3] Flux w motor feedb

Not necessary (default)

[0] No operation (default)

Not necessary (default)

Not necessary (default)

[1] All to Keypad

3

3.4.2 Tuning PID Speed Control

The following tuning guidelines are relevant when using one of the Flux motor control principles in applications where the load is mainly inertial (with a low amount

of friction).

The value of par. PI-02 Speed PID Proportional Gain is dependent on the combined inertia of the motor and load, and the selected bandwidth can be calculated

using the following formula:

Par. PI

− 02 =

Note: Par. P-07 Motor Power [kW] is the motor power in [kW] (i.e. enter ‘4’ kW instead of ‘4000’ W in the formula). A practical value for the Bandwith is 20 rad/s.

Check the result of the Par. PI-02 Speed PID Proportional Gain calculation against the following formula (not required if you are using a high resolution feedback

such as a SinCos feedback):

Par. PI

− 02

Total inertia kgm

MAXIMUM

=

Par. P

0.01 x 4 x

2

x

par. P

− 07 x 9550

− 06

Encoder Resolution x Par. PI

2

x

π

x Bandwidth rad/s

− 06

x Max torque ripple

%

29

Loading...

Loading...